automatic transmission fluid HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 32 of 1395

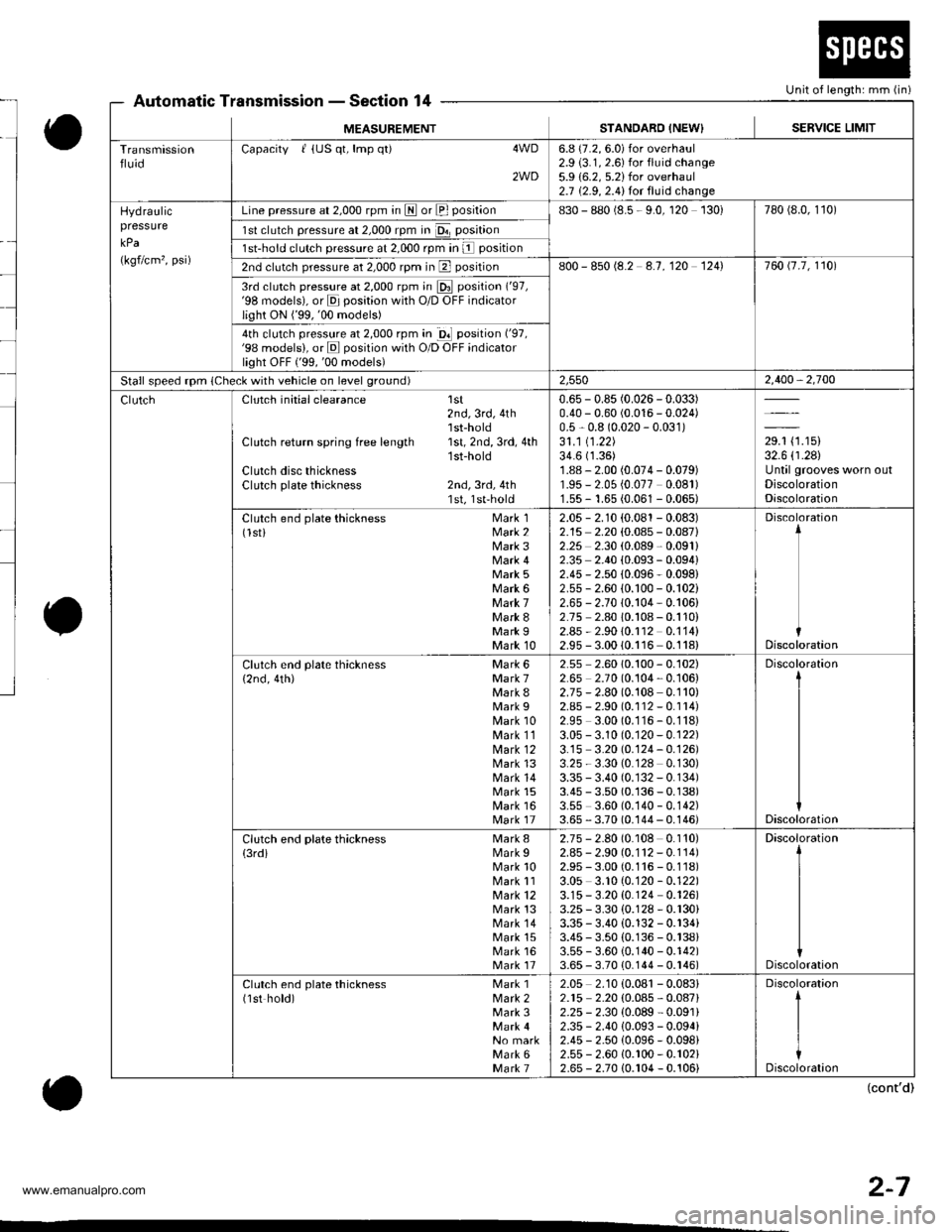

Unit of length: mm (in)Automatic TransmissionSection 14

MEASUREMENTSTANDARO INEW}SERVICE LIMIT

TransmissionfluidCapacity I {US qt, lmp q0 4WD

2WD

6.8 (7.2, 6.0) for overhaul2.9 (3.1, 2.6) for fluid change5.9 {6.2, 5.2)for overhaul2.7 {2.9, 2.4}for fluid change

Hydraulicpressure

kPa

(kgflcm'�, psi)

Line pressure at 2,000 rpm in LII or El position830 - 880 (8.5 - 9.0, 120 130)780 (8.0, 1'�t0)

1sl clutch pressure at 2,000 rpm in Da position

1st-hold clutch pressure at 2,000 rpm In l position

2nd clutch pressure at 2,000 rpm in El position800 - 850 (8.2 4.7,120 1241760 t7.7, 1101

3rd clutch pressure at 2,000 rpm in E position ('97,'98 models), or E position with O/D OFF indicatorlight ON ('99,'00 models)

4th clutch pressure at 2,000 rpm in gl position ('97,'98 models), or E position with O/D OFF indicatorlight oFF ('99,'00 models)

Stall speed rpm (Check with vehicle on level ground)2,5502,400,2,700

Clutch initial clearance 1st2nd,3rd,4th'lst-hold

Clutch return spring free length 1st, 2nd, 3rd, 4th'1st-hold

Clutch disc thicknessClutch plate thickness 2nd, 3rd, 4th1st, 1st-hold

0.65 - 0.85 (0.026 -0.033)

0.40 - 0.60 (0.016 - 0.024)0.5 - 0.8 (0.020 - 0.031)31 .1 11 .22)34.6 (1.36)

1.88 - 2.00 (0.074 - 0.079)'r.95 - 2.05 {0.077 0.081)'1.55- 1.65 (0.061 - 0.065)

29.1 (1.15)

32.6 (r.28)

Until grooves worn outDiscolorationDiscoloration

Clutch end plate thickness Mark 1(lsti Mark 2Mark 3Mark 4Mark 5Mark 6Mark 7Mark 8Mark IMark 10

2.05 - 2.r0 (0.081 - 0.083)2.15 2.20 (0.085 - 0.08712.25 2.30 (0.089,0.091)

2.35 2.40 {0.093 - 0.094}2.45 - 2.50 {0.096- 0.098}2.55 - 2.60 (0.100 - 0.102)2.65 - 2.70 (0.104 - 0.106)2.75 2.80 i0.108 - 0.110)2.85 - 2.9010.r 12 0.114)2.95 - 3.0010.116 0.118)

Discoloration

Discoloration

Clutch end plate thickness Mark 6{2nd, 4th) Mark 7Mark 8Mark 9Mark 10Mark 11lvlark 12Mark 13Mark 14Mark 15Mark 16Mark 17

2.55 2.60 10.100 - 0.102)2.65 2.70(0.104,0.106)2.75 - 2.80 (0.108 0.110)2.85 - 2.90 (0.112 -0.rr4)

2.95 3.00 (0.116-0.118)

3.05 - 3.10 (0.120 - 0.122)3.15 3.20 (0.124-0.126)

3.25 - 3.30 (0.128 0.130)3.35 - 3.40 (0. r32 - 0.134)3.45 - 3.50 (0.136 - 0.138)3.55 3.60 (0.140 - 0.142)3.65 - 3.70 (0.144 - 0.146)

Discoloration

Discoloration

Clutch end plate thickness Mark 8

{3rdi Mark IMark 10Mark 11Mark 12Mark 13Mark 14Mark 15Mark 16Mark 17

2.75 - 2.80 (0.108 0.110)2.85- 2.90 (0.112 - 0.114)2.95 - 3.00 (0.116 - 0.1'�j8)3.05 3.10 (0.120 - 0.122)3.15-3.20 {0.124 0.126)3.25 - 3.30 (0.128 - 0.r30)3.35 - 3.40 (0.132 - 0.r34i3.45 - 3.50 (0.136 - 0.138)3.55 - 3.60 {0.140 - 0.142)3.65 - 3.70 {0.144 - 0.r46)

Discoloration

Discoloration

Clutch end plate thickness Mark 1(1st hold) Mark 2Mark 3

No markMark 6Mark 7

2.05 2.10 (0.081 - 0.08312.r5 2.20 (0.085 - 0.087)2.25 - 2.30 {0.089 - 0.091}2.35 - 2.40 10.093 - 0.094i2.45 - 2.50 (0.096- 0.098i2.55 - 2.60 (0.r00 - 0.102)2.65 - 2.70 (0.r04 - 0.106)

(cont'd)

2-7

www.emanualpro.com

Page 35 of 1395

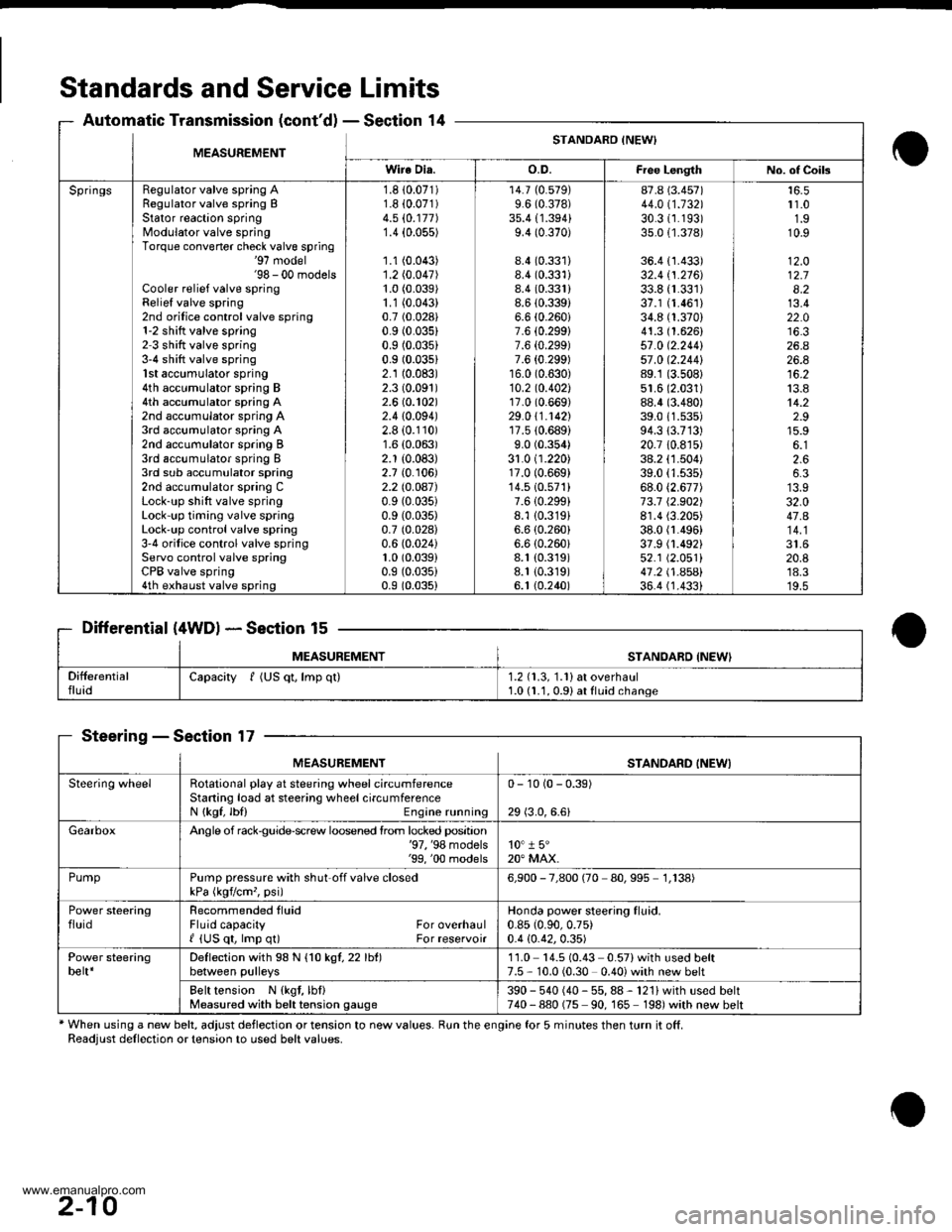

Standards and Service Limits

Automatic Transmission (cont'dl - Section 14

Differential (4WDl * Section 15

MEASUREMENTSTANOABD {NEW'

SteeringSection 17

* When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.Readjust dellection or tension to used belt values.

MEASUREMENTSTANDARO INEWI

Wire Dia.o.D.Fiee LengthNo. of Coils

SpringsRegulator valve spring ARegulator valve spring BStator reaction springModulator valve springTorque convener check valve spring'97 model'98 - 00 modelsCooler relief valve springRelief valve spring2nd orilice control valve spring1-2 shitt valve spring2 3 shift valve spring3-4 shift valve spring1st accumulator spring4th accumulator spring B4th accumulator spring A2nd accumulator spring A3rd accumulator spring A2nd accumulator spring B3rd accumulator spring I3rd sub accumulator spring2nd accumulator spring CLock-up shift valve springLock-up timing valve springLock'up control valve spring3'4 orifice control valve springServo control valve springCPB valve spring4th exhaust valve spring

1.8 10.071)1.8 i0.071)4.5 (0.177)

1.4 {0.055)

1.1 (0.043)

1.2 (0.047)

1.0 (0.039)

1.1 (0.043)

0.7 (0.028)

0.9 (0.035)

0.9 (0.035)

0.9 (0.03s1

2.1 (0.083)

2.3 (0.091)

2.6 (0.102)

2.410.094)2.8 (0.110)

1.6 (0.063)

2.1 (0.083)

2.7 {0. r06)2.2lO.OA7)0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

0.6 (0.024)

1.0 (0.039)

0.9 (0.035)

0.9 (0.035)

14.7 (0.579)

9.6 (0.378)

35.4 {1.394}9.4 (0.370)

8.4 (0.331)

8.4 (0.331)

8.4 (0.331)

8.6 (0.3391

6.6 (0.260i

7.6 {0.299}7.6 {0.299)7.6 {0.299)16.0 (0.630)

10.2 to.402l17.0 (0.669)

29.0 \1.1421'r7.510.689)

9.0 (0.354)

31.0 (1.220)17.0 (0.669)

14.510.571)7.610.299i8.1 {0.319}6.6 (0.260)

6.6 (0.260i

8.1 (0.319)

8.1 {0.319)6. t (0.240)

87.8 (3.457)

44.011.132130.31r.193)35.0 {1.378)

36.4 {1.433)32.4 tl.216J33.8 {r.331)37.1 (1.461)

34.8 (1.370)

41.3 (1.626)

57 .0 (2.2441

57 .0 12.244189.1 (3.508)

51.6 (2.031)

88.4 (3.480)

39.011.s35)94.313.713)20.7 10.8r5)38.2 (1.504)

39.0 (1.535)

68.0 (2.677)

73.7 12.902)8r.4 (3.205)

38.0 fl.496)37.9 (1.492)

52.1 (2.051)

41 .2 t .A5Al36.4 (1.4331

r 1.01.910.9

12.O12.78.213.422.0

26.426.8

13.814.22.915.9

2.66.3

32.047.A

20.8'18.3'19.5

Capacity f (US qt, lmp ql)1.2 (1.3, 1.1) at overhaul1.0 (1.1, 0.91 at fluid change

MEASUREMENTSTANDARD INEWI

Steering wheelRotational play at steering wheel circumferenceStaning load at steering wheelcircumferenceN {kgf, lbl) Engine running

0- 10 (0 - 0.39)

29 (3.0,6.6)

GearboxAngle of rack$uide-screw loosened lrom locked position'97, '98 models'99, '00 models10" 1 5"20" MAX.

PumpPump pressure with shut off valve closedkPa (kgvcm,, psi)6,900 - 7,800 (70 80,995 1,138)

Power steeringfluidRecommended tluidFluid capacity For overhaulI {US qt, lmp q0 For reservoir

Honda power steering fluid.0.85 (0.90,0.75)

0.4 {0.42,0.35)

Power steeringbelt*Deflection with 98 N {1O kgl,22lht)between pulleys11.0 14.5 (0.43 0.57)with used belt7.5 - 10.0 (0.30 0.40) with new belt

Belt tension N {kgt, lbf}Measured with belt tension gauge390 - 540 (40 - 55, 88 - 121) with used belt740-880 (75 90, 165 198)with new belt

2-10

www.emanualpro.com

Page 41 of 1395

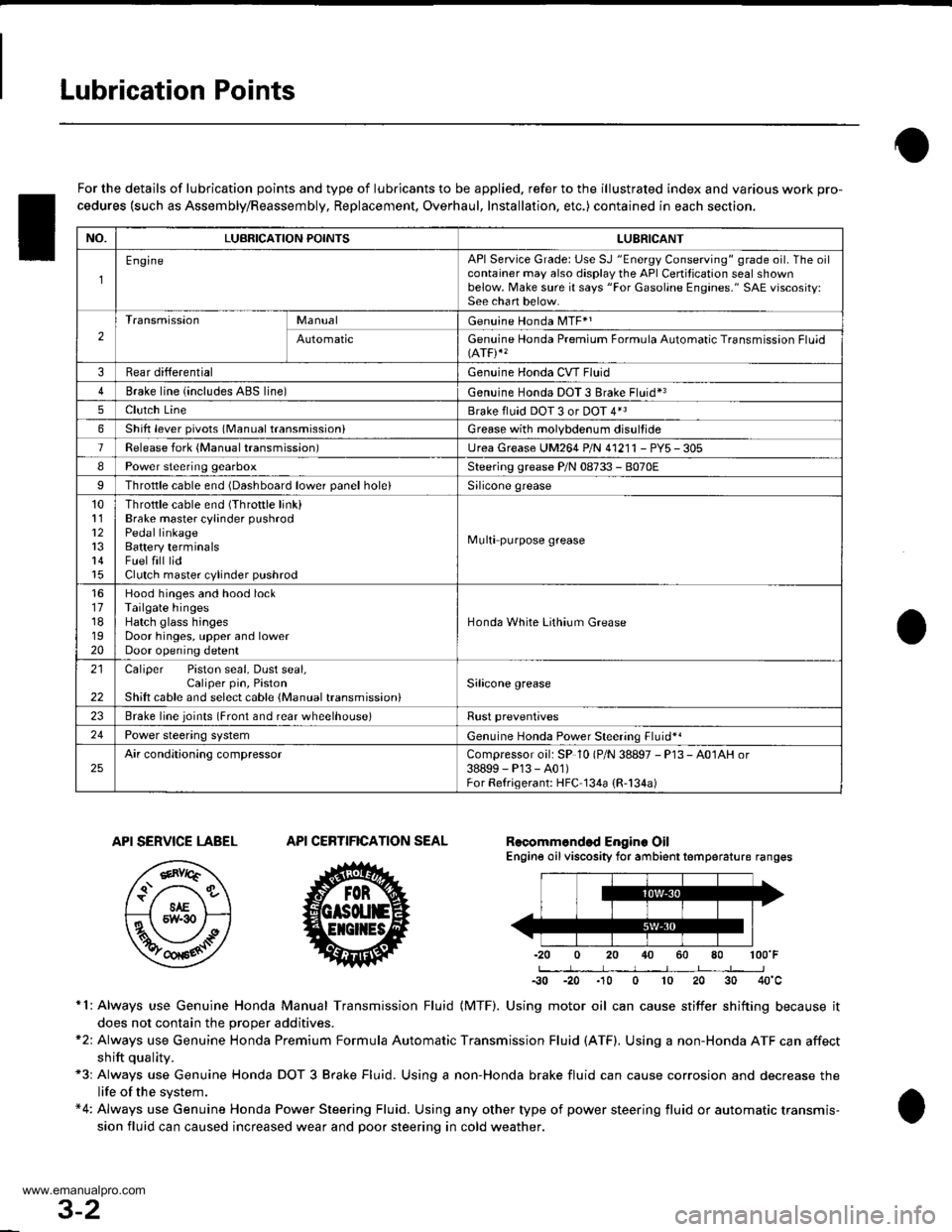

Lubrication Points

For the details of lubrication points and type of lubricants to be applied. refer to the illustrated index and various work pro-

cedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

Recomm6nded Engine OilEngine oil viscosity for ambient temperature ranges

100'F

-30 -20 .10 0 10 20 30 40'c

r1: Always use Genuine Honda Manual Transmission Fluid {MTF). Using motor oil can cause stiffer shifting because it

does not contain the orooer additives.*2: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift qualitv.+3r Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.*4: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-

sion fluid can caused increased wear and poor steering in cold weather.

API SERVICE LABEL

/,.*-G\

/.'z-\e\t/6AE\ll-;-1 5w-30 /---l

w

API CERTIFICATION SEAL

ffi-20 0 20

NO.LUBRICATION POINTSLUBRICANT

EngineAPI Service Grade: Use SJ "Energy Conserving" grade oil. The oilcontainer may also display the API Certitication seal shownbelow. Make sure it says "For Gasoline Engines." SAE vjscosity:See chart below.

2

TransmissionManualGenuine Honda MTF*1

AutomaticGenuine Honda Premium Formula Automatic Transmission Fluid(ATF)*'

3Rear differentialGenuine Honda CVT Fluid

4Brake line (includes ABS line)Genuine Honda DOT 3 Brake Fluid*3

5Clutch LineBrake fluid DOT 3 or DOT 4*3

6Shift lever pivots (Manual transmission)Grease with molybdenum disultide

1Release fork (Manual transmission)LJrea Grease UM264 P/N 4'1211 - PYs - 305

IPower steering gearboxSteering grease P/N 08733 - B070E

Throttle cable end {Dashboard lower panel holelSilicone grease

10l112

14

Throttle cable end (Throttle link)Brake master cylinder pushrodPedal linkageBattery terminalsFuelfill lidClutch master cylinder pushrod

Multi purpose grease

1617181920

Hood hinges and hood lockTailgate hingesHatch glass hingesDoor hinges, upper and lowerDoor opening detent

Honda White Lithium Grease

21

22

Caliper Piston seal, Dust seal,Caliper pin, PistonShilt cable and select cable {Manual transmission)Silicone grease

23Brake line ioints (Front and rear wheelhouse)Rust preventives

24Power steering systemGenuine Honda Power Steering Fluid-.

25Air conditioning compressorCompressor oil: SP 10 lP/N 38897 - P13 - A0lAH or38899-P13-A01)For Refrigerant: HFC 134a (R,134a)

3-2

www.emanualpro.com

Page 517 of 1395

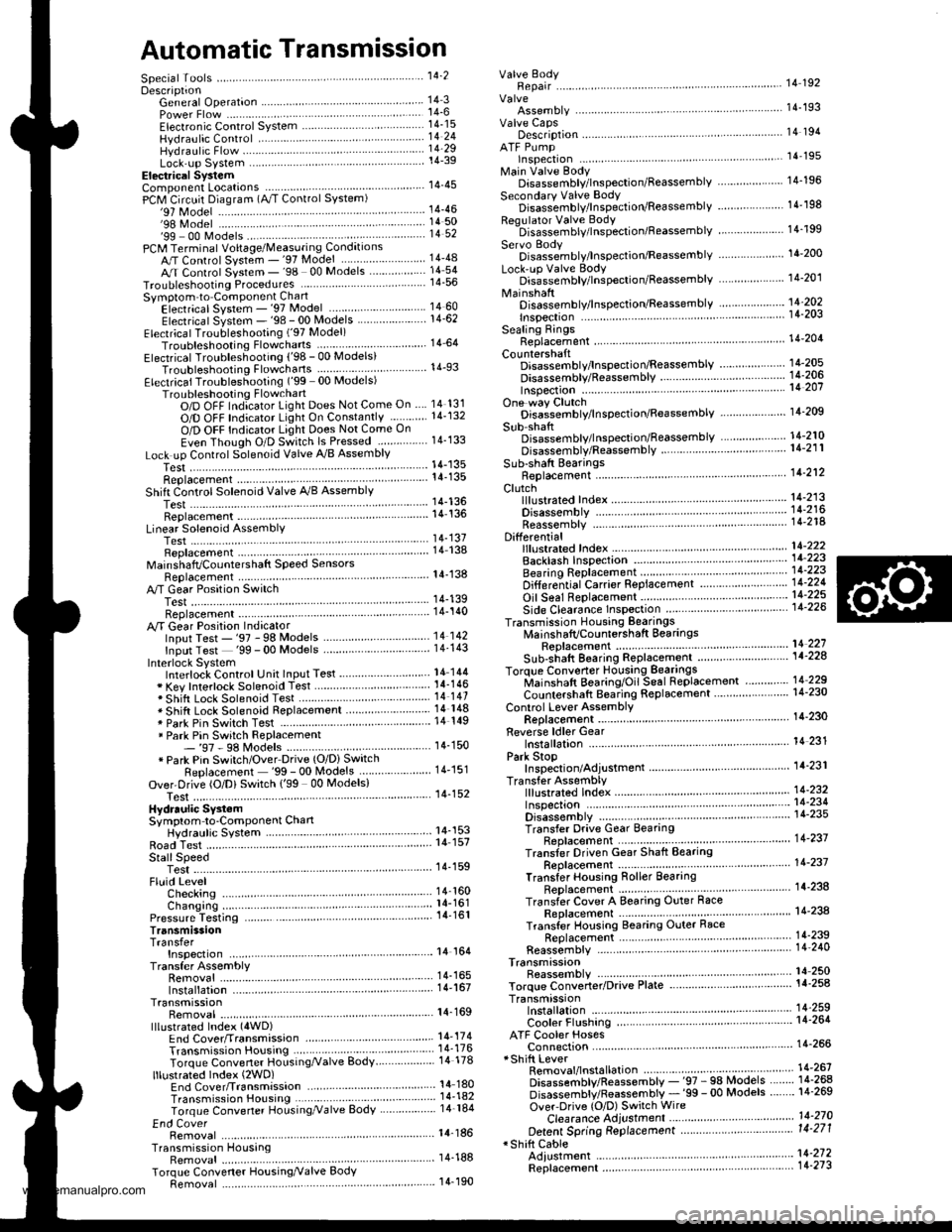

Automatic Transmission

Special Tools . 14'2OescriptionGeneral Operation . .... 14 3Power Flow . . .. '14_6

Electronic Control System .. .. . . .. .14_15Hydraulic Control .. 14 24Hydraulic Flow....-....... .. . .... .. .. . 14_29Lock'up Syslem .. .'t4'39Electrical SystemComponenl Locdlrons 14 45

PCM Circuil Dragram (A/T Control Svstem)'97 Model ....................... . . .. - . ... .14-46'98Model ................. . ... .. .. .1450'99 00Models.... . .... . . . 1452

PCM Terminal Voltage/Measuring ConditionsA"/T Control System-'97Model ...... ..14'48A,/T Control System -'98 00 Models . . .. . . 14 54

Troubleshooting Procedures .. ..... ... - 14_56Svmotom to comoonent CharlEiectr,cal Syslem -'97 Model . . 14 60Electrical System -'98 - OO Models . .. . . 14_62Electrical Troubleshooting ('97 Model)Troubleshooting Flowaharts .... ..... . .. . . 14_64

Electrical Troubleshooting ('98 - 00 Models)Troubleshootinq Flowclt"n" .... . ....- . .14-93ElectricalTroublesliooting('99 00Models)Troubleshootino FlowchartO/D OFF Indicator Light Does Not Come On 14 131

O/D OFF Indicator Liaht On ConstantlY . . . .1!-132O/D OFF Indicator Light Does Not Come OnEven Though O/D Switch ls Pressed . .... - 14_133

Lock up Control Solenoid Valve A,/B AssemblyTest....................-......... . .14-135Replacement . .ll_135Shifr ControlSolenoid Valve Ay'B Assembl,Test .............................. . .. 14-136

Replacement..............- . .14'136Linear Solenoid AssemblYTest.............................................. .. .... . 14_137Replacement .. . 14138Marnshaftlcountershafl Speed SensorsReplacement ...-... 14_138A/T Gear Position SwitchTest ..........................-... . .. 14-139ReplacementA/T Gear Positionlndicator.................. 14-140

Valve Eodynepair ............................... ..... . . .. - . .. ... 14 192

Assembly .................... .. 1{_193

Valve CapsDesciiption....-........................ .. ...... 14194

tnspeition ................... .. 14' 195

N4ain Valve BodyDisassembly/lnspection/Reassemblv - ...... .. 14_196

Secondarv Valve BodYDisassemblv4nspectron/ReassemblY .. . 14 198

Reoulator Valve Bodvbisassembtv,lnspiction/Reassemblv . 14199

Servo EodvDisassembly/lnspection/Reassembly ... ....14'200

Lock'uo Valve BodYDis;ssembly/lnspection/Reassembly .... . 14_201

MainshaftDisassembly/lnspection/Reassembly .. .. .. ..14'202

Inspection ....-.............. ..11_203

Sealing RingsReilaceient ...... ..... . 14'204

CountershaftDisassembly/lnspection/Reassembly .. . . . . . 11-205

Disassembly/Reassemb|y . . ........ ...... . .. 14_206Inspedron ................ . .... . 14 207

One wav ClutchDisassembly/lnspection/ReassemblY ... 11_209

Sub-shaftDisassembly/lnspection/Reassembly ... . .. . 14-210

oisassembly/Re6ssembly . . ... .-...... . . ..14-211

Sub-shaft BearingsReplacement .......14'212

Clutchllfustrated Index .......... . . .14-213

Disassembly .... .. .....14-216Reassembfy .... . .. .. . 14'218

Differentialllfustrated Index " 14-222Backlash Inspection . .... . .14'223

Bearing Repiacement .. 11-223

Differe-ntial Carrier Replacement .. .. . . . .. ..11-2?4

OifSeal Replacement. . .. 14'225

Side Clearance lnspection . . - .. ... . - ...... . .. 11'226

Transmission Housing BearingsMainshaJVCountershaft EearingsRepfacement .......14221Sub'siralt Eearing Replacement . . . . . . . . . ..11'224

Toroue Converter Housing BearingsMainshattEearing/OilSe6lReplacement . .. l4229

Countershaft Bea;ing Replacement.. .... .. ..14-230

Input Test - '97 - 98 ModelsInput Test '99 - 00 Models

Symptom to-Component ChartHydraulic System ...............

Checking

Removal ...,lllustrated Index (4WD)

Interlock SystemInterlock ControlUnit lnputTest. -..... -.. .... . - 14 144* Key Interlock Solenoid Test .- .. . . . - . . . ..... 14_146* Shift Lock Solenoid Test ..............-.-. . .. . ... .... 14 147*Shift LockSolenoidReplacement...... .. . .. .. 14 148* park pin Switch Test ......... 14 119' Park Pin Switch Replacement- '97 - 98 Models ....... 14-150* Park Pin Swirch/Over Drive (O/Di SwitchReplacemenl '99-00Models . .. 14_151over-Drive (O/D) Switch {'99 00 [4odels]Test........_..................... .......14-152Hydr.ulic System

..............._............... t4 142.................................. 14-143

Control Lever AssemblyR6placement ......,.,Reverse ldler Gear

lllustrated lndex

.......... 14-230

14 231

11-231

1nsta1|ation ..................Park StopInspeclion/AdjustmenlTransfer AssemblY.......14.232

RoadTest.............-.... ........ .StallSpeedTest ....._........................ ....... 14-159Fluid Level......_................... 14'160

Disessembly .................... 14-235Transfer Drive Gear BearingReplacementTrans{er Driven Gesf Shaft BearingReplacementTransfer Housing Roller BearingReplacementTransfer Cov€r A Bearing Outer RaceReplacementTransfer Housing Bearing Outer RaceReplacement ......-..,,,,,.....ReassemblvTransmassaonBeassembly ... -.. .... .14 250

Torque Converier/Drive Plate . .-. .... .. . ... .....14_258

Transmissionlnstatlation .................. ....... 14'259

Cooler Flushing . . ......11-261ATF Cooler HosesConnection.................. ....... 14-266I Shift LeverRemoval/lnstallation . .. 14'261

Disassemblv/Reassemblv - '97 - 98 Models . . 14_264

Disassembli/Reassemblv -'99 - 00 Models . 14-269

Over'Orive (O/D) Switch WireClearanceAdjustment. - ... . . . .. .. . 14'270

Detent Spring Replscement . . -.. ... .14'271*Shift CableAdiustment ....... 14'272

Repfacement.............. . 11'273

14 15711-237

11-237

14-238

$-234

11-23914-240

Transmigrion

Inspeclron ....., ...........Transfer AssemblyRemova1,.,,,..............,lnstallalion ........... .. ...Transmission

14 164

14-16514,167

14-169

End Cover/Transmissio . 14'174Transmission Housing .... ... .. . . .... .. 14-176Torque Converter Housingly'alve Body.. - ... -. 14 178

lllustrated lndex (2WD)End Cover/Transmissio ....... 14 180Transmission Housing . . ... . .. .... ... 14'182Torque Convener Housing/r'alve Body ......- 14-184

End CovefRemovat ...................... ....... 14'186Transmission HousingRemoval ...................... .. 14_188Torque Convener HousingA/alve BodYRemovat ................-..... .-..... 14-190

www.emanualpro.com

Page 519 of 1395

Description

General Operation

The Automatic transmission is a 3-element torque converter and triple-shaft electronically controlled unit which provides 4

speeds forward and 1 reverse speed The unit is positioned in line with the engine'

There are two tvoes of automatic transmission on CR-V; the four-wheel drive (4WD) model ('97 - 00)' and the front-wheel

drive (2WD) model ('98 - 00).

Toroue Converter, G€ars, and Clutches

The torque converter consists of a pump. turbine. and stator assembly in a single unit. The torque converter is connected to

the engine crankshatt. These parts turn together as a unit as the engine turns. Around the outside of the torque converter is

a ring gear which meshes with the starter pinion when the engine is started. The torque converter assembly serves as a fly-

wheel while transmitting power to the transmission mainshaft.

The transmission has three parallel shafts: the mainshaft. the countershaft, and the sub-shaft. The mainshaft is in line with

the engine crankshaft. The mainshaft includes the 1st, 2nd. and 4th clutches, and gears lor 3rd,2nd,4th. reverse and 1st

(3rd gear is integral with the mainshaft, while reverse gear is integral with the 4th gear). The countershaft includes the 3rd

clutch and gears for 3rd,2nd, 4th, reverse, 1st, and park. Reverse and 4th gears can be locked to the countershaft at its cen-

ter, providing 4th gear or reverse, depending on which way the selector is moved. The sub-shaft includes the lst-hold

clutch and gears for lst and 4th.

The gears on the mainshaft are in constant mesh with those on the countershaft and sub-shaft. When certain combinations

of gears are engaged by the ctutches, power is transmitted from the mainshaft to the countershaft to provide E, D!, tr, tr,

and E position ('97 - 98 models). and E. E, E, and E position ('99 - 00 models)'

Electlonic Control

The electronic controt system consists of the Powenrain Control Module (PCM), sensors, a linear solenoid, and four

solenoid valves. Shifting and lock-up are electronically controlled for comfortable driving under all conditions. The PCM is

located below the dashboard, under the kick panel on the passenger's side.

Hydraulic Control

The valve bodies include the main valve body, the secondary valve body, the regulator valve body, the servo body, and

the lock up valve body. They are bolted to the torque converter housing. The main valve body contains the manual valve,

the 1-2 shift valve, the 2nd orifice control valve. the CPB {Clutch Pressure Back-up) valve, the modulator valve, the servo

control valve. the relief valve, and ATF pump gears. The secondary valve body contains the 2-3 shift valve, the 3-4 shift

valve, the 3,4 orifice control valve. the 4th exhaust valve and the CPC (Clutch Pressure Control) valve. The regulator valve

bodv contains the pressure regulator valve, the torque converter check valve, the cooler relief valve, and the lock-up con-

trol valve. The servo body contains the servo valve which is integrated with the reverse shift tork, and the accumulators

The lock-up valve body contains the lock-up shift valve and the lock-up timing valve. The linear solenoid and the shift con-

trol solenoid valve Ay'B are bolted to the outside of the transmission housing, and the lock-up control solenoid valve Ay'B is

bolted to the outside of the torque converter housing. Fluid trom the regulator passes through the manual valve to the

various control valves. The clutches receive fluid from their respective feed pipes or internal hydraulic circuit

ShiftControl Mechanism

input from various sensors located throughout the vehicle determines which shift control solenoid valve the PCM will acti-

vate. Activating a shift control solenoid valve changes modulator pressure, causing a shift valve to move. This pressurizes

a line to one of the clutches. engaging that clutch and its corresponding gear. The shift control solenoid valves A and B are

controlled by the PCM.

Lock-up Mechanism

tn E! position (,97 - 98 modets) and in E position ('99 - O0 models), in 3rd and 4th, and in Del position in 3rd ('97 - 98

models) and in El position with Over,Drive (O/D) is OFF (by pressing rhe O/D switchl in 3rd ('99 - 00 models), pressurized

fluid is drained from the back of the torque converter through a fluid passage, causing the lock-up piston to be held

against the torque converter cover, As this takes place, the mainshaft rotates at the same speed as the engine crankshaft.

Together with hydraulic control, the PcM optimizes the timing of the lock-up mechanism The lock-up valves control the

range of lock-up according to lock-up control solenoid valves A and B, and the linear solenoid. When lock-up control

solenoid valves A and B activate, the modulator pressure changes. The lock-up control solenoid valves A and B and the

linear solenoid are controlled by the PCM.

{cont'd)

14-3

www.emanualpro.com

Page 546 of 1395

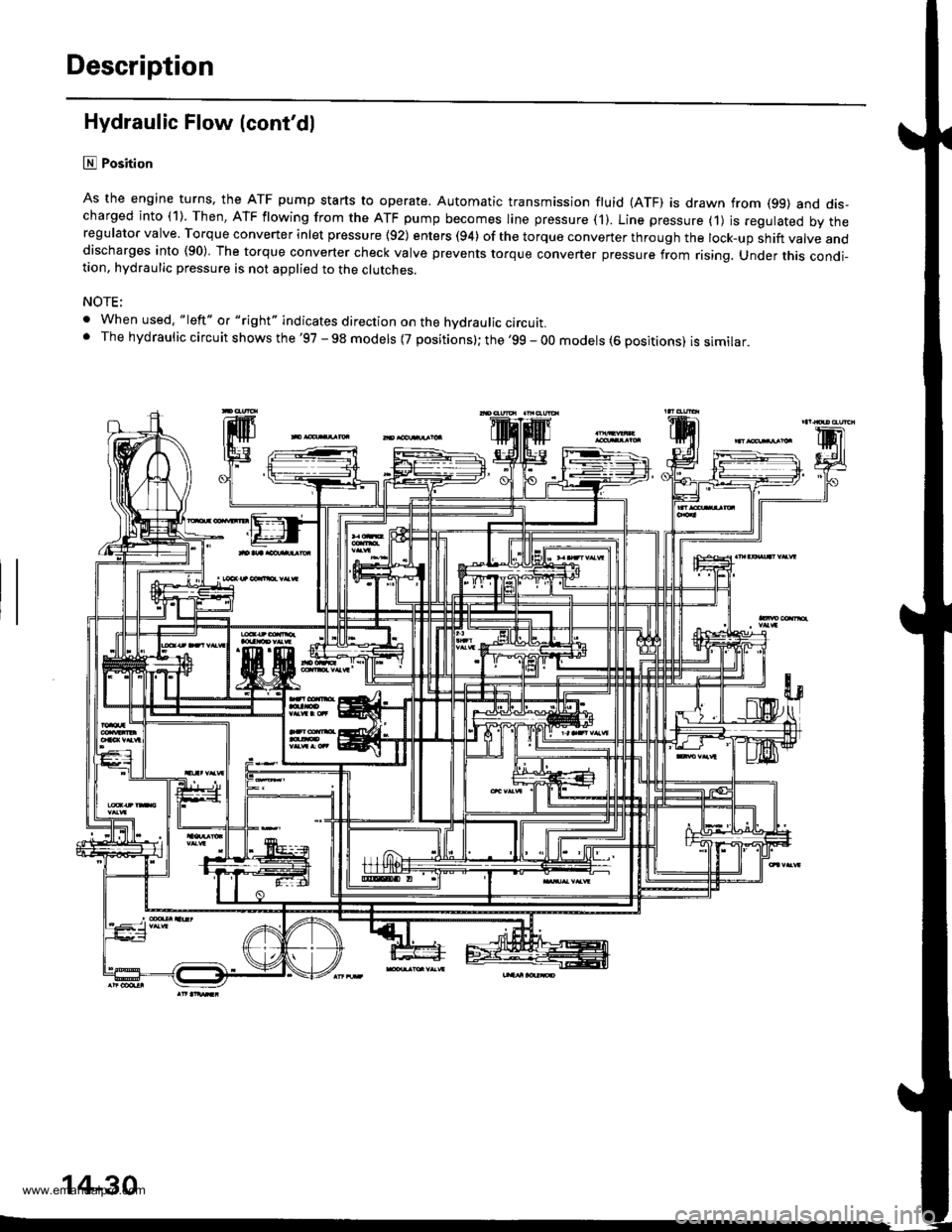

Description

Hydraulic Flow (cont'dl

lll Position

As the engine turns, the ATF pump starts to operate. Automatic transmission fluid (ATF) is drawn from (99) and dis-charged into (1). Then, ATF flowing from the ATF pump becomes line pressure ('l). Line pressure (1) js regulated by theregulator valve. Torque converter inlet pressure {92) enters (94) of the torque conveTter through the lock-up shift valve anddischarges into (90) The torque converter check valve prevents torque converter pressure from rising. Under this condi-tion, hydraulic pressure is not applied to the clutches.

NOTE;

. When used. "|eft" o. "right" indicates direction on the hvdraulic circutt.. The hydraulic circuit shows the '97 - 98 models {7 positions}; the '99 - 00 models (6 positions) is similar.

'lF'.j.l

14-30

www.emanualpro.com

Page 676 of 1395

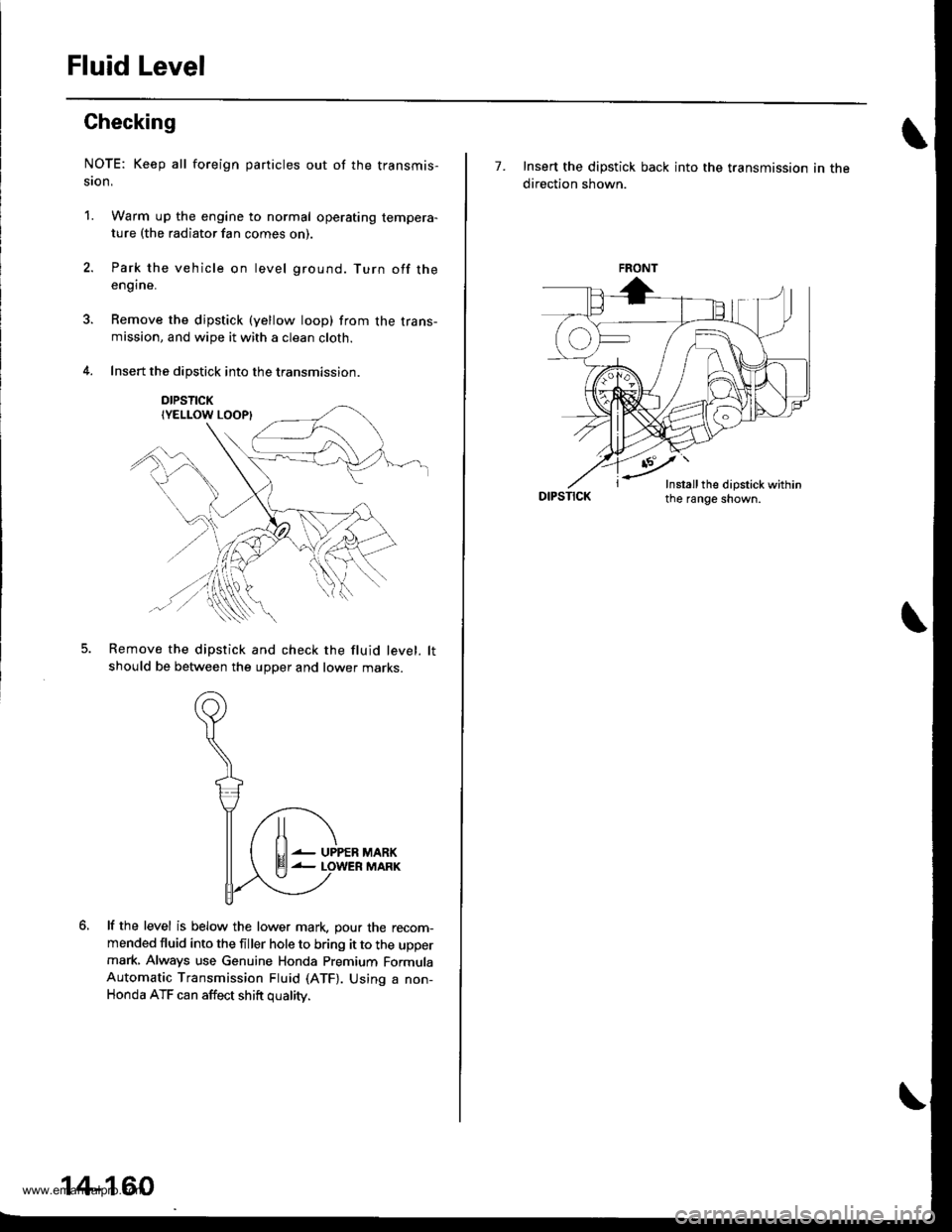

Fluid Level

Checking

NOTE: Keep all foreign particles out of the transmis-

ston,

1. Warm up the engine to normal operating tempera-ture (the radiator fan comes on)

Park the vehicle on level ground. Turn off theengine.

Remove the dipstick (yellow loop) from the trans-mission, and wipe it with a clean cloth.

Insert the dipstick into the transmission.

DIPSTICK

Remove the dipstick and check the fluid level. lt

should be between the upper and lower marKs.

lf the level is below the lower mark. pour the recom-mended fluid into the filler hole to bring it to the uppermark, Always use Genuine Honda Premium FormulaAutomatic Transmission Fluid (ATF). Using a non-Honda ATF can affect shift oualitv.

lt

El--

UPPERMARKMARK

14-160

7. Insert the dipstick back into the transmission in the

direction shown.

DIPSTICK

FRONT

-'-Y'

Insrall the dipstick within

www.emanualpro.com

Page 677 of 1395

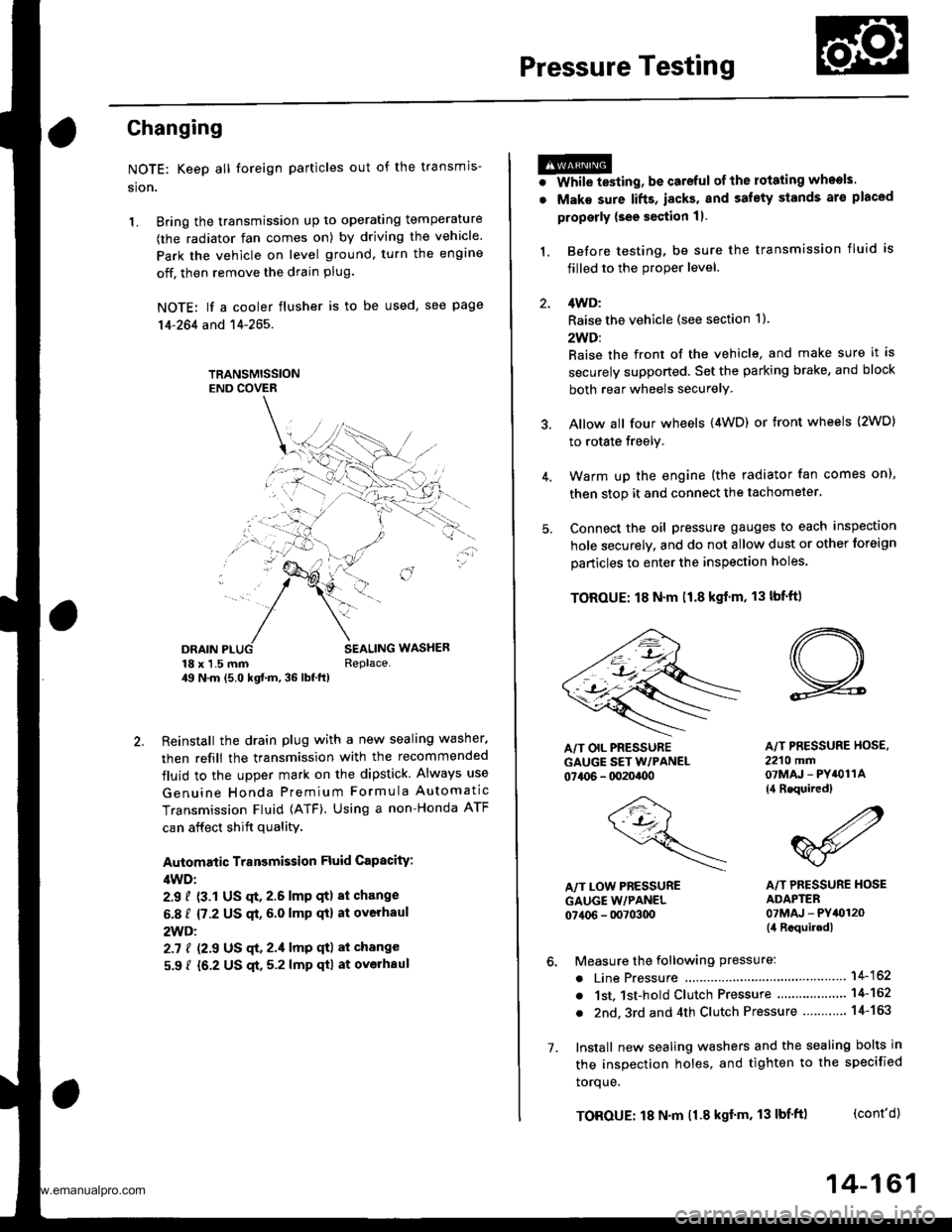

Pressure Testing

Changing

NOTE: Keep all foreign particles out of the transmis-

sion.

1. Bring the transmission up to operating temperature

(the radiator fan comes on) by driving the vehicle.

Park the vehicle on level ground. turn the engane

off. then remove the drain Plug.

NOTE: lf a cooler flusher is to be used, see page

14-264 and 14-265.

TRANSMISSIONEND COVER

DRAIN18 x 1.5 mmSEALING WASHEBReplace.49 N.m {5.0 kgt.m, 36 lbf.tl)

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid to the uDper mark on the dipstick. Always use

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF) Using a non-Honda ATF

can affect shift quality.

Automatic Transmission Fluid Capacity:

4WD;

2.9 { (3.1 US qt. 2.6 lmp qt) 8t change

5.8 ? {7.2 US $, 6.0 lmp qt} at ovethaul

2WD:

2.7 | l2.S US qt,2.1lmp qtl ai change

5.9 ? {6.2 US $, 5.2 lmp qtl at ovolhaul

2.

a

a

1.

Wlrile testing, be careful of the rotaling wheols.

Mako sure lifts, iacks, and safety stands ar€ placed

properly (see scction 11.

Before testing, be sure the transmission fluid is

filled to the proPer level.

4WD:

Raise the vehicle (see section 11.

2WD:

Raise the front of the vehicle, and make sure it is

securely supported. Set the parking brake, and block

both rear wheels securely.

Allow all four wheels {4WD) or front wheels (2wD}

to rotate freely.

Warm up the engine (the radiator fan comes on),

then stop it and connect the tachometer.

Connect the oil pressure gauges to each inspection

hole securely, and do not allow dust or other foreign

particles to enter the inspection holes.

TOROUE: 18 N'm ll.8 kgf'm, 13 lbf'ft)

5.

A/T PRESSURE HOS€,2210 mm07MAJ - PYiOllA

{4 Requircd}

,4'/"' ,a

W'

A/T PRESSURE HOSEADAPTER07MAJ - PYt0120(il Rcquiledl

6. Measure the following Pressure:. Line Pressure ..........,14-162

. 1st. 1st-hold Clutch Pressure .............'. 14-162

. 2nd,3rd and 4th Clutch Pressure .......... 14-163

7. Install new sealing washers and the sealing bolts in

the inspection holes, and tighten to the specified

toroue.

(cont'd)

A/T OIL PRESSUREGAUGE SET W/PANEL07{06 - 0020400

/4\\-J-- (

+..\.-.\-'-\

A/T LOW PBESSUREGAUGE w/PANEL07406 - 0070300

TOROUE: 18 N'm 11.8 kgf'm, 13 lbf'ft)

14-161

www.emanualpro.com

Page 681 of 1395

Transfer Assembly

Removal

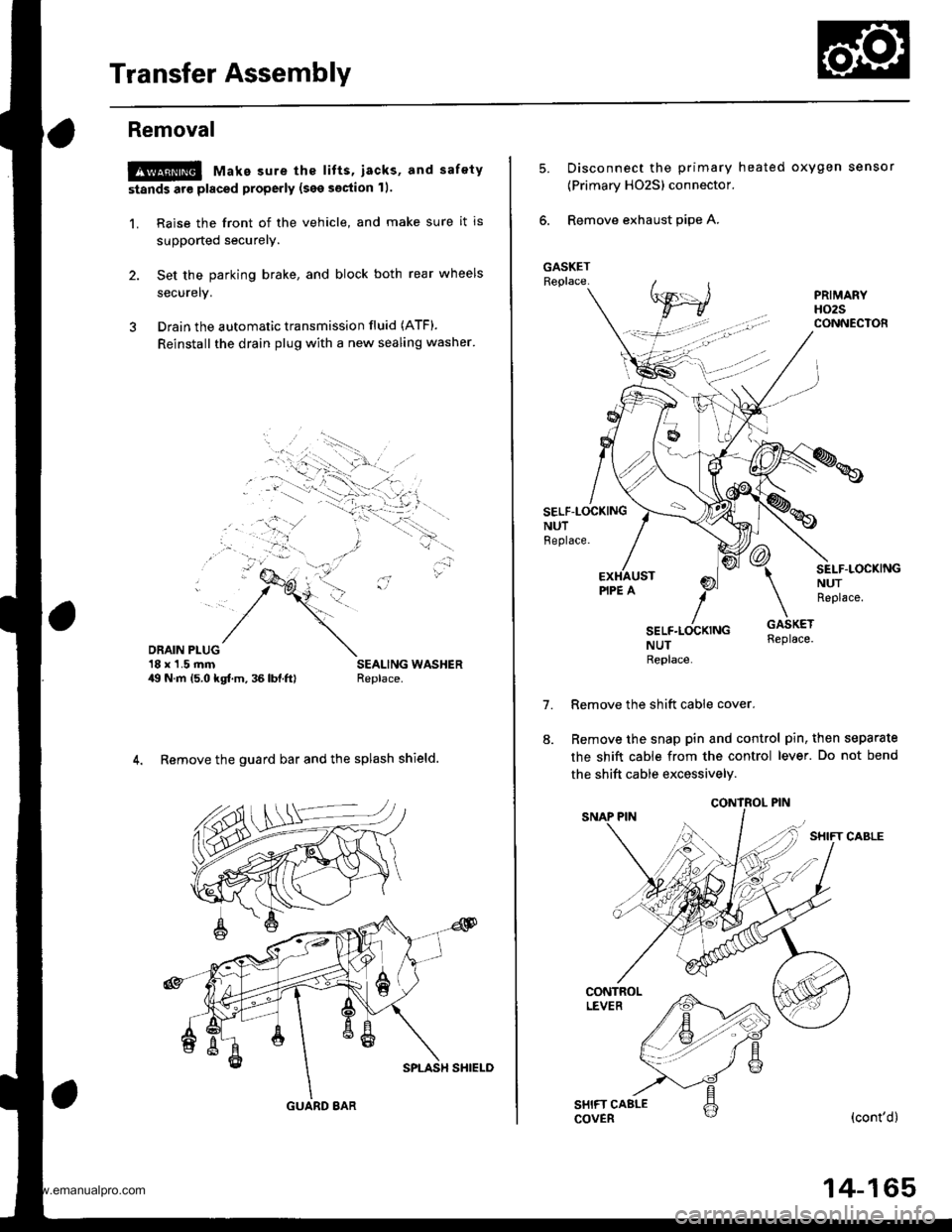

@ Make sure the lifts, iacks, and safety

stands are placed properly (see section 11.

1. Raise the front of the vehicle, and make sure it is

supported securely.

2. Set the parking brake, and block both rear wheels

securelv.

3 Drain the automatic transmission fluid (ATF).

Reinstall the drain plug with a new sealing washer'

DRAIN PLUG'18 x'1.5 rnm49 N.m 15.0 kgf.m, 36 lbl.ftl

4. Remove the guard bar and the splash shield.

GUARD 8AR

14-165

5.Disconnect the primary heated oxygen sensor

{Primary HO2S) connector.

Remove exhaust pipe A.

SELF-LOCKINGNUTBeplace.

7.

SEI-F.LOCKINGNUTReplace.

NUTReplace

Remove the shift cable cover.

Remove the snap pin and control pin, then separate

the shift cable from the control lever. Do not bend

the shift cable excessively.

(cont'd)

www.emanualpro.com

Page 686 of 1395

Transmission

Removal (cont'd)

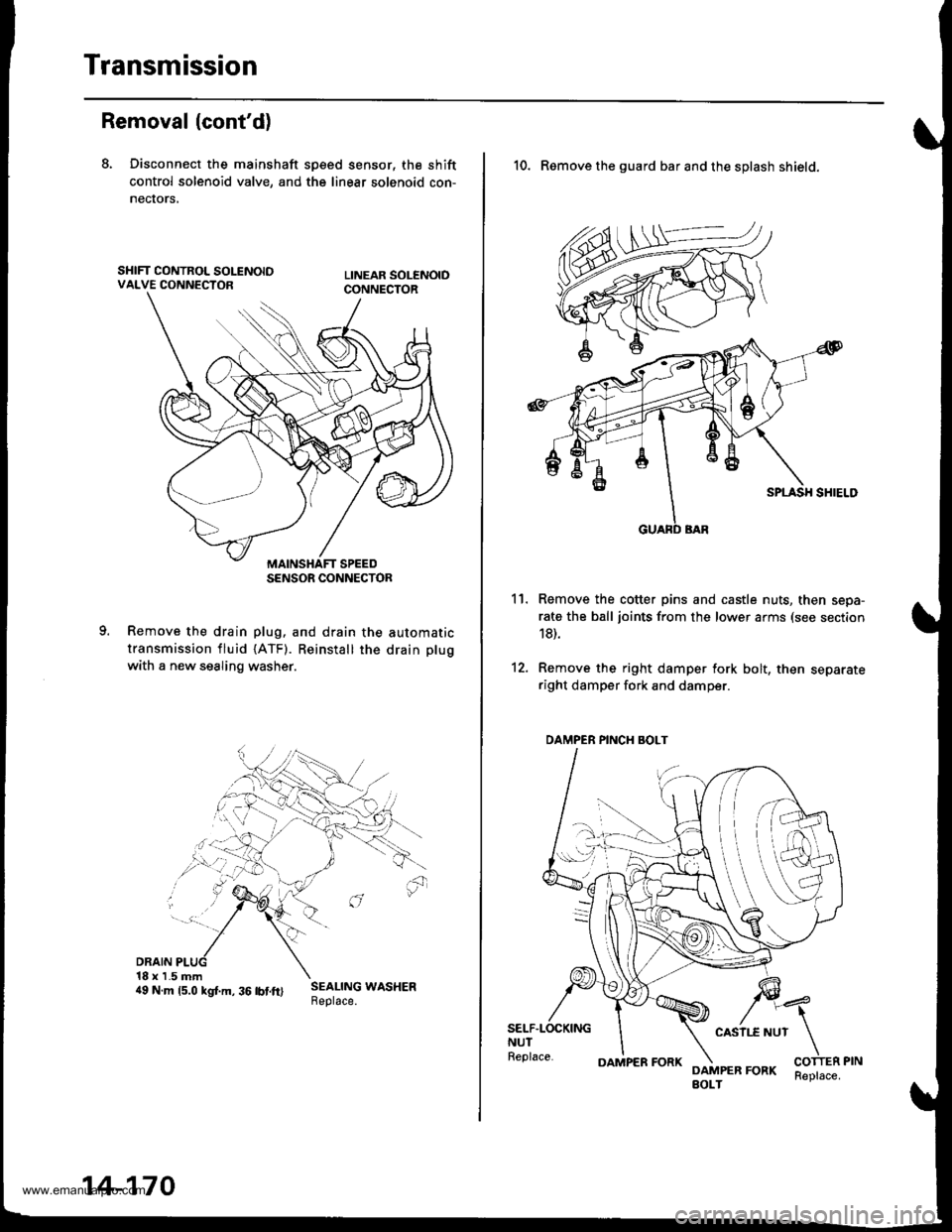

8. Disconnect the mainshaft sp€ed sensor, the shift

control solenoid valve, and the linear solenoid con-

necrors,

Remove the drain plug. and drain the automatic

transmission fluid {ATF). Reinstall the drain plug

with a new sealing washer.

DRAIN18 x 1.5 mm4e N.m rs.o ksr.m. 36 rbrft) ;:i:$: *o"*."

SENSOR CONNECTOR

14-170

OAMPER FORKReplace.

10. Remove the guard bar and the splash shield.

Remove the cotter pins and castle nuts, then sepa-

rate the ball joints from the lower arms (see section

18).

Remove the right damper fork bolt, then separateright damper fork and damper.

11.

12.

SELF.LOCKINGNUTReplace.

CASII.E NUT

DAMPER FORKBOLT

DAMPER PINCH BOLT

www.emanualpro.com