air con drive belt HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 15 of 1395

G: FRONT SEAT PASSENGER AIRBAG MODULE DANGEN

A DANGEREXPLOSIVE/FLAMMABLECONTACT WITH ACID, WATER. OR I{EAVY METALS SUCH

AS COPPER. T.EAD. OR MERCURY MAY PRODUCE HARMFUL

AND IRRITATING GASES OR EXPLOSIVE COMPOUNDS.

STORAGE TEMPERATURES MUST NOT EXCEED 2OO"F

IlOO'C). FOR PROPER HANDLING, STORAGE, AND

DISPOSAL PROCEDURES REFER TO THE SERVICE MANUAL,

SRS SUPPLEMENT.POTSONCONTAINS POTSONOUS SODIUM AZIDE ANO POTASSIUM

NITRATE.FIRST AIDIF CONTENTS ARE SWALLOWED, INDUCE VOMITING. FOR

EYE CONTACT, FLUSH EYES WITH WATER FOR 15

MINUTES. IF GASES (FROM ACID OR WATEN CONTACT)

ARE INHALEO. SEEK FRESH AIR. IN EVERY CASE, GET

PROMPT MEDICAL ATTENTION.KEEP OUT OF REACH OF CHILDREN.

A WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND, IF

ACCIDENTALLY DEPLOYED, CAN SERIOUSLY HURT OR

KILL YOU.. DO NOT USE ELECTRICAL TEST EOUIPMENT OR

PROBING DEVICES,THEY CAN CAUSE ACCIDENTAL DEPLOYMENT.. NO SERVICEABI-E PARTS lNSlDE. DO NOT DISASSEMBII.

. PLACE AIRBAG UPRIGHT WHEN REMOVEO.

. FOLLOW SERVIC€ MANUAL INSTRUCTIONS CAREFULLY

H: PASSENGER INFORMATION lU S.A. modell

{U.S.A.'97 model}

AIEBAG SEE OTHER SIDE,

{U.S.A.'98 - 00 modelsl

AIRBAG WARNINGFLIP VISOR OVER.

l: SRS INFORMATION

lU.s.A.'97 model ilcanada '97 - 00 mod€ls I

CAUTIONTO AVOID SERIOUS INJURY:. FOR MAXIMUM SAFEW PROTECTION lN ALL TYPES OF

CRASHES, YOU MUST ALWAYS WEAR YOUR SAFETY

8ELT.o OO NOT INSTALL REARWARD-FACING CHILO SEATS lN

ANY FRONT PASSENGER SEAT POSITION.. DO NOT SIT OR LEAN UNNECESSARILY CLOSE TO THE

AIRBAG.. DO NOT PLACE ANY OBJECTS OVER THE AIRBAG OR

BETWEEN THE AIRBAG AND YOURSELF.. SEE THE OWNER'S MANUAL FOR FURTHER

INFORMATION AND EXPLANATIONS. THE SRS MUST BE INSPECTED TEN YEARS AFTER lT lS

INSTALLED.. THE DATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

lU.S.A.'98 - 00 models)

WARNINGDEATH OR SERIOUS INJURY CAN OCCUR'

. CHILDREN 12 ANO UNDER CAN BE KILLED BY THE

AIRBAG.. THE BACK SEAT lS THE SAFEST PLACE FOR CHILDREN.

. NEVER PUT A REAR-FACING CHILD SEAT lN THE

FRONT.o SIT AS FAR BACK AS POSSIBLE FROM THE AIRBAG

. ALWAYS USE SEAT BELTS AND CHll-D RESTRAINTS.

. THE SRS MUST BE TNSPECTED TEN YEAnS AFTER lT lS

INSTALLED.. THE OATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

J: FRONT PASSENGER AIRBAG WARNING

lU.S.A.'98 - 00 models)

WARNINGCHILDREN CAN BE KILLED OR INJURED 8Y THE

PASSENGER AIRBAG.THE BACK SEAT IS THE SAFEST PLACE FOR CI{ILDREN 12

AND UNDER.MAKE SURE ALL CHILDREN USE SEAT BELTS OR CHILD

SEATS.

K: FRONT SEATBELT TENSIONER WARNING

WABNINGEXPLOSIVE MATERIAL INSIDEYOU CAN BE SERIOUSLY HURT OR BURNED,

. DO NOT TAMPER OR DISASSEMBLENO SERVICEABLE PARTS INSIDE.. REFER TO SERVICE MANUAL FOR COMPLETE

INSTRUCTIONS.

(cont'd)

1-13

www.emanualpro.com

Page 38 of 1395

--

-

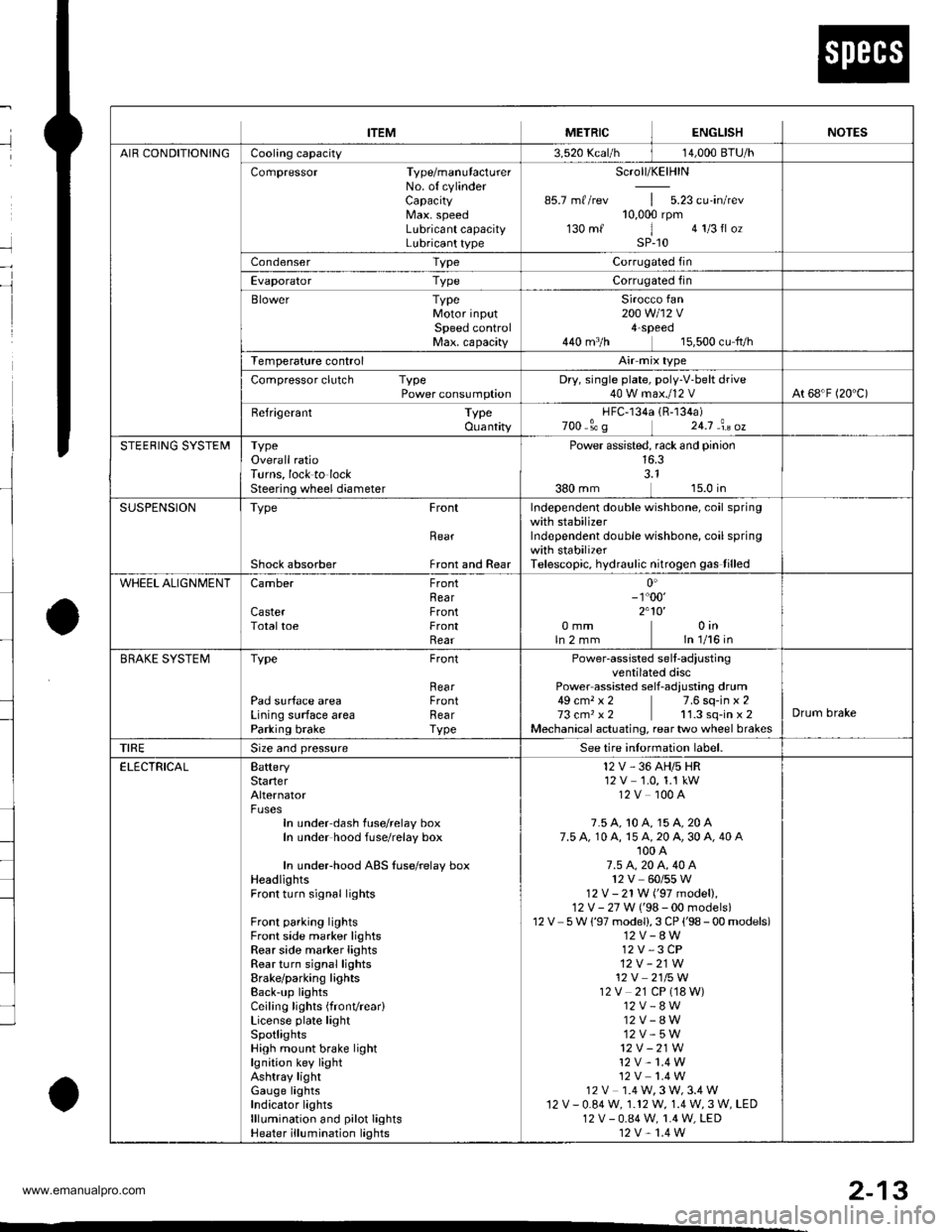

METRICITEMENGLISHNOTES

AIR CONDITIONINGCooling capacity3,520 Kcal/h j 14,000 BTU/h

Compressor Type/manutacturerNo. of cylinderCaPacityMax. speedLubricant capacityLubricant type

Scroll/KElHlN

85.7 mf/rev | 5.23 cu'in/rev10,000 rpm130mf 1 algIlozsP-10

Condenser TypeCorrugated fin

Evaporator TypeCorrugated fin

Blower TypeMotor inputSpeed controlMax. capacity

Sirocco fan200 w 112 v4-Speeo440 m3/h 15,500 cu fvh

Temperature control

Compressor clutch TypePower consumptionDry, single plate, poly-V-belt drive40 W max./12 VAt 68'F (20 C)

Befrigerant TypeOuantity

HFC-134a 1R-134a)zoo o' g 24j an oz

STEERING SYSTEMTypeOverall ratioTurns, lock to lockSteering wheel diameter

Power assisted, rack and pinion

SUSPENSIONType Front

Bear

Shock absorber Front and Rear

Independent double wishbone, coil springwith stabilizerIndependent double wishbone, coil springwith stabilizerTelescopic, hydraulic nitrogen gas tilled

WHEEL ALIGNMENTCamber

CasterTotaltoe

FronthearFrontFrontRear0inln 1/16 in0mmln2mm

0'- r"00'2.10'�

BRAKE SYSTEMTvpe

Pad surface areaLining surface areaParking brake

Front

RearFrontRearTvpe

Power-assisted selt-ad,ustingventilated discPower assisted self-adiusting drum49 cm, x 2 7.6 sq-in x 273 cm, x2 11.3 sq-in x 2Mechanical actuating, rear two wheel brakes

Drum brake

TIRESize and pressureSee tire inlormation label.

ELECTRICALBafteryStarterAlternator

In under-dash fuse/relay boxIn under hood fuse/relay box

In underhood ABS fuse/relay boxHeadlightsFront turn signal lights

Front parking lightsFront side marker lightsRear side marker lightsRear turn signal lightsErake/parking lightsBack-up lightsCeiling lights {fronvrear)License plate lightSpotlightsHigh mount brake lightlgnition key lightAshtray lightGauge lightsIndicator lightslllLrmination and pilot IightsHeater illumination lights

12 V, 36 AH/s HR12V 1.0, 1.1 kW12V 100A

7.5 A, 10 A, 15 A, 20 A7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A'100 A7.5 4,20 A. 40 A12V 60/55 W12 V- 21 W ('97 model),12 V - 27 W ('98-00 models)12V 5 W {'97 model),3 CP ('98 - 00 models)12V-8W12 V,3 CP12V-21W12 V 2115 W12V 21 CP (18 W)12V-8W12V-8W12V-5W12V -21W

12 V- 1.4 W12V 1.4 W12 V 1.4 W,3 W,3.4 W12V-0.84W, 1.12 W, 1.4 W,3 W, LED12 V - 0.84 W, 1.4 W, LED12 V,1.4 W

2-13

www.emanualpro.com

Page 123 of 1395

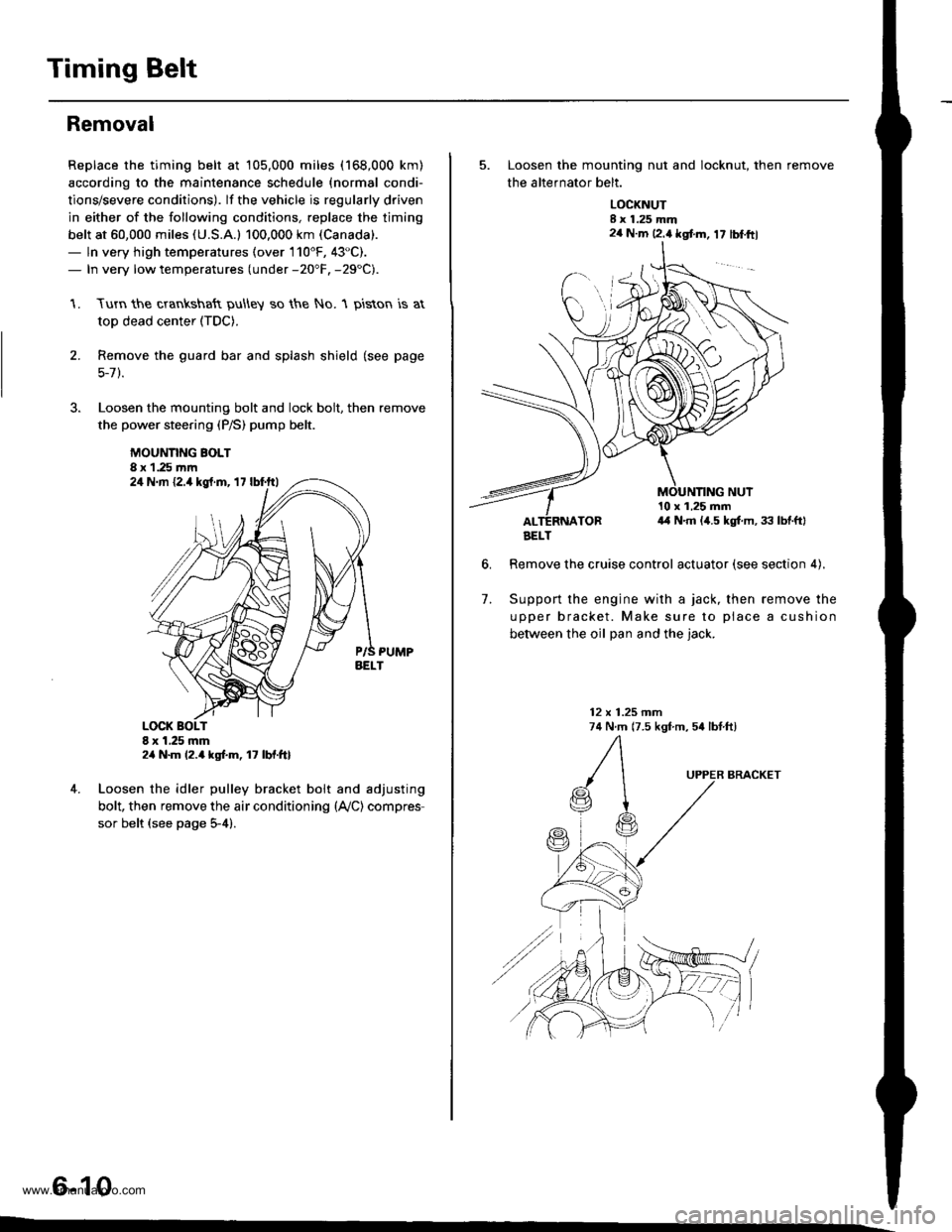

Timing Belt

Removal

Replace the timing belt at 105,000 miles (168,000 km)

according to the maintenance schedule {normal condi-

tions/severe conditions). lf the vehicle is regularly driven

in either of the following conditions, replace the timing

belt at 60,000 miles (U.S.A.l 100.000 km (Canada).

- ln very high temperatures (over 110'F, 43"C).- In very low temperatures (under -20"F. -29"C).

Turn the crankshaft pu\ley so the No. 1 piston is at

top dead center (TDC).

Remove the guard bar and splash shield (see page

5-7 ).

Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt.

MOUNNNG BOLT8 x 1.25 rnm

1.

2.

,l

4. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (lVC) compres

sor belt (see page 5-4).

6-10

24 N.m {2.4 kgt.m, 17 lbf.ftl

24 N.m 12.4 kgf.m, lt lbf.ftl

5. Loosen the mounting nut and locknut, then remove

the altefnator belt.

LOCKNUTI x 1.25 mm2a N.m 12.4 kgt m, 17 lblftl

6.

10 x 1,25 mm4,1 N.m (,1.5 kgt m, 33 lbtftl

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil Dan and the iack.

12 x 1.25 mm74 N.m (7.5 kgf m, 54 lbtftl

7.

BRACKET

AELT

www.emanualpro.com

Page 179 of 1395

1.

2.

3.

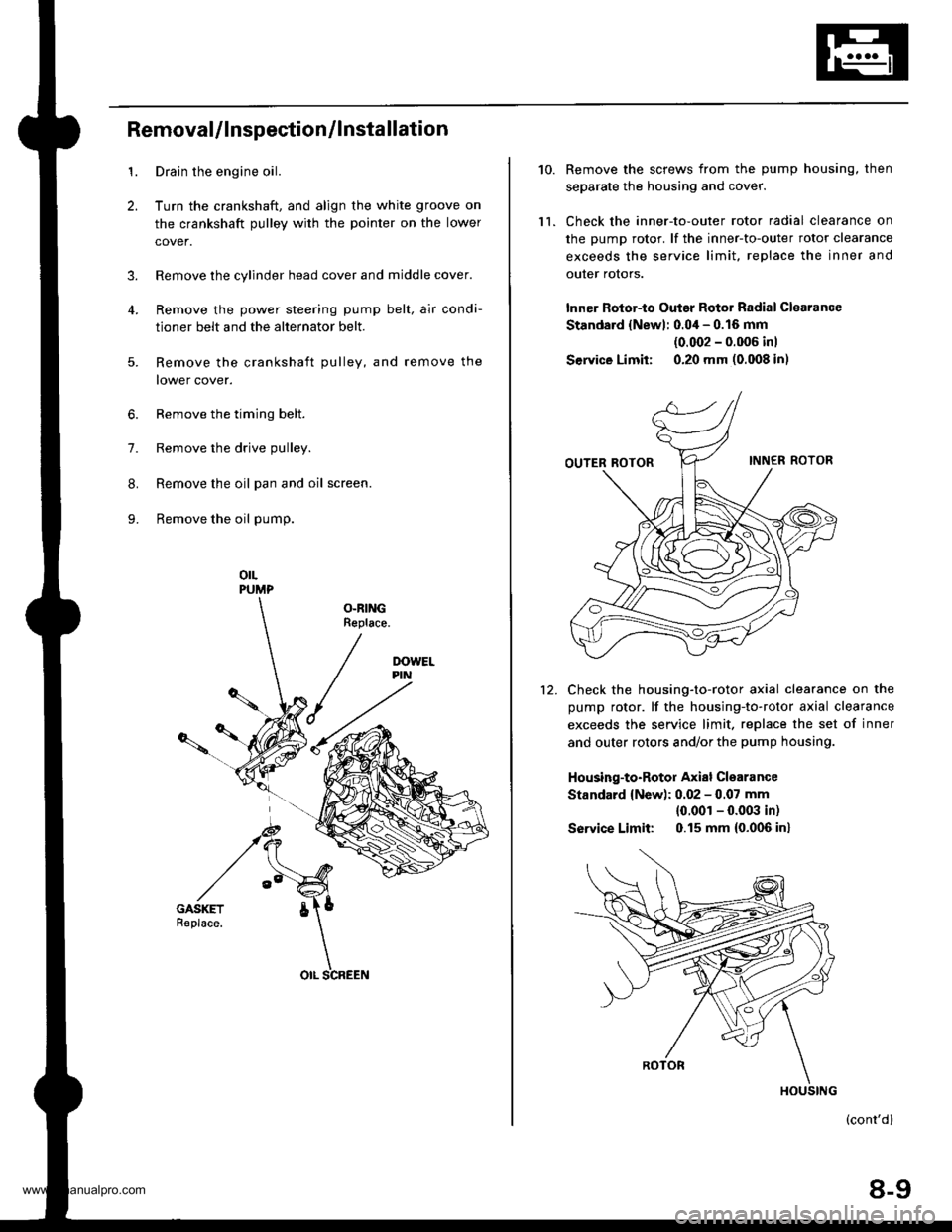

RemovaUlnspection/lnstallation

Drain the engine oil.

Turn the crankshaft, and align the white groove on

the crankshaft pulley with the pointer on the lower

cover.

Remove the cylinder head cover and middle cover.

Remove the power steering pump belt, air condi-

tioner belt and the alternator belt.

Remove the crankshaft pulley, and remove the

lower cover.

6. Remove the timing belt.

7. Remove the drive pulley.

8. Remove the oil pan and oil screen.

9. Remove the oil pump.

orLPUMP

OLRINGReplace.

5.

OIL SCREEN

10.

ll.

Remove the screws from the pump housing, then

separate the housing and cover.

Check the inner-to-outer rotor radial clearance on

the pump rotor. lf the inner-to-outer rotor clearance

exceeds the service limit. replace the inner and

outer rotors.

lnner Rotor-to Outar Rotor Radial Clearance

Standard {Newl: 0.04 - 0.16 mm

{0.002 - 0.006 inl

Service Limit: 0.20 mm (0.008 in)

Check the housing-to-rotor axial clearance on the

pump rotor. lf the housing-to-rotor axial clearance

exceeds the service limit. replace the set of inner

and outer rotors and/or the pump housing.

Housing-to-Rotor Axial Clearance

Standard {New): 0.02 - 0.07 mm

{0.001 - 0.003 in)

So|'�ice Limit: 0.15 mm (0.006 inl

(cont'd)

8-9

HOUSING

www.emanualpro.com

Page 846 of 1395

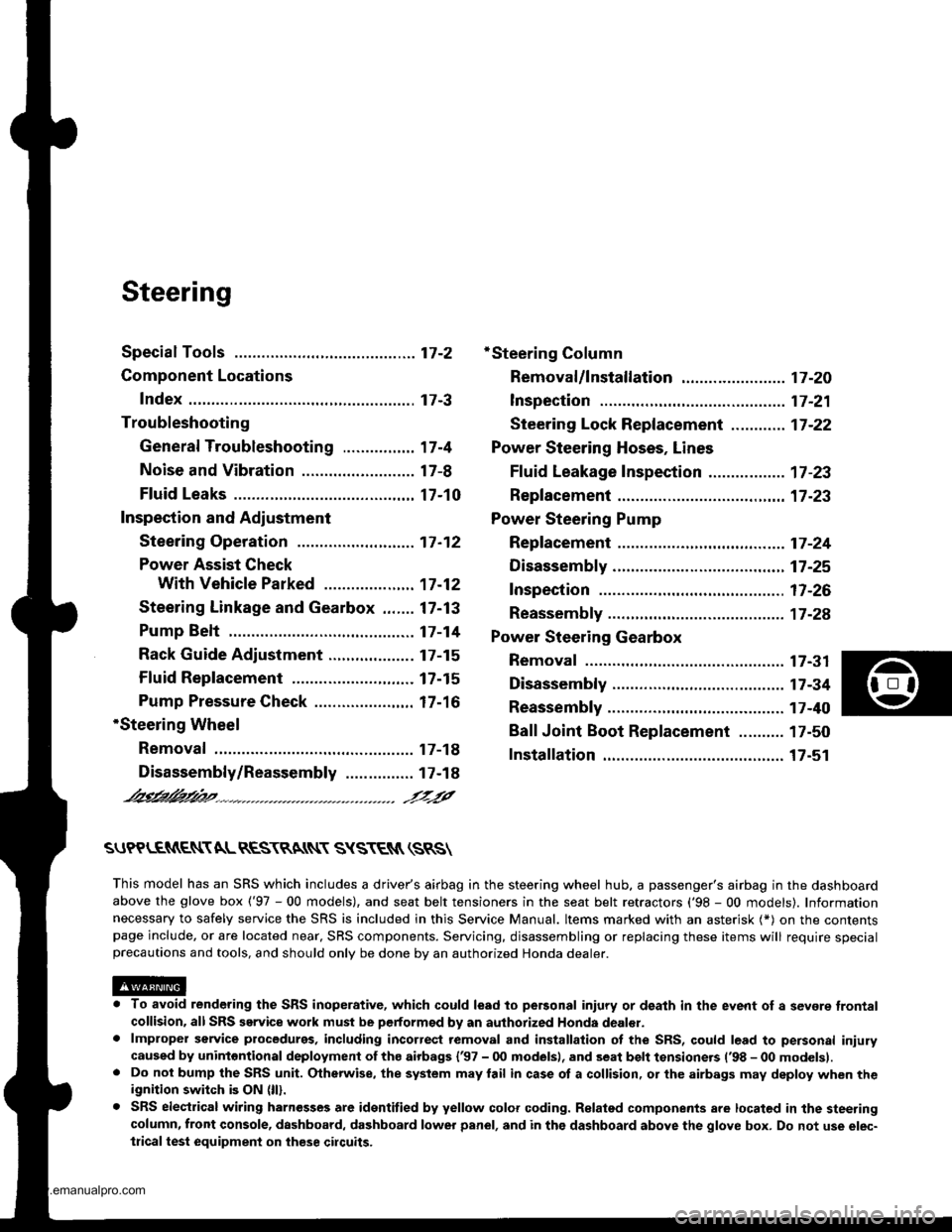

Steering

Special Toofs ............. 17-2

Component Locations

Index ................ ....... 17-3

Troubleshooting

General Troubleshooting ................ 1 7-4

Noise and Vibration ......................... 17-8

Fluid Leaks ............. 17-10

Inspection and Adiustment

Steering Operation .......................... 17-12

Power Assist Check

With Vehicle Parked ....................

Steering Linkage and Gearbox .......

Pump Belt

Rack Guide Adjustment ...................

Fluid Rep|acement ...................,,.,....

Pump Pressure Check .................,,...

*Steering Wheel

Removal ................. 17-18

*Steering Column

Removal/lnstallation ................ ....... 17 -2O

lnspection .............. 17-21

Steering Lock Replacement ............ 17 -22

Power Steering Hoses, Lines

Ffuid Leakage Inspection ................. 17 -23

Repfacement .......... 17-23

Power Steering Pump

Repfacement .......... 17-24

Disassembly ...........17-25

fnspection .............. 17-26

Reassembly ............ 17-28

Power Steering Gearbox

Removal ................. 17-31

Disassembly ........... 17-34

Reassembly ............ 17-40

Ball Joint Boot Replacement .......... 17-50

Installation ............. 17-51

17-12

17-13

17-14

l7-15

17-15

17-16

Disassembly/Reassembly............... 17-18

4'%/b.......... -r'-7--a/

SUPPLEN\EN AL RES\RA(N SYSTES{ (SRS\

This model has an SRS which includes a driver's airbag in the steering wheel hub. a passenger's airbag in the dashboardabove the glove box ('97 - 00 models), and seat belt tensioners in the seat belt retractors ('98 - 00 models). Informationnecessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk (*) on the contentspage include, or are located near, SBS components. Servicing. disassembling or replacing these items will require specialprecautions and tools, and should only be done by an authorized Honda oearer.

To avoid rendering the SRS inoperative, which could lead to peFonal iniury or death in the event of a sevore trontalcollision. allSRS service work must be performod by an authorized Honda dealer.lmproper service procedurgs, including incorrect removal and installalion of the SRS, could lead to personal iniurycaused by unintontional deployment of th€ airbags {'97 - 00 models), and seat belt tensioners ('98 - 00 modelsl.Do not bump the SRS unit. Otherwise, the system may lail in case ot a collision, or the airbags may deploy when theignition switch is ON (lll.

SRS electrical wiring harnesses are identitied by yellow colof coding. Ralated components are located in the steeringcolumn, front console, dashboard, dashboard lower panel, and in the dashboard above the glove box. Do not use elec-trical test equipment on these cilcuits,

www.emanualpro.com

Page 852 of 1395

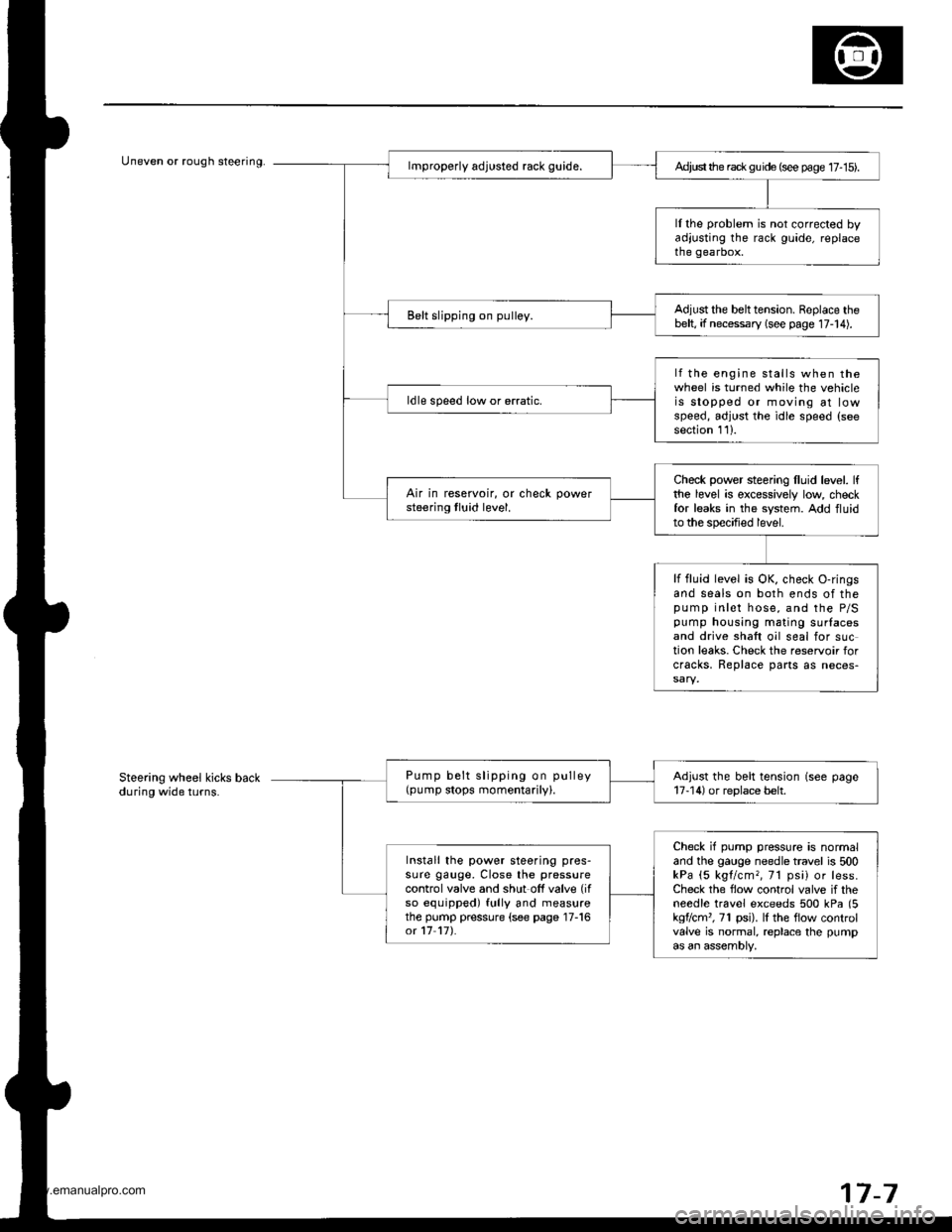

Uneven or rough steering.Ad,ust the rack gu ide (see page 17- 15).

ll the problem is not corrected byadjusting the rack guide, replacethe gearbox.

Adjust the belttension. Replace thebelt, if necessary (see page 17-14).Belt slipping on pulley.

lf the engine stalls when thewheel is turned while the vehicleis stopped or moving at lowspeed, adjust the idle speed (seesection 111.

ldle speed low or erratic.

Check power steering lluid level. lfthe level is excessively low checkfor leaks in the system. Add fluidto the specified level.

Air in reservoir, or check powersteering tluid level.

lf fluid level is OK, check O-ringsand seals on both ends of thepump inlet hose, and the P/Spump housing mating surlacesand drive shaft oil seal for suction leaks. Check the reservoir forcracks, Replace parts as neces-

Pump belt slipping on pulley(pump stops momentarily).Adjust the belt tension (see page17-14) or replace belt.

Check if pump pressure is normaland the gauge needle travel is 500kPa (5 kgl/cm,, 71 psi) or less.Check the flow control valve if theneedle travel exceeds 500 kPa (5kgflcm'�, 71 psi). lI the flow controlvalve is normal, replace the pumpas an assembly,

Install the power steering pres-sure gauge, Close the pressurecontrol valve and shut off valve (if

so equipped) fully and measurethe pump pressure (see page 17-16ot 17 17).

Steering wheel kicks backduring wide turns.

7-7

www.emanualpro.com

Page 1090 of 1395

a

Heater and Air Conditioning

Heater ...........21

NOTE: Section 21 ("Heater") is included in section 22.

Air Conditioning ......'..'.. '.'22'1

SUPPLEMENTAL RESTRAINT SYSTEM (SRS}

This model has an SRS which includes a driver's airbag in the steering wheel hub, a passenger's airbag in the dashboard

above the glove box ('97,00 models). and seat belt tensioners in the seat belt retractors ('98 - 00 models). Information

necessary to safely service the SRS is included in this Service Manual. ltems marked with an asterisk (*) on the contents

page include. or are located near, SRS components. Servicing, disassembling or replacing these items will require special

precautions and tools, and should only be done by an authorized Honda dealer.

@. To avoid rendering the SRS inoperative, which could lead to personal iniury or death in the event of 8 severe frontal

collision, all SRS service work must be performed by an authotized Honda dealer.

lmproper service procedures, including incorrect removal and installation of the SRS, could lead to personal iniury

caused by unintentional deployment of the airbags ('97 - 00 models), and seat belt tensioners 138 - 00 models).

Do not bump the SRS unit. Otherwise, the system may fail in case of a collision, or the airbags may deploy when the

ignition switch is ON {lll.

SRS eleqtrical wiring harnesses are identified by yellow color coding. Related components are located in the steering

column, front console, dashboard, dashboard lower panel, and in the dashboard above the glove box. Do not use elec-

tricaltest equipment on thes€ cilcuils.

www.emanualpro.com

Page 1310 of 1395

)

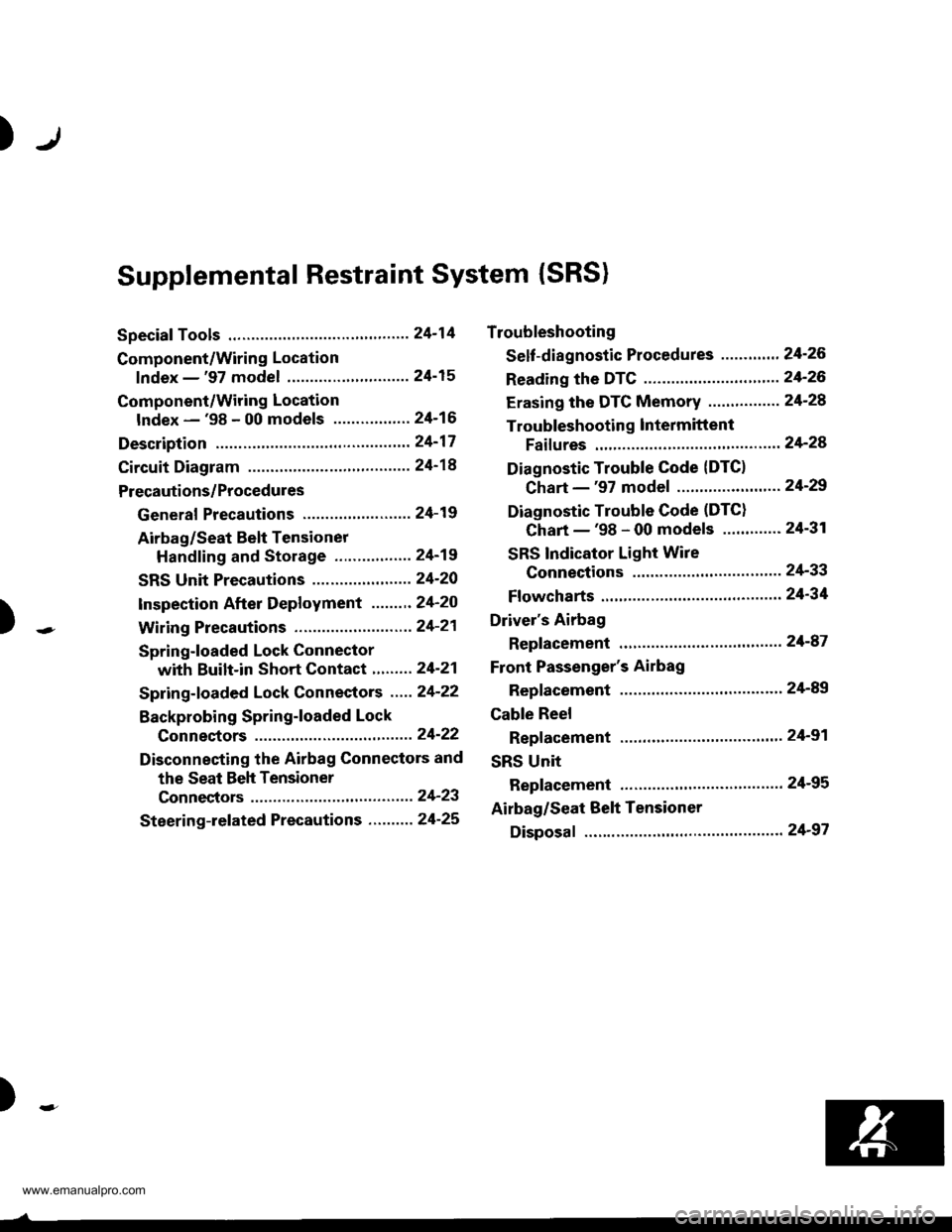

Supplemental Restraint System (SRS)

Special Tools .."....."" 24-14

Component/Wring Location

lndex - '97 model ..........'.." '.....""" 24-15

Component/Wiring Location

lndex - '98 - 00 models ..............." 24-16

Description .'.........."'.24'17

Circuit Diagram .........24'14

Precautions/Procedures

General Precautions ......".."'........... 24-19

Airbag/Seat Belt Tensioner

Handling and Stolage ....''........... 24-19

SRS Unit Precautions ...............'...... 24-20

lnspeciion After Deployment .......'.24'20

)

with Built-in Short Contact '...'....24-21

Spring-loaded Lock Connectors .."' 24-22

BackProbing SPring-loaded Lock

Conneetors ,.......24-22

Disconnecting the Airbag Connectors and

the Seat Beh Tensioner

Connectors ....'....24-23

Steering-lelated Precautions .......... 24-25

Troubleshooting

Self -diagnostic Procedures ............. 24-26

Reading the DTC .................. .....".."' 24'26

Erasing the DTC Memory ................24-28

Troubleshooting lntermittent

Faifures "'...........24'24

Diagnostic Trouble Gode {DTC}

Chart -'97 model ....""....... "......24-29

Diagnostic Trouble Gode (DTCI

Chart -'98 - 00 models ............. 24-31

SRS Indicator Light Wire

Connections ','," 24'33

Ff owcharts ....-........24'34

Driver's Airbag

Repf acement ..'......21'87

Front Passenger's Airbag

Repfacement .....'.',24'AS

Gable Reel

Replacement .......'.24-91

SRS Unit

Replacement .........24-95

Airbag/Seat Belt Tensioner

Disposaf .................24'97

)-e

www.emanualpro.com

Page 1313 of 1395

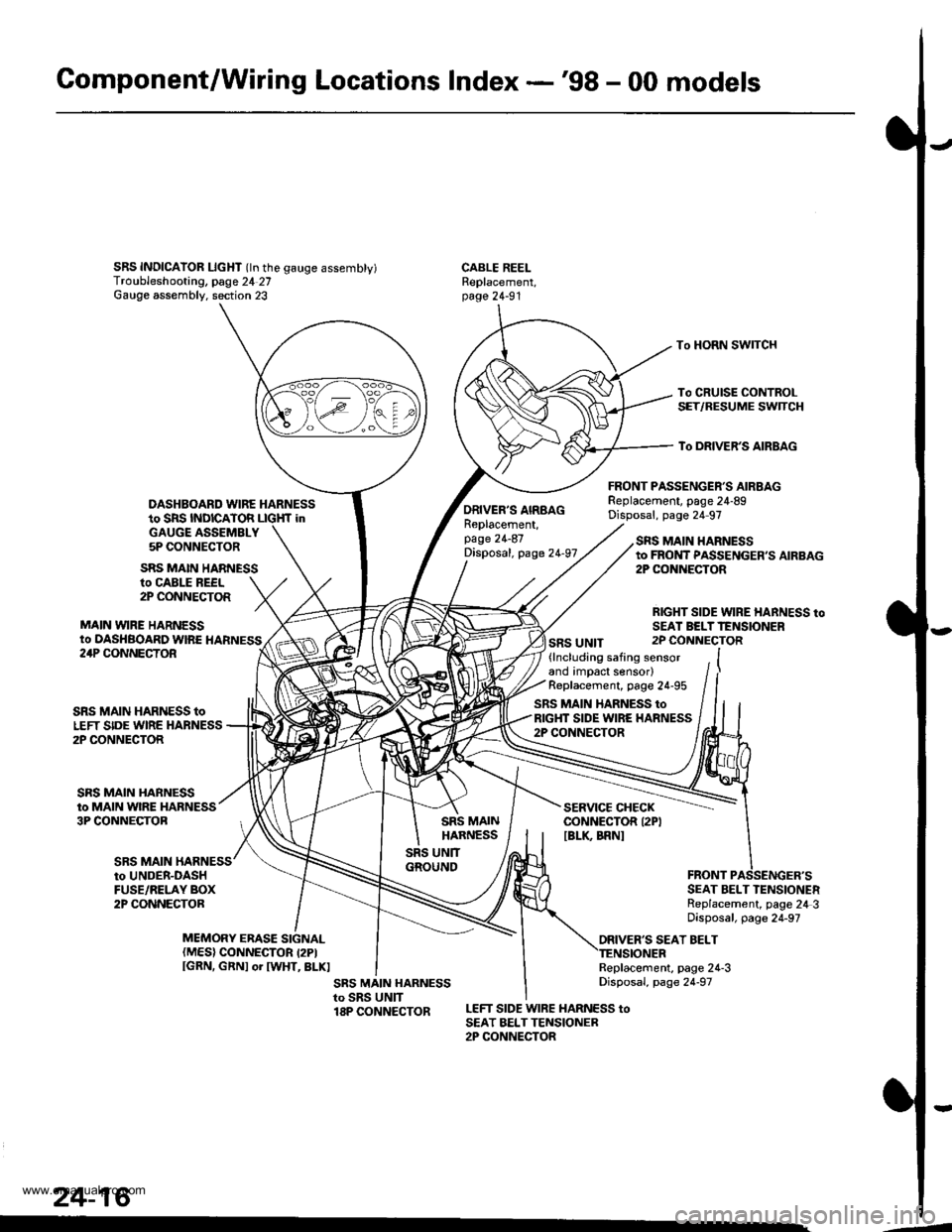

Gomponent/Wiring Locations Index -'98 - 00 models

SRS INDICAIOR LIcHT (ln the gauge assembty)Troubleshooting, page 24 27Gauge assembly. section 23

DASHBOARD WIRE HARNESSto SRS INDICATOR LIGHf inGAUGE ASSEMBLY5P CONNECTOR

FRONT PASSENGER'S AIRBAGReplacement, page 24-89Disposal, page 24 97

CABLE REELReplacement,page 24-91

To HORN SWITCH

To CRUISE CONTROLSET/RESUME SWTCH

To DRIVER'S AIRBAG

ro CABLE REEL2P CONNECTOR

MAIN VYIRE HARNESSto DASHBOARD WIRE HARNESS

SRS MAIN HARNESS

ORIVER'S AIRBAGReplacement,page 24-87Disposal, page 24-97

SRS UNIT

SRS MAIN HARNESSto FROI{T PASSENGER,S AIRBAG2P CONiIECTOR

RIGHT SIDE WIRE HARNESS toSEAI BELTTENSIONER2P CONNECTOR24P CONNECTOR

SRS MAIN

SRS MAIN HARNESS toLEFT SIDE WIRE HARNESS2P CONNECTOR

SRS MAIN HARNESSto MAIN WIRE HARNESS3P CONNECTOB

(lncluding safing sensorand impact sensor)Replacement, page 24-95

SRS MAIN HARNESS toRIGHT SIDE WIRE HARNESS2P CONNECTOR

SERVICE CHECKCONNECTOR I2PIIBLK BRNI

to UNDER-DASHFUSE/RELAY BOX2P CONNECTORSEAT BELT TENSIONERReplacement, page 24 3Disposal, page 24-97

ORIVER'S SEAT BELTMEMORY ERASE SIGNAL(MES) CONNECTOR I2PIIGRN, GRNI or IWHT, BLKIReplacement, page 24-3Disposal, page 24-97

LEFT SIDE WIRE HARNESS toSEAT BELTTENSIONER2P CONNECTOR

24-16

.4

www.emanualpro.com

Page 1314 of 1395

Description

J)

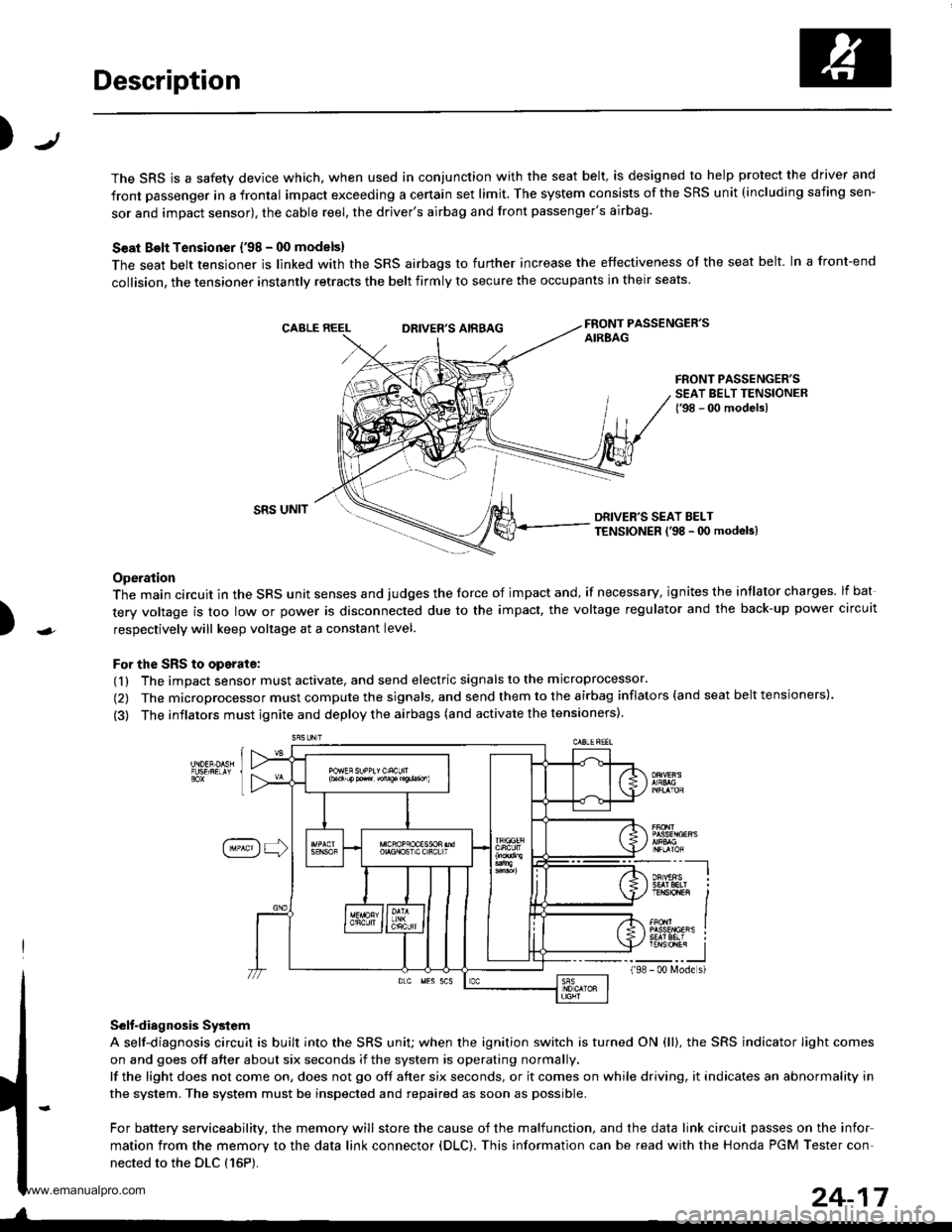

The SRS is a safety device which, when used in conjunction with the seat belt, is designed to help protect the driver and

front passenger in a frontal impact exceeding a certain set limit. The system consists of the SRS unit (including safing sen-

sor and impact sensor), the cable reel, the driver's airbag and front passenger's airbag.

Seat Bolt Tensioner {'98 - 00 models}

The seat belt tensioner is linked with the SRS airbags to further increase the effectiveness of the seat belt. In a front-end

collision, the tensioner instantly retracts the belt firmly to secure the occupants in their seats

FRONT PASSENGER'SAIREAGDRIVER'S AIRBAG

FRONT PASSENGER'SSEAT BELT TENSIONER{'98 - 00 modelsl

)

SRS UNITDRIVER'S SEAT BELTTENSIONER l'98 - 0O modeb)

Operation

The main circuit in the SRS unit senses and judges the force of impact and, if necessary, ignites the intlator charges. lf bat

tery voltage is too low or power is disconnected due to the impact, the voltage regulator and the back-up power circuit

respectively will keep voltage at a constant level.

For the SRS to operate:

(1) The impact sensor must activate, and send electric signals to the microprocessor.

(2) The microprocessor must compute the signals, and send them to the airbag inflators (and seat belt tensioners).

(3) The inflators must ignite and deploy the airbags (and activate the tensioners).

Selt-diagnosis System

A self-diagnosis circuit is built into the SRS uniU when the ignition switch is turned ON (ll), the SRS indicator Iight comes

on and goes off after about six seconds if the system is operating normally.

lf the light does not come on, does not go off after six seconds, or it comes on while driving, it indicates an abnormality in

the system. The system must be inspected and repaired as soon as possible.

For battery serviceability, the memory will store the cause of the malfunction, and the data link circuit passes on the infor

mation from the memory to the data link connector (DLC). This information can be read with the Honda PGM Tester con-

nected to the DLC {16P).

198

---__-l

TENSTO1En II

_-___J- 00 N4ode s)

24-17

www.emanualpro.com