4-40 HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 51 of 1395

Engine Electrical

Speciaf Tools ............. 4-2

Starting System

Component Location Index ............ 4-3

Circuit Diagram ................................ 4-4

Starter Test ........... 4-5

Starter Solenoid Test ...................... 4'5

Starter Replacement ....................... 4-7

Field Winding Test ........................... 4-7

Starter Overhaul ............................,. 4-8

Brush Inspection ...........................,., 4-9

Overrunning Glutch Inspection ...... 4-9

Armature lnspection and Test ........4-10

Brush Holder Test ............................ 4-12

Starter Reassemb|y ......................... 4-1 2

Perf ormance Test ............................. 4- 1 3

lgnition System

Component Location Index ............ 4-14

Circuit Diagram ................................ 4-15

lgnition Timing Inspection and

Setting .......................................... 4-16

Distributor Replacement ........,........ 4-17

Distributor Overhaul .............,,......... 4-18

lgnition Control Module (lCM) Input

Test ..............................,................ 4-19

fgnition Coil Test .............................. 4-2O

lgnition Wire Inspection and

Test ............................................... 4-20

Spark Plug Inspection ..................... 4-21

-+

ENGINE

Charging System

Component Location Index ............ 4-22

Circuit Diagram ....................,........... 4-23

Troubleshooting .............................. 4-24

Alternator Replacement ..........,....... 4-30

Alternator Overhaul .......,,................ 4-31

Rectifier Test .........4-32

Alternator Brush Inspection ........... 4-32

Rotor Slip Ring Test ........................ 4-33

Stator Test ............. 4-33

Alternator Belt Inspection and

Adiustment ........4-34

Gruise Control

Component Location Index .,,,........ 4-36

Circuit Diagram ................................ 4-37

Control Unit Input Test ................... 4-38

Main Switch Test/Replacement ..... 4-40

Set/Resume Switch Test/

Replacement .......................,........ 4'40

Actuator Test ....,,., 4-41

Actuator Replacement ...............,.... 4-42

Actuator Cable Adiustment ............ 4-43

Clutch Switch Test .......................... 4-43

Brake Switch Test .................. .......... 4-44

Actuator Solenoid Test .............. ...,. 4-44

Actuator Disassembly ..................... 4-45

www.emanualpro.com

Page 86 of 1395

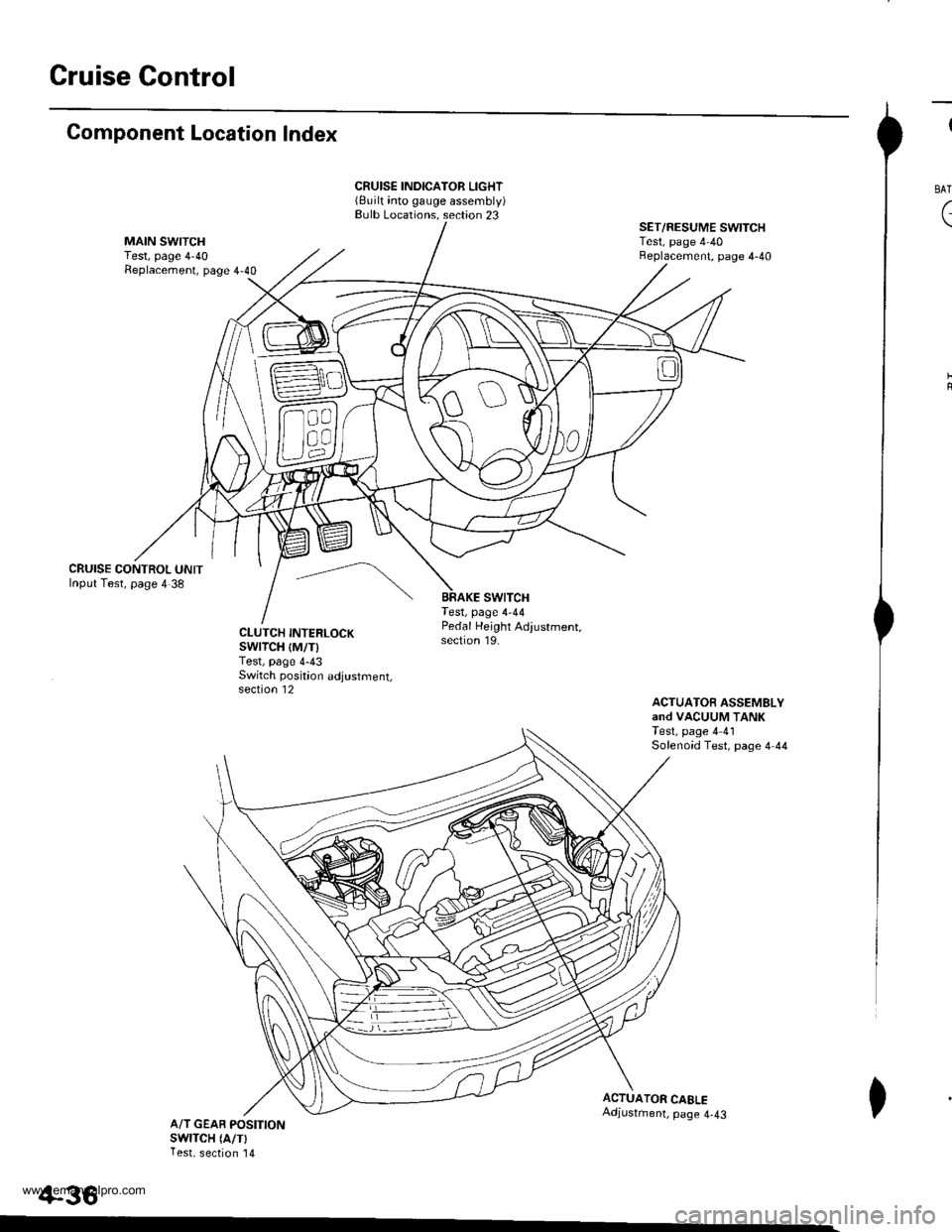

Gruise Control

Component Location Index

CRUISE CONTROL UNITInput Test, page 4 38

CRUISE INDICATOR LIGHT(Built into gauge assembly)Bulb Locations. section 23

swtTcHTest, page 4-44

SET/RESUME SWITCHTest, page 4 40Beplacement, page 4-40

ACTUATOfi ASSEMBLYand VACUUM TANKTest, page 4 41Solenoid Test, page 4 44

CLUTCH INTERLOCKswrTcH {M/T)Test, page 4-43Switch poskion adjustment,section 12

Pedal Height Adjustment,section 19.

ACTUATOR CAELEAdjustment, page 4-43A/T GEAB POSITIONswlTcH (A/TlTest, section '14

+36

I

BAT

(

I

www.emanualpro.com

Page 90 of 1395

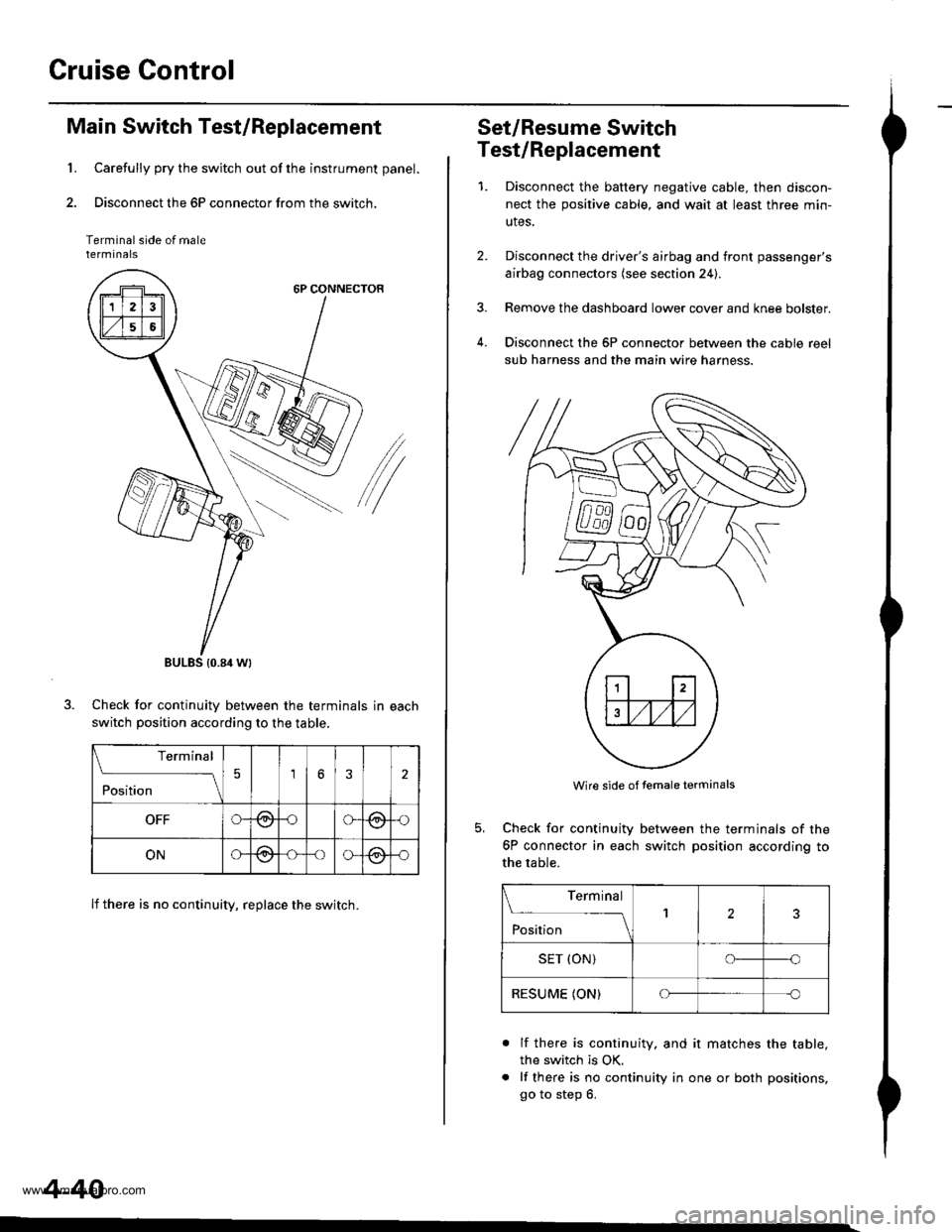

Cruise Control

1.

Main Switch Test/Replacement

Carefully pry the switch out of the instrument panel.

Disconnect the 6P connector from the switch,

Terminal side of malerermtnats

6P CONNECTOR

/

Check for continuitv between the terminals in each

switch position according to the table.

lf there is no continuity, replace the switch.

BULES {0.84 Wt

Terminal

;;;

-_\56

OFFG-@oG(9,{)

ONG@-oo-@-o

4-40

Set/Resume Switch

Test/Replacement

1.Disconnect the baftery negative cable, then discon-

nect the positive cable, and wait at least three min-

utes.

Disconnect the driver's airbag and front passenger's

airbag connectors (see section 24).

Remove the dashboard lower cover and knee bolster.

Disconnect the 6P connector between the cable reel

sub harness and the main wire harness.

4.

Wire side of temale terminals

Check for continuity

6P connector in each

the table.

between the terminals of the

switch position according to

Terminal

;;;

--_l2

SET (ON)o--o

RESUME (ON)Cf-c

a

lf there is continuity. and it matches the table,

the switch is OK.

lf there is no continuity in one or both positions,

go to step 6.

www.emanualpro.com

Page 556 of 1395

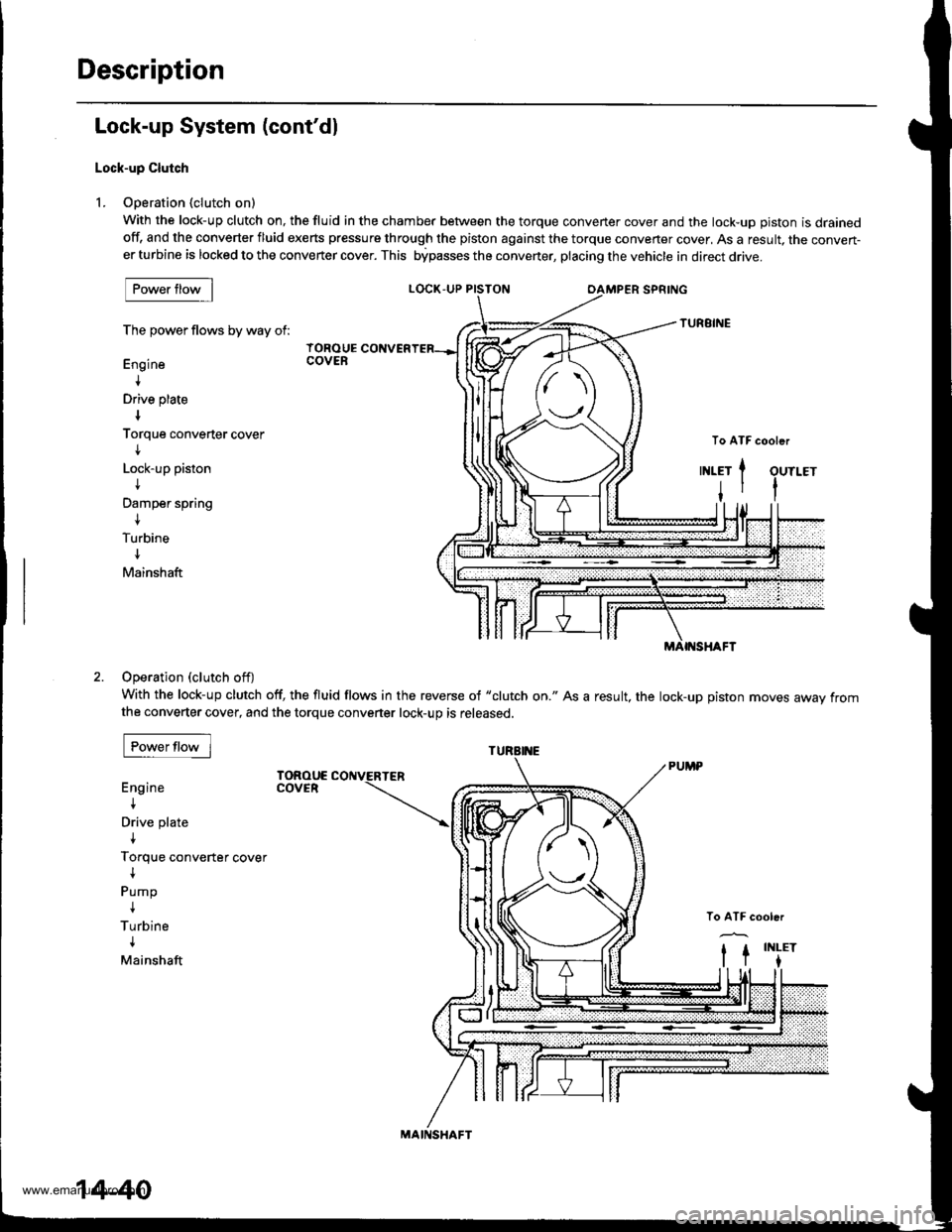

Description

Lock-up System (cont'dl

Lock-up Clutch

L Ooeration (clutch on)

With the lock-up clutch on, the fluid in the chamber between the torque convener cover and the lock-uD oiston is drainedoff, and the converter fluid exerts pressure through the piston against the torque converter cover, As a result, the conven-er turbine is locked to the converter cover. This bipasses the converter, placing the vehicle in direct drive.

LOCK,UP PISTON

The power flows by way of:

Engine

+

Drive plate

Torque converter cover

I

Lock-up piston

t

Damper spring

{

Turbine

Mainshaft

IOROUECOVER

Operation (clutch off)

With the lock-up clutch off, the fluid flows in the reverse of "clutch on." As a result, the lock-up piston moves away fromthe converter cover, and the torque converter lock-up is released.

Engine

I

Drive plate

{

Torque converter cover

{

Pump

I

Turbine

{

Mainshaft

TOROUECOVER

To ATF cooler{(1\\n1INLET

t

Jtl

ort

MAIf{SHAFT

MAII{SHAFT

14-40

www.emanualpro.com

Page 674 of 1395

Road Test

(cont'd)

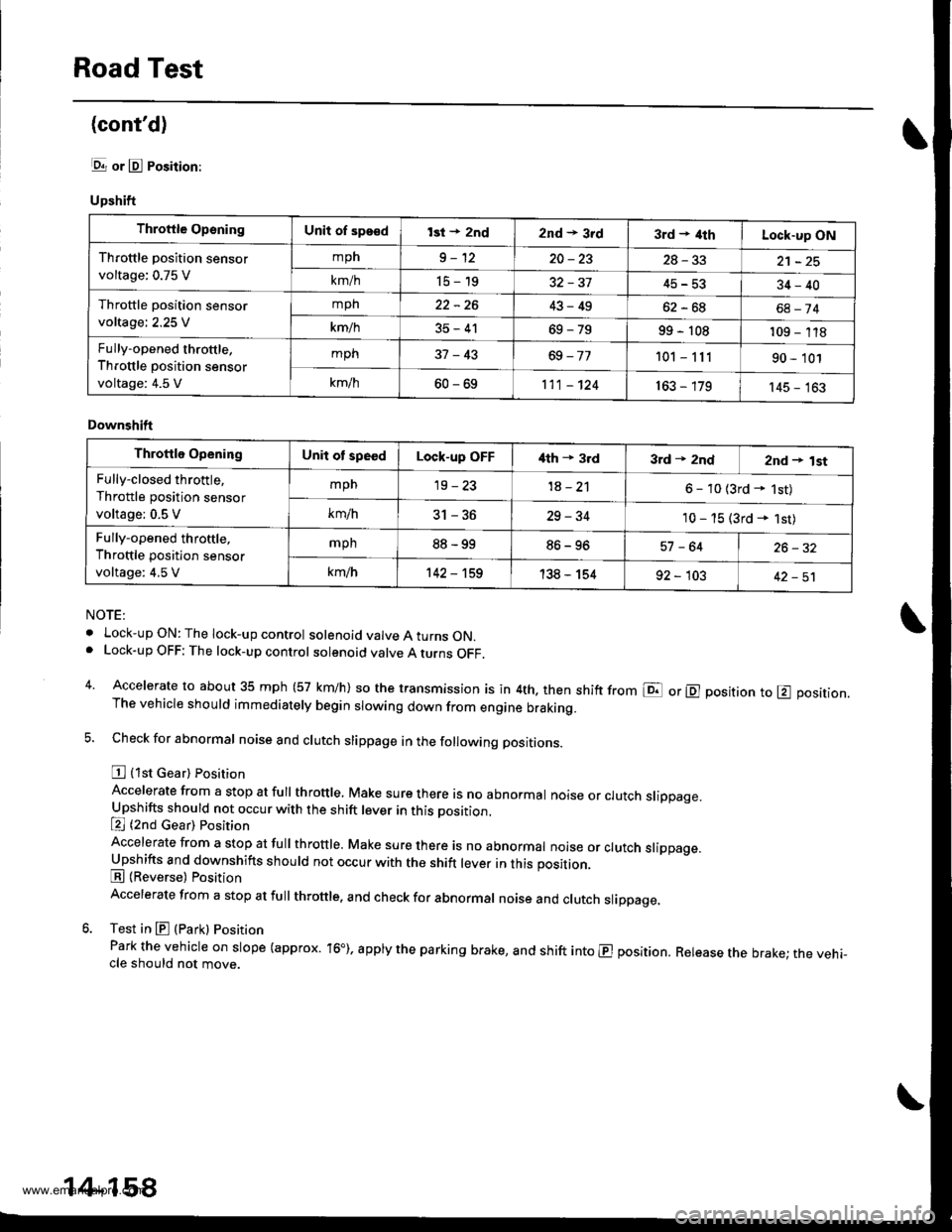

lgrr or E Position:

Upshift

NOTE:

. Lock-upON:The lock-up control solenoid valve A turns ON.. Lock-up OFF: The lock-up control solenoid valve A turns OFF.

4. Accelerate to about 35 mph (57 km/h) so the transmission is in 4th. then shift from E or E position to E position.The vehicle should immediately begin slowing down from engine braking.

5. Check for abnormal noise and clutch slippage in the following positions.

E {1st Gear) Position

Accelerate from a stop at full throttle, Make sure there is no abnormal noise or clutch slippage.Upshifts should not occur with the shift lever in this position.

E (2nd cear) Position

Accelerate from a stop at fuI throttre. Make sure there is no abnormar noise or crutch srippage.Upshifts and downshifts should not occur with the shift lever in this position.

E (Reverse) Position

Accelerate from a stop at full throttle. and check for abnormal noise and clutch slippage.

6. Test in E (Park) Position

Park the vehicle on slope (approx. 16"), apply the parking brake, and shift into E position. Release the brake; the vehi-cle should not move.

Throftle OpsningUnit of sps€dlsi + 2nd2nd * 3rd3rd + ilthLock-up ON

Throttle position sensor

voltage: 0.75 V

mph9-1220-2328-33

km/h15-1945-5334-40

Throttle position sensor

voltage; 2.25 V

mph22-2643-49oz - ott68-74

km/h35-4169-7999 - 108109 - 118

Fully-opened throttle,

Throttle position sensor

voltage: 4.5 V

mph37-43101 - 11190 - 101

k-/h60-69111 - 124163 - 179145 - 163

Downshift

Throttle OpeningUnit ot speedLock-up OFFi{th + 3rd3rd * 2ndznd + lst

Fully-closed throttle,

Throttle position sensor

voltage; 0.5 V

mpn19-231A - 2'l6 - 10 {3rd - 1st)

km/h5t-5D29-3410 - 15 (3rd * 1st)

Fully-opened throttle,

Throttle position sensor

voltage: 4,5 V

mph88-9986-9657 -6426-32

km/h142 - 't59138 - 15492 - 10342-51

14-158

www.emanualpro.com

Page 1335 of 1395

Troubleshooting

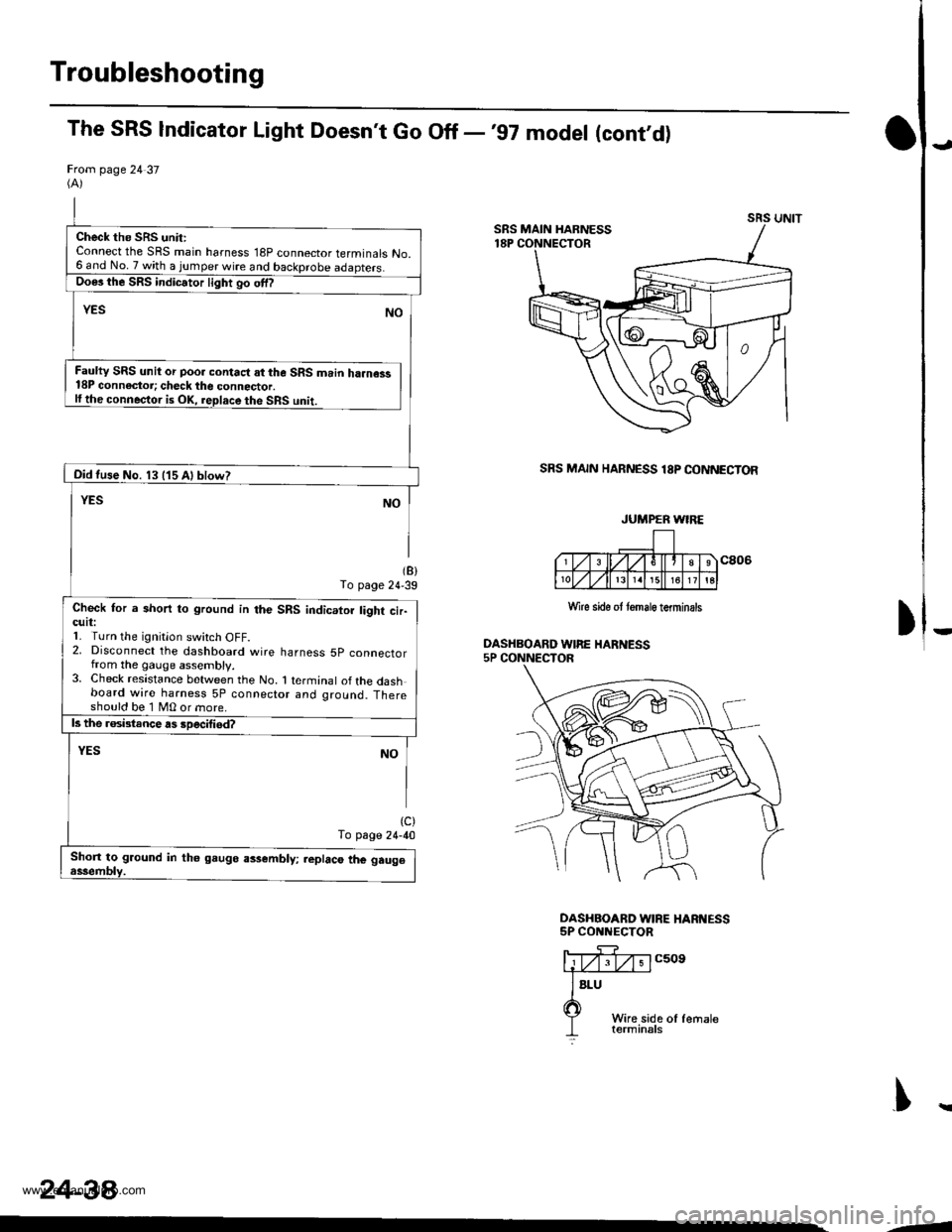

The SRS Indicator Light Doesn't Go Off - '97 model (cont,d)

From page 24 37(A)

SRS MAIN HARNESS 18P CONNECTOR

(B)To page 24'39

DASHBOARD WIRE HARNESS5P CONNECTOR

(c)To page 24-40

DASHBOAND WIRE HARI{ESS5P CONNECTOR

)

J

c509

Wire side ol femaleterminals

T

Check the SRS unit:Connect the SRS main harness 18P connector terminals No.6 and No.7 with a jumper wire and backprobe

Faulty SRS unit or poo. contact at the SRS main ha.ness18P connectoi; check the connector.lfthe conneqtor is OK, replace the SRS unit.

Oid tuse No. 13 (15 Al blow?

Check for a short to ground in the SRS indicator tight cir-cutl:1. Turn the ignitlon switch oFF.2, Disconnect the dashboard wire harness 5p connectorfrom the gauge assembly.3. Check resistance between the No. 1 terminal ofthe dashboard wire harness 5P connector and ground. Thereshould be 1 MO or more.

Shon to ground in th6 gaugo assembly; replaco the gau96

JUMPER WIRE

Wlre sido ot tomale terminsls

243a

--

www.emanualpro.com

Page 1337 of 1395

Troubleshooting

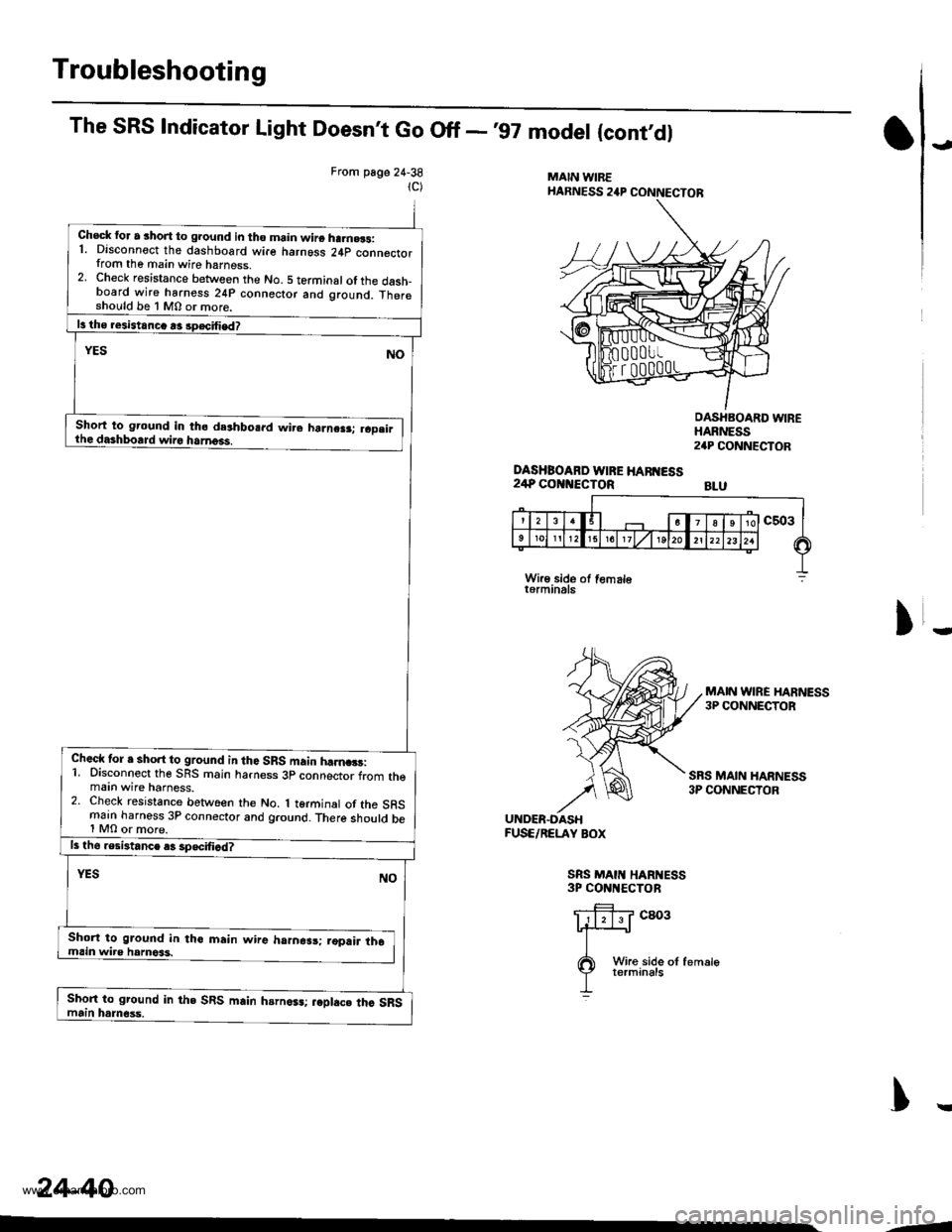

The SRS Indicator Light Doesnt Go Off -'97 model {cont'dl

From page 24-38

1C)

Check for a short to ground in tho main wire ha.n.3s:1. Disconnect the dashboard wire harngss 24p connectorfrom the main wire harness,2. Check resistance between the No. 5 terminal of the dash_board wire harness 24P connector and ground. Thereshould be 1 M0 or more.

Short to ground in tho deshbosrd wire harne.r; raD.irthe dashboard wiro harness.

Check tor a short to ground in tho SRS main hfina3!:1. Disconnect the SBS main harness 3p connector from themaan wire harness.2. Check resistance between the No. 1 terminal of the SRSmain harness 3P connector and ground. There should be1 MO or more.

Short to ground in tho main wire harnesr; ,opair th6main wire hamoss.

Short to ground in the SRS main hsrn6sa;.oplac. thc SRSmain harn6ss.

i,

MAIN WIREHARNESS 24P CONNECTOR

DASHBOARD WIRE HAff{ESS24P COi{NECTOR

OASHBOARD WIREHARNESS24P CONNECTOR

BLU

)

MAIN wlRE HARNESS3P CONNECTOB

SRS MAIN HARNESS3P CONNECTOR

UNDER.OASHFUSE/RELAY BOX

SRS MAII{ HARI{ESS3P CONNECTOR

cao3

)r

24-40

Wire side of femalet6rminals

-1

www.emanualpro.com