battery HONDA CR-V 1998 RD1-RD3 / 1.G Owners Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1129 of 1395

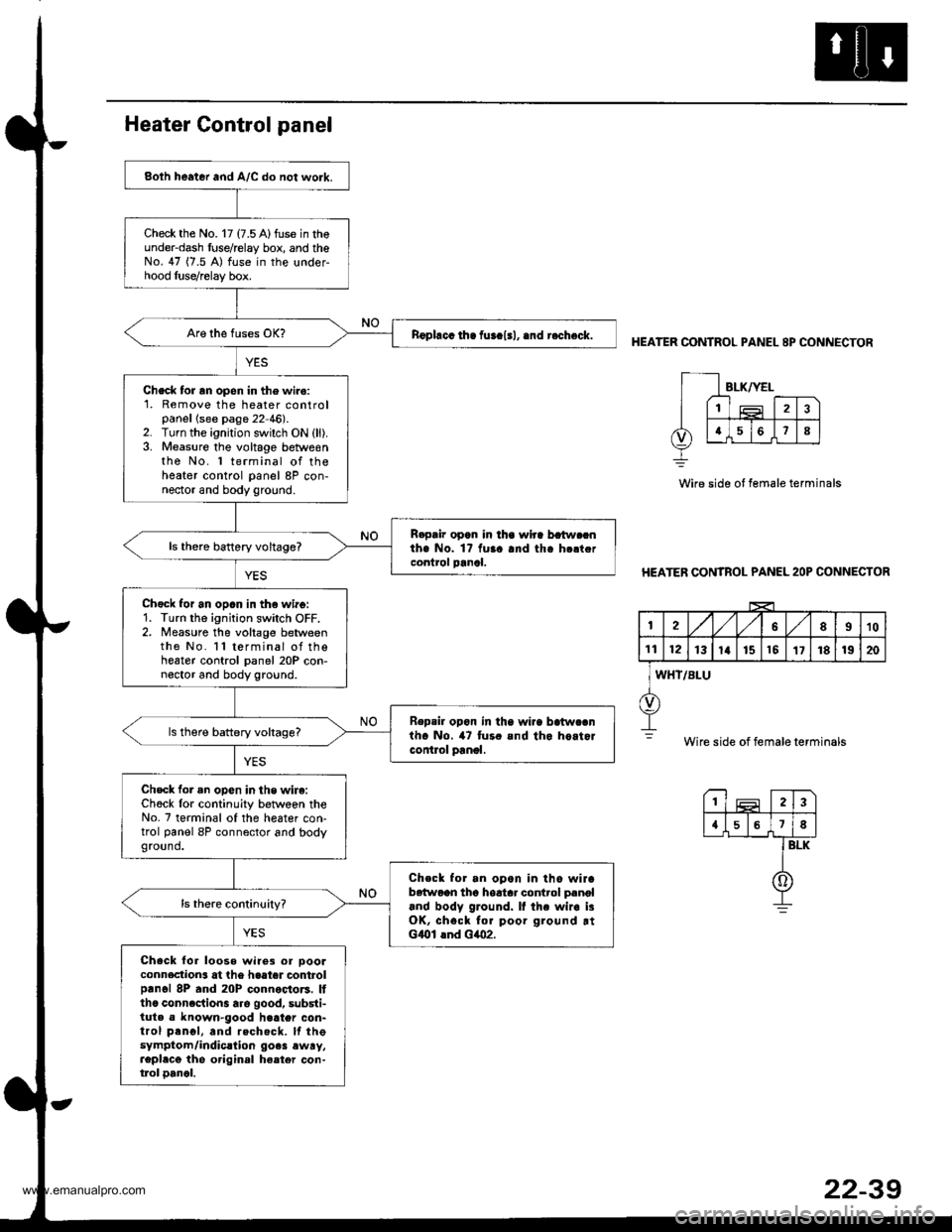

Both heater and A/C do not work.

Check the No. 17 (7.5 A)fuse in theunder-dash fuse/relay box, and theNo. 47 (7.5 A) fuse in the under-hood luse/relay box.

nophcc ih. fur.l.l, .nd r.check.

Check tor rn open in the wiro:1. Remove the heater controlpanellsee page 22 46).2. Turn the ignition switch ON (ll).3. Measure the voltage betweenthe No. 1 terminal of theheater control panel 8P con-nector and body ground.

R.pair opan in lha wlra batw.cnthe No. 1? fuaa and tha h.ltcrcontrol panal.ls thero battery voltage?

Chgck for an opan in th€ wirg:1. Turn the ignition switch OFF.2. Measure the voltage betweenthe No. l l terminal of thoheater control panel 20P con-noctor and body ground.

Repsil opon in tha wi.a batwcanth. No. 47 tur. and tho hoitorcontlol panol.

ls there battery voltags?

Check for an opon in the wire:Ch6ck lor continuity betwoen theNo. 7 terminal of the heater con-trol panel 8P connector and bodyground.

Check for an opon in tho wirab6{woon tho hoatar control p.noland body ground. It the wir. i3OK, chsck for poor ground rtGlOl lnd Glo2.

Check for loose wire3 or oooaconnection3 at the haater controlprnol 8P and 20P connoctors. Itthc conncction3 are good, substi-tuta a known-good h€ater con-trol prnol, and rechecft. lf thesymptom/indic.lion go.3 ewry,repl.cg the original ha.ter con-tlol oancl.

HEATER CONTROL PANEL 8P CONNECTOR

Wire side ot female terminals

HEATER CONTROL PANEL 2OP CONNECTOR

I2A,/1,/58910

1t12131a151517181920

WHT/BLU

Wire side of female terminals

23

{578

BLK

0

www.emanualpro.com

Page 1131 of 1395

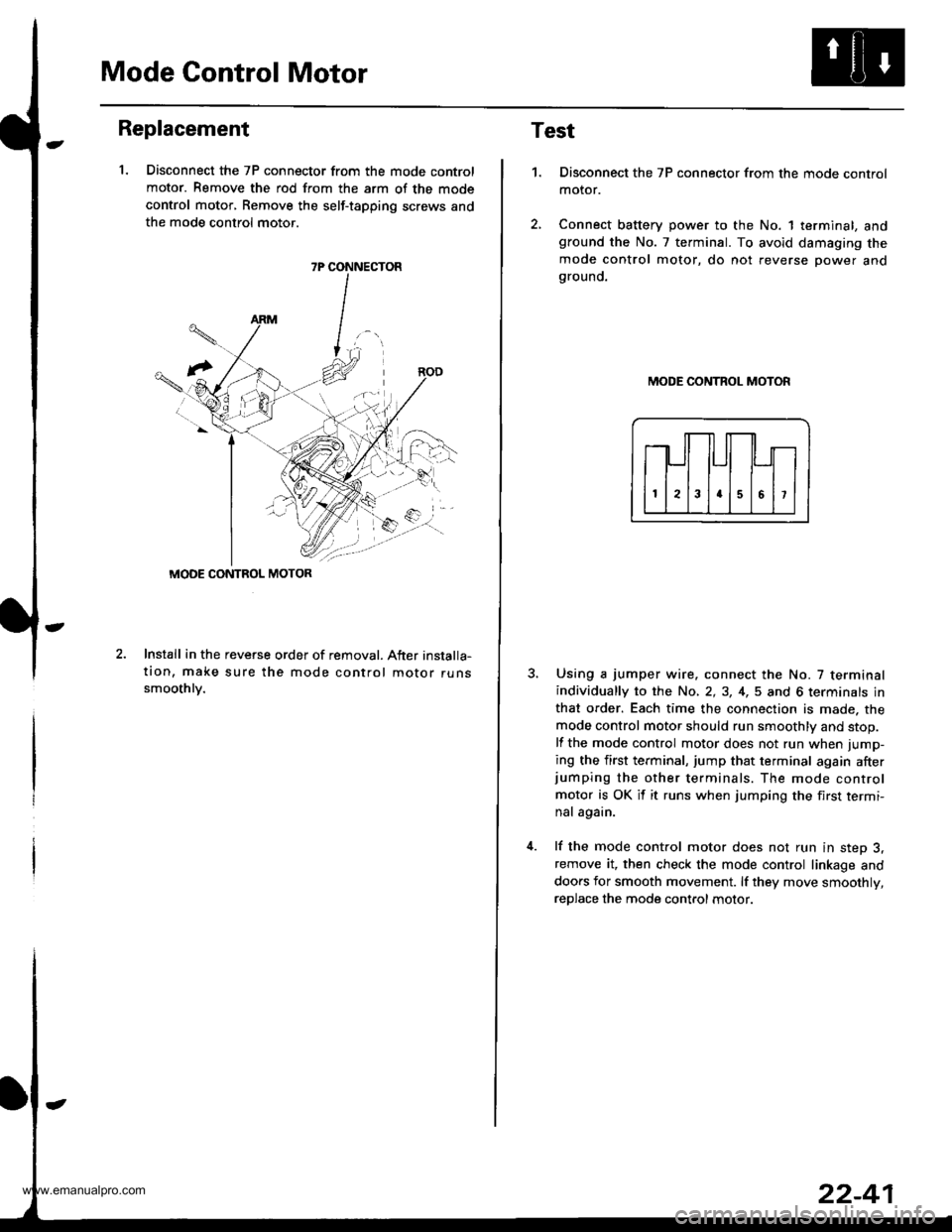

Mode Control Motor

Replacement

1. Disconnect the 7P connector from the mode control

motor. Remove the rod from the arm of the mode

control motor, Remove the self-tapping screws and

the mode control motor.

2.Install in the reveGe order of removal. After installa-

tion, make sure the mode control motor runssmoothlv.

7P CONNECTOR

MODE CONTROL MOTOR

Test

1.Disconnect the 7P connector from the mode control

motor.

Connect battery power to the No. 1 terminal, andground the No. 7 terminal. To avoid damaging the

mode control motor, do not reverse power andgrouno.

MODE CONTROL MOTOR

Using a jumper wire. connect the No. 7 terminalindividually to the No, 2,3, 4,5 and 6 terminals in

that order. Each time the connection is made. the

mode control motor should run smoothly and stop.

lf the mode control motor does not run when jump-

ing the first terminal, jump that terminal again afterjumping the other terminals. The mode control

motor is OK it it runs when jumping the first termi-

nal again.

lf the mode control motor does not run in step 3,remove it, then check the mode control linkage and

doors for smooth movement. lf they move smoothly,

reDlace the mode control motor.

www.emanualpro.com

Page 1132 of 1395

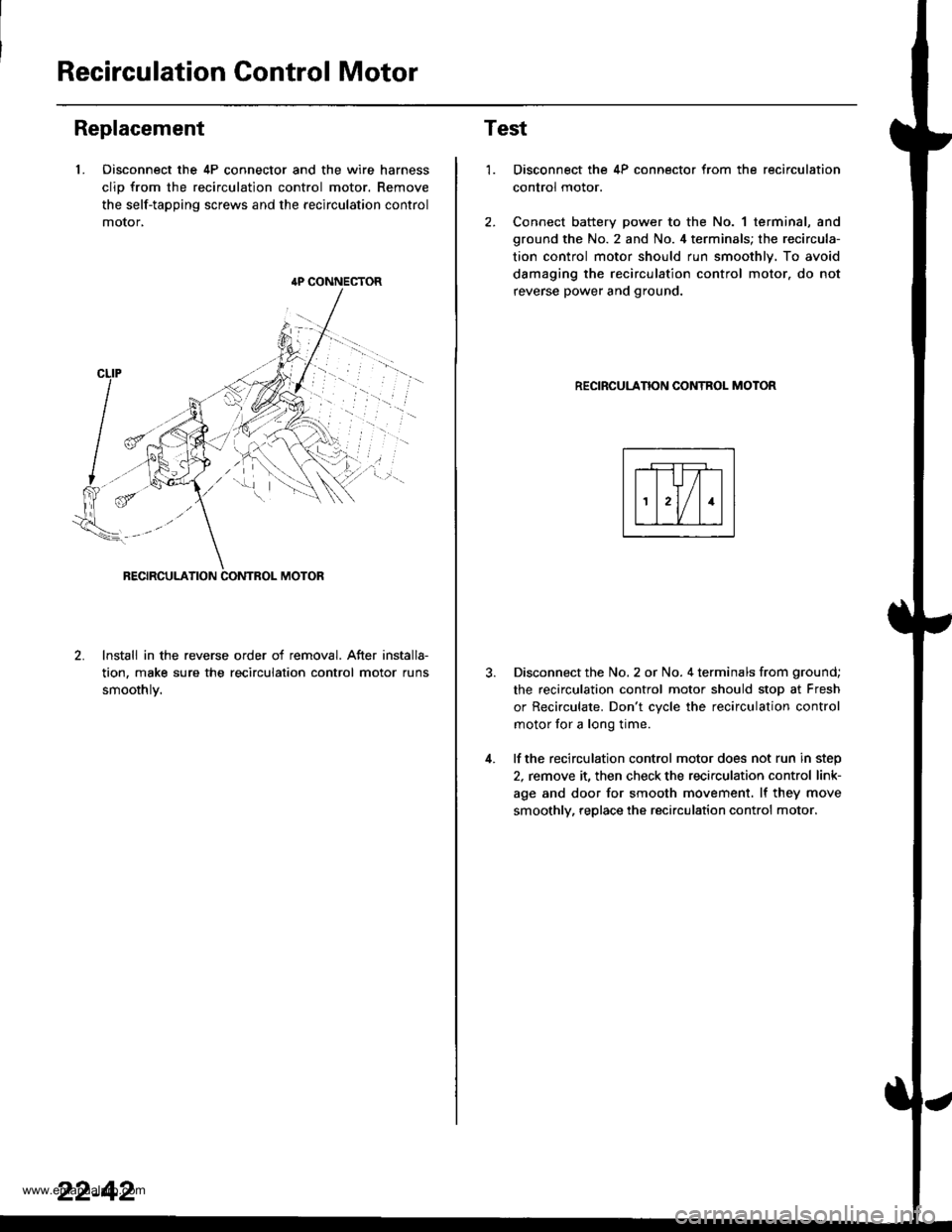

Recirculation Control Motor

Replacement

1. Oisconnect the 4P connector and the wire harness

clio from the recirculation control motor. Remove

the self-tapping screws and the recirculation control

motor,

lnstall in the reverse order of removal. After installa-

tion, make sure the recirculation control motor runs

smoothlv.

{P CONNECTOR

22-42

Test

1.

4.

Disconnect the 4P connector from the recirculation

control motor.

Connect battery power to the No. 1 terminal, and

ground the No. 2 and No. 4 terminals; the recircula-

tion control motor should run smoothly. To avoid

damaging the recirculation control motor. do not

reverse power and ground.

RECIRCULANON CONTROL MOTOR

Disconnect the No. 2 or No. 4 terminals from ground;

the recirculation control motor should stop at Fresh

or Recirculate. Don't cvcle the recirculation control

motor for a long time.

lf the recirculation control motor does not run in step

2, remove it, then check the recirculation control link-

age and door for smooth movement. lf they move

smoothly, replace the recirculation control motor.

www.emanualpro.com

Page 1133 of 1395

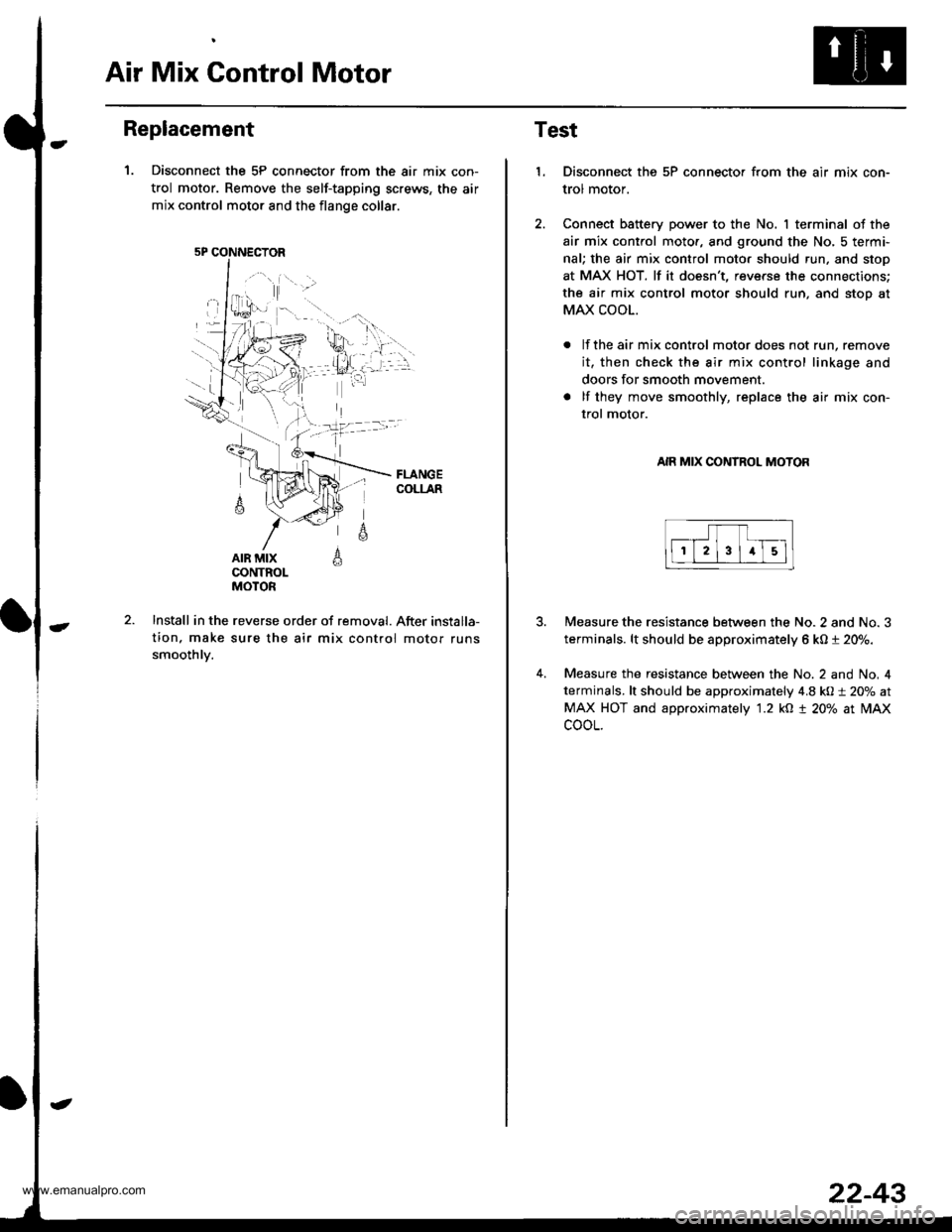

Air Mix Gontrol Motor

Replacement

1. Disconnect the 5P connector from the air mix con-

trol motor. Remove the self-tapping screws, the air

mix control motor and the flange collar.

AIR MIXCONTROLMOTOR

A

6

Install in the reverse order of removal. After installa-

tion. make sure the air mix control motor runs

smoothlv.

5P CONNECTOR

22-43

Test

1.Disconnect the 5P connector from the air mix con-

trol motor.

Connect battery power to the No. I terminal of the

air mix control moto., and ground the No, 5 termi-

nal; the air mix control moto. should run, and stop

at MAX HOT. lf it doesn't, reverse the connections;

the air mix control motor should run, and stoo at

MAX COOL.

lf the air mix control motor does not run, remove

it, then check the air mix control linkage and

doors for smooth movement.

lf they move smoothly, replace the air mix con-

trol motor.

AIR MIX CONTROL MOTOR

4.

Measure the resistance between the No. 2 and No. 3

terminals. lt should be approximately 6 kO t 20%.

Measure the resistance between the No. 2 and No, 4

terminals, lt should be approximately 4.8 kO:t 20% at

MAX HOT and approximately '1.2 kO t 20% at lilAx

cooL.

www.emanualpro.com

Page 1138 of 1395

Evaporator

Replacement

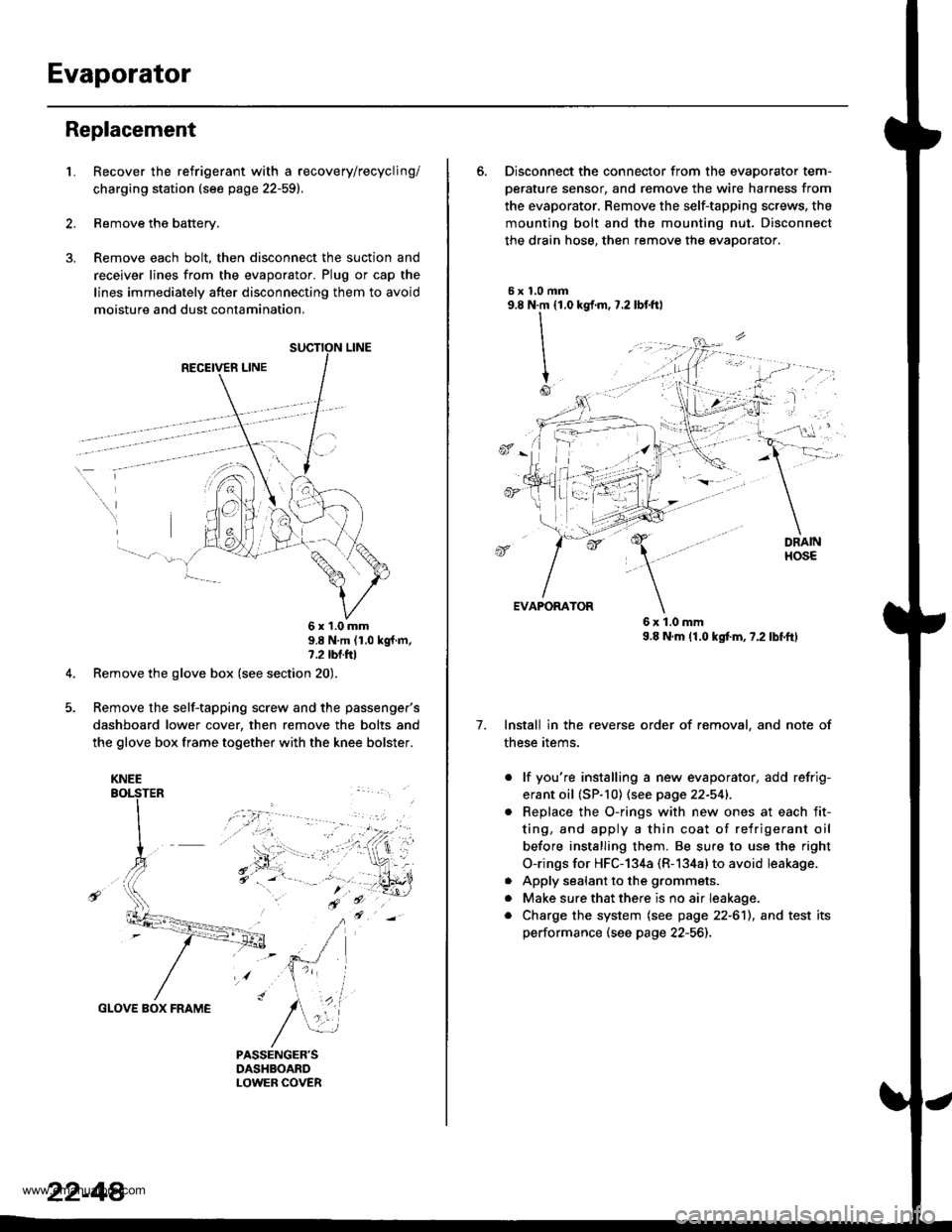

1.Recover the refrigerant with a recovery/recycling/

charging station (see page 22-59).

Remove the battery.

Remove each bolt, then disconnect the suction and

receiver lines from the evaporator. Plug or cap the

lines immediately after disconnecting them to avoid

moisture and dust contamination,

RECEIVER LINE

..

\

6x1.0mm9.8 N'm (1.0 kgf m,7.2 tbl.ttl

Remove the glove box (see section 20).

Remove the self-tapping screw and the passenger's

dashboard lower cover, then remove the bolts and

the glove box frame together with the knee bolster.

GLOVE BOX FRAME

KNEE

22-44

6. Disconnect the connector from the evaoorator tem-

oerature sensor. and remove the wire harness from

the evaporator. Remove the self-tapping screws, the

mounting bolt and the mounting nut. Disconnect

the drain hose, then remove the evaporator.

5xl,0mm9.8 N.m {1.0

II

I

Io

kgf.m, 7.2 lbf.ftl

, -l: "

7.

EVAPORATOR

6x1.0mm9.8 N.m (1.0 kgtm,7.2lbf.ftl

Install in the reverse order of removal, and note of

these items.

. lf you're installing a new evaporator, add refrig-

erant oil (SP.10) (see page 22-541.

Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them. Be su.e to use the right

O-rings for HFC-134a (R-134alto avoid leakage.

Apply sealant to the grommets.

Make sure that there is no air Ieakage.

Charge the system (see page 22-6'll, and test its

performance (see page 22-56]-,

a

a

a

www.emanualpro.com

Page 1140 of 1395

A/C FilterHeater Unit

Replacement

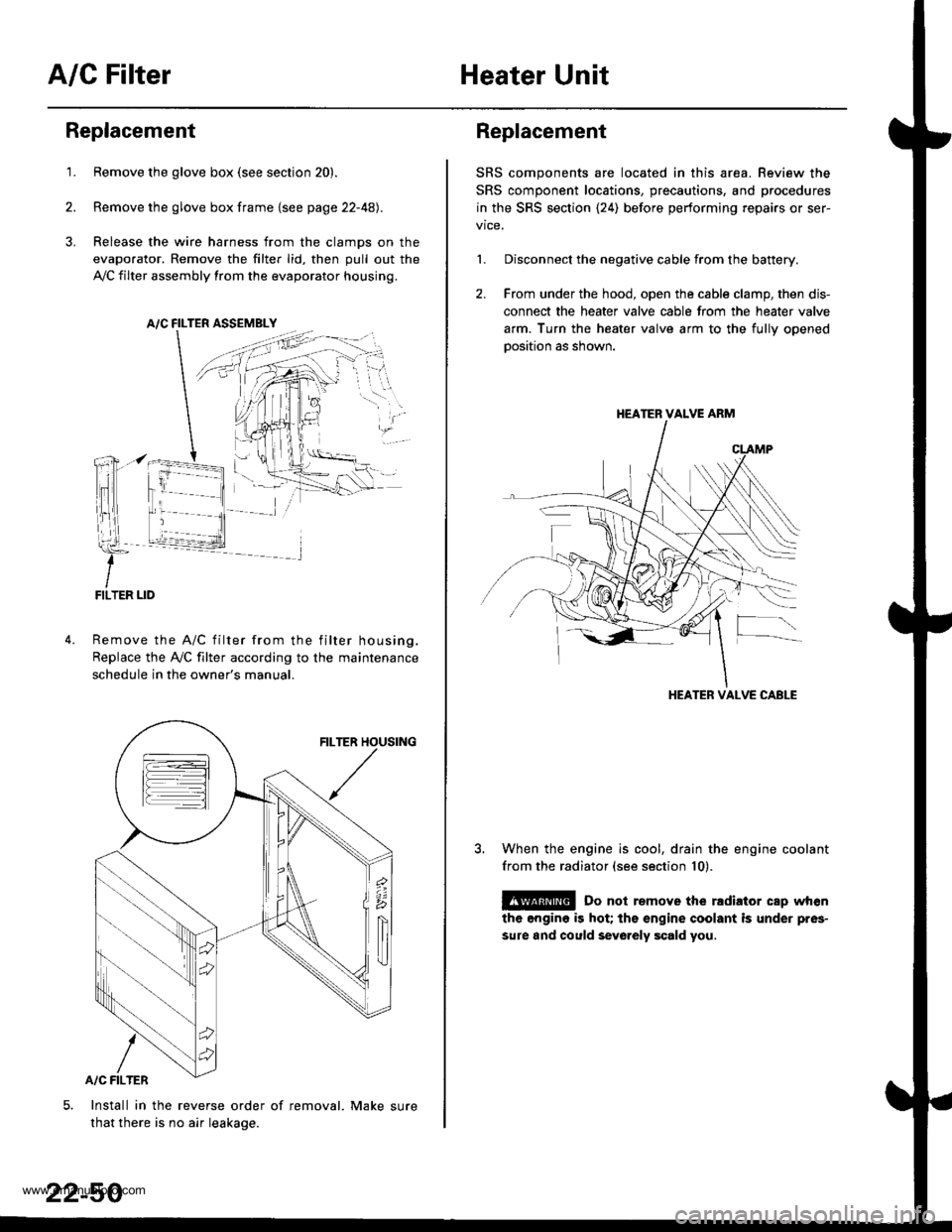

1.Remove the glove box (see section 20).

Remove the glove box frame {see page 22-4A).

Release the wire harness from the clamps on the

evaporator. Remove the filter lid, then pull out the

,VC filter assembly from the evaporator housing.

A/C FILTER ASSEMELY

Remove the A/C filter from the filter housing.

Replace the Ay'C filter according to the maintenance

schedule in the owner's manual.

Install in the reverse order of removal. Make sure

that there is no air leakage.

22-50

Replacement

SRS components are located in this area. Review the

SRS component locations, precautions, and procedures

in the SRS section {24) before performing repairs or ser-

1. Disconnect the negative cable from the battery.

2. From under the hood, open the cable clamp, then dis-

connect the heater valve cable from the heater valve

arm. Turn the heater valve arm to the fullv ooened

oosition as shown.

When the engine is cool, drain the engine coolant

from the radiator (see section 10).

@ Do not remove the rldiator cap when

the engine is hot; the engine coolant is under pres-

sure and could sevo.ely scald you.

HEATER VALVE ARM

HEATER VALVE CABLE

www.emanualpro.com

Page 1144 of 1395

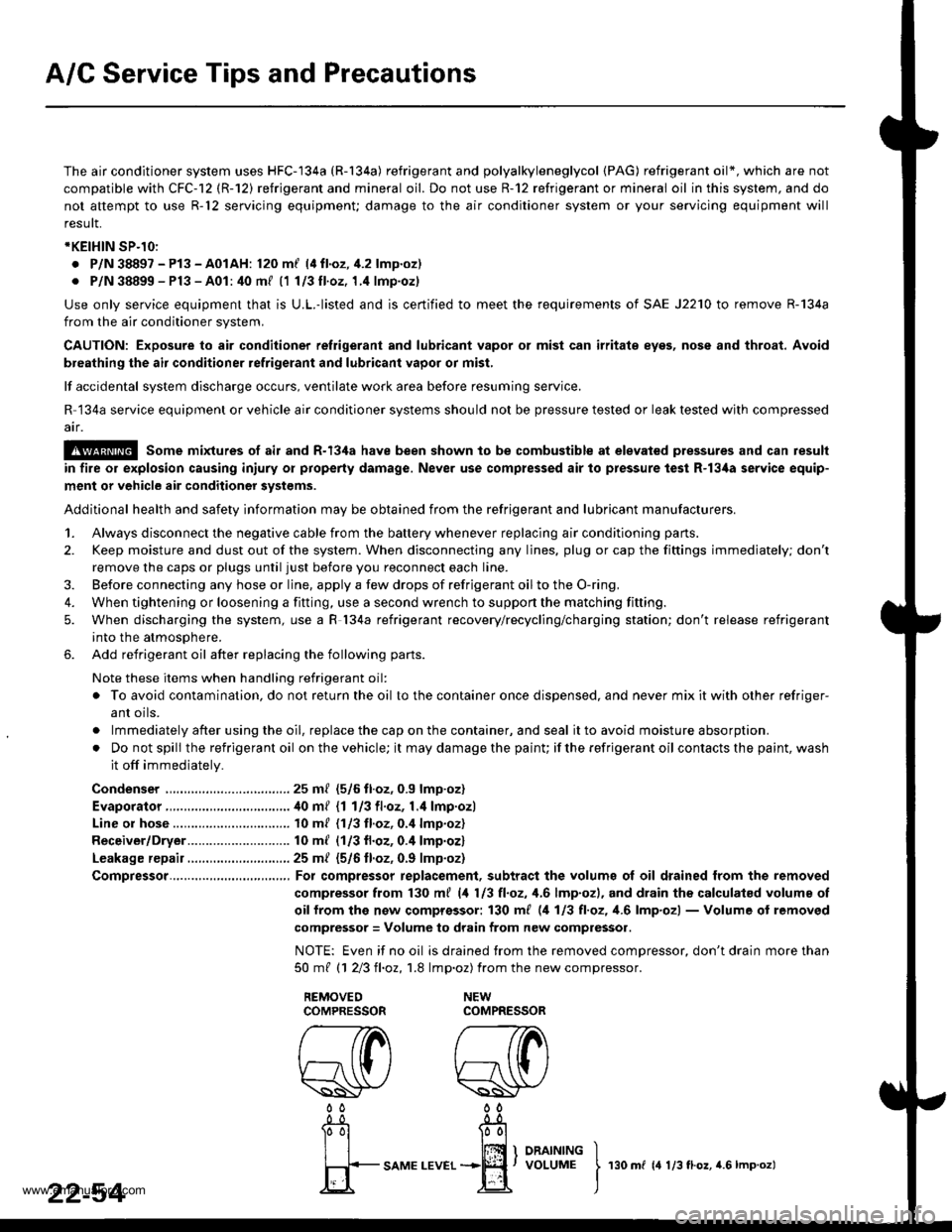

A/C Service Tips and Precautions

The air conditioner system uses HFC-'134a (R-134a) refrigerant and polyalkyleneglycol {PAG) refrigerant oil*, which are not

compatible with CFC-12 (R-12) refrigerant and mineral oil. Do not use R-12 refrigerant or mineral oil in this system, and do

not attempt to use R-12 servicing equipmenu damage to the air conditioner system or your servicing equipment will

resutr.

*KEIHIN SP-10:

. P/N 38897 - Pl3 - A01AH: 120 m{ (4 fl.oz, il.2 lmp.oz)

. P/N 38899 - Pl3 - A01: 40 mf 11113tl.oz,1.4 lmp.oz)

Use only service equipment that is U.L.-listed and is certified to meet the requirements of SAE J2210 to remove R-134a

from the air conditioner system,

CAUTION: Exposure to air conditioner refrigerant and lubricant vapor or misl can irritats eyes, nose and throat. Avoid

breathing the air conditioner refrigerant and lubricant vapor or mist,

lf accidental system discharge occurs, ventilate work area before resuming service.

R 134a service equipment or vehicle air conditioner systems should not be pressure tested or leak tested with compressed

air.

E@ Some mixtures of air and R-13,1a have been shown to be combustible at elevat€d pressures and can result

in fire or explosion causing iniury or property damage. Never use complessed air to pressure test R-l3,[a service equip-

ment or vehicle air conditioner systems.

Additional health and safety information may be obtained from the refrigerant and lubricant manufacturers.

1. Always disconnect the negative cable from the battery whenever replacing air conditioning parts.

2. Keep moisture and dust out of the system. When disconnecting any lines, plug or cap the fittings immediately; don't

remove the caps or plugs until just before you reconnect each line.

3. Before connecting any hose or line. apply a few drops of refrigerant oilto the O-ring,

4. When tightening or loosening a fitting, use a second wrench to support the matching fitting.

5. When discharging the system, use a R l34a refrigerant recovery/recycling/charging station; don't release refrigerant

into the atmosphere.

6. Add refrigerant oil after replacing the following parts.

Note these items when handling refrigerant oil:

o To avoid contamination, do not return the oil to the container once dispensed, and never mix it with other refriger-

ant oils.

. lmmediately after using the oil, replace the cap on the container, and seal it to avoid moisture absorption.

. Do not spill the refrigerant oil on the vehicle; it may damage the painu if the refrigerant oil contacts the paint, wash

it off immediately.

Condenser . 25 ml (5/6 tl.oz, 0.9 lmp.oz)

Evaporator.,................................40 m/ 11 113ll.oz,l.4 lmp.ozl

Line or hose ........... 10 ml (1/3 fl.oz, 0.4 lmp.oz)

Receiver/Dryer....... 10 ml (1/3 fl.oz, 0.4 lmp.oz)

Leakage repair............................ 25 m/ (5/6 ll.oz, 0.9 lmp.oz)

Compressor.......,..., For compressor replacement, subtract the volumg ol oil drained from the removed

compressor from 130 m{ (4 113 tl.oz, 1,6lmp.ozl, and drain the calculatsd volume of

oif from the now comprossor: 130 ml (,1 113 tl,oz, 1.6lmp'ozl - Volume of removed

compressor = Volume to drain from new compressor.

NOTE: Even if no oil is drained trom the removed compressor, don't drain more than

50mt 11 213ll,oz,1.8 lmp.oz) from the newcompressor.

22-54I

rso m r rr:0.o., r.s r-o.o.t

www.emanualpro.com

Page 1152 of 1395

Compressor

Replacement

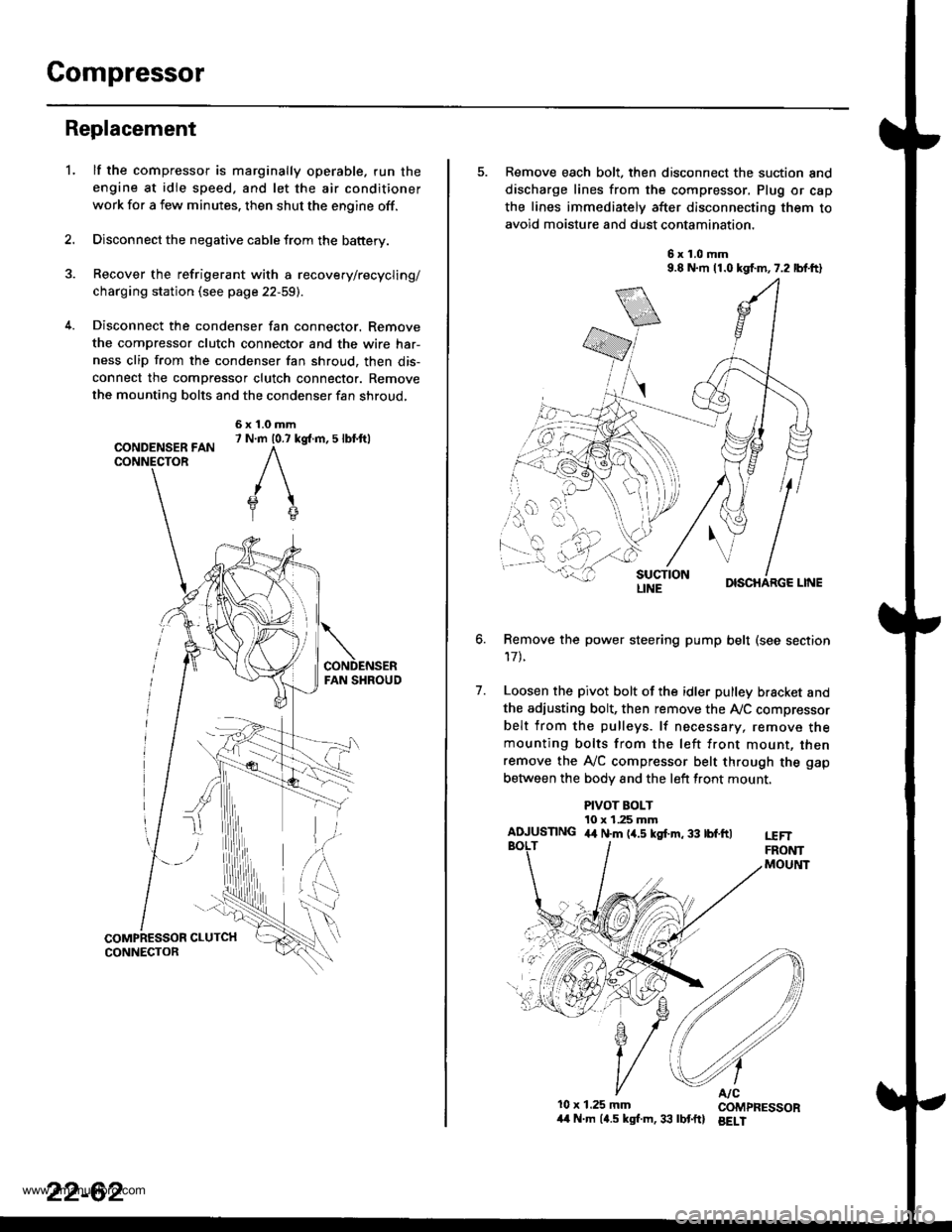

lf the compressor is marginally operable. run the

engine at idie speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-59).

Disconnect the condenser fan connector. Remove

the compressor clutch connector and the wire har-

ness clip from the condenser fan shroud, then dis-

connect the compressor clutch connector. Remove

the mounting bolts and the condenser fan shroud,

CONDENSER FANCONNECTOR

6x1.0mm7 N.m 10.7 kg{.m, 5 lbl.ftl

'L

2.

5. Remove each bolt, then disconnect the suction and

discharge lines from the compressor. Plug or cap

the lines immediately after disconnecting them to

avoid moisture and dust contamination,

6x1.0mm9.8 N.m 11.0 kgf.m,7.2 lbf.ft)

DISCHARGE LINE

Remove the power steering pump belt (see section

17t.

Loosen the pivot bolt of the idler pulley bracket and

the adiusting bolt, then remove the Ay'C compressor

belt from the pulleys. lf necessary, remove themounting bolts from the left front mount, thenremove the A,/C compressor belt through the gap

between the bodv and the left front mount.

6.

7.

PIVOT BOLT10 x 1.25 mmAIUUSTING 4,t N.m (4.5 kgf.m, 33 tbf.ftlt€FTFRONTMOUltlT

10x 1.25 mm COMPRESSOR/t4 N.m (4.5 kgl.m,33 lbtftl BELI

LINE

www.emanualpro.com

Page 1161 of 1395

Body Electrical

Speciaf Toofs ,...,..,.............-.23-2

Troubleshooting

Tips and Precautions ......,.,..........,.................. 23-3

Five-step Troubleshooting ........,.,.,...,,.,......... 23-5

Wire Color Codes ...,....,.. 23-5

Relay and Control Unit Locations

Engine Compartment ..,.,......,......................... 23-6

Dashboard ,.,.,..............-.- 23-7

Door ....................... .........23-10

Index to Cilcuits and Sysiems

Accessory Socket .. ,....,.,..,.,. 23-95*Airbags ................ .,....,. Sestion 24

Air Conditioning ,.,.,.... Section 22

Alternator ................... Section 4

Anti-lock Brake System {ABSI ................... Section 19'A/T Gear Position Indicator ....................... Section 1,1

Automatic Transmission System ...........,.. Section 14

Battery ................... ..............23-50

Blower Controls .,...,.,, Section 22

Charging System ....... Seqtion il

Clock -'98 Model ................ 23-98

Connector ldentification and Wire HarnessRouting .................. ......... 23.11

Cruise Control ............ Ssction 4

Dash Lights Brightness Contlo||er ..................... 23-90

Fan Conlrols ...,......,.... Section 10

Fuel Pump ,..,.,...,....,.... Section 11

Fuses...................... .,,.,.,.,.,,.,23-40*Gauges

Circuit Diagram ......-....-..23-58

Fuel Gauge .....,.,..... Section 11

Speedometer ..,..........,... 23-56

Ground Distribution ,....,.,...23-46

Hatch Glsss ODenor .........................,.,.,.,.,..,.,.,.,,. 23-121

Heater Controls .-........ Soction 21*Horns.,...,..,.,.,....... ................23"104*fgnition Switch ,,.,.,..,.,.,,.,.,.,23-51

lgnition Key Light System -'97 Mod6l .............. 23.88

-+

BODY

www.emanualpro.com

Page 1163 of 1395

Troubleshooting

Tips and Precautions

Bef ore Troubleshootin g

. Check applicable fuses in the appropriate fuse/relay

box.

. Check the battery for damage, state of charge, and

clean. and tight connections.

. Check the alternator belt tension.

CAUTION:

. Do not quick-charge a battery unless the battery

ground cable has been disconnected, otherwise you

will damage the alternator diodes.

. Do not attempt to crank thc engins wilh the battery

ground cable loosely connected or you will severely

damage the wiring.

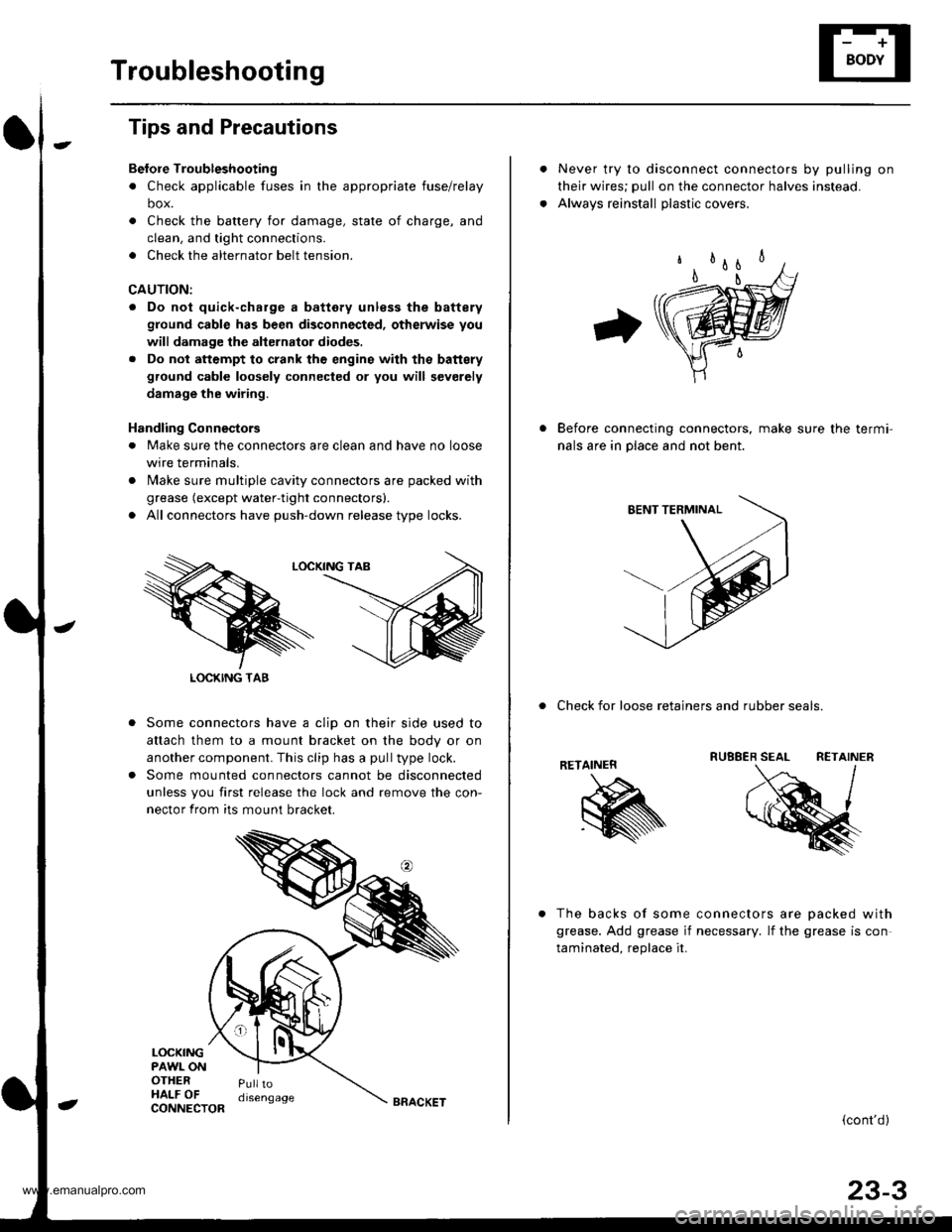

Handling Connestors

. Make sure the connectors are clean and have no loose

wire terminals,

. N4ake sure multiple cavity connectors are packed with

grease (except water-tight connectors).

. All connectors have push-down release type locks.

Some connectors have a clip on their side used to

attach them to a mount bracket on the body or on

another component. This clip has a pull type lock.

Some mounted connectors cannot be disconnected

unless you first release the lock and remove the con-

nector from its mount bracket.

LOCKINGPAWL ONOTHERHALF OFPulltodisengage

LOCKING TAB

CONNECTORBRACKET

Never try to disconnect connectors by pulling on

their wires; pull on the connector halves instead.

Alwavs reinstall olastic covers.

Before connecting connectors, make sure the termi-

nals are in place and not bent.

. Check for loose retainers and rubber seals.

RETAINER

The backs of some connectors are oacked with

grease. Add grease if necessary. lf the grease is con

taminated. reolace it.

{cont'd}

23-3

www.emanualpro.com