Seat fold HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 128 of 1395

-?E

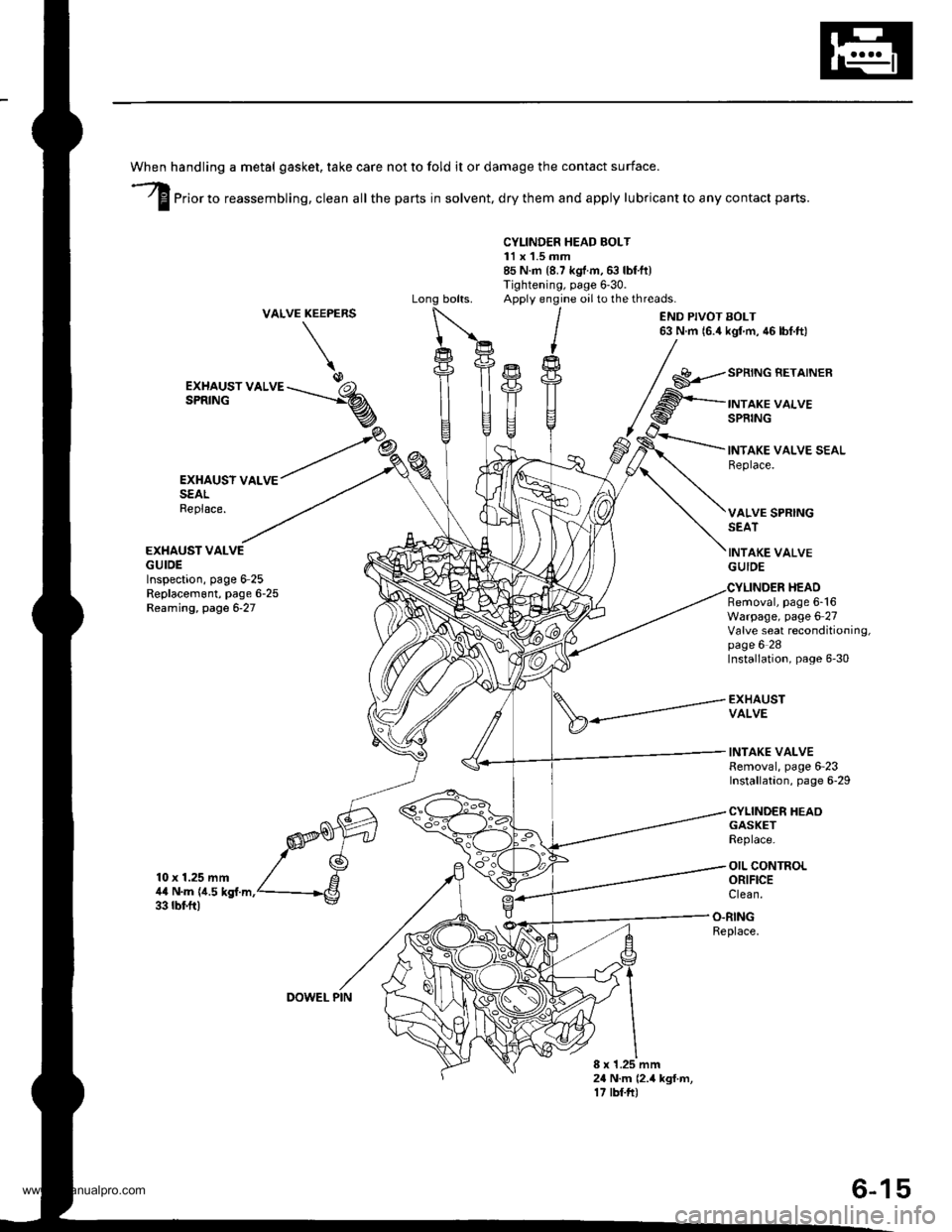

handling a metal gasket. take care not to fold it or damage the contact surface.

Prior to reassembling, clean all the parts in solvent, dry them and apply lubricant to any contact parts.

CYLINDER HEAD BOLT11 x 1.5 mm85 N.m {8.7 kgf.m,6:} lbf.ft)Tightening, page 6'30.Apply engine oilto the threads.VALVEKEEPERS

\

END PIVOT BOLT63 N.m 16.4 kgl m, 46 lbf.ft)

EXHAUSY VALVESEALReplace.

EXHAUST VALVEGUIDEInspection, page 6-25Replacem6nt, page 6-25Reaming, page 6-27

10 x 1.25 mm4,0 N.m {i1.5 kgf.m.33 rbf.ft)

GASKETReplace.

OIL CONTROLORIFICEClean.

EXHAUST VALVESPRING

SPRING BETAINER

INTAKE VALVESPRING

INTAKE VALVE SEALReplace.

VALVE SPRINGSEAT

INTAKE VALVEGUIDE

Removal, page 6-16Warpage, page 6 27Valve seat reconditioning,page 6 28Installation, page 6-30

EXHAUSTVALVE

INTAKE VALVERemoval, page 6-23Installation, page 6-29

CYLINDER HEAO

HEAD

O.RINGReplace.

8 x 1.25 mm24 N.m (2.4 kgf.m,17 tbf.ft)

DOWEL PIN

6-15

www.emanualpro.com

Page 385 of 1395

Fuel Pump

Testing

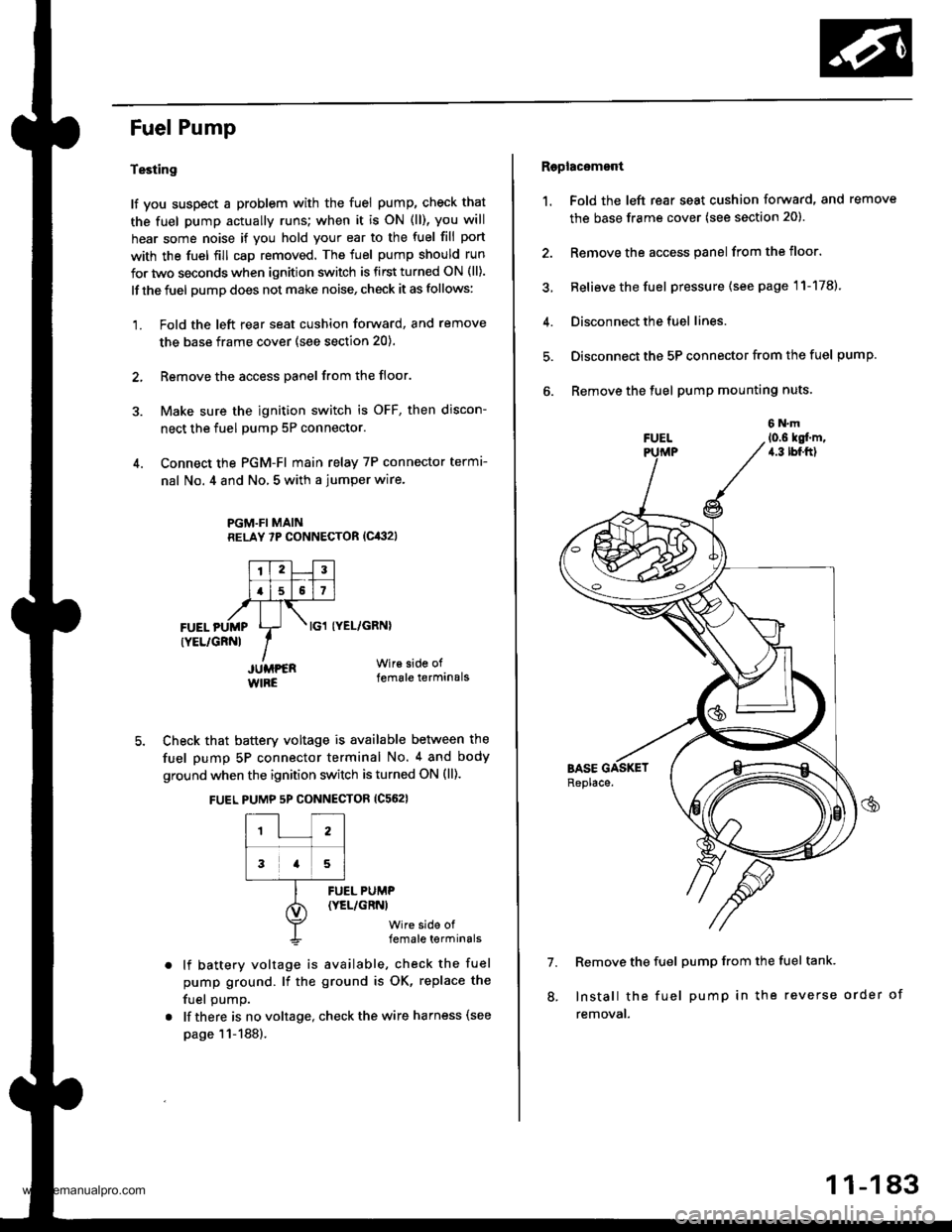

lf you suspect a problem with the fuel pump, check that

the fuel pump actually runs; when it is oN (ll), you will

hear some noise if you hold your ear to the fuel fill port

with the fuel fill cap removed. The fuel pump should run

for two seconds when ignition switch is first turned ON (ll).

lf the fuel pump does not make noise, check it as follows:

1. Fold the left rear seat cushion forward, and remove

the base frame cover (see section 20).

2, Remove the access panel from the floor.

3. Make sure the ignition switch is OFF, then discon-

nect the fuel pumP 5P connector.

4. Connect the PGM-FI main relay 7P connector termr-

nal No. 4 and No, 5 with a jumper wire.

PGM.FI MAINRELAY 7P CONNECTOR (Cit:}2l

I'TtlJilt f -r'-r ll.l5l517l,frTt-,at\FUEL pUMp Lr- . tcl tyEL/cRNl

rYEL/cRNl IIJUMPER Wir€ side of

WIRE female terminals

5. Check that battery voltage is available between the

fuel pump 5P connector terminal No. 4 and body

ground when the ignition switch is turned ON (ll).

FUEL PUMP 5P CONNECTOR {C562}

12

3a5

lf battery voltage is available, check the fuel

pump ground. lf the ground is OK, replace the

fuel oumo.

lf there is no voltage, check the wire harness (see

page 11-188).

FUEL PUMP(YEL/GRNI

wire side offemale terminals

Raplac6mont

1. Fold the left rear seat cushion forward, and remove

the base frame cover (see section 20).

2. Remove the access panel from the floor.

3, Relieve the fuel pressure (see page 11-178).

4. Disconnect the fuel lines.

5. Disconnect the 5P connector from the fuel pump.

6. Remove the fuel pump mounting nuts.

7. Remove the fuel pump from the fuel tank.

Install the fuel pump in the reverse order of

removal.

8.

11-183

www.emanualpro.com

Page 386 of 1395

Fuel Supply System

Fuel Gauge

Tssting

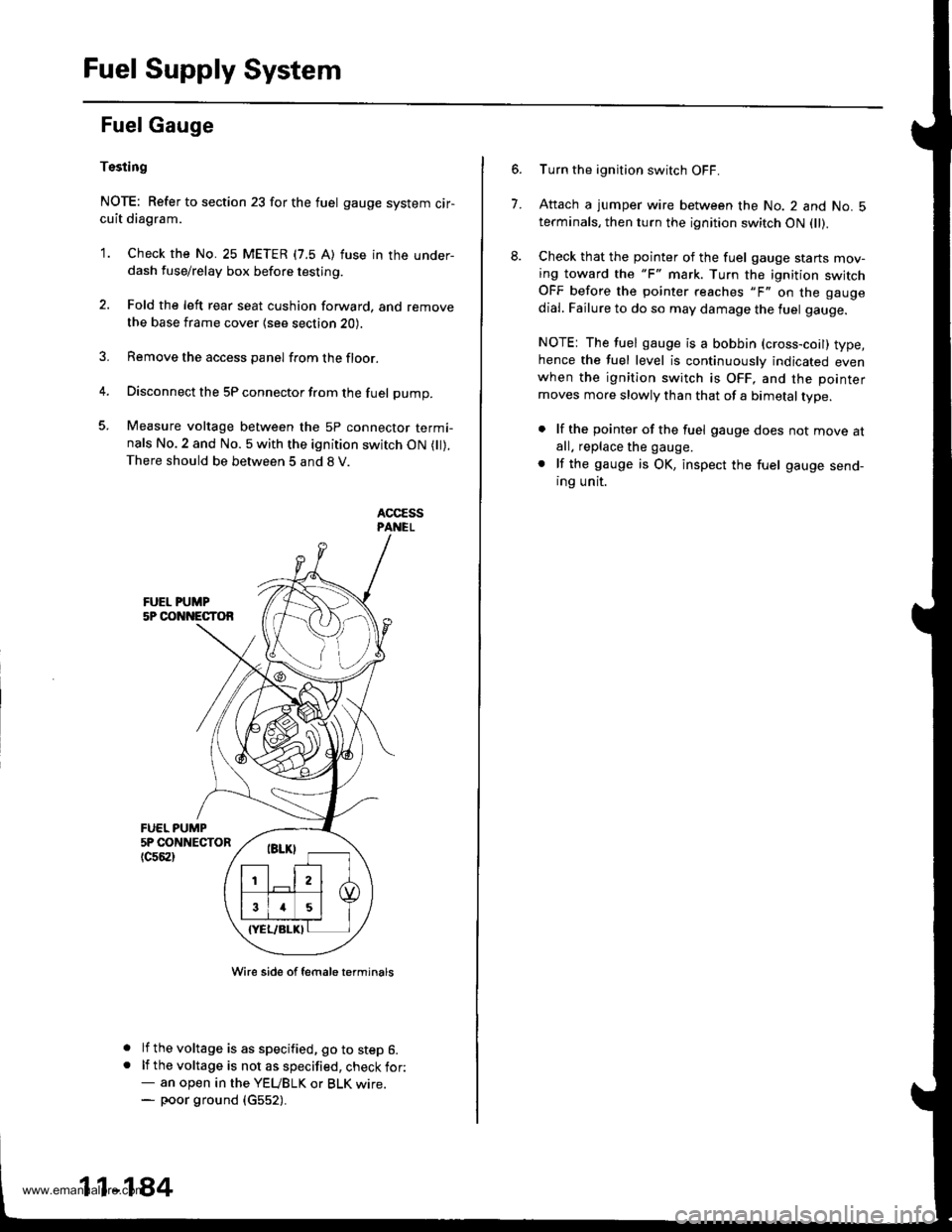

NOTE: Refer to section 23 for the fuel gauge system cir-cuit diagram.

'1. Check the No. 25 METER (7.5 A) fuse in the under-dash fuse/relay box before testing.

2. Fold the left rear seat cushion forward, and remove

the base frame cover {see section 20).

3. Remove the access panel from the floor.

4. Disconnect the 5P connector from the fuel pump.

5. Measure voltage between the 5P connector termi-nals No.2 and No. 5 with the ignition switch ON ( ).There should be between 5 and 8 V.

FUEL PUMP5P CONNECTOR

tc56al

a

a

Wire side of female t€rminals

lf the voltage is as specified, go to step 6.lf the voltage is not as specified, check for:- an open in the YEUBLK or BLK wrre.- poor ground (c552).

11-184

7.

Turn the ignition switch OFF.

Attach a jumper wire between the No. 2 and No. 5terminals, then turn the ignition switch ON fll).

Check that the pointer of the fuel gauge starts mov-ing toward the "F" mark. Turn the ignition switchOFF before the pointer reaches "F" on the gauge

dial. Failure to do so may damage the luel gauge.

NOTE: The fuel gauge is a bobbin (cross-coil) type,hence the fuel level is continuously indicated evenwhen the ignition switch is OFF, and the pointer

moves more slowly than that of a bimetal type.

. lf the pointer of the fuel gauge does not move atall. replace the gauge.

. lf the gauge is OK, inspect the fuel gauge send-ing unit.

www.emanualpro.com

Page 387 of 1395

Fuel Gauge Sending Unit

Tgsting

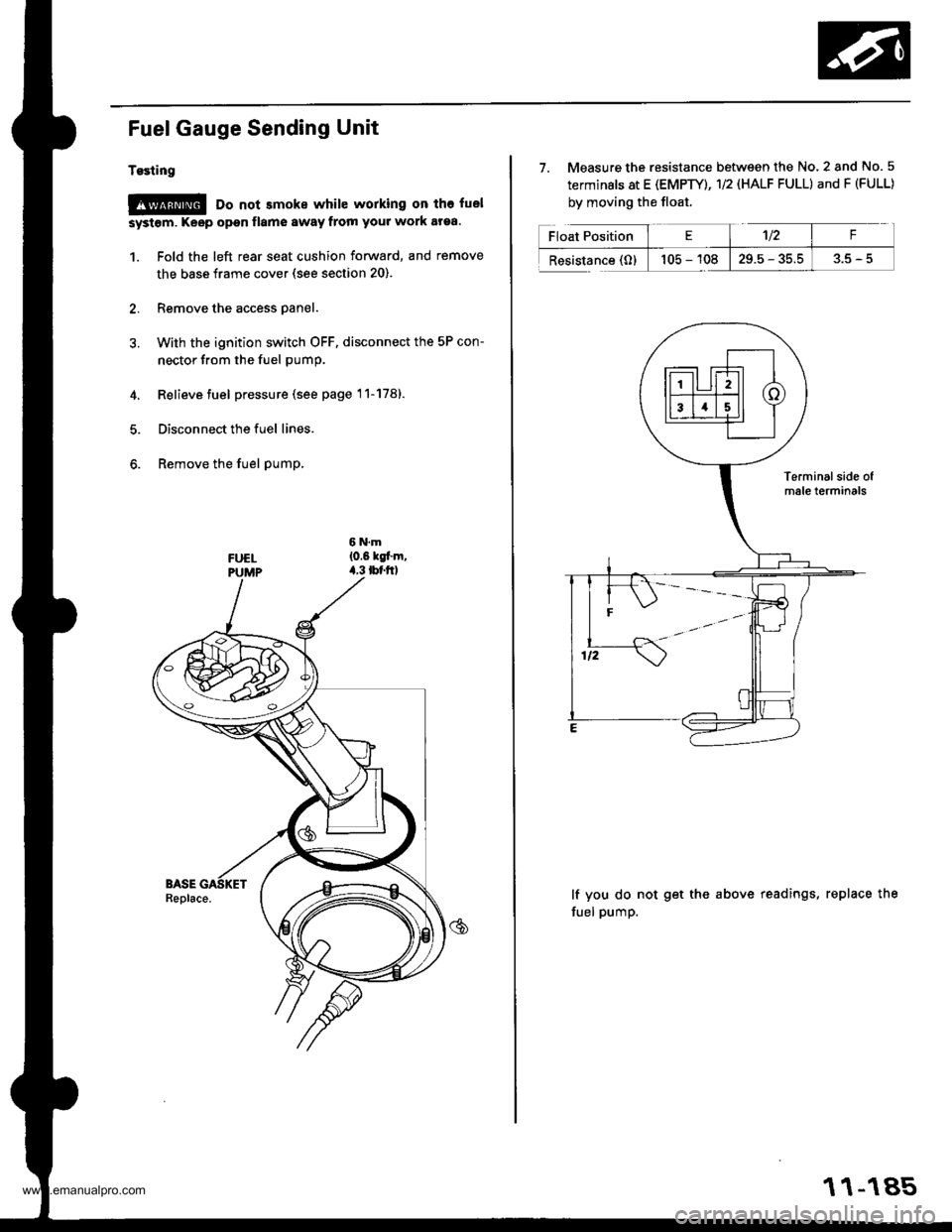

@ Do not smoke while working on tho fuel

systom. Keop open flamo 8waY from your work araa.

1. Fold the left rear seat cushion forward, and remove

the base frame cover (see section 20).

2. Remove the access panel.

3. With the ignition switch OFF. disconnect the 5P con-

nector from the fuel pump.

4. Relieve fuel pressure (see page 11-178).

5. Disconnect the fuel lines.

6. Remove the fuel pump,

7. Measure the resistance between the No. 2 and No. 5

terminals at E (EMPTY), 1/2 (HALF FULL) and F (FULL)

by moving the float.

lf you do not get the above readings, replace the

fuel pump.

11-185

www.emanualpro.com

Page 393 of 1395

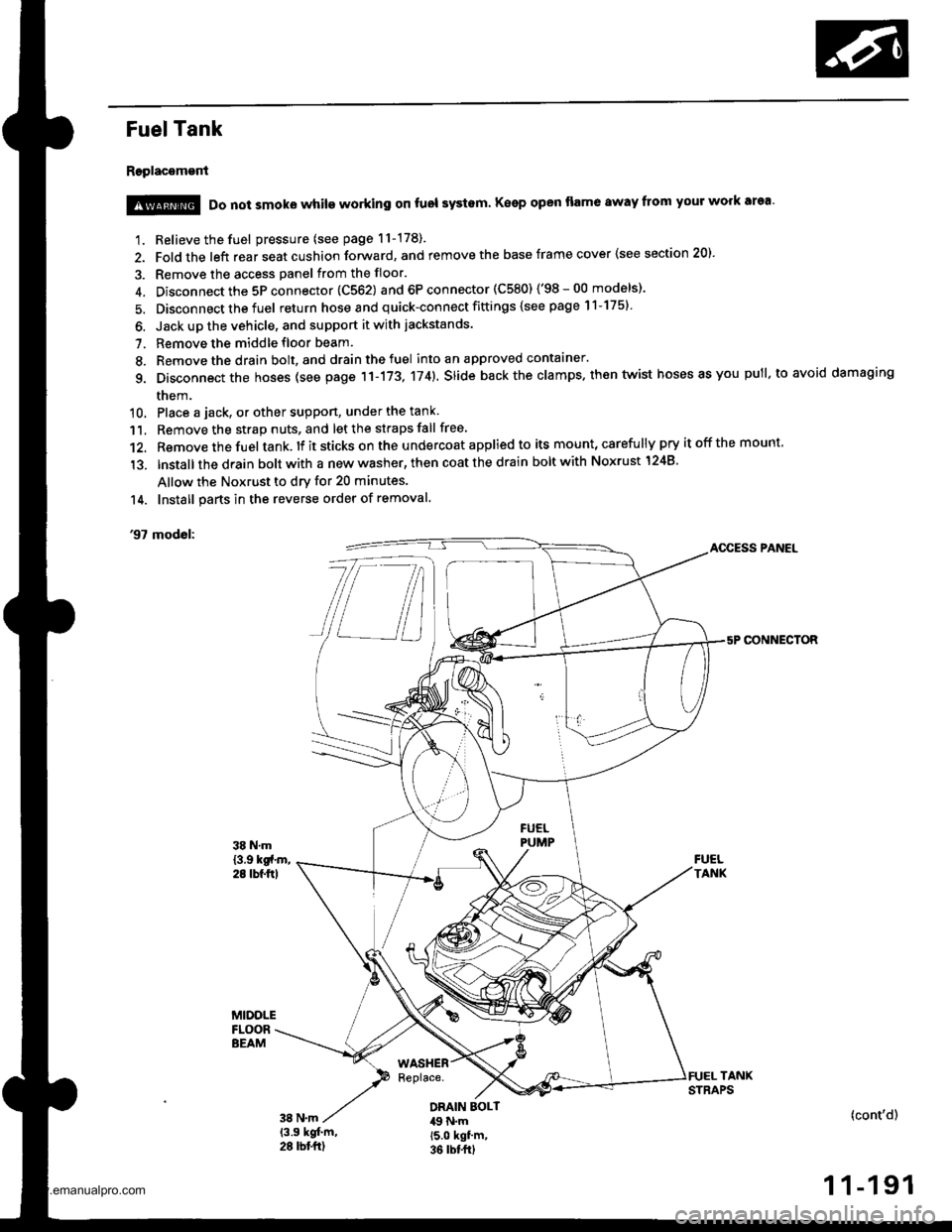

Fuel Tank

Replacement

1. Relieve the fuel pressure (see page 11-178).

2. Fold the left rear seat cushion forward, and remove the base frame cover {see section 20).

3. Remove the access panel from the floor.

4. Disconnect the 5P connector 1C562) and 6P connector (C580) ('98-00 models)'

5. Disconnect the fuel return hose and quick-connect fittings {see page 11-175}

6. Jack up the vehicle, and support it with jackstands.

7. Remove the middle floor beam.

8. Remove the drain bolt, and drain the fuel into an approved contaaner.

g. Disconnect the hoses (see page 11-173, 174). slide back the clamps. then twist hoses as you pull, to avoid damaging

them.

10. Place a jack, or other suppon, under the tank

11. Remove the strap nuts, and let the straps fall free

12. Remove the fuel tank. lf it sticks on the u ndercoat applied to its mount, carefu lly pry it off the mount,

'13. lnstallthe drain bolt with a new washer, then coat the drain bolt with Noxrust 1248'

Allow the Noxrust to dry for 20 minutes.

14. Install parts in the reverse order of removal.

'97 modol:AOCESS PANEL

CONNECTOR

@ Do not smoke while working on fuol systam Keep open flame away from your work area'

DRAIN EOLT49 N.m15.0 kgf'm,36 rbt frl

(cont'd)

1 1-191

www.emanualpro.com

Page 1025 of 1395

lnterior Trim

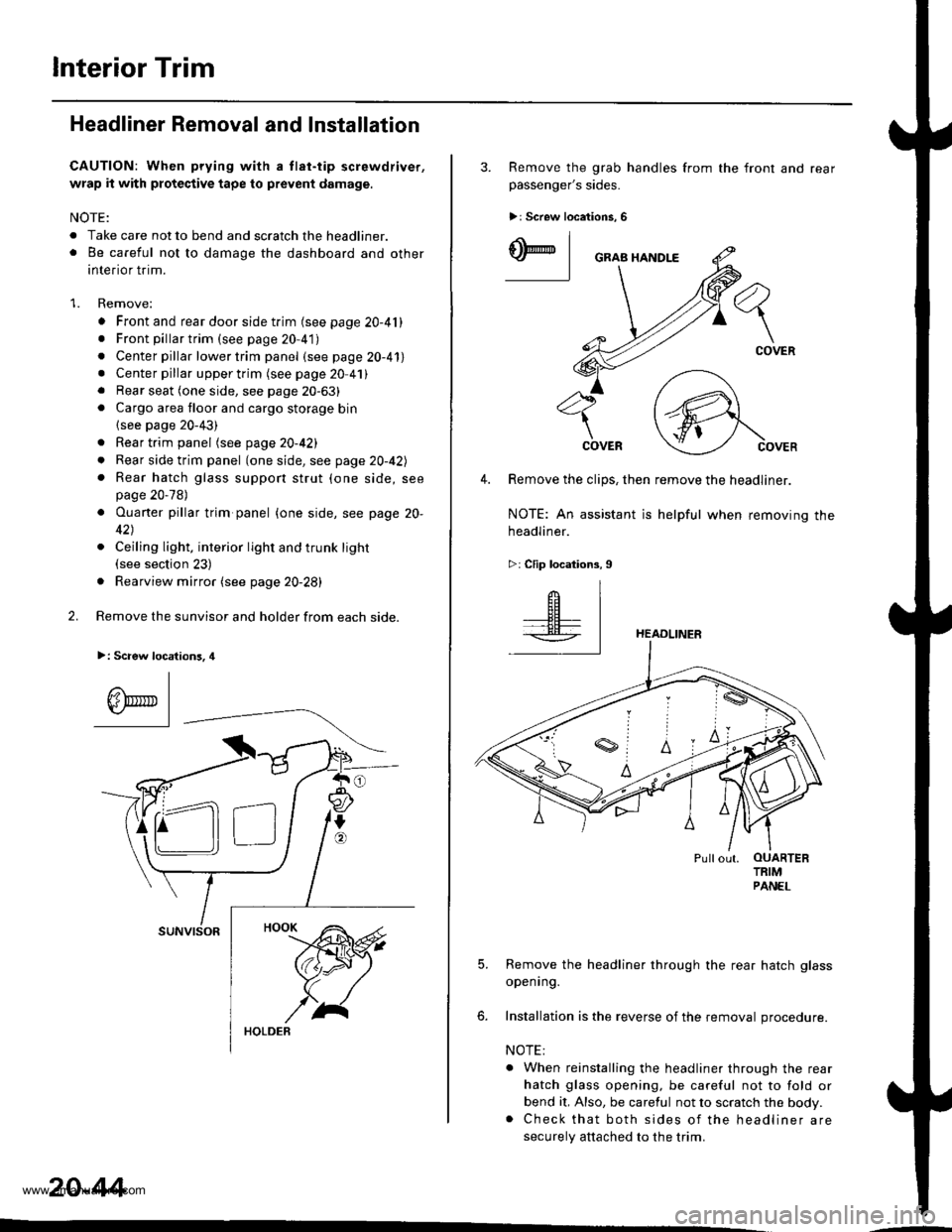

Headliner Removal and Installation

CAUTION: When prying with a tlat-tip screwdriver,

wrap it with protective tape to prevent damage.

NOTE:

. Take care not to bend and scratch the headliner.o Be careful not to damage the dashboard and other

interior trim.

1. Remove:

. Front and rear door side trim (see page 20-41). Front pillartrim (see page 20-41)

. Center pillar lower trim panel (see page 20-41). Center pillar upper trim (see page 20 41). Rear seat (one side, see page 20-63). Cargo area floor and cargo storage bin

{see page 20-43)

. Rear trim panel (see page 20-421

. Rear side trim panel (oneside, see page 20-42l,

. Rear hatch glass support strut (one side, seepage 20-78)

. Ouaner pillar trim panel {one side, see page 20-

42)

. Ceiling light, interior light and trunk light(see section 23)

. Rearview mirror (see page 20-28)

2. Remove the sunvisor and holder from each side.

>: Scaew location3, 4

I

A\"r- |Yr* || -

suNvtsoR

20-44

3. Remove the grab handles from

passenger's sides.

>r Screw locations, 6

the front and rear

ry_l

COVER

4. Remove the clips, then remove the headliner.

NOTE: An assistant is helpful when removing the

headliner.

>: Clip locations,9

HEADLINER

Pullout. OUARTERTRIMPANEL

5. Remove the headliner through the rear hatch glass

openrng.

6. Installation is the reverse of the removal procedure.

NOTE:

. When reinstalling the headliner through the rear

hatch glass opening, be careful not to fold or

bend it, Also, be careful not to scratch the body.. Check that both sides of the headliner are

securely attached to the trim.

www.emanualpro.com

Page 1042 of 1395

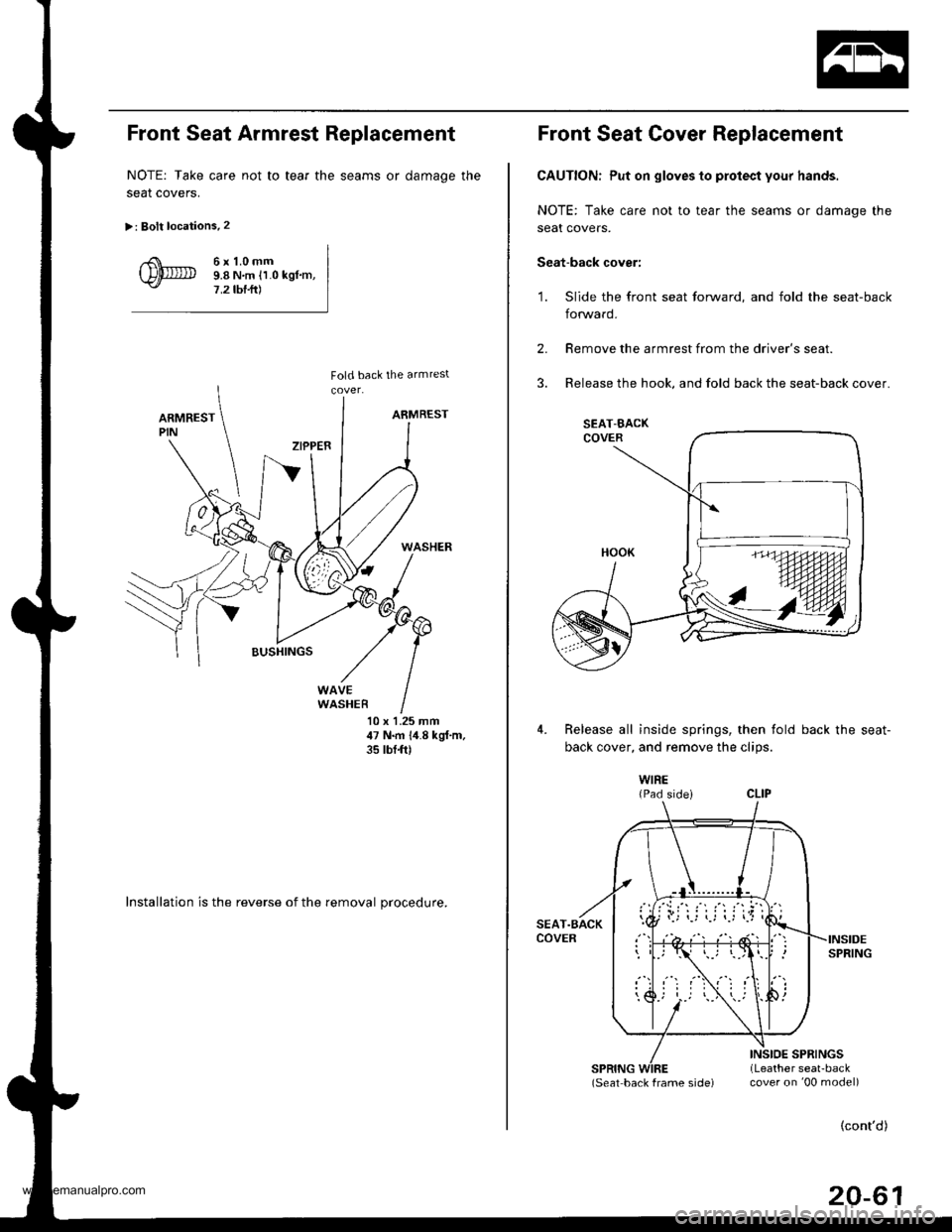

Front Seat Armrest Replacement

NOTE: Take care not to tear the seams or damage the

seat coverS.

>: Bolt locations.2

6r1.0mm9.8 N,m ll.0 kgl.m,7,2 tbf.ft)

10 x 1.25 mm47 N.m 1,1.8 kgf,m,35 tbt{t)

Installation is the reverse of the removal procedure.

Front Seat Cover Replacement

CAUTION: Put on gloves to protect your hands.

NOTE: Take care not to tear the seams or damage the

seat covers.

Seat-back cover:

'1. Slide the front seat forward, and fold the seat-back

forward.

2.

3.

Remove the armrest from the driver's seat.

Release the hook, and fold back the seat-back cover.

4.Release all inside springs, then fold back the seat-

back cover. and remove the clios.

WIRE{Pad sidei

(Seat back frame sjde) cover on '00 model)

(cont'd)

20-61

SEAT-BACK

www.emanualpro.com

Page 1045 of 1395

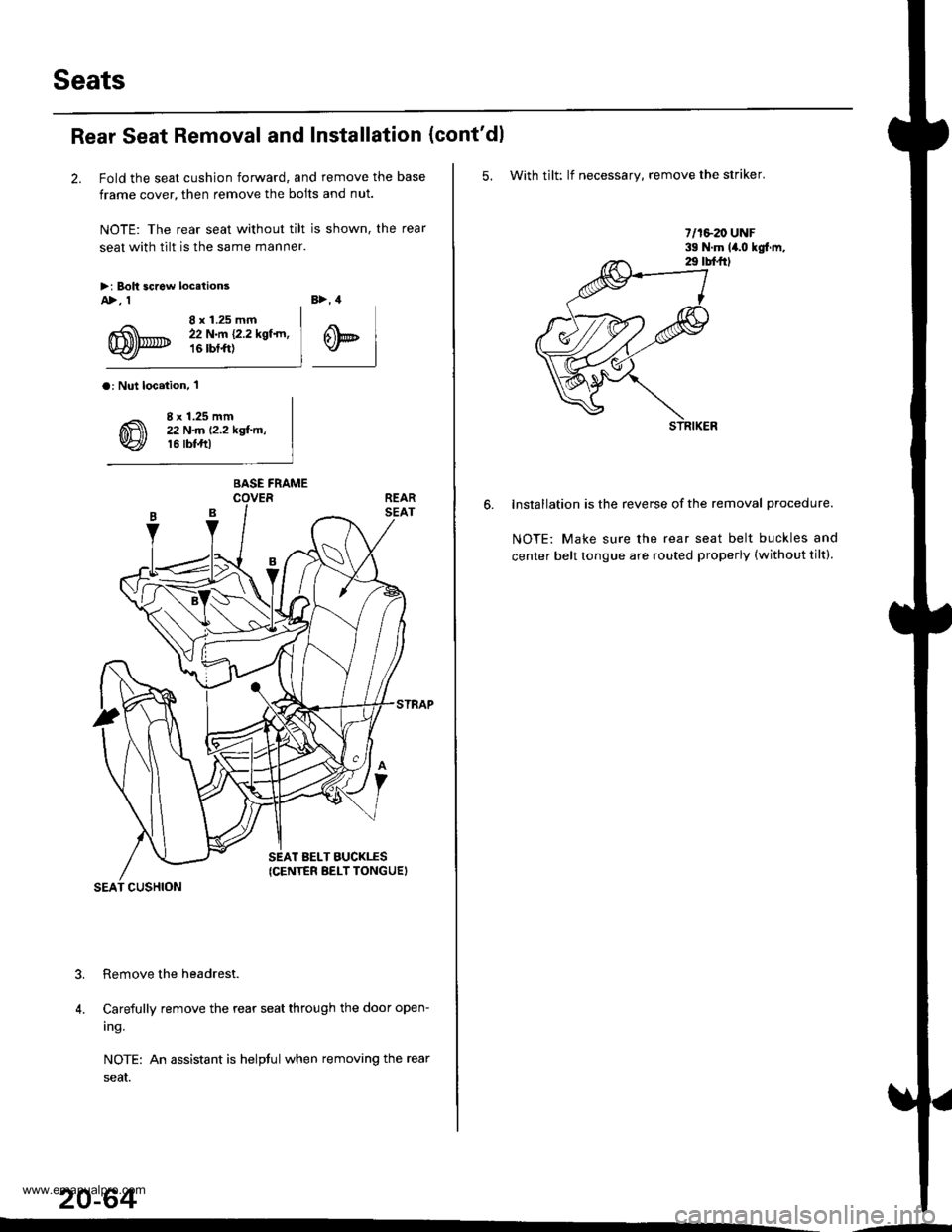

Seats

Rear Seat Removal and Installation

2. Fold the seat cushion forward, and remove the base

frame cover, then remove the bolts and nut.

NOTE: The rear seat without tilt is shown, the rear

seat with tilt is the same manner.

>i Boh screw locetionsA>, 1

8 x 1.25 mm22 N.m {2.2 kgf.rn,16 rbtft)

B>, 4

@t

a: Nut loc.iion, 'l

8 x 1.25 mm22 N

Carefully remove the rear seat through the door open-

ing.

NOTE: An assistant is helptul when removing the rear

seaI.

20-64

?

4.

BASE FRAME

SEAT BELT BUCKTES(CENTER BELT TONGUEI

SEAT CUSHION

(cont'dl

5. With tilt: lf necessary, remove the striker.

lnstallation is the reverse of the removal procedure.

NOTE: Make sure the rear seat belt buckles and

center belt tongue are routed properly (without tilt).

.-

www.emanualpro.com

Page 1305 of 1395

)J

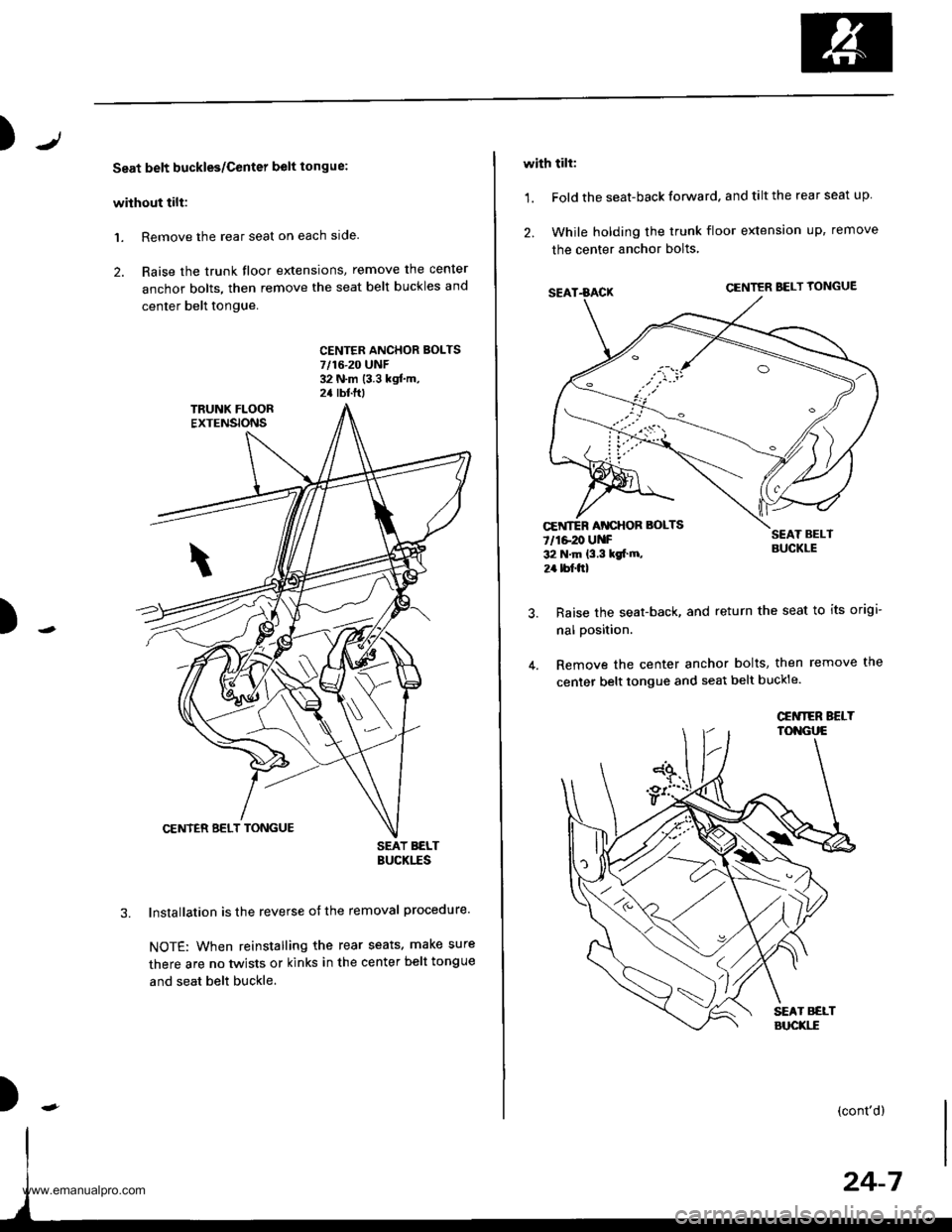

Seat belt buckles/Center belt tongue:

without tilt:

1. Remove the rear seat on each slde.

2. Raise the trunk floor extensions, remove the cenler

anchor bolts, then remove the seat belt buckles and

center belt tongue.

CENTFR ANCHOR BOLTS7/16-20 UNF32 N.m (3.3 kgf.m,2a rbtftt

)

SEAT BELTBUCKITS

lnstallation is the reverse of the removal procedure.

NOTE: When reinstalling the rear seats. make sure

there are no twists or kinks in the center belt tongue

and seat belt buckle.

)

with tilt:

1. Fold the seat-back forward. and tilt the rear seat up

2. While holding the trunk floor extension up, remove

the center anchor bolts

SEAT.BACKCENTER BELT YONGUE

SEAT BELTBUCKLE

Raise the seat-back, and return the seat to its origi-

nal position.

Remove the center anchor bolts, then remove the

center belt tongue and seat belt buckle.

CEiITER AT{CHOR BOLTS

7/1e20 UNF32 N.m {3.3 kgt m,

2r bf.frl

\\

(cont'd)

www.emanualpro.com