back seat HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 15 of 1395

G: FRONT SEAT PASSENGER AIRBAG MODULE DANGEN

A DANGEREXPLOSIVE/FLAMMABLECONTACT WITH ACID, WATER. OR I{EAVY METALS SUCH

AS COPPER. T.EAD. OR MERCURY MAY PRODUCE HARMFUL

AND IRRITATING GASES OR EXPLOSIVE COMPOUNDS.

STORAGE TEMPERATURES MUST NOT EXCEED 2OO"F

IlOO'C). FOR PROPER HANDLING, STORAGE, AND

DISPOSAL PROCEDURES REFER TO THE SERVICE MANUAL,

SRS SUPPLEMENT.POTSONCONTAINS POTSONOUS SODIUM AZIDE ANO POTASSIUM

NITRATE.FIRST AIDIF CONTENTS ARE SWALLOWED, INDUCE VOMITING. FOR

EYE CONTACT, FLUSH EYES WITH WATER FOR 15

MINUTES. IF GASES (FROM ACID OR WATEN CONTACT)

ARE INHALEO. SEEK FRESH AIR. IN EVERY CASE, GET

PROMPT MEDICAL ATTENTION.KEEP OUT OF REACH OF CHILDREN.

A WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND, IF

ACCIDENTALLY DEPLOYED, CAN SERIOUSLY HURT OR

KILL YOU.. DO NOT USE ELECTRICAL TEST EOUIPMENT OR

PROBING DEVICES,THEY CAN CAUSE ACCIDENTAL DEPLOYMENT.. NO SERVICEABI-E PARTS lNSlDE. DO NOT DISASSEMBII.

. PLACE AIRBAG UPRIGHT WHEN REMOVEO.

. FOLLOW SERVIC€ MANUAL INSTRUCTIONS CAREFULLY

H: PASSENGER INFORMATION lU S.A. modell

{U.S.A.'97 model}

AIEBAG SEE OTHER SIDE,

{U.S.A.'98 - 00 modelsl

AIRBAG WARNINGFLIP VISOR OVER.

l: SRS INFORMATION

lU.s.A.'97 model ilcanada '97 - 00 mod€ls I

CAUTIONTO AVOID SERIOUS INJURY:. FOR MAXIMUM SAFEW PROTECTION lN ALL TYPES OF

CRASHES, YOU MUST ALWAYS WEAR YOUR SAFETY

8ELT.o OO NOT INSTALL REARWARD-FACING CHILO SEATS lN

ANY FRONT PASSENGER SEAT POSITION.. DO NOT SIT OR LEAN UNNECESSARILY CLOSE TO THE

AIRBAG.. DO NOT PLACE ANY OBJECTS OVER THE AIRBAG OR

BETWEEN THE AIRBAG AND YOURSELF.. SEE THE OWNER'S MANUAL FOR FURTHER

INFORMATION AND EXPLANATIONS. THE SRS MUST BE INSPECTED TEN YEARS AFTER lT lS

INSTALLED.. THE DATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

lU.S.A.'98 - 00 models)

WARNINGDEATH OR SERIOUS INJURY CAN OCCUR'

. CHILDREN 12 ANO UNDER CAN BE KILLED BY THE

AIRBAG.. THE BACK SEAT lS THE SAFEST PLACE FOR CHILDREN.

. NEVER PUT A REAR-FACING CHILD SEAT lN THE

FRONT.o SIT AS FAR BACK AS POSSIBLE FROM THE AIRBAG

. ALWAYS USE SEAT BELTS AND CHll-D RESTRAINTS.

. THE SRS MUST BE TNSPECTED TEN YEAnS AFTER lT lS

INSTALLED.. THE OATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

J: FRONT PASSENGER AIRBAG WARNING

lU.S.A.'98 - 00 models)

WARNINGCHILDREN CAN BE KILLED OR INJURED 8Y THE

PASSENGER AIRBAG.THE BACK SEAT IS THE SAFEST PLACE FOR CI{ILDREN 12

AND UNDER.MAKE SURE ALL CHILDREN USE SEAT BELTS OR CHILD

SEATS.

K: FRONT SEATBELT TENSIONER WARNING

WABNINGEXPLOSIVE MATERIAL INSIDEYOU CAN BE SERIOUSLY HURT OR BURNED,

. DO NOT TAMPER OR DISASSEMBLENO SERVICEABLE PARTS INSIDE.. REFER TO SERVICE MANUAL FOR COMPLETE

INSTRUCTIONS.

(cont'd)

1-13

www.emanualpro.com

Page 62 of 1395

Starting System

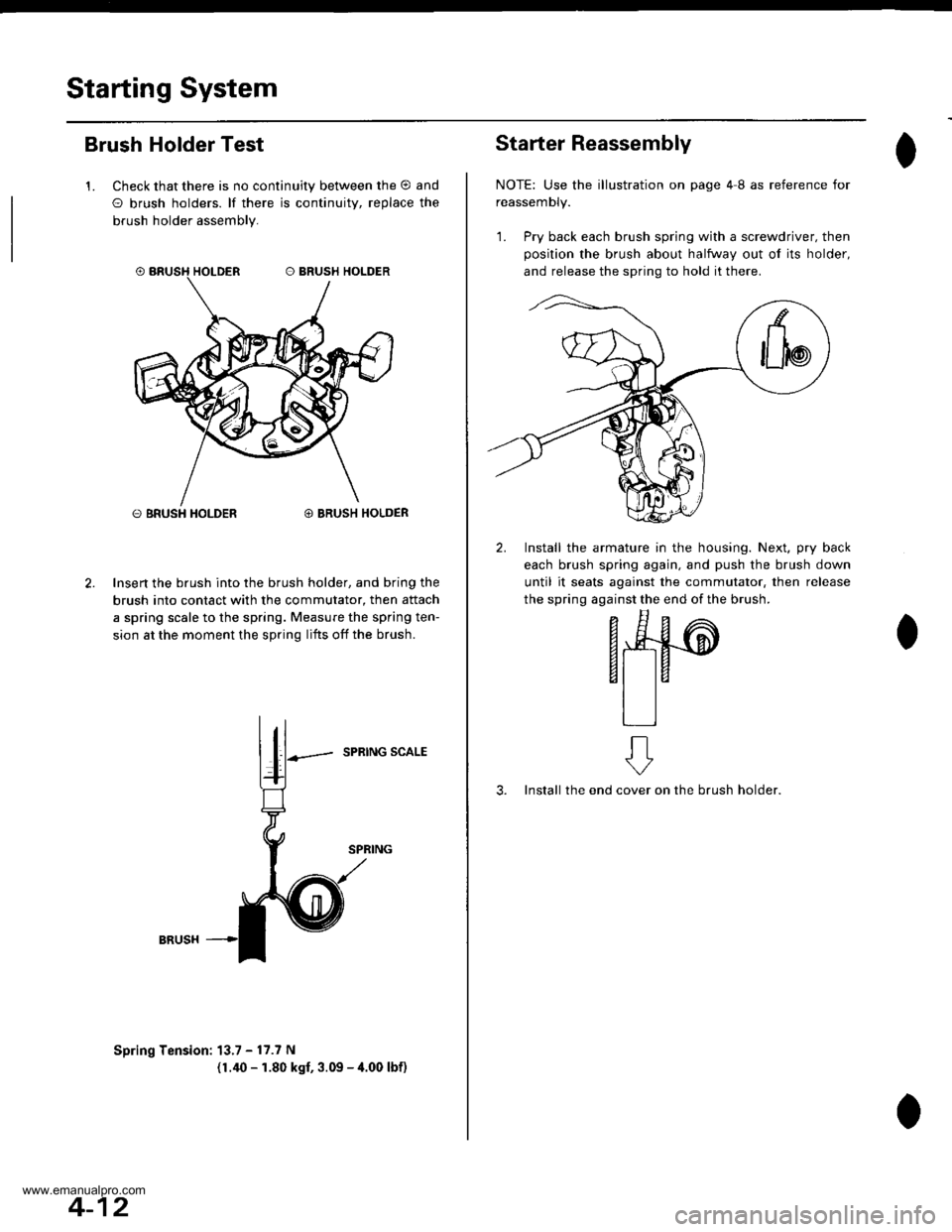

Brush Holder Test

1. Check that there is no continuity between the O and

O brush holders. lf there is continuitv, replace the

brush holder assembly.

O BRUSH HOLDER@ BRUSH HOLDER

Insert the brush into the brush holder, and bring the

brush into contact with the commutator, then attach

a spring scale to the spring. Measure the spring ten-

sion at the moment the spring lifts off the brush.

SPRING SCALE

Spring Tension: 13.7 - 17.7 N

(1.40 - 1.80 kgf, 3.09 - 4.00 lbf)

4-12

Starter Reassembly

NOTE: Use the illustration on page 4I as reference for

reassemDty.

1. Pry back each brush spring with a screwdriver, then

position the brush about halfway out ol its holder,

and release the spring to hold it there.

2. Install the armature in the housing. Next, pry back

each brush spring again, and push the brush down

until it seats against the commutator, then release

the spring against the end of the brush.

- E^

F*4#-@

6t taal la

tlll

3. Install the endon the brush holder.

ft

cover

www.emanualpro.com

Page 135 of 1395

Camshafts

4.

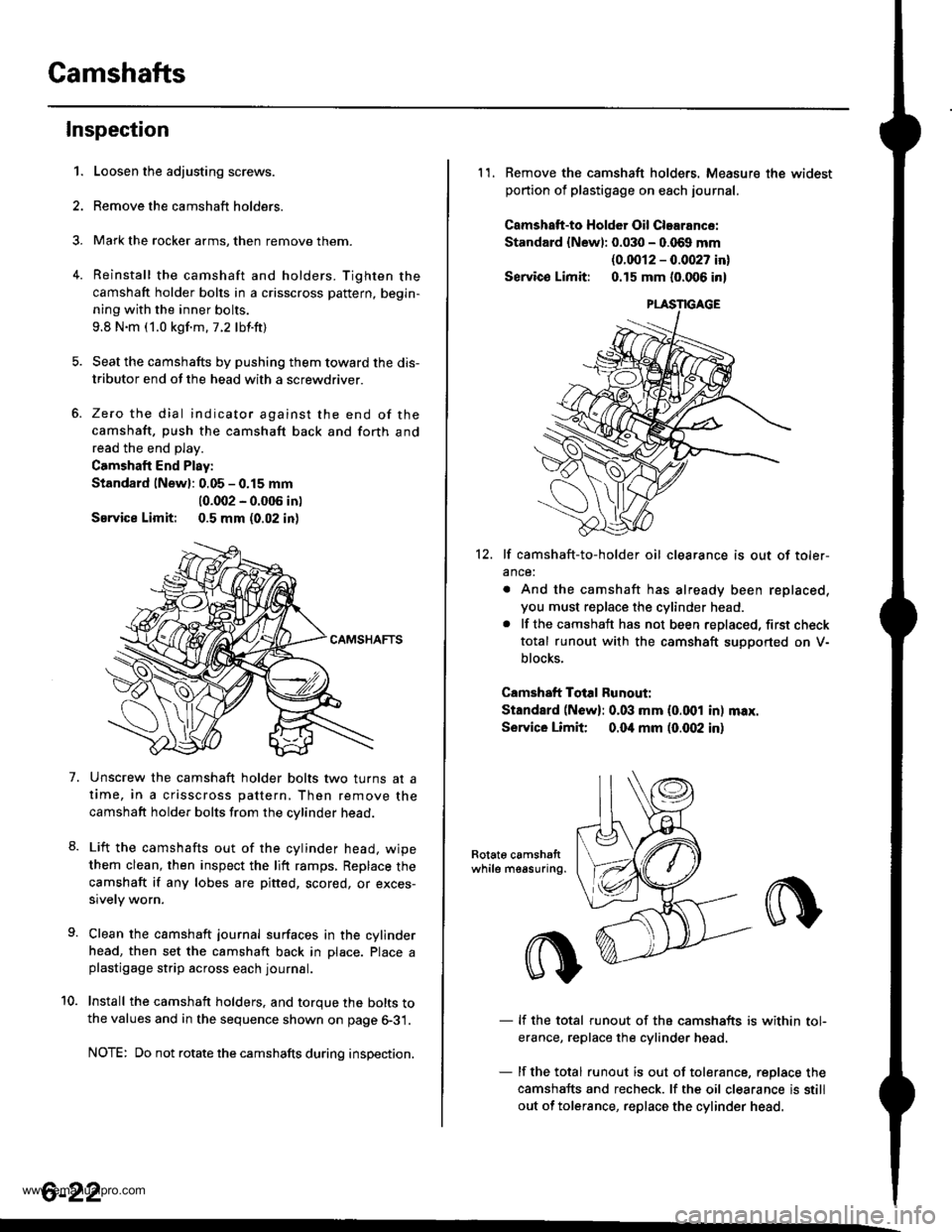

Inspection

1.

7.

Loosen the adjusting screws.

Remove the camshaft holders.

Mark the rocker arms, then remove them.

Reinstall the camshaft and holders. Tighten the

camshaft holder bolts in a crisscross pattern, begin-

ning with the inner bolts.

9.8 N.m (1.0 kgf.m.7.2 lbf.ft)

Seat the camshafts by pushing them toward the dis-

tributor end of the head with a screwdriver.

Zero the dial indicator against the end of the

camshaft, push the camshaft back and forth and

read the end play.

Camshaft End Play:

Standard lNewl: 0.05 - 0.15 mm

10.002 - 0.005 in)

Service Limit: 0.5 mm (0.02 in)

Unscrew the camshaft holder bolts two turns at a

time, in a crisscross pattern, Then remove the

camshaft holder bolts from the cvlinder head.

Lift the camshafts out of the cylinder head. wipe

them clean, then inspect the lift ramps, Replace the

camshaft if any lobes are pitted, scored, or exces-

sively worn.

Clean the camshaft journal surfaces in the cylinder

head, then set the camshaft back in Dlace. Place aplastigage strip across each journal.

Install the camshaft holders. and torque the bolts tothe values and in the sequence shown on page 6-31.

NOTE: Do not rotate the camshafts during inspection.

8.

10.

6-22

11. Remove the camshaft holders. Measure the widest

portion of plastigage on each journal.

Camshatt-to HoldGr Oil Clearance:

Standard {Newl: 0.030 - 0.069 mm

{0.0012 - 0.0027 in}

Servico Limit: 0.15 mm (0.006 in)

12. lf camshaft-to-holder oil clearance is out of toler-

ance:

. And the camshaft has already been replaced,

you must replace the cylinder head.. lf the camshaft has not been replaced, first check

total runout with the camshaft suoDorted on V-

blocks.

Camshaft Total Runout:

Standard (N6w): 0.03 mm (0.001 in) max.

Service Limit 0.04 mm (0.(X)2 in)

Rotat6 camshattwhile measuring.

- lf the total runout of the camshafts is within tol-

erance, replace the cylinder head

- lf the total runout is out of tolerance, replace the

camshafts and recheck. lf the oil clearance is still

out of tolerance, replace the cylinder head.

www.emanualpro.com

Page 145 of 1395

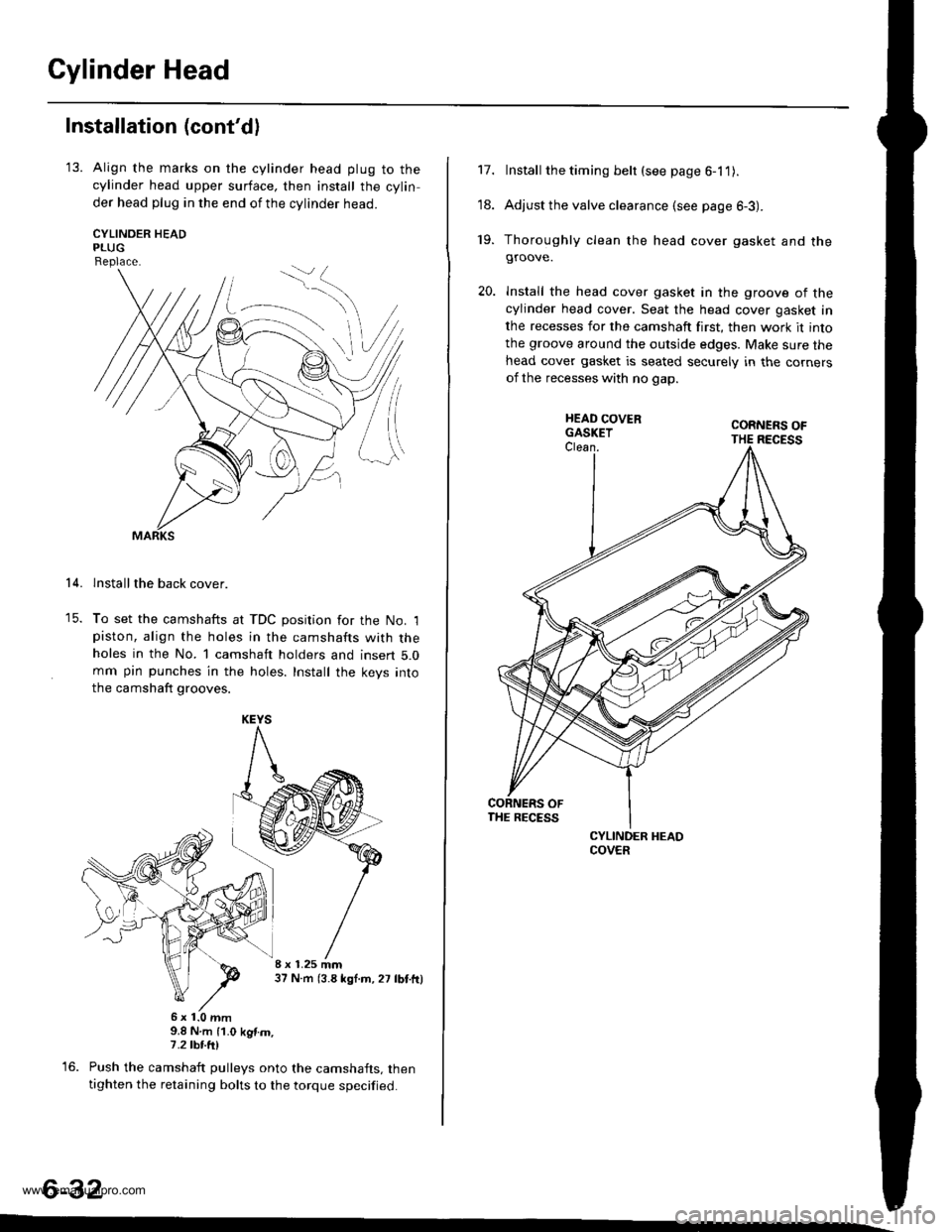

Cylinder Head

Installation (cont'dl

'13. Align the marks on the cylinder head plug to thecylinder head upper surface, then install the cylin

der head plug in the end of the cylinder head.

CYLINOER HEADPLUGReplace.

lnstallthe back cover.

To set the camshafts at TDC position for the No. lpiston, align the holes in the camshafts with theholes in the No. l camshaft holders and insert 5.0mm pin punches in the holes. Install the keys into

the camshaft grooves.

37 N m (3.8 *gl.m, 27 lbt.tr)

9.8 N.m (1.0 kgtm,7.2|hrftl

Push the camshaft pulleys onto the camshafts. thentighten the retaining bolts to the torque specified.

6-32

14.

KEYS

I x 1.25 mm

6x1.0mm

Install the timing belt (see page 6-1 1).

Adjust the valve clearance (see page 6-3).

Thoroughly clean the head cover gasket and thegroove.

lnstall the head cover gasket in the groove of thecylinder head cover. Seat the head cover gasket in

the recesses for the camshaft first, then work it into

the groove around the outside edges. Make sure thehead cover gasket is seated securely in the corners

of the recesses with no gap.

17.

'18.

19.

www.emanualpro.com

Page 146 of 1395

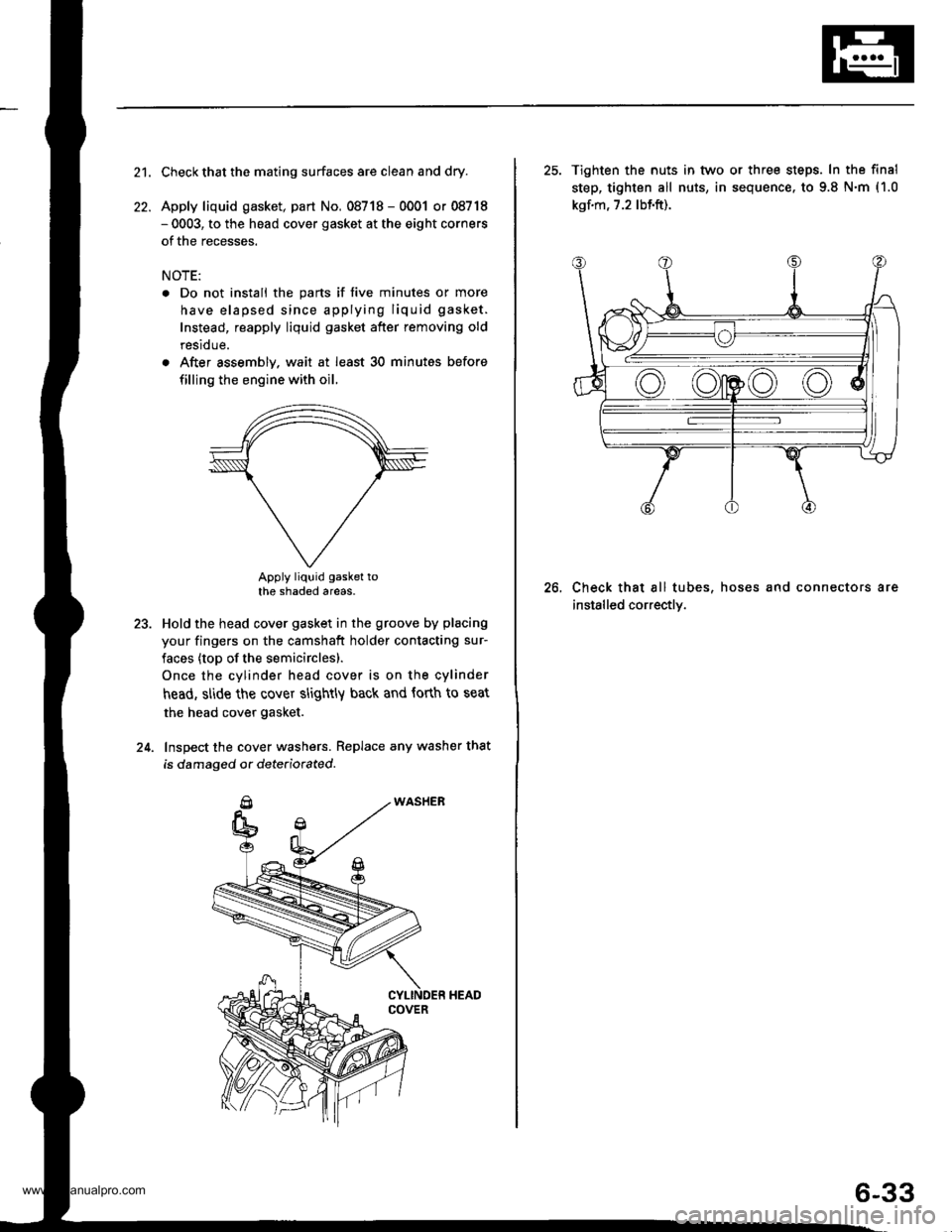

21.

22.

Check that the mating surfaces are clean and dry.

Apply liquid gasket, part No. 08718 - 0001 or 08718- 0003, to the head cover gasket at the eight corners

of the recesses.

NOTE:

. Do not install the parts if five minutes or more

have elapsed since applying liquid gasket.

Instead, reapply liquid gasket after removing old

residue.

. After assembly. wait at least 30 minutes before

filling the engine with oil.

Apply liquid gasket tothe shaded areas.

Hold the head cover gasket in the groove by placing

your fingers on the camshaft holder contacting sur-

faces (top of the semicirclesl.

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

Inspect the cover washers. Replace any washer that

is damaged or dete(iorated.

23.

24.

25. Tighten the nuts in tvvo or three steps. In the final

step, tighten all nuts, in sequence. to 9.8 N.m (1.0

kgf.m, 7.2 lbf.ft).

Check that all tubes, hoses and connectors are

installed correctly.

26.

6-33

www.emanualpro.com

Page 393 of 1395

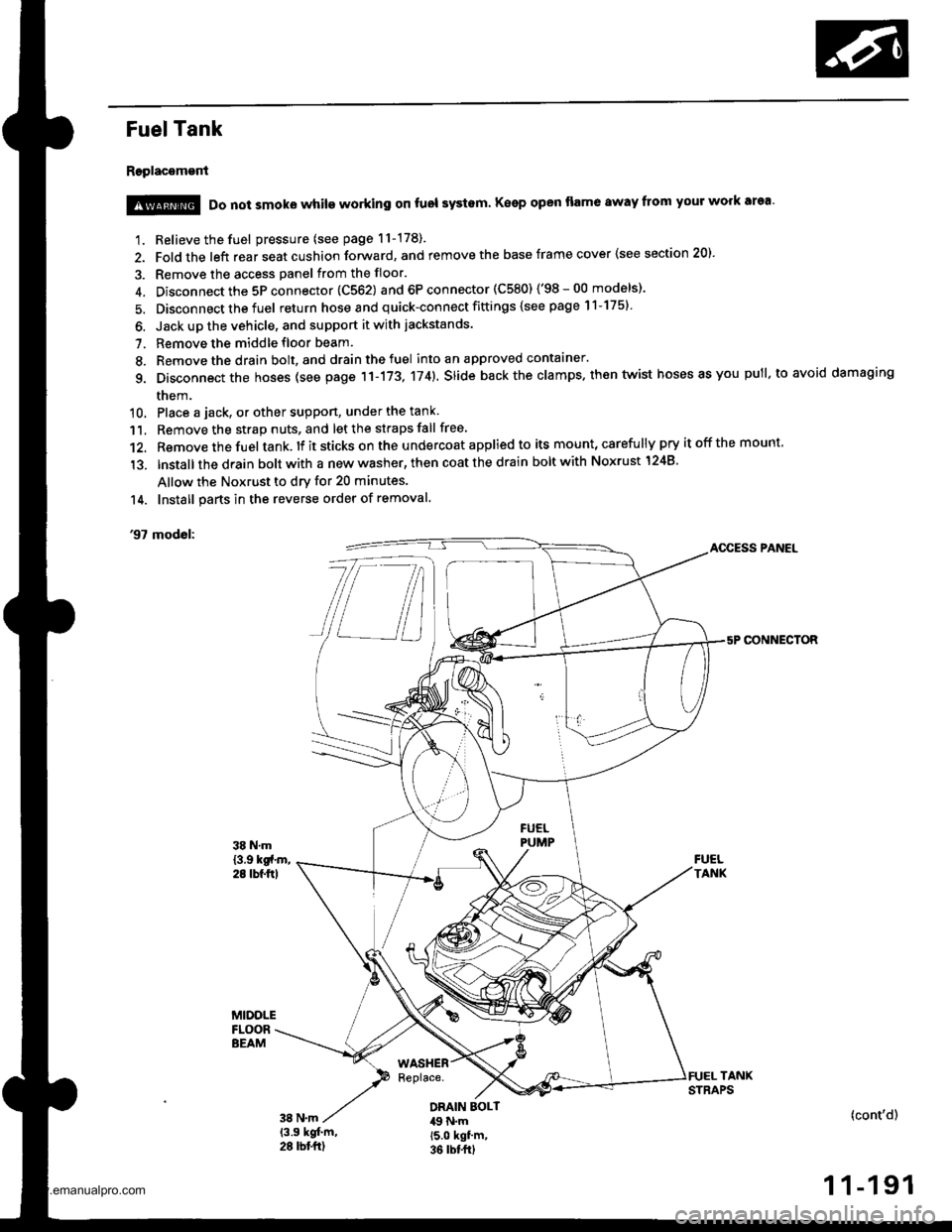

Fuel Tank

Replacement

1. Relieve the fuel pressure (see page 11-178).

2. Fold the left rear seat cushion forward, and remove the base frame cover {see section 20).

3. Remove the access panel from the floor.

4. Disconnect the 5P connector 1C562) and 6P connector (C580) ('98-00 models)'

5. Disconnect the fuel return hose and quick-connect fittings {see page 11-175}

6. Jack up the vehicle, and support it with jackstands.

7. Remove the middle floor beam.

8. Remove the drain bolt, and drain the fuel into an approved contaaner.

g. Disconnect the hoses (see page 11-173, 174). slide back the clamps. then twist hoses as you pull, to avoid damaging

them.

10. Place a jack, or other suppon, under the tank

11. Remove the strap nuts, and let the straps fall free

12. Remove the fuel tank. lf it sticks on the u ndercoat applied to its mount, carefu lly pry it off the mount,

'13. lnstallthe drain bolt with a new washer, then coat the drain bolt with Noxrust 1248'

Allow the Noxrust to dry for 20 minutes.

14. Install parts in the reverse order of removal.

'97 modol:AOCESS PANEL

CONNECTOR

@ Do not smoke while working on fuol systam Keep open flame away from your work area'

DRAIN EOLT49 N.m15.0 kgf'm,36 rbt frl

(cont'd)

1 1-191

www.emanualpro.com

Page 485 of 1395

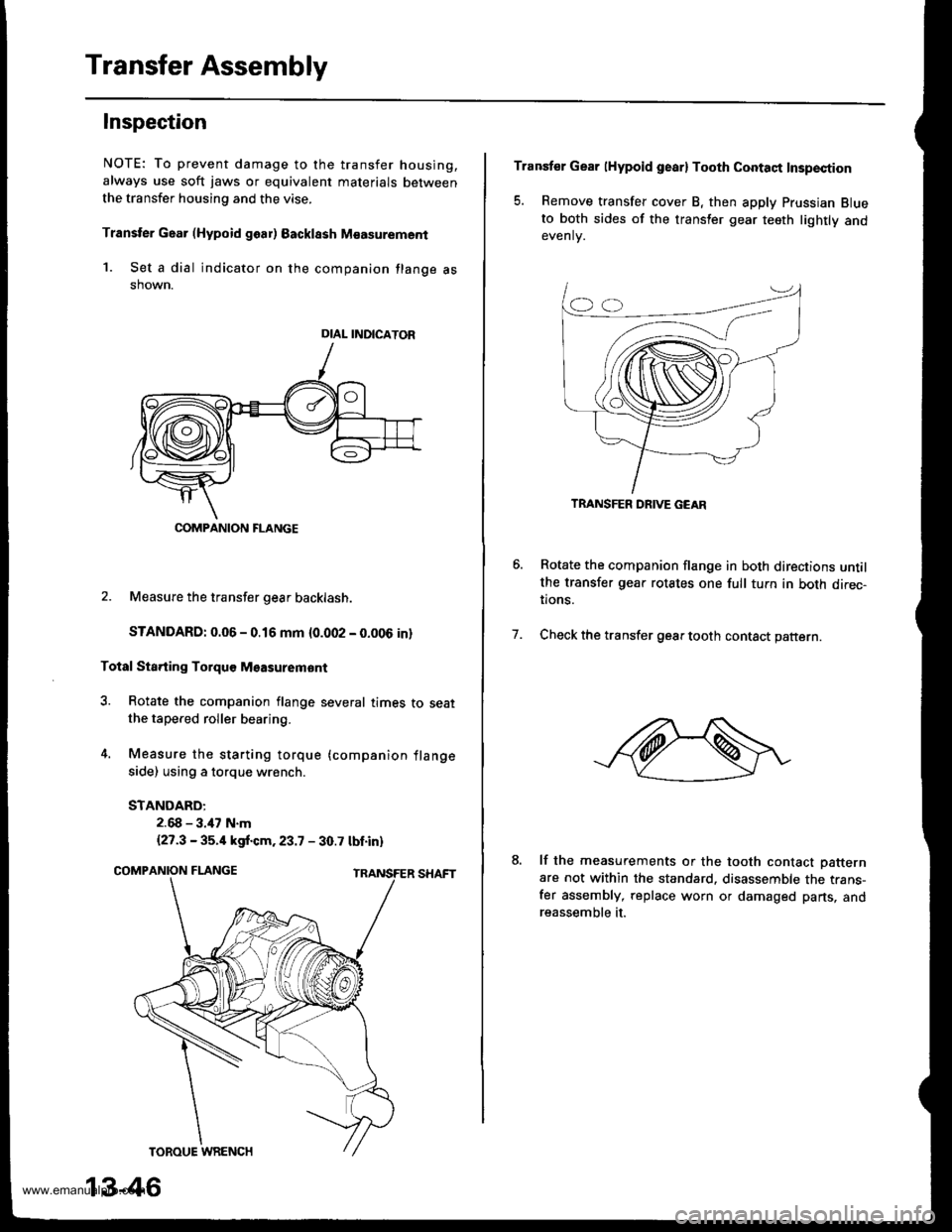

Transfer Assembly

Inspection

NOTE: To prevent damage to the transfer housing,

always use soft jaws or equivalent materials between

the transfer housing and the vise.

Transter Gaar (Hypoid goar) Backlssh M€asurement

1. Set a dial indicator on the companion flange asshown.

2. Measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm {0.002 - 0.006 in}

Total Sta.ting Torquo Msasuremont

3. Rotate the companion flange several times to seatthe tapered roller bearing.

4. Measure the starting torque (companion flange

side) using a torque wrench.

STANDARD:

2.68 - 3.47 N.m

{27.3 - 35.4 kgf.cm.23.7 - 30.7 tbt.in)

DIAL INDICATOR

COMPANION FLANGE

13-46

Transfer Gear lHypoid gearl Tooth Contaqt Insp€ction

5. Remove transfer cover B, then apply Prussian Blueto both sides of the transler gear teeth lightly andevenlv.

Rotate the companion flange in both directions untilthe transfer gear rotates one full tuln in both direc-tions.

Check the transfer gear tooth contact pattern.7.

lf the measurements or the tooth contact Datternare not within the standard. disassemble the trans-fer assembly, replace worn or damaged parts, andreassemble it.

TRANSFER DRIVE GEAR

www.emanualpro.com

Page 494 of 1395

TOROUE WRENCH

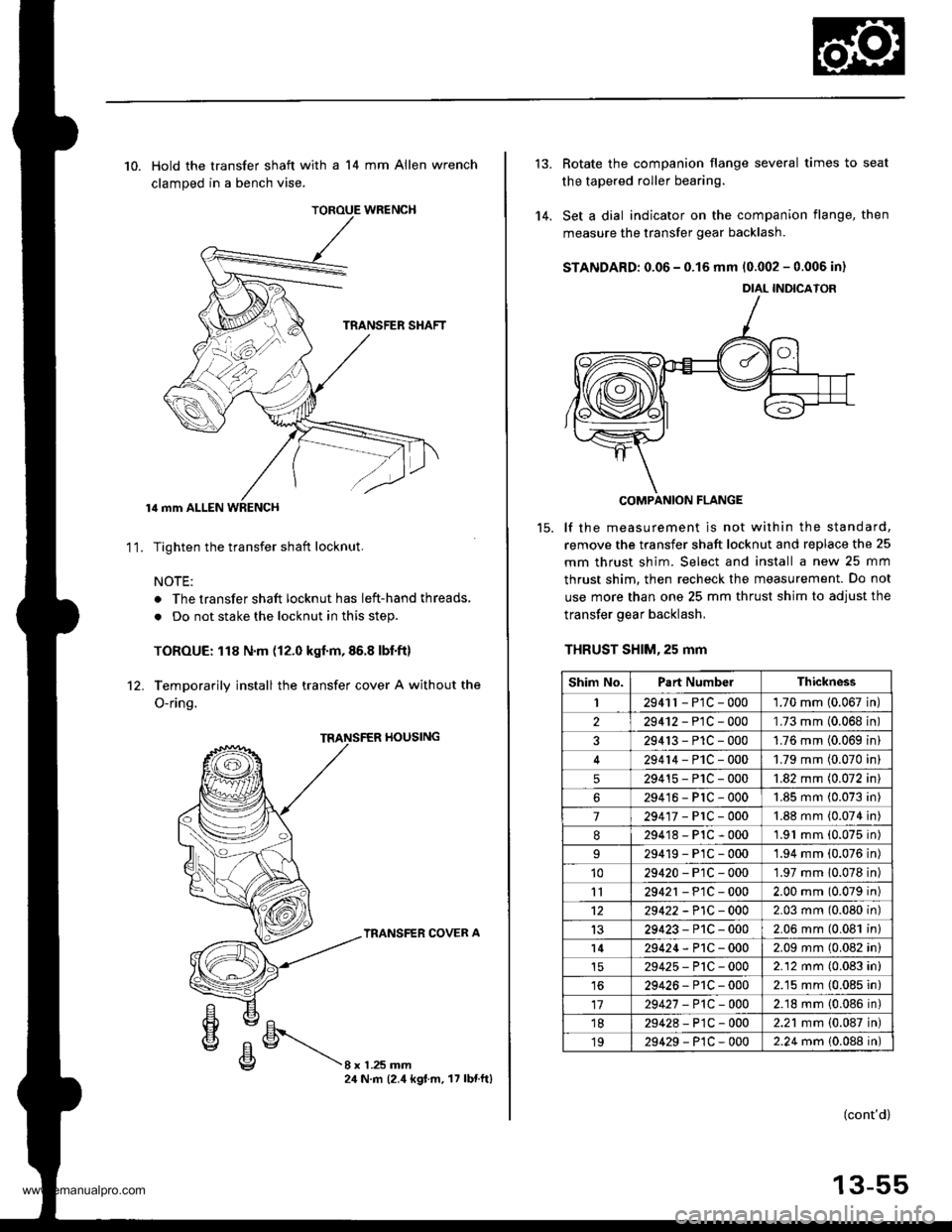

10. Hold the transfer shaft with a 14 mm Allen wrench

clamped in a bench vise.

lil mm ALLEN WRENCH

Tighten the transfer shaft locknut.

NOTE:

. The transfer shaft locknut has left-hand threads,

. Do not stake the locknut in this step.

TOROUE: 118 N.m (12.0 kgf.m,86.8 lbf.ft)

Temporarily install the transfer cover A without the

O-ring.

11.

rl0ustNG

TRANSFER COVER A

8xL25mm24 N.m (2.4 kgt.m. 17 lbnftl

'14.

Rotate the companion flange several times to seat

the tapered roller bearing.

Set a dial indicator on the companion flange, then

measure the transfer gear backlash.

STANDARD: 0.06 - 0.15 mm 10.002 - 0.006 in)

COMPANION FLANGE

lf the measurement is not within the standard,

remove the transfer shaft locknut and replace the 25

mm thrust shim. Select and install a new 25 mm

thrust shim. then recheck the measurement. Do not

use more than one 25 mm thrust shim to adjust the

transfer gear backlash,

THRUST SHlM,25 mm

DIAL INDICATOR

Shim No.Part NumbelThickness

I2941r - P1C - 0001.70 mm 10.067 in

229412-PlC-000'L73 mm (0.068 in

329413-P1C-0001.76 mm (0.069 in

29414-PlC-0001.79 mm (0.070 in

529415-P1C-0001.82 mm (0.072 in

629416-PlC-0001.85 mm (0.073 in

7294'�17-PrC-0001.88 mm (0.074 in

8294'18-P1C-0001.91 mm (0.075 in)

29419-PlC-0001.94 mm (0.076 in)'1029420-P1C-0001.97 mm 10.078 in)

1129421 - P1C - 0002.00 mm (0.079 in)

1229422 -P1C - 0002.03 mm (0.080 in)

1329423-P1C-0002.06 mm (0.081 in)

l429424-P1C-0002.09 mm (0.082 in)

29425-P'tC-0002.12 mm (0.083 in)

1629426-P1C-0002.15 mm (0.085 in)

1729427 -P1C-0002.18 mm {0.086 in)'1829428-P1C-0002.21 mm {0.087 in)

1929429-P1C-0002.24 mm 10.088 in)

(cont'd)

13-55

www.emanualpro.com

Page 505 of 1395

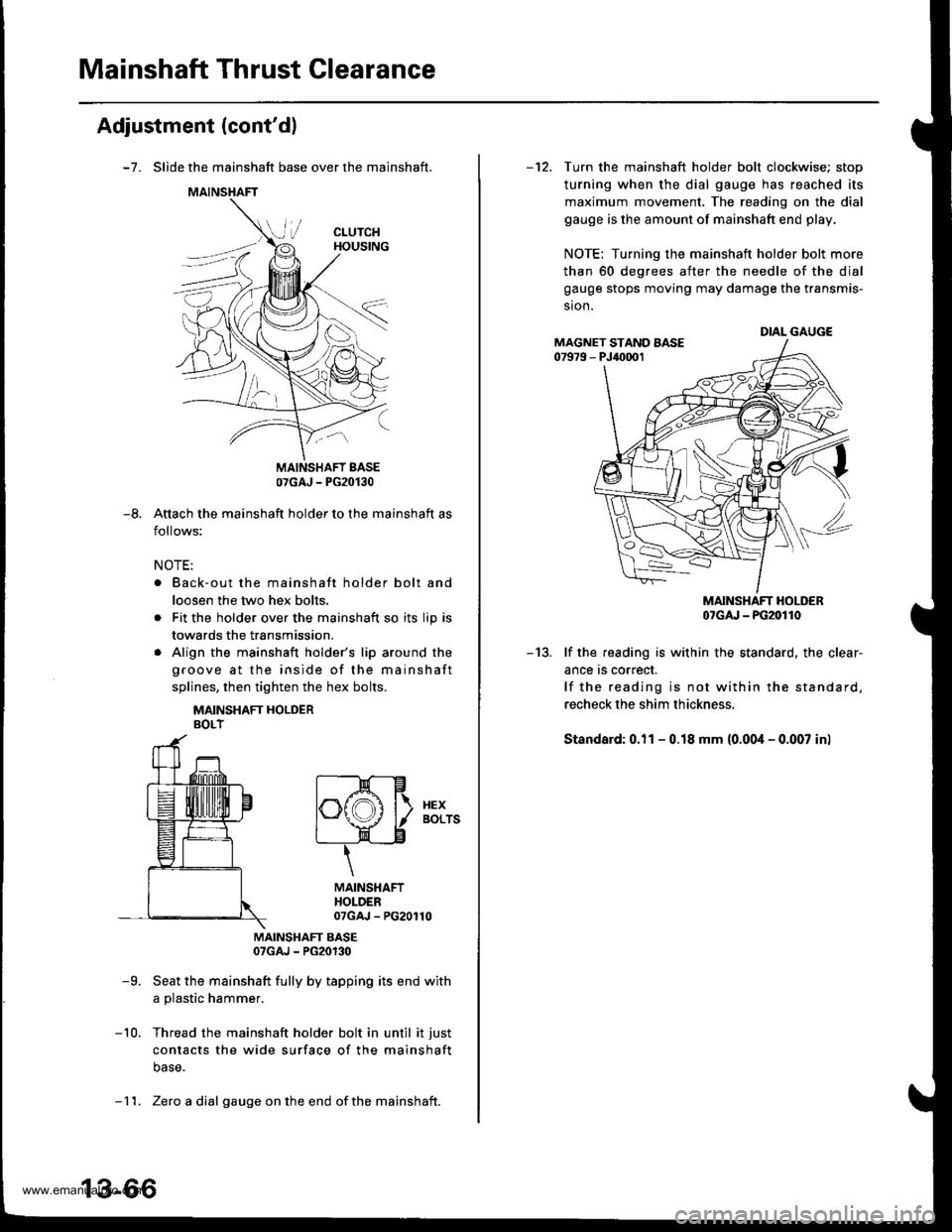

Mainshaft Thrust Clearance

Adjustment (cont'dl

-7. Slide the mainshaft base over the mainshaft.

Attach the mainshaft holder to the mainshaft as

follows:

NOTE:

. Back-out the mainshaft holder bolt and

loosen the two hex bolts.

. Fit the holder over the mainshaft so its lip is

towards the transmission.

. Align the mainshaft holder's lip around the

groove at the inside of the mainshaft

splines, then tighten the hex bolts.

MAINSHAFT HOLDERBOLT

MAINSHAFT EASE07GAJ - PG20130

-9. Seat the mainshaft fully by tapping its end with

a plastic hammer.

-10. Thread the mainshaft holder bolt in until it just

contacts the wide surface of the mainshaft

base.

07GAJ - PG20130

-8.

t--E-Hlf\f,A l\. xex

l"\y I aors

t____=__)"n-____"8

\

MAINSHAFTHOLDER07GAJ - PG20110

- 11. Zero a dial gauge onthe end ofthe mainshait.

-12. Turn the mainshaft holder bolt clockwise; stop

turning when the dial gauge has reached its

maximum movement, The reading on the dial

gauge is the amount of mainshaft end play.

NOTE: Turning the mainshaft holder bolt more

than 60 degrees after the needle of the dial

gauge stops moving may damage the transmis-

sion.

MAINSHAFT HOLDER07cru - PG20110

-13. lf the reading is within the standard, the clear-

ance rs correct.

lf the reading is not within the standard,

recheck the shim thickness.

Standard: 0.11 - 0.18 mm (0.00i1- 0.007 inl

DIAL GAUGEMAGNET STAND AASE07979 - PJ40001

www.emanualpro.com

Page 750 of 1395

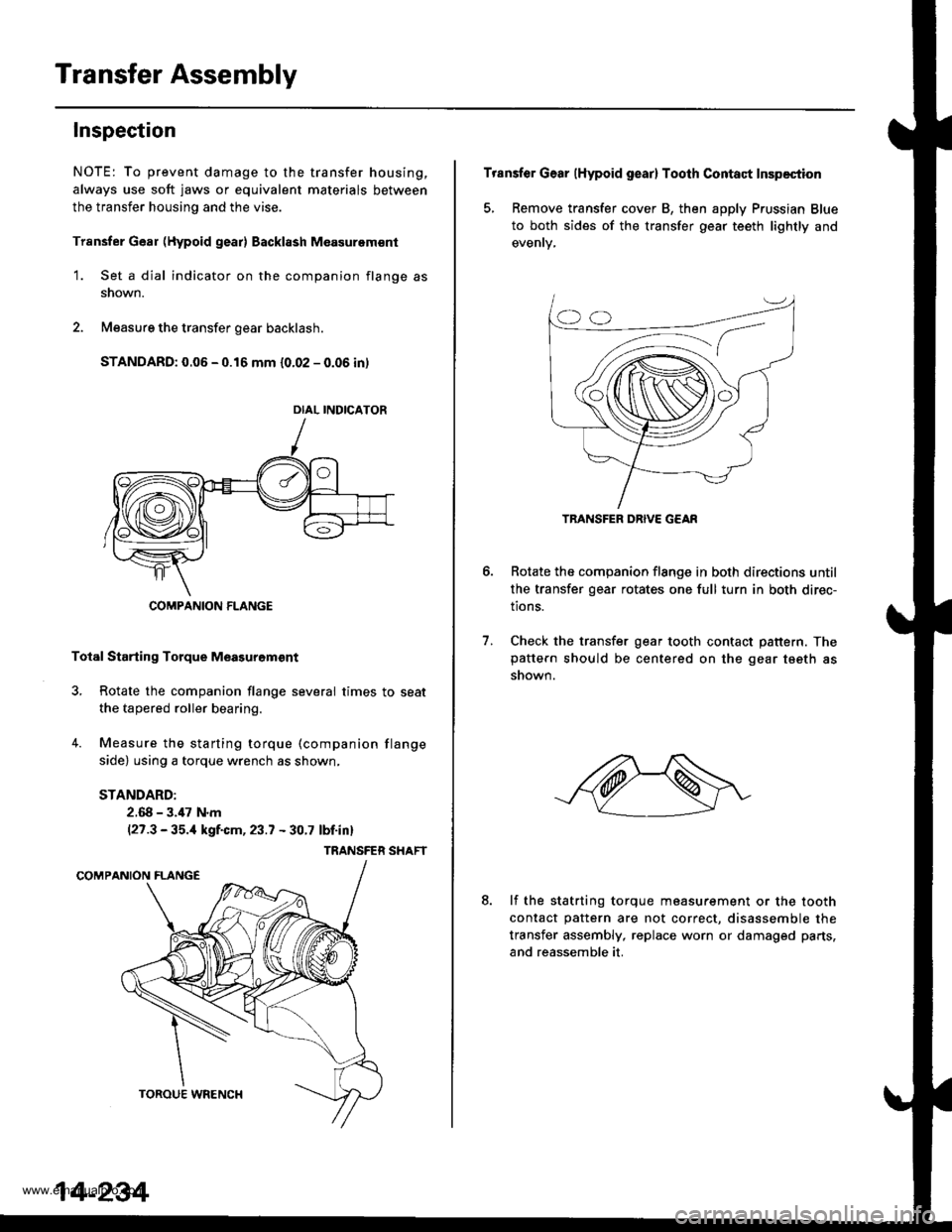

Transfer Assembly

Inspection

NOTE: To prevent damage to the transfer housing,

always use soft jaws or equivalent materials between

the transfer housing and the vise.

Trsnsfer Gear (Hypoid gear) Backl8sh M€asurem€nt

1. Set a dial indicator on the companion flange as

snown.

2. Measure the transfer gear backlash.

STANDARD: 0.06 - 0.16 mm {0.02 - 0.06 in)

Total Starting Torque Meagurgm€nt

3, Rotate the companion flange several times to seat

the tapered roller bearing.

4. Measure the starting torque (companion flange

side) using a torque wrench as shown,

STANDARD:

2.68 - 3.,17 N.m(27.3 - 35.,1 kgf.cm, 23.7 - 30.7 lbf.inl

TRANSFER SHAFT

DIAL INDICATOR

COMPANION FLANGE

14-234

Transfer Gear (Hypoid gear) Tooth Contact Inspection

5, Remove transfer cover B, then apply Prussian Blue

to both sides of the transfer gear teeth lightly and

Rotate the companion flange in both directions until

the transfer gear rotates one full turn in both direc-

tions.

Check the transfer gear tooth contact pattern. Thepattern should be centered on the gear tseth as

snown.

6.

7.

8.lf the statrting torque measurement or the tooth

contact pattern are not correct, disassemble the

transfer assembly, replace worn or damaged parts,

and reassemble it.

TRANSFER DRIVE G€AR

www.emanualpro.com