ABS sensor HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 277 of 1395

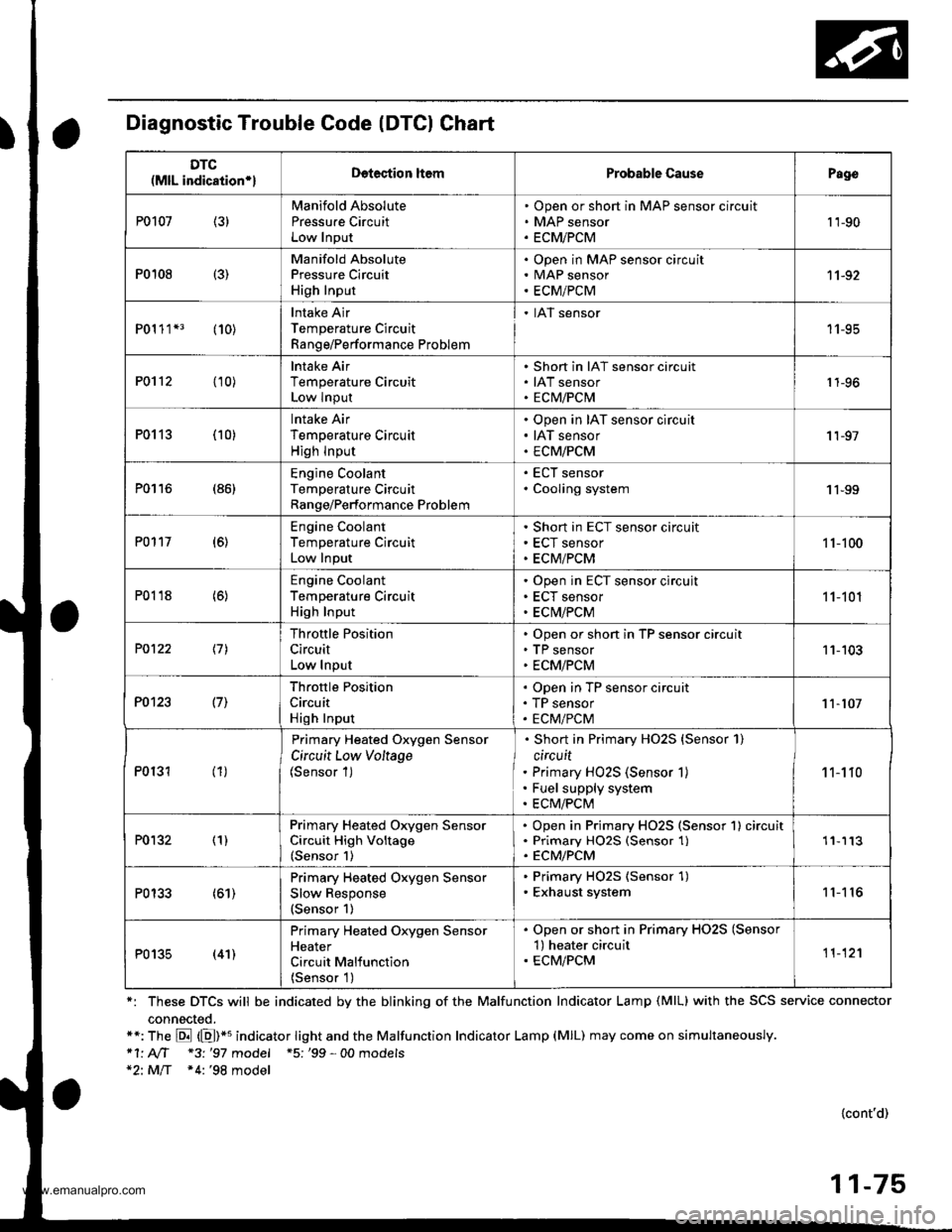

Diagnostic Trouble Code (DTCI Chart

*: These DTCS will be indicated by the blinking of the Malfunction Indicator Lamp (MlL) with the SCS service connector

connected.**: The E (E)*u indicator tight and the Malfunction Indicator Lamp (MlL) may come on simultaneously.*1' AIT *3 '97 model +5; '99 - 00 models*2: MlT *4:'98 model

{cont'd)

11-75

DTC(MlL indication*lDetection ltemProbable CausePago

P0107 (3)Manifold Absolute

Pressu.e CircuitLow Input

Open or short in MAP sensor circuit

MAP sensor

ECMiPCM

't 'l-90

P0108 {3)

Manifold AbsolutePressure Circuit

High Input

Open in MAP sensor circuitMAP sensor

ECM/PCM

11-92

P01 1 1*3 (10)Intake Air

Temperature Circuit

Range/Performance Problem

. IAT sensor

11-95

P0112 (10)lntake Air

Temperature CircuitLow Input

Short in IAT sensor circuit

IAT sensorECM/PCM1 1-96

P0113 (10)lntake Air

Temperature Circuit

High lnput

Open in IAT sensor circuit

IAT sensor

ECM/PCM

'I 1-97

P0116 (86)Engine CoolantTemperature CircuitRange/Performance Problem

ECT sensor

Cooling system1 1-99

P0117 (6)Engine Coolant

Temperature Circuit

Low Input

Short in ECT sensor circuit

ECT sensor

ECM/PCM

1 1-100

P0118 (6)Engine Coolant

Temperature CircuitHigh Input

Open in ECT sensor circujt

ECT sensor

ECM/PCM

11-101

P0122 \11

Throttle Position

Circuit

Low Input

Open or short in TP sensor circuitTP sensor

ECM/PCM

11-103

P0123 l7l

Throftle Position

Circuit

High Input

Open in TP sensor circuit

TP sensor

ECM/PCM11-107

P0131 (1)

Primary Heated Oxygen Sensor

Circuit Low Voltage(Sensor 1)

Short in Primary HO2S {Sensor 1)

circuit

Primary HO2S (Sensor 1)

Fuel supply system

ECM/PCM

1 1-1 10

P0132 (1)Primary Heated Orygen SensorCircuit High Voltage(Sensor 1)

Open in Primary HO2S (Sensor 1) circuitPrimary HO25 (Sensor 1)ECM/PCM

'11113

P0133 (61)Primary Heated Oxygen Sensor

Slow Response(Sensor 1)

. Primary HO2S (Sensor 1). Exhaust system11'I 16

P0135 (41)

Primary Heated Oxygen SensorHeater

Circuit Malfunction

{Sensor 1)

. Open or short in Primary HO2S (Sensor'l) heater circuit. ECM/PCM11-12'l

www.emanualpro.com

Page 279 of 1395

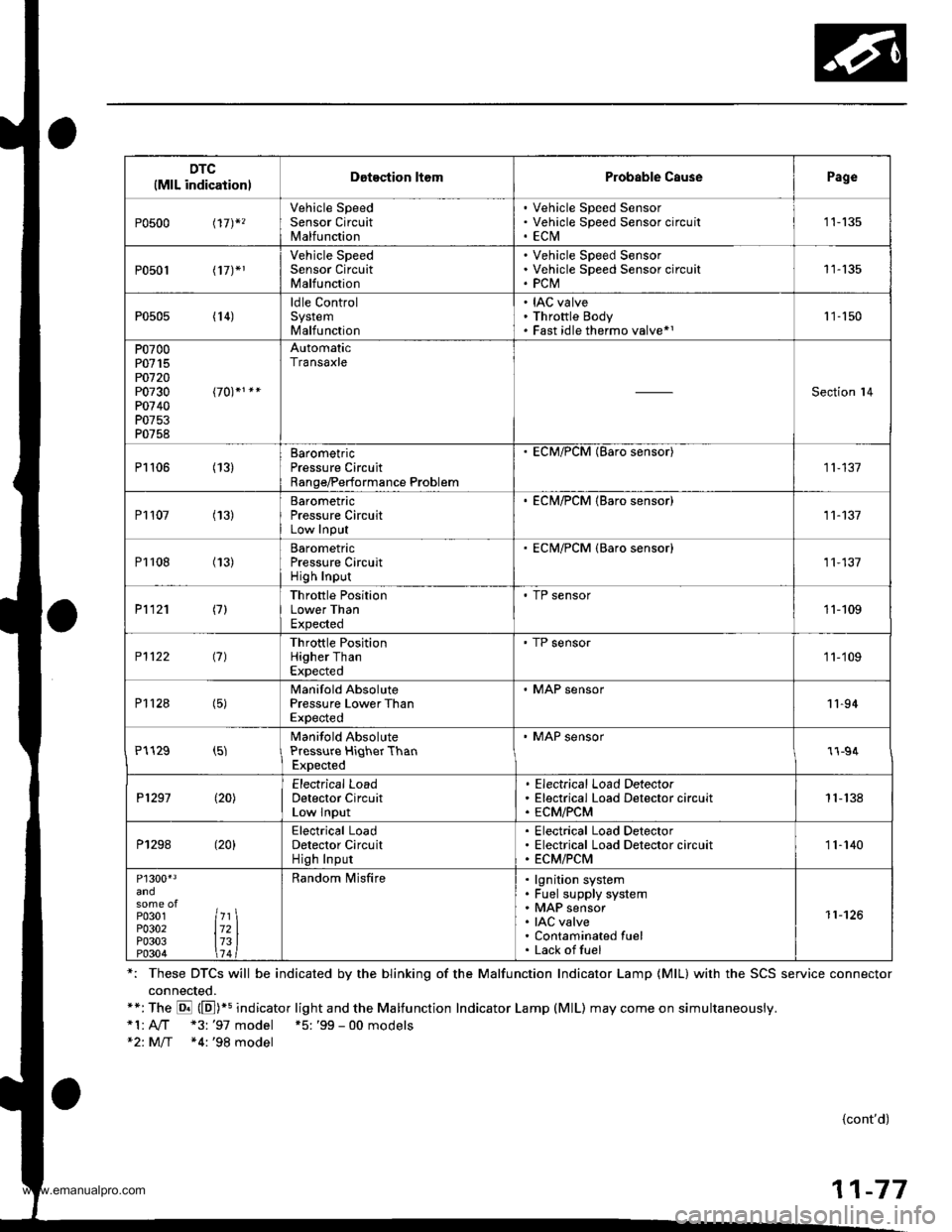

DTC(MlL indicationlDotection ltomProbable CausePage

P0500 t17)*,

Vehicle SpeedSensor CircuitMalfunction

Vehicle Speed SensorVehicle Speed Sensor circu itECtVI1 1-135

P0501 l17J*1

Vehicle SpeedSensor CircuitMalfunction

Vehicle Speed SensorVehicle Speed Sensor circuitPCM11-135

P0505 (14)ldle ControlSystemMalfunction

IAC valveThrottle BodyFast idle thermo valve*11 '�]- 150

P0700P0715PO720P0730P0740P0753P0758

AutomaticTransaxle

Section l4

P1106 (13)BarometricPressure CircuitRange/Performance Problem

ECM/PCM (Baro sensor)

11-137

P1107 (13)BarometricPressure CircuitLow InPut

. ECM/PCM {Baro sensor)11-137

P1108 (13)BarometricPressure CircuitHigh Inpur

ECM/PCM {Baro sensor)11,137

P1121 (7)Throttle PositionLower ThanExpected

. TP sensor11-109

P1122 (7)Throttle PositionHigher ThanExpected

' TP sensor1 1-'109

P112a (5)Manifold AbsolutePressure Lower ThanExpected

. MAP sensor11-94

P1129 (5)Manifold AbsolutePressure HiqherThanExpected

' MAP sensor1l-94

P1297 (20)Electrical LoadDetector CircuitLow Input

Electrical Load DetectorElectrical Load Detector circuitECM/PCM1 1- 138

P1298 (20)Electrical LoadDetector CircuitHigh Input

Electrical Load DetectorElectrical Load Detector circuitECM/PCM11-140

P1300'3

P0301P0302P0303P0304

7l721314

Random lvlisfirelgnition systemFuel supply systemMAP sensorIAC valveContaminated fuelLack offuel

11-126

*: These DTCS will be indicated by the blinking of the Malfunction Indicator Lamp {MlL} with the SCS service connector

connected.**:The E (E])+s indicator light and the Malfunction Indicator Lamp (MlL) may come on simultaneously.*1:A,./T "3: '97 model +5: '99 - 00 models*2: M/T *4:'98 model

{cont'd)

11-77

www.emanualpro.com

Page 292 of 1395

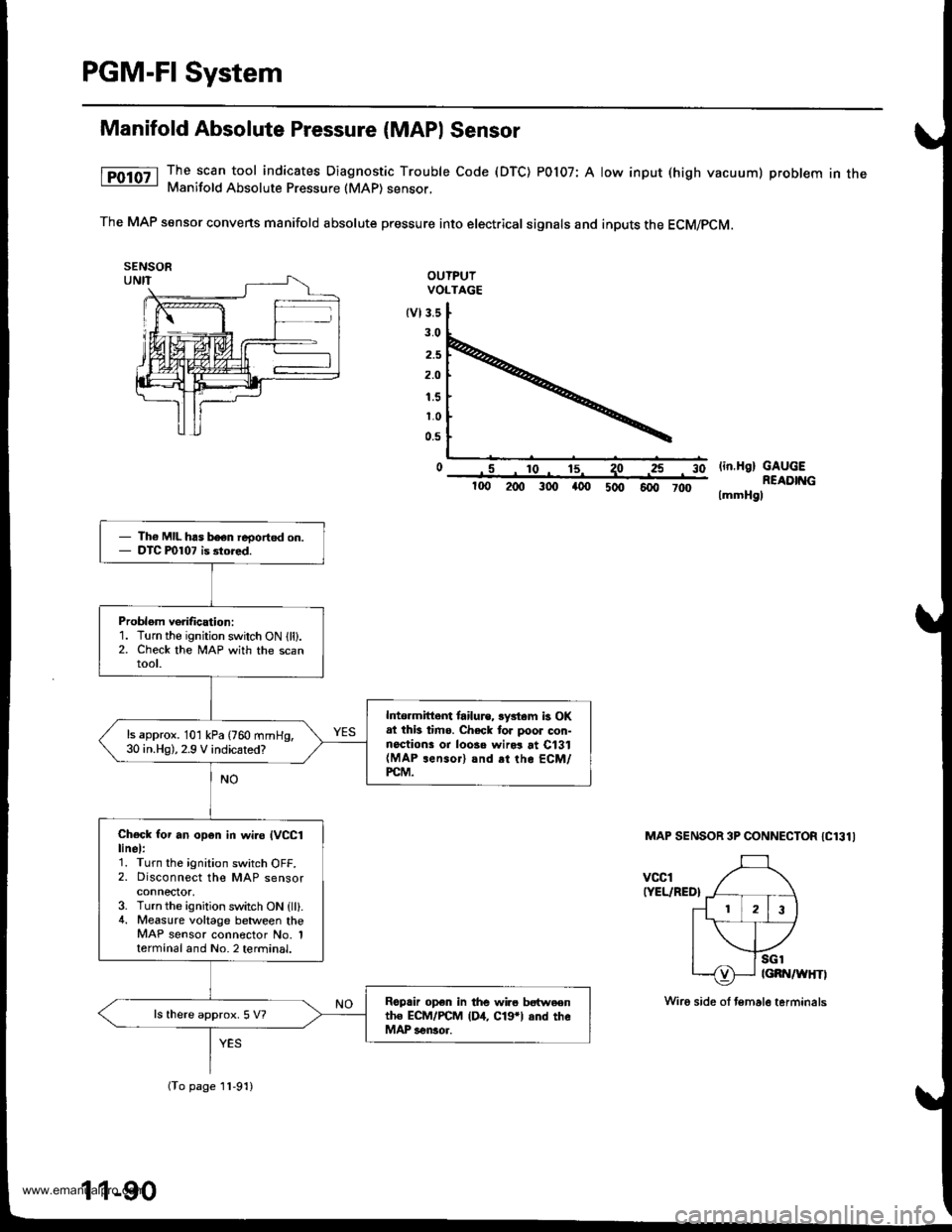

PGM-FI System

Manifold Absolute Pressure (MAPI Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) POl07: A low input (high vacuum) problem in theManifold Absolute Pressure (MAP) sensor,

The MAP sensor convens manifold absolute pressure into electrical signals and inputs the ECM/pCM.

OUTPUIVOLTAGE

tvl3.s

3.0

2.5

2.O

1.5

1.0

0.5

o .5 ro- 15^ 1olin.H9) GAUGEREADIT{G

lmmHgl

3025

100 200 300 a00 5oo 6fi, 7d)

MAP SENSOR 3P CONNECTOR IC131I

vccl(YEL/RED}

Th6 MIL has b€en reoorted on.DTC P0107 is 3tored.

Problom verification:1. Turn the ignition switch ON lll).2. Check the lvlAP with the scanroot.

lrtormittem tailu.e, lystam b OKat thb timo. Check tor poor con-noctions or loosa wird at C131(MAP rensor) and rt the ECM/PCM.

ls approx. 101 kPa (760 mmHg,30 in.Hg),2.9 V indicated?

Check for an op6n in wi.o IVCC1linel:1. Turn the ignition switch OFF.2. Disconnect the MAP sensorconnector,3. Turn the ignition switch ON {ll}.4. Measure voltage between theMAP sensor connector No. 1termanal and No. 2 terminal.

Roprir op€n in the wir6 bstweentho ECM/PCM (D4, C19*l and theMAP sensor.

ls there approx. 5 V?

(To page 11-91)

11-90

Wiro side ol temale terminals

www.emanualpro.com

Page 294 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (contd)

[tn,t nn-] The scan tool indicates Diagnostic Trouble Code (DTC) P0108: A high voltage (low vacuum) problem in the|jg Manifold Absolute HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (contd)

[tn,t nn-] The scan tool indicates Diagnostic Trouble Code (DTC) P0108: A high voltage (low vacuum) problem in the|jg Manifold Absolute](/img/13/5778/w960_5778-293.png)

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (cont'd)

[tn,t nn-] The scan tool indicates Diagnostic Trouble Code (DTC) P0108: A high voltage (low vacuum) problem in the|jg Manifold Absolute Pressure (MAP) sensor.

MAP SENSOR 3P CONNECTOR IC131I

Wire side of female terminals

vcclIYEL/RED}

PCM CONNECTOR D I16PI

JUMPER WIRE

sGlIGRN/WHTI

Wire side of lemale termin6ls

1

(To page 11,93)': '98 - 00 models

1-92

tcRN/wHrll IIRED/GRN|

The MIL has boen reported on.DTC m108 is slored.

Problem veritication:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on, thenlet it idle.2. Check the MAP with the scantool.

Intermittent tailuro, system i3 OKat this time. Check tor ooor con-nections or loose wires at C131IMAP s6nsor) snd the ECM/rcM.

ls 101 kPa {760 mmHg,30 in.Hg),2.9 V or higher indicated?

Check Ior an open in the MAPsensor:1. Turn the ignition switch OFF.2. Disconnect the MAP sensor3P connector.3. lnstall a jumper wire betweenthe MAP sensor 3P connectorterminals No.3 and No.2.4. Turn the ignition switch ON {ll).5. Check the MAP with the scantool.

ls 10'l kPa (760 mmHg,30 in.Hg),2.9 V or higher indicated?

Check for an open in wire (SGlliDel:1. Remove the jumper wire.2. Measure voltage between theMAP sensor 3P connector ter-minals No. 1 and No- 2.

R6p.ir open in the wire betwoenthe ECM/PCM (D12, CTrl and theMAP sensor.

ls there approx. 5 V?

Check for an open in the wire(MAP line):1. Turn the ignition switch OFF.2. lnstall a iumper wire on thePCM connectors between D3and D12.3. Turn the ignition switch ON (ll).4. Check the MAP wirh the scantool.

Ropair opon in the wire betweenthe PCM {D3, .nd the MAP son-3('t.

ls 101 kPa 1760 mmHg, 30 in.Hg),2.9 V or higher indicated?

YES

www.emanualpro.com

Page 296 of 1395

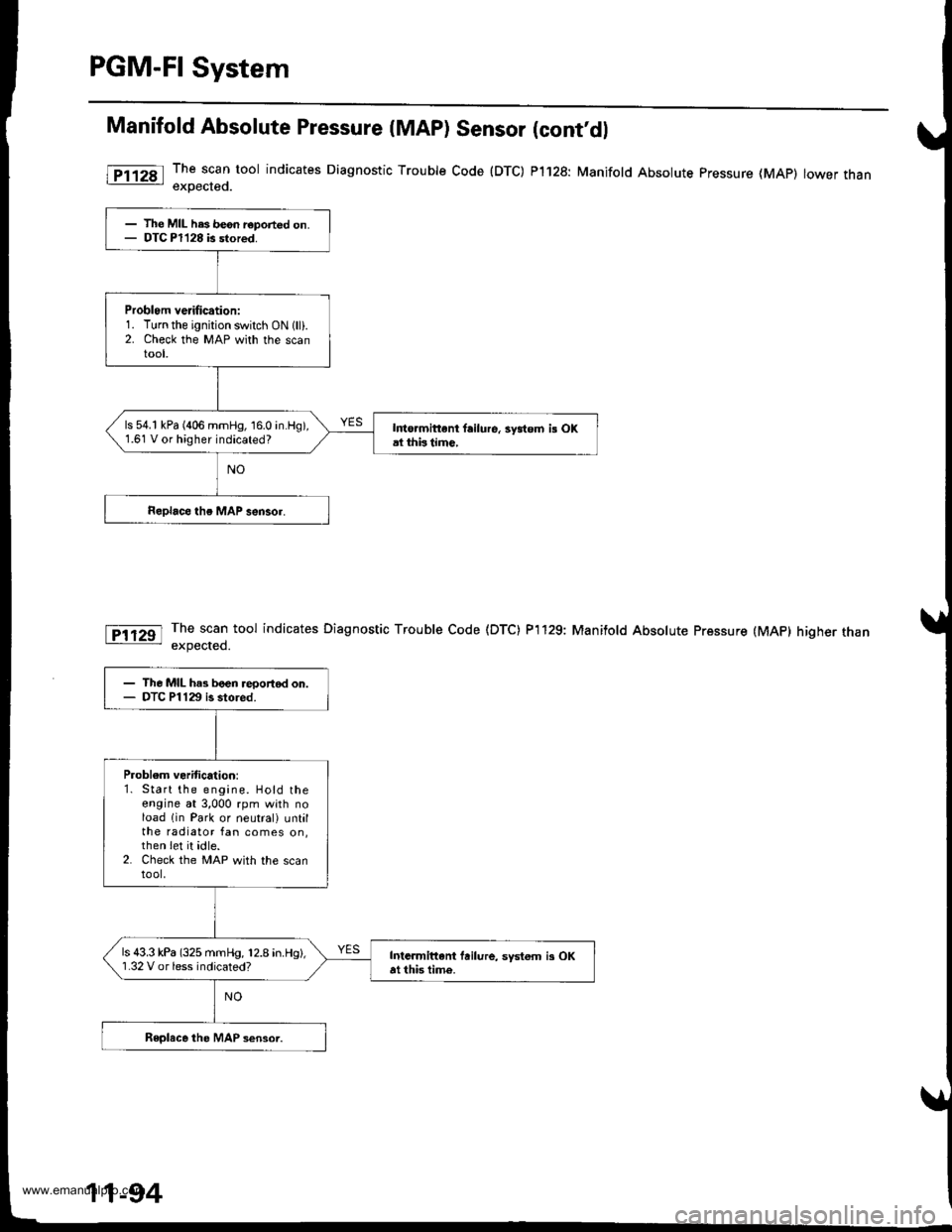

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (cont'dl

The scan tool indicates Diagnostic Trouble Code (DTC) P1128: Manifold Absolute pressure (MAp) lower thanexoected.

The scan tool indicates Diagnostic Trouble Code (DTC) P'l129: Manifold Absolute Pressure (MAP) higher thanexpected.

l

- The MIL has be6n r€ported on.- DTC Pl128 is stored.

Problom verification:1. Turn the ignition switch ON 1lli.2. Check the MAP with the scantool,

ls 54.1 kPa (406 mmHg, 16.0 in.Hg),1.61 V or higher indicated?I to.mittent failure, 3ydom i! OKal thbtimc,

- The MIL has boen reportod on.- DTC Pl129 is stored.

Problem veritication:1. Start the engine. Hold theengine at 3,000 rpm with noload lin Park or neutral) untilthe radiator fan comes on,then Iet it idle.2. Check the MAP with the scantool,

ls 43.3 kPa (325 mmHg, 12.8 in.Hg),'1.32 V or less indicated?Intarmittani fuilure, systom i3 OKat this time.

11-94

www.emanualpro.com

Page 411 of 1395

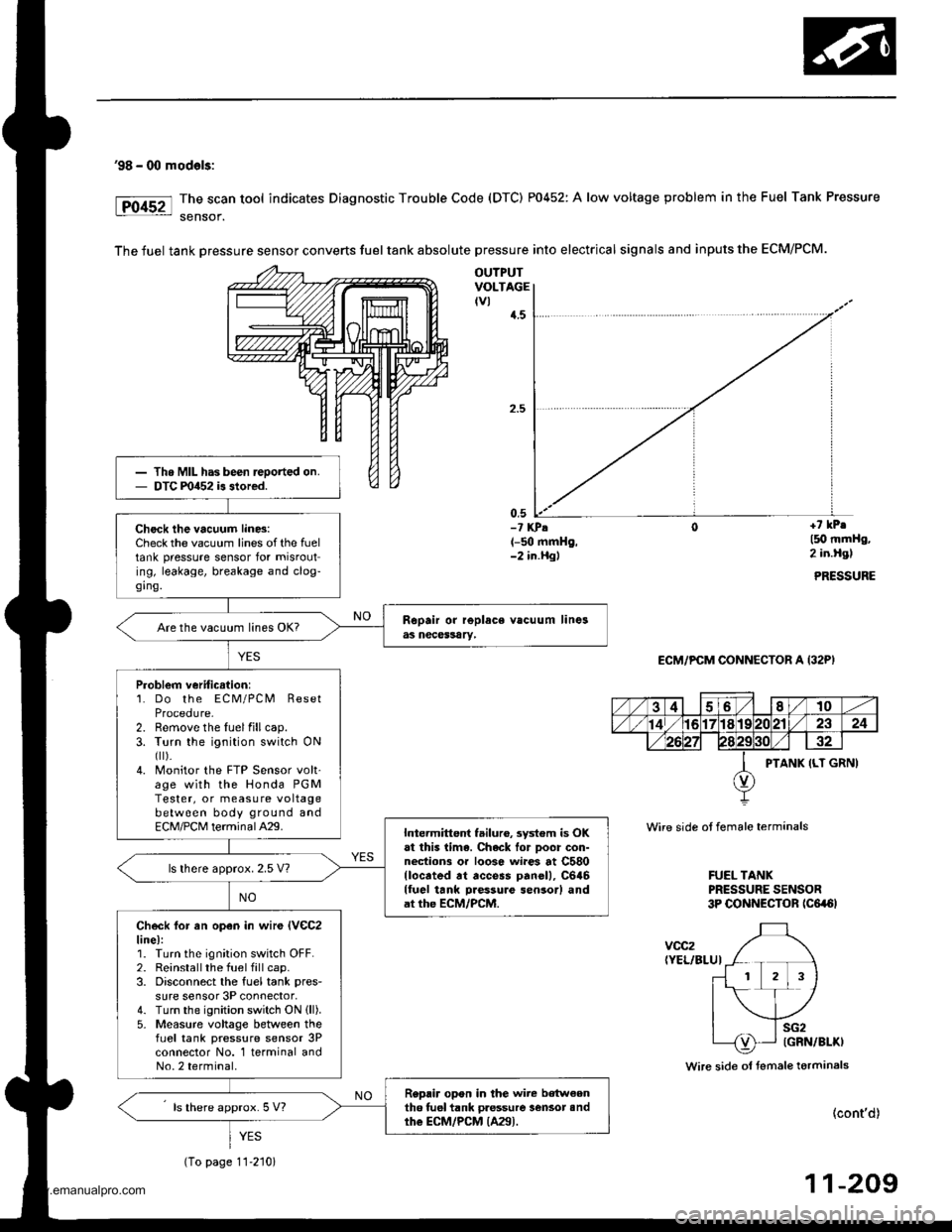

'98 - 00 mod€ls:

The scan tool indicates Diagnostic Trouble Code (DTC) P0452: A low voltage problem in the Fuel Tank Pressure

sensof.

The fuel tank Dressure sensor converts fuel tank absolute pressure into electrical signals and inputs the ECM/PCM.

OUTPUTVOLTAGEtvl{.5

0,5-? KPA(-50 mmHg,-2 in.Hgl

+7 kPr

l5O mmHg,2 in.Hgl

PRESSURE

ECM/PCM CONNECTOR A (32P)

Wire side ot female terminals

FUEL TANKPRESSURE SENSOR3P CONNECTOR tc6a6l

voc2(YEL/BLUI

Wire side ol fsmale terminals

(cont'd)

11-209

Th. MIL has been reoorted on.DTC m452 is stored.

Check the vacuum lin6:Check the vacuum lines of the fueltank pressure sensor for misrouting, leakage, breakage and clog-ging.

Are the vacuum lines OK?

Problem veriticstion:1. Do the ECM/PCM ResetProcedure-2. Remove the luelfillcap.3. Turn the ignition switch ONfl r).4. Monitor the FTP Sensor volt'age with the Honda PGMTester, or measure voltagebetween body ground andECM/PCM terminalA29.Intermittent failuro, system is OKat this lima. Chack lor Door con-nections or loose wi.es at C580llocrted rt access panell, C646lluel tank Daessure sensor) andat the ECM/PCM.

ls lhere approx. 2.5 V?

Check lor an open in wir€ lVeC2line):1. Turn the ignition switch OFF.2. Reinstallthe fuel fill cap.3. Disconnect the fuel tank pres-

sure sensor 3P connector,4. Turn the ignition switch ON (ll).

5- Measure voltage between thefLrel tank pressure sensor 3Pconnector No. 1 terminal andNo.2 terminal.

Replir opon in the wire b€tw€enth6 tuel tank pressure lensot andthe ECM/PCM {A29).ls there approx. 5 V?

YES

(To page 11-210)

www.emanualpro.com

Page 908 of 1395

Front Suspension

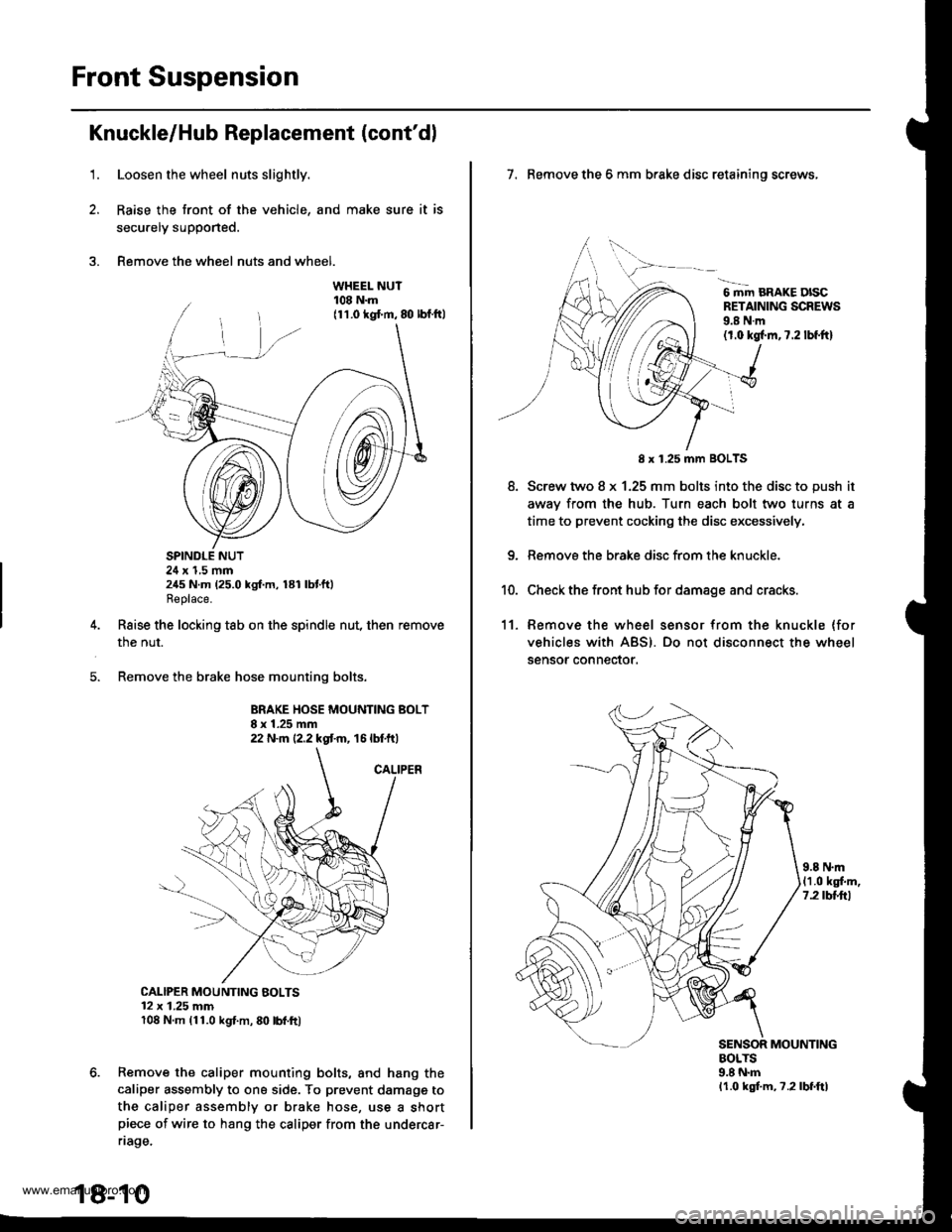

Knuckle/Hub Replacement (cont'dl

1.Loosen the wheel nuts slightly.

Raise the front of the vehicle, and make sure it is

secu.ely supported.

Remove the wheel nuts and wheel.

SPINDLE NUT24 x 1,5 mm245 N.m (25.0 kgf.m, 181 lbtft)Replace.

Raise the locking tab on the spindle nut, then remove

the nut.

Remove the brake hose mounting bolts.

BRAKE HOSE MOUNTING BOLT8 x 1.25 mm22 N.m {2.2 kgt m, 16 lbtft)

CALIPER MOUNTING BOLTS12 x 1.25 mm108 N.m (11.0 kgl.m, 80 lbl.ft)

Remove the caliper mounting bolts, and hang the

caliper assembly to ona side. To prevent damagg to

the caliper assembly or brake hose, use a shortpiece of wire to hang the caliper from the undercar-

riage.

18-10

7. Remove the 6 mm brake disc retaining screws,

6 mm BRAKE DISCRETAINING SCREWS9.8 N.m(1.0 kgl.m,7.2 lbf.ftl

8.

8 x 1.25 mm BOLTS

Screw two 8 x 1.25 mm bolts into the disc to push it

awav from the hub. Turn each bolt two turns at a

time to prevent cocking the disc excessively,

Remove the brake disc from the knuckle.

Check the front hub for damage and cracks.

11. Remove the wheel sensor from the knuckle (for

vehicles with ABS). Do not disconnect the wheel

sensor connector.

9.8 N.m(1.0 kgf.m,7.2 tbttrl

MOUNTINGBOLTS9.8 N.mlr.0 kgf.m, ?.2lbf.ftl

www.emanualpro.com

Page 919 of 1395

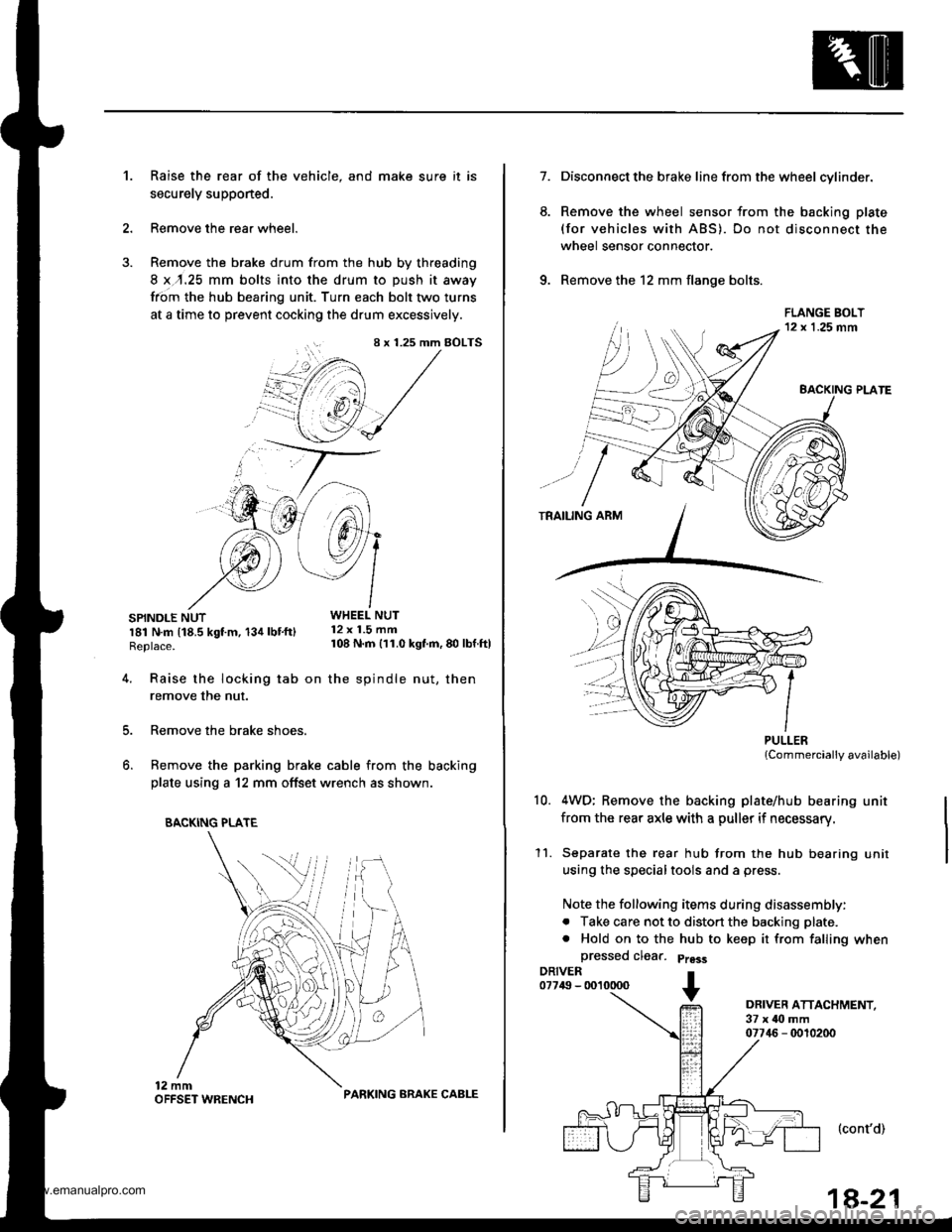

Raise the rear of the vehicle, and make sure it is

securely supponed.

Remove the rear wheel.

Remove the brake drum from the hub by threading

8 x,r.25 mm bolts into the drum to push it away

from the hub bearing unit. Turn each bolt two turns

at a time to prevent cocking the drum excessively.

SPINDLE NUTWHEEL NUT

r81 N.m t18.5 kgt m, 134 lbt'ftl 12 x 1.5 mm

Replace. 108 N m 111.0 kgf'm, 80 lbf ftl

't.

4.

8 x 1.25 mm BOLTS

i+/3 /',1

"@,1 /

.'--7 J-->-

5.

6.

Raise the locking tab on the spindle nut, then

remove the nut.

Remove the brake shoes.

Remove the parking brake cable from the backing

plate using a 12 mm offset wrench as shown.

BACKING PLATE

PARKING ARAKE CABLE

1a-21

7.

6.

Disconnect the brake line from the wheel cylinder.

Remove the wheel sensor from the backing plate

(for vehicles with ABS). Do not disconnect the

wheel sensor connector.

Remove the 12 mm flange bolts.

PULLERlCommercially available)

4WD; Remove the backing plate/hub bearing unit

from the rear axle with a puller if necessary.

Separate the rear hub from the hub bearing unit

using the specialtools and a press.

Note the following items during disassembly:

. Take care not to distort the backing plate.

. Hold on to the hub to keep it from falling when

a

10.

11.

DRIVER ATTACHMENT,37 x ilo mm07746 - 0010200

(cont'd)

www.emanualpro.com

Page 948 of 1395

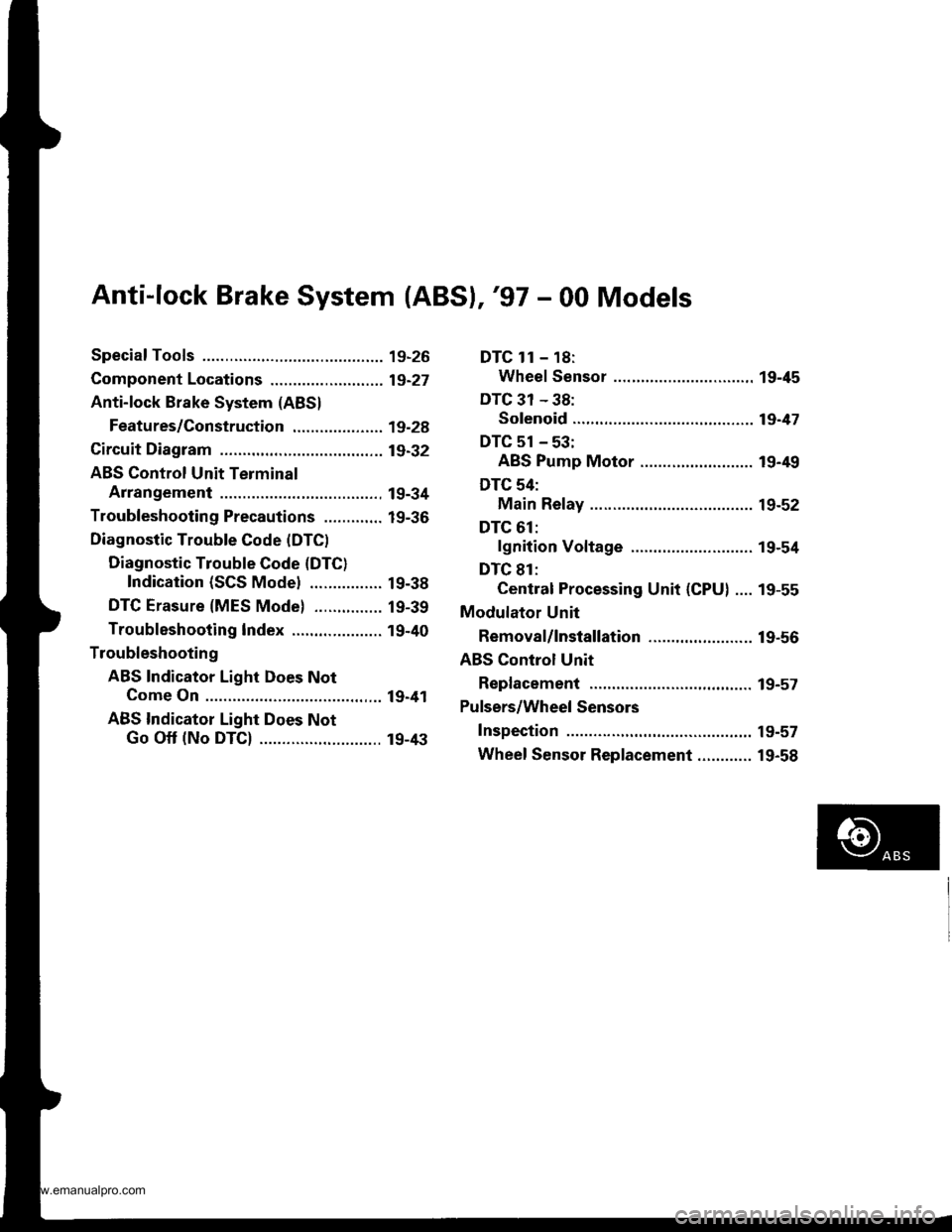

Anti-lock Brake System (ABSI,'97 - 00 Models

Special Tools ............. 19-26

Component Locations ......................... 19-27

Anti-lock Brake System (ABS)

Features/Construction ............. ......, 19-2A

Circuit Diagram ......... 19-32

ABS Control Unit Terminal

Arrangement ......... 19-34

Troubleshooting Precautions ............. 19-36

Diagnostic Trouble Gode (DTC)

Diagnostic Trouble Code (DTC)

Indication (SCS Model ................ 19-38

DTG Erasure (MES Mode) ............... 19-39

Troubleshooting lndex .................... 19-40

Troubleshooting

ABS Indicator Light Does Not

Come On ............ 19-41

ABS Indicator Light Does Not

Go Off (No DTC) ........................... 19-43

DTC 1r - 18:

Wheel Sensor .... 19-45

DTC 31 - 38:

Solenoid ............. 19-47

DTC 51 - 53:

ABS Pump Motor ......................... 19-49

DTC 54:

Main Relay ......... 19-52

DTC 61:

lgnition Voltage ........................... 19-54

DTC 81:

Central Processing Unit (CPU) .... 19-55

Modulator Unit

Removal/lnstallation ....................... 19-56

ABS Control Unit

Replacement ..,...... 19-57

Pulsers/Wheel Sensors

Inspection .............. 19-57

Wheel Sensor Replacement ............ 19-58

www.emanualpro.com

Page 950 of 1395

Component Locations

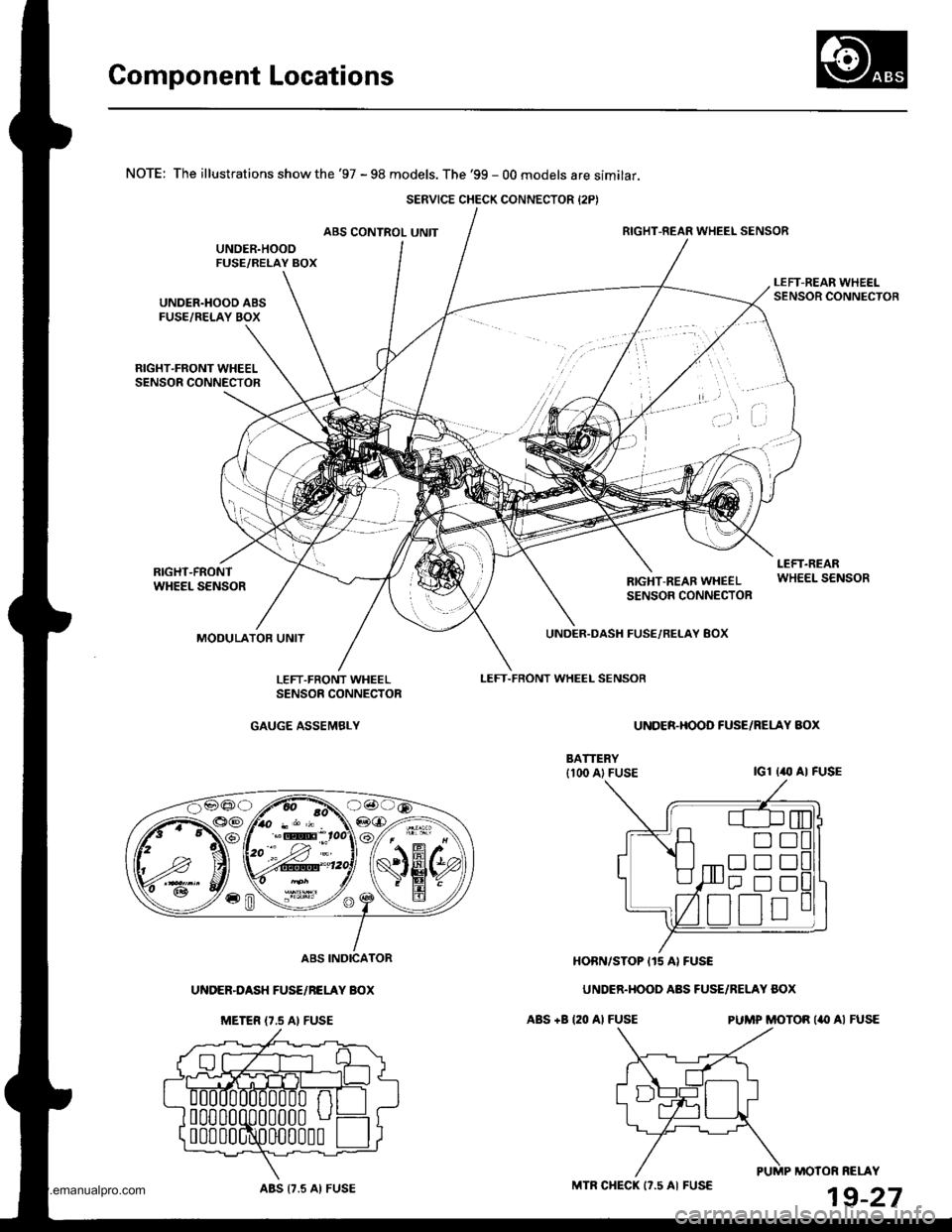

NOTE: The illustrations show the '97 - 98 models. The '99 - 00 models are similar.

ABS CONTROL UNITRIGHT-REAR WHEEL SENSOR

UNDER.HOOD ABSFUSE/RELAY BOX

RIGHT.FRONT WHEELSENSOR CONNECTOR

RIGHT-FRONTWHEEL SENSORRIGHT-REAB WHEELSENSOR CONNECTOR

MODULATOR UNIT

LEFT.FRONT WHEEL SENSOB

UNDER.DASH FUSE,/RELAY 8OX

UNDER.HOOO FUSE/RELAY AOX

IGl I(, AI FUSE

ABS +B 120 Al FUSEPUMP MOTOR ('II AI FUSE

HOBN/STOP I15 AI FUSE

UNDER.HOOD ABS FUSE/RELAY BOX

LEFT.FRONT WHEELSENSOE CONNECTOR

GAUGE ASSEMBLY

ABS INDICATOR

UNDER-DASH FUSE/NELAY BOX

METER {7.5 AI FUSE

MOTOR RELAY

19-27

SERVICE CHECK CONNECTOR {2PI

D!

trtrtr

[r D!

ABS {7.5 AI FUSEMTR CHECK 17.5 AI FUSE

www.emanualpro.com