Rack HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1011 of 1395

Glass

Windshield Replacement

CAUTION:

. Put on gloves to protect your hands.

. Use seat covers to avoid damaging any surfaces.

1. To remove the windshield, first remove the:

. Rearview mirror (see page 20-28)

. Sunvisors and holders (see page 20-44l'

. Ceiling light (see section 23)

. Grab handle (see page 20-44)

. Front door trim (see page 20-41)

. Front pillar trim (see page 20-41)

. Windshield wiper arms and cowl cover (see page

20-98)

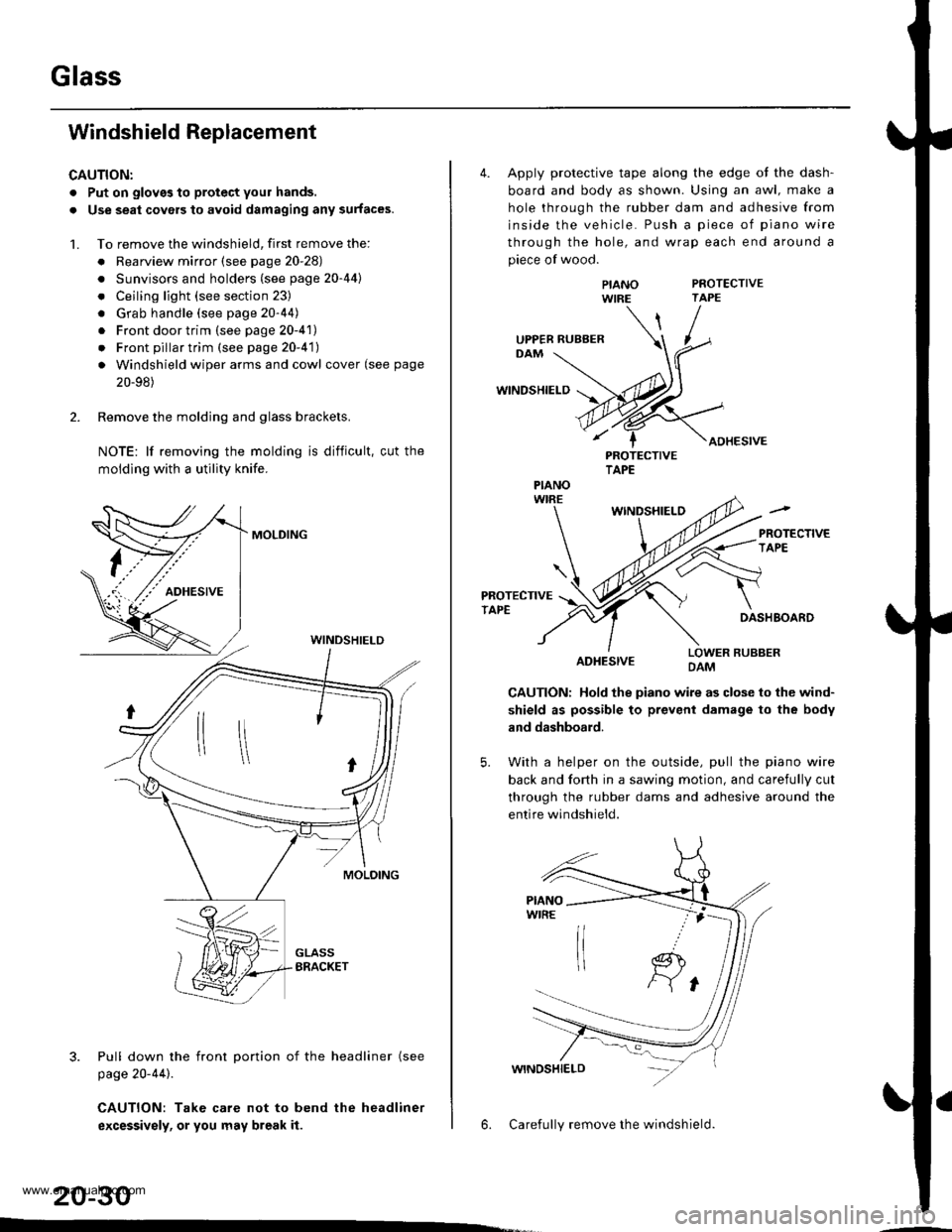

2. Remove the molding and glass brackets.

NOTE: lf removing the molding is difficult, cut the

moldlng with a utility knife.

MOLDING

3. Pull down the front Dortion of the headliner (see

page 20-44).

CAUTION: Take care not to bend the headliner

excessivsly, or you may break it.

WINDSHIELD

20-30

4. Apply protective tape along the edge ot the dash-

board and body as shown. Using an awl, make a

hole through the rubber dam and adhesive from

inside the vehicle. Push a piece of piano wire

through the hole, and wrap each end around a

piece of wood.

PROTECTIVETAPE

WINDSHIELD

ADHESIVE

PIANOWIRE

PROTECTIVETAPE

WINDSHIELO

PROTECTIVETAPEDASHBOARD

ADHESIVELOWER RUBBERDAM

CAUTION: Hold the piano wire as close to the wind-

shield as possible to prevent damage to the body

and dashboard.

5. With a helper on the outside, pull the piano wire

back and fo(h in a sawing motion, and carefully cut

through the rubber dams and adhesive around the

entire windshield.

6. Carefully remove the windshield.

UPPER RUBBER

PIANO

www.emanualpro.com

Page 1012 of 1395

7.

8.

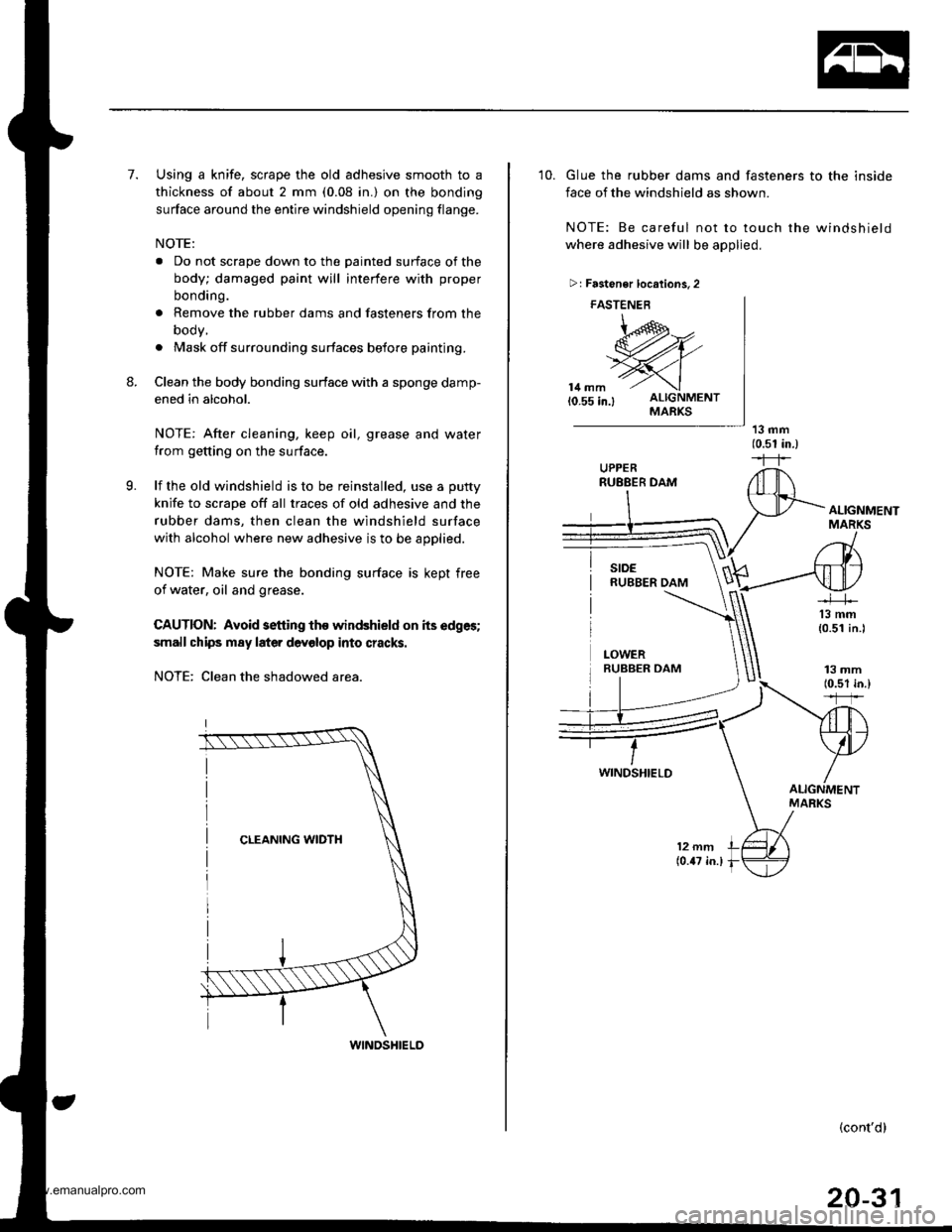

Using a knife, scrape the old adhesive smooth to a

thickness of about 2 mm (0.08 in.) on the bonding

surface around the entire windshield opening flange.

NOTE:

a Do not scrape down to the painted surface of the

body; damaged paint will interfere with proper

bonding.

. Remove the rubber dams and fasteners from the

oooy,

. Mask off surrounding surfaces before painting.

Clean the body bonding surface with a sponge damp-

ened in alcohol.

NOTE: After cleaning, keep oil, grease and water

from getting on the surface.

lf the old windshield is to be reinstalled, use a putty

knjfe to scrape off all traces of old adhesive and the

rubber dams, then clean the windshield surface

with alcohol where new adhesive is to be applied.

NOTE: Make sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid setting tho windshield on its edges;

small chips m8y later devolop into cracks.

NOTE: Clean the shadowed area.

9.

WINDSHIELD

10. Glue the rubber dams and fasteners to the inside

face of the windshield as shown

NOTE: Be careful not to touch the windshield

where adhesive will be applied,

13 mm(0.51 in.)--r-r

>r Fastener locrtions. 2

FASTENEB

\,@,--

w,{,.'>Yl

14 mm -'- \l0.55 in.l ALIGNMENTMARKS

ALIGNMENTMARKS

13 mm(0.51 in.l

13 mm10.51 in.)*ffi

ALIGNMENTMARKS

12 mm(0.47 in.l

(cont'd)

20-31

www.emanualpro.com

Page 1014 of 1395

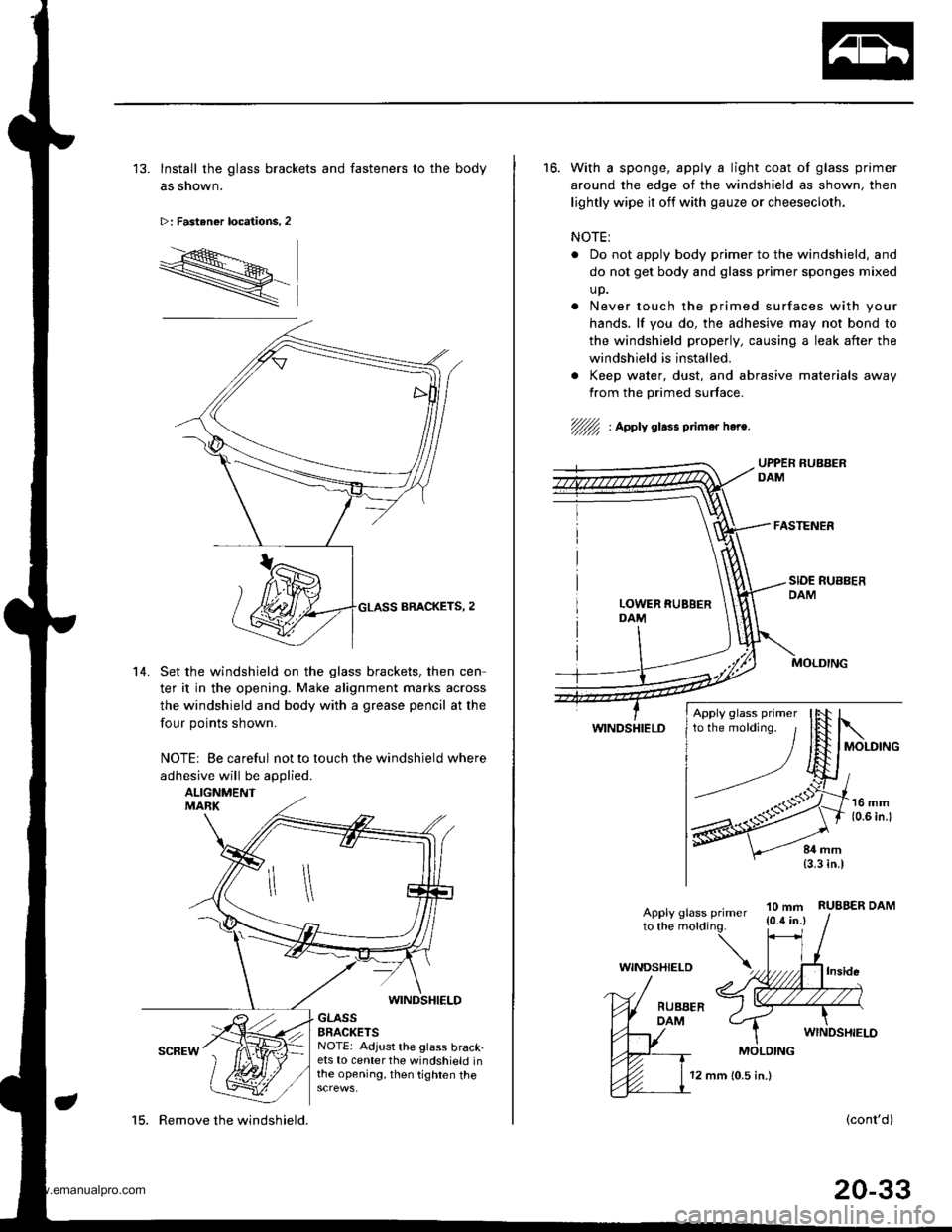

'13. Install the glass brackets and fasteners to the body

as shown.

>: Fastener locations, 2

R-

14. Set the windshield on the glass brackets. then cen

ter it in the opening. Make alignment marks across

the windshield and body with a grease pencil at the

four points shown.

NOTE| Be careful not to touch the windshield where

adhesive will be applied.

ALIGNMENTMABK

WINDSHIELD

GLASSBRACKETSNOTE: Adjust the glass brack-ets to center the windshield inthe opening, then tighten the

15. Remove the windshield.

12 mm 10.5 in.)

16. With a sponge, apply a light coat of glass primer

around the edge of the windshield as shown, then

lightly wipe it off with gauze or cheesecloth.

NOTE:

Do not apply body primer to the windshield, and

do not get body and glass primer sponges mixed

up.

Never touch the primed surfaces with your

hands. lf you do, the adhesive may not bond to

the windshield properly, causing a leak after the

windshield is installed.

. Keep water, dust, and abrasive materials away

from the primed surface.

//fu : Apply glass ptimar hea.

WINDSHIELD

10 mm{0.4 in.}RUBBER DAMApply glass primerto the molding.

(cont'd)

20-33

Apply glass primer

WINDSHIELD

MOLDING

www.emanualpro.com

Page 1026 of 1395

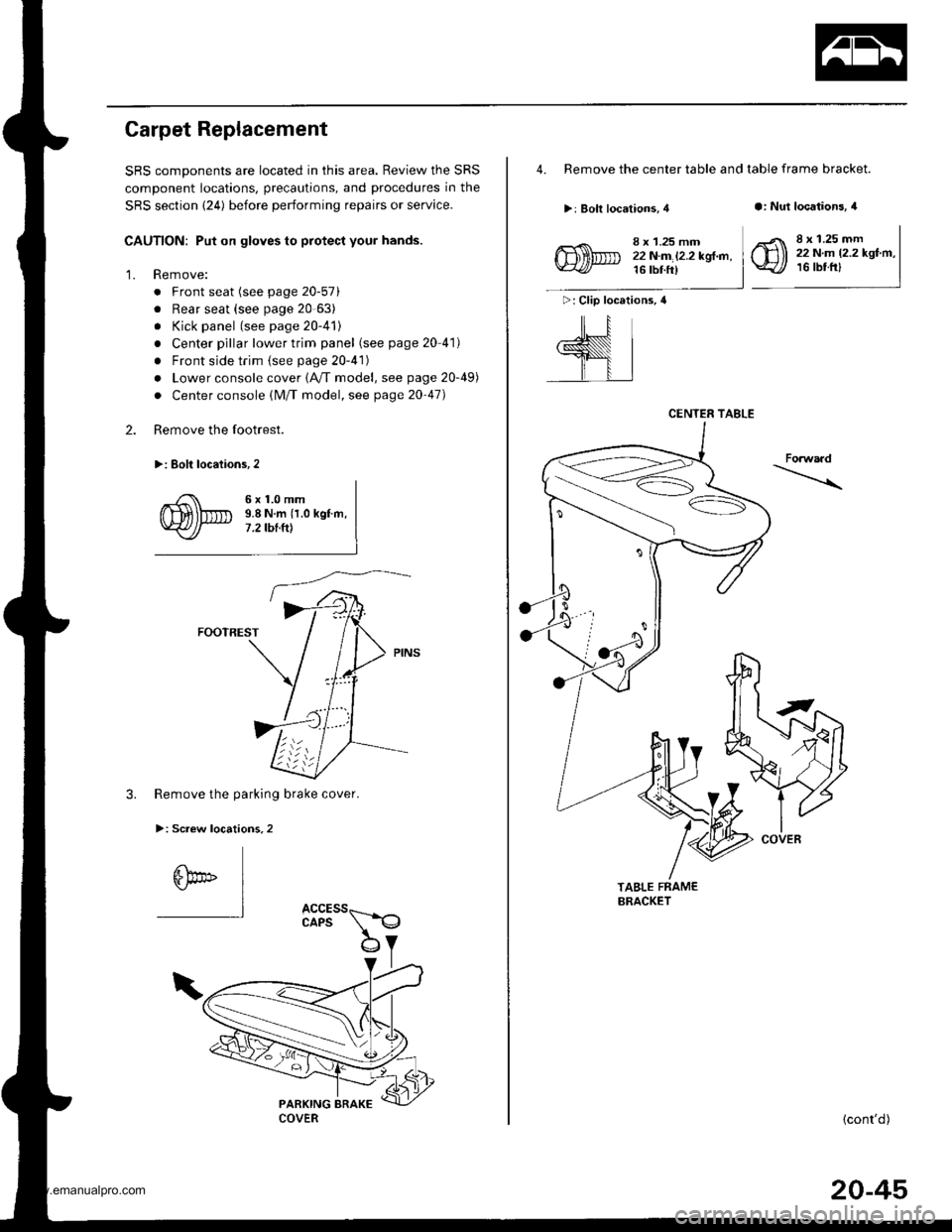

Carpet Replacement

SRS comDonents are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section {24) before performing repairs or service.

CAUTION: Put on gloves to protect your hands.

Remove:

. Front seat (see page 20-571

. Rear seat (see page 20 63)

. Kick panel (see page 20-41)

. Center pillar lower trim panel (see page 20 41)

. Front side trim {see page 20-41)

. Lower console cover 1A,/T model, see page 20-49)

. Center console (lM/T model, see page 2o-47)

Remove the footrest.

>: Eolt locaiions,2

2.

'1.

6x1.0mm9.8 N.m {1.0 kgf.m,7 .2 tbt.ttt

FOOTREST

3. Remove the parking brake cover.

>: Screw locations,2

6bo" I"l

4. Remove the center table and table frame bracket.

>: Bolt locations, 4a: Nut locations, 4

>: Clip locations, 4

ill

,l

8 x 1.25 mm22N.m l2.2kgl.n,16 tbt ft)

8 x 1.25 mm22 N.m 12.2 kgf.m,16 tbtfrl

Forwaad

TABLE FRAMEBRACKET

{cont'd)

CENTER TABLE

COVER

20-45

www.emanualpro.com

Page 1030 of 1395

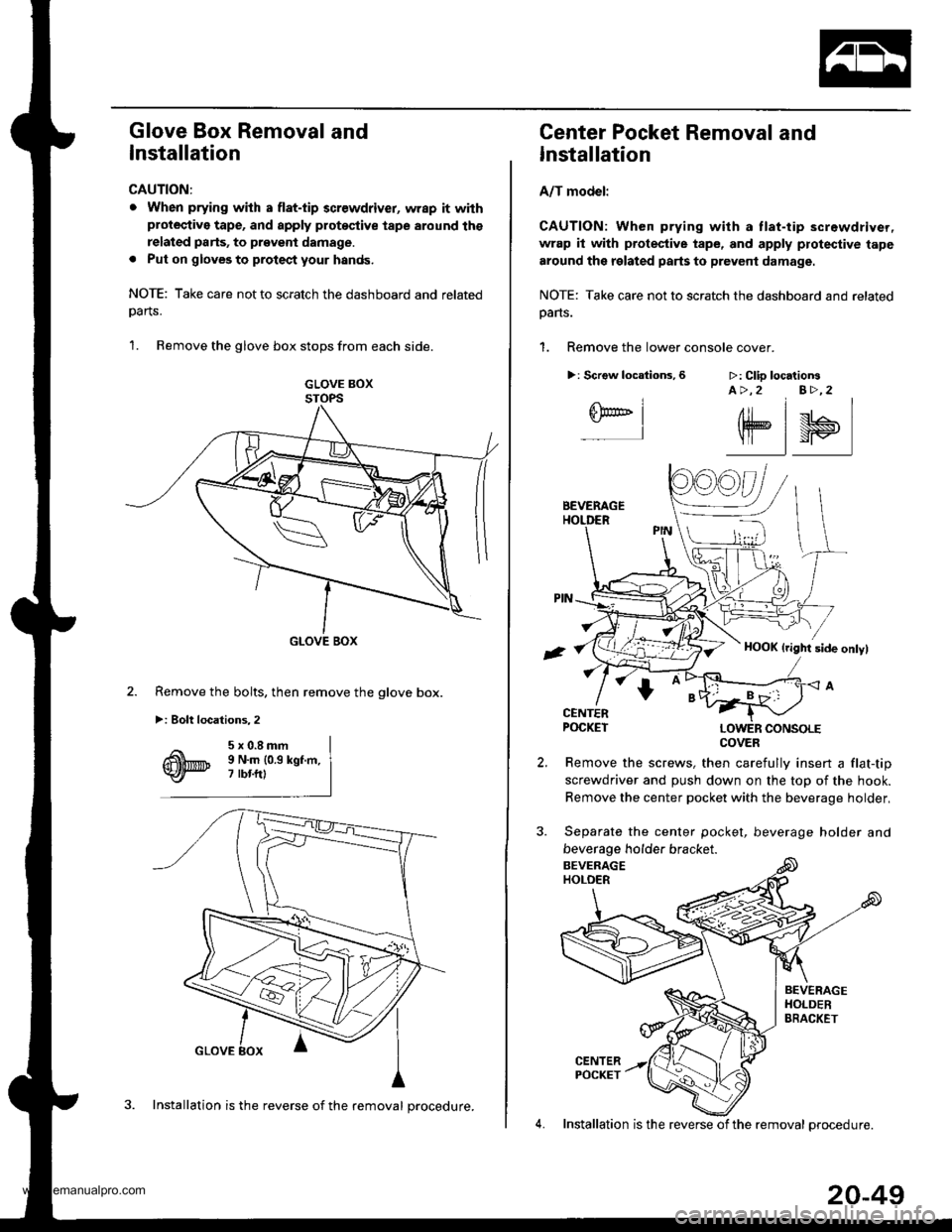

Glove Box Removal and

Installation

CAUTION:

. When prying with a flat-tip 3crewdriver, wrap it withprotective tape, and apply protoqtive tape around ths

related parts, to prgveni damage.

. Put on gloveg to protect your hands.

NOTE: Take care not to scratch the dashboard and related

oarts.

1. Remove the glove box stops from each side.

GLOVE BOXSTOPS

GLOVE BOX

Remove the bolts, then remove the glove box.

>i Bolt locations,2

3. Installation is the reverse of the removal procedure.

20-49

Center Pocket Removal and

Installation

A/T model:

CAUTION: When prying with a tlat-tip screwdriver,

wrap it with protestive tape, and apply protective tape

around the related parts to prevent damage.

NOTE: Take care not to scratch the dashboard and related

oans.

1. Remove the lower console cover.

>: Scrgw locations,6 >: Clip locationsA >,2 B>,2

6F@'' I-l

elsl

Remove the screws, then carefully insert a flat-tip

screwdriver and push down on the top of the hook.

Remove the center pocket with the beverage holder,

Separate the center pocket, beverage holder and

beverage holder bracket.

4. Installation is the reverse of the removal orocedure.

COVER

www.emanualpro.com

Page 1034 of 1395

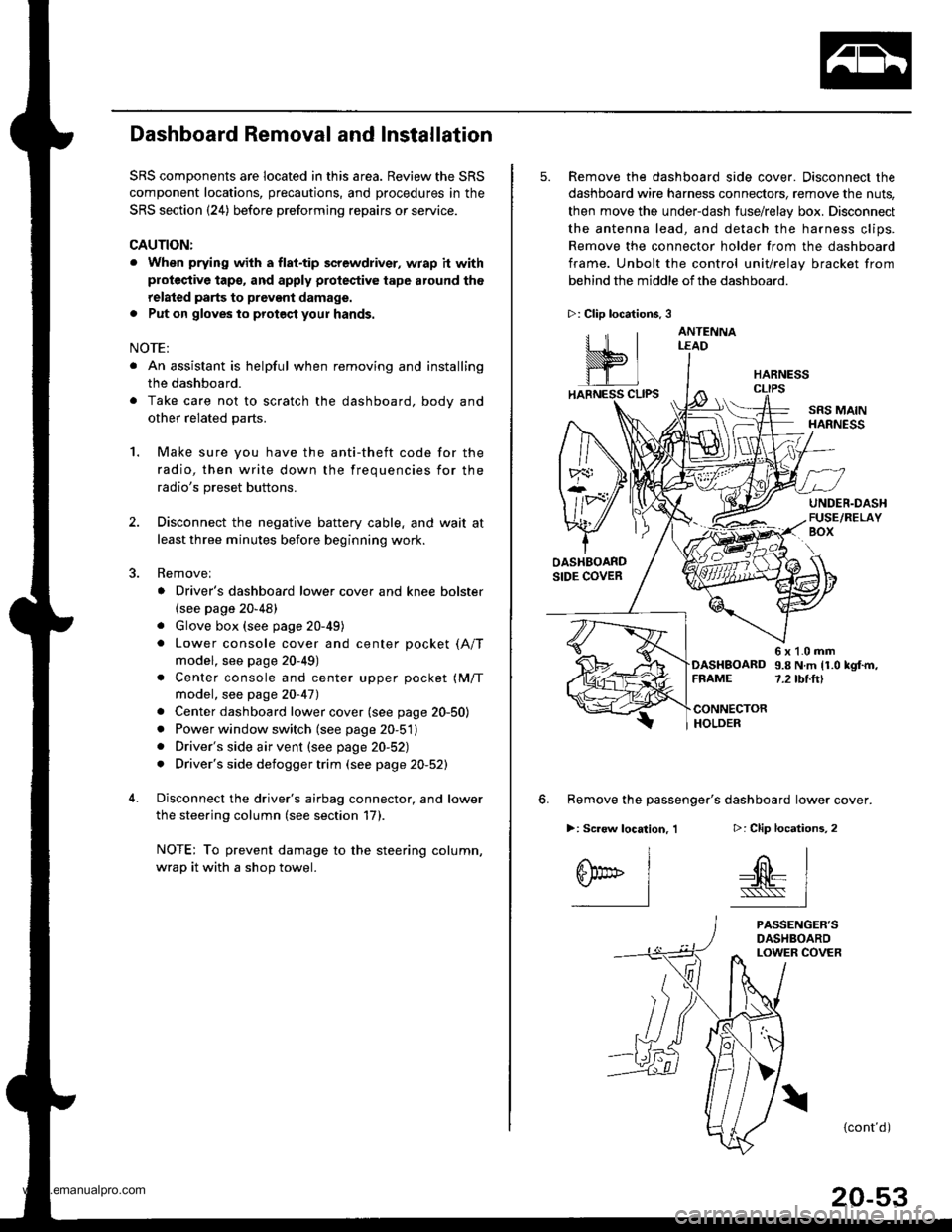

Dashboard Removal and Installation

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section {24) before preforming repairs or service.

CAUTION:

. When prying with a flat-tip screwdriver, wrap h withprotective tap€, and apply protective tape around the

related parts to prevgnt damage.

. Put on gloves to prot€ct your hands.

NOTE:

. An assistant is helpful when removing and installing

the dashboard.

. Take care not to scratch the dashboard, bodv and

other related parts.

1.Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons.

Disconnect the negative battery cable. and wait at

least three minutes before beginning work.

Removei

a Driver's dashboard lower cover and knee bolster(see page 20-48)

. Glove box (see page 20-49)

. Lower console cover and center pocket (A/T

model, see page 20-49)

. Center console and center upper pocket (M/T

model, see page 20-47)

. Center dashboard lower cover (see page 20-50)

. Power window switch (see page 20-51)

. Driver's side air vent (see page 20-52)

. Driver's side defogger trim (see page 20-52)

Disconnect the driver's airbag connector, and lower

the steering column (see section 17)

NOTE: To prevent damage to the steering column,

wrap it with a shop towel.

2.

5. Remove the dashboard side cover. Disconnect the

dashboard wire harness connectors, remove the nuts,

then move the under-dash fuse/relay box. Disconnect

the antenna lead, and detach the harness clips.

Remove the connector holder from the dashboard

frame. Unbolt the control unit/relay bracket from

behind the middle of the dashboard.

HARNESS

6. Remove the passenger's dashboard lower cover.

D: Clip locations,

nl

-$t- Issj

I

ANTENNALEAD

>: Clip locations.

rttl

slllll

>: Scr€w location, 1

I

SF:oo I-l

SRS MAINHARNESS

UNDER.DASHFUSE/RELAYBOX

OASHBOARDSIDE COVER

6x1.0mm9.8Nm11.0kgf.m,7.2tbt.ftlDASHBOARDFFAME

CONNECTORHOLDER

PASSENGER'SDASHBOARDLOWER COVER

{cont'd)

www.emanualpro.com

Page 1038 of 1395

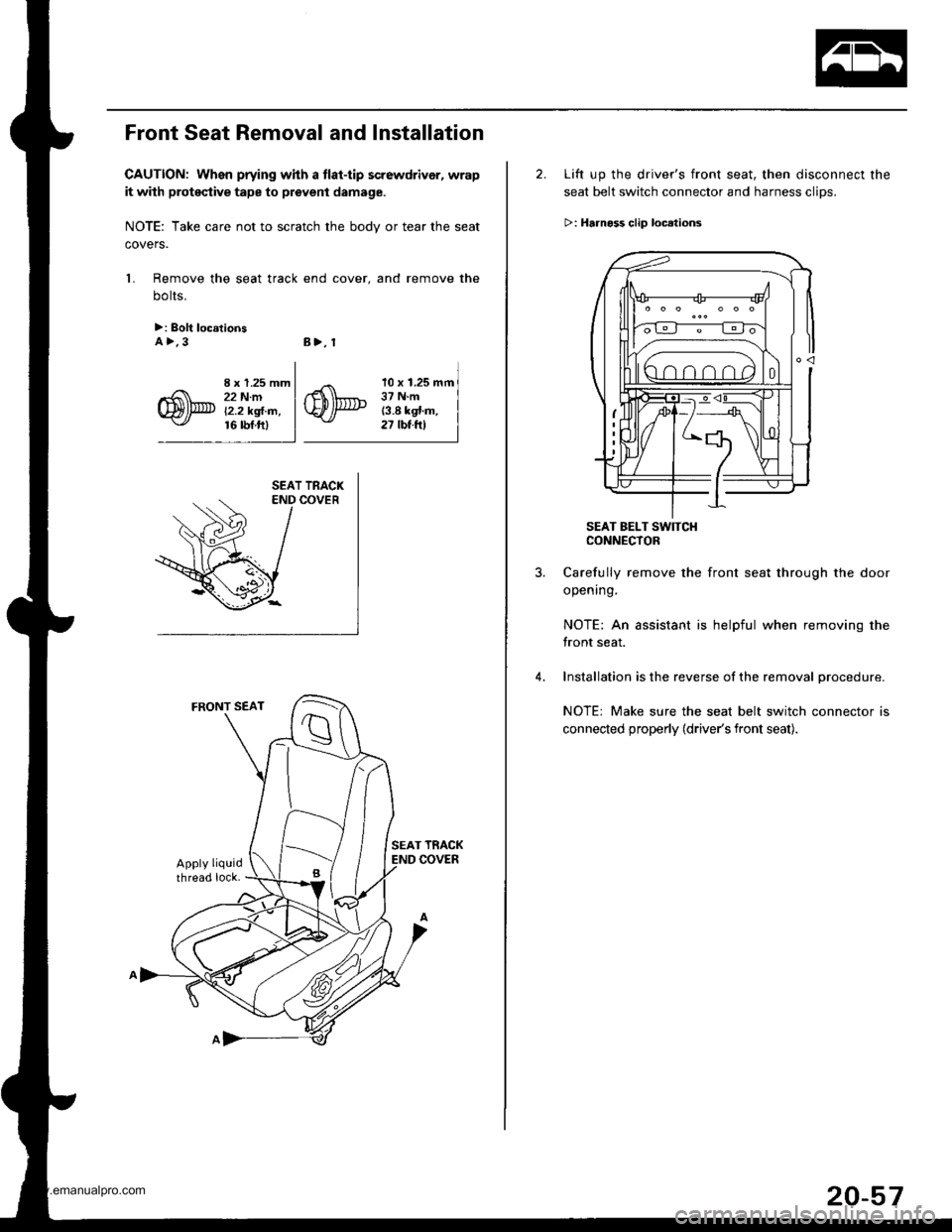

Front Seat Removal and Installation

CAUTION: When prying whh a tlat-tip screwdrivor, wrap

it with proteqtive tape to prevent damage.

NOTE: Take care not to scratch the bodv or tear the seat

covers.

1. Remove the seat track end cover, and remove the

bolts.

>: Bolt loc.tionsA>.3B>, 1

I x 1.25 mm22 N.mi'2.2 kgl.m,16 rbf.ftl

10 x 1.25 mm37 N.m13.8 kgt.m,27 tbt.ftl

2. Lift up the driver's front seat, then disconnect the

seat belt switch connector and harness clips.

>: Hrrnoss clip loc.lions

SEAT BELT SW]TCHCONNECTOR

Carefully remove the front seat through the door

opening.

NOTE: An assistant is helpful when removing the

front seat.

Installation is the reverse of the removal procedure.

NOTE: Make sure the seat belt switch connector is

connected properly (driver's front seat).

20-57

www.emanualpro.com

Page 1048 of 1395

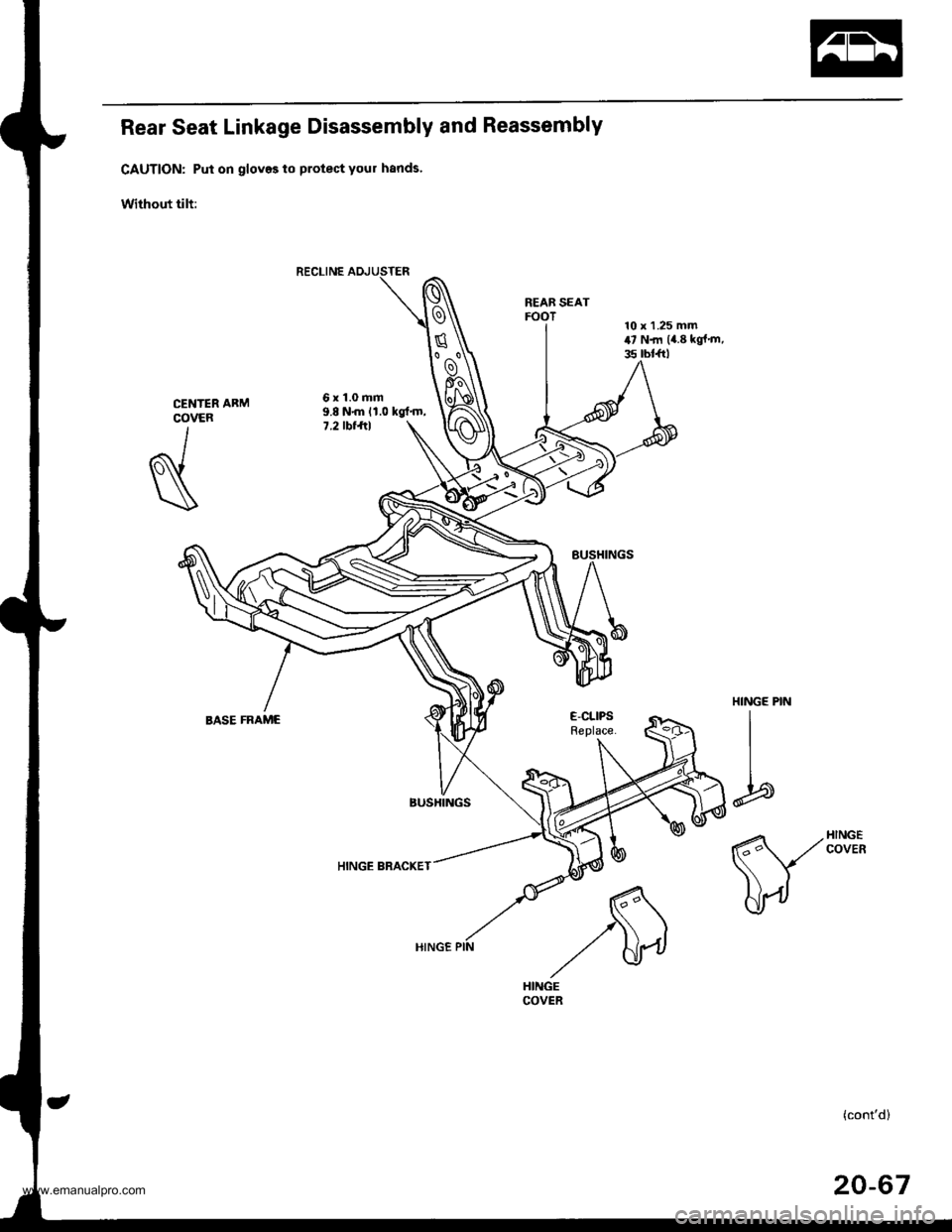

Rear Seat Linkage Disassembly and Reassembly

CAUTION: Put on gloves to protect your hands'

Without tilt:

REAB SEATFOOT

6x1.0mm9.8 N{n 11.0 kgt'm,7.2 tbt ftl

HINGE BRACKET

CENTERCOVER

I

N

HINGE PIN

I

I

b

E-CLIPSReplace.BASE FRAME

(cont'd)

20-67

www.emanualpro.com

Page 1053 of 1395

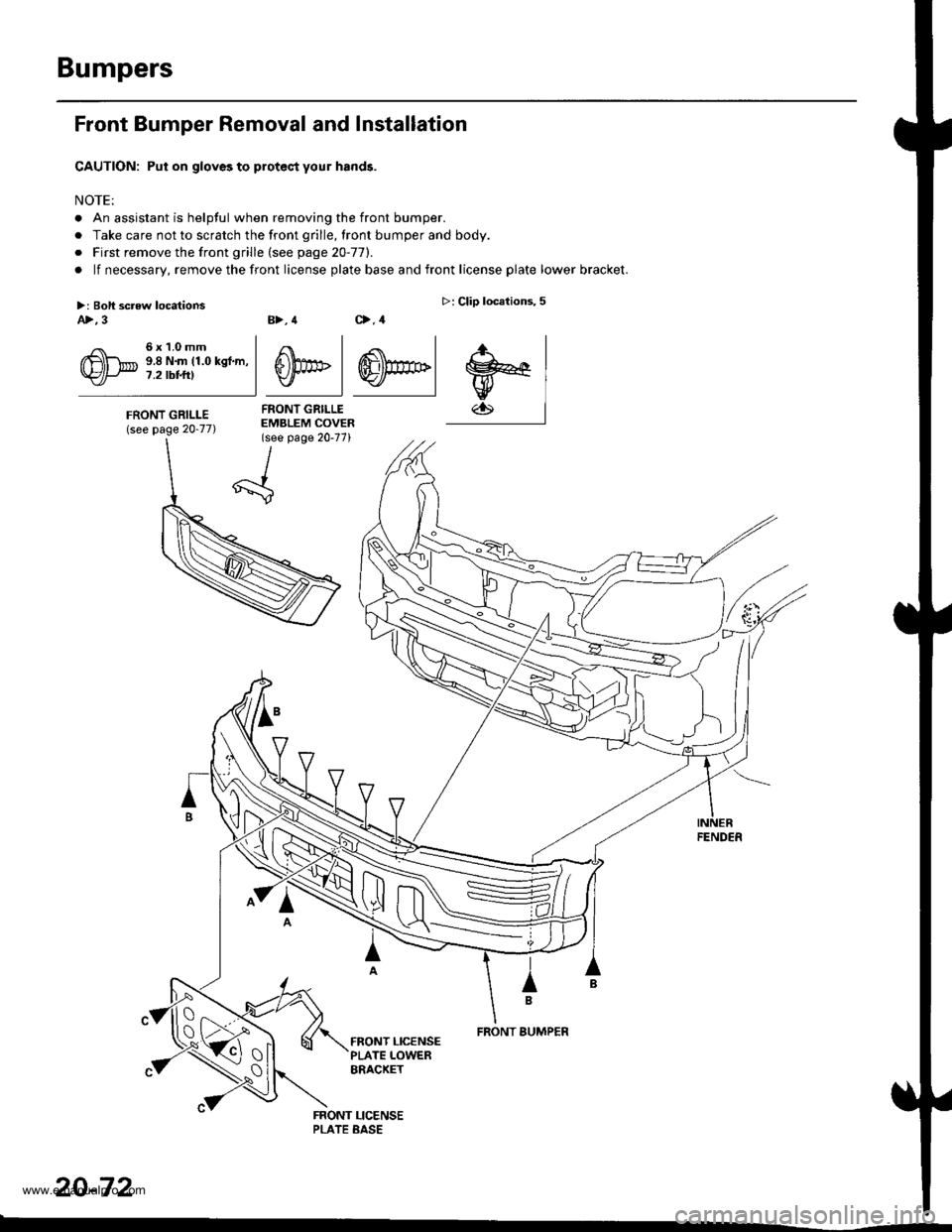

Bumpers

Front Bumper Removal and Installation

CAUTION: Put on gloves to protec,t your hands.

NOTE:

. An assistant is helpful when removing the front bumper.

. Take care not to scratch the front grille, lront bumper and body.

o First remove the front grille (see page 20-77).

. lf necessary, remove the front license plate base and front license plate lower bracket.

B>, 4 C>,4

4 .<\l

S))PF | ffi)m>lv I Y./ |

FRONT GRILLEEMBLEM COVER(see page 20-77)

>: Clip locations,5

.r., I

w€lw

FENDER

IB

FRONT BUMPER

20-72

>: Boli screw locationsA>,3

6x1.0mm9.8 N.m (1.0 kgf.m,7.2 tbt t0

FRONT GRILLE(see page 20-77)

tx -

\{_:

www.emanualpro.com

Page 1145 of 1395

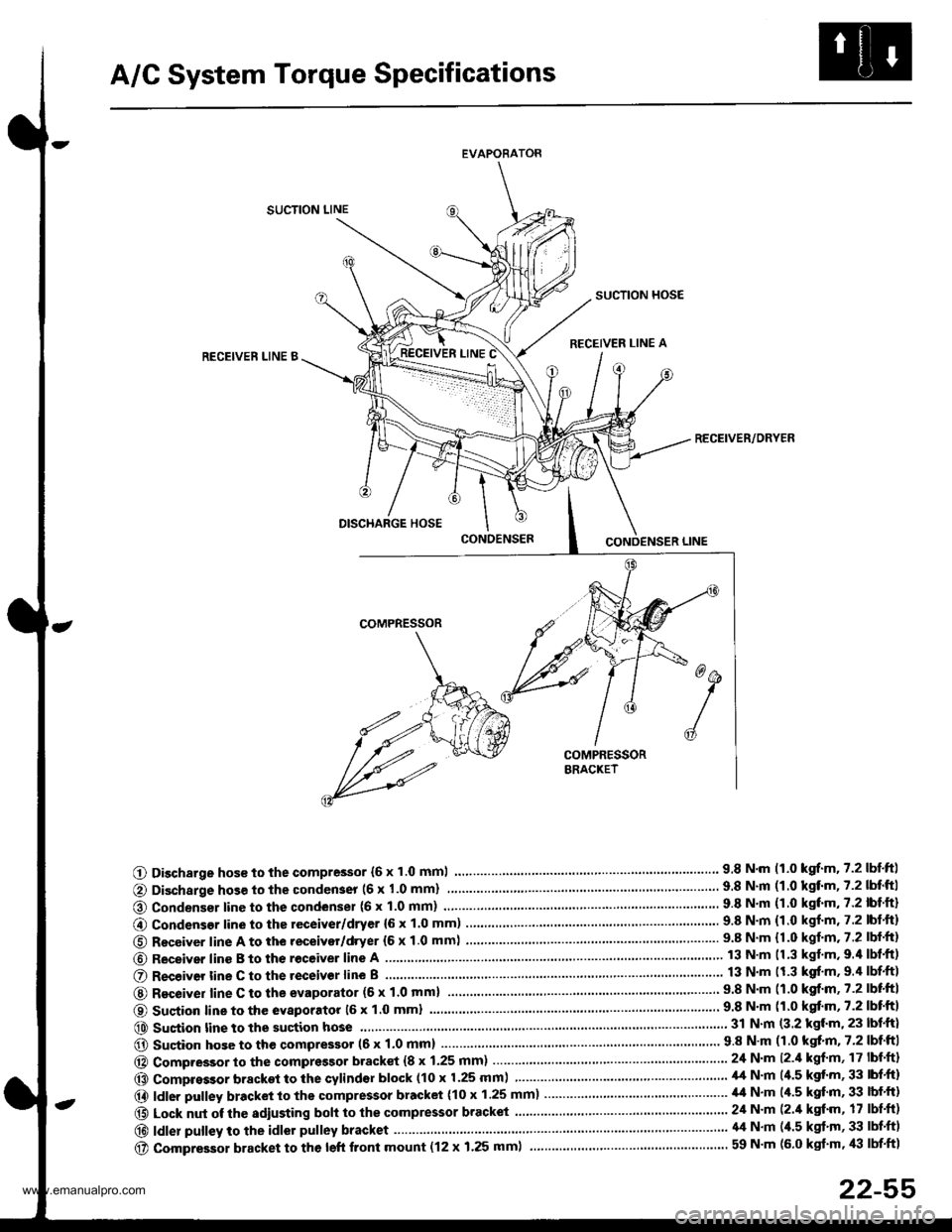

A/C System Torque Specifications

EVAPORATOR

SUCTION LINE

SUCTION HOSE

RECEIVER LINE ARECEIVEN LINE B

RECEIVER/ORYER

O Discharge hos€ to the compressor {6 x 1.0 mml.... 9.8 N.m 11.0 kgrf.m.7.2lbtftl

@ Condenser line to the condenser (6 x 1.0 mm)

@ Condensor line to the receiver/dryer {6 x 1.0 mm) ........9.8 N.m {1.0 kgf.m, 7.2 lbt.ft)

O Receiver line A to the receivor/dryer (6 x 1.0 mm) ...... ....................... 9.8 N.m {1.0 kgf.m.7.2 lbf.ft}

@ Receiver line B to th€ receive. line A

O R€ceiver tine C to the receivor line B

@ Recoiver line C to the evaporator (6 x 1'0 mml9.8 N'm (1.0 kgf.m,7.2lbtftl

O Sustion line to the evaporatot 16 x 1.0 mml

@ Sustion line to the suction hose...... 31 N.m (3.2 kgl.m, 23 lbf.ft)

@ Sucion hose to the qompressor (6 x 1.0 mm) .....'...' 9 8 N'm (1 0 kgt'm, 7'2 lbf'ftI

@ Compressor to the compressor bracket {8 x 1.25 mm) ... 24 N.m l2.il kgf'm, 17 lbf'ft}

@ Compressor bracket to the cylindsr block (10 x 1.25 mm) ................ ......... il,t N'm (4.5 kgt'm, 33 lbf'ft)

@ ldler pulley bracket to the compressor bracket (10 x 1.25 mm)..................... ,14 N.m (/r.5 kgf'm, 33 lbf'ft)

@ Lock nut of the sdiusting boh to the compressor bracket ......................... 24 N'm (2./t kgt'm, 17 lbf'ft)

@|d|erpu||eytotheid|orpu||eybracket.....'..........................'....\

.'.....'........'....44N.m(4.5kg''m'33|bf.f)

@ compressor bracket to the left front mount (12 x 1.25 mml ................... ............................ 59 N'm (6.0 kgt'm, /l:| lbf'ft1

22-55

www.emanualpro.com