Torque HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 31 of 1395

Standards and Service Limits

Manual Transmission {cont'd} - Section 13

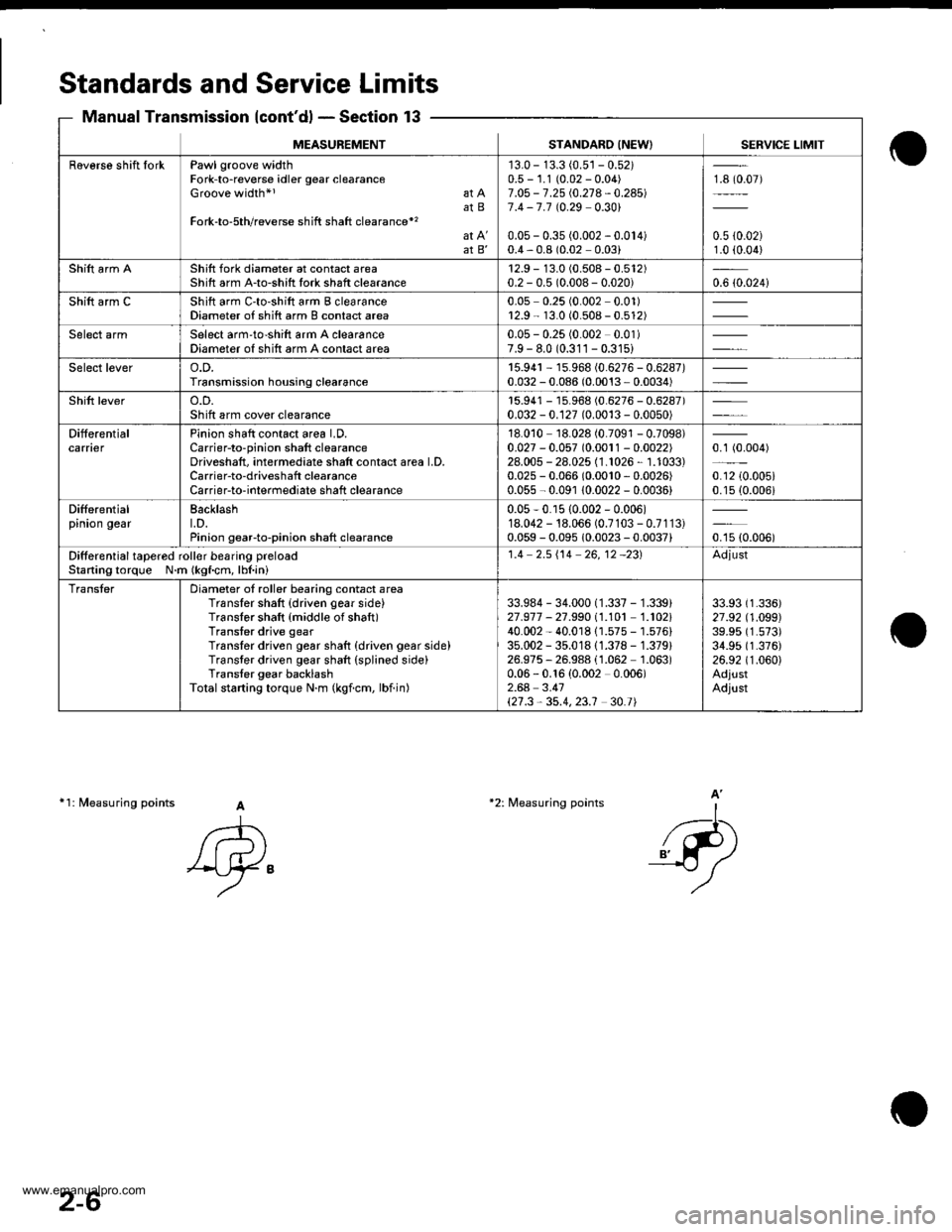

11: fuleasuring points A

A

'Ay"

-l-...

_{-P)

A'*2: Measuring points

MEASUREMENTSTANDARO INEW) SERVICE LIMIT

Raverse shift IorkPawl groove widthFork-to-reverse idler gear clearanceGroove width*l at AatBFork-to-5th/reverse shift shaft clearance*'�

at B'

'13.0 - 13.3 (0.5'�j - 0.52)0.5 - 1.1 (0.02 - 0.04)7.O5 - 7.25 i.0.21 4 - 0.24517.4 -7.7 t0.29 0.301

0.05 - 0.35 (0.002 - 0.014)0.4,0.8 (0.02 0.03)

18 (0.07)

0.5 {0.02)1.0 (0.04)

Shift arm AShift fork diameter at contact areaShift arm A-to-shitt tork shaft clearance12.9 - 13.0 (0.508 - 0.512)0.2 - 0.5 (0.008- 0.020)0.6 {0.024i

Shift arm CShift arm C'to-shift arm B clearanceDiameter of shift arm B contact area0.05 0.25 (0.002 0.01)r2.9 - 13.0 (0.508 - 0.512)

Select armSelect arm'to-shift arm A clearanceDiameter of shift arm A contact area0.05 - 0.25 (0.002 0.01)7.9 - 8.0 (0.311 - 0.31s)

Select levero.D.Transmission housing clearance15.94r - 15.968 (0.6276 - 0.6287)0.032 - 0.086 (0.0013 - 0.0034)

Shift levero.D.Sh ift arm cover clearancer5.941 - 15.968 (0.6276 - 0.6287)0.032 - 0.127 (0.0013 - 0.0050)

DifferentialcarnerPinion shaft contact area LD.Carrier-to-pinion shaft clearanceDriveshaft, intermediate shatt contact area LD,Carrier-to-driveshaft clearanceCarrierto-interrnediate shaft clearance

18.010 18.028 (0.7091 - 0.7098)0.027 - 0.057 (0.0011 - 0.0022)28.005 - 28.025 (1.1026, 1.1033)0.025 - 0.066 (0.0010,0.0026)

0.055 - 0.091 10.0022 - 0.0036)

0.1 (0.004)

0.12 {0.005i0.15 (0.006i

Differentialpinion gearBacklasht.D.Pinion gearto-pinion shaft clearance

0.05-0.r5 {0.002 - 0.006)18.042 - 18.066 (0.7103 - 0.7113)0.059 - 0.095 10.0023 - 0.0037)oru ro.ooor

Ditferential tapered roll€r besring preloacStaning torque N.m (kgf.cm, lbl.ini

1.4 2.5i'14 26,12 -231Adjust

TransterDiameter of roller bearing contact areaTransler shaft {driven gear side}Translor shaft {middle of shaft)Transter drive gearTranslor driven gear shaft {driven gear side)Transter driven gear shaft (splined side)Trans{er gear backlashTotalstarting torque N.m (kgicm, lbiin)

33.984 - 34.000 (1.337 - 1.339)21.977 - 27.99011.101 1.102140.002 - 40.01811.575 - 1.576)35.002 - 35.01811.378 - 1.379)26.975, 26.988 (1.062 1.063)0.06 - 0.16 {0.002 0.006)2.64 3.41\21.3,35.4,23.1 30.t|

33.93 (1.336)

27 .92 (1 .O99)39.95 (1.573)

34.95 (1.376)

26.92 (1.060)

AdjustAdjust

2-6

www.emanualpro.com

Page 33 of 1395

Standards and ServiceLimits

Section 14Automatic Transmission (cont'd)-

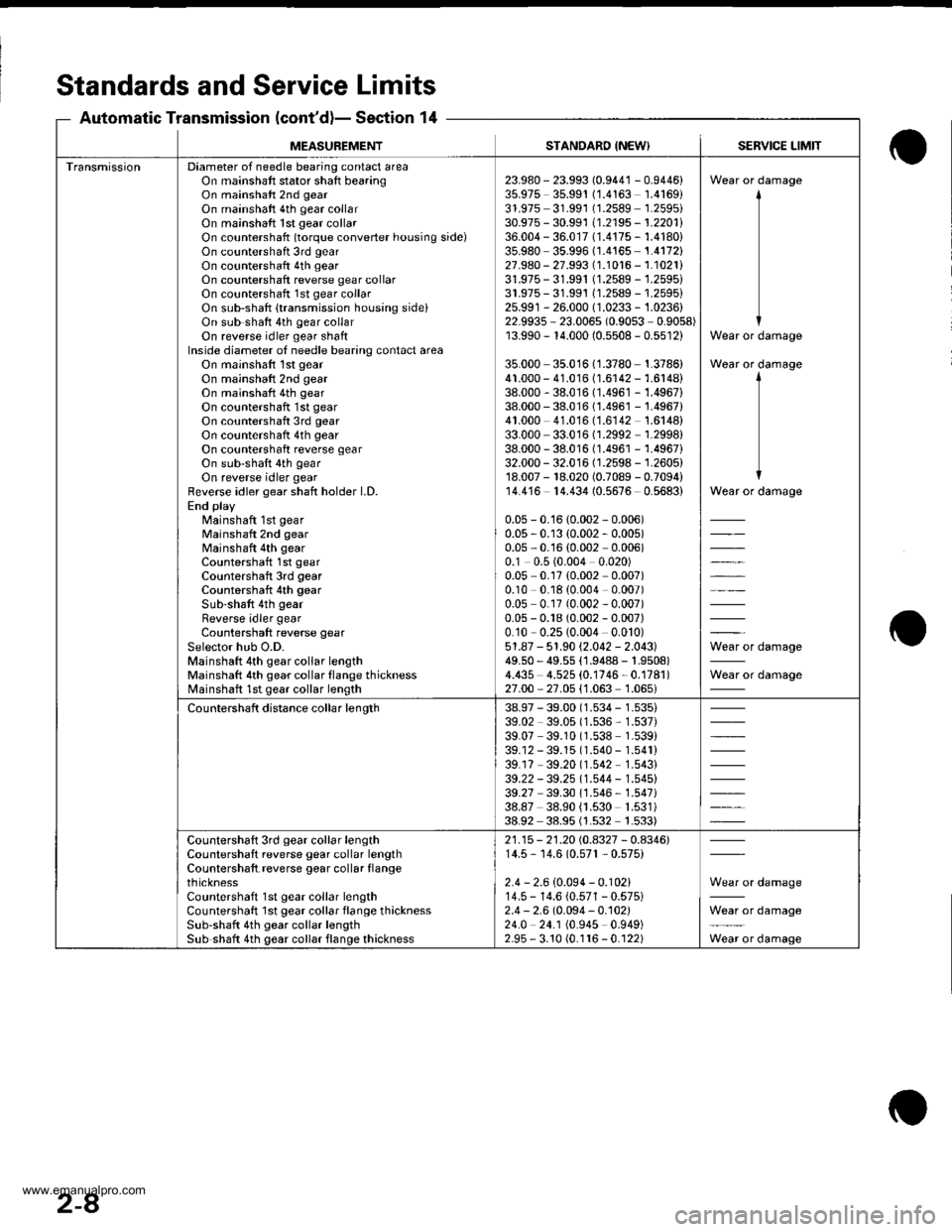

MEASUBEMENTSTANDARD {NEW}SERVICE LIMIT

TransmissionDiameter of needle bearing contact areaOn mainshaft stator shaft bearingOn mainshaft 2nd gear

On mainshaft 4th gear collarOn mainshaft 1st gear collarOn countershatt (torque converter housing side)On countershaft 3rd gear

On countershaft 4th gearOn countershaft reverse gear collarOn countershaft 1st gear collarOn sub-shaft {transmission housing sideiOn sub shaft 4th gear collarOn reverse idler gear shaftInside diameter of needle bearing contact areaOn mainshaft 1st gear

On mainshaft 2nd gearOn mainshaft 4th gear

On countershaft 1st gear

On countershaft 3rd gear

On countershaft 4th gear

On countershaft reverse gearOn sub-shaft 4th gear

On reverse idler gearfleverse idler gear shaft holder l.D.End playMainshaft 1st gearMainshaft 2nd gearMainshaft 4th gearCountershaft 1st gearCountershaft 3rd gearCountershaft 4th gear

Sub-shaft 4th gear

Reverse idler gearCountershaft reverse gear

Selector hub O.D.Mainshaft 4th gear collar lengthMainshaft 4th gear collar flange thicknessMainshaft 1st gear collar length

23.980- 23.993 (0.9441 - 0.9446)35.975 35.99'! (1.4163 1.4169)31.975 31.991 (1.2589 1.2595i30.975 - 30.991 11.2195 - 1.2201l'36.004 - 36.017 (1.4175 - 1.4180)35.980 35.996 (1.4165 1.4172)27.980 - 27.993 (1.1016 - 1.1021i31.975- 31.991 (1.2589 -'�j.2595i

31.975- 31.991 (1.2589 - 1.2595)25.991 - 26.000 (1.0233 - 1.0236)22.9935 - 23.006s (0.9053 0.9058)13.990 - r4.000 (0.5508 - 0.5512)

35.000 35.016 (1.3780 1.3786)41.000 - 41.016 (1.6142 - 1.6148)38.000 - 38.016 (1.4961 -'�1.4967)

38.000 - 38.016 (1.496'1 - 1.4967)41.000 41.016 (1.6142 1.6148)33.000 - 33.016 (1.2992 1.2998)38.000 - 38.016 (1.4961 - 1.4967)32.000 - 32.016 (1.2598 - 1.2605)18.007 - 18.020 (0.7089 - 0.7094)14.416 14.434 (0.5676 0.5683)

0.05 - 0.16 {0.002 - 0.006)0.05 - 0.13 (0.002 - 0.005)0.05,0.'16 (0.002 0.006)0.1 0.5 (0.004 0.020)0.05 0.17 {0.002 0.007)0.10 0.18 (0.004 0.007)0.0s 0.17 (0.002 - 0.007)0.05 - 0.18 (0.002 - 0.007)0.10,0.25(0.004 0.010)51.87 - 51.90 (2.042 - 2.043)49.50 - 49.55 (1.9488 - |.9508)4.435 4.525 (0.1746-0.1781)

27.00,27.05 {1.063'1.065i

Wear or damage

Wear or damage

Wear or damage

Wear or damage

il*=lo'. d"'.n"n"

Wear or damage

Countershaft distance collar length38.97 - 39.00 (1.534 - 1.535)39.02 39.05 (1.536, 1.537)39.07 39.10 (1.538 1.539)39.12 - 39.15 (1.540 - 1.541)39.17 - 39.20 (1.542 * 1.543)39.22 - 39.25 11.544 - 1.545)39.27 39.30 1'1.546 - 1.547i38.87 38.90 {1.530 1.531)38.92 38.95 (1.s32 1.533)

Countershaft 3rd gear collar lengthCountershaft reverse gear collar lengthCountershaft reverse gear collar flangethicknessCountershaft 1st gear collar lengthCountershaft lst gear collar flange thicknessSub-shaft 4th gear collar lengthSub shatt 4th gear collar flange thickness

21.15 - 21.20 rc.4327 - 0.4346)14.5, 14.6 (0.57't , 0.575)

2.4 - 2.6 (0.094 - 0.102)14.5 - 14.6 (0.571 - 0.575)2.4 - 2.6 (0.094 - 0.102)24.0 24.1 (0.945 0.949)2.95 - 3.10 (0.116 - 0.122)

Wear or damage

Wear or damage

Wear or damage

2-8

www.emanualpro.com

Page 34 of 1395

2-9

Automatic Transmission - Section 14

o

Unit of length: mm (in)

o

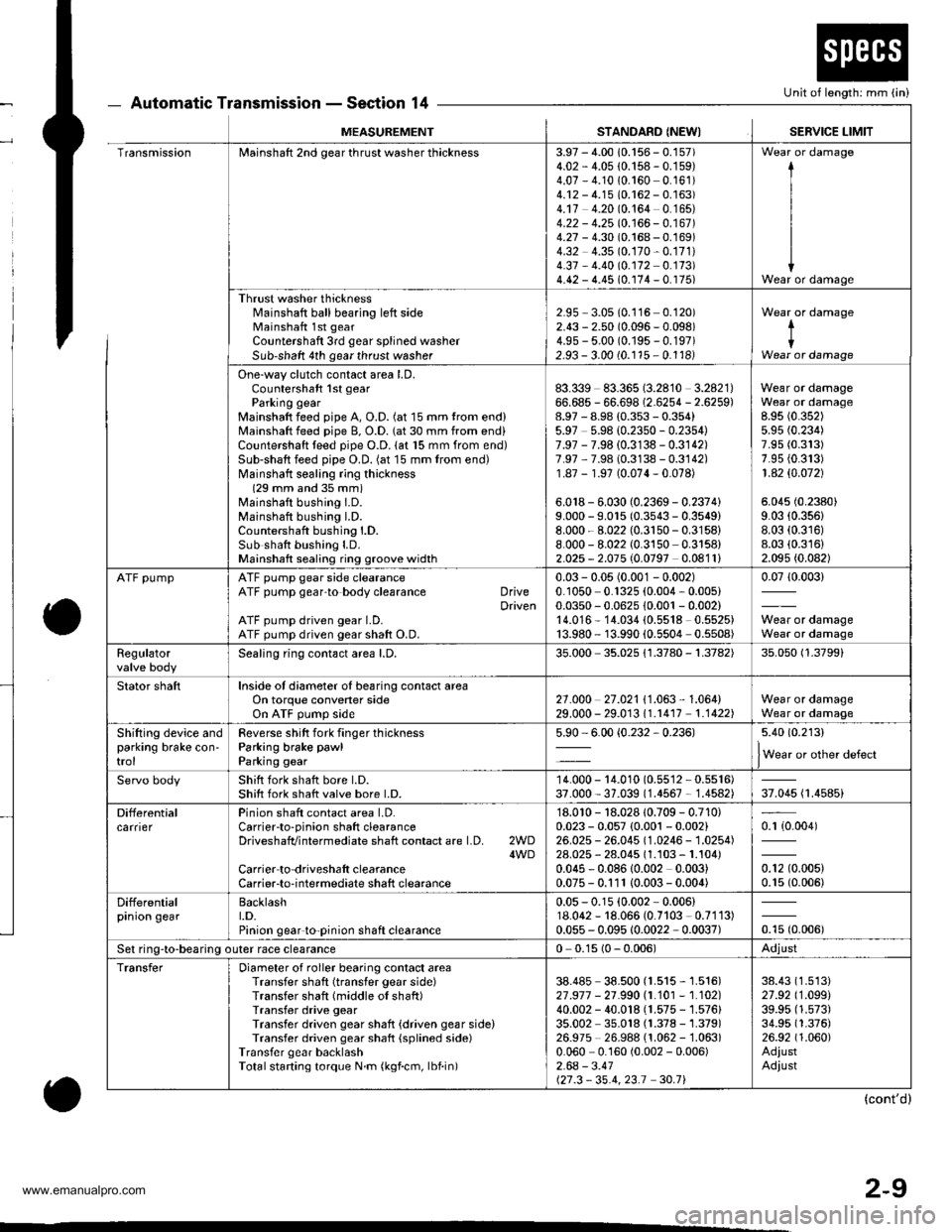

MEASUREMENTSTANDARD (NEWISERVICE LIMIT

TransmissionMainshaft 2nd gear thrust washer thickness3.97 - 4.00 10.156 - 0.157)4.02 - 4.05 {0.158 - 0.159)4.07 - 4.1010.160 0.161)4.12 - 4.15 (0.162 - 0.163)4.17 4.20 (0.164 0.165)4.22 - 4.25 10.166 - 0.167 )4.27 - 4.30 (0.168 - 0.169)4.32 4.35 (0.170-0.171)

4.37 - 4.40 (0.172 0.173)4.42 - 4.45 (0.174 - 0. r75)

I

I

IWear or damage

Thrust washer thicknessl'rainshaft ball bearing left sideMainshaft 1st gear

Countershaft 3rd gear splined washerSub-shaft 4th gear thrust washer

2.95 3.05 (0.116 0.120)2.43 - 2.50 (0.096 - 0.098)4.9s - 5.00 (0.195 - 0.197)2.93 - 3.00 (0.115 - 0.1181

Wear or damage

tIWear or damage

One-way clutch contact area LD.Countershaft 1st gearParking gearMainshaft feed pipe A, O.D. (at 15 mm trom end)Mainshaft feed pipe B, O.D. (at 30 mm from end)Countershaft teed pipe O.D. lat 15 mm from end)Sub-shaft feed pipe O.D. (at 15 mm from end)Mainshatt sealing ring thickness(29 mm and 35 mm)Mainshaft bushing I.D.Mainshaft bushing l.D.Countershaft bushing l.D.Sub shatt bushing LD.Mainshaft sealing ring groove width

83.339 83.365 (3.2810 3.2821)66.685 - 66.698 (2.6254 - 2.6259)8.97 - 8.98 (0.353 - 0.354)5.97 5.98 {0.2350 - 0.2354)7.97 - 7.98 (0.3138 - 0.3142)7.97 ,7.98 (0.3138 - 0.3142)1.87 - 1.97 (0.074-0.078)

6.018 - 6.030 (0.2369 - 0.2374)9.000 - 9.015 (0.3543 - 0.3549)8.000 - 8.022 (0.3150-0.3158)

8.000 - 8.022 (0.3150 0.3158)2.025 - 2.075 (0.0797 0.0811)

Wear or damageWear or damage8.95 (0.352)

5.95 (0.234)

7.95 (0.313)

7.95 {0.313)1 .42 $.O72)

5.045 (0.2380)

9.03 (0.356)

8.03 (0.316)

8.03 (0.316)

2.095 (0.082)

ATF pumpATF pump gear side clearanceATF pump gear'to body clearance DriveDrivenATF pump driven gear LD.ATF pump driven gear shaft O.D.

0.03 - 0.05 (0.001 - 0.002)0.1050 0.1325 (0.004, 0.005)0.0350 - 0.0625 10.001 - 0.002)14.016* 14.034 (0.5518 0.5525)13.980 - 13.990 {0.5504 0.5508)

0.0710.003)

Wear or damageWear or damage

Regulatorvalve bodySealing ring contact area l.D,35.000 35.025 {1.3780 - 1.3782)35.050 (1.3799)

Stator shaftInside of diameter oI bearing contact areaOn torque convener sideOn ATF pump side2't .o00 27 .021 I '1 .063 , 1 .064)29.000 - 29.01311.r417 1.1422)Wear or damageWear or damage

Shifting device andparking brake con'trol

Reverse shitt fork finger thicknessParking brake pawl

Parking gear

5.90 - 6.00 {0.232,0.236)5.40 (0.213)

lWear or other defect

Servo bodyShift fork shatt bore l.D.Shift fork shatt valve bore l.D.14.000 - 14.010 (0.55'�l2 - 0.5516)37.000 - 37.039 (1.4567 - 1.4582)37.045 (1.4585)

DifferentialcarrierPinion shaft contact area LD.Carrierto-pinion shaft clearanceDriveshafvintermediate shaft contact are l.D. 2WD4WDCarrier to driveshalt clearanceCarrier-to-intermediate shaft clearance

'18.010 - 18.028 10.709 - 0.710)0.023 - 0.057 {0.001 - 0.002}26.025 - 26.045 (1.0246 - 1.0254)28.025 - 28.045 (1.103 - 1.104)0.045 - 0.08610.002 0.003)0.075 - 0.111 10.003- 0.004)

0.r {0.004)

0.12 (0.005)

0.15 (0.006)

Differentialprnron gearBacklasht.D.Pinion gear'to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.062 - 18.066 (0.7103 - 0.7113)0.055 - 0.095 10.0022 - 0.0037)otu to.oout

Set ring-to-bearing outer race clearance0 0.15 (0 - 0.006)Adjust

TransferDiameter of roller bearing contact areaTransfer shaft (transfer gear side)Transfer shaft (middle of shaft)Transfer drive gearTransfer driven gear shaft {driven gear side)Transfer driven gear shaft {splined side)Transfer gear backlashTotalstarting torque N.m (kgf.cm, lbf.in)

38.485 38.500 (1.515 - 1.516)27 .917 - 21 .990 |.1.101 - 1.102)40.002 - 40.018 (1.575 - 1.576)35.002 35.018 (1.378 - 1.379)26.975 26.988 (1.062 -'�l.063)

0.060 0.160 (0.002 - 0.006)2.64 - 3.41127.3 - 35.4,23.1 30.71

38.43 (1.513)

27.92 (1.099)

39.95 (1.573)

34.95 (1.376)

26.92 (1.060)

AdiustAdiust

(cont'd)

www.emanualpro.com

Page 35 of 1395

Standards and Service Limits

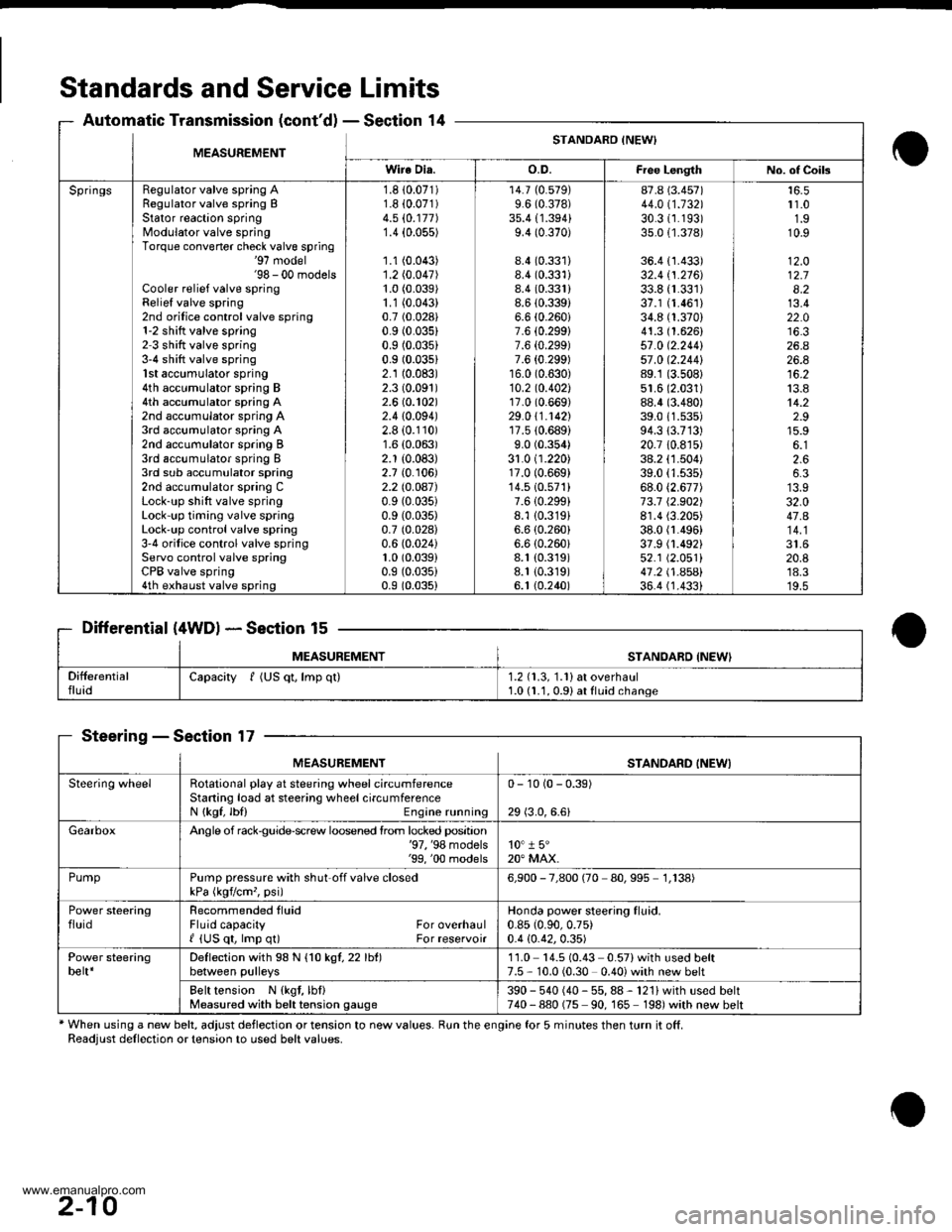

Automatic Transmission (cont'dl - Section 14

Differential (4WDl * Section 15

MEASUREMENTSTANOABD {NEW'

SteeringSection 17

* When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.Readjust dellection or tension to used belt values.

MEASUREMENTSTANDARO INEWI

Wire Dia.o.D.Fiee LengthNo. of Coils

SpringsRegulator valve spring ARegulator valve spring BStator reaction springModulator valve springTorque convener check valve spring'97 model'98 - 00 modelsCooler relief valve springRelief valve spring2nd orilice control valve spring1-2 shitt valve spring2 3 shift valve spring3-4 shift valve spring1st accumulator spring4th accumulator spring B4th accumulator spring A2nd accumulator spring A3rd accumulator spring A2nd accumulator spring B3rd accumulator spring I3rd sub accumulator spring2nd accumulator spring CLock-up shift valve springLock-up timing valve springLock'up control valve spring3'4 orifice control valve springServo control valve springCPB valve spring4th exhaust valve spring

1.8 10.071)1.8 i0.071)4.5 (0.177)

1.4 {0.055)

1.1 (0.043)

1.2 (0.047)

1.0 (0.039)

1.1 (0.043)

0.7 (0.028)

0.9 (0.035)

0.9 (0.035)

0.9 (0.03s1

2.1 (0.083)

2.3 (0.091)

2.6 (0.102)

2.410.094)2.8 (0.110)

1.6 (0.063)

2.1 (0.083)

2.7 {0. r06)2.2lO.OA7)0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

0.6 (0.024)

1.0 (0.039)

0.9 (0.035)

0.9 (0.035)

14.7 (0.579)

9.6 (0.378)

35.4 {1.394}9.4 (0.370)

8.4 (0.331)

8.4 (0.331)

8.4 (0.331)

8.6 (0.3391

6.6 (0.260i

7.6 {0.299}7.6 {0.299)7.6 {0.299)16.0 (0.630)

10.2 to.402l17.0 (0.669)

29.0 \1.1421'r7.510.689)

9.0 (0.354)

31.0 (1.220)17.0 (0.669)

14.510.571)7.610.299i8.1 {0.319}6.6 (0.260)

6.6 (0.260i

8.1 (0.319)

8.1 {0.319)6. t (0.240)

87.8 (3.457)

44.011.132130.31r.193)35.0 {1.378)

36.4 {1.433)32.4 tl.216J33.8 {r.331)37.1 (1.461)

34.8 (1.370)

41.3 (1.626)

57 .0 (2.2441

57 .0 12.244189.1 (3.508)

51.6 (2.031)

88.4 (3.480)

39.011.s35)94.313.713)20.7 10.8r5)38.2 (1.504)

39.0 (1.535)

68.0 (2.677)

73.7 12.902)8r.4 (3.205)

38.0 fl.496)37.9 (1.492)

52.1 (2.051)

41 .2 t .A5Al36.4 (1.4331

r 1.01.910.9

12.O12.78.213.422.0

26.426.8

13.814.22.915.9

2.66.3

32.047.A

20.8'18.3'19.5

Capacity f (US qt, lmp ql)1.2 (1.3, 1.1) at overhaul1.0 (1.1, 0.91 at fluid change

MEASUREMENTSTANDARD INEWI

Steering wheelRotational play at steering wheel circumferenceStaning load at steering wheelcircumferenceN {kgf, lbl) Engine running

0- 10 (0 - 0.39)

29 (3.0,6.6)

GearboxAngle of rack$uide-screw loosened lrom locked position'97, '98 models'99, '00 models10" 1 5"20" MAX.

PumpPump pressure with shut off valve closedkPa (kgvcm,, psi)6,900 - 7,800 (70 80,995 1,138)

Power steeringfluidRecommended tluidFluid capacity For overhaulI {US qt, lmp q0 For reservoir

Honda power steering fluid.0.85 (0.90,0.75)

0.4 {0.42,0.35)

Power steeringbelt*Deflection with 98 N {1O kgl,22lht)between pulleys11.0 14.5 (0.43 0.57)with used belt7.5 - 10.0 (0.30 0.40) with new belt

Belt tension N {kgt, lbf}Measured with belt tension gauge390 - 540 (40 - 55, 88 - 121) with used belt740-880 (75 90, 165 198)with new belt

2-10

www.emanualpro.com

Page 37 of 1395

Design Specifications

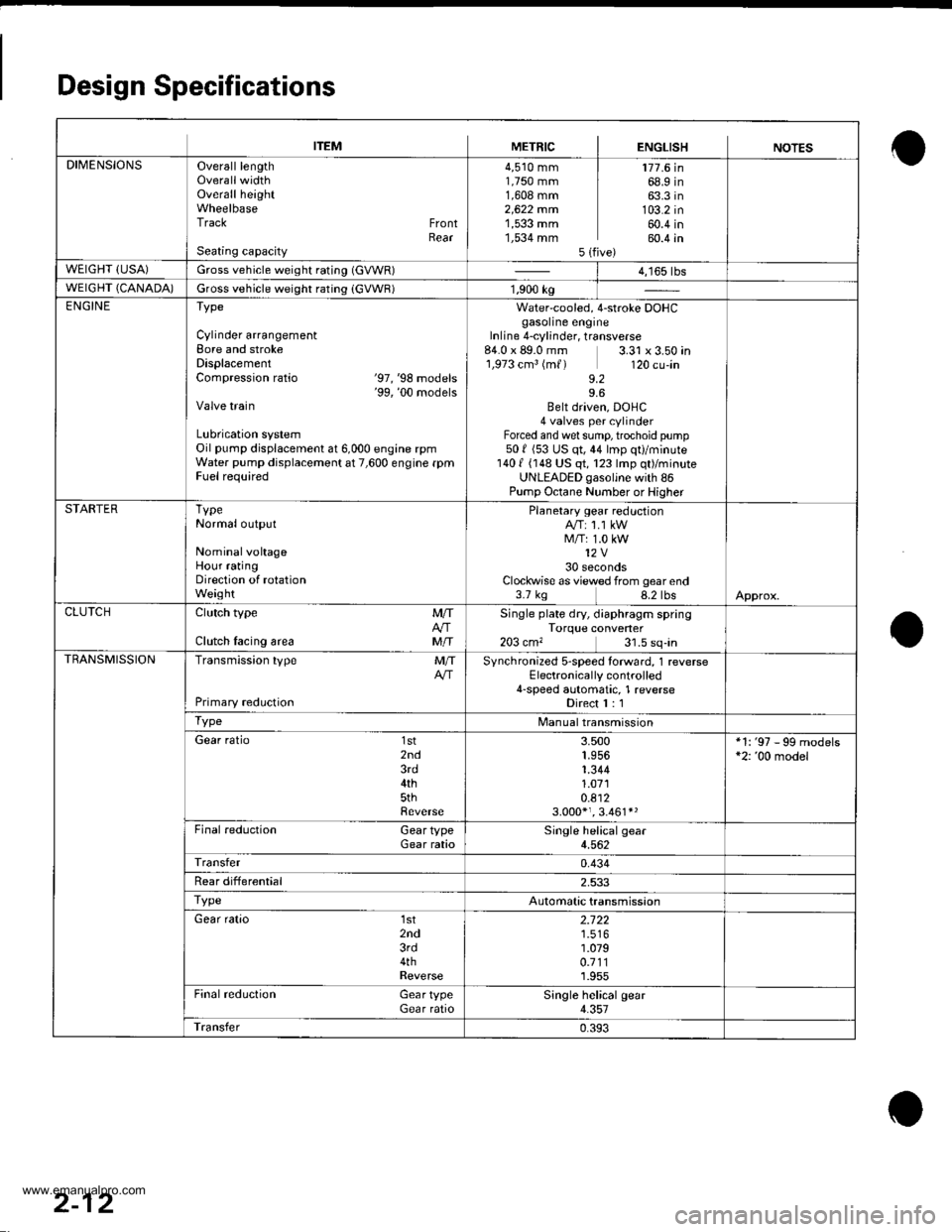

ITEMMETRICENGLISHNOTES

DIMENSIONSOverall lengthOverallwidthOverall heightWheelbaseTrack FrontRearSeating capacity

4,510 mm1,750 mm1,608 mm2,622 mrn1,533 mm1,534 mm5lf

177.6 in68.9 in63.3 in103.2 in60.4 in60.4 in

WEIGHT (USA)Gross vehicle weight rating (GVWR)| 4,165 tbs

WEIGHT (CANADA)Gross vehicle weight rating (GVWR)1,900 kg

ENGINEType

Cylinder arrangementBore and strokeDisplacementCompression ratio '97,'98 mooers'99, '00 modelsValve train

Lubrication systemOil pump displacement at 6,000 engine rpmWater pump displacement at 7,600 engine rpmFuel required

Water-cooled, 4-stroke DOHCgasoline engineInline 4-cylinder, transverse84.0 x 89.0 mm.1,973 cm3 (m{)

9.2

3.31 x 3.50 in120 cu-in

9.6Belt driven, DOHC4 valves per cylinderForced and wet sump, trochoid pump501 (53 US qt,44 lmp qt)/minute1401 (148 US qt, 123 lmp qt)/minuteUNLEADED gasoljne with 86Pump Octane Number or Higher

STARTERTypeNormal output

NominalvohageHour ratingDirection of rotationWeight

Planetary gear reductionA/T: 1.1 kWM/T: 1.0 kW12V30 secondsClockwise as viewed from gear end3.7 kg 8.2 lbsApprox.

CLUTCHClutch type

Clutch lacing area

MIT

MIT

Single plate dry, diaphragm springTorque converter203 cm, 31.5 sq-in

TRANSMISSIONTransmission type

Primary redLrction

MITSynchronized s-speed torward, 1 reverseElectronically controlled4-speed automatic, 1 reverseDirect I : 1

TypeManualtransmission

Gear ratio 1st2nd3rd4th5thReverse

3.5001.9561.3441.0710.8123.000*,. 3.461*'

*1: '97 - 99 models*2: '00 model

Final reduction Gear typeGear rataoSingle helical gear4.562

Transfer0.434

Rear differential2.533

TypeAutomatic transmission

Gear ratio 1st2nd3rd4thReverse

2.722

1.0790.7111.955

Final reduction Gear typeGear ratioSingle helical gear4.357

Transfer0.393

2-12

www.emanualpro.com

Page 56 of 1395

Starting System

Starter Test (cont'dl

Check lor Wear and D8mage

The starter should crank the engine smoothly and

steadily. lf the staner engages, but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter ring gear or flywheel ring gear for

oamage.

Check the drive gear overrunning clutch for binding or

slipping when the armature is rotated with the drive

gear held. lf damaged, replace the gears.

Check Cranking Voltage and Current Draw

Cranking voltage should be no less than 8.7 volts on Ay'T

models, and 8.0 volts on M/T moders.

Current draw should be no more than 230 amperes on

A,/T models, and 200 amperes on M/T models.

lf cranking voltage is too low, or current draw too high,

check for:

. dead or low battery.

a open circuit in starter armature commutator seg,

ments.

. starter armature dragging.

. shorted armature winding.

. excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm.

lf speed is too low, check for:

a loose baftery or starter terminals.

. excesslvely worn staner brushes

. open circuit in commutator segments.

. dirty or damaged helical splines or drive gear.

a defective drive gear overrunning clutch.

Check Starter Disengagement

With the shift lever in @ or @ position (A,iT) or with the

clutch pedal depressed {M/T). turn the ignition switch to

START (lll). and release to ON (ll).

The starter drive gear should disengage from the torque

converter ring gear or flywheel ring gear when you

release the key.

lf the drive gear hangs up on the torque converter ring

gear or flywheel ring gear, check for

. solenoid plunger and switch malfunction.

. dirty drive gear assembly or damaged overrunning

clutch.

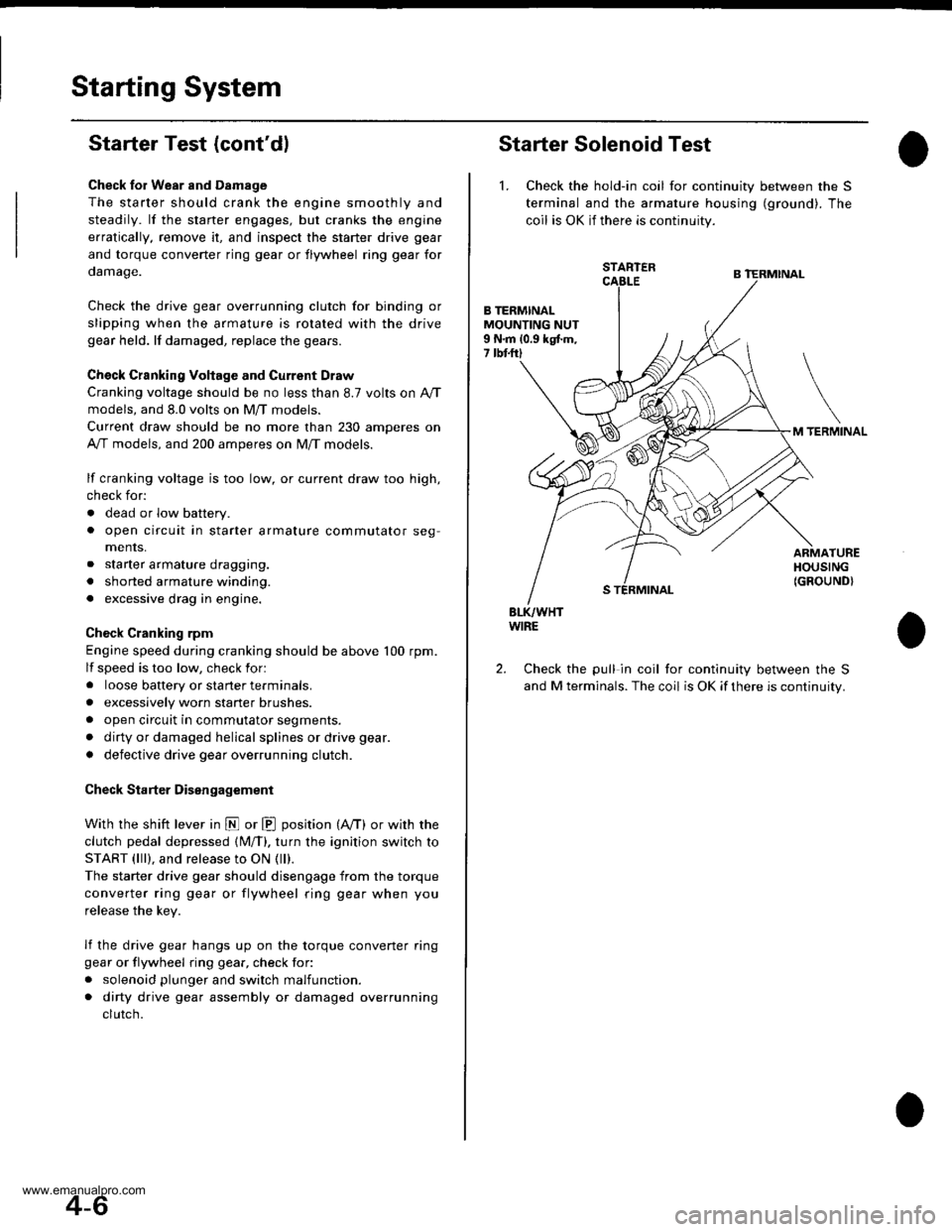

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and lhe armature housing (ground). The

coil is OK if there is continuity.

STARTER

B TERMINALMOUNTING NUT9 N.m 10.9 kgtm,7 tbtftl

TERMINAL

ARMATUREHOUSING(GROUND}

BLK/WHTWIRE

Check the pull in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

2.

4-6

www.emanualpro.com

Page 59 of 1395

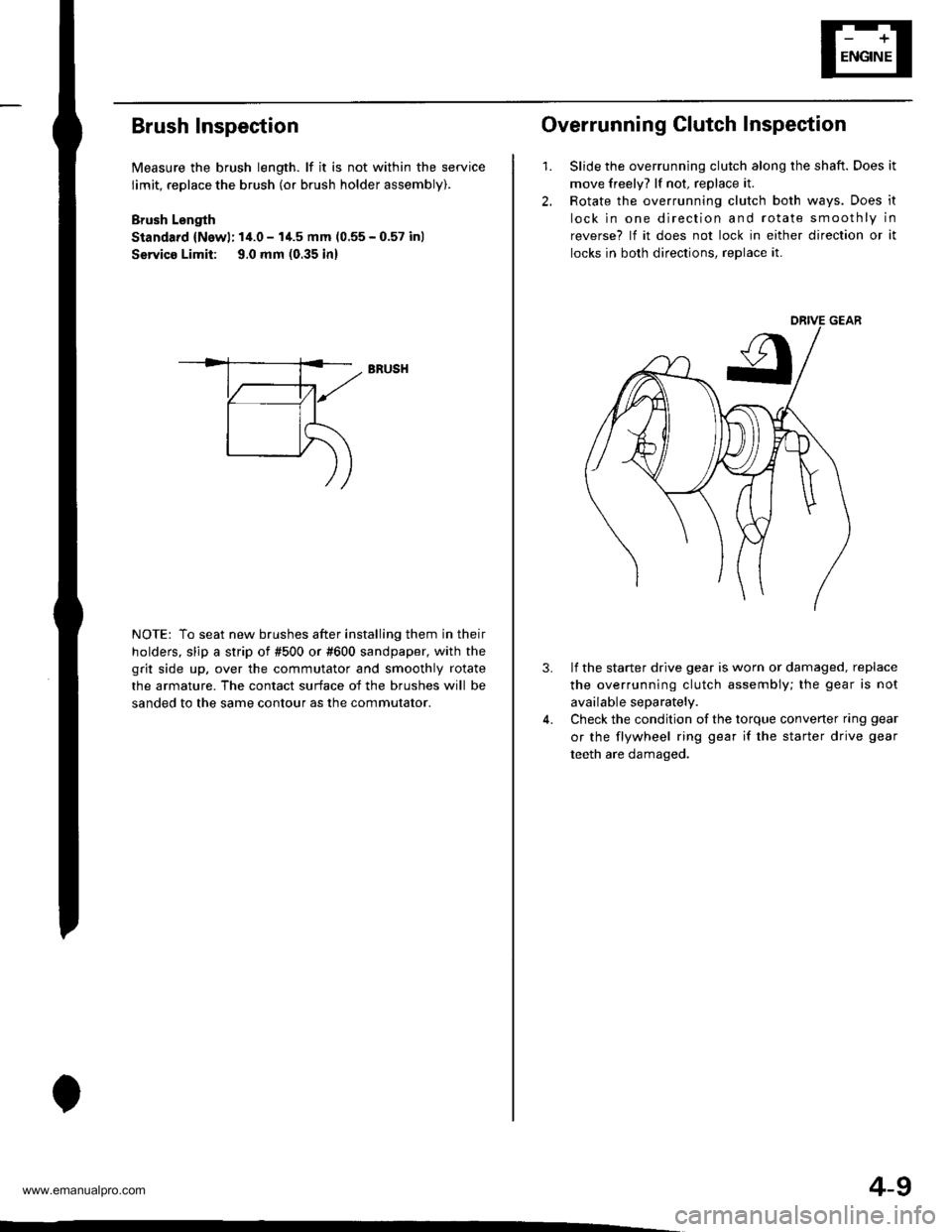

Brush Inspection

Measure the brush length. lf it is not within the service

limit, replace the brush (or brush holder assembly).

Brush Lsngth

Standard {Newl: 14.0 - I'1.5 mm (0.55 - 0.57 inl

Servico Limit: 9.0 mm (0.35 in)

NOTE: To seat new brushes after installing them in their

holders. slip a strip of #500 or #600 sandpaper, with the

grit side up, over the commutator and smoothly rotate

the armature. The contact surface of the brushes will be

sanded to the same contour as the commutator.

BRUSH

4-9

2.

1.

Overrunning Clutch Inspection

Slide the overrunning clutch along the shaft. Does it

move freely? lf not, replace it.

Rotate the overrunning clutch both ways. Does it

lock in one direction and rotate smoothly in

reverse? lf it does not lock in either direction or it

locks in both directions, reDlace it.

3.lf the starter drive gear is worn or damaged, replace

the overrunning clutch assembly; the gear is not

available separately.

Check the condition of the torque converter ring gear

or the flywheel ring gear if the starter drive gear

teeth are damaged.

www.emanualpro.com

Page 71 of 1395

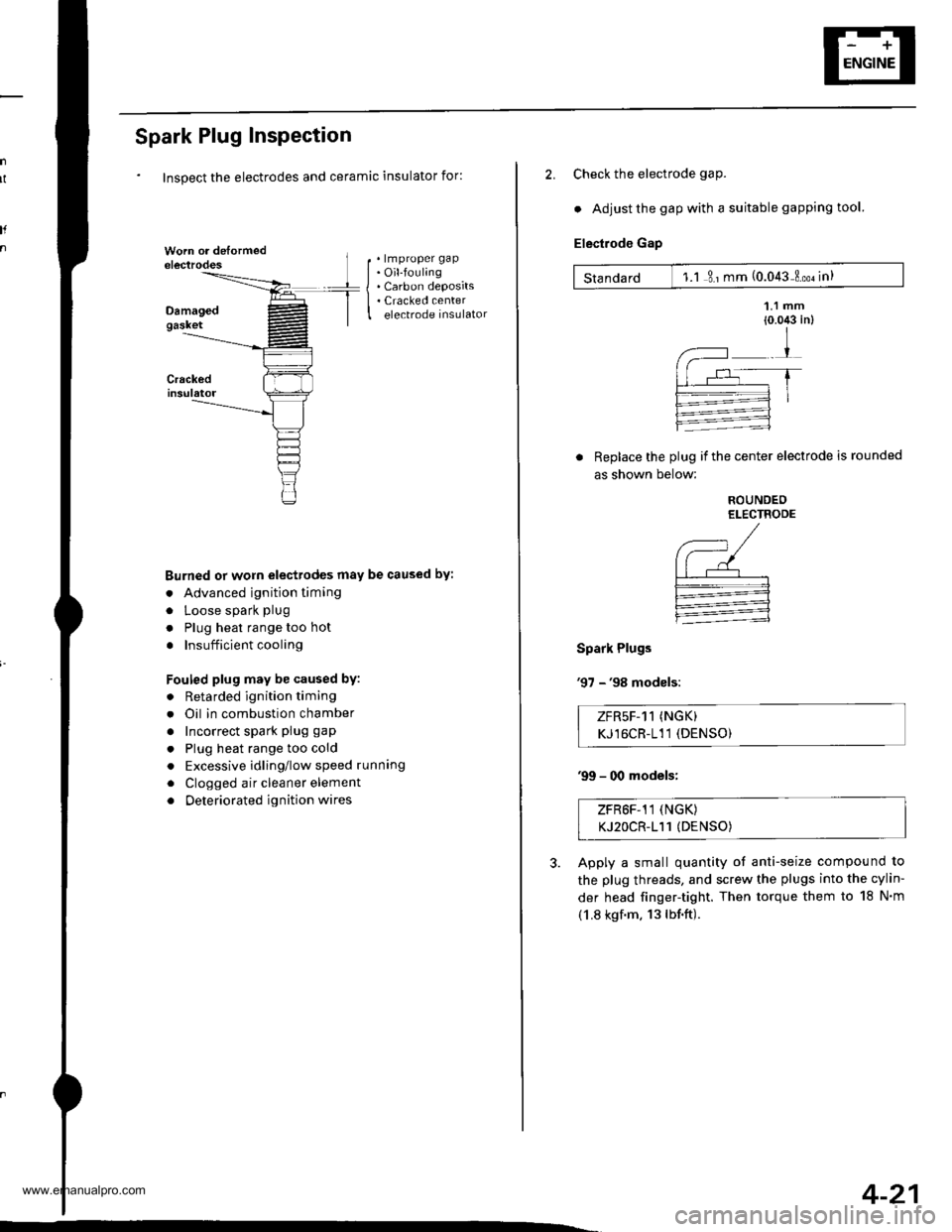

Spark Plug Inspection

Inspect the electrodes and ceramic insulator for:

. lmproper gap. Oil-fouling. Carbon deposits. Cracked centerelectrode insulator

Burned or worn electrodes may be caused by:

. Advanced ignition timing

. Loose spark plug

. Plug heat range too hot

. Insufficient cooling

Fouled plug may be caused by:

. Retarded ignition timing

. Oil in combustion chamber

. Incorrect spark plug gap

. Plug heat range too cold

. Excessive idling/low speed runnang

. Clogged air cleaner element

. Deteriorated ignition wires

I

2. Check the electrode gaP.

. Adjust the gap with a suitable gapping tool.

Electrode Gap

Standard 1.1 3 ' mm (0.043 Loo. in)

Replace the plug if the center electrode is rounded

as shown below:

Spark Plugs

'97 - '98 modsls:

ROUNDEOELECTRODE

,--, /(--/| | r--'--'--r-.--l-:=---:1

:

ZFR5F-11 (NGK)

KJ16CR-111 (DENSO)

'99 - 00 models;

ZFR6F-11 (NGK)

KJ2OCR-111 (DENSO)

Apply a small quantity of anti-seize compound to

the plug threads, and screw the plugs into the cylin-

der head finger-tight. Then torque them to 18 N'm

(1.8 kgf.m. 13lbf.ft).

4-21

www.emanualpro.com

Page 108 of 1395

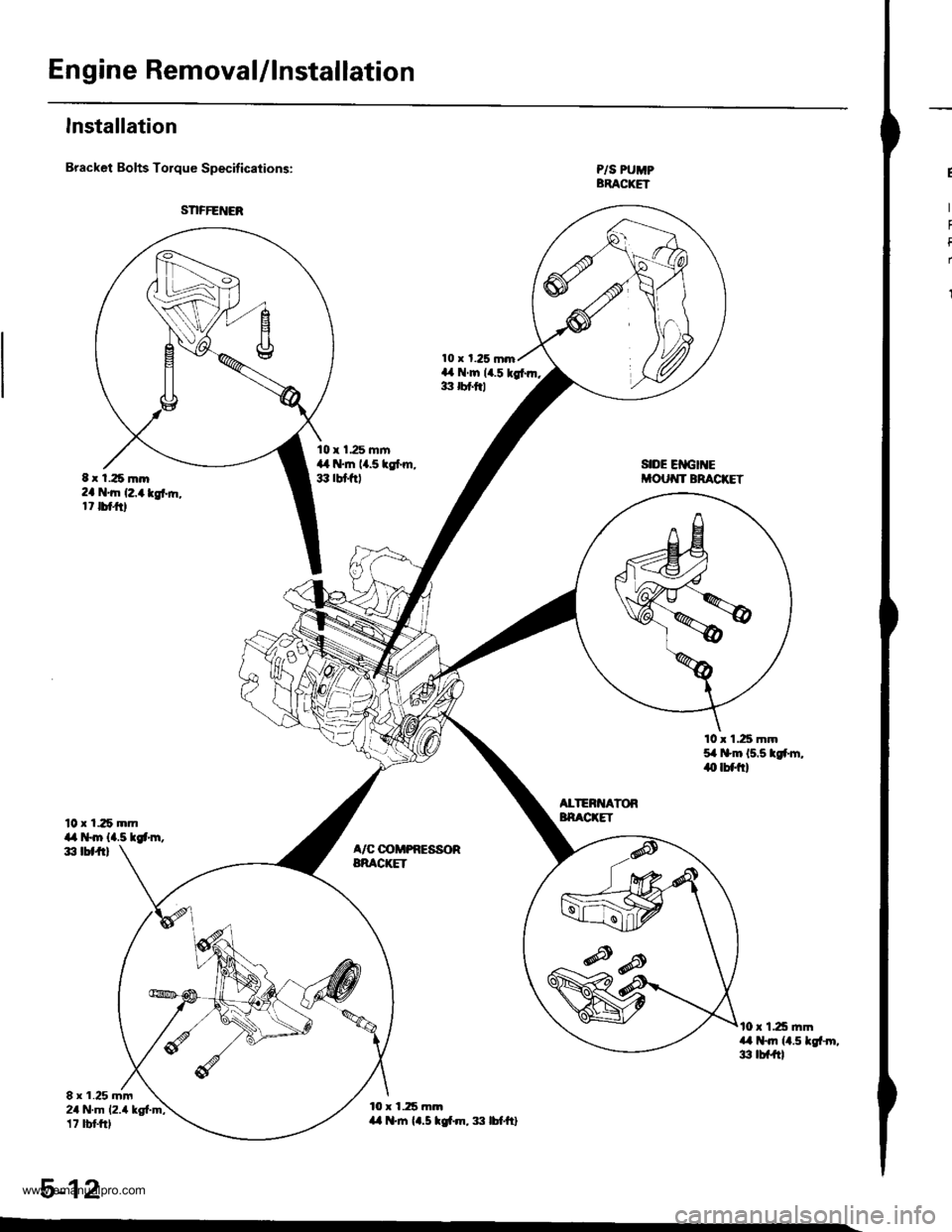

En gine Removal/lnstallation

Installation

Bracket Bolts Torque Specifications:

10 x 125 mmil,a t*m {4.5 tgt'm,d, tbtft)

8 r 1.25 mm24 N.m 12.4 kg{.m;17 tbt frl

10 x 1.25 mrn,L il.tn {1.5 tgt m, :|:l lbf'ft}

P/S PUMPBRACKET

SIDE EIIGII{Ei'OUT{T BRACKET

10 x 1.25 mm54 t$m 15.5 tgfm,iO lbflrl

ALTERI{ATORBNACKET

A/C @MPRESSORBRACIGT

t0 r 125 ]nma,l t+Jn ll.5 lgf-rn,3 tbf{tl

5-12

t t 1.25 m.D2a 'tn (2,4 kgt ft,17 tbtftl

www.emanualpro.com

Page 117 of 1395

Valve Clearancev

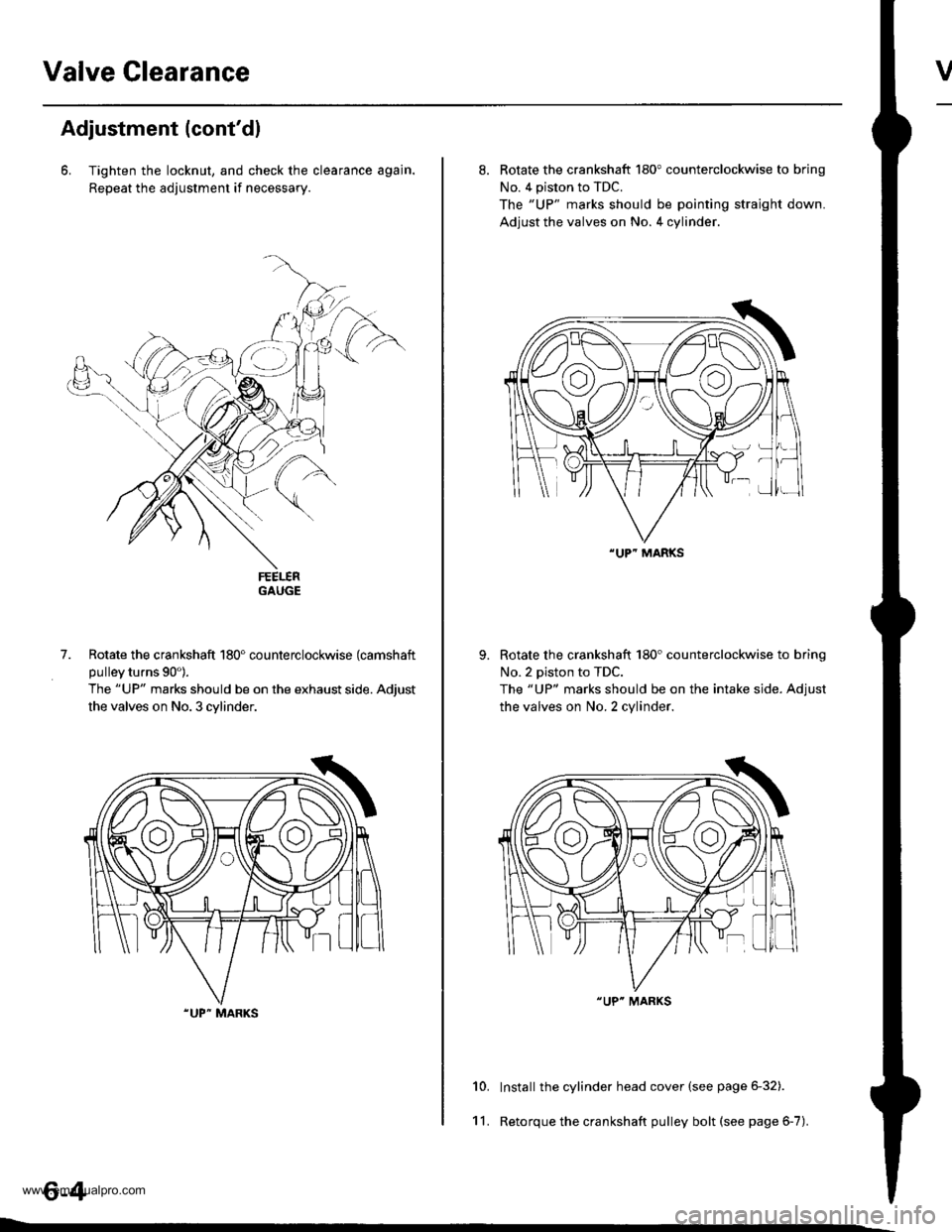

Adjustment (cont'dl

6. Tighten the locknut, and check the clearance agajn.

Repeat the adjustment if necessary.

GAUGE

Rotate the crankshaft 180" counterclockwise (camshaft

pulley turns 90').

The "UP" marks should be on the exhaust side. Adjust

the valves on No. 3 cylinder.

.UP" MARKS

7.

8. Rotate the crankshaft 180" counterclockwise to brinq

No. 4 piston to TDC.

The "UP" marks should be pointing straight down.

Adjust the valves on No. 4 cylinder.

Rotate the crankshaft 180'counterclockwise to brino

No.2 piston to TDC.

The "UP" marks should be on the intake side. Adiust

the valves on No. 2 cylinder.

Install the cylinder head cover (see page 6-32).

Retorque the crankshaft pulley bolt (see page 6-7).

10.

11.

"UP" MARKS

"UP" MARKS

www.emanualpro.com