pgm HONDA CR-V 1997 RD1-RD3 / 1.G Manual Online

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 622 of 1395

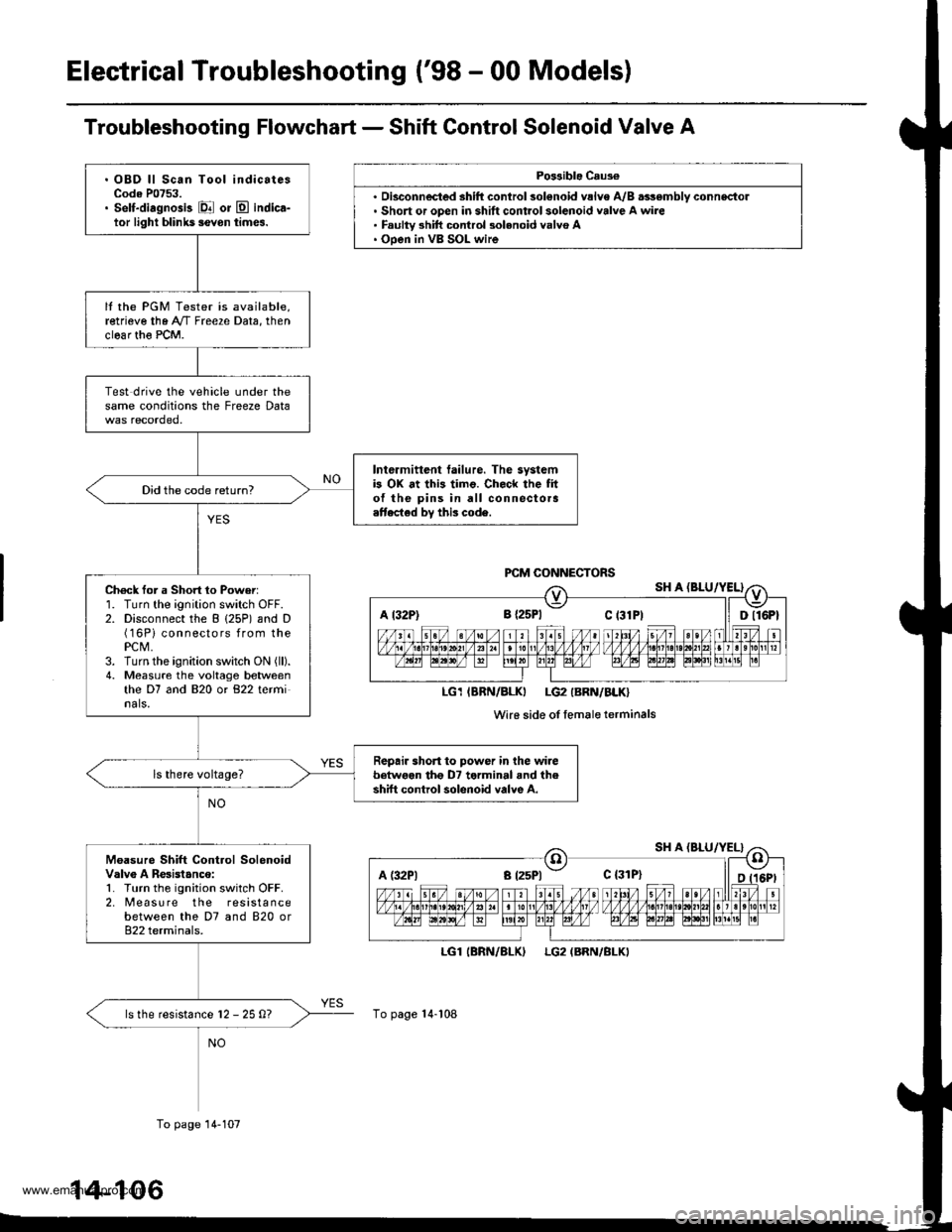

Electrical Troubleshooting ('98 - 00 Models)

Troubleshooting Flowchart - Shift Control Solenoid Valve A

Po$ible Caus€

'. Short or open in shift control solenoid valve A wire. Faulty 3hift control 3olenoid valvo A. Ooen in VB SOL wire

LGl

To page 14-108

(BRN/BLKILG2 (BRN/BLKI

A t32P) 8 {2sPl Ct3lPt ll Dll6Pt

LG1IBRN/BLKI LG2IBRN/BLK}

Wi16 side of femaleterminals

A (:l2Pl a t25Pl - c {31P}

. OBD ll Scan Tool indicatesCode P0753.. Self-diagnosis El or E indica-tor light blihk5 ievon times.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear th€ PCM.

Test drive the vehicle under thesame conditions the Freeze Data

Intermittent tailure. The systemb OX at this timo. Check the fito{ the pins in all connectora.ttected by this code.

Did the code return?

Ch6ck for a Short 1o Power:1. Turn the ignition switch OFF.2. Disconnect the B (25P) and D(16Pi connectors from thePCM,3. Turn the ignition switch ON (ll).

4. Measure the voltage betweenthe D7 and 820 or 822 terminals.

Repair short to power in the wirebetwoen tho D7 terminal and theshift control solenoid valve A.

Moasure Shift Control SolenoidValv6 A Resistanco:1. Turn the ignition switch OFF.2. [reasu re the resistancebetween the D7 and 820 or822 terminals.

ls the resistance l2 - 25 0?

To page 14-107

14-106

www.emanualpro.com

Page 625 of 1395

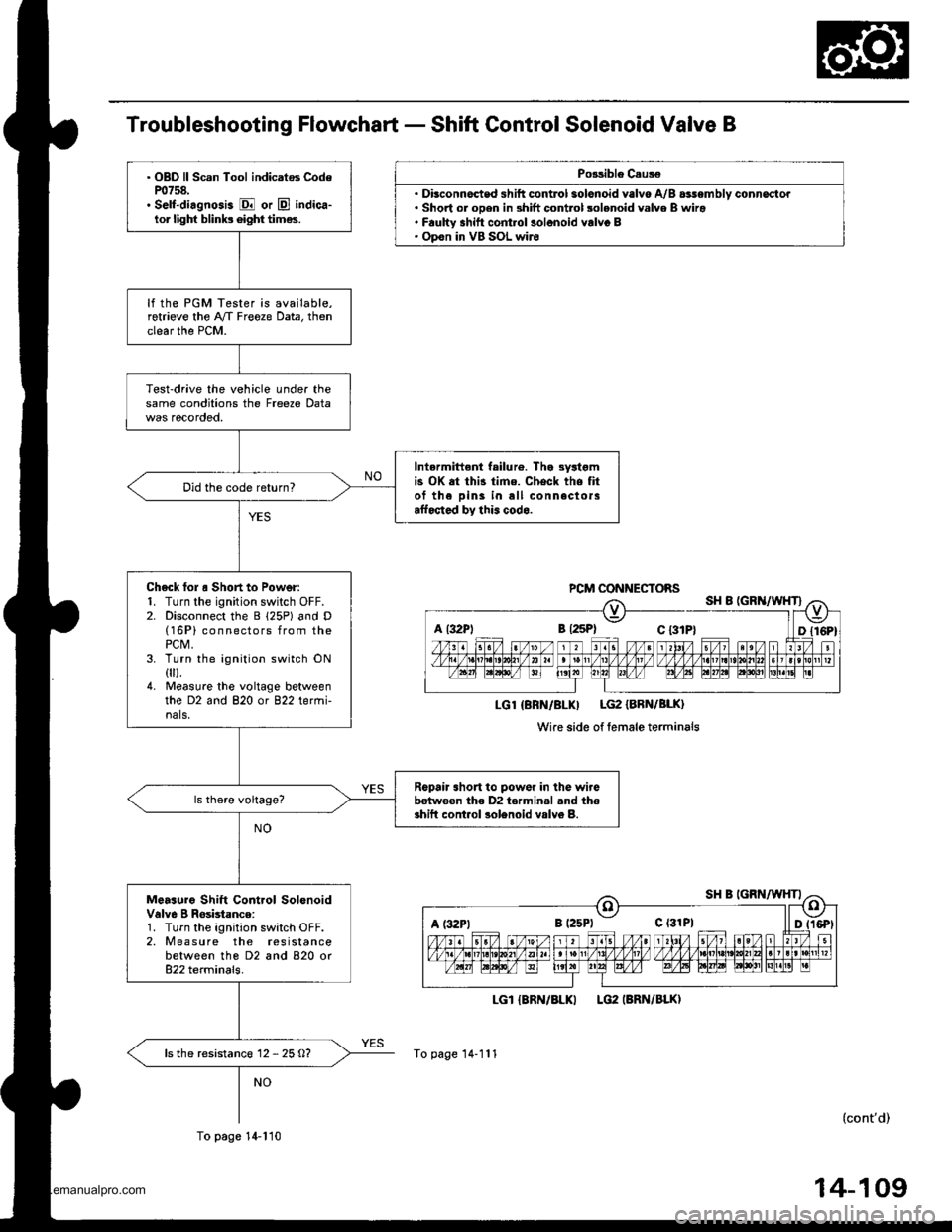

Troubleshooting Flowchart - Shift Control Solenoid Valve B

Po3sible C.us€

.Dt. Short or oDen in shift control solenoid valve B wira' F.ulW shitt cont.ol solonoid valvc B. Opon in VB SOL wir6

LGI {8RN/BLKI

To page 14-111

PCM CONNECTOBS

LGl {BRN/BLKI LG2 {BRN/BLK}

Wire side of lemale terminals

a l32Pl B {2sPl c t3tP}

c (31P1

. OBD ll Scan Tool indicatos CodeP0758.. Self-di.gnosis E or E indica-lor lighf blinb 6ight times.

lf the PGM Tester is available.retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intermittent failu16. Tha 3yltgmis OK at thi3 time. Check the fitof the Dins in all connectorsaffocted by this codo.

Did the code return?

Check lol o Short to Power:1. Turn the ignition switch OFF.2. Disconnect the B 125P) and D(16P) connectors from thePCM,3. Turn the ignition switch ON0ll.4. Measu.e the voltage betweenthe D2 and 820 or 822 termi-nals.

Ropair short to powor in lhe wirebetwoon the D2 termin.l .nd thoshift cont.ol solenoid vslv6 B.

Measuro Shift Control SolonoidValve I Rosbtance:1. Turn the ignition switch OFF.2. M easu re the resistancebetween tho D2 and 820 or822 terminals.

ls the resistanc€ 12 - 25 O?

To page 14-110

LG2 IBRN/BLKI

(cont'd)

www.emanualpro.com

Page 628 of 1395

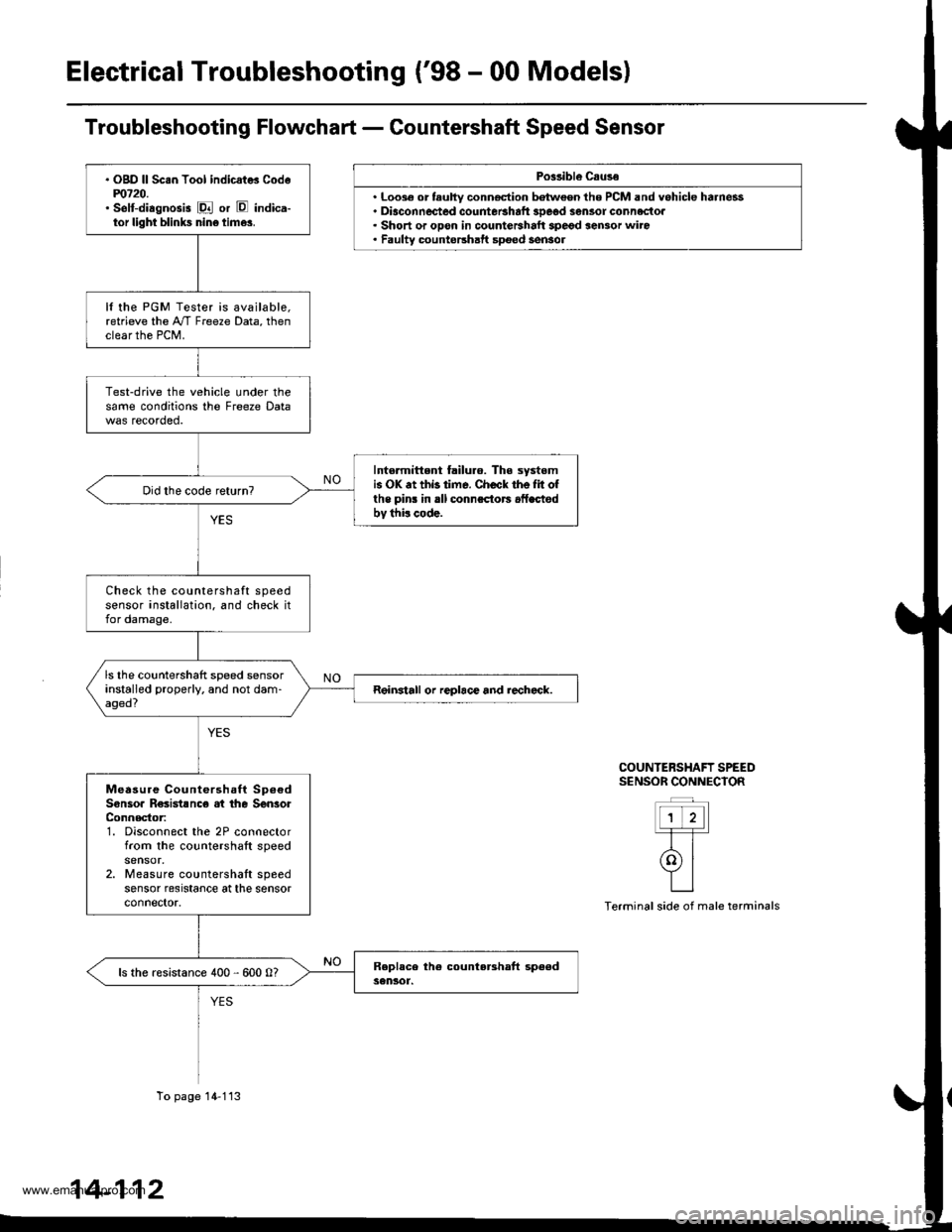

Electrical Troubleshooting ('98 - 00 Models)

Po$ibl€ Csuse

. Loo3€ or tauhy conn€ction batween the PCM and vehicle harness. Diaconnected countetshaft 3Deod sensor connectoa. Short or opon in countershalt spegd sensor wiro. Faulty countershatt spoed sensol

COUNTERSHAFT SPEEDS€NSOR CONNECIOR

ttt'l-T-T-

rolYILI

Terminal side of male terminals

. OgD ll Sc.n Tool indicat* Codem720.' selt-diagnosis E or E indica-tor light blinks nin6 time3.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intormittent failuro. The systomis OK .t thb time. Check the Iit ofthe pins in rll connsctors .fLctodbv thi! code.

Check the countershaft speedsensor installation. and check itfor damage.

ls the countershaft speed sensorinstalled properly. and not dam-aged?Reinstall or replace and rechcck.

Measure Countershaft Sp6€dSonsoa R€sistsnc€ at the SenlorConnector:1. Disconnect the 2P connectorfrom the countershaft speed

2. Measure countershaft speedsensor resrstance at the sensorconnector.

ls the resistance 400 - 600 0?

To page 14-113

14-112

www.emanualpro.com

Page 630 of 1395

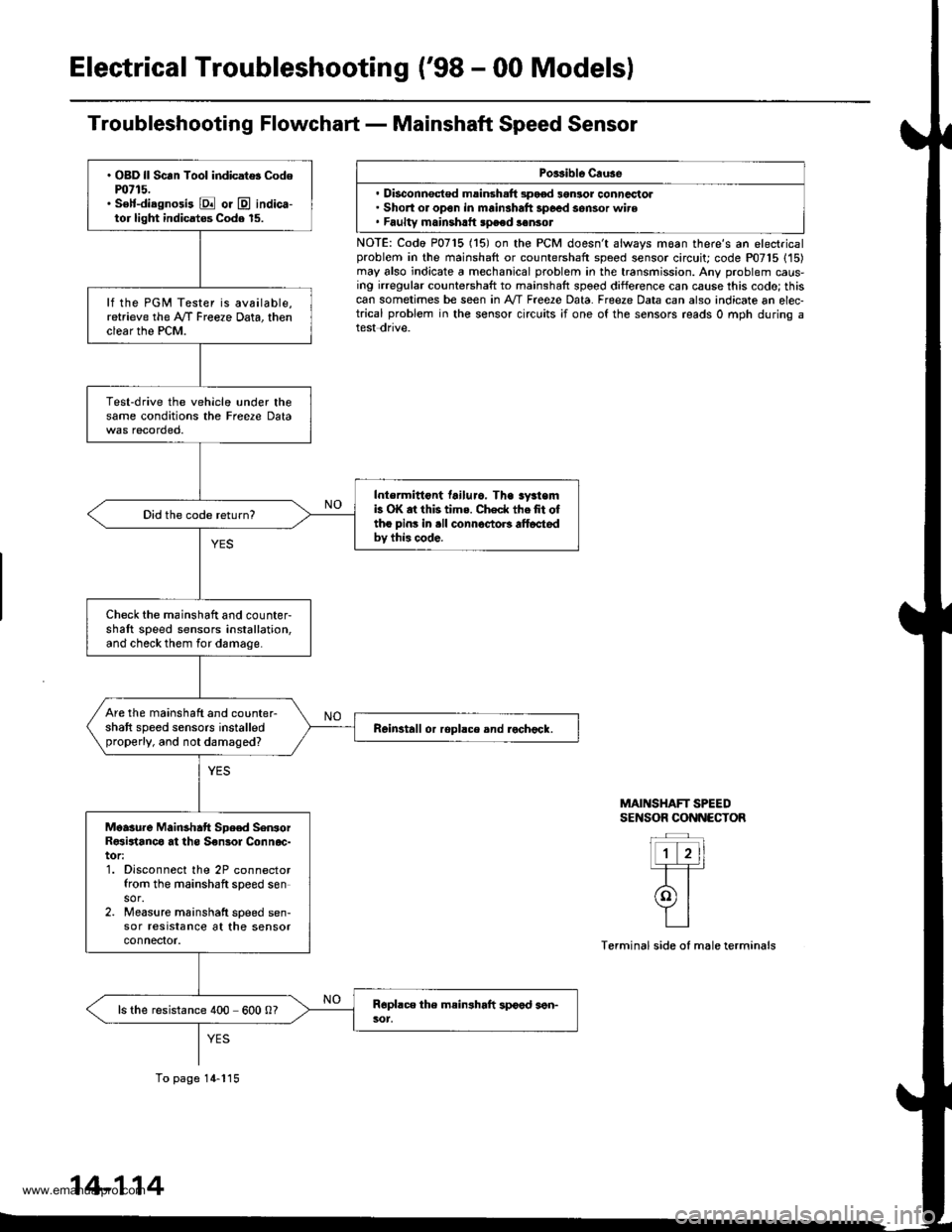

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - Mainshaft Speed Sensor

Porsible Cruse

. Disconnsct€d msinsh.ft 3pood 3gnlor conncctol. Short or open in mainshaft 3poed sensor wire. Faultv mainshrtt speed sonsot

NOTE: Codo P0715 (15) on the PCM doesn't always moan there's an electricalproblem in the mainshaft or countershaft speed sensor circuit; code P07'15 (15)may also indicate a mechanical problem in the transmission. Any problem caus-ing irregular countershaft to mainshaft spoed difference can cause this codo; thiscan sometimes be seen in A'/T Free2e Data. Freeze Data can also indicate an elec-trical problem in the sensor circuits ;f one of the sensors reads 0 mph during atest dnve.

MAINSHAFT SPEEDSENSOR CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indicat$ Codem715.. S€lf-diagnosi3 E or @ indica-tor light indicatos Code 15.

lf the PGM Tester is available,retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freere Data

Intermittont tailuro. Tha sy3temb OK at this tims. Check thefit oftho pins in .ll connoctoB alt6ctedbv this code.

Did the code return?

Check the mainshaft and counter-shaft speed sensors installation,and check them for damage.

Are the mainshaft and counter-shaft speed sensors installedproperly, and not damaged?Reinstall or ropllce and rochock.

Moasure Mainshatt Spe€d SenrorR€sirtanco at ths S€nsol Connoc-tor:1. Disconnect the 2P connectorfrom the mainshaft speed sensor.2. Measure mainshatt speed sen-sor resrstance at the sensorconnefior.

ls the resistance 400 600 0?

To page 14-115

14-114

www.emanualpro.com

Page 633 of 1395

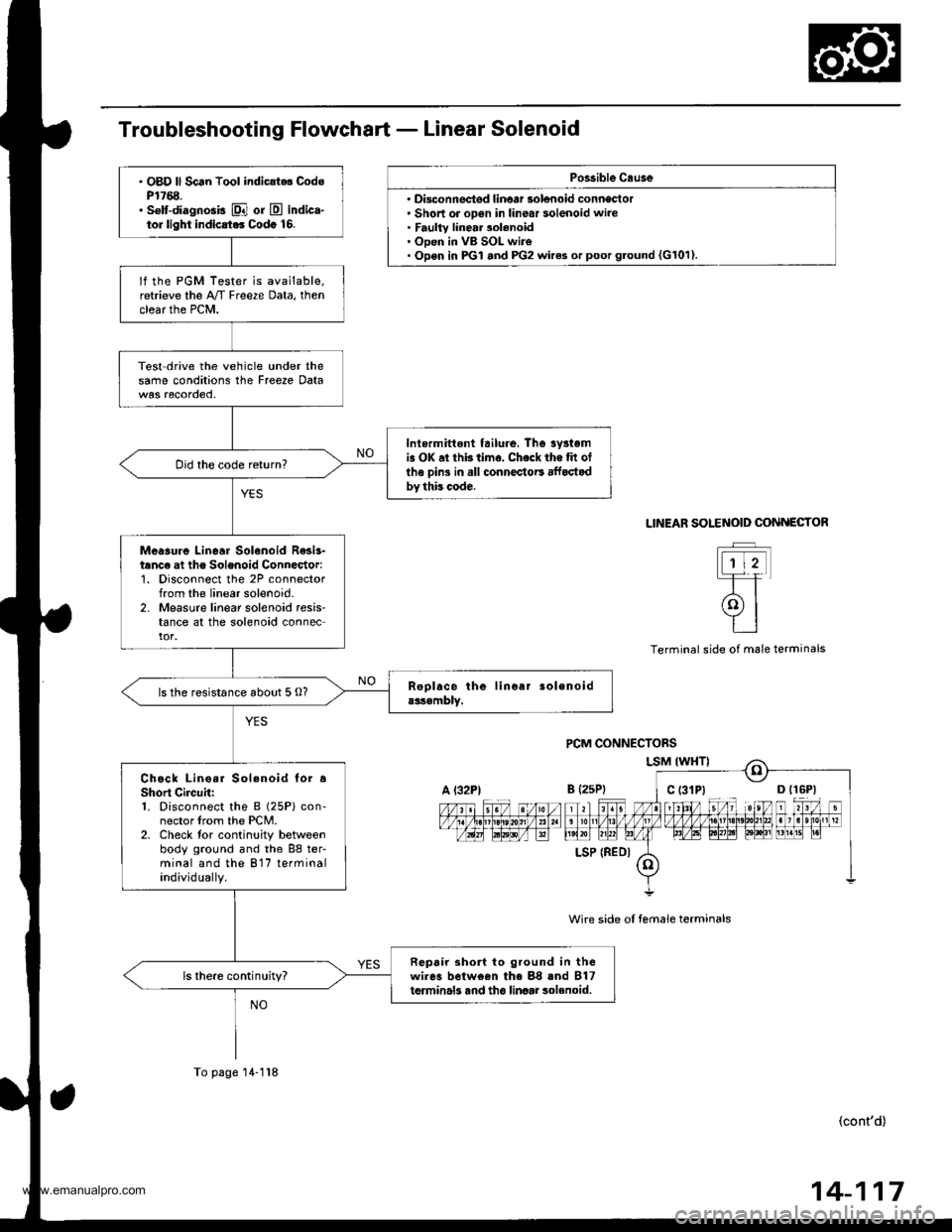

Po$ible Cau3e

' Disconnectsd linoar solenoid conneclol. Short or open in linear solenoid wire. Faulty linear 3olenoid. Open in VB SOL wire. Open in PGI and PG2 wires or poot g.ound {G101).

. OBD ll Scan Tool indic{t.. CodsP1768.. selt-diagnosis El or E indica-tor light indicrt.. Codo 16.

lf the PGM Tester is available.retrieve the A/T Freeze Data, thenclear the PCM.

Test drive the vehicle under thesame conditions the Freeze Data

Inlermittont tailure, The 3yrtomis OK at thb time. Check the tit otlhe oins in all connectoE affoctodby this code.

Did the code return?

Meaaure Linear Solenoid R€sis-tanc€ at the Solenoid Connector:1. Disconnect the 2P connectorfrom the linear solenoid-2. Measure linear solenoid resis-tance at the solenoid connector.

ls the resistance about 5 O?

Chock Lino.r Sol.noid to. aShort Circuh:1. Disconnect the B (25P) con-nector lrom the PCM.2. Check tor continuity betweenbody ground and the 88 ter-minal and the 817 terminalindividually.

Repair 3ho to ground in thewires belween the 88 rnd B17terminals and tho linaar 3olenoid.ls there continuity?

A l32PtB {2sP)

LSP (REDI

To page 14-118

SOLENOID COiINECTOR

t-rtt

(9l

tt

LINEAR

Terminal side ol male terminals

wire side oI temale terminals

(cont'd)

14-117

www.emanualpro.com

Page 635 of 1395

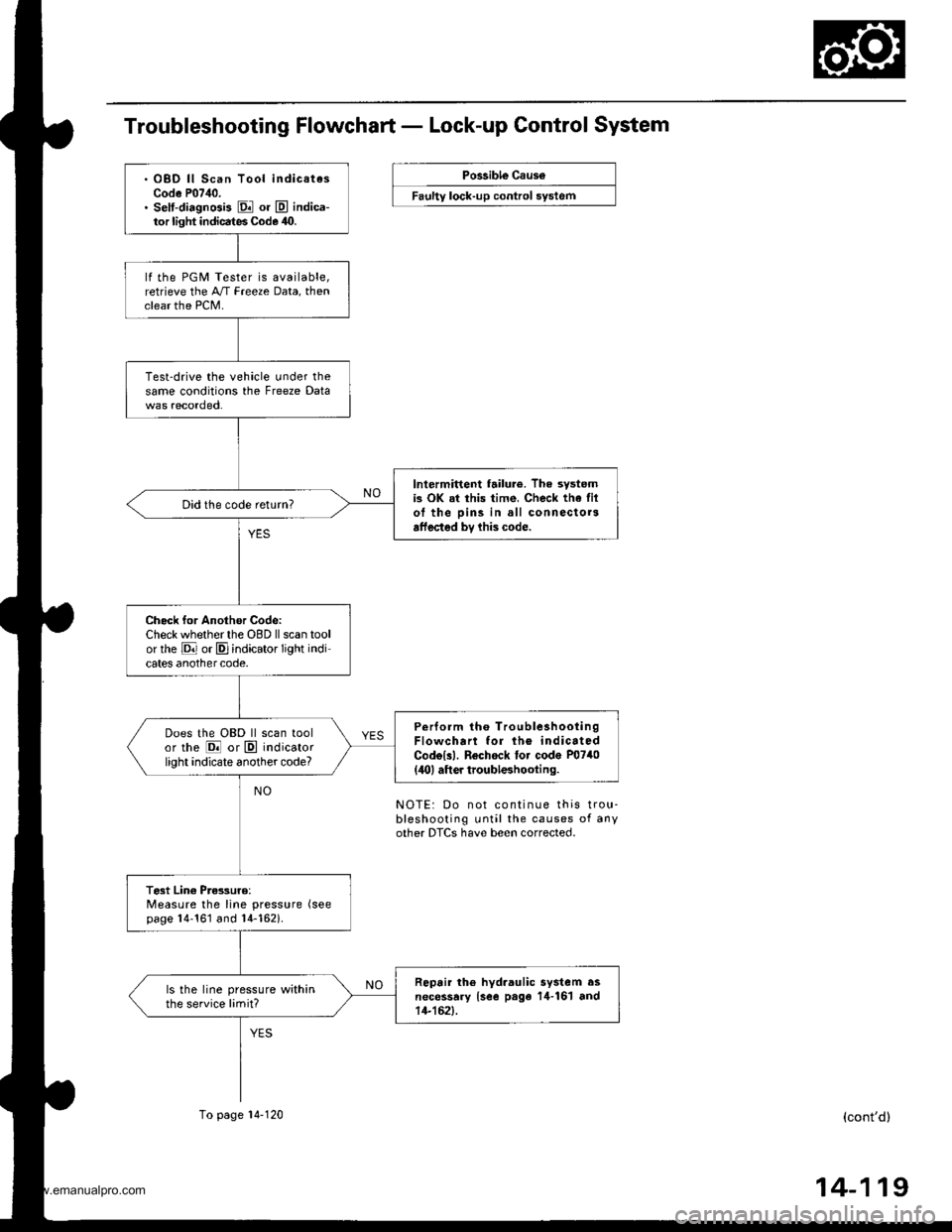

Troubleshooting Flowchart - Lock-up Control System

Possible Caus6

Faulty lock-up control system

. OBD ll Scan Tool indicatesCode P07,10.. selt-diagnGis El or E indica-tor light indicates Code 40.

lf the PGM Tester is available,retrieve the A/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

lntermittent failur6. The systemis OK at this time, Check the filol the pins in all connectorsaffected bv lhis code.

Did the code return?

Check for Another Codc:Check whether the OBD ll scan toolor rhe E or E]indicator light indicates anothercode,

Perform tho TroubleshootingFlowchart for lh6 indicatedCodolll. Rechock tor code P0740(,lO) aft er troubleshooting.

Does the OBD ll scan toolor the @ or E indicatorlight indicate another code?

Test Lin€ Pres3uro:Measure the line pressure (see

page 14'161 and 14-162i.

Repair th6 hyd.aulic system asnecessary {see page 14-161 and14-152).

ls the line pressure withinthe service limit?

To page 14-120

NOTE: Do not continue this trou-bleshooting until the causes of anyother DTCS have been corrected.

(cont'd)

14-119

www.emanualpro.com

Page 637 of 1395

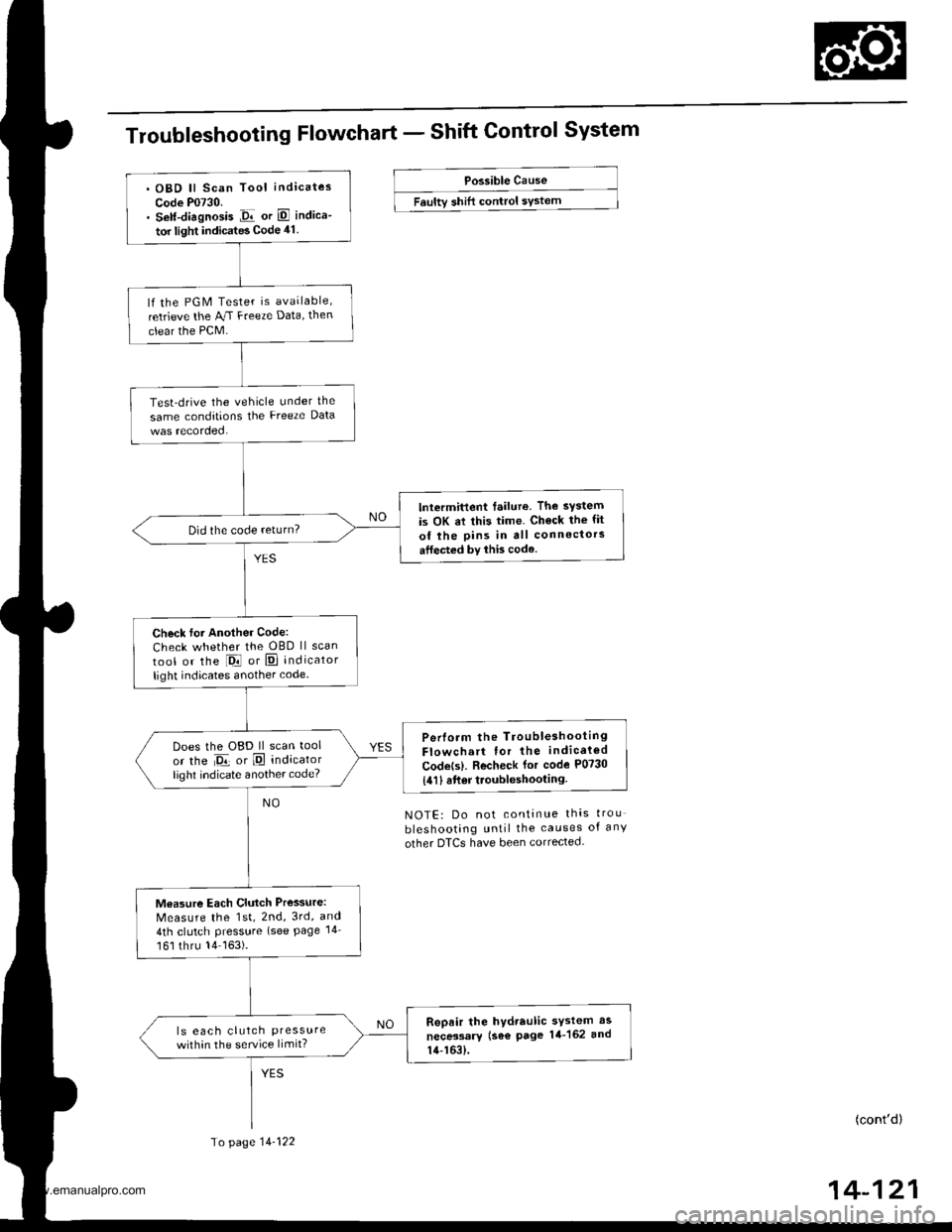

Troubleshooting Flowchart - Shift Control System

Possible Cause

Faultv shift control sYstem

NOTE: Do not continue thas trou

bleshooting until the causes of any

other DTCS have been corrected.

(cont'd)

14-121

. OBD ll Scan Tool indicates

Code P0730.. Self-diagnosis Jir or E indica-

tor light indicates Code 41.

lf the PGM Tester is available,

retrieve the AJ.I Freeze Data, then

clear the PCM.

Test-drive the vehicle under the

same conditions the Freeze Data

lntermittent failure. The system

is OK at this time. Ch€ck the fit

of the pins in all connectors

atfected by this code.

Did the code return?

Check for Another Code:

Check whether the OBD ll scan

tool or the l-Drl or E] indicator

light indicates another code.

Perlorm the TroubleshootingFlowchart for the indicaled

Codets). Recheck for code P0730

{411 6ft6r troubleshooting.

Does the OBD ll scan tool

or the Da or E indicatorlighl indicate another code?

Measure Each Clutch Pressure:

Measure the 1st, 2nd, 3rd, and

4th clutch Pressure (see Page 14

161 thru 14163).

Repair the hydraulic sYstem as

necessary (se€ page 14-162 and

14-163).

ls eac h clutch Pressurewithin the service limit?

To page 14-122

www.emanualpro.com

Page 639 of 1395

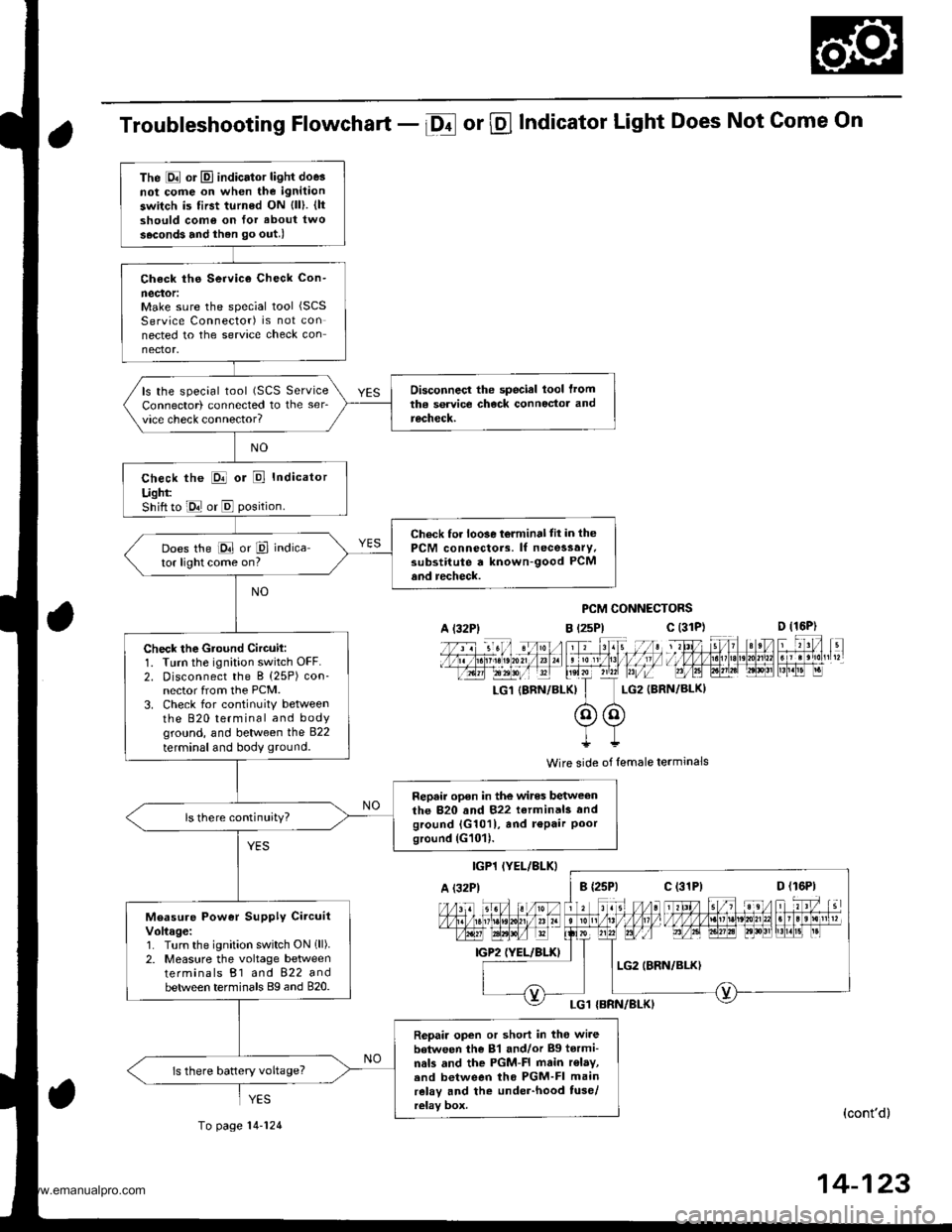

Troubleshooting Flowchart - Df or @ Indicator Light Does Not Come On

PCM CONNECTORS

B t2sPl c (31D (16P)

l*f4tr 8-

f - -- -6 3 rol ,: irr t lrpri$fe?0?r/a)1 e 'oI 13 11/ / l//|rrr I , ltelx ?r2? r,/i-T_LG1 {8RN/BI-KI I LG2 (BRN/BL()I

@@I++

Wire side of lemale terminals

(cont'd)

14-123

The E or El indicator light doe3not cofie on when the ignitaon

switch is first turned ON {ll). {ltshould como on for about two

s.cond3 and ihen go out.l

Check ths Service Check Con-

neclor:Make sure the special tool (SCS

Service Connector) is not connected to the service check connector.

Disconnecl the special lool lromtha service check connoctor andrecheck.

ls the special tool (SCS ServiceConnector) connected to the ser_vice check connector?

check the E or E Indicator

Ught:Shift to E or E position.

Check for loo3e t6lminal tit in thePCM connectors. lf necessary.substitute a known-good PCMand recheck.

Does the E or P indica-tor light come on?

Check the Gtound Circuil:1. Turn the ignition switch OFF.2. Disconnect the B (25P) con-nector from the PCM.3. Check for continuitY betweenthe 820 terminal and bodyground, and between the 822

terminal and body ground.

Repair open in the wires betweenthe 820 and 822 terminals andground {G1011, and r€Pair Poorground (G101).

ls there continuity?

Measure Power Supply CircuitVoltage:1. Turn the ignition switch ON 1ll).2. Measure the voltage betweenterminals B1 and 822 andbetween terminals Bg and 820.

Repair open or short in tho wi.ebetween the 81 and/or Bg tormi-nals and the PGM-FI main r€lay,.nd between tho PGM-FI mainrelay and the under-hood tuse/relay box.

ls there battery voltage?

A l32Plc (31P)

c (31P)

YES

To page 14-124

www.emanualpro.com

Page 642 of 1395

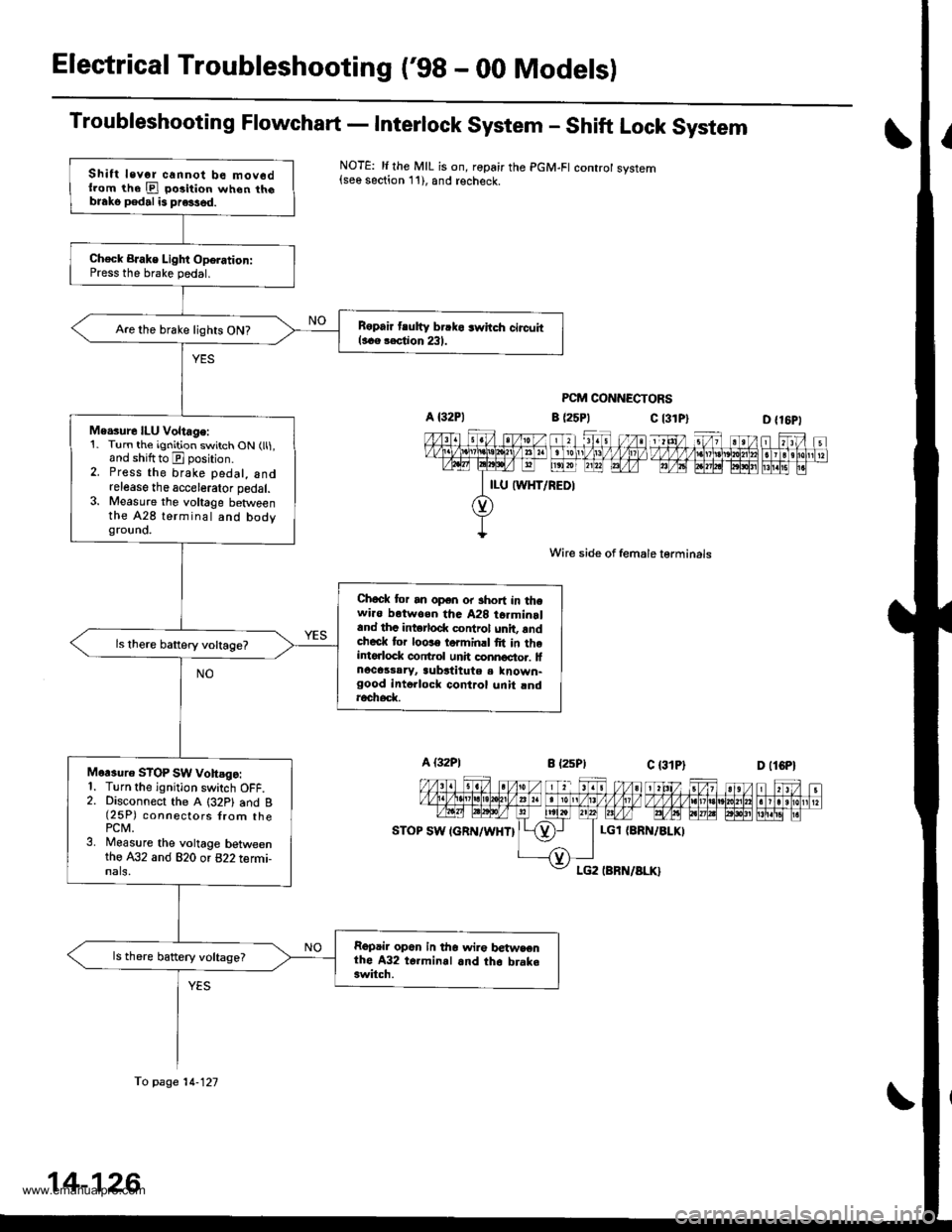

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - Interlock System - Shift Lock System

NOTE: li the MIL is on, ropair the PGM-FI controt system{see section 11), and recheck.

PCM CONNECTORS

c l3lPl

Wire side of female lerminals

c t3lPt

D {16P1

1 tttt/ 5t/ 1 a t /tlt 1 t\/t ,/ VVV tl t ttj,r\1e\10l211n . I 3 rholr1 t?m@-@Effilil"

D (lCPl

| 2ttt/ ;t /n) ).tt)/ 1 21:/ tvvvvv nnvl.lnl2

I r r ero

12wE gp]P] polr EI!l!!i r.

a (25P1

LGl {8RN/ALKI

Shift levor cannot be mov6dllom the E po3ition when th6blako pedal is pre3sed.

Ch€ck BJake Light Oporation:Press the brake pedal.

B6pair tlutty brrko 3whch circuitl..e rection 231.Are the brake lights ON?

Me.sure ILU Voltage:1. Turn the ignition switch ON (ll1,and shiftto E position.2. Press the brake pedal, andrelease the accelerator pedal.3. Measure the voltage betweenthe A28 terminal and bodygrouno.

Chock tor an open or short in thewi.o botwoen tha A28 t6rminrland thc intorlod( control unit, rndcheck tor loose torminrl fit in theintorlock conftol unh connoctor. lfnocassaryr aubstitute a known-good intollock control unit rndroch6d(

Mor3uro STOP SW vohsgo:1. Turn the ignition switch OFF.2. Disconnect the A (32P1 and B(25P) connectors {rom thePCM.3. Measure the voltage betweenthe A32 and 820 or 822 termi-nals,

Repair op6n in tho wir€ betwsenthe A32 t6.minal and th6 brake3witch.

ls there battery voltage?

fo page 14-121

14-126

www.emanualpro.com

Page 673 of 1395

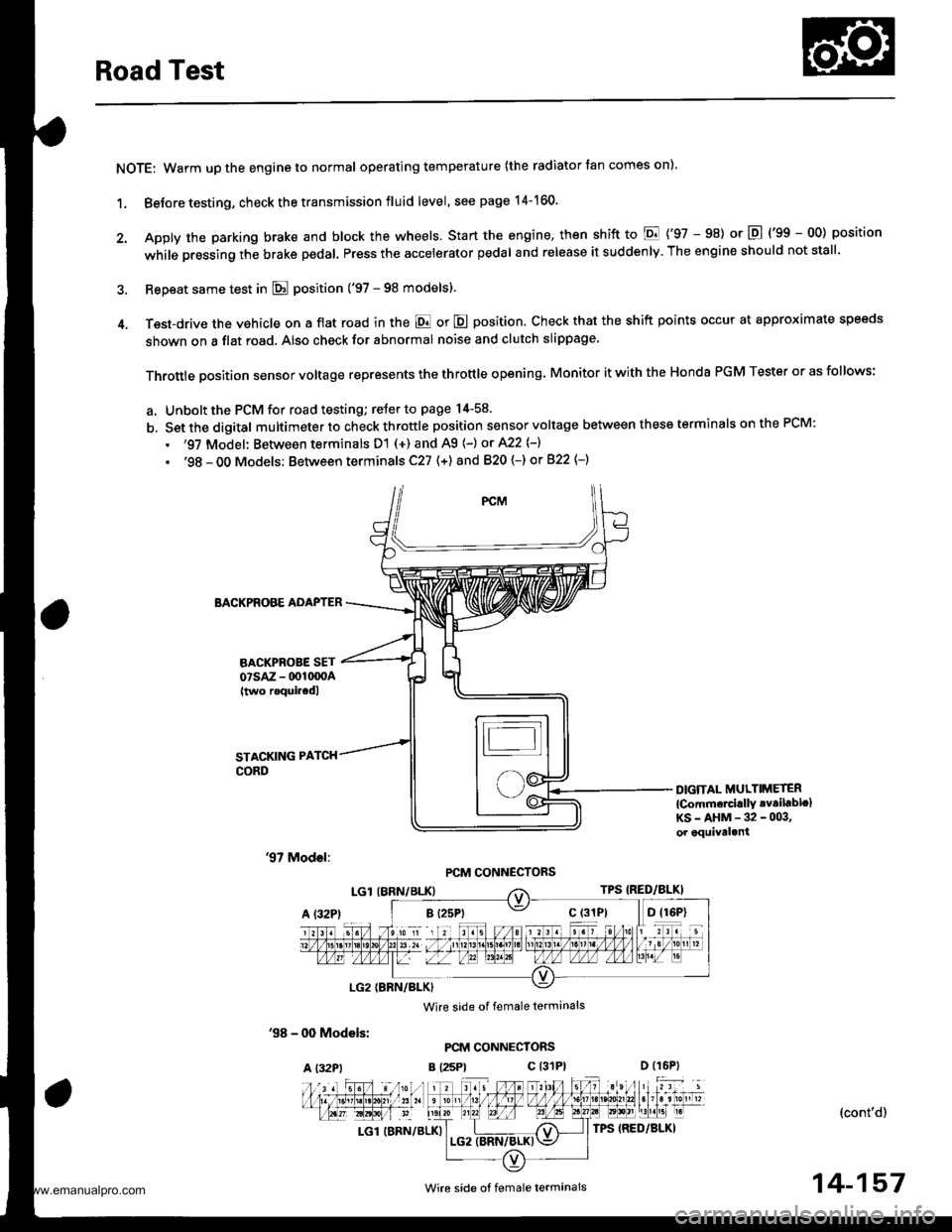

Road Test

NOTE: Warm up the engine to normal operating temperature (the radiator tan comes on).

1. Before testing, check the transmission fluid level, see page 14-160.

2. Apply the parking brake and block the wheels. start the engine, then shift to E {'97 - 98) or E {'gg - 00) position

while pressing the brake pedal. Press the accelerator pedal and release it suddenly. The engine should not stall.

3. Repeat same test in E position ('97 - 98 models).

4. Test-drive the vehicle on a flat road in the E or E position. Check that the shift points occur at approximate speeds

shown on a flat road. Also check for abnormal noise and clutch slippage.

Throttle position sensor voltage represents the throttle opening. Monitor it with the Honda PGM Tester or as follows:

a. Unbolt the PCM for road testing; reJer to page 14-58.

b. Set the digital multimeter to check throttle position sensor voltage between these terminals on the PCM:

. '97 Model: Between terminals D'! (+) and A9 (-) or A22 {-}

. '98 - OO Models; Between terminals C27 (+) and 820 (-) or 822 {-)

BACKPROBE ADAPTER

BACKPROBE SETorsAz - 001moA(two roquircdl

STACKING PATCH

CORD

DIGiTAL MULTIMETER

{Comm€rcirllY .vailablc}KS-AHM-32-003,or equival.nt

'97 Model:PCM CONNECTORS

'98 - 0O Models:

A l32Pt

Wire side of female terminals

PCM CONNECTORS

B {25Pt c l31P}

(cont'd)

LGl (BRN/BLK)

'. //B 1 l'o ti , jl. to a 2r / / 11111t1.t nait la t1 t213tr / t6t, tl / / / / 1 3 / 10n v

t-'a:IM-&E -Llfiffi-fl)\"".'E

Wire side ot female termanals14-157

www.emanualpro.com