key switch HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 56 of 1395

Starting System

Starter Test (cont'dl

Check lor Wear and D8mage

The starter should crank the engine smoothly and

steadily. lf the staner engages, but cranks the engine

erratically, remove it, and inspect the starter drive gear

and torque converter ring gear or flywheel ring gear for

oamage.

Check the drive gear overrunning clutch for binding or

slipping when the armature is rotated with the drive

gear held. lf damaged, replace the gears.

Check Cranking Voltage and Current Draw

Cranking voltage should be no less than 8.7 volts on Ay'T

models, and 8.0 volts on M/T moders.

Current draw should be no more than 230 amperes on

A,/T models, and 200 amperes on M/T models.

lf cranking voltage is too low, or current draw too high,

check for:

. dead or low battery.

a open circuit in starter armature commutator seg,

ments.

. starter armature dragging.

. shorted armature winding.

. excessive drag in engine.

Check Cranking rpm

Engine speed during cranking should be above 100 rpm.

lf speed is too low, check for:

a loose baftery or starter terminals.

. excesslvely worn staner brushes

. open circuit in commutator segments.

. dirty or damaged helical splines or drive gear.

a defective drive gear overrunning clutch.

Check Starter Disengagement

With the shift lever in @ or @ position (A,iT) or with the

clutch pedal depressed {M/T). turn the ignition switch to

START (lll). and release to ON (ll).

The starter drive gear should disengage from the torque

converter ring gear or flywheel ring gear when you

release the key.

lf the drive gear hangs up on the torque converter ring

gear or flywheel ring gear, check for

. solenoid plunger and switch malfunction.

. dirty drive gear assembly or damaged overrunning

clutch.

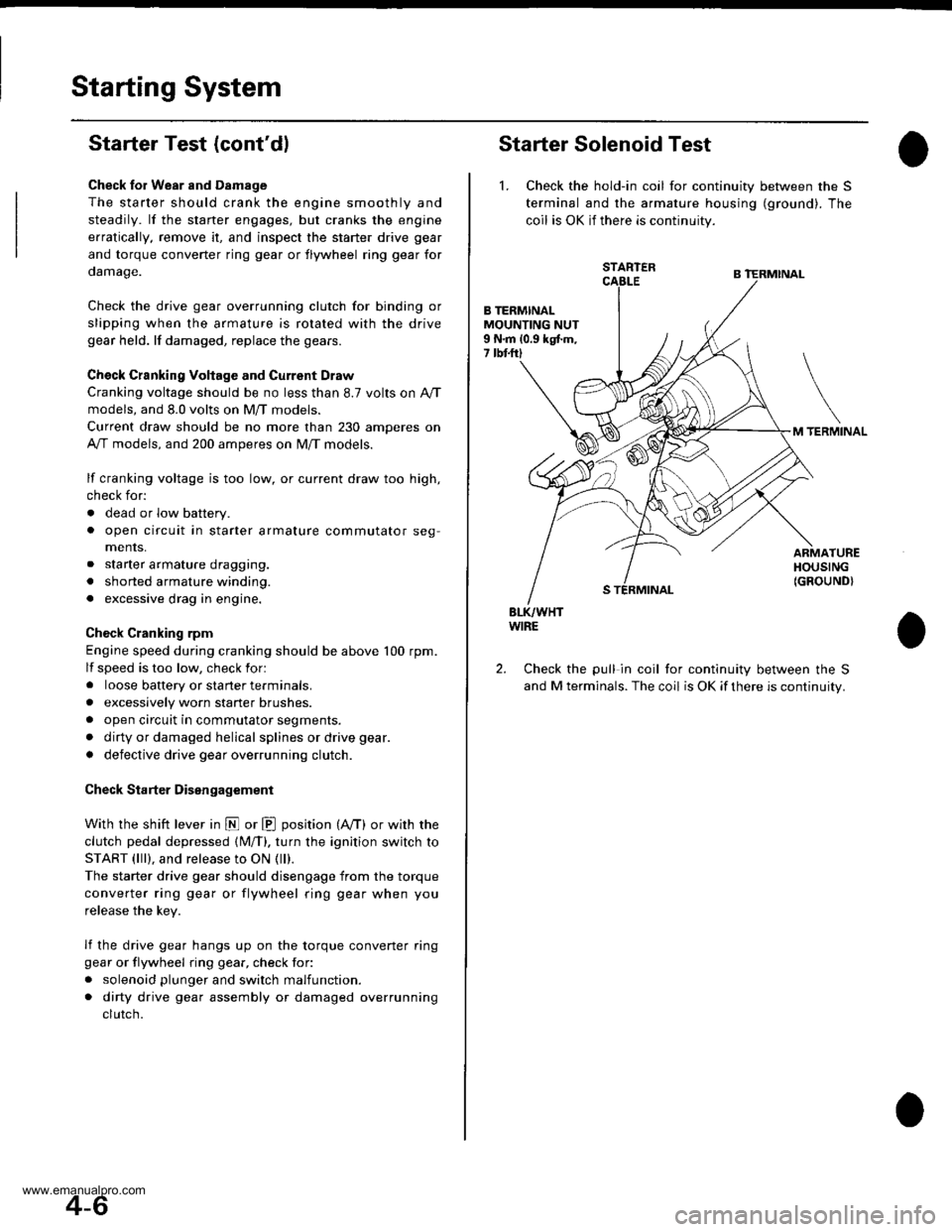

Starter Solenoid Test

1. Check the hold-in coil for continuity between the S

terminal and lhe armature housing (ground). The

coil is OK if there is continuity.

STARTER

B TERMINALMOUNTING NUT9 N.m 10.9 kgtm,7 tbtftl

TERMINAL

ARMATUREHOUSING(GROUND}

BLK/WHTWIRE

Check the pull in coil for continuity between the S

and M terminals. The coil is OK if there is continuity.

2.

4-6

www.emanualpro.com

Page 517 of 1395

Automatic Transmission

Special Tools . 14'2OescriptionGeneral Operation . .... 14 3Power Flow . . .. '14_6

Electronic Control System .. .. . . .. .14_15Hydraulic Control .. 14 24Hydraulic Flow....-....... .. . .... .. .. . 14_29Lock'up Syslem .. .'t4'39Electrical SystemComponenl Locdlrons 14 45

PCM Circuil Dragram (A/T Control Svstem)'97 Model ....................... . . .. - . ... .14-46'98Model ................. . ... .. .. .1450'99 00Models.... . .... . . . 1452

PCM Terminal Voltage/Measuring ConditionsA"/T Control System-'97Model ...... ..14'48A,/T Control System -'98 00 Models . . .. . . 14 54

Troubleshooting Procedures .. ..... ... - 14_56Svmotom to comoonent CharlEiectr,cal Syslem -'97 Model . . 14 60Electrical System -'98 - OO Models . .. . . 14_62Electrical Troubleshooting ('97 Model)Troubleshooting Flowaharts .... ..... . .. . . 14_64

Electrical Troubleshooting ('98 - 00 Models)Troubleshootinq Flowclt"n" .... . ....- . .14-93ElectricalTroublesliooting('99 00Models)Troubleshootino FlowchartO/D OFF Indicator Light Does Not Come On 14 131

O/D OFF Indicator Liaht On ConstantlY . . . .1!-132O/D OFF Indicator Light Does Not Come OnEven Though O/D Switch ls Pressed . .... - 14_133

Lock up Control Solenoid Valve A,/B AssemblyTest....................-......... . .14-135Replacement . .ll_135Shifr ControlSolenoid Valve Ay'B Assembl,Test .............................. . .. 14-136

Replacement..............- . .14'136Linear Solenoid AssemblYTest.............................................. .. .... . 14_137Replacement .. . 14138Marnshaftlcountershafl Speed SensorsReplacement ...-... 14_138A/T Gear Position SwitchTest ..........................-... . .. 14-139ReplacementA/T Gear Positionlndicator.................. 14-140

Valve Eodynepair ............................... ..... . . .. - . .. ... 14 192

Assembly .................... .. 1{_193

Valve CapsDesciiption....-........................ .. ...... 14194

tnspeition ................... .. 14' 195

N4ain Valve BodyDisassembly/lnspection/Reassemblv - ...... .. 14_196

Secondarv Valve BodYDisassemblv4nspectron/ReassemblY .. . 14 198

Reoulator Valve Bodvbisassembtv,lnspiction/Reassemblv . 14199

Servo EodvDisassembly/lnspection/Reassembly ... ....14'200

Lock'uo Valve BodYDis;ssembly/lnspection/Reassembly .... . 14_201

MainshaftDisassembly/lnspection/Reassembly .. .. .. ..14'202

Inspection ....-.............. ..11_203

Sealing RingsReilaceient ...... ..... . 14'204

CountershaftDisassembly/lnspection/Reassembly .. . . . . . 11-205

Disassembly/Reassemb|y . . ........ ...... . .. 14_206Inspedron ................ . .... . 14 207

One wav ClutchDisassembly/lnspection/ReassemblY ... 11_209

Sub-shaftDisassembly/lnspection/Reassembly ... . .. . 14-210

oisassembly/Re6ssembly . . ... .-...... . . ..14-211

Sub-shaft BearingsReplacement .......14'212

Clutchllfustrated Index .......... . . .14-213

Disassembly .... .. .....14-216Reassembfy .... . .. .. . 14'218

Differentialllfustrated Index " 14-222Backlash Inspection . .... . .14'223

Bearing Repiacement .. 11-223

Differe-ntial Carrier Replacement .. .. . . . .. ..11-2?4

OifSeal Replacement. . .. 14'225

Side Clearance lnspection . . - .. ... . - ...... . .. 11'226

Transmission Housing BearingsMainshaJVCountershaft EearingsRepfacement .......14221Sub'siralt Eearing Replacement . . . . . . . . . ..11'224

Toroue Converter Housing BearingsMainshattEearing/OilSe6lReplacement . .. l4229

Countershaft Bea;ing Replacement.. .... .. ..14-230

Input Test - '97 - 98 ModelsInput Test '99 - 00 Models

Symptom to-Component ChartHydraulic System ...............

Checking

Removal ...,lllustrated Index (4WD)

Interlock SystemInterlock ControlUnit lnputTest. -..... -.. .... . - 14 144* Key Interlock Solenoid Test .- .. . . . - . . . ..... 14_146* Shift Lock Solenoid Test ..............-.-. . .. . ... .... 14 147*Shift LockSolenoidReplacement...... .. . .. .. 14 148* park pin Switch Test ......... 14 119' Park Pin Switch Replacement- '97 - 98 Models ....... 14-150* Park Pin Swirch/Over Drive (O/Di SwitchReplacemenl '99-00Models . .. 14_151over-Drive (O/D) Switch {'99 00 [4odels]Test........_..................... .......14-152Hydr.ulic System

..............._............... t4 142.................................. 14-143

Control Lever AssemblyR6placement ......,.,Reverse ldler Gear

lllustrated lndex

.......... 14-230

14 231

11-231

1nsta1|ation ..................Park StopInspeclion/AdjustmenlTransfer AssemblY.......14.232

RoadTest.............-.... ........ .StallSpeedTest ....._........................ ....... 14-159Fluid Level......_................... 14'160

Disessembly .................... 14-235Transfer Drive Gear BearingReplacementTrans{er Driven Gesf Shaft BearingReplacementTransfer Housing Roller BearingReplacementTransfer Cov€r A Bearing Outer RaceReplacementTransfer Housing Bearing Outer RaceReplacement ......-..,,,,,.....ReassemblvTransmassaonBeassembly ... -.. .... .14 250

Torque Converier/Drive Plate . .-. .... .. . ... .....14_258

Transmissionlnstatlation .................. ....... 14'259

Cooler Flushing . . ......11-261ATF Cooler HosesConnection.................. ....... 14-266I Shift LeverRemoval/lnstallation . .. 14'261

Disassemblv/Reassemblv - '97 - 98 Models . . 14_264

Disassembli/Reassemblv -'99 - 00 Models . 14-269

Over'Orive (O/D) Switch WireClearanceAdjustment. - ... . . . .. .. . 14'270

Detent Spring Replscement . . -.. ... .14'271*Shift CableAdiustment ....... 14'272

Repfacement.............. . 11'273

14 15711-237

11-237

14-238

$-234

11-23914-240

Transmigrion

Inspeclron ....., ...........Transfer AssemblyRemova1,.,,,..............,lnstallalion ........... .. ...Transmission

14 164

14-16514,167

14-169

End Cover/Transmissio . 14'174Transmission Housing .... ... .. . . .... .. 14-176Torque Converter Housingly'alve Body.. - ... -. 14 178

lllustrated lndex (2WD)End Cover/Transmissio ....... 14 180Transmission Housing . . ... . .. .... ... 14'182Torque Convener Housing/r'alve Body ......- 14-184

End CovefRemovat ...................... ....... 14'186Transmission HousingRemoval ...................... .. 14_188Torque Convener HousingA/alve BodYRemovat ................-..... .-..... 14-190

www.emanualpro.com

Page 577 of 1395

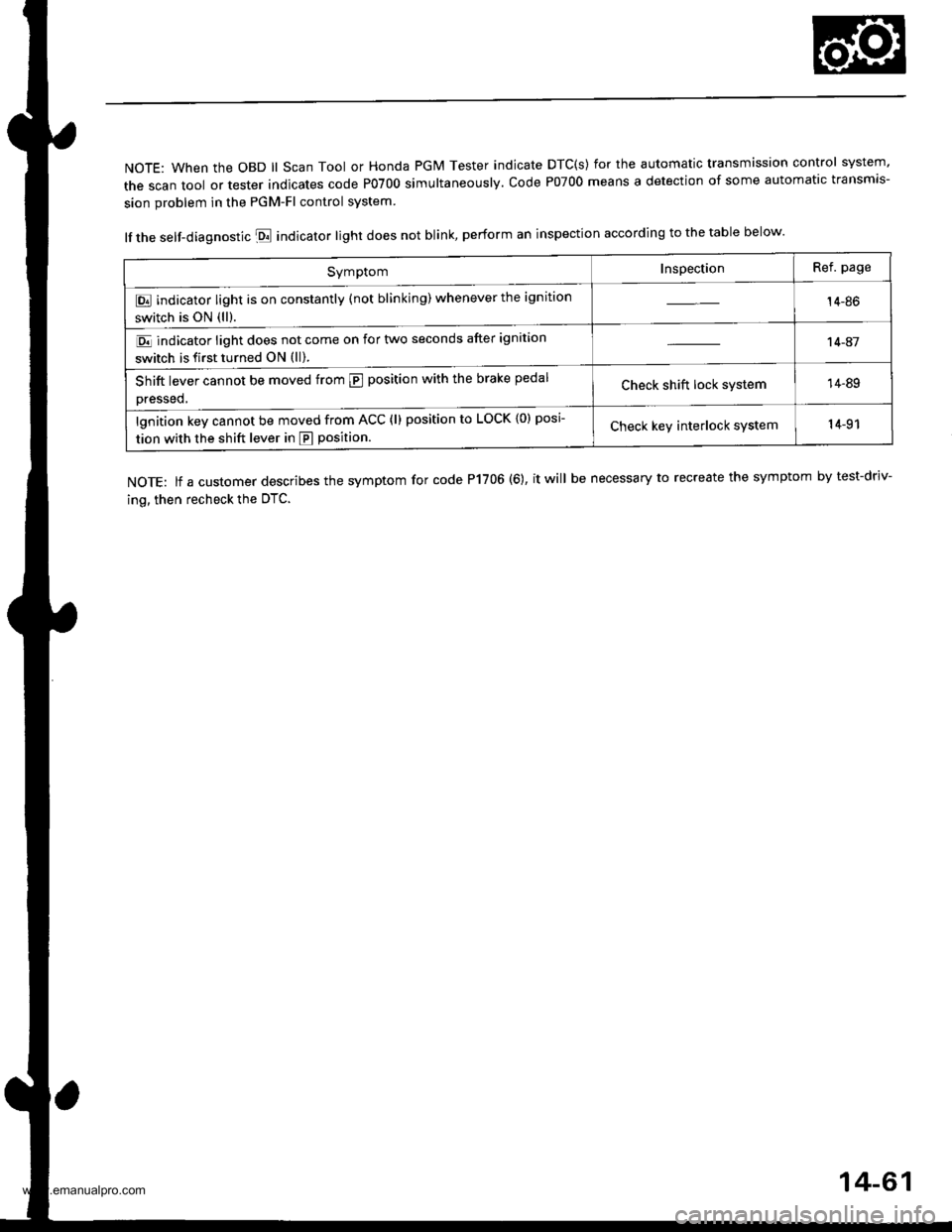

NOTE: When the OBD ll Scan Tool or Honda PGM Tester indicate DTC(s) for the automatic transmission control system'

the scan tool or tester indicates code P0700 simultaneously. code P07oo means a detection of some automatic transmis-

sion problem in the PGM-Fl control system

lf the self-diagnostic E indicator light does not blink, perform an inspection according to the table below.

NOTE: lf a customer describes the symptom for code P1706 (6), it will be necessary to recreate the symptom by test-driv-

ing, then recheck the OTC.

SymptomInspectionRef. page

E indicator light is on constantly (not blinking) whenever the ignition

switch is ON (ll).14-86

E indicator light does not come on for two seconds after ignition

switch is first turned ON (ll).

't 4-41

Shift lever cannot be moved from @ position with the brake pedal

Dressed,Check shift lock system14-89

lgnition key cannot be moved from ACC (l) position to LOCK {0) posi

tion with the shift lever in E position.Check keY interlock system14-91

14-61

www.emanualpro.com

Page 579 of 1395

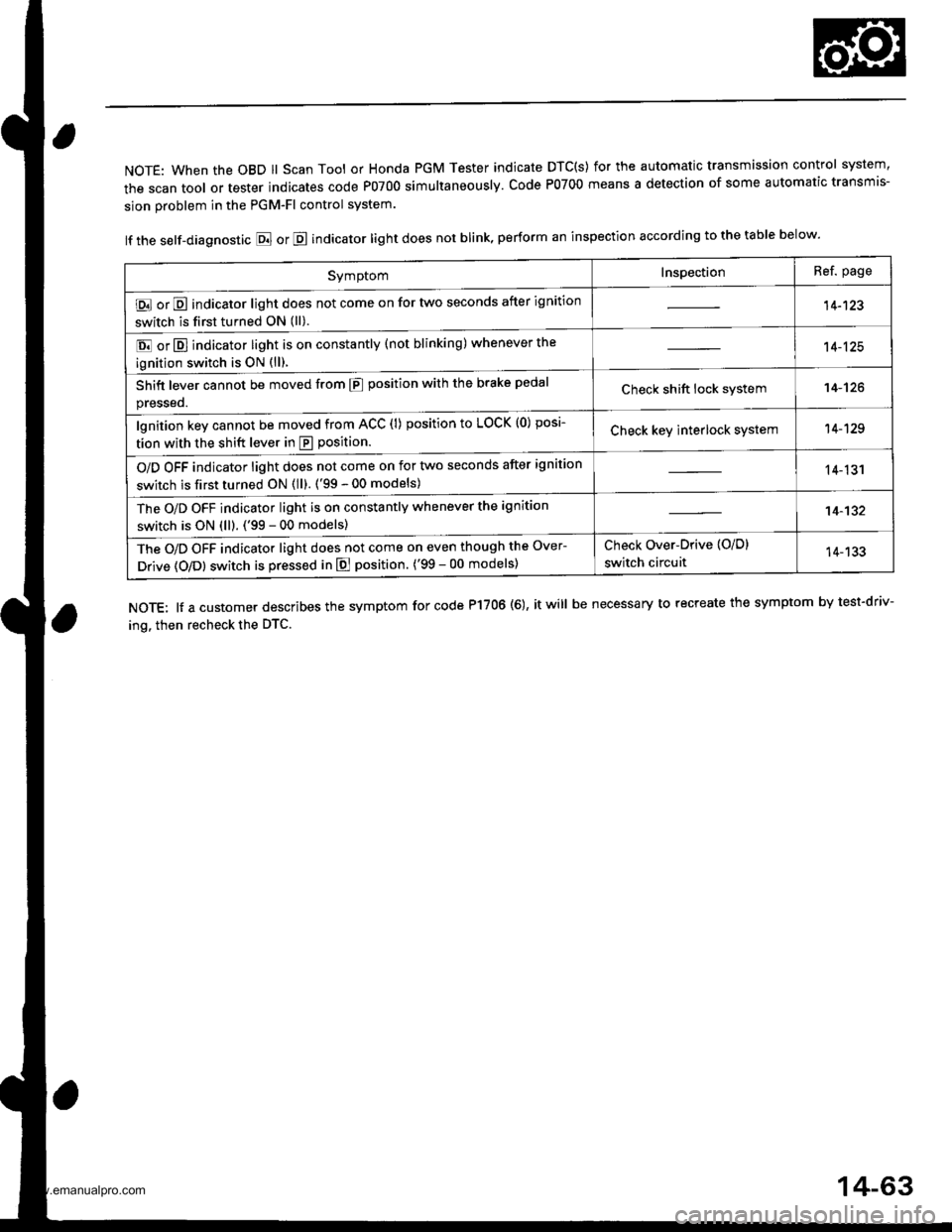

NOTE: When the OBD ll Scan Tool or Honda PGM Tester indicate DTC(S) for the automatic transmission control system,

the scan tool or tester indicates code P0700 simultaneously. Code P0700 means a detection of some automatic transmis-

sion problem in the PGM-Fl control system.

lf the self-diagnostic E or E indicator light does not blink, perform an inspection according to the table below.

NOTE: lf a customer describes the symptom for code P17OO (6), it will be necessary to recreate the symptom by test-driv-

ing. then recheck the DTC.

SymptomInspectionRef. page

E or E indicator light does not come on for two seconds after ignition

switch is first turned ON (ll).14-123

E or E] indicator light is on constantly (not blinking) whenever the

ignition switch is oN {ll).

14-125

Shift lever cannot be moved from E position with the brake pedal

presseo.Check shift lock system14-'t26

lgnition key cannot be moved from ACC (l) position to LOCK (0) posi-

tion with the shift lever in E position.Check key interlock system14-129

O/D OFF indicator light does not come on for two seconds after ignition

switch is first turned ON (ll). ('99 - 00 models)14-131

The O/D OFF indicator light is on constantly whenever the ignition

switch is ON (ll). ('99 - 00 models)14-132

The O/D OFF indicator light does not come on even though the Over-

Drive (O/Dl switch is pressed in E position. ('99 - 00 models)

Check Over-Drive {O/D}

switch circuit14-133

14-63

www.emanualpro.com

Page 607 of 1395

![HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont](/img/13/5778/w960_5778-606.png)

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SW]TCH 6P CONNECTOR

KEY LOCK SOL

{WHT/BLU)

ACC PUSH SW (WHT/YELI

Wire side oI female terminals

KEY LOCK SOL(WHT/BLUI

(cont'd)

lgnition key cannot be moved

Irom ACC (l) pGition to LOCK (0)

position while Pushing the igni-

tion kev with the shift lever in lllposifio;, and the shift lever but-

ton rcleased.

Check Key Interlock Solenoid

Op€ration:1. Disconnect the ignition switch

connector (6P).

2. Connect the No. 4 terminal of

the ignition switch 6P connec-

tor to the battery Positive ter

minal, and connect the No. 3

terminal to the battery nega

tive terminal.3. Check the key interlock sole

noid operation A clicking

so!nd sho!ld be heard.

Faulty koy interlock solenoid.

Replace the ignition key cylinder/

steedng lock as36mbly

Does the key interlock

solenoid operate properly?

Check Key Interlock Switch OPer'

adon:1. Connect the No. 5 terminal of

the ignition switch connector

to the battery Positive termi

nal, and connect the No 3 ter

minal to the baftery negative

termrnal,2. Turn the ignition switch to

ACC (l), then push rt.

3. Check the key interlock sole'

noid operation. A clicking

sound should be heard whilepushing the ignition key.

Faulty key inte.lock switch

Replaco the ignition key cylindor/

stoering lock a3r.mblY.

Does the key interlocksolenoid operate ProPerlY?

To page 14 92

14-91

www.emanualpro.com

Page 608 of 1395

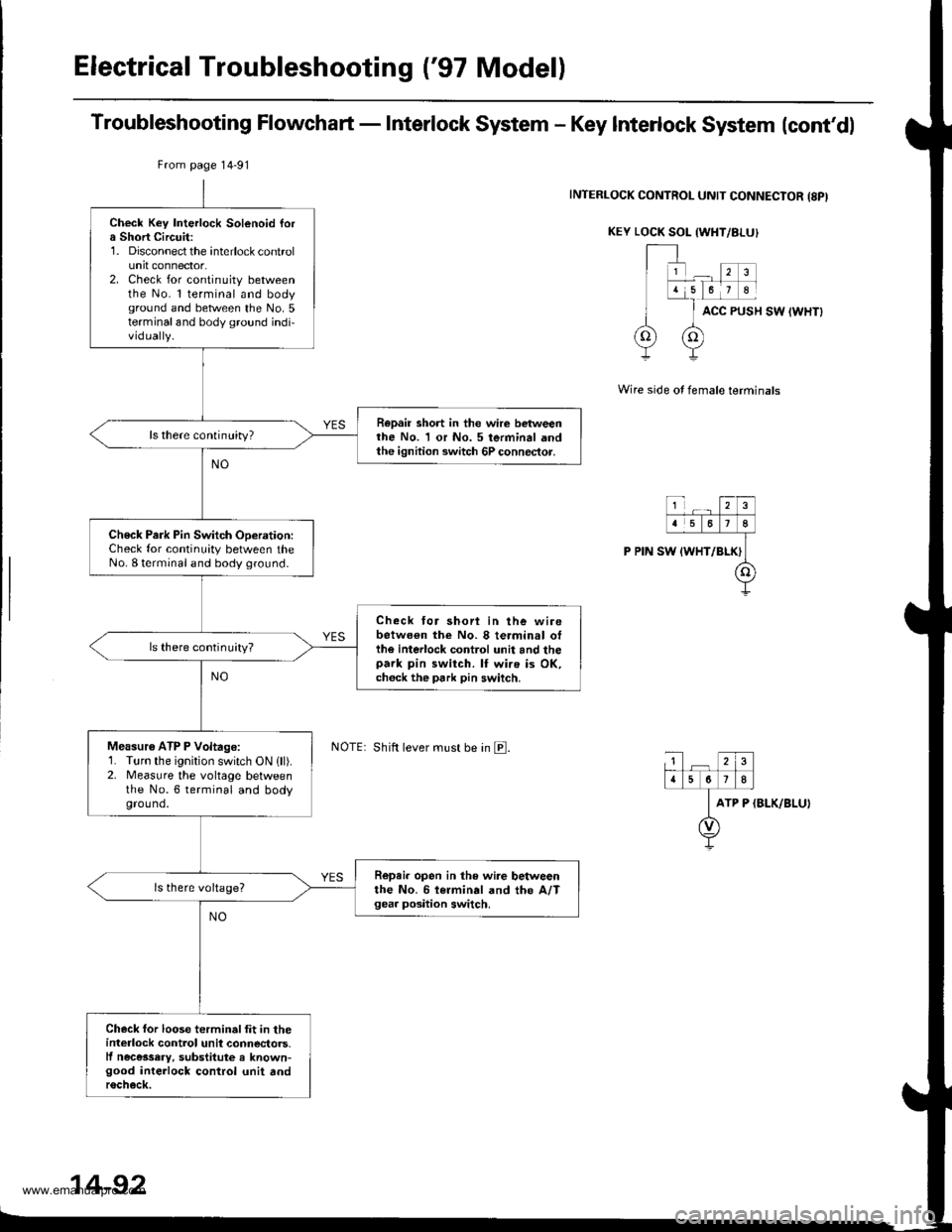

Electrical Troubleshooting {'97 Model)

Troubleshooting Flowchart - Interlock System - Key Interlock System lcont'dl

INTERLOCK CONTROL UNIT CONNECIOR {8PI

KEY LOCK SOL {WHT/8I-UI

ACC PUSH SW IWHTI

Wire side of female terminals

ATP P (BLK/BLU)

Check Key Interlock Solenoid fora Short Circuit:1. Disconnect the interlock controlunit connector.2. Check for continuity betweenthe No. l terminal and bodyground and between the No.5terminaland body ground indi-vidually.

Repair short in the wire betweenthe No. 1 or No. 5 terminal andthe ignition switch 6P connector.

ls there continuity?

Check Park Pin Switch ODeration:Check for continuity between theNo. I terminal and body ground.

Check tor shori in the wirebetwo€n the No. 8 terminal otthe interlock control unit and thepark pin switch. lf wire is OK,ch6ck the park pin switch.

ls there continuity?

Measu16 ATP P Voltage:1. Turn the ignition switch ON lll).2. Measure the vohage betweenthe No.6 terminal and bodyground.

R6pei. open in the wire betweenthe No. 6 i€rminal and the A/Tgea. position switch.

Check for loose terminalfit in theinterlock control unil connectors.lf necessery, substitute a known-good interlock control unit andr6check.

From page 14-91

Shift lever must be in E.

14-92

www.emanualpro.com

Page 645 of 1395

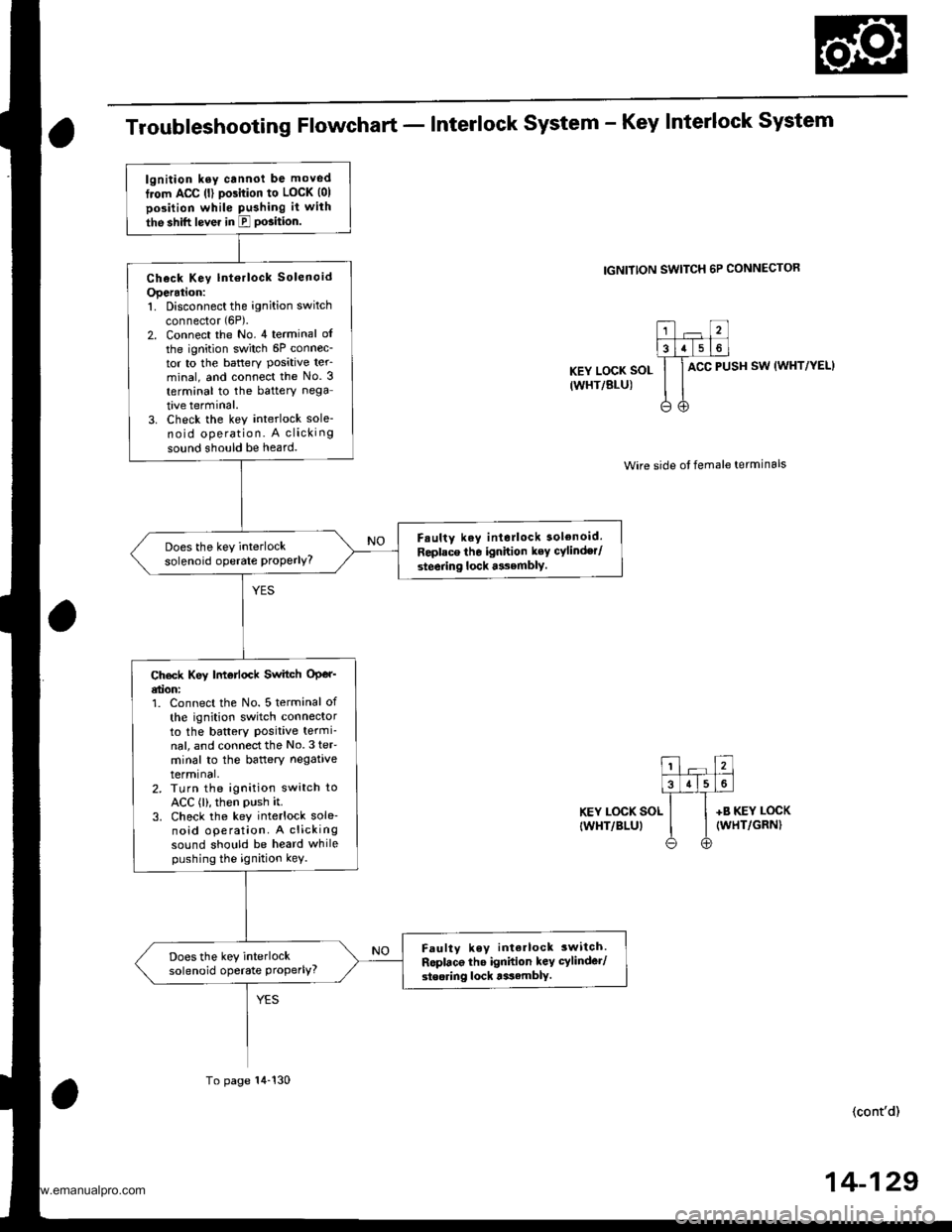

Troubleshooting Flowchart - Interlock system - Key Interlock system

IGNITION SWITCH 6P CONNECTOR

KEY LOCK SOL

IWHT/BLU)

ACC PUSH SW (WHT/YEL}

Wire side ot female terminals

KEY LOCK SOL

IWHT/BLUI

+B KEY LOCK(WHT/GRN)

(cont'd)

lgnition ksy cannot be moved

from ACC (l) pGition to LOCK (01

position while Pushing it with

the shift lever in E PGition.

Check Key lntorlock Solenoid

Operation:1. Disconnect the ignition switch

connector (6P).

2. Connect the No. 4 terminal of

the ignition switch 6P connec-tor to the battery Posative ter_minal, and connect the No. 3

terminal to the battery nega

tive terminal.3. Check the key interlock sole-no id operation. A clicking

sound should be heard.

F.ulty key interlock solenoid.

Replace tho ignition key cylinder/

steering lock asembly.

Does the key interlocksolenoid operate ProPerlY?

Ch€ck Key |motlock Switch OPer'etion:1. Connect the No. 5 terminal of

th€ ignition switch connectorto the battery Positive termi-nal, and connectthe No.3 teF

minal to the baftery negativetermrnal,2. TLrrn the ignition switch toACC (l), then PUsh it.3. Check the key interlock sole-noid operation. A clickingsound should be heard whilepushing the ignition kev.

Faulty key interlock 3witch.

Roplaco the ignidon key cylinder/

steoring lock tssamblY.

Does the key interlocksolenoid operate Properly?

To page 14-130

14-129

www.emanualpro.com

Page 646 of 1395

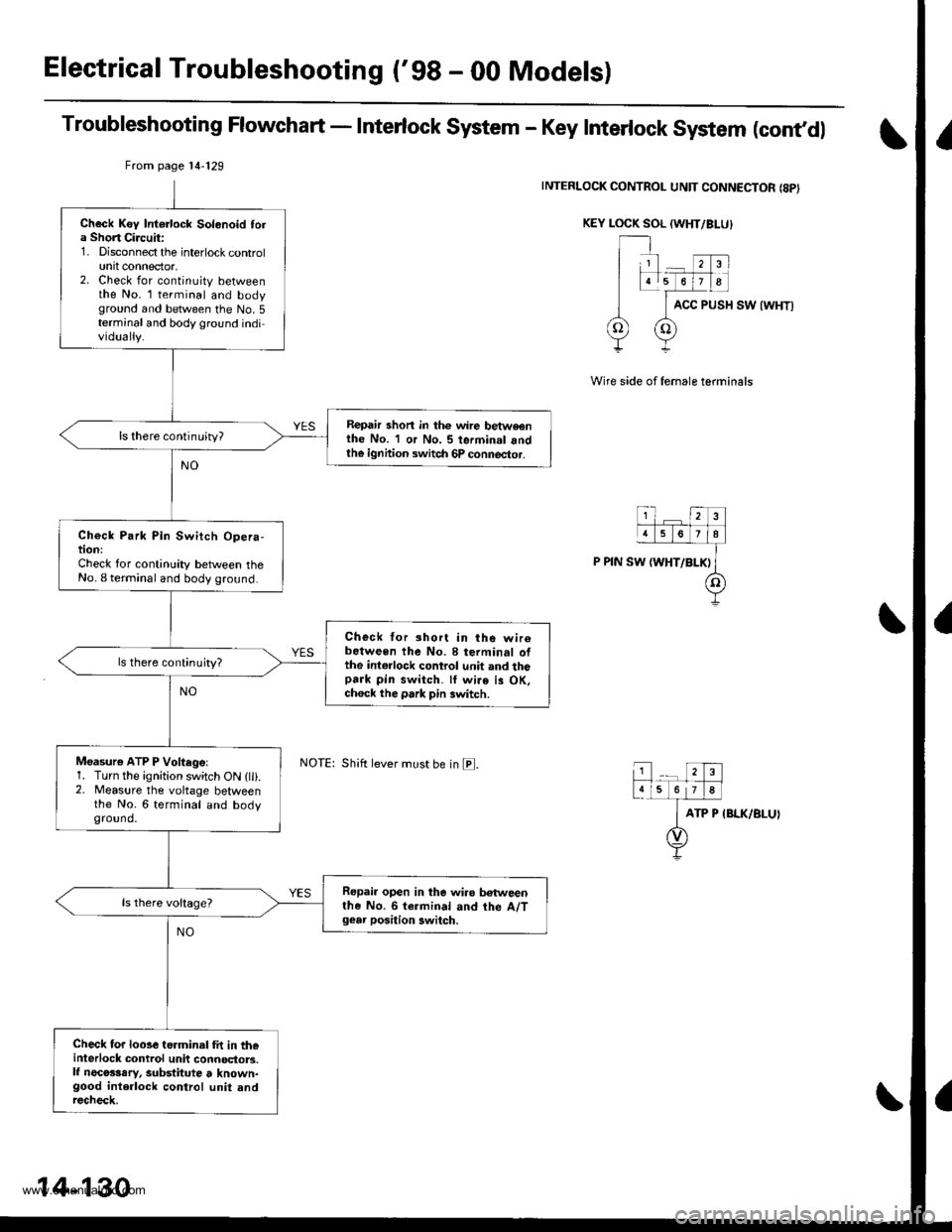

Electrical Troubleshooting ('98 - 00 Models)

Troubleshooting Flowchart - Interlock System - Key Interlock System (cont,dl

INTERLOCK CONTROL UNIT CONNECTOR {8PI

KEY LOCK SOL (WHT/BI-U}

ACC PUSH SW {WHT)

Wire side of female terminals

ATP P IBLK/BLUI

From page 14'129

Shift lever must be in E.

Check Key Intorlock Solonoid tola Short Circuit:1. Disconnect the interlock controlunit connector,2. Check for continuity betweenthe No. l terminal and bodyground and between the No.5terminal and body ground individually.

Repair shon in thc wire betweonthe No. 1 or No. 5 terminal andth€ ignhion switch 6P connector.

ls there continuity?

Check Park Pin Switch Opera-tion:Check for continuity between theNo. I terminal and body ground.

Check for short in the wir6between the No. 8 terminal ofthe int€rlock control unit and thopark pin switch. ll wire is OK,ch6ck the park pin switch.

ls there continujty?

Moasure ATP P Voftegel1. Turn the ignition switch ON (lli.2. Measure the voltage betweenthe No. 6 terminal and bodyground.

Repair open in the wiro betweenthe No. 6 termin.l and the A/Tgear position 3witch.

Check for looseterminal fit in th€interlock control unit connoctors.lf necosssry, substitute t known-good interlock control unit andrecheck.

14-130

www.emanualpro.com

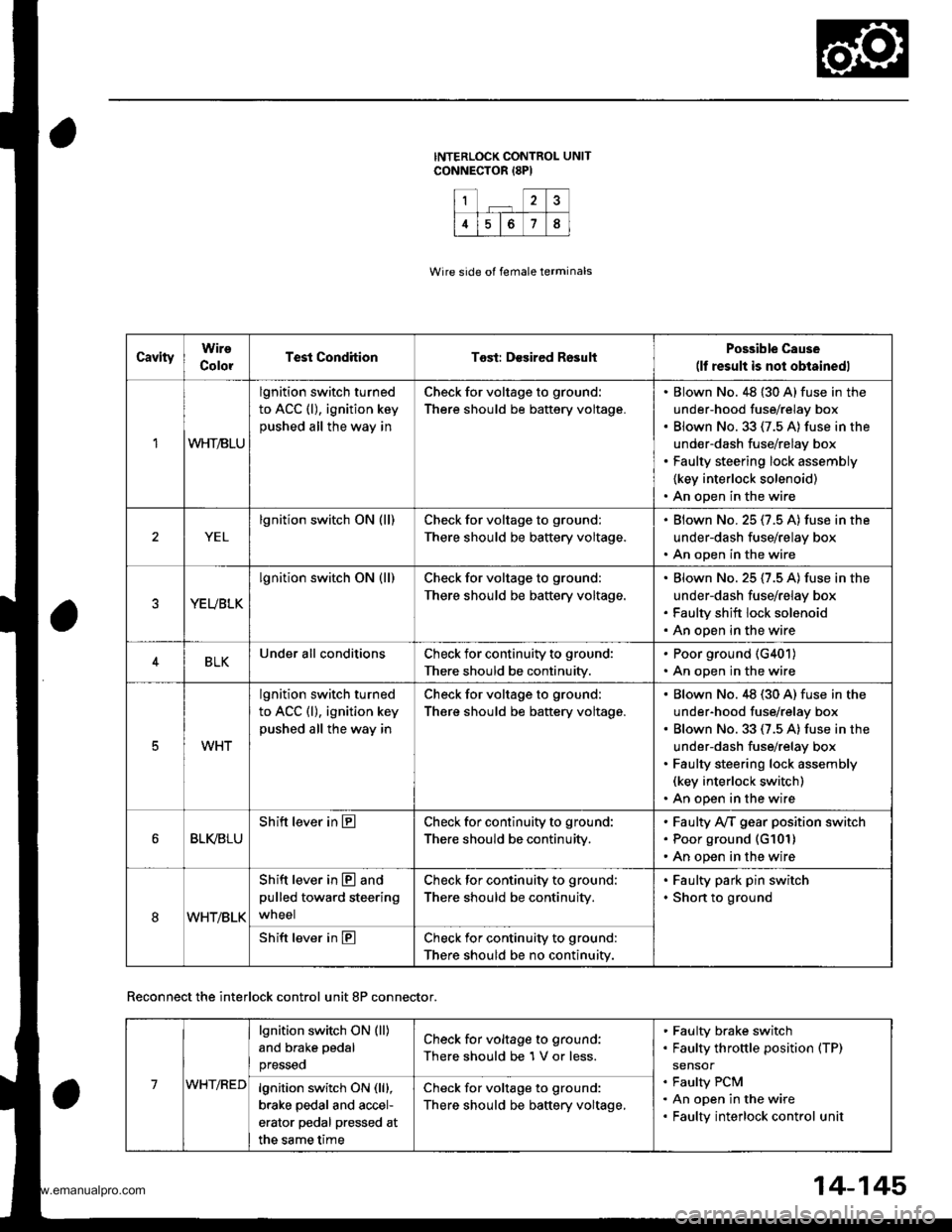

Page 661 of 1395

1?

4678

CavityWire

ColorTest CondhionTost: Desired RosultPossible Cause(lf result is not obtainedl

1WHT/BLU

lgnition switch turned

to ACC (l), ignition key

pushed all the way in

Check for voltage to ground:

There should be battery voltage.

Blown No. 48 {30 A} fuse in the

under-hood fuse/relay box

Blown No.33 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty steering lock assembly

{key interlock solenoid)

An open in the wire

YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

Blown No.25 (7.5 A) fuse in the

under-dash fuse/relay box

An open in the wire

YEUBLK

lgnition switch ON (ll)Check for voltage to ground:

There should be baftery voltage.

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty shift lock solenoid

An open in the wire

4BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401)

. An open in the wire

5WHT

lgnition switch turned

to ACC (l), ignition key

pushed all the way in

Check for voltage to ground:

There should be battery voltage.

Blown No.48 (30 A) fuse in the

under-hood fuse/relay box

Blown No. 33 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty steering lock assembly(key interlock switch)

An open in the wire

BLI(BLU

Shift lever in ECheck for continuity to ground:

There should be continuity,

Faulty Ay'T gear position switch

Poor ground (G101)

An open in the wire

8WHT/BLK

Shift lever in @ and

pulled toward steering

wneel

Check for continuity to ground:

There should be continuity.

Faulty park pin switch

Shon to ground

Shift lever in ECheck for continuity to ground:

There should be no continuity.

Wire side of female terminals

Reconnect the interlock control unit 8P connector.

14-145

7WHT/RED

lgnition switch ON (ll)

and brake pedal

presseo

Check for voltage to ground:

There should be 1 V or less.

Faulty brake switch

Faulty throttle position (TP)

sensor

Faulty PCM

An open in the wire

Faulty interlock control unit

lgnition switch ON (lll,

brake pedal and accel-

erator pedal pressed at

the same time

Check for voltage to ground:

There should be baftery voltage,

www.emanualpro.com

Page 662 of 1395

lnterlock System

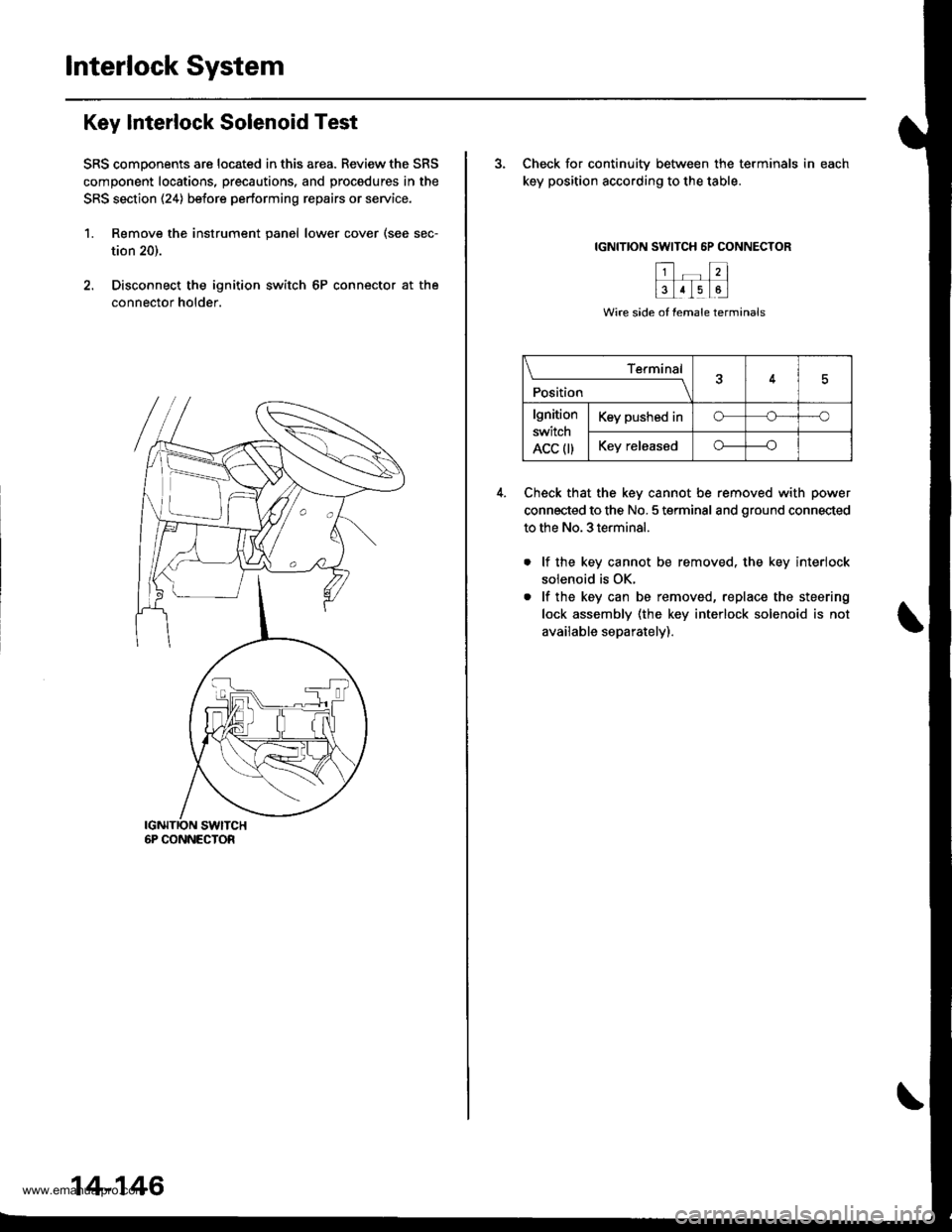

Key Interlock Solenoid Test

SRS comoonents are located in this area. Review the SRS

component locations, precautions. and procedures in the

SRS section (24) before pertorming repairs or service.

1. Remove the instrument panel lower cover (see sec-

tion 20).

2. Disconnect the ignition switch 6P connector at the

connector holder.

6P CONNECTOR

14-146

3. Check for continuitv between the terminals in each

key position according to the table.

IGNITION SWITCH 6P CONNECTOR

Check that the key cannot be removed with power

connected to the No. 5 terminal and ground connected

to the No. 3 terminal.

lf the key cannot be removed. the key interiock

solenoid is OK.

lf the key can be removed, replace the steering

lock assembly (the key interlock solenoid is not

available separately).

\____________r{r4

Position

lgnition

switch

ACC 0)

Key pushed ino---'o

Key releasedo----o

www.emanualpro.com