Lock nut HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 811 of 1395

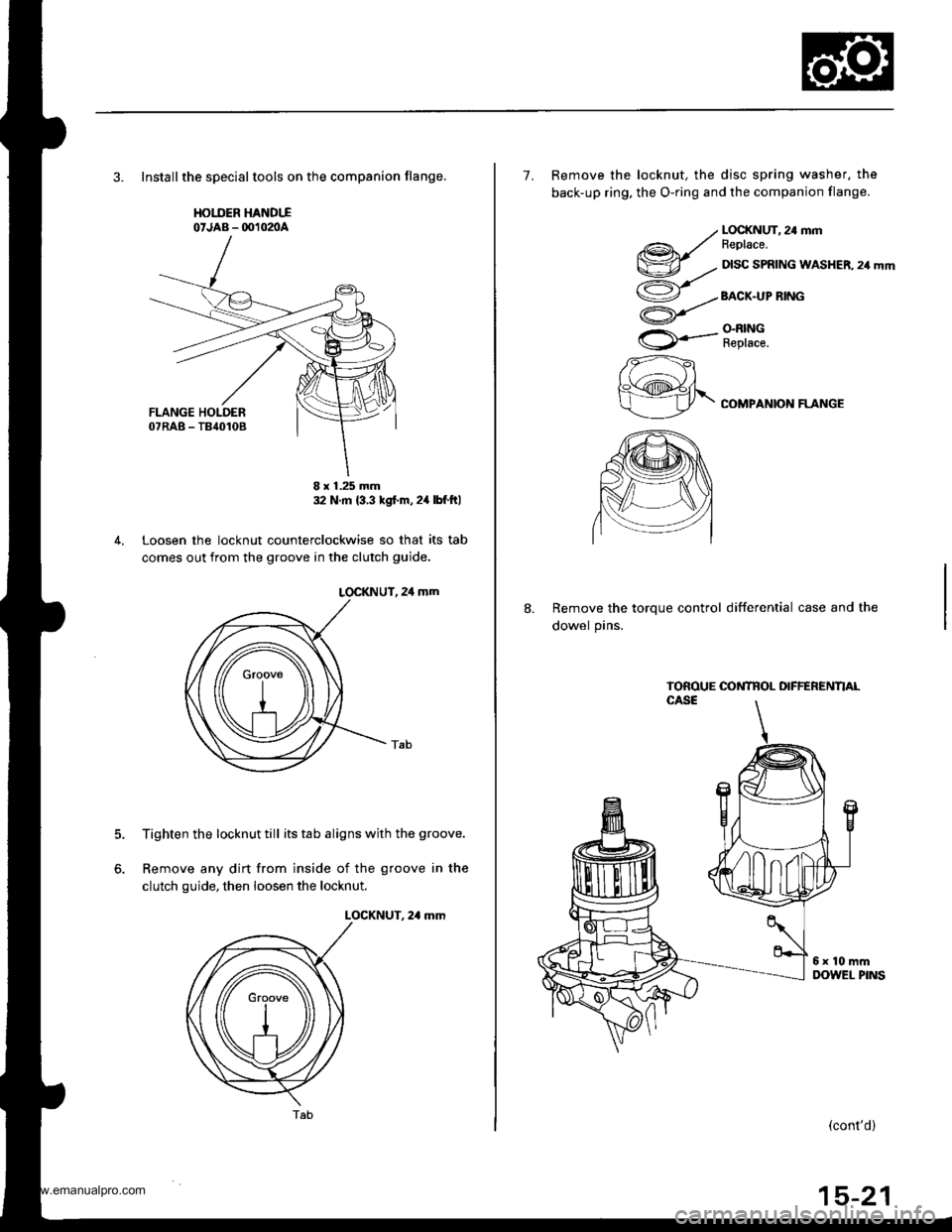

3. Installthe speclaltools on the companion flange,

HOIIIER HANDTIo'JAB - OO102nA

32 N m {3 3 tgt m,24lbf ftl

Loosen the locknut counterclockwise so that its tab

comes out from the groove in the clutch guide.

LOCKNUT, 24 mm

Tighten the locknut till its tab aligns with the groove.

Remove any dirt from inside of the groove in the

clutch guide, then loosen the locknut.

LOCKNUT. 2,1 mm

5.

6.

8 x 1.25 mm

Tab(cont'd)

7. Remove the locknut, the disc spring washer, the

back-up ring, the O-ring and the companion flange.

@r/v-.,.

ao/

U

rA*..-

zzft

h\@fr\

LOCKNUT, 24 mmFeplace.

DISC SPRING WASHER, 24 mm

BACX.UP RING

O.N|NGReplace.

COMPANION FLANGE

8.Remove the torque control differential case and the

dowel pins.

www.emanualpro.com

Page 814 of 1395

Rear Differential Assembly

Reassembly (cont'dl

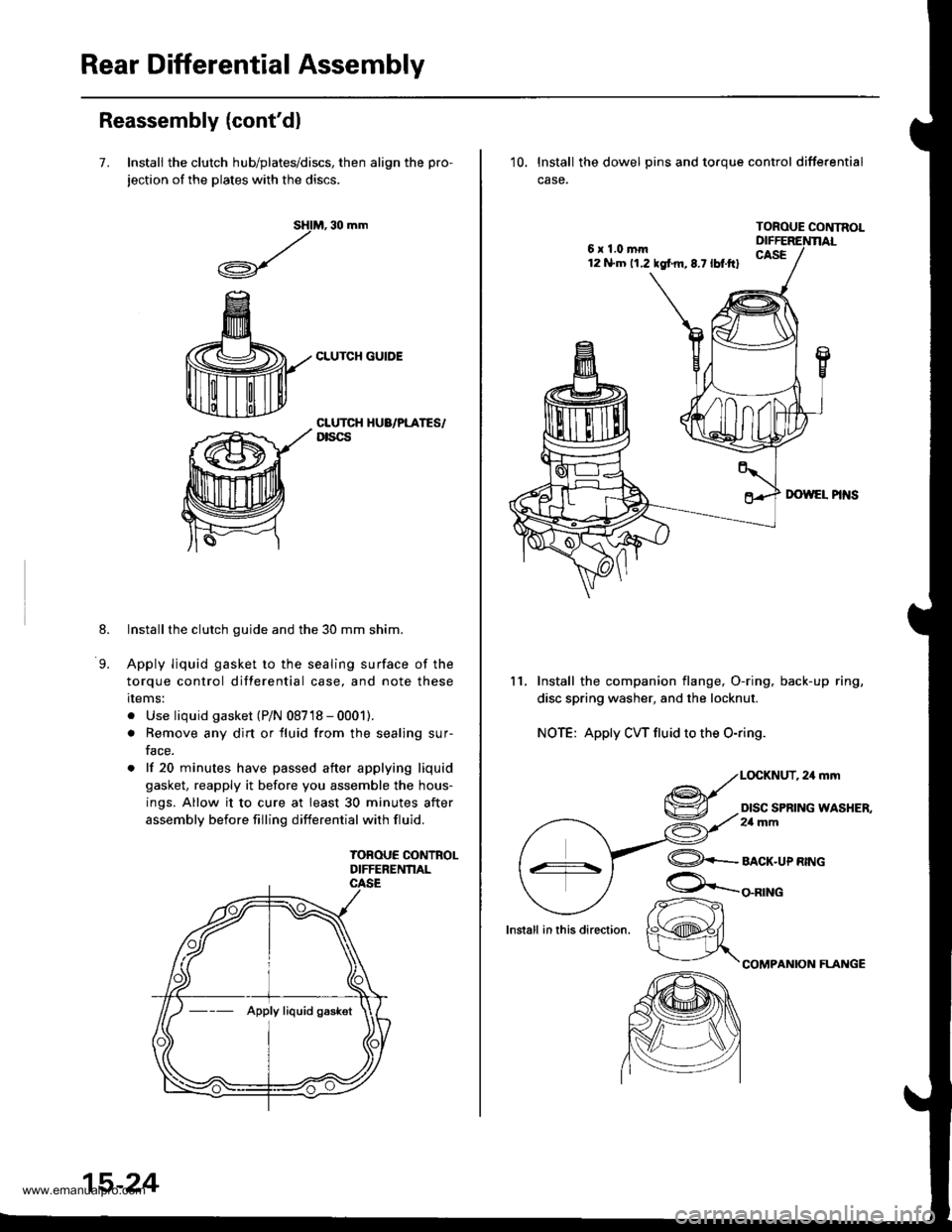

7. Install the clutch hub/plates/discs, then align the pro-

jection of the plates with the discs.

M, 30 mm

CLUTCH GUIDE

sHl

,/

.A-\,/r\-7

8.

9.

CLUTCH HUA/PLATES/Dtscs

Installthe clutch guide and the 30 mm shim.

Apply liquid gasket to the sealing surface of the

torque control differential case, and note these

rlems:

. Use liquid gasket (P/N 08718 - 0001).

. Remove any dirt or fluid from the sealing sur-

face.

. lf 20 minutes have passed after applying liquid

gasket, reapply it before you assemble the hous-

ings. Allow it to cure at least 30 minutes after

assembly before filling differential with fluid.

TOBOUE CONTROLDIFFERENNAL

--- Apply liquid gaskot

15-24

6x1.0mm12 N.m 11.2 tgf m,8.7lbt.ftl

10. lnstall the dowel pins and toroue control differential

case.

TOROUE CONTNOL

11. Install the companion flange, O-ring, back-up ring,

disc spring washer, and the locknut.

NOTE: Apply CW fluid to the O-ring.

,24mm

DISC SPRING WASHER,2a mm

lnstall in this direction.

@+-_alcr-upnwc

COMPANION FLAI{GE

/r-

K@#/

www.emanualpro.com

Page 815 of 1395

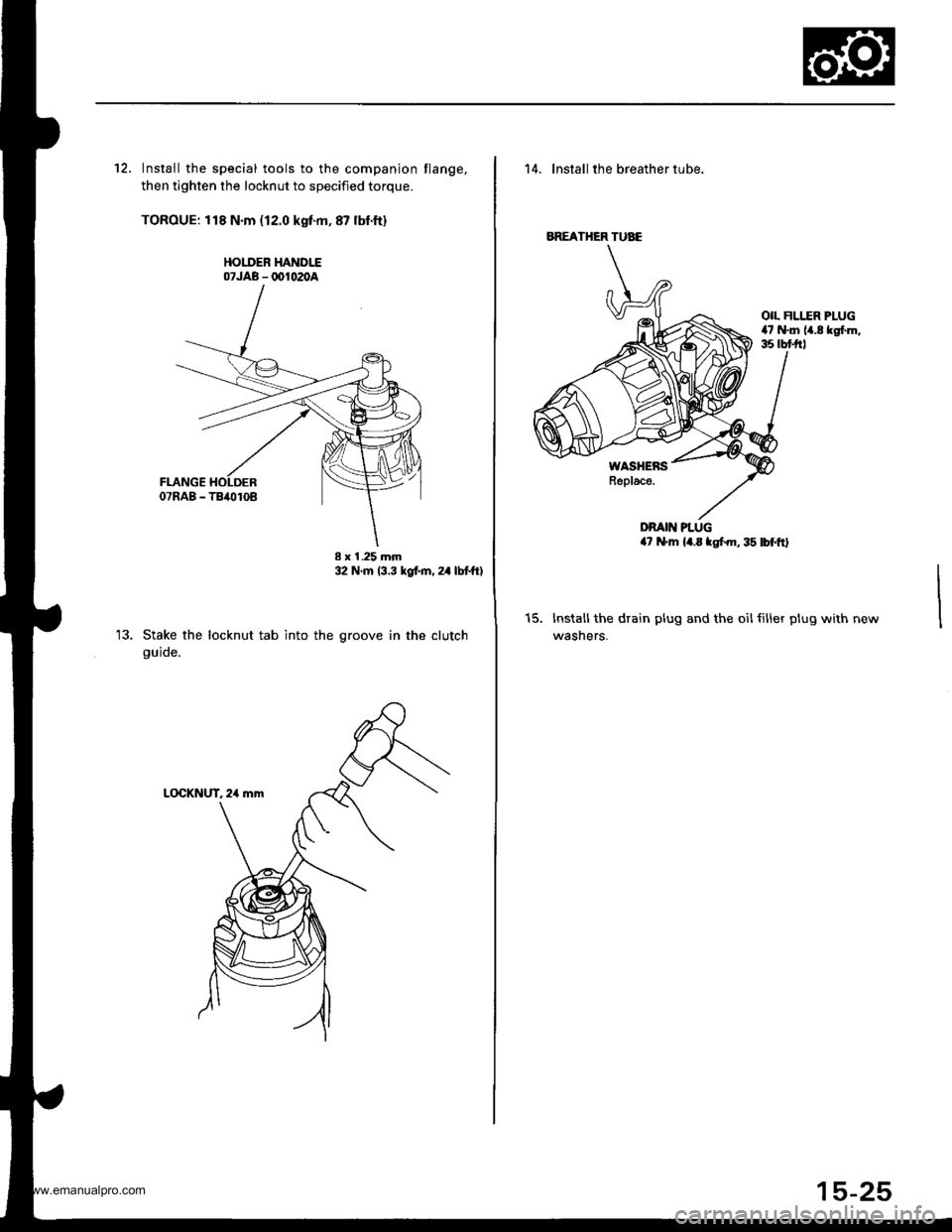

12. Install the special tools to the companion flange,

then tighten the locknut to specified torque.

TOROUE: 118 N.m (12.0 kgf-m,87 lbf'ft)

HOLDEB HANDLE07JAB - @1020A

Stake the locknut tab into the

guide.

I x I .25 mm32 N'm (3.3 kgt m, 24 lbtftl

groove in the clutch

14. lnstall the breather tube.

OIL FILI..ER PLUG47 N.m 14.8 kgf.m,35 tbt frl

WASHENSReplace.

DRAIN PLUG4? N'm l4.E tgf.m, 35 lbf'ftl

t5.Installthe drain plug and the oilfiller plug with

wasners.

BREATHER TUAE

www.emanualpro.com

Page 818 of 1395

DriveshaftsFront Driveshafts

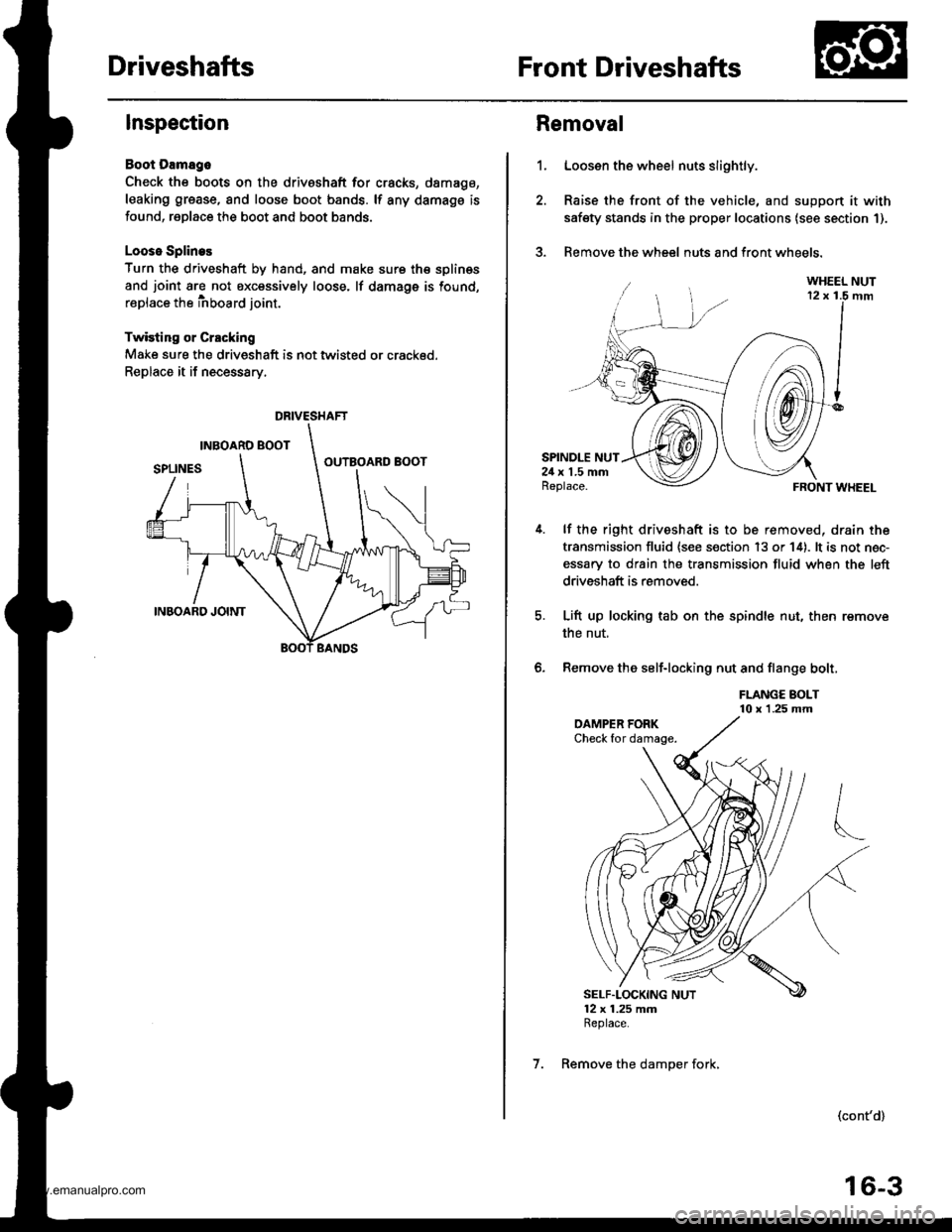

Inspection

Boot Damago

Check the boots on the driveshaft for cracks, damago,

leaking grease, and loose boot bands. lf any damags is

found, replace the boot and boot bands.

Looso Splines

Turn the driveshaft by hand, and make sure th€ splin€s

and joint are not excessively loose. lf damage is found,

replace the inboard joint.

Twisting or Crscking

Make sure the driveshaft is not twisted or crackod.

Replace it if necessary.

DRIVESHAFT

1.

Removal

Loosen the wheel nuts slightly.

Raise the front of the vehicle, and suppon it with

safety stands in the proper locations (see section 1).

Remove the wheel nuts and front wheels.?

SPINDLE NUT24 x 1.5 mmReplace.

lf the right driveshaft is to be removed, drain the

transmission fluid {see s€ction 13 or 14). lt is not nec-

essary to drain the transmission fluid when the left

driveshaft is removed.

Lift up locking tab on the spindle nut, then remove

the nut,

Remove the self-locking nut and flange bolt,

FLANGE BOLT10 x 1.25 mm

FRONT WHEEL

(cont'd)

6.

SELF"LOCKING NUT12 x 1.25 mmReplace.

7. Remove the damper fork,

16-3

www.emanualpro.com

Page 832 of 1395

Front Driveshafts

lnstallation

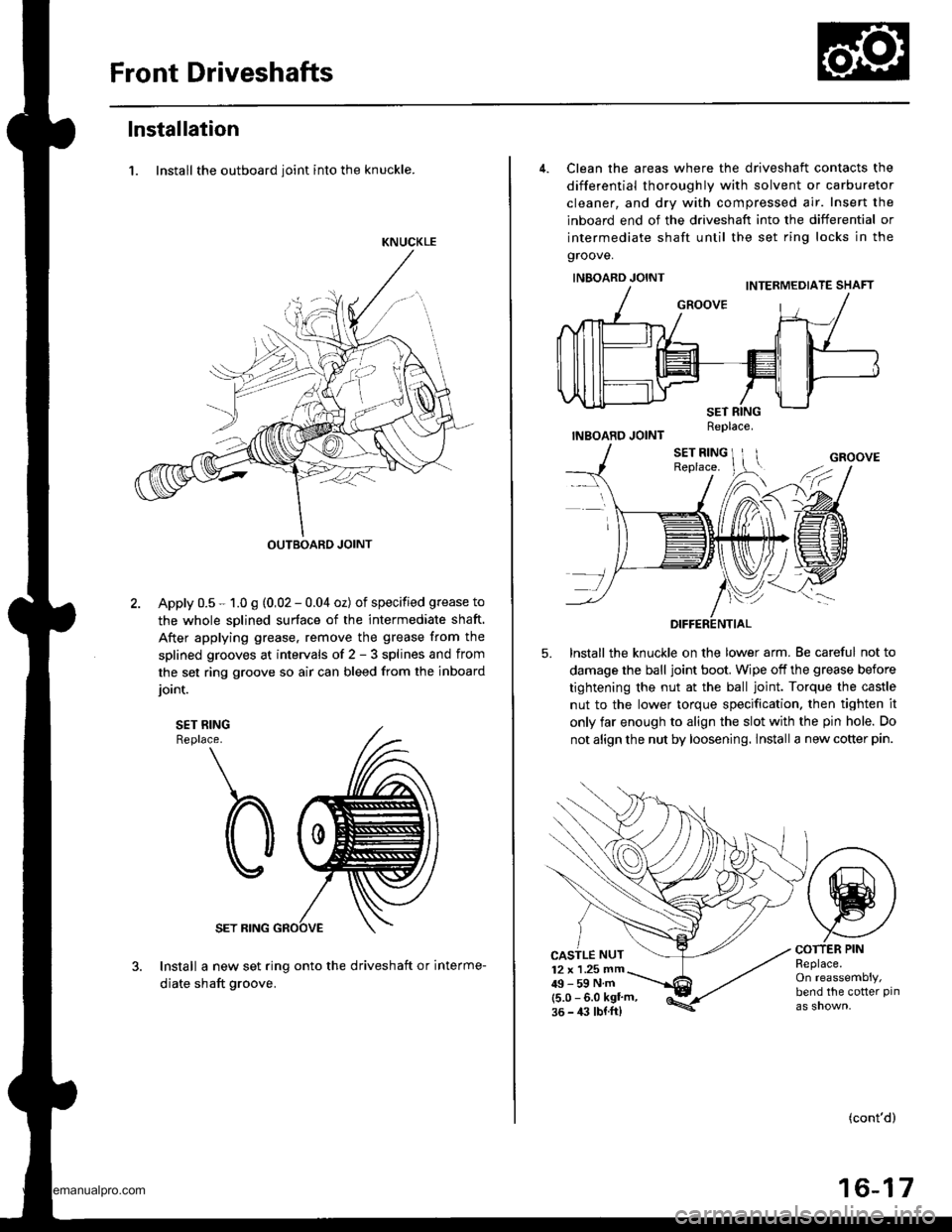

1. Install the outboard ioint into the knuckle.

KNUCKLE

OUTBOARD JOINT

Apply 0.5 - 1.0 g (0,02 - 0.04 oz) of specified grease to

the whole sDlined surface of the intermediate shaft.

After applying grease. remove the grease from the

splined grooves at intervals of 2 - 3 splines and from

the set ring groove so air can bleed from the inboard

ioint.

SET RINGReplace.

SET RING

Install a new set ring onto the driveshaft or interme-

diate shaft groove.

4. Clean the areas where the driveshaft contacts the

differential thoroughly with solvent or carburetor

cleaner, and dry with compressed air. Insert the

inboard end of the driveshaft into the differential or

intermediate shaft until the set ring locks in the

groove.

INBOARD JOINT

INBOARD JOINT

lnstall the knuckle on the lower arm. Be careful not to

damage the ball joint boot. Wipe off the grease before

tightening the nut at the ball joint. Torque the castle

nut to the lower torque specification. then tighten it

only far enough to align the slot with the pin hole. Do

not align the nut by loosening. lnstall a new cotter pin.

5.

CASTLE NUT12 x 1 .25 mm49-59Nm(5.0 - 6.0 kgl'm,36 - 4:l lbl.ft)

COTTER PINReplace.On reassembly,bend the cotter pin

(cont'd)

16-17

Replace.

www.emanualpro.com

Page 833 of 1395

Front DriveshaftsIntermediate Shaft

Installation {cont'd}

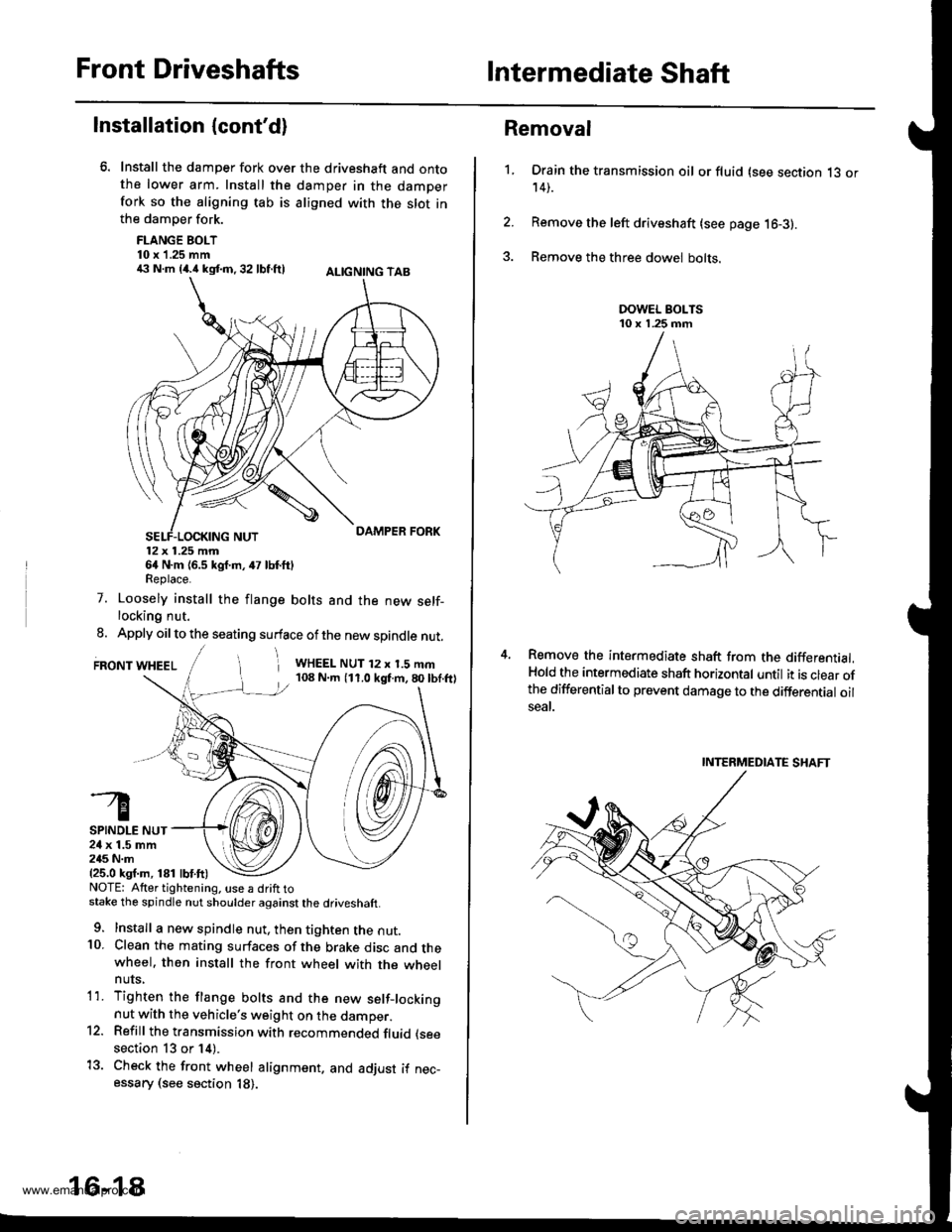

Install the damper fork over the driveshaft and ontothe lower arm. Install the damper in the damperfork so the aligning tab is aligned with the slot inthe damper fork.

FLANGE BOLT10 x 1.25 mm€ N.m {4.i1kst.n,32 lbf.ftl ALtcNtNG TAB

12x 1.25 mm64 N.m {6.5 kgf.m, 47 lbf.ftlReplace.

7. Loosely install the flange bolts and the new self-locking nut.

8. Apply oil to the seating surface of the new spindle nut.

FRONT WHEELi WHEEL NUT 12 x 1.5 mm108 N.m (11.0 kgf.m,80lbf.ftl

SPINDLE NUT24 x 1.5 mm245 N.m{25.0 ksf.m, 181 lbf.ft)NOTE: Atter tightening. use a drift tostake the spindle nut shoulder against the driveshaft.

9. Install a new spindle nut, then tighten the nut.10. Clean the mating surfaces of the brake disc and thewheel. then install the front wheel with the wheelnuts,

1'1. Tighten the flange bolts and the new setf-lockingnut with the vehicle's weight on the damper.12. Refill the transmission with recommended fluid (see

section 13 or 14).

13. Check the front wheel alignment. and adjust if nec-essary (see section 18).

16-18

1.

Removal

Drain the transmission oil or fluid (see section 13 or14).

Remove the left driveshaft (see page 16-3).

Remove the three dowel bolts.

Remove the intermediate shaft from the differential.Hold the intermediate shaft horizontal until it is clear ofthe differentialto prevent damage to the differential oilseal.

INTERMEDIATE SHAFT

www.emanualpro.com

Page 837 of 1395

Rear Driveshafts

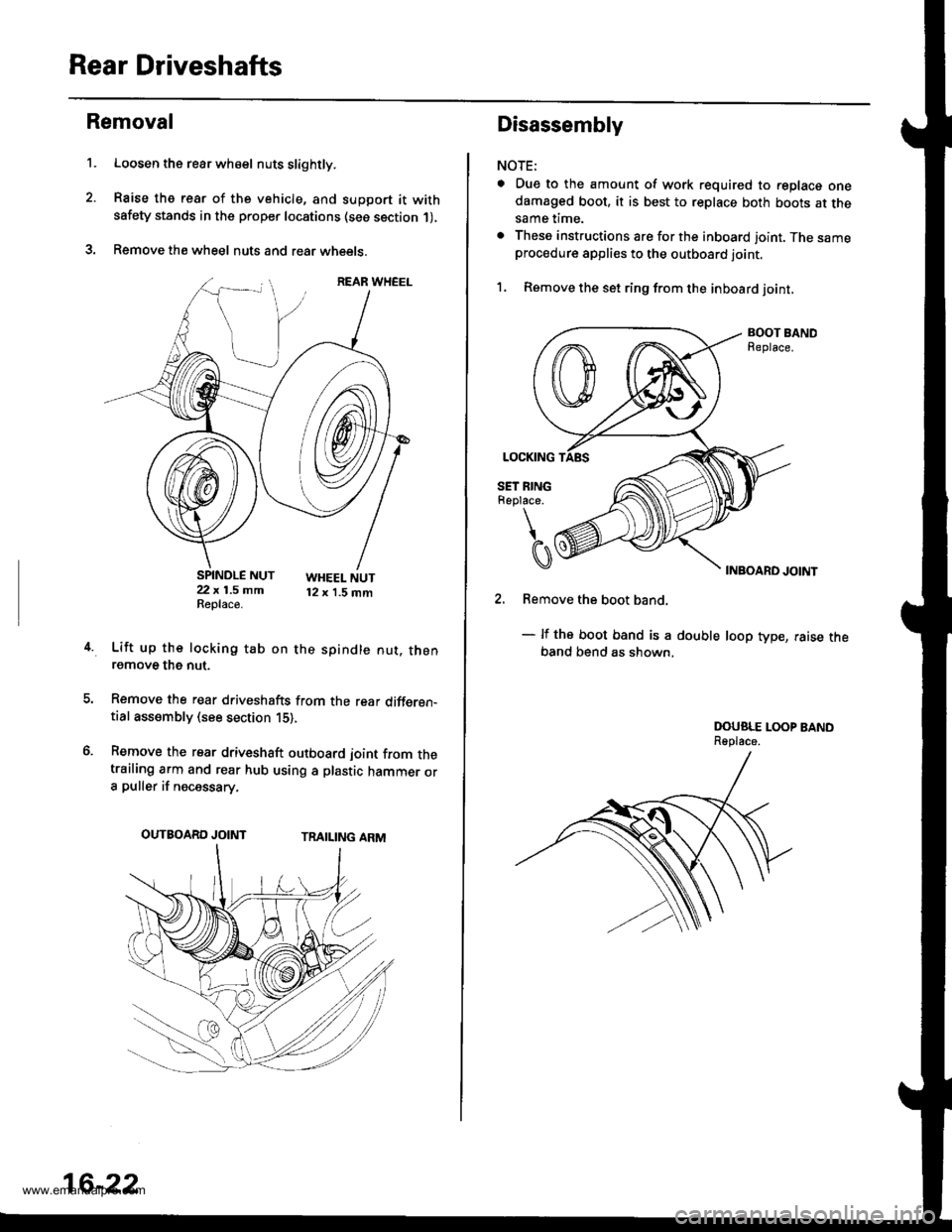

't.

Removal

Loosen the rear wh€el nuts slightly.

Raise the rear of the vehicle, and support it withsafety stands in the proper locations (see section 1),

Remove the wheel nuts and rear wheets.

SPINDLE NUT22 x 1.5 mmReplace.

WHEEL NUT12 x 1.5 mm

4.Lift up the locking tab on the spindle nut. thenremove the nut.

Remove the rear driveshafts from the rear differen-tial assembly (see section 15),

Remove the rear driveshaft outboard joint from thetrailing arm and rear hub using a plastic hammer ora puller if necessary.

TRAILING ARMOUTBOARD JOINT

16-22

Disassembly

NOTE:

a Due to the amount of work required to replace onedamaged boot, it is best to replace both boots at thesame time.

. These instructions are for the inboard joint. The sameprocedure applies to the outboard joint.

1, Remove the set ring from the inboard joint,

BOOT BANDReplace.

INBOARD JOINT

2. Remove the boot band.

- lf the boot band is a double loop type, raise theband bend as shown,

DOUSLE LOOP BANDReplace.

www.emanualpro.com

Page 847 of 1395

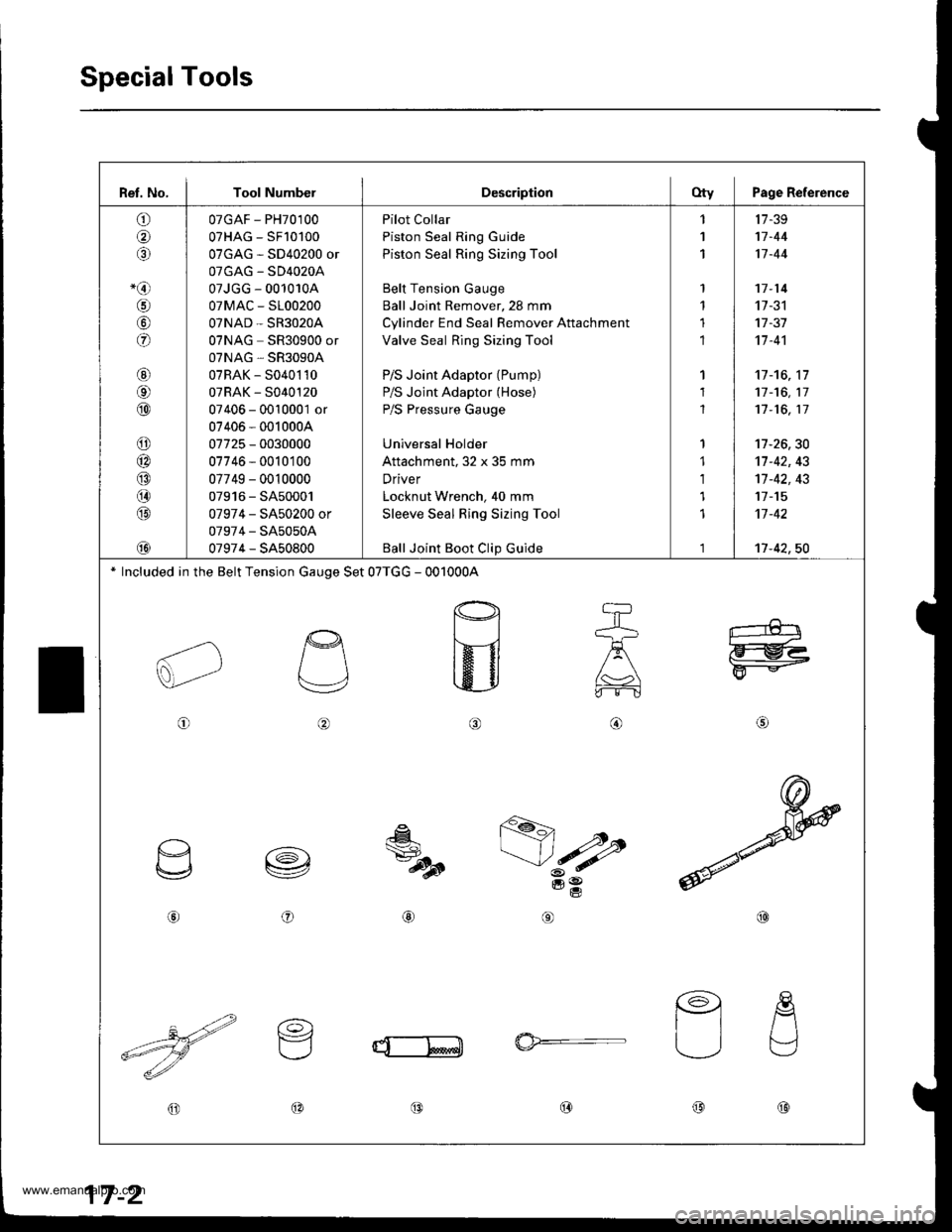

Ret. No, I Tool NumbelDescriptionfty Page Reference

o

o

-@

€r

o

@rol

@

o

@

@(}

@

@

07GAF - PH70100

07HAG - SF10100

07GAG - SD40200 or

OTGAG - SD4O2OA

07JGG - 001010A

07MAC - S100200

OTNAD _ SR3O2OA

07NAG SR30900 or

07NAG , SR3OgOA

07RAK - 50401 10

07RAK - 5040120

07406 - 0010001 or

07406 - 0010004

07725 - 0030000

07746 - 0010100

07749 - 0010000

07916 - SA50001

07974 - SA50200 or

07974 - SA5050A

07974 - SA50800

Pilot Collar

Piston Seal Ring Guide

Piston Seal Ring Sizing Tool

Belt Tension Gauge

Ball Joint Remover,23 mm

Cylinder End Seal Remover Attachment

Valve Seal Ring Sizing Tool

P/S Joint Adaptor (Pump)

P/S Joint Adaptor (Hose)

P/S Pressure Gauge

Universal Holder

Attachment, 32 x 35 mm

Driver

Locknut Wrench, 40 mm

Sleeve Seal Ring Sizing Tool

Ball Joint Boot Clip Guide

'l

1

1

1

1

1

1

1

1

1

1

1

1,l

1

1

11-39

17-44

11-44

17 -14't]-31

17 -37't7 -4'l

17-'t6, 17

17-16, 17

11-16, 17

17-26,30't]-42, 43't1-42, 43

11-15't]-42

11-42, 50

* Included in the Belt Tension Gauge Set 07TGG - 001000,4

o@

\J

,/:\

I

o

,€l-

=tt

@@

aA)

l:I/\L----.--.--------_

@o(D(9@@

17-2

www.emanualpro.com

Page 853 of 1395

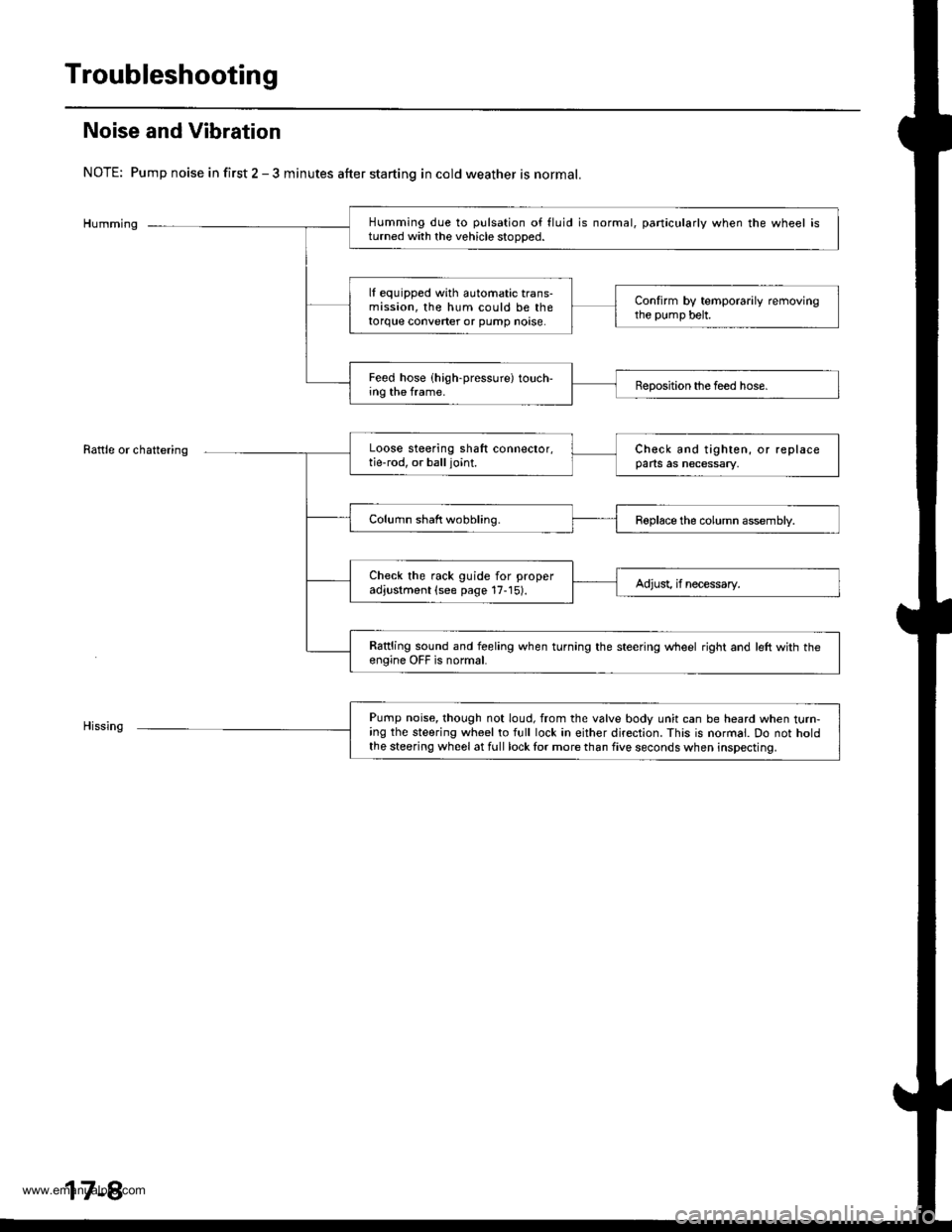

Troubleshooting

Noise and Vibration

NOTE: Pump noise in first 2 - 3 minutes after starting in cold weather is normal.

Humming

Rattle or chattering

Humming due to pulsation of fluid is normal, particularly when the wheel isturned with the vehicle stooDed.

lf equipped with automatic trans-mission, the hum could be thetorque converter or pump noase.

Confirm by temporarily removingthe pump belt.

Feed hose (high-pressure) touch-ing the frame.Beposition the feed hose.

Loose steering shaft connector,tie-rod, or balljoint.Check and tighten, or replaceparts as necessary,

Column shaft wobbling.Roplace the column assembly.

Check the rack guide for properadjustment (see page 17-15).Adjust, if necessary.

Rattling sound and feeling when turning the steering wheel right and left with th€engine OFF is normal.

Pump noise, though not loud, from the valve body unit can be heard when turn-ing the steering wheel to full lock in either direction. This is normal. Do not holdthe steering wheel at full lock lor more than five seconds when inspecting.

17-8

www.emanualpro.com

Page 858 of 1395

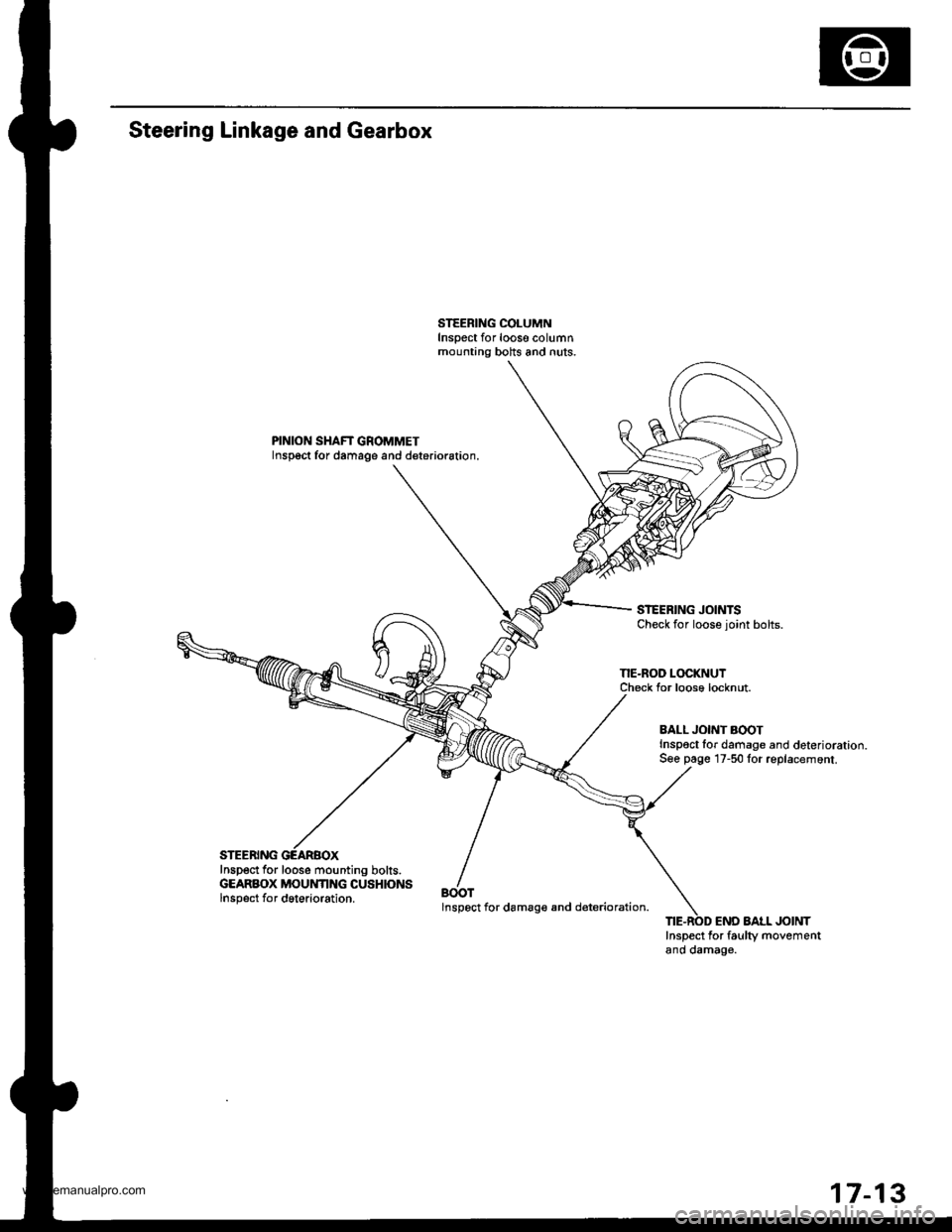

Steering Linkage and Gearbox

PINION SHAFT GROMMETInspoct for damage and deterioration.

STEERING JOINTSCheck for loose joint bolts.

NE-ROD LOCKNUTCheck Ior loose locknut.

Inspect for loose mounting bolts.GEARBOX MOUNTING CUSHIONSlnsp6ct for dgterioration.BOOTlnspect for damag€ and d€terioration.

BALL JONT AOOTInspoct lor damage and deterioration.S€e page 17-50 for replacemont.

END AAtL JOINTInspect for faulty movementano oamag€.

17-13

www.emanualpro.com