PCM HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 573 of 1395

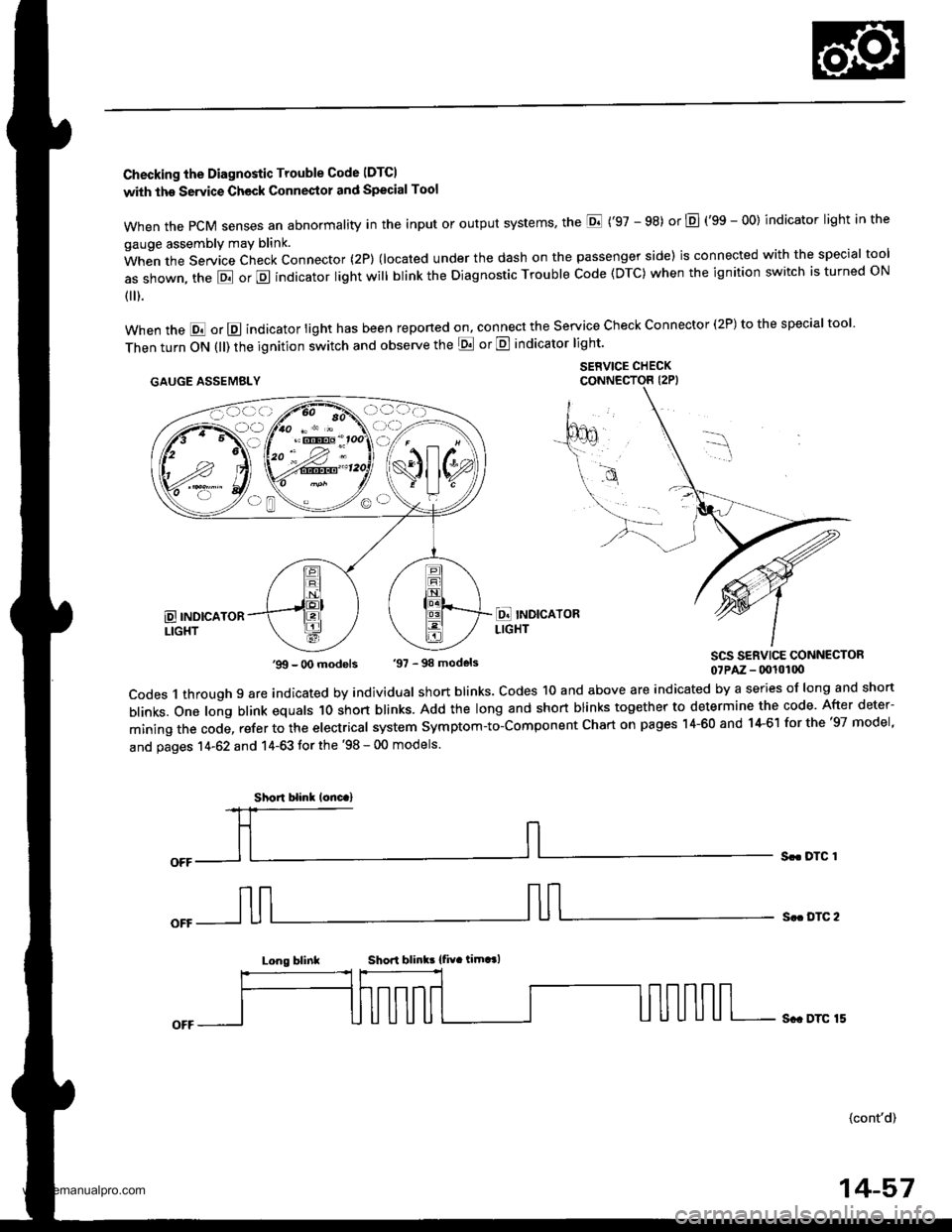

Checking the Diagnostic Trouble Code IDTCI

with the Servic€ Check Connestol and Special Tool

when the PcM senses an abnormality in the input or output systems' the E ('97 - 98) or E (gS - OO) indicator light in the

gauge assembly may blink.

When the Service Check Connector (2P) (located under the dash on the passenger side) is connected with the special tool

as shown, the E or E indicator light will blink the Diagnostic Trouble Code (DTC) when the ignition switch is turned ON

{ ).

when the E or E indicator light has been reponed on, connect the service check connector (2P) to the special tool

Then turn ON (ll) the ignition switch and observe the E or E indicator light'

.AUGE AssEMaLY $1,"^f:tT"'ff,

SCS SERVICE CONNECTOR07PAz - (x!l0100

codes 1 through 9 are indicated by individual short blinks. codes 1o and above are indicated by a series of long and short

blinks. one long blink equals 1o short blinks. Add the long and short blinks together to determine the code. After deter-

mining the code, refer to the electrical system symptom-to-component chart on pages 14-60 and 14-61 for the '97 model,

and pages 14-62 and 14-63 tor the '98 - 00 models.

Sr. DTC 1

S.. DTC 2

Long blinkShori blink! {fiv. timt l

Sc. DTC 15

(cont'd)

'99 - O0 models '97 - 98 models

Short blinl lonc.)

14-57

www.emanualpro.com

Page 574 of 1395

Troubleshooting Procedures

(cont'dl

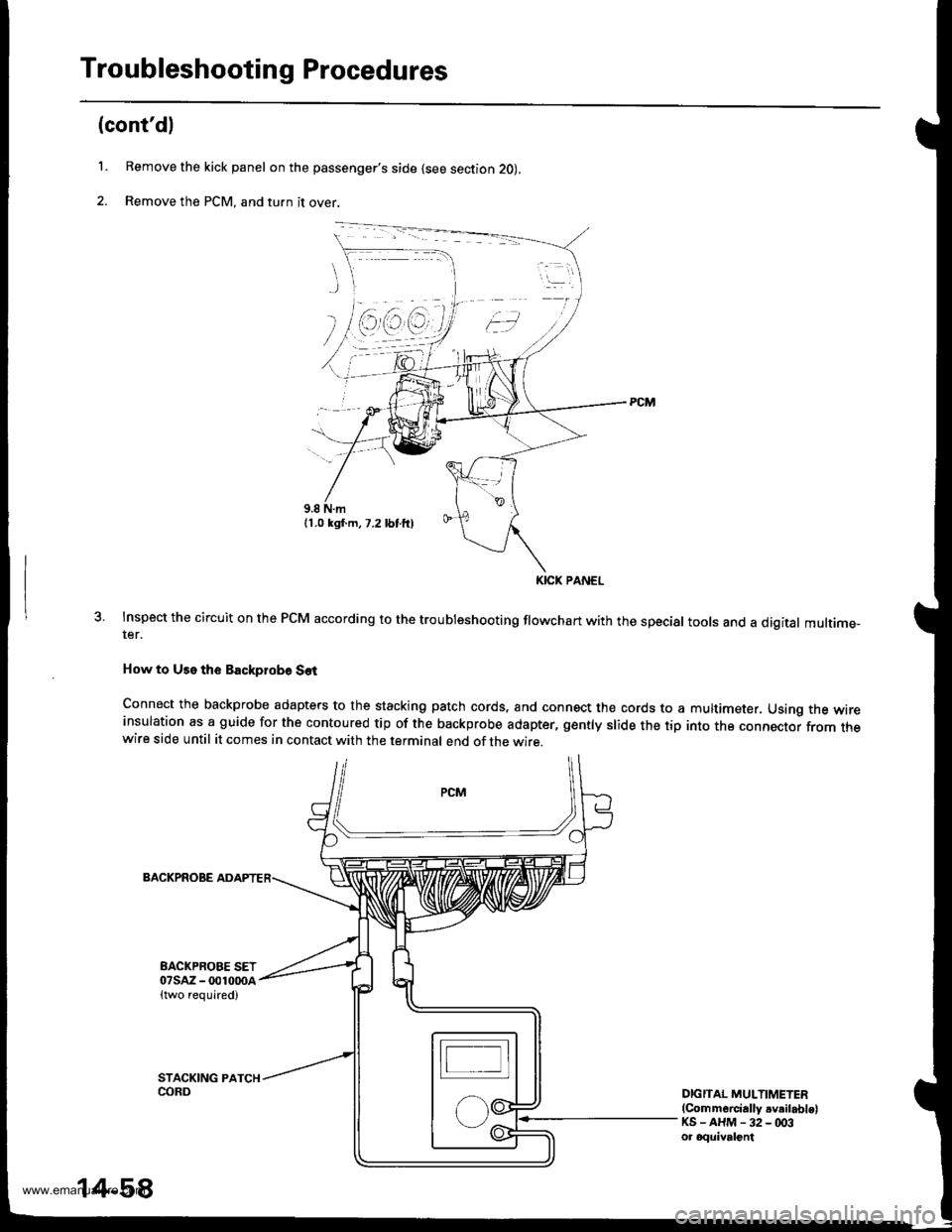

L Remove the kick panel on the passenger's side (see section 2O),

2. Remove the PCM, and turn it over.

Inspect the circuit on the PCM according to the troubleshooting flowchart with the special tools and a digital multime-ter.

How to Use the Backplobe Set

Connect the backprobe adapters to the stacking patch cords, and connect the cords to ainsulation as a guide for the contoured tip of the backprobe adapter, gently slide the tipwire side until it comes in contact with the terminal end of the wire.

multimeter. Using the wire

into the connector from the

BACKPROBE

EACKPROBE SET07sAz - 001000a{two required)

DIGITAL MULTIMETER(Commercially .v.ilablelKS-AHM-32-003ot oquivalont

KICK PANEL

14-58

www.emanualpro.com

Page 575 of 1395

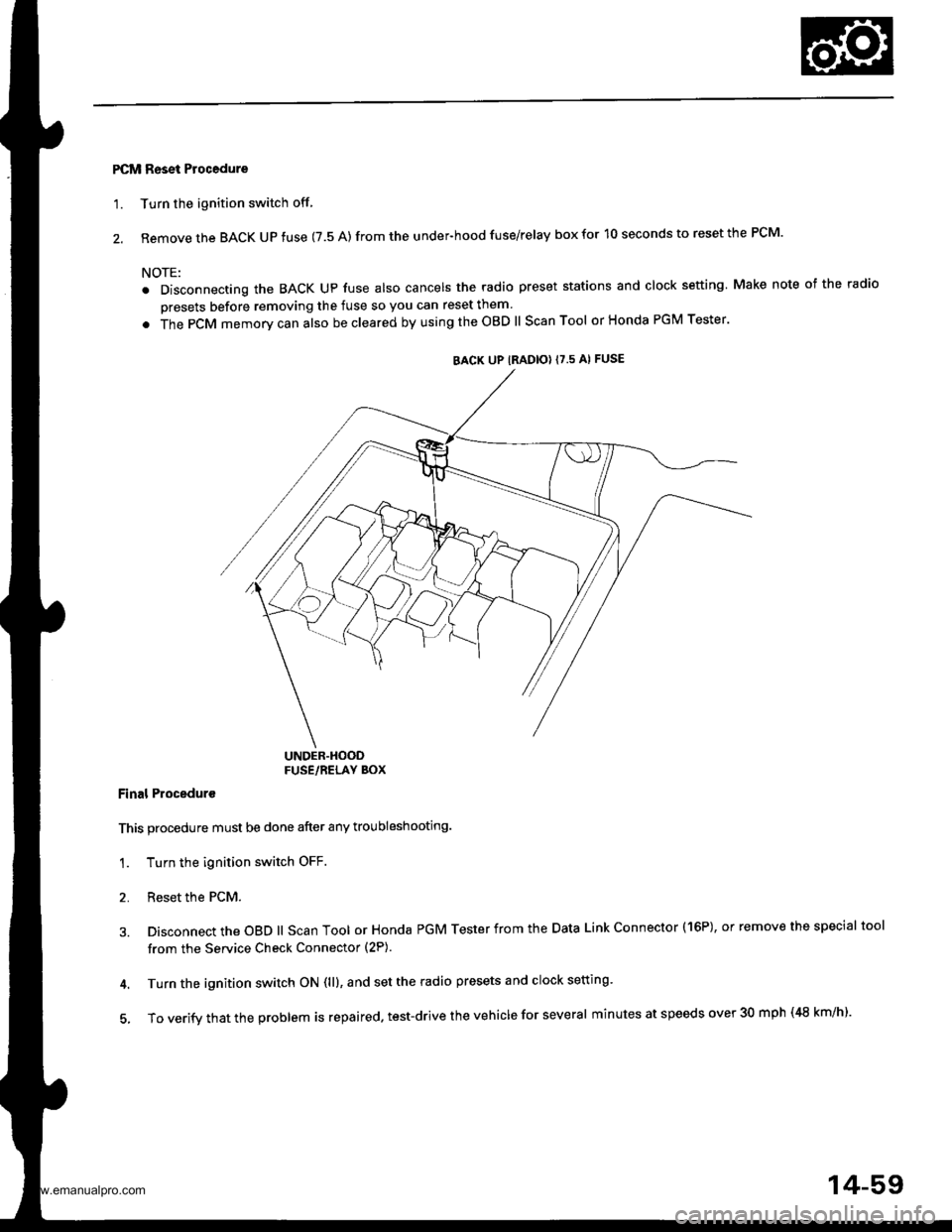

PCM Reset Procedure

'1. Turn the ignition switch off

2. Remove the BACK UP fuse (7.5 A) from the under-hood fuse/relay box for 10 seconds to reset the PCM.

NOTE:

. Disconnecting the BACK Up fuse also cancels the radio preset stations and clock setting Make note of the radio

presets before removing the fuse so you can reset them

. The PCM memorv can also be cleared by using the OBD ll Scan Tool or Honda PGM Tester'

UNDER.HOODFUSE/RELAY BOX

Final Proceduro

This procedure must be done after any troubleshooting.

1. Turn the ignition switch OFF.

2. Reset the PCM.

3. Disconnect the OBD ll Scan Tool or Honda PGM Tester from the Data Link Connector (16P), or remove the special tool

from the Service Check Connector (2P).

4. Turn the ignition switch ON (ll), and set the radio presets and clock setting'

5, To verify that the problem is repaired. test-drive the vehicle for several minutes at speeds over 30 mph (48 km/h).

BACK UP IRADIO} {7.5 AI FUSE

14-59

www.emanualpro.com

Page 580 of 1395

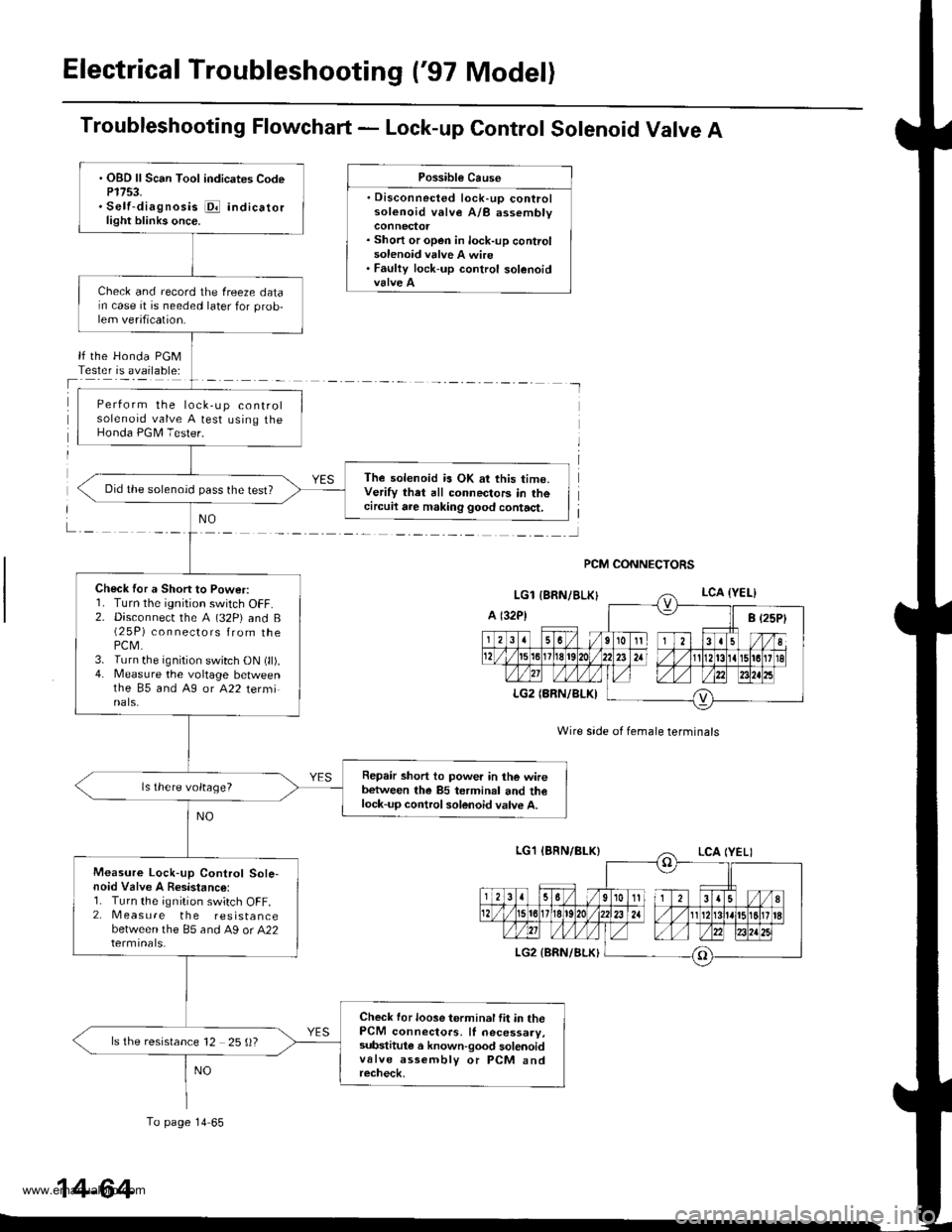

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Lock-up Control Solenoid Valve A

Possible Cause

. Disconnected lock-up controlsolenoid valve A/B assembly

. Short or open in lock-up controlsolenoid valve A wire. Faulty lock-up control solenoid

lf the Honda PGMTester is available:

NO

Wire side of female terminals

PCM CONNECTORS

. OBD ll Scan Tool indicates CodeP1753.. Self-diagnosis i@ indicatorlight blinks once.

Check and record the freeze datarn case it is needed later for prob-lem verification.

Perform the lock,up controlsolenoid valve A test using theHonda PGM Tester.

The solenoid is OK at this time.Verify that all connectors in thecircuil are making good contact,

Did the solenoid pass the test?

Check for a Short to Power:r. I urn rne tgntUon swttch ut-f.2. Disconnecr the A (32P) and B(2 5P) connectors from thePCM.3. Turn the ignition switch ON (ll).4. Measure the voltage betweenthe 85 and A9 or A22 terminals.

Repair short to power in the wirebetween the 85 terminal and thelock-up control solenoid valve A.

ls there voltage?

Measure Lock-up Control Sole-noid Valve A Resistance:1. Turn the ignition switch OFF.2. Measure the resistancebetween the 85 and A9 or A22

Check for loose terminal fit in thePCM connectors, ll necessary,substitule a known-good solenoidvalve assembly or PCM andrecheck,

ls the resistance 12 25 ()?

To page 14 65

14-64

www.emanualpro.com

Page 581 of 1395

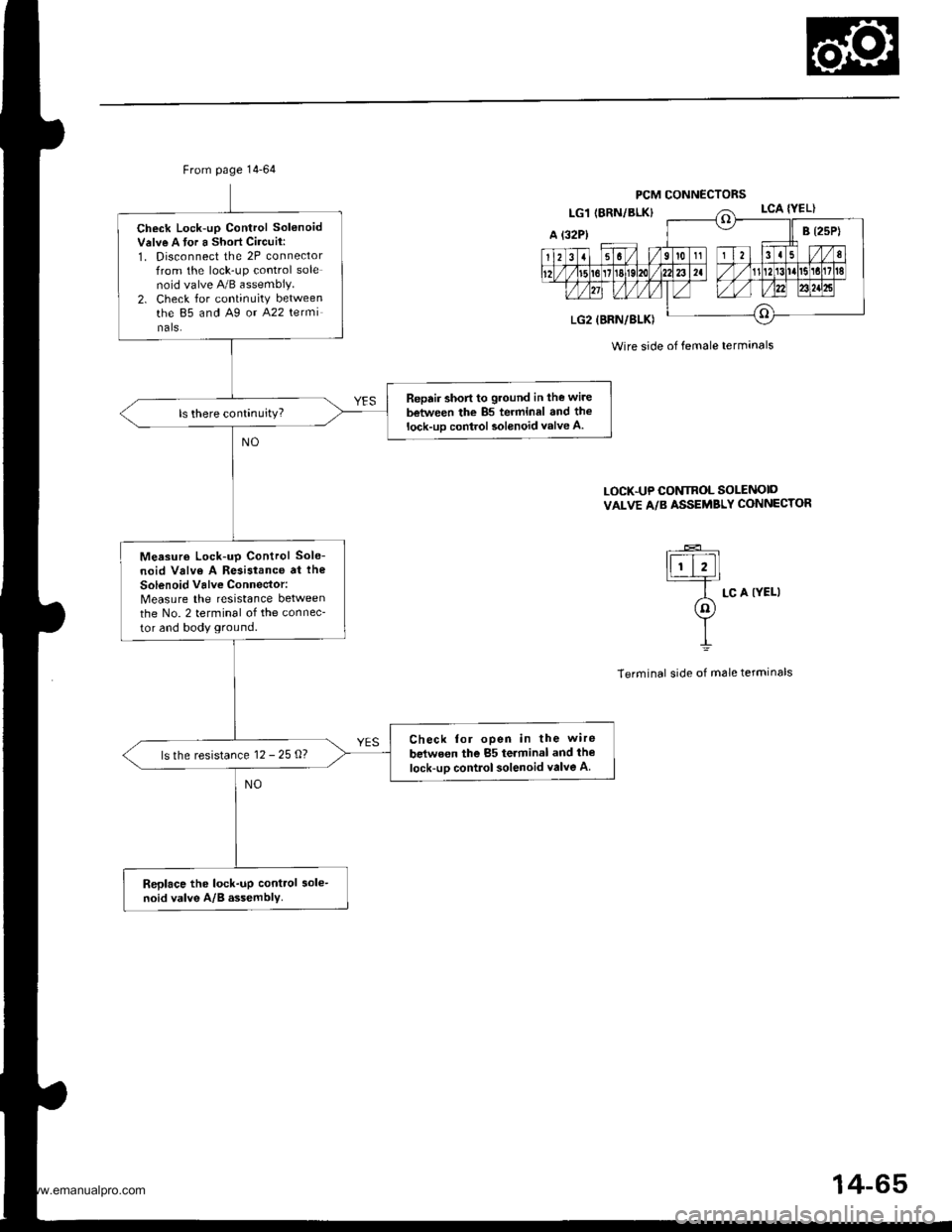

From page 14-64

Check Lock-up Control Sol6noidValve A tor a Short Circuit:1. Disconnect the 2P connectorfrom the lock-up control solenoid valve 4!/B assembly.2. Check for continuity betweenthe 85 and A9 or A22 terminals.

Reprir short to ground in the wire

between the 85 terrninal and thelock-uD contiol solenoid valve A.

Measuro Lock-up Control Sole-

noid Valve A Resistance at the

solenoid valve Connector:Measure the resistance betweenthe No. 2 terminal of the connec-

tor and body ground.

Check for open in the wire

belwe€n the 85 teiminal and the

lock-uo control solenoid valve Als the resistance 12 - 25 O?

Replace the lock-np control sole-noid valve A/B assembly.

PCM CONNECTORS

Wire side of female terminals

LOCK.UP CONTROL SOLENOID

VALVE A/B ASSEMBLY CONNECTOR

----E-

lFr].=--

A Lc A IYELI(nJY

t

Terminal side of male terminals

14-65

www.emanualpro.com

Page 582 of 1395

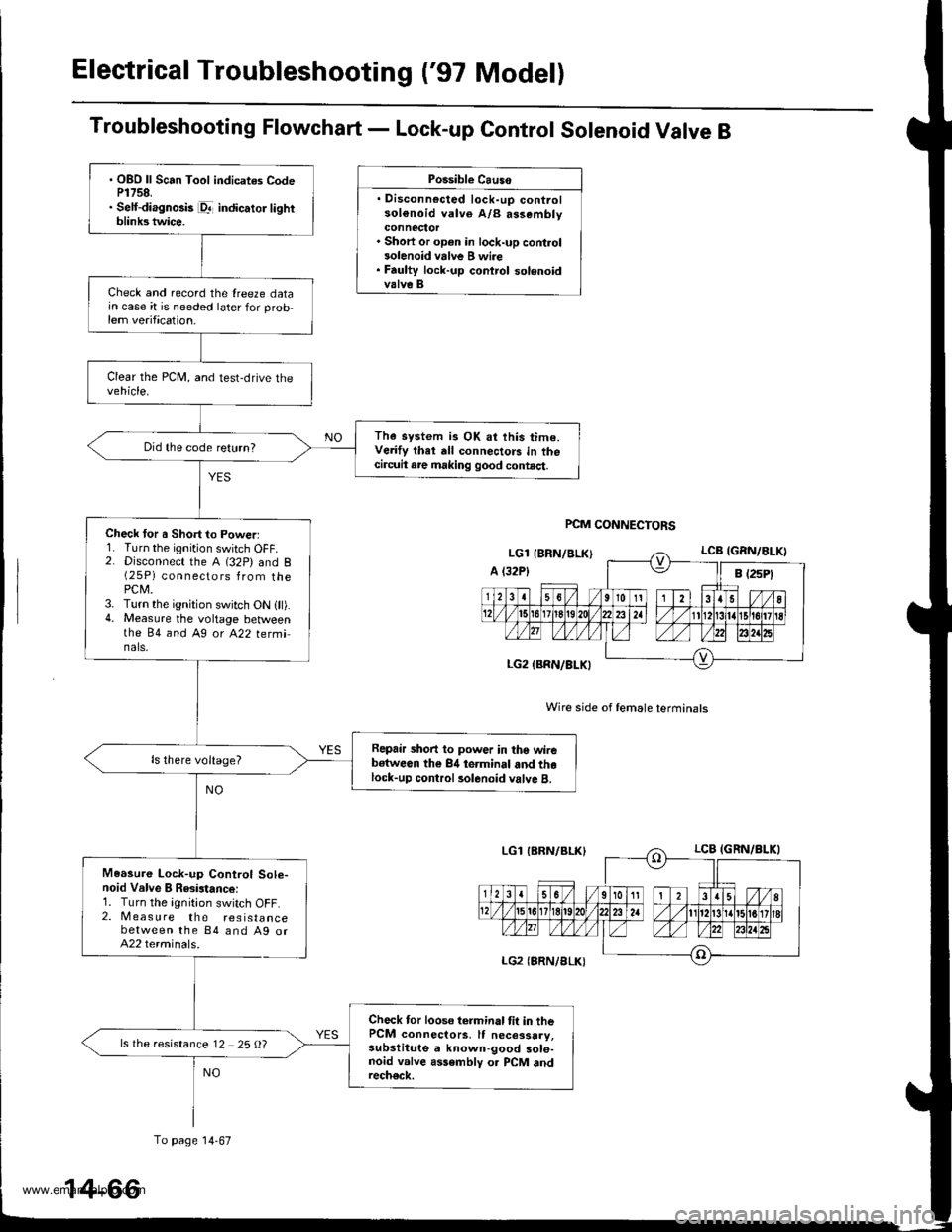

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Lock-up Control Solenoid Valve B

Possible Causo

. Disconnocted lock-up controlsol€noid valve A/B assembly

. Short or op€n in lock-up control3olenoid vrlve B wi.e. Faulty lock-up control solenoidvalve B

Wire side of female terminals

PCM CONNECTORS

. OBO ll Scan Tool indicates CodeP1758.. Self-diagnosis pr- indicator lightblink3 twice.

Check and record the {reeze datajn case it is needed later for prob,lem verification.

The system is OK at this time.Verify thet dll connectors in thecircuit are making good contact.

Did the code return?

Check tor a Short to Powerl1. Turn the ignition switch OFF.2. Disconnect the A (32P) and B(25P) connectors from thePCM.3. Turn the ignition switch ON {ll).4. Measure the voltage betweenthe 84 and Ag ot A22 tetminals,

Repair short to power in tho wirebstween the 84 terminal and thelock-up control rolenoid valve B.

Measure Lock-up Control Sole-noid Valve B Resistance:1. Turn the ignition switch OFF.2. Measure the resistancebetween the 84 and Ag orA22 terminals.

Check tor loose terminal tit in thePCM connectors, It necessary,subslitute a known-good sole-noid valve assembly o. PCM andrech€ck.

ls the resistance 12 25 O?

To page 14-67

14-66

www.emanualpro.com

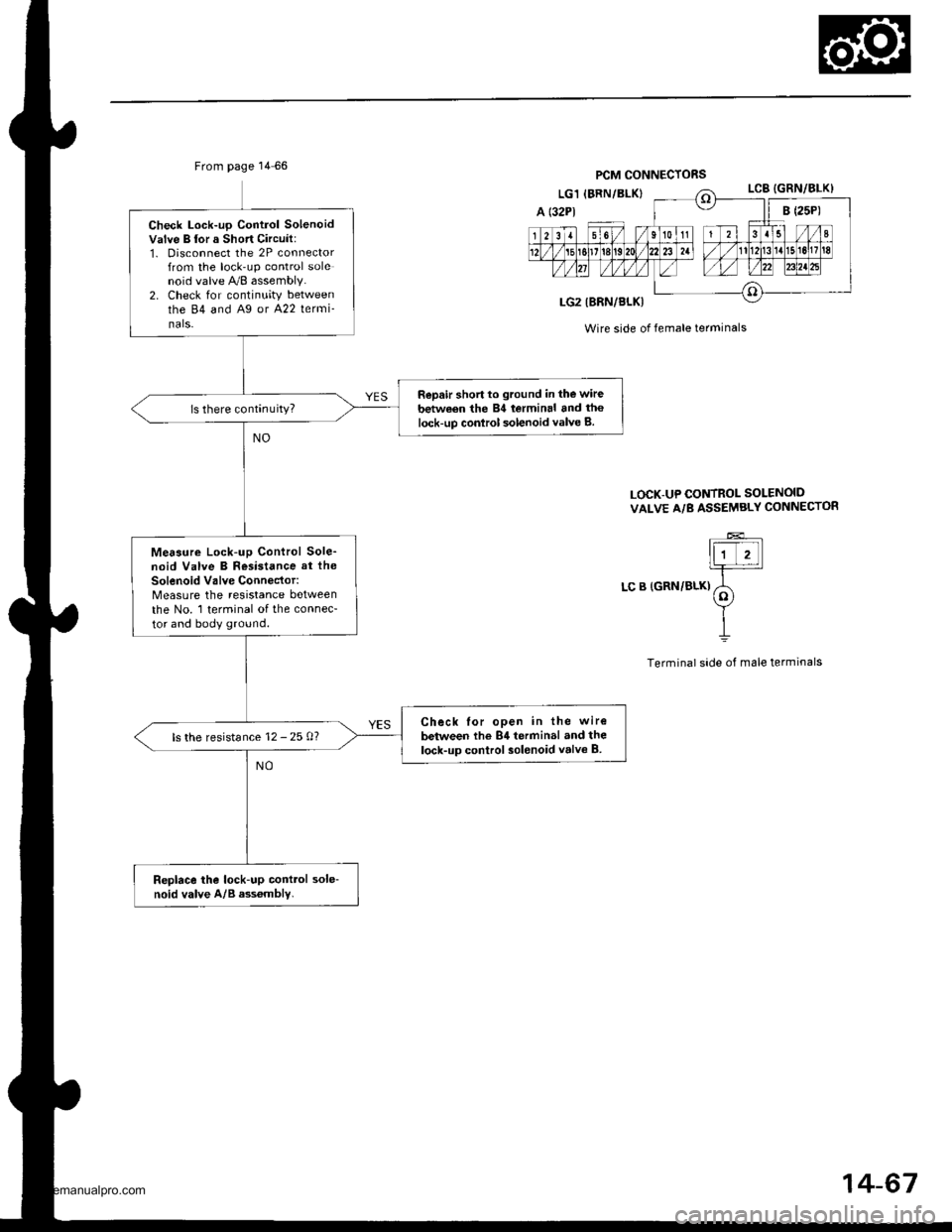

Page 583 of 1395

Check Lock-up Control SolenoidValve B lor a Short Circuit:1. Disconnect the 2P connectorfrom the lock-up control solenoid valve A/8 assembly.2. Check for continuity betweenthe 84 and A9 or A22 lermi_nals-

Repair short to ground in the wirebetween the 84 lerminal and the

lock-up conlrol solenoid valve B.

Me6aure Lock-up Control Sole_noid Valve B Resistance at the

Solenoid Valve Connector:Measure the resistance betweenthe No. 1 terminal of the connec-

tor and body ground.

Check lor open in the wire

bctween the 84 terminal and thelock-up control solenoid volva B.ls the resistance 12 - 25 0?

Replace the lock-up conttol sole-noid valve A/B ass6mbly.

From page 14 66PCM CONNECTORS

Wire side of female terminals

LOCK-UP CONTROL SOLENOID

VAI-VE A/B ASSEMBLY CONNECTOR

LC B (GRN/BLK)

14-67

www.emanualpro.com

Page 584 of 1395

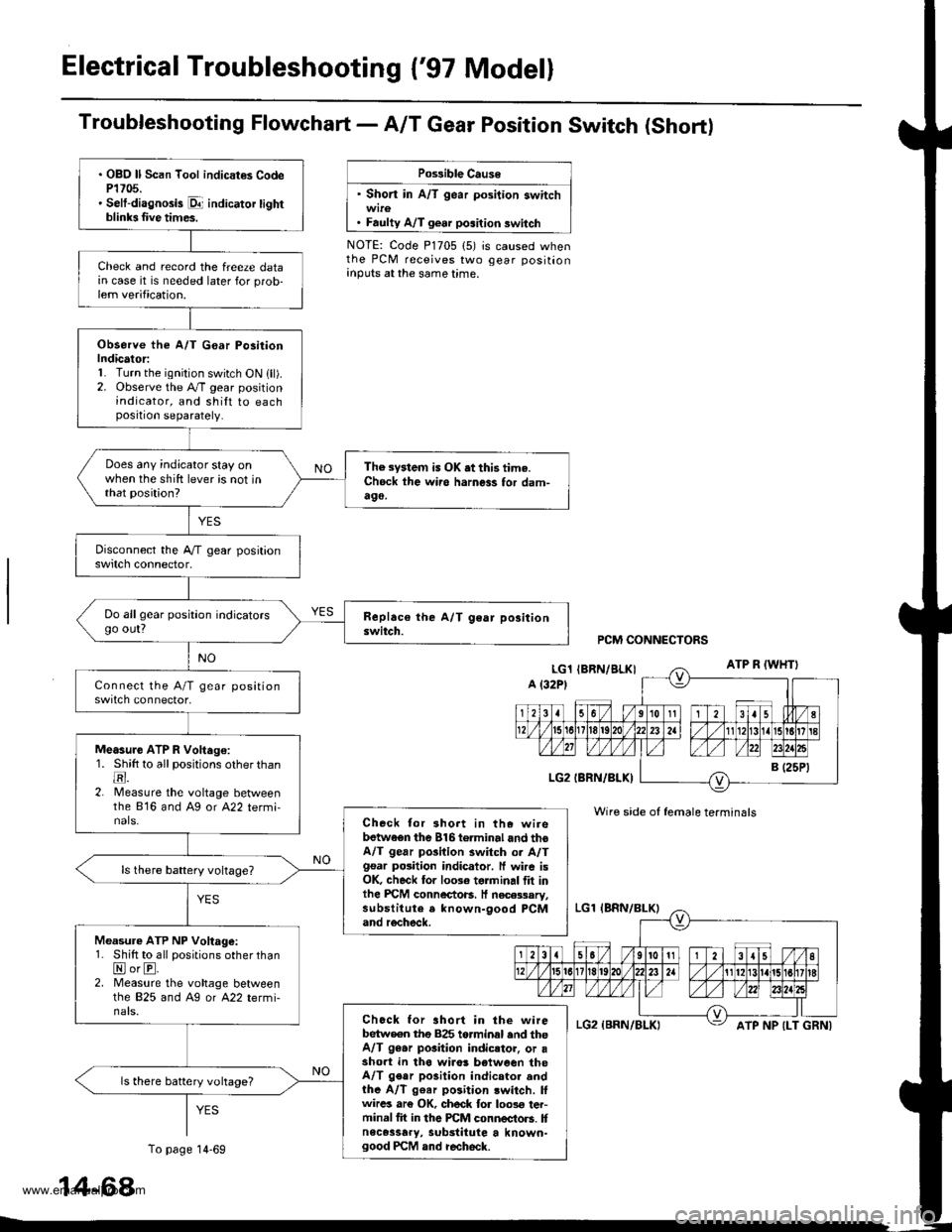

Electrical Troubleshooting {'97 Model}

Troubfeshooting Flowchart- AIT Gear Position Switch (Short)

Po$ible Cause

' Short in A/T gear position switch

. Faulty A/T gear position switch

NOTE: Code P1705 (5) is caused whenthe PCM receives two gear positionanputs at the same time.

. OBO ll Scan Tool indicat€s CodeP1705.' Selt-diagnosis p1- indicator tightblinb Iive times.

Check and record the freeze datain case it is needed later for prob-lem verification.

Observe the A/T G€ar Po3itionIndicator:1. Turn the ignition switch ON lll).2. Observe the A./T gear positionindicator, and shilt to eachposition separately.

Does any indicator stay onwhen the shift lever is not inthat position?

The system is OK .t this time.Ch6ck ihe wii6 harness for dam-490,

Do allgear position indicatorsgo out?

Measure ATP R Voltago:1. Shitt to all positions other thantr.2. lMeasure the voltage betweenthe 816 and Ag or A22 termi-nals.Check tor 3hort in the wirebetwaen the 816torminal and thoA/T gear pGilion switch or A/Tgsar posiiion indicator. ff wire isOK, check for 10036 torminal flt inlhe PICM connectoB. It necessary,substitute a known-9ood PCMand recheck.

Measure ATP NP Voltage:1. Shift to all positions other thanNorE.2. Measure the vohage betweenlhe 825 and Ag or A22 termi-nals.Chock for ahort in the wirebetw€en tho 825 torminal end theA/T 96.r pGition indicstor, or asho.t in tha wiro! b€tween theA/T gear po3ition indicator andthe A/T g€ar position lwitch. lfwircs ar€ OK, ch6ck for loos€ ter-minal fit in the PCM connectors. Itnece3sary, substitute a known-good PCM and recheck.

ls there battery vohage?

PCM CONNECTORS

Wire side of female terminals

ATP NP {LT GRNI

14-68

To page 14-69

www.emanualpro.com

Page 585 of 1395

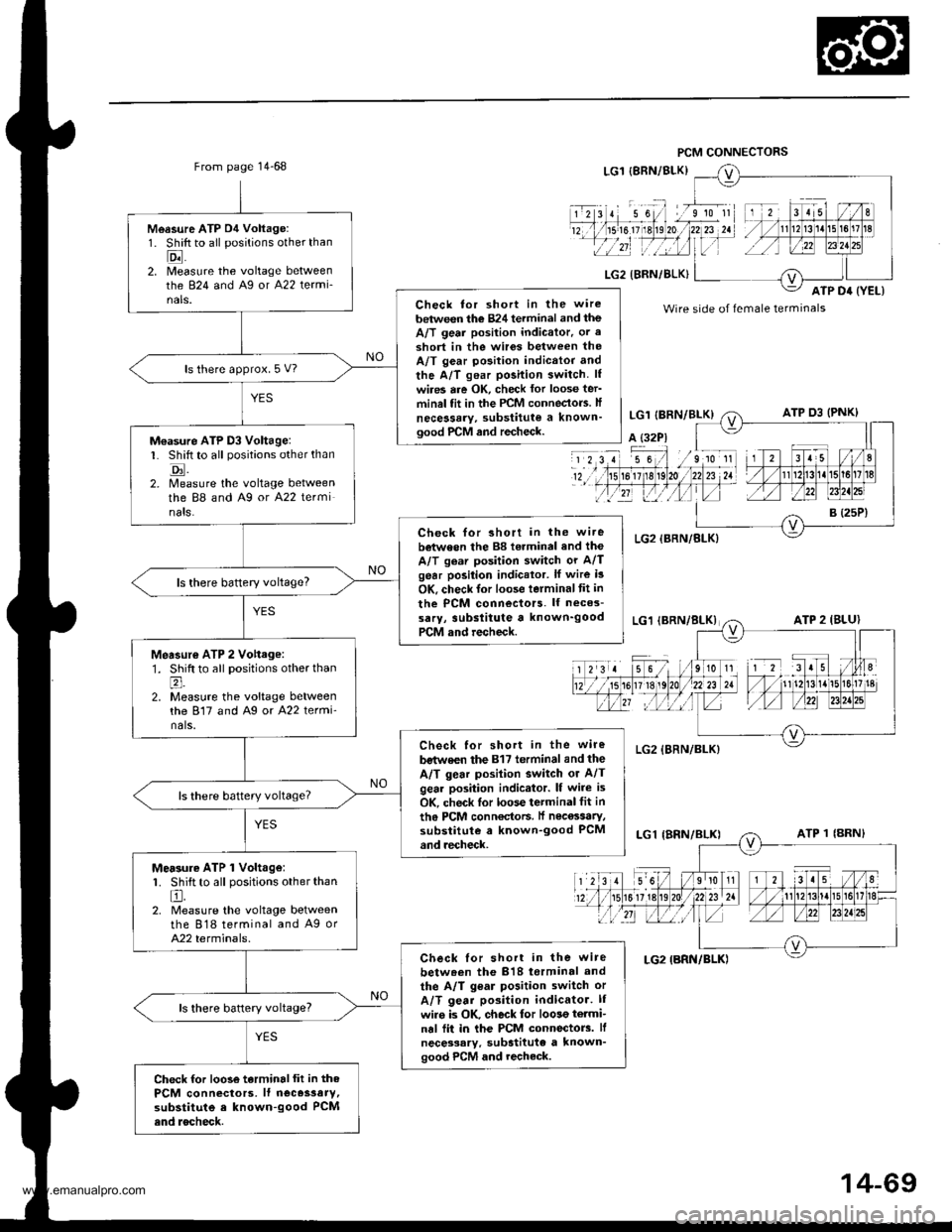

From page 14-68

Measure ATP D4 Voltage:1. Shift to all positions other than

Eil2. [/leasure the voltage betweenthe 824 and Ag or A22 termi-nals.Check tor short in the wire

between the 824 terminal and theA/T geai position indicator. or a

3hort in the wir6s between theA/T gear position indicttor and

the A/T gear position switch. lf

wires are OK, check lor loose ter'minal fit in the PCM conneclo.s. lf

necessary, substitute a known'good PrCM and recheck.

ls there approx. 5 V?

M€asure ATP D3 Voltage:L Shift to all positions other than

tr.2. Measure the voltage betweenthe 88 and A9 or A22 terminats.

Check for short in the wi.ebetween the 88 torminal and the

A/T gear position switch or A/Tgear position indicator. lf wire i3

OK, check lor loose terminaltit in

the PCM connectors. lf neces-

sarY, 3ubslitute a known'goodPCM and recheck.

ls there baftery voltage?

Measur€ ATP 2 Vohage:1. Shift to all positions other thanl;

2. Measure the voltage betweenthe 817 and Ag or A22 termi'nals.

Check for short in the wire

bstwe€n the 817 terminal and the

A/T gear posilion switch or A/Tgear position indicator. lf wire is

OK, check lor loose terminal fit in

th6 PCM conn€ctoF. lf nec€ssaty,substitute a known-good PCMand recheck.

Mersure ATP 1 Volt.ge:1. Shift to all positions other than

El.2. Measure the voltage betweenthe 818 terminal and A9 orA22 terminals.

Check lor short in the wire

betw.en the 818 torminal and

the A/T gear position switch or

A/T gear position indicator. lI

wiro is OK. check for loose termi-nal fii in the PCM connectorc. lf

necessary. substitute a known'good PCM and recheck.

ls there battery voltage?

Check for loose terminalfit in thePCM connectors, lf neces3aty,substitute e known-good PCMend rocheck.

Wire side of female terminals

14-69

www.emanualpro.com

Page 587 of 1395

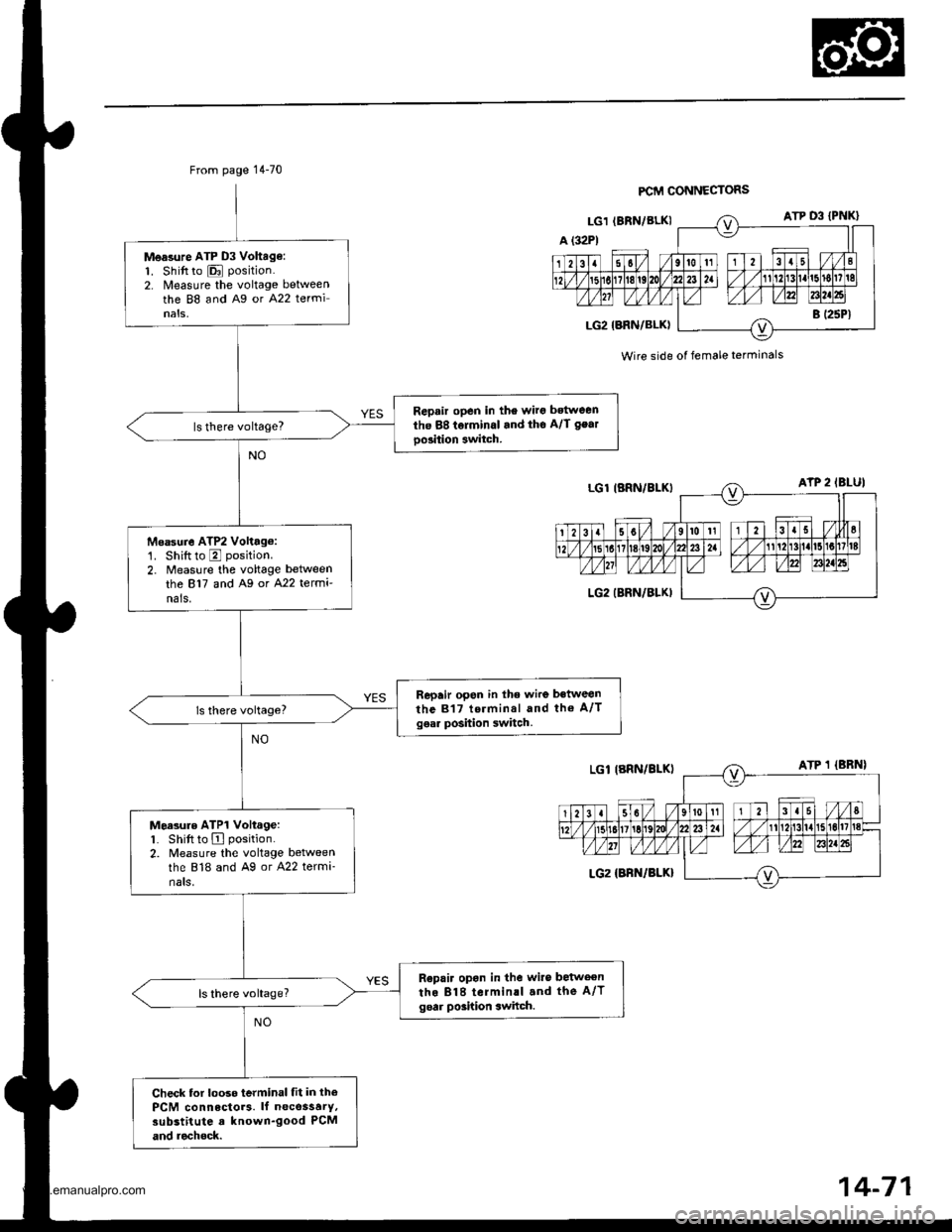

From page 14-70

Measure ATP D3 Vohag€:1. Shift to E position.

2. Nleasure the voltage betweenthe 88 and Ag or A22 terminals,

Repair open in the wirg bstween

the 88 tolminal and tho A/l gear

oo3ition 3witch.

Msasure ATP2 Volttg6:'1. Shiftto E position.

2. Measure the voltage between

the 817 and A9 or A22 termi'nals.

Repair open in lhe wire between

the 817 terminal and tho A/Tgear position switch.

Moasure ATP1 Voltage:1. Shift to A position.

2. Measure the voltage betweenthe 818 and Ag or A22 termi-nats,

R€pair opon in the wiro betweenthe 818 terminll and the A/Tgoar poshion switch.

Check tor looso terminal fit in thePCM connectors. lf necossarY,substitute a known-good PCM

and rechock.

FCM CONNECTORS

Wire side of female terminals

www.emanualpro.com