differential HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 31 of 1395

Standards and Service Limits

Manual Transmission {cont'd} - Section 13

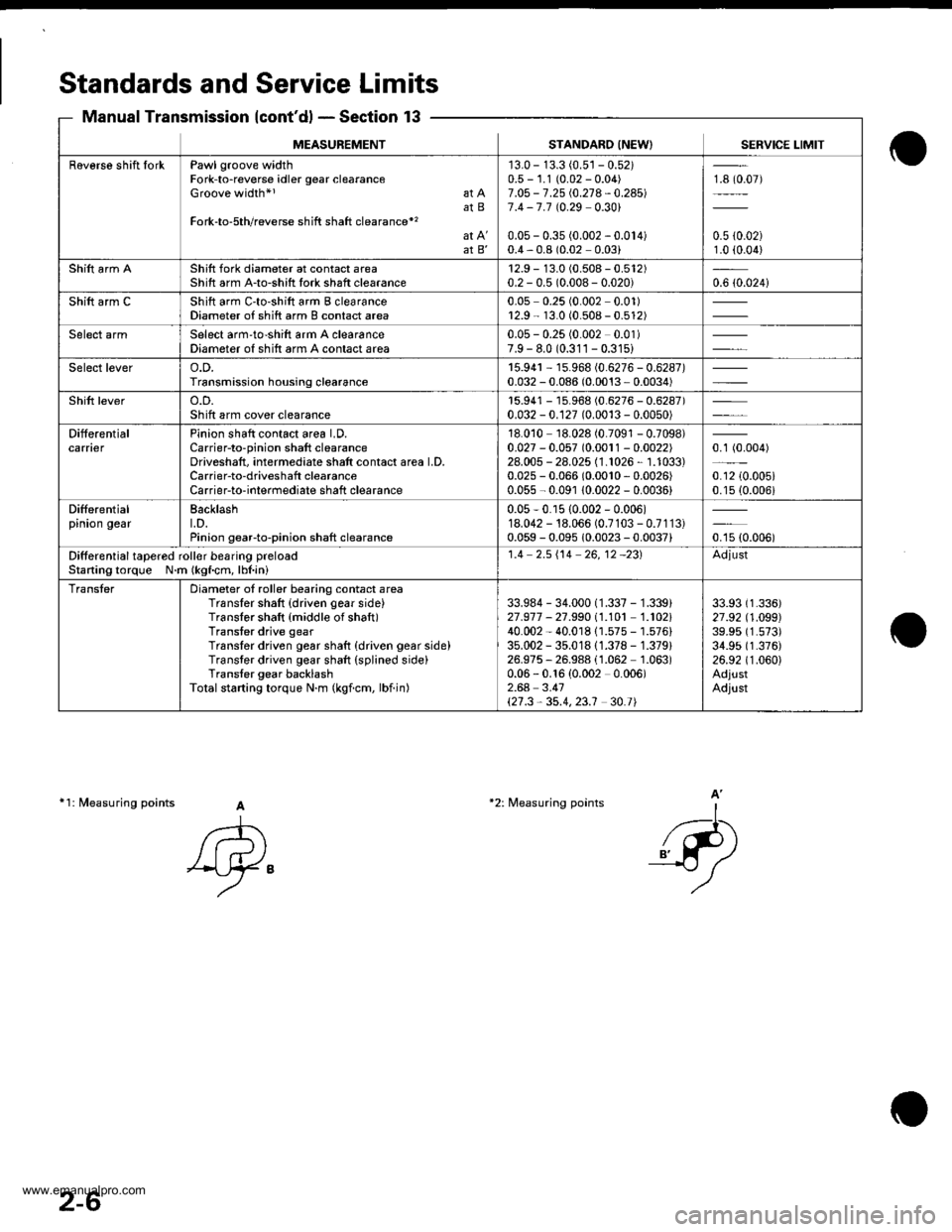

11: fuleasuring points A

A

'Ay"

-l-...

_{-P)

A'*2: Measuring points

MEASUREMENTSTANDARO INEW) SERVICE LIMIT

Raverse shift IorkPawl groove widthFork-to-reverse idler gear clearanceGroove width*l at AatBFork-to-5th/reverse shift shaft clearance*'�

at B'

'13.0 - 13.3 (0.5'�j - 0.52)0.5 - 1.1 (0.02 - 0.04)7.O5 - 7.25 i.0.21 4 - 0.24517.4 -7.7 t0.29 0.301

0.05 - 0.35 (0.002 - 0.014)0.4,0.8 (0.02 0.03)

18 (0.07)

0.5 {0.02)1.0 (0.04)

Shift arm AShift fork diameter at contact areaShift arm A-to-shitt tork shaft clearance12.9 - 13.0 (0.508 - 0.512)0.2 - 0.5 (0.008- 0.020)0.6 {0.024i

Shift arm CShift arm C'to-shift arm B clearanceDiameter of shift arm B contact area0.05 0.25 (0.002 0.01)r2.9 - 13.0 (0.508 - 0.512)

Select armSelect arm'to-shift arm A clearanceDiameter of shift arm A contact area0.05 - 0.25 (0.002 0.01)7.9 - 8.0 (0.311 - 0.31s)

Select levero.D.Transmission housing clearance15.94r - 15.968 (0.6276 - 0.6287)0.032 - 0.086 (0.0013 - 0.0034)

Shift levero.D.Sh ift arm cover clearancer5.941 - 15.968 (0.6276 - 0.6287)0.032 - 0.127 (0.0013 - 0.0050)

DifferentialcarnerPinion shaft contact area LD.Carrier-to-pinion shaft clearanceDriveshaft, intermediate shatt contact area LD,Carrier-to-driveshaft clearanceCarrierto-interrnediate shaft clearance

18.010 18.028 (0.7091 - 0.7098)0.027 - 0.057 (0.0011 - 0.0022)28.005 - 28.025 (1.1026, 1.1033)0.025 - 0.066 (0.0010,0.0026)

0.055 - 0.091 10.0022 - 0.0036)

0.1 (0.004)

0.12 {0.005i0.15 (0.006i

Differentialpinion gearBacklasht.D.Pinion gearto-pinion shaft clearance

0.05-0.r5 {0.002 - 0.006)18.042 - 18.066 (0.7103 - 0.7113)0.059 - 0.095 10.0023 - 0.0037)oru ro.ooor

Ditferential tapered roll€r besring preloacStaning torque N.m (kgf.cm, lbl.ini

1.4 2.5i'14 26,12 -231Adjust

TransterDiameter of roller bearing contact areaTransler shaft {driven gear side}Translor shaft {middle of shaft)Transter drive gearTranslor driven gear shaft {driven gear side)Transter driven gear shaft (splined side)Trans{er gear backlashTotalstarting torque N.m (kgicm, lbiin)

33.984 - 34.000 (1.337 - 1.339)21.977 - 27.99011.101 1.102140.002 - 40.01811.575 - 1.576)35.002 - 35.01811.378 - 1.379)26.975, 26.988 (1.062 1.063)0.06 - 0.16 {0.002 0.006)2.64 3.41\21.3,35.4,23.1 30.t|

33.93 (1.336)

27 .92 (1 .O99)39.95 (1.573)

34.95 (1.376)

26.92 (1.060)

AdjustAdjust

2-6

www.emanualpro.com

Page 34 of 1395

2-9

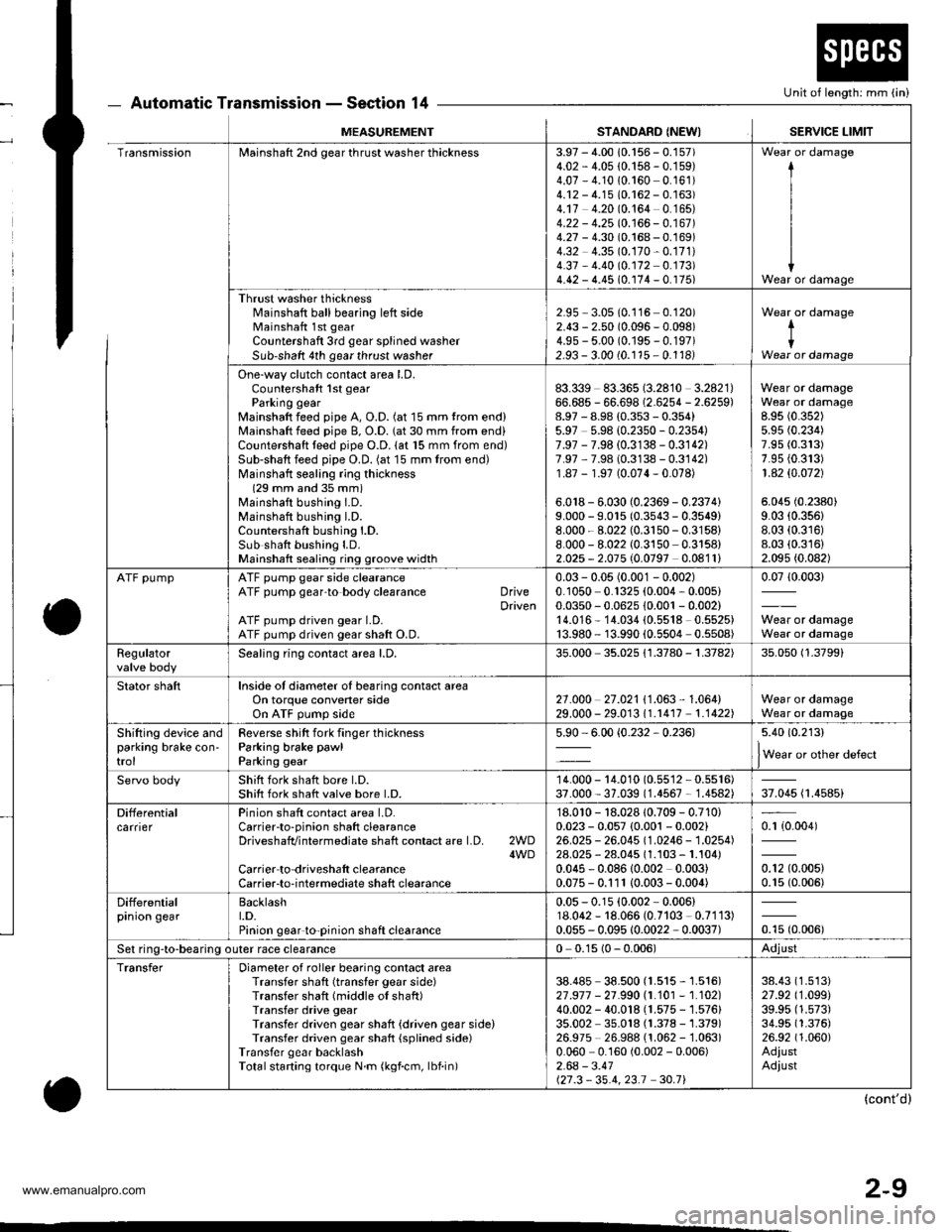

Automatic Transmission - Section 14

o

Unit of length: mm (in)

o

MEASUREMENTSTANDARD (NEWISERVICE LIMIT

TransmissionMainshaft 2nd gear thrust washer thickness3.97 - 4.00 10.156 - 0.157)4.02 - 4.05 {0.158 - 0.159)4.07 - 4.1010.160 0.161)4.12 - 4.15 (0.162 - 0.163)4.17 4.20 (0.164 0.165)4.22 - 4.25 10.166 - 0.167 )4.27 - 4.30 (0.168 - 0.169)4.32 4.35 (0.170-0.171)

4.37 - 4.40 (0.172 0.173)4.42 - 4.45 (0.174 - 0. r75)

I

I

IWear or damage

Thrust washer thicknessl'rainshaft ball bearing left sideMainshaft 1st gear

Countershaft 3rd gear splined washerSub-shaft 4th gear thrust washer

2.95 3.05 (0.116 0.120)2.43 - 2.50 (0.096 - 0.098)4.9s - 5.00 (0.195 - 0.197)2.93 - 3.00 (0.115 - 0.1181

Wear or damage

tIWear or damage

One-way clutch contact area LD.Countershaft 1st gearParking gearMainshaft feed pipe A, O.D. (at 15 mm trom end)Mainshaft feed pipe B, O.D. (at 30 mm from end)Countershaft teed pipe O.D. lat 15 mm from end)Sub-shaft feed pipe O.D. (at 15 mm from end)Mainshatt sealing ring thickness(29 mm and 35 mm)Mainshaft bushing I.D.Mainshaft bushing l.D.Countershaft bushing l.D.Sub shatt bushing LD.Mainshaft sealing ring groove width

83.339 83.365 (3.2810 3.2821)66.685 - 66.698 (2.6254 - 2.6259)8.97 - 8.98 (0.353 - 0.354)5.97 5.98 {0.2350 - 0.2354)7.97 - 7.98 (0.3138 - 0.3142)7.97 ,7.98 (0.3138 - 0.3142)1.87 - 1.97 (0.074-0.078)

6.018 - 6.030 (0.2369 - 0.2374)9.000 - 9.015 (0.3543 - 0.3549)8.000 - 8.022 (0.3150-0.3158)

8.000 - 8.022 (0.3150 0.3158)2.025 - 2.075 (0.0797 0.0811)

Wear or damageWear or damage8.95 (0.352)

5.95 (0.234)

7.95 (0.313)

7.95 {0.313)1 .42 $.O72)

5.045 (0.2380)

9.03 (0.356)

8.03 (0.316)

8.03 (0.316)

2.095 (0.082)

ATF pumpATF pump gear side clearanceATF pump gear'to body clearance DriveDrivenATF pump driven gear LD.ATF pump driven gear shaft O.D.

0.03 - 0.05 (0.001 - 0.002)0.1050 0.1325 (0.004, 0.005)0.0350 - 0.0625 10.001 - 0.002)14.016* 14.034 (0.5518 0.5525)13.980 - 13.990 {0.5504 0.5508)

0.0710.003)

Wear or damageWear or damage

Regulatorvalve bodySealing ring contact area l.D,35.000 35.025 {1.3780 - 1.3782)35.050 (1.3799)

Stator shaftInside of diameter oI bearing contact areaOn torque convener sideOn ATF pump side2't .o00 27 .021 I '1 .063 , 1 .064)29.000 - 29.01311.r417 1.1422)Wear or damageWear or damage

Shifting device andparking brake con'trol

Reverse shitt fork finger thicknessParking brake pawl

Parking gear

5.90 - 6.00 {0.232,0.236)5.40 (0.213)

lWear or other defect

Servo bodyShift fork shatt bore l.D.Shift fork shatt valve bore l.D.14.000 - 14.010 (0.55'�l2 - 0.5516)37.000 - 37.039 (1.4567 - 1.4582)37.045 (1.4585)

DifferentialcarrierPinion shaft contact area LD.Carrierto-pinion shaft clearanceDriveshafvintermediate shaft contact are l.D. 2WD4WDCarrier to driveshalt clearanceCarrier-to-intermediate shaft clearance

'18.010 - 18.028 10.709 - 0.710)0.023 - 0.057 {0.001 - 0.002}26.025 - 26.045 (1.0246 - 1.0254)28.025 - 28.045 (1.103 - 1.104)0.045 - 0.08610.002 0.003)0.075 - 0.111 10.003- 0.004)

0.r {0.004)

0.12 (0.005)

0.15 (0.006)

Differentialprnron gearBacklasht.D.Pinion gear'to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.062 - 18.066 (0.7103 - 0.7113)0.055 - 0.095 10.0022 - 0.0037)otu to.oout

Set ring-to-bearing outer race clearance0 0.15 (0 - 0.006)Adjust

TransferDiameter of roller bearing contact areaTransfer shaft (transfer gear side)Transfer shaft (middle of shaft)Transfer drive gearTransfer driven gear shaft {driven gear side)Transfer driven gear shaft {splined side)Transfer gear backlashTotalstarting torque N.m (kgf.cm, lbf.in)

38.485 38.500 (1.515 - 1.516)27 .917 - 21 .990 |.1.101 - 1.102)40.002 - 40.018 (1.575 - 1.576)35.002 35.018 (1.378 - 1.379)26.975 26.988 (1.062 -'�l.063)

0.060 0.160 (0.002 - 0.006)2.64 - 3.41127.3 - 35.4,23.1 30.71

38.43 (1.513)

27.92 (1.099)

39.95 (1.573)

34.95 (1.376)

26.92 (1.060)

AdiustAdiust

(cont'd)

www.emanualpro.com

Page 35 of 1395

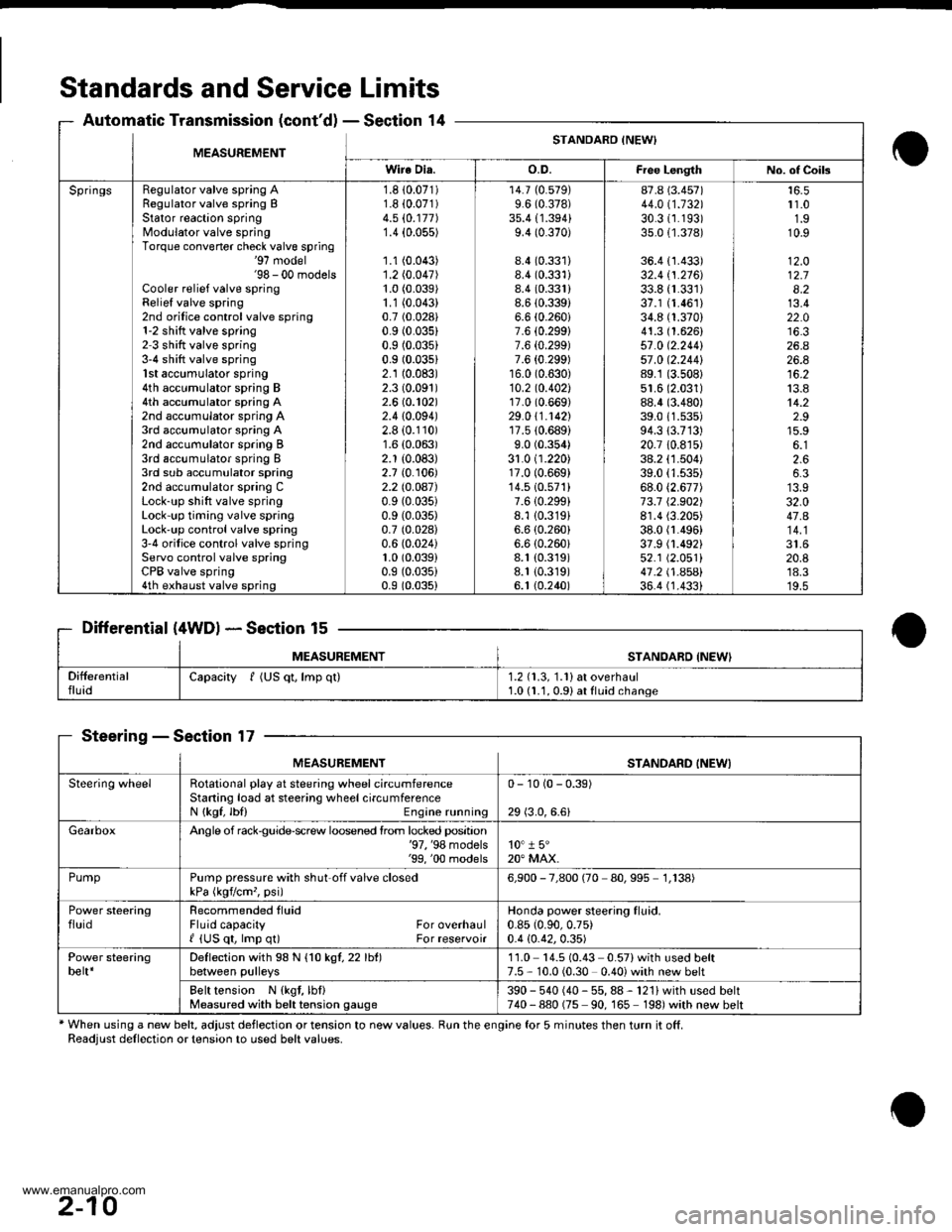

Standards and Service Limits

Automatic Transmission (cont'dl - Section 14

Differential (4WDl * Section 15

MEASUREMENTSTANOABD {NEW'

SteeringSection 17

* When using a new belt, adjust deflection or tension to new values. Run the engine for 5 minutes then turn it off.Readjust dellection or tension to used belt values.

MEASUREMENTSTANDARO INEWI

Wire Dia.o.D.Fiee LengthNo. of Coils

SpringsRegulator valve spring ARegulator valve spring BStator reaction springModulator valve springTorque convener check valve spring'97 model'98 - 00 modelsCooler relief valve springRelief valve spring2nd orilice control valve spring1-2 shitt valve spring2 3 shift valve spring3-4 shift valve spring1st accumulator spring4th accumulator spring B4th accumulator spring A2nd accumulator spring A3rd accumulator spring A2nd accumulator spring B3rd accumulator spring I3rd sub accumulator spring2nd accumulator spring CLock-up shift valve springLock-up timing valve springLock'up control valve spring3'4 orifice control valve springServo control valve springCPB valve spring4th exhaust valve spring

1.8 10.071)1.8 i0.071)4.5 (0.177)

1.4 {0.055)

1.1 (0.043)

1.2 (0.047)

1.0 (0.039)

1.1 (0.043)

0.7 (0.028)

0.9 (0.035)

0.9 (0.035)

0.9 (0.03s1

2.1 (0.083)

2.3 (0.091)

2.6 (0.102)

2.410.094)2.8 (0.110)

1.6 (0.063)

2.1 (0.083)

2.7 {0. r06)2.2lO.OA7)0.9 (0.035)

0.9 (0.035)

0.7 (0.028)

0.6 (0.024)

1.0 (0.039)

0.9 (0.035)

0.9 (0.035)

14.7 (0.579)

9.6 (0.378)

35.4 {1.394}9.4 (0.370)

8.4 (0.331)

8.4 (0.331)

8.4 (0.331)

8.6 (0.3391

6.6 (0.260i

7.6 {0.299}7.6 {0.299)7.6 {0.299)16.0 (0.630)

10.2 to.402l17.0 (0.669)

29.0 \1.1421'r7.510.689)

9.0 (0.354)

31.0 (1.220)17.0 (0.669)

14.510.571)7.610.299i8.1 {0.319}6.6 (0.260)

6.6 (0.260i

8.1 (0.319)

8.1 {0.319)6. t (0.240)

87.8 (3.457)

44.011.132130.31r.193)35.0 {1.378)

36.4 {1.433)32.4 tl.216J33.8 {r.331)37.1 (1.461)

34.8 (1.370)

41.3 (1.626)

57 .0 (2.2441

57 .0 12.244189.1 (3.508)

51.6 (2.031)

88.4 (3.480)

39.011.s35)94.313.713)20.7 10.8r5)38.2 (1.504)

39.0 (1.535)

68.0 (2.677)

73.7 12.902)8r.4 (3.205)

38.0 fl.496)37.9 (1.492)

52.1 (2.051)

41 .2 t .A5Al36.4 (1.4331

r 1.01.910.9

12.O12.78.213.422.0

26.426.8

13.814.22.915.9

2.66.3

32.047.A

20.8'18.3'19.5

Capacity f (US qt, lmp ql)1.2 (1.3, 1.1) at overhaul1.0 (1.1, 0.91 at fluid change

MEASUREMENTSTANDARD INEWI

Steering wheelRotational play at steering wheel circumferenceStaning load at steering wheelcircumferenceN {kgf, lbl) Engine running

0- 10 (0 - 0.39)

29 (3.0,6.6)

GearboxAngle of rack$uide-screw loosened lrom locked position'97, '98 models'99, '00 models10" 1 5"20" MAX.

PumpPump pressure with shut off valve closedkPa (kgvcm,, psi)6,900 - 7,800 (70 80,995 1,138)

Power steeringfluidRecommended tluidFluid capacity For overhaulI {US qt, lmp q0 For reservoir

Honda power steering fluid.0.85 (0.90,0.75)

0.4 {0.42,0.35)

Power steeringbelt*Deflection with 98 N {1O kgl,22lht)between pulleys11.0 14.5 (0.43 0.57)with used belt7.5 - 10.0 (0.30 0.40) with new belt

Belt tension N {kgt, lbf}Measured with belt tension gauge390 - 540 (40 - 55, 88 - 121) with used belt740-880 (75 90, 165 198)with new belt

2-10

www.emanualpro.com

Page 37 of 1395

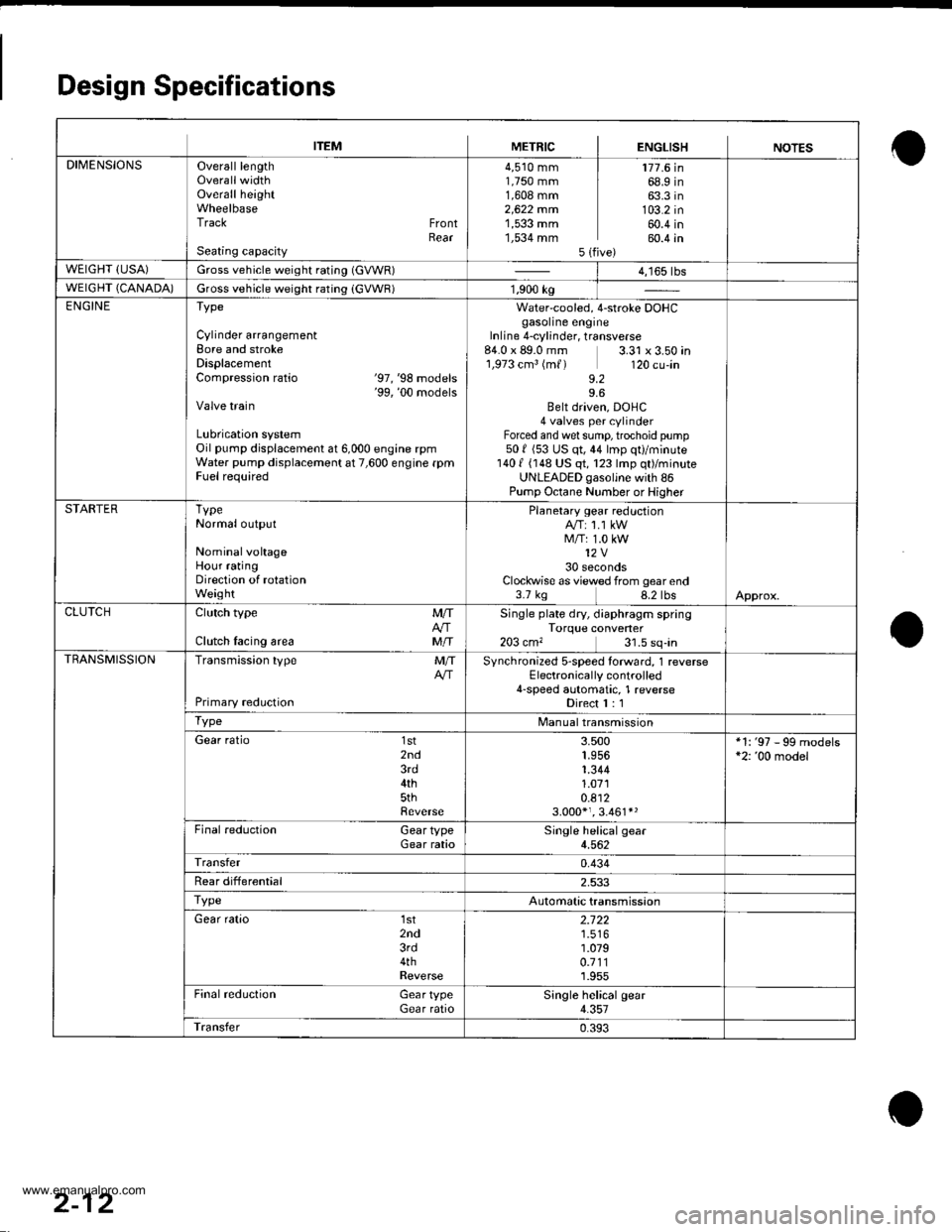

Design Specifications

ITEMMETRICENGLISHNOTES

DIMENSIONSOverall lengthOverallwidthOverall heightWheelbaseTrack FrontRearSeating capacity

4,510 mm1,750 mm1,608 mm2,622 mrn1,533 mm1,534 mm5lf

177.6 in68.9 in63.3 in103.2 in60.4 in60.4 in

WEIGHT (USA)Gross vehicle weight rating (GVWR)| 4,165 tbs

WEIGHT (CANADA)Gross vehicle weight rating (GVWR)1,900 kg

ENGINEType

Cylinder arrangementBore and strokeDisplacementCompression ratio '97,'98 mooers'99, '00 modelsValve train

Lubrication systemOil pump displacement at 6,000 engine rpmWater pump displacement at 7,600 engine rpmFuel required

Water-cooled, 4-stroke DOHCgasoline engineInline 4-cylinder, transverse84.0 x 89.0 mm.1,973 cm3 (m{)

9.2

3.31 x 3.50 in120 cu-in

9.6Belt driven, DOHC4 valves per cylinderForced and wet sump, trochoid pump501 (53 US qt,44 lmp qt)/minute1401 (148 US qt, 123 lmp qt)/minuteUNLEADED gasoljne with 86Pump Octane Number or Higher

STARTERTypeNormal output

NominalvohageHour ratingDirection of rotationWeight

Planetary gear reductionA/T: 1.1 kWM/T: 1.0 kW12V30 secondsClockwise as viewed from gear end3.7 kg 8.2 lbsApprox.

CLUTCHClutch type

Clutch lacing area

MIT

MIT

Single plate dry, diaphragm springTorque converter203 cm, 31.5 sq-in

TRANSMISSIONTransmission type

Primary redLrction

MITSynchronized s-speed torward, 1 reverseElectronically controlled4-speed automatic, 1 reverseDirect I : 1

TypeManualtransmission

Gear ratio 1st2nd3rd4th5thReverse

3.5001.9561.3441.0710.8123.000*,. 3.461*'

*1: '97 - 99 models*2: '00 model

Final reduction Gear typeGear rataoSingle helical gear4.562

Transfer0.434

Rear differential2.533

TypeAutomatic transmission

Gear ratio 1st2nd3rd4thReverse

2.722

1.0790.7111.955

Final reduction Gear typeGear ratioSingle helical gear4.357

Transfer0.393

2-12

www.emanualpro.com

Page 41 of 1395

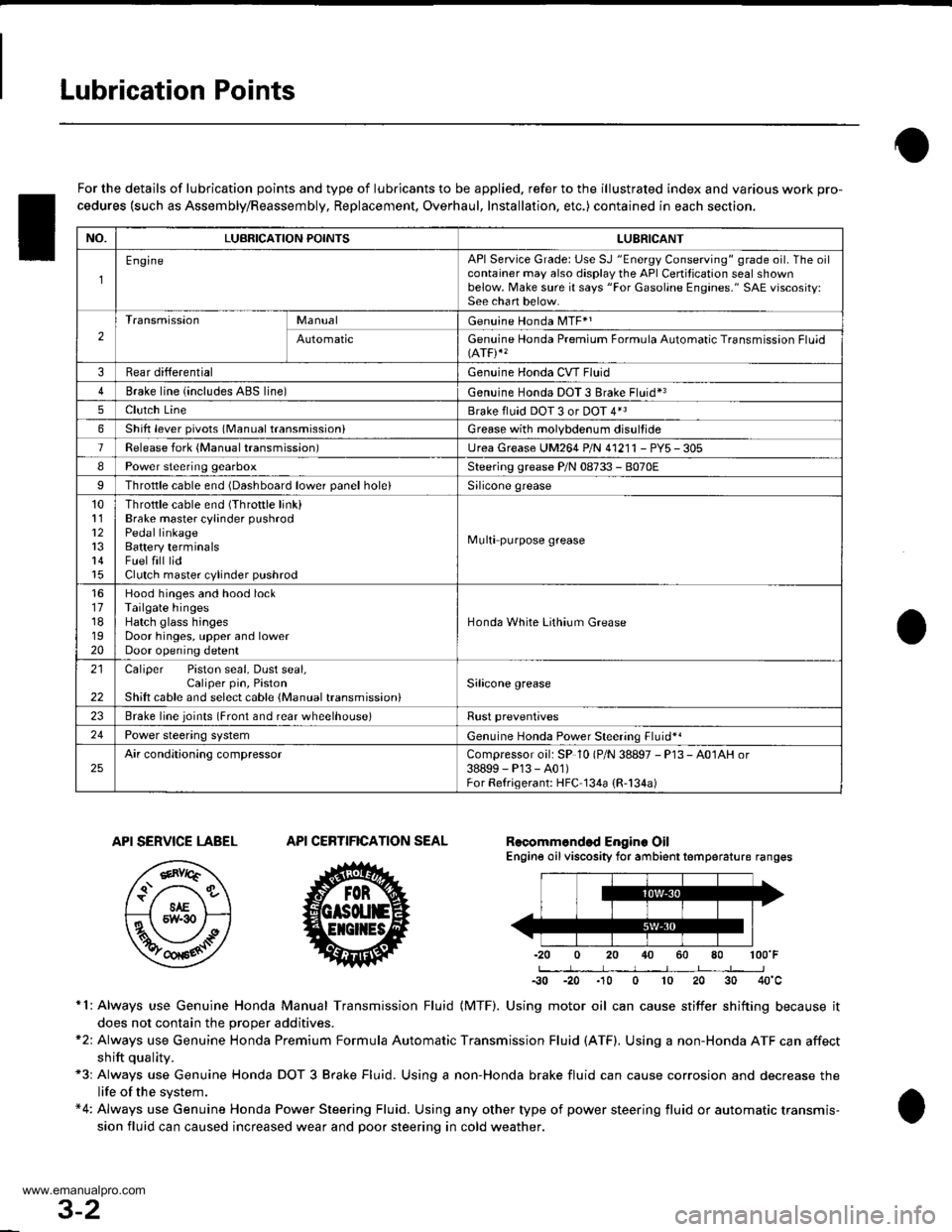

Lubrication Points

For the details of lubrication points and type of lubricants to be applied. refer to the illustrated index and various work pro-

cedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

Recomm6nded Engine OilEngine oil viscosity for ambient temperature ranges

100'F

-30 -20 .10 0 10 20 30 40'c

r1: Always use Genuine Honda Manual Transmission Fluid {MTF). Using motor oil can cause stiffer shifting because it

does not contain the orooer additives.*2: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift qualitv.+3r Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.*4: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-

sion fluid can caused increased wear and poor steering in cold weather.

API SERVICE LABEL

/,.*-G\

/.'z-\e\t/6AE\ll-;-1 5w-30 /---l

w

API CERTIFICATION SEAL

ffi-20 0 20

NO.LUBRICATION POINTSLUBRICANT

EngineAPI Service Grade: Use SJ "Energy Conserving" grade oil. The oilcontainer may also display the API Certitication seal shownbelow. Make sure it says "For Gasoline Engines." SAE vjscosity:See chart below.

2

TransmissionManualGenuine Honda MTF*1

AutomaticGenuine Honda Premium Formula Automatic Transmission Fluid(ATF)*'

3Rear differentialGenuine Honda CVT Fluid

4Brake line (includes ABS line)Genuine Honda DOT 3 Brake Fluid*3

5Clutch LineBrake fluid DOT 3 or DOT 4*3

6Shift lever pivots (Manual transmission)Grease with molybdenum disultide

1Release fork (Manual transmission)LJrea Grease UM264 P/N 4'1211 - PYs - 305

IPower steering gearboxSteering grease P/N 08733 - B070E

Throttle cable end {Dashboard lower panel holelSilicone grease

10l112

14

Throttle cable end (Throttle link)Brake master cylinder pushrodPedal linkageBattery terminalsFuelfill lidClutch master cylinder pushrod

Multi purpose grease

1617181920

Hood hinges and hood lockTailgate hingesHatch glass hingesDoor hinges, upper and lowerDoor opening detent

Honda White Lithium Grease

21

22

Caliper Piston seal, Dust seal,Caliper pin, PistonShilt cable and select cable {Manual transmission)Silicone grease

23Brake line ioints (Front and rear wheelhouse)Rust preventives

24Power steering systemGenuine Honda Power Steering Fluid-.

25Air conditioning compressorCompressor oil: SP 10 lP/N 38897 - P13 - A0lAH or38899-P13-A01)For Refrigerant: HFC 134a (R,134a)

3-2

www.emanualpro.com

Page 427 of 1395

Transaxle

Clutch ...........12-1

Manual Transmission ............................ 13-1

Automatic Transmission .................. ..... 1 4-1

Differential ... 15-1

Driveshafts ... 16-1

www.emanualpro.com

Page 448 of 1395

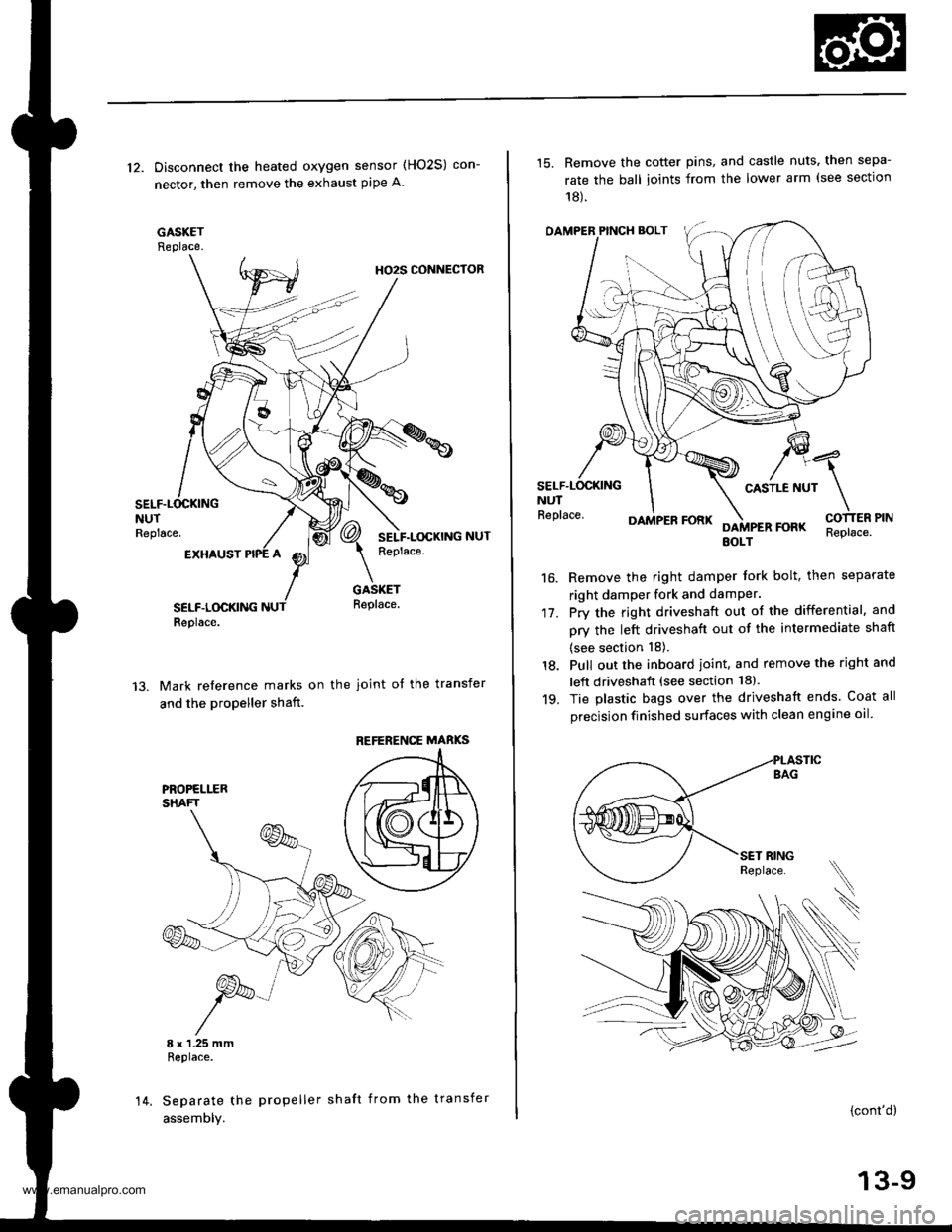

12. Disconnect the heated oxygen sensor (HO2S) con-

nector, then remove the exhaust pipe A.

GASKETReplace.

HO2S CONNECTOR

NUTReplace.

EXHAUST

SELF.LOCKINGReplace.

GASKETReplace.

Mark reference marks on the joint of the transfer

and the propeller shaft.

8 x 1.25 mmReplace.

Separate the propeller shaft from the transfer

assemDly.

REFERENCE MABKS

14.

15. Remove the cotter pins, and castle nuts. then sepa-

rate the ball ioints from the lower arm (see sectlon

18).

OAMPER PINCH BOLT

CASTLE NUTNUTReplace.

17.

16.

DAMPER FORKFOFKEOLTReplace.

Remove the right damper tork bolt, then separate

right damper fork and damPer.

Pry the right driveshaft out of the differential, and

pry the left driveshaft out of the intermediate shaft

(see section 18).

Pull out the inboard ioint, and remove the right and

left driveshaft (see section 18).

Tie plastic bags over the driveshatt ends. Coat all

precision finished surfaces with clean engine oil

18.

19.

\

{cont'd}

13-9

www.emanualpro.com

Page 451 of 1395

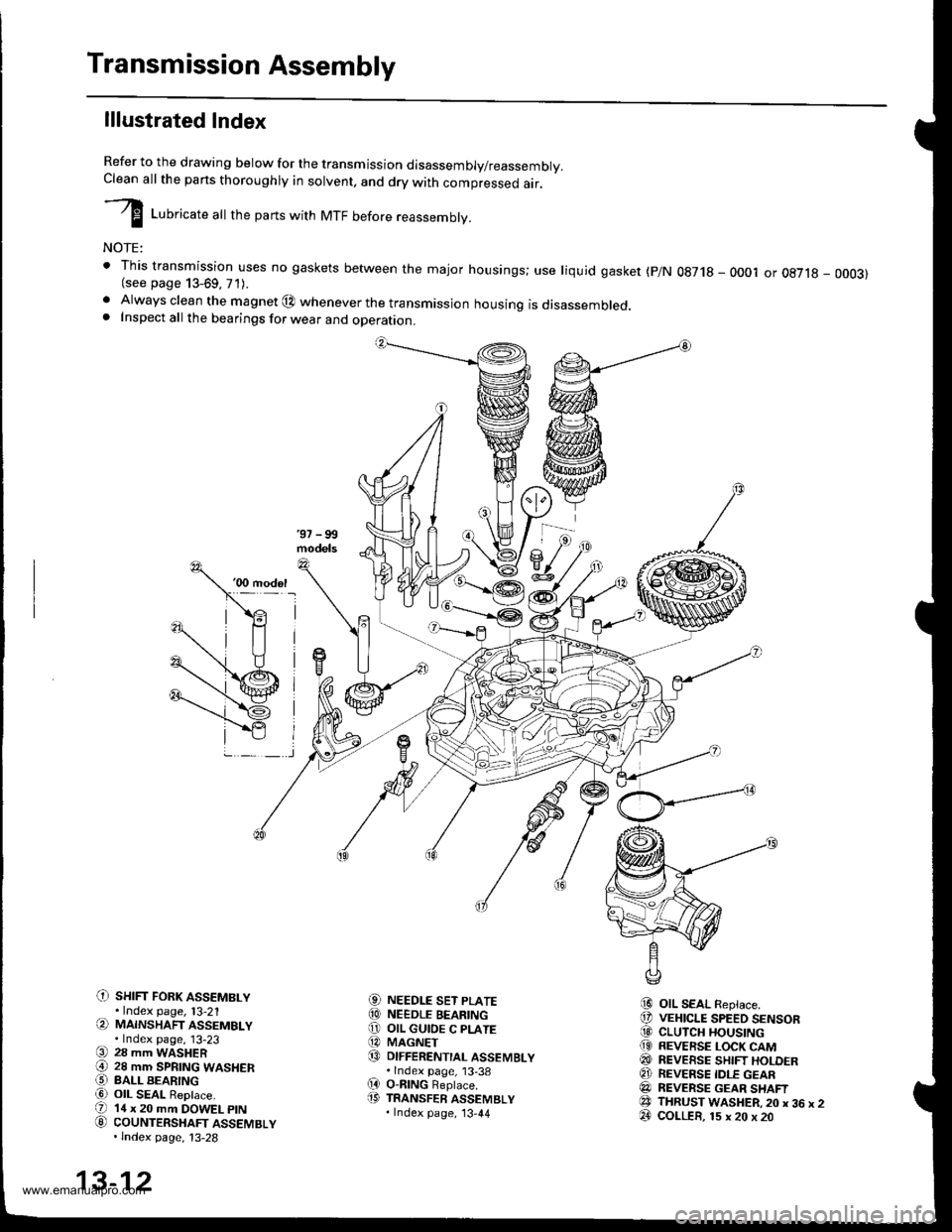

Transmission Assembly

lllustrated Index

Refer to the drawing below for the transmission disassembly/reassembly.Clean all the pans thoroughly in solvent, and drv with comoressed air.

I LuUri""r" utt the parts with MTF before reassembly.

NOTE:

t This transmission uses no gaskets between the major housings; use liquid gasket (p/N 0g718 - 0001 or oE7l8 - 0003)(see page 13-69, 71).. Always clean the magnet @ whenever the transmissjon housing is disassembled.. Inspect all the bearings for wear and operation.

C) sHrFr FoRK ASSEMBLY.Index page, l3-21(a MAINSHAFT ASSEMBLY.Index page, 13-23(9 28 mm WASHER€) 28 mm SPRTNG WASHERO BALL BEARINGa6) OIL SEAL ReDlace.(D 14 x 20 mm DOWEL ptN

G) couNTERSHAFT ASSEMBLY.lndex page, 13-28

NEEDLE SET PLATENEEDLE BEARINGOIL GUIOE C PLATEMAGNETDIFFERENTIAL ASSEMBLY.lndex page, 13-38O-nlNG Beplace.TRANSFER ASSEMBLY.Index page, '13,44

OIL SEAL Replace.VEHICLE SPEED SENSORCLUTCH HOUSINGREVERSE LOCK CAMREVEESE SHIFT HOLDERREVERSE IDLE GEARREVERSE GEAR SHAFTTHRUST WASHER,20 x 36 x 2COLLER, 15 x 20 x 20

aol

@o@@

(D

i9

@@@(9

@@@e3@

13-12

www.emanualpro.com

Page 456 of 1395

20.

2't.

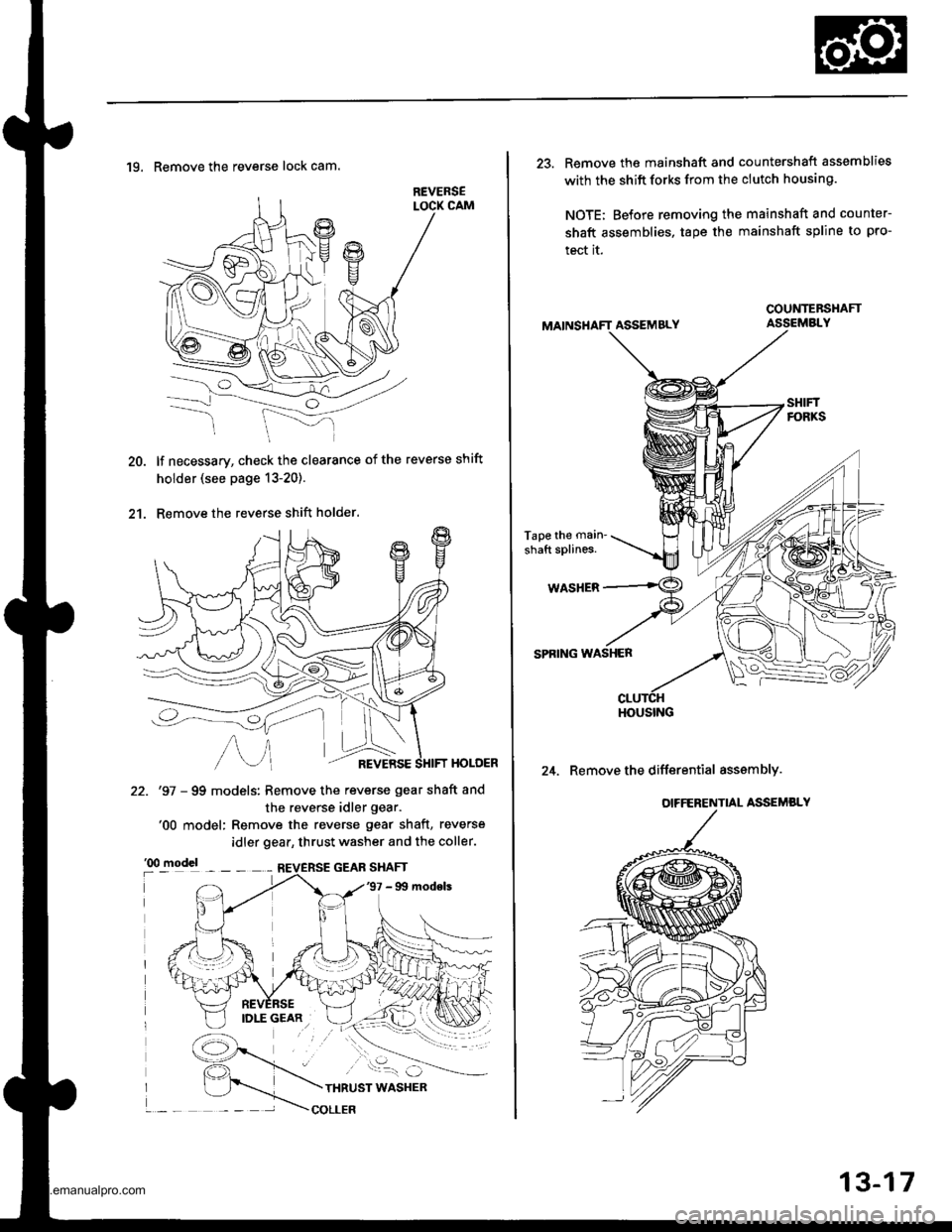

19. Remove the reverse lock cam.

lf necessary, check the clearance of the reverse shift

holder (see page 13-20).

Remove the reverse shift holder.

HOLOER

22. '97 - 99 models: Remove the reverse gear shaft and

the reverse idler gear.'00 model: Remove the reverse gear shaft, reverse

idler gear, thrust washer and the coller.

13-17

23. Remove the mainshaft and countershaft assemblies

with the shift forks from the clutch housing.

NOTE; Before removing the mainshaft and counter-

shaft assemblies, tape the mainshaft spline to pro-

tect it.

ASSEMBLY

Tape the main'

shaft splines.

WASHER

SPRING WASHER

24. Remove the differential asssmbly.

COUNTEBSHAFT

HOUSING

www.emanualpro.com

Page 477 of 1395

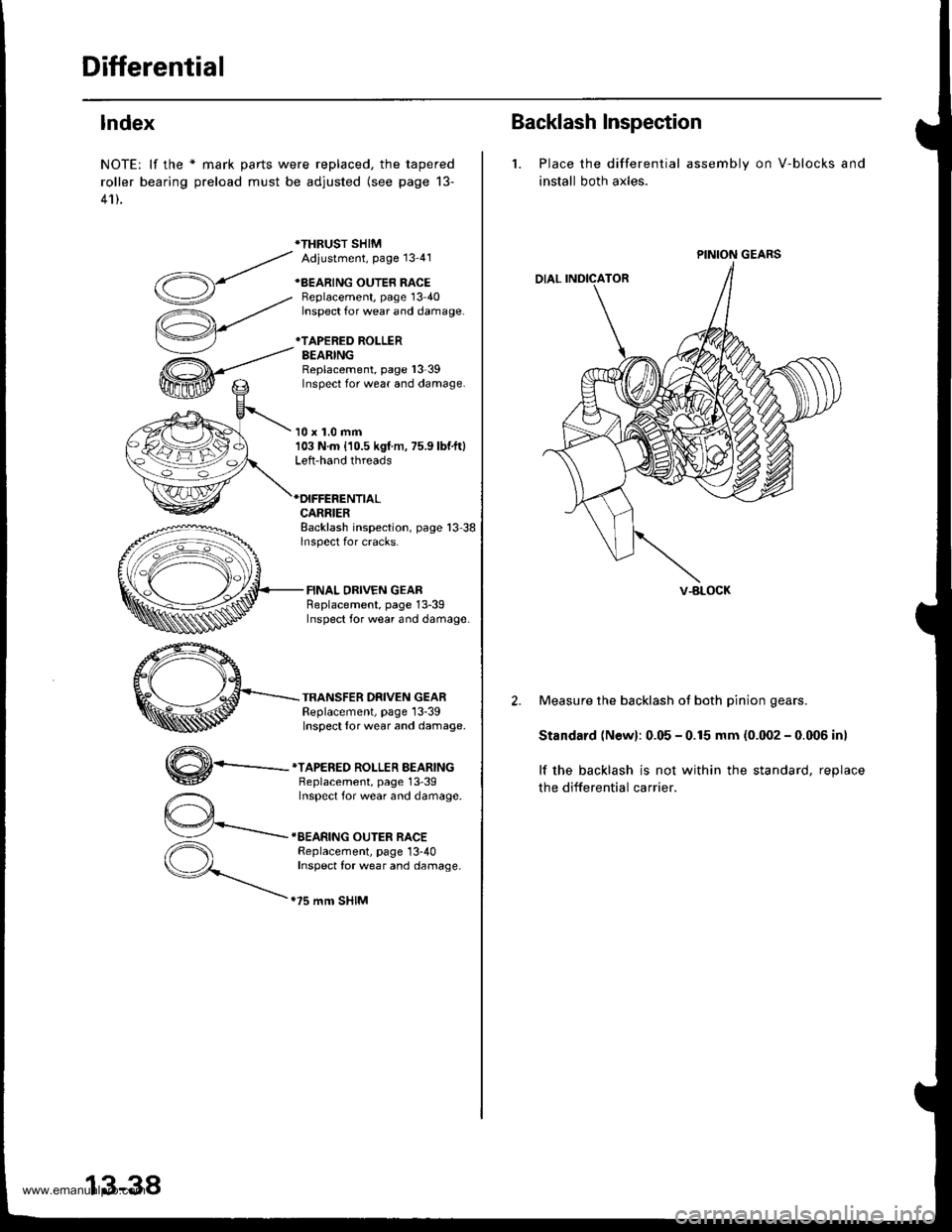

Differential

lndex

NOTE: lf the * mark parts were replaced, the tapered

roller bearing preload must be adjusted (see page 13-

41).

*THRUST SHIMAdiustment, Page 13'41

+BEARING OUTER RACEBeplacement, page 13 40Inspect for wear and damage.

*TAPERED ROLLERBEARINGReplacement, page l3-39Inspect for wear and damage.

10 x 1.0 mm103 N.m {10.5 kgf m, 75.9 lbf.ft}Left-hand threads

CARRIERBacklash inspection, page 13 38lnspect for cracks.

FINAL DRIVEN GEARReplacement, page 13-39Inspect for wear and damage

TRANSFER DRIVEN GEARReplacement, page 13-39Inspect {or wear and damage.

,,4\

W-

*TAPERED ROLLER BEARINGBeplacement, page 13'39Inspect for wear and damage.

IEEARING OUTER RACEReplacement, page 13-40Inspect for wear and damage.

.75 mm SHIM

13-38

Backlash Inspection

1. Place the differential

install both axles.

assembly on V-blocks and

PINION GEARS

V-BLOCK

2. Measure the backlash ot both pinion gears.

Standard (Newl: 0.05 - 0.15 mm (0.002 - 0.006 inl

lf the backlash is not within the standard, reolace

the differential carrier.

www.emanualpro.com