top Engine bolt HONDA CR-V 1997 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1997, Model line: CR-V, Model: HONDA CR-V 1997 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 123 of 1395

Timing Belt

Removal

Replace the timing belt at 105,000 miles (168,000 km)

according to the maintenance schedule {normal condi-

tions/severe conditions). lf the vehicle is regularly driven

in either of the following conditions, replace the timing

belt at 60,000 miles (U.S.A.l 100.000 km (Canada).

- ln very high temperatures (over 110'F, 43"C).- In very low temperatures (under -20"F. -29"C).

Turn the crankshaft pu\ley so the No. 1 piston is at

top dead center (TDC).

Remove the guard bar and splash shield (see page

5-7 ).

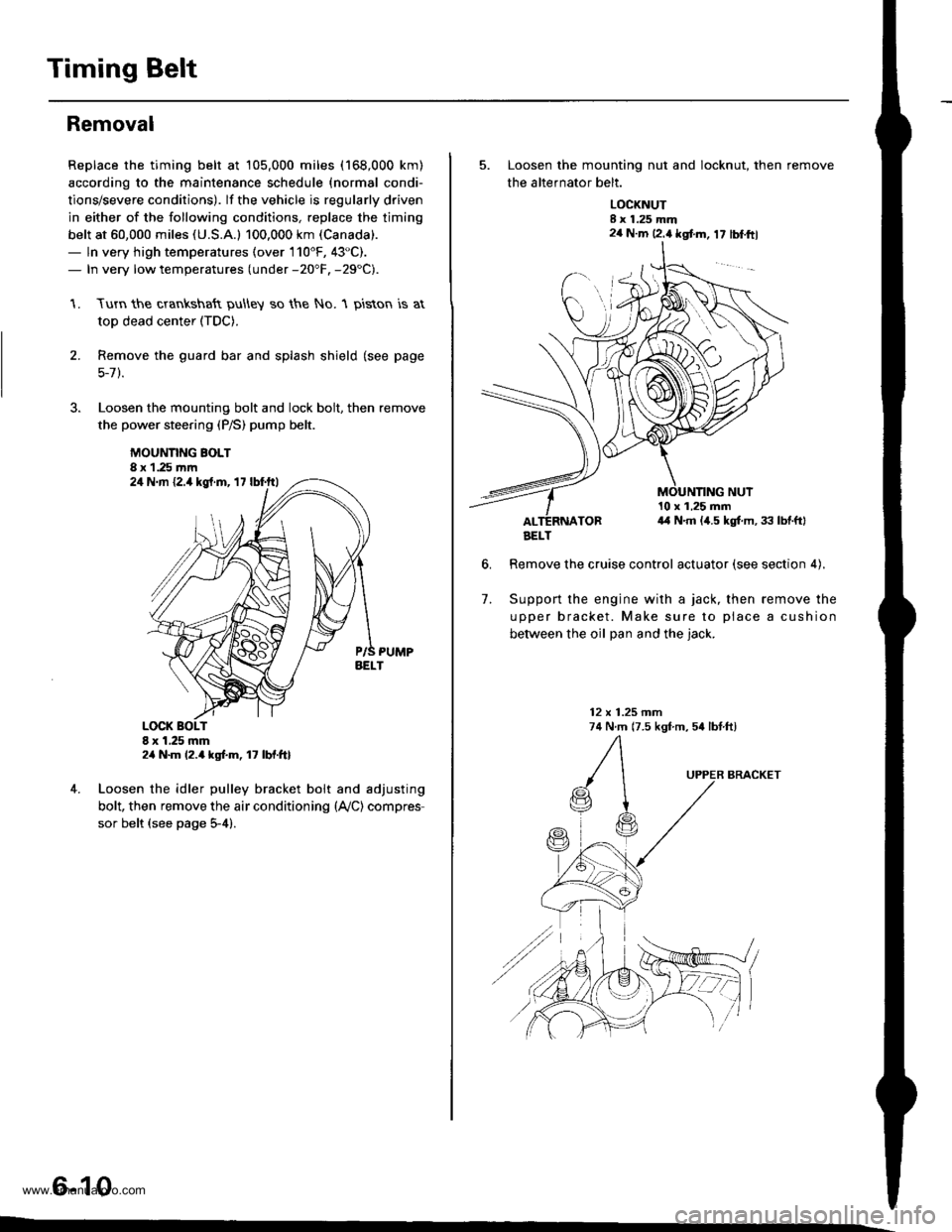

Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt.

MOUNNNG BOLT8 x 1.25 rnm

1.

2.

,l

4. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (lVC) compres

sor belt (see page 5-4).

6-10

24 N.m {2.4 kgt.m, 17 lbf.ftl

24 N.m 12.4 kgf.m, lt lbf.ftl

5. Loosen the mounting nut and locknut, then remove

the altefnator belt.

LOCKNUTI x 1.25 mm2a N.m 12.4 kgt m, 17 lblftl

6.

10 x 1,25 mm4,1 N.m (,1.5 kgt m, 33 lbtftl

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil Dan and the iack.

12 x 1.25 mm74 N.m (7.5 kgf m, 54 lbtftl

7.

BRACKET

AELT

www.emanualpro.com

Page 150 of 1395

lllustrated Index (cont'd)

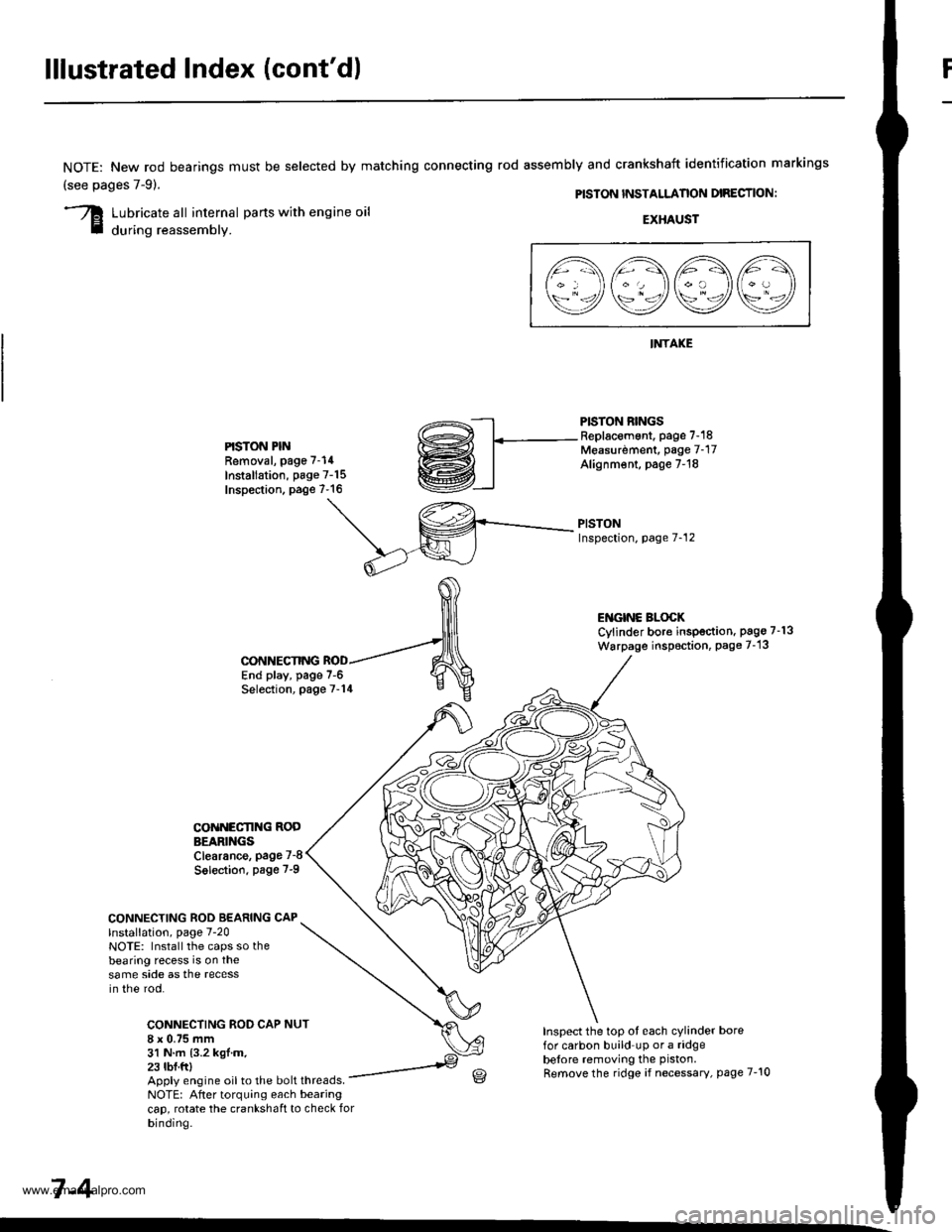

NOTE: New rod bearings

(see pages 7-91.

must be selected by matching connecting rod assembly and crankshaft identification markings

PISTON INSTALLANON DIRECTION:

Lubricate all internal parts with engine oil

during reassembly.EXHAUST

INTAKE

PISTON RINGSReplacement. page 7-18Measurdment, page 7-17Alignm€nt, page 7-18

PISTONInspection, page 7-12

l1\AAtr\

\9q9Q9e/

PISTON PINRemoval, page 7-14

Installation, page 7-15Inspection. page 7-16

ENGINC BLOCKCylinder bore inspection. pago 7-13

Warpage inspoction, Page 7-'13

CONNECTING ROD BEARING CAPlnstallation, page 7-20NOTE: Install the caps so thebearing recess is on thesame side as the recessin the rod.

CONNECTING ROD CAP8 x 0.75 mm31 N.m {3.2 kgl.m.23 tbf.ftl

CONNECTING

COiINECI'ING RODBEARINGSClearance, page 7-8

Solection. page 7-9

NUT

End play, page 7-6Selection, page 7-14

Inspect the top ot each cylinder borefor carbon build up or a ridgebelore removing the piston.

Remove the ridge if necessary, page 7-10Apply engine oil to the bolt threads.NOTE: After torquing each bearingcap, rotate the crankshaft to check forbinding.

7-4

www.emanualpro.com

Page 156 of 1395

Pistons and Crankshaft

Removal (cont'dl

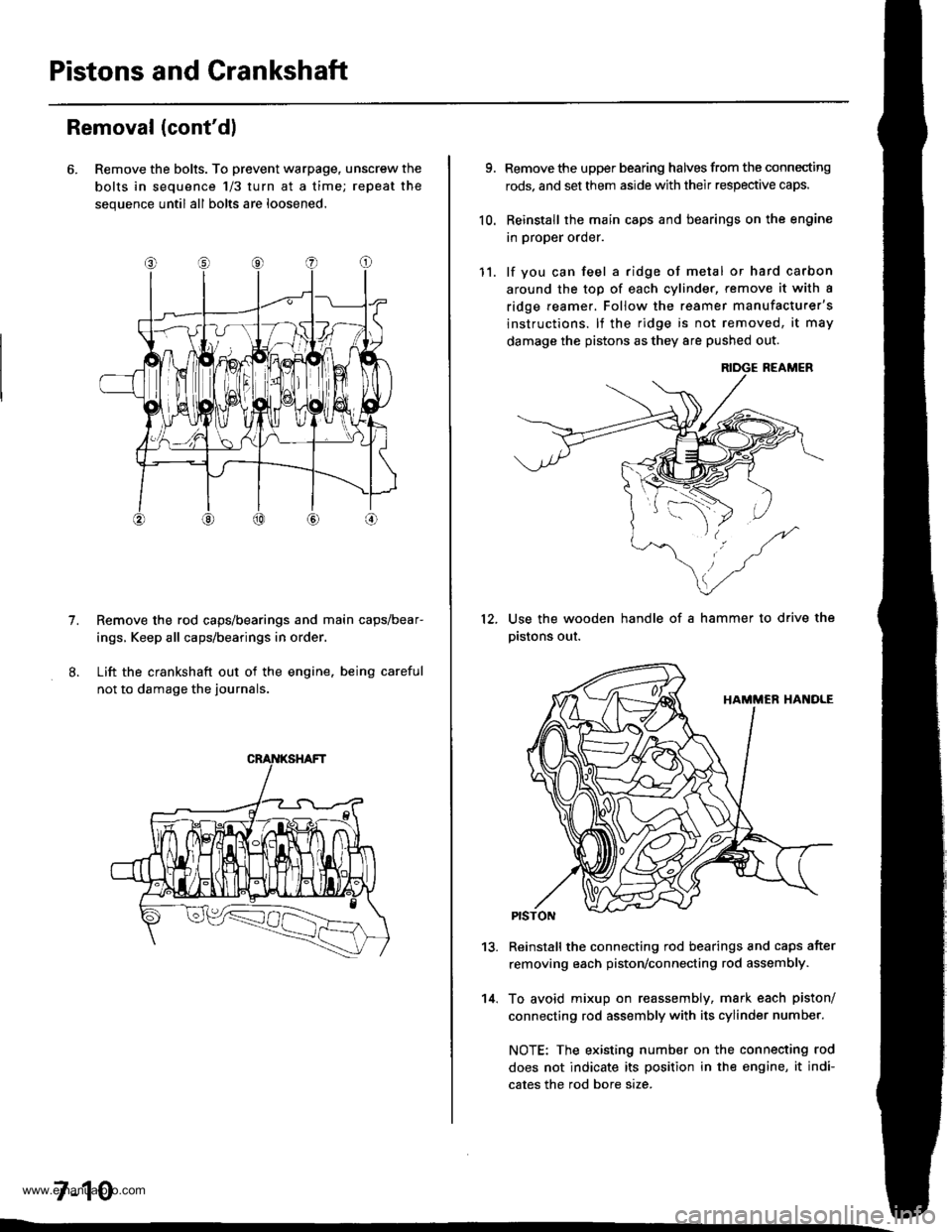

6. Remove the bolts. To prevent warpage, unscrew the

bolts in sequence 1/3 turn at a time; repeat the

sequence until all bolts are loosened.

Remove the rod caps/bearings and main caps/bear-

ings, Keep all caps/bearings in order

Lift the crankshaft out of the engine. being careful

not to damage the journals.

7.

7-10

9.

10.

Remove the upper bearing halves from the connecting

rods, and set them aside with their respective caps.

Reinstall the main caps and bearings on the engine

in proper order.

lf you can feel a ridge of metal or hard carbon

around the top of each cvlinder, remove it with a

ridge reamer. Follow the reamer manufacturer's

instructions. lf the ridge is not removed, it may

damage the pistons as they 8re pushed out.

12.

11.

14.

Use the wooden handle of a hammer to drive the

pistons out.

13.Reinstall the connecting rod bearings and caps after

removing each piston/connecting rod assembly.

To avoid mixup on reassembly, mark each piston/

connecting rod assembly with its cylinder number.

NOTE: The existing number on the connecting rod

does not indicate its position in the engine, it indi-

cates the rod bore size.

www.emanualpro.com

Page 166 of 1395

PistonsCrankshaft

Installation

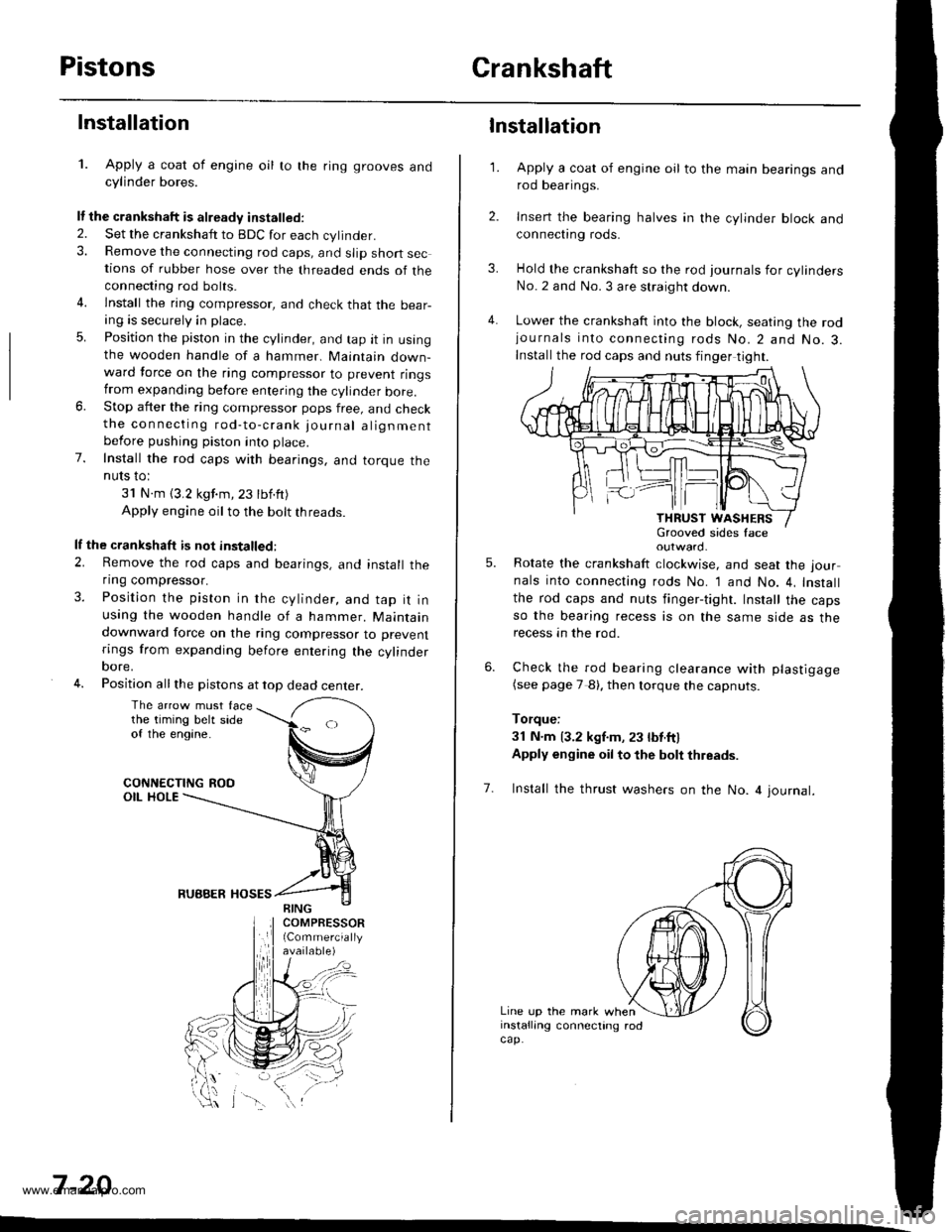

1. Apply a coat of engine oil to the ring grooves andcylinder bores.

It the crankshaft is already installed.

2. Set the crankshatt to BDC for each cylinder.3. Remove the connecting rod caps, and slip short sections of rubber hose over the threaded ends of theconnecting rod bolts.

4. lnstall the ring compressor, and check that the bear-ang is securely in place.

5. Position the piston in the cylinder, and tap it in usingthe wooden handle of a hammer. Maintain down-ward force on the ring compressor to prevent ringstrom expanding before entering the cylinder bore.6. Stop after the ring compressor pops free, and checkthe connecting rod-to-crank journal alignmentbefore pushing piston into place.

7. Install the rod caps with bearings, and torque theNUIS IO:

31 N.m (3.2 kgf.m,23 tbf.ft)

Apply engine oil to the bolt threads.

lf the crankshaft is not installed:

2. Remove the rod caps and bearings, and install theflng compressor.

3. Position the piston in the cylinder, and tap it inusing the wooden handle of a hammer. Maintaindownward force on the ring compressor to prevent

rings from expanding before entering the cylinderoore,

4. Position all the pistons at top dead center.

The arrow must facethe timing belt sideof the engine.

CONNECTING ROOOIL HOLE

RUBBER HOSES

7 -20

\-\

3.

4.

1.

6.

Installation

Apply a coat of engine oil to the main bearings androd bearings.

Insert the bearing halves in the cylinder block andconnect|ng rods.

Hold the crankshaft so the rod journals for cylindersNo.2 and No. 3 are straight down.

Lower the crankshaft into the block, seating the rodjournals into connecting rods No.2 and No.3.Install the rod caps and nuts finger tight.

outward.

Rotate the crankshaft clockwise, and seat the jour

nals into connecting rods No. 1 and No. 4, Install

the rod caps and nuts finger-tight. Install the capsso the bearing recess is on the same side as therecess an the rod.

Check the rod bearing clearance with plastigage(see page 7 8). then lorque the capnuts.

Torque:

3l N.m 13.2 kgf.m, 23 lbt.ftl

Apply engine oil to the bolt thleads.

5.

7. Install the thrust washers on the No. 4 journal.

Line up the mark wheninstalling connecting rodcap.

www.emanualpro.com

Page 677 of 1395

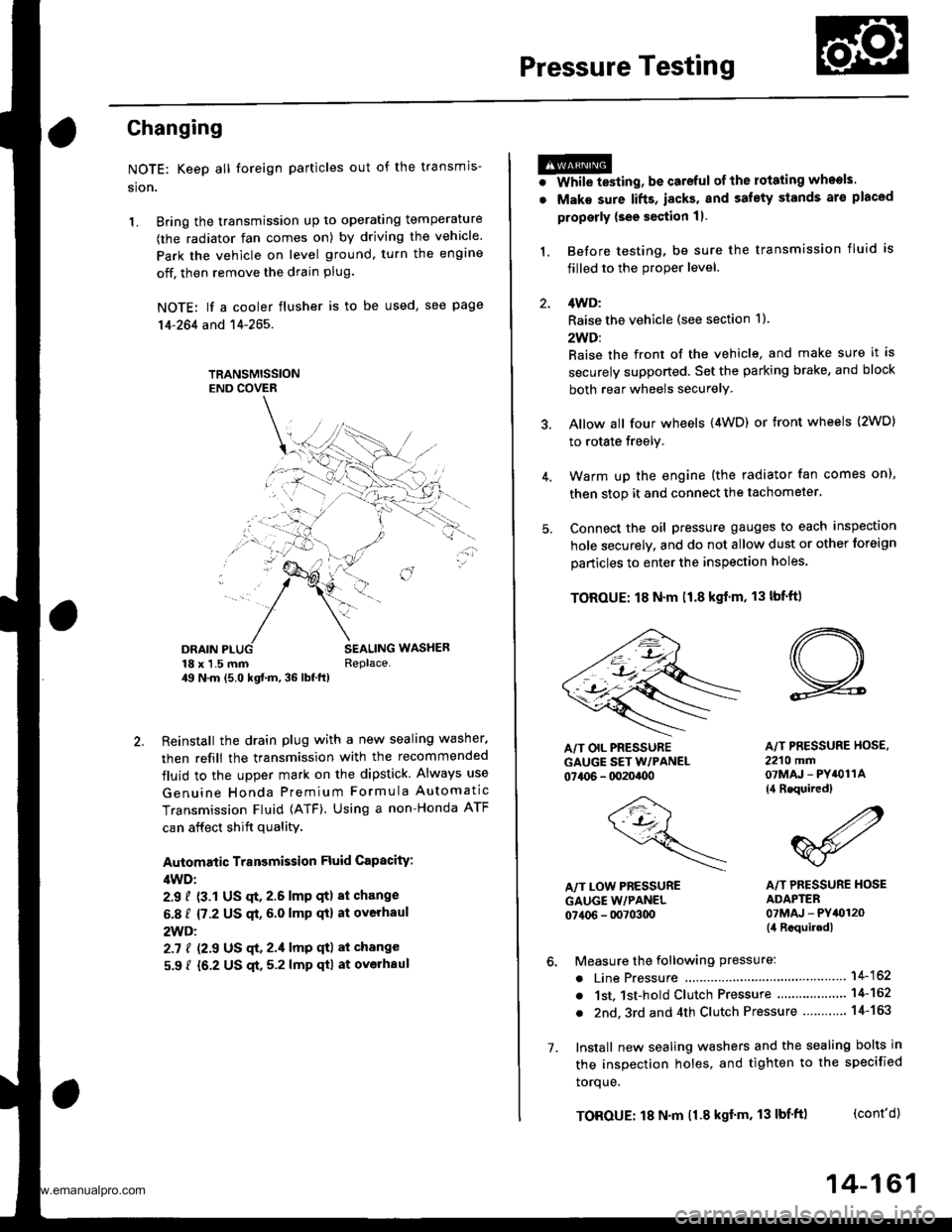

Pressure Testing

Changing

NOTE: Keep all foreign particles out of the transmis-

sion.

1. Bring the transmission up to operating temperature

(the radiator fan comes on) by driving the vehicle.

Park the vehicle on level ground. turn the engane

off. then remove the drain Plug.

NOTE: lf a cooler flusher is to be used, see page

14-264 and 14-265.

TRANSMISSIONEND COVER

DRAIN18 x 1.5 mmSEALING WASHEBReplace.49 N.m {5.0 kgt.m, 36 lbf.tl)

Reinstall the drain plug with a new sealing washer,

then refill the transmission with the recommended

fluid to the uDper mark on the dipstick. Always use

Genuine Honda Premium Formula Automatic

Transmission Fluid (ATF) Using a non-Honda ATF

can affect shift quality.

Automatic Transmission Fluid Capacity:

4WD;

2.9 { (3.1 US qt. 2.6 lmp qt) 8t change

5.8 ? {7.2 US $, 6.0 lmp qt} at ovethaul

2WD:

2.7 | l2.S US qt,2.1lmp qtl ai change

5.9 ? {6.2 US $, 5.2 lmp qtl at ovolhaul

2.

a

a

1.

Wlrile testing, be careful of the rotaling wheols.

Mako sure lifts, iacks, and safety stands ar€ placed

properly (see scction 11.

Before testing, be sure the transmission fluid is

filled to the proPer level.

4WD:

Raise the vehicle (see section 11.

2WD:

Raise the front of the vehicle, and make sure it is

securely supported. Set the parking brake, and block

both rear wheels securely.

Allow all four wheels {4WD) or front wheels (2wD}

to rotate freely.

Warm up the engine (the radiator fan comes on),

then stop it and connect the tachometer.

Connect the oil pressure gauges to each inspection

hole securely, and do not allow dust or other foreign

particles to enter the inspection holes.

TOROUE: 18 N'm ll.8 kgf'm, 13 lbf'ft)

5.

A/T PRESSURE HOS€,2210 mm07MAJ - PYiOllA

{4 Requircd}

,4'/"' ,a

W'

A/T PRESSURE HOSEADAPTER07MAJ - PYt0120(il Rcquiledl

6. Measure the following Pressure:. Line Pressure ..........,14-162

. 1st. 1st-hold Clutch Pressure .............'. 14-162

. 2nd,3rd and 4th Clutch Pressure .......... 14-163

7. Install new sealing washers and the sealing bolts in

the inspection holes, and tighten to the specified

toroue.

(cont'd)

A/T OIL PRESSUREGAUGE SET W/PANEL07{06 - 0020400

/4\\-J-- (

+..\.-.\-'-\

A/T LOW PBESSUREGAUGE w/PANEL07406 - 0070300

TOROUE: 18 N'm 11.8 kgf'm, 13 lbf'ft)

14-161

www.emanualpro.com

Page 859 of 1395

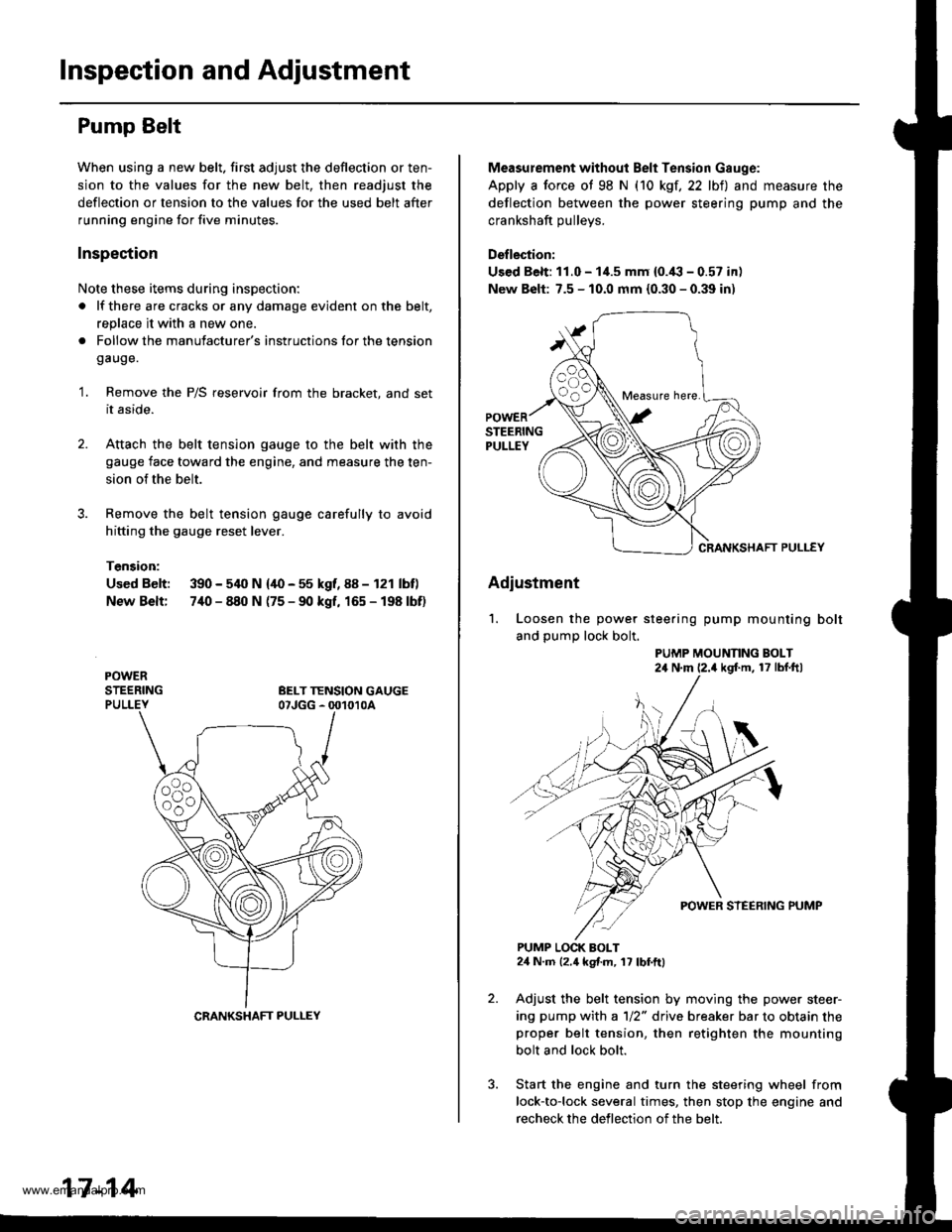

Inspection and Adjustment

Pump Belt

When using a new belt. first adjust the deflection or ten-

sion to the values for the new belt, then readjust the

deflection or tension to the values for the used belt after

running engine for five minutes.

Inspection

Note these items during inspection:

a lf there are cracks or any damage evident on the belt,

replace it with a new one.

. Follow the manufacturer's instructions lor the tension

gauge.

'1. Remove the P/S reservoir from the bracket, and set

it aside.

2. Attach the belt tension gauge to the belt with the

gauge face toward the engine, and measure the ten-

sion of the belt.

Remove the belt tension gauge carefully to avoid

hitting the gauge reset lever.

Tension:

Used Belt: 390 - 540 N {40 - 55 kgf, 88 - 121 lbf)

New Belt: 7,[0 - 840 N (75 - 90 kgf, 165 - 198 lbf)

CRANKSHAFT PULLEY

17-14

Measurement without Belt Tension Gauge:

Apply a force ot 98 N (10 kgf,22 lbt) and measure the

deflection between the power steering pump and the

crankshaft oullevs.

Deflection:

Used Belt: 11.0 - 1i1.5 mm {0.'(l - 0.57 in)

New Belt: 7.5 - 10.0 mm {0.30 - 0.39 in)

CRANKSHAFT PULLEY

Adiustment

'1. Loosen the power steering pump mounting bolt

and pump lock bolt.

PUMP MOUNNNG BOLT24 N'm (2.4 kgf'm, 17 lbf ftl

PUMP LOCK BOLT24 N.m 12.4 kgf.m, 17 lbf.ftl

Adjust the belt tension by moving the power steer-

ing pump with a 1/2" drive breaker bar to obtain theproper belt tension, then retighten the mounting

bolt and lock bolt.

Start the engine and turn the steering wheel from

lock-to-lock several times, then stop the engine and

recheck the deflection of the belt.

Measure here.

www.emanualpro.com