Cooling HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 203 of 1395

Goolant Temperature Gauge

Gauge Testing

1. Check the No. 25 (7.5 A) fuse in the under-dash

fuse/relay box before testin9.

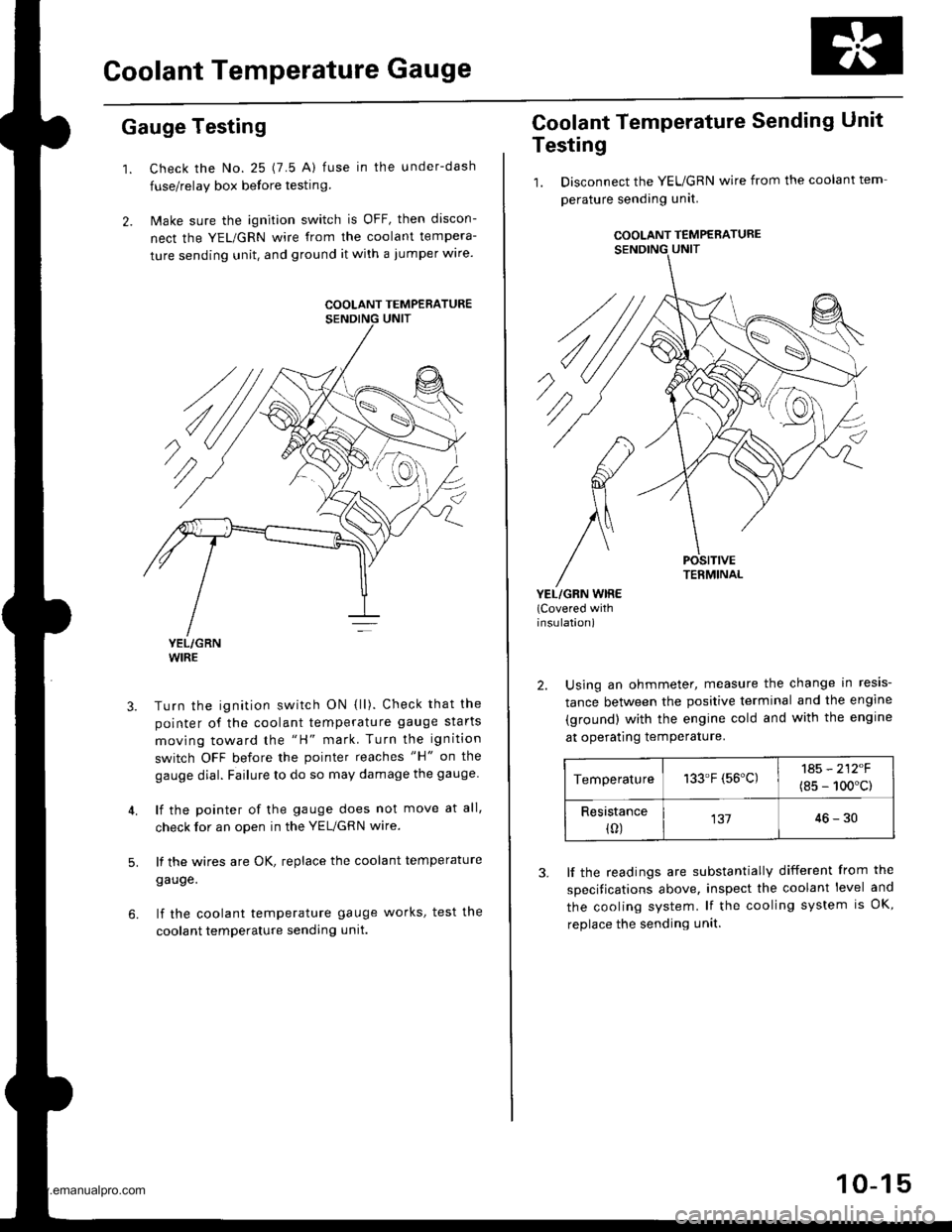

2. Make sure the ignition switch is OFF, then discon-

nect the YEL/GRN wire from the coolant tempera-

ture sending unit. and ground it with a jumper wire.

YEL/GRNWIRE

Turn the ignition switch ON {ll). Check that the

pointer of the coolant temperature gauge starts

moving toward the "H" mark. Turn the ignition

switch OFF before the pointer reaches "H" on the

gauge dial. Failure to do so may damage the gauge.

lf the pointer of the gauge does not move at all,

check for an open in the YEL/GRN wire.

lf the wires are OK, replace the coolant temperature

gauge.

lf the coolant temperature gauge works, test the

coolant temperature sending unit.

5.

COOLANT TEMPERATURE

Coolant Temperature Sending Unit

Testing

1. Disconnect the YEUGRN wire from the coolant tem

perature sending unit.

COOLANT TEMPERATURE

POSITIVETERMINAL

YEL/GRN WIRE(Covered withinsulation)

2. Using an ohmmeter, measure the change in resis-

tance between the positive terminal and the engine

(ground) with the engine cold and with the engine

at operating temPerature.

Temperature133.F (56'C)1A5 - 212F

(8s - 100'c)

Resistance(0)13746-30

3. lf the readings are substantially different from the

specitications above, inspect the coolant level and

the cooling system. lf the cooling system is OK,

replace the sending unit.

10-15

www.emanualpro.com

Page 277 of 1395

Diagnostic Trouble Code (DTCI Chart

*: These DTCS will be indicated by the blinking of the Malfunction Indicator Lamp (MlL) with the SCS service connector

connected.**: The E (E)*u indicator tight and the Malfunction Indicator Lamp (MlL) may come on simultaneously.*1' AIT *3 '97 model +5; '99 - 00 models*2: MlT *4:'98 model

{cont'd)

11-75

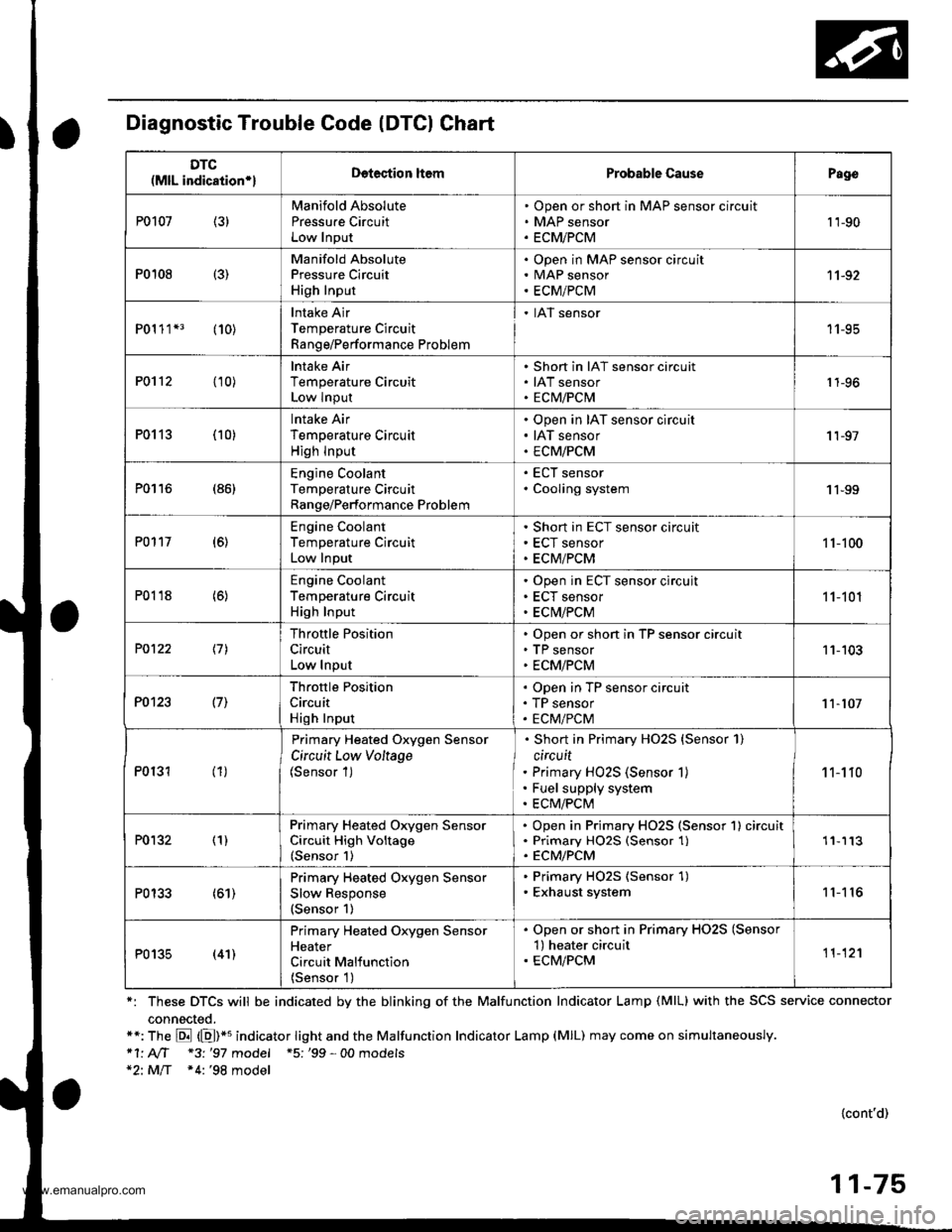

DTC(MlL indication*lDetection ltemProbable CausePago

P0107 (3)Manifold Absolute

Pressu.e CircuitLow Input

Open or short in MAP sensor circuit

MAP sensor

ECMiPCM

't 'l-90

P0108 {3)

Manifold AbsolutePressure Circuit

High Input

Open in MAP sensor circuitMAP sensor

ECM/PCM

11-92

P01 1 1*3 (10)Intake Air

Temperature Circuit

Range/Performance Problem

. IAT sensor

11-95

P0112 (10)lntake Air

Temperature CircuitLow Input

Short in IAT sensor circuit

IAT sensorECM/PCM1 1-96

P0113 (10)lntake Air

Temperature Circuit

High lnput

Open in IAT sensor circuit

IAT sensor

ECM/PCM

'I 1-97

P0116 (86)Engine CoolantTemperature CircuitRange/Performance Problem

ECT sensor

Cooling system1 1-99

P0117 (6)Engine Coolant

Temperature Circuit

Low Input

Short in ECT sensor circuit

ECT sensor

ECM/PCM

1 1-100

P0118 (6)Engine Coolant

Temperature CircuitHigh Input

Open in ECT sensor circujt

ECT sensor

ECM/PCM

11-101

P0122 \11

Throttle Position

Circuit

Low Input

Open or short in TP sensor circuitTP sensor

ECM/PCM

11-103

P0123 l7l

Throftle Position

Circuit

High Input

Open in TP sensor circuit

TP sensor

ECM/PCM11-107

P0131 (1)

Primary Heated Oxygen Sensor

Circuit Low Voltage(Sensor 1)

Short in Primary HO2S {Sensor 1)

circuit

Primary HO2S (Sensor 1)

Fuel supply system

ECM/PCM

1 1-1 10

P0132 (1)Primary Heated Orygen SensorCircuit High Voltage(Sensor 1)

Open in Primary HO2S (Sensor 1) circuitPrimary HO25 (Sensor 1)ECM/PCM

'11113

P0133 (61)Primary Heated Oxygen Sensor

Slow Response(Sensor 1)

. Primary HO2S (Sensor 1). Exhaust system11'I 16

P0135 (41)

Primary Heated Oxygen SensorHeater

Circuit Malfunction

{Sensor 1)

. Open or short in Primary HO2S (Sensor'l) heater circuit. ECM/PCM11-12'l

www.emanualpro.com

Page 283 of 1395

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors iscutoffto improvefuel economyat

speeds over 970 rpm ('97 - 98 models), 920 rpm ('99 - 00 modelsl.

. Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm ('97 - 98 models), 6900 rpm ('99 - 00

models), regardless of the position of the throttle valve, to protect the engine from over-rewing.

With Ay'T model. the PCM cuts the fuel at engine speeds over 5,000 rpm when the vehicle is not moving.*'�

4,./C Comoressor Clutch Relav

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure a smooth transition to the Ay'C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is above 154"F (68'C), the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister,

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode.

which reduces the engine load to improve the fuel economy.

PCM Fail-saf e/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pre

grammed value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self-diagnosis Function IMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the MIL and stores the DTC

in erasable memory. When the ignition is initially turned on {ll), the ECM/PCM supplies ground for the MIL for two

seconds to check the MIL bulb condition.

4. Two Trio Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S*1, fuel metering-related. idle control

system, ECT sensor and EVAP control system self-diagnostic functions. When an abnormality occurs, the ECM/PCM

stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (ll) again,

the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is cancelled

when you jump the service check connector, The MIL will then blink immediately when an abnormality occurs.

5. Two (or Three) Driving Cycle Detection Method {'97 model)

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles.

or TWC deterioration is detected during three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to

ease troubleshooting, this function is cancelled when you jump the service check connector. The MIL will then blink

immediately when an abnormality occurs.

*1: '97 - 98 models*2: '99 - 00 models

5.

www.emanualpro.com

Page 301 of 1395

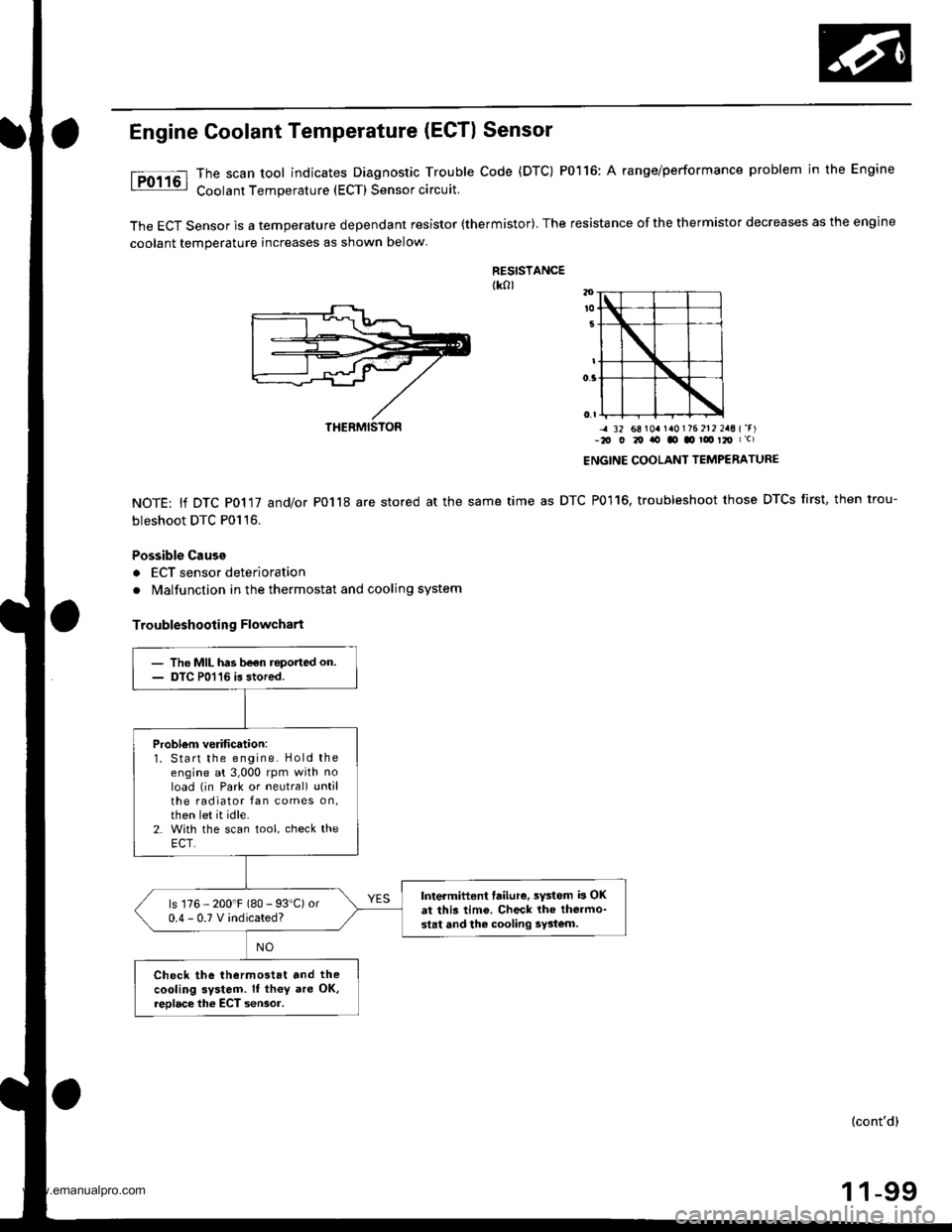

Engine Goolant Temperature (ECTI Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0116: A range/performance problem in the Engine

Coolant Temperature (ECT) Sensor circuit.

The ECT Sensor is a temperature dependant resistor (thermistor). The resistance of the thermistor decreases as the engine

coolant temperature increases as shown below

RESISTANCEtk0l

NOTE: lf DTC P0117 and/or P0118 are stored at the same

bleshoot DTC P0116.

Possible Cause

a ECT sensor deterioration

. Malfunction in the thermostat and cooling system

Troubleshooting Flowchart

-4 32 68 r0a r a0176 212 2aE {'r)-2O O 20 ito tO .o ! t2O I c)

ENGINE COOLANT TEMPERATURE

time as DTC P0116, troubleshoot those DTCS first, then trou-

THERMISTON

- The MIL has be€n roported on.- DTC P01'16 is stored.

Probl6m verification:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on,then let it idle.2. With the scan tool, check theECT.

Intermittent failure, sYstem b OKat this tim6. Check lhe thermo-stat and the cooling 5y3tom.

ls 176 - 200'F (80 - 93"C) or0.4-0.TVindicated?

Check the thermostat and the

cooling system. It th€y are OK,reolace the ECT seNor.

(cont'd)

1 1-99

www.emanualpro.com

Page 353 of 1395

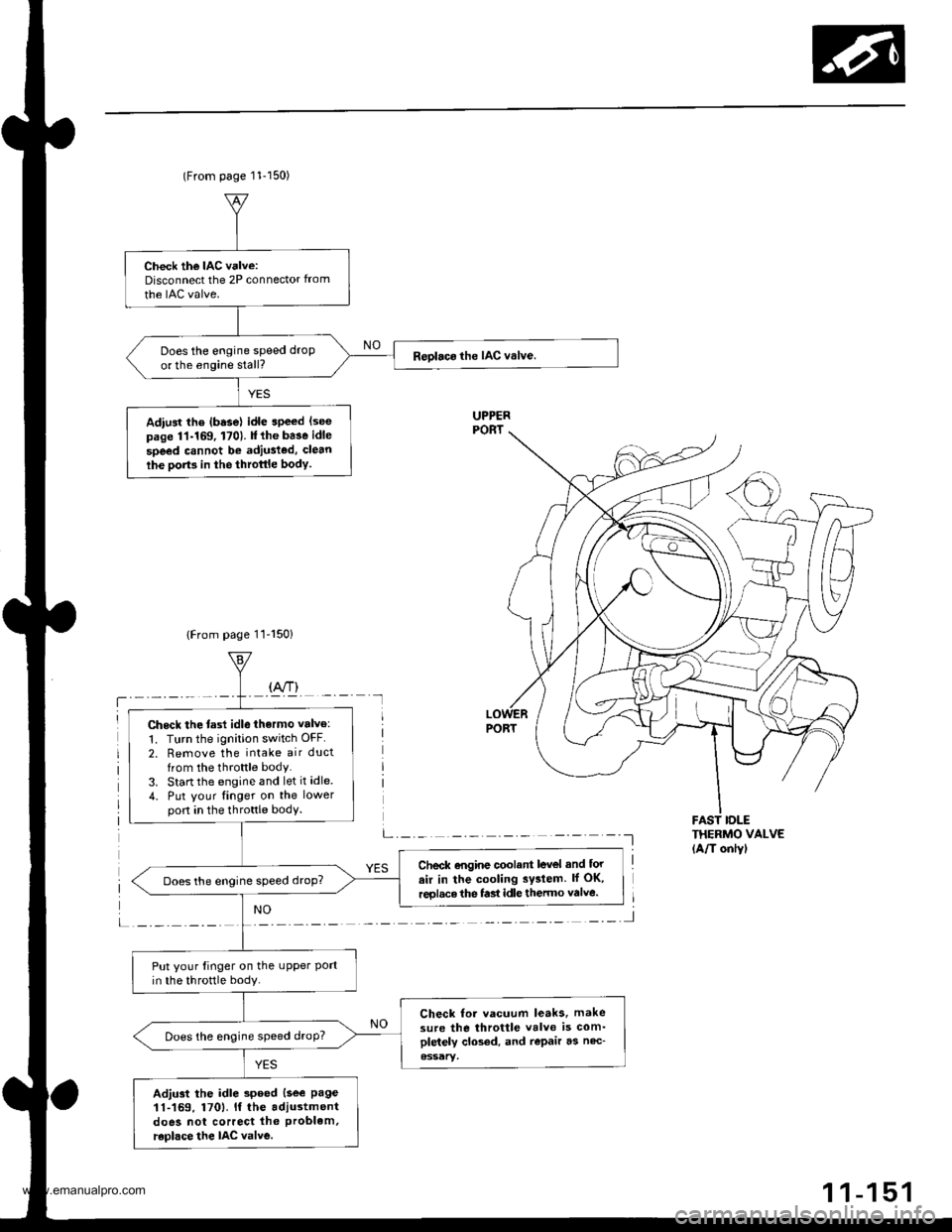

(From page 11-150)

{From page 11-150}

THERMO VALVE(A/T onlyl

Check the IAC valve:Disconnect the 2P connector from

the IAC valve.

Does the engine speed droP

or the engine stall?

Adiust the (basel idl€ speed lseepage 11-169, 1t0). Itihe ba3e idle

speed cannot be adiust€d, clean

the Dorts in the throttle body.

UPPER

Check the tast idle lhermo valve:

1. Turn the ignition switch OFF.

2. Remove the intake air ductfrom the throttle body.3. Start the engine and let it idle.

4. Put your finger on the lowerpon in the throttle body.

Check engine cool.nt level and for

air in the cooling sy3lem. lf OK,

reolace the f.st idle thermo valve.Does the engine speed drop?

Put your Iinger on the uPPer Portin the throttle body.

Check for vacuum leaks, make

sure the throttle valve is com'pletely clo3ed. and repair as nec-Does the engine speed droP?

Adjust the idle spoed lsee Page11-169. 1701. lf the adiustmentdoes not correct lhe problem,

r.olace the IAC valve.

www.emanualpro.com

Page 357 of 1395

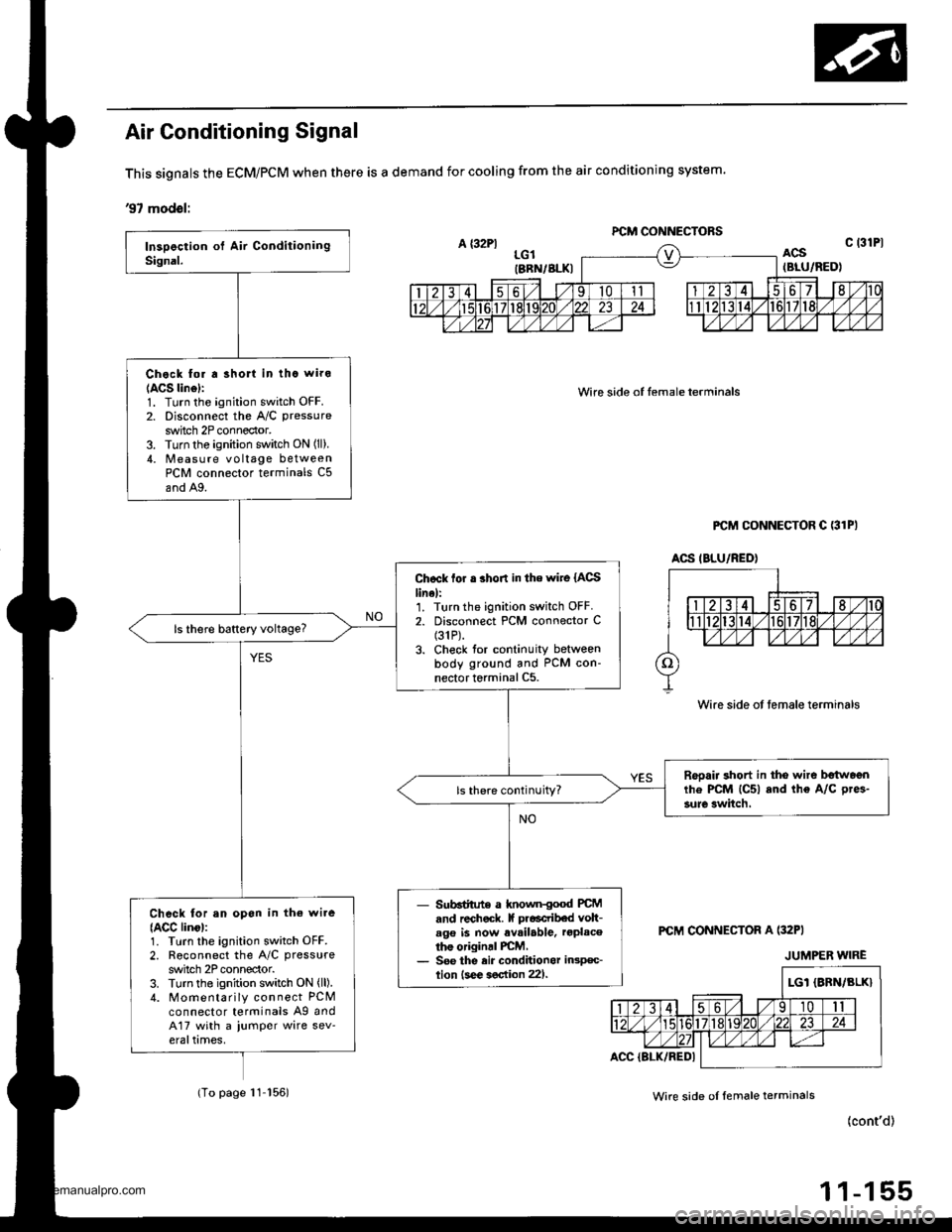

Air Conditioning Signal

This signals the EcM/PcM when there is a demand for cooling from the air conditioning system.

'97 modol:

Wire side of lemale terminals

PCM CONNECTOR C (31PI

ACS IBLU/RED)

PCM CONNECTOR A (:TIPI

(cont'd)

1 1-1 55

Chock for a shorl in thc wiro(ACS linol:1. Turn the ignition switch OFF.2. Disconnect the A/C pressure

switch 2Pconneclor.3. Turn the ignition switch ON (ll).,1. [Ieasu re voltage betweenPCM connector terminals C5

and A9.

Check for . .hon in the wire IAGSlinel:1. Turn the ignition switch OFF.2. Disconnect PCM connector C(31P).

3. Check for continuity betweenbody ground and PCM con-nector torminal C5.

Reoaii short in tho wire b€twoenrh6 PCM (Csl and the A/C pres-

3urc 3witch.

- Subcdtrte a known{ood PCMand recheck. lf pr6actibed volt-age is now av{ilable, roplacethe origind PCM,- Soe the eir conditionor in3p€c-lion lsee soction 221.

Check tor an opon in the wite(ACC lino):1. TLrrn the ignition switch OFF.2. Roconnect the A/C pressure

switch 2P connector.3. Turn the ignition switch ON (ll).

4. Momenta rily connect PCMconnector terminals A9 and417 with a iumper wire sev'eraltimes,

Wire side of female terminals

JUMPER WIRE

(To page 11-156)Wire side oI Iemale terminals

www.emanualpro.com

Page 370 of 1395

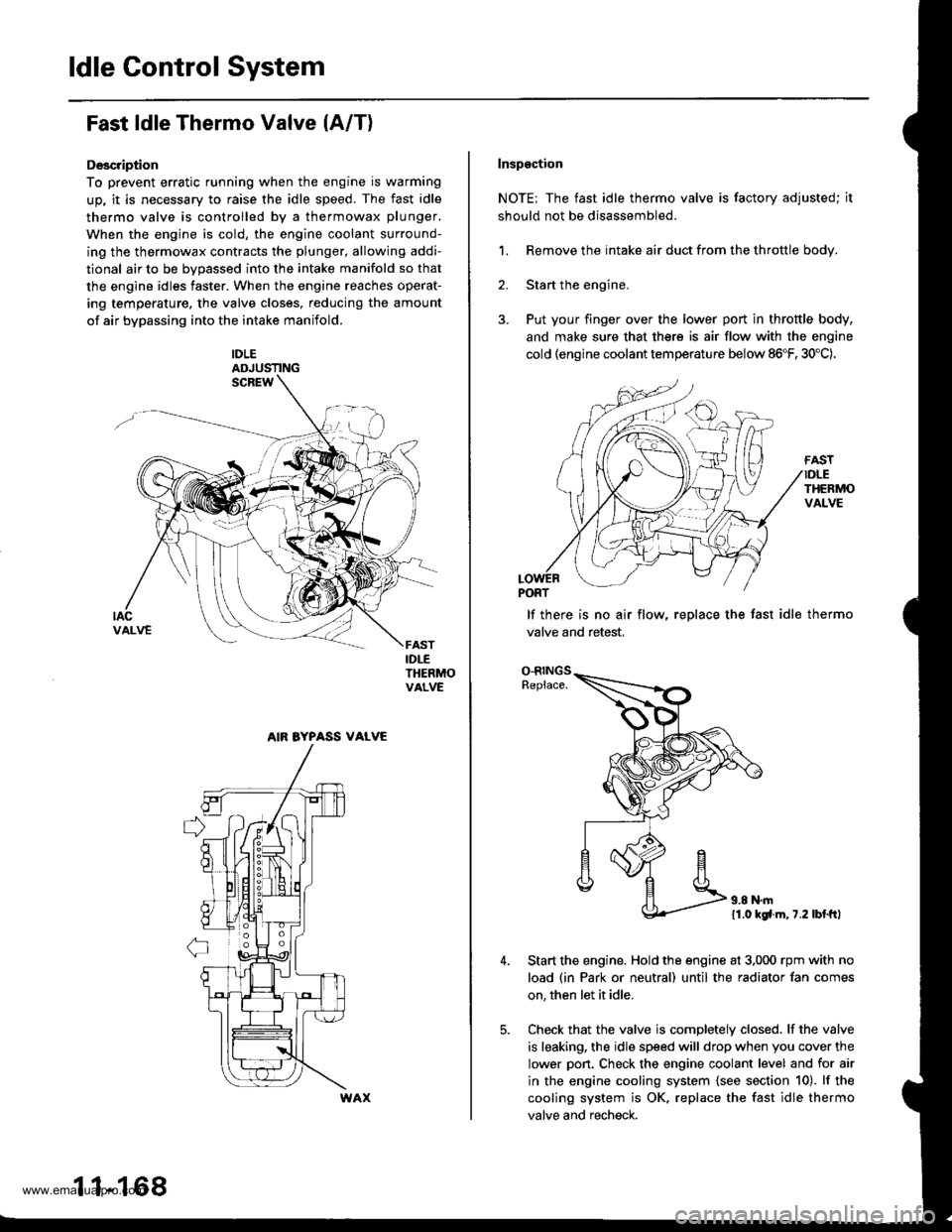

ldle Control System

Fast ldle Thermo Valve lA/T)

Description

To prevent erratic running when the engine is warming

up, it is necessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surround-

ing the thermowax contracts the plunger, allowing addi-

tional air to be bvDassed into the intake manifold so that

the engine idles faster. When the engine reaches operat-

ing temperature. the valve closes, reducing the amount

of air bypassing into the intake manifold.

IDLEADJUSTING

IDLETHERMOVALVE

AIR BYPASS VALVE

11-168

Inspgction

NOTE: The fast idle thermo valve is factory adjusted; it

should not be disassembled.

1. Remove the intake air duct from the throttle body.

2. Start the engine,

3. Put your finger over the lower port in throttle body,

and make sure that there is air flow with the engine

cold (engine coolant temperature below 86"F, 30'C).

lf there is no air flow, replace the fast idle thermo

valve and retest,

O-RINGSReplace.

11.0 kgfl.m, 7.2 lbl.ftl

Start the engine. Hold the engine at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on, then let it idle.

Check that the valve is completely closed. lf the valve

is leaking, the idle speed will drop when you cover the

lower pon. Check the engine coolant level and for air

in the engine cooling system {see section 10). lf the

cooling system is OK, replace the fast idle thermo

valve and recheck.

www.emanualpro.com

Page 401 of 1395

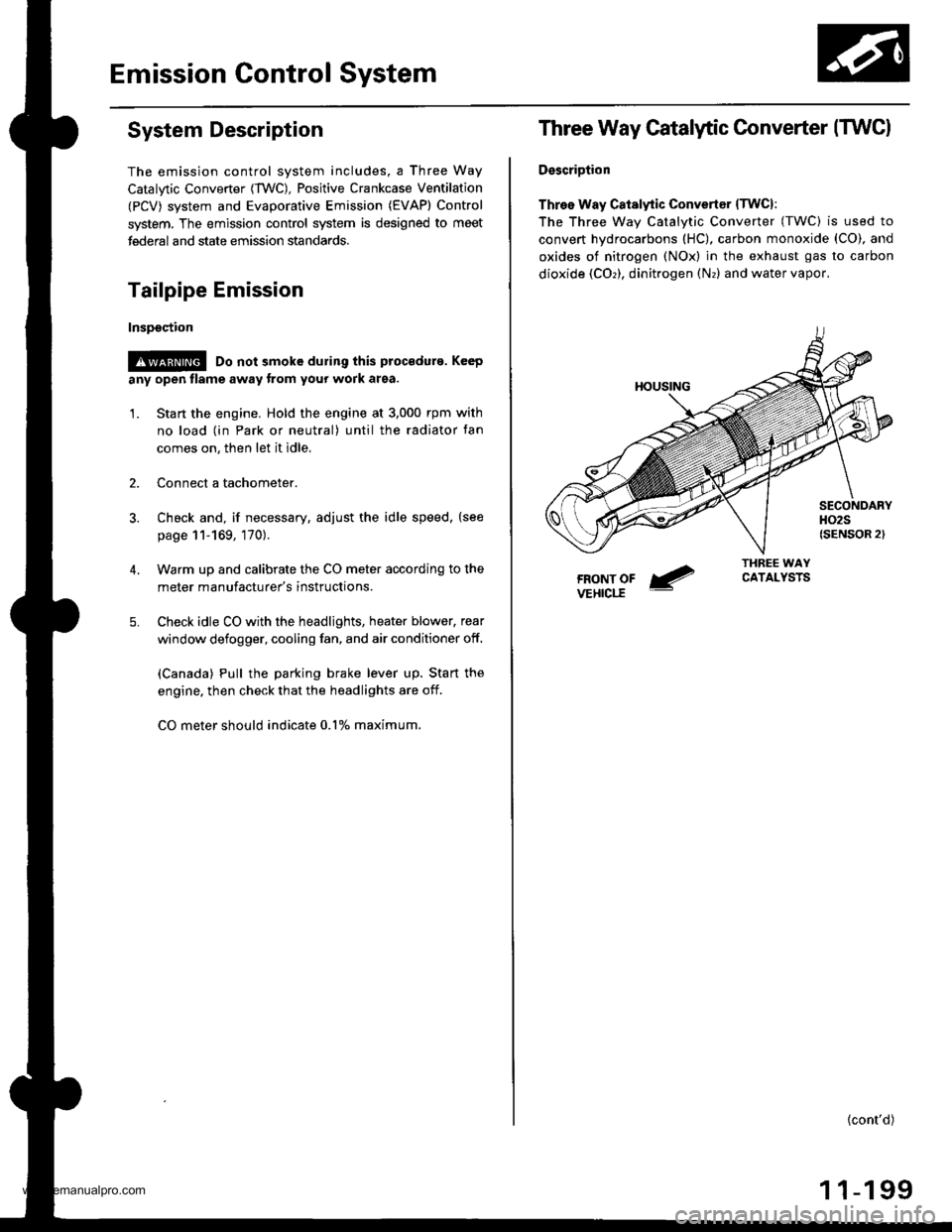

Emission Control System

System Description

The emission control system includes, a Three Way

Catalytic Converter {TWC), Positive Crankcase Ventilation

(PCV) svstem and Evaporative Emission (€VAP) Control

system. The emission control system is designed to meet

federal and state emission standards.

Tailpipe Emission

Inspsction

!@ Do not smoke during this procsdura. Keep

any open tlame away from your work area.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle,

Connect a tachometer.

Check and, if necessary, adjust the idle speed, (see

page 11-169, 170).

Warm up and calibrate the CO meter according to the

meter manufacturer's instructions.

Check idle CO with the headlights, heater blower, rear

window defogger, cooling fan, and air conditioner off.

(Canada) Pull the parking brake lever up. Start the

engine, then check that the headlights are off.

CO meter should indicate 0.1% maximum.

4.

Three Way Catalytic Converter (TWCI

DsscriDtion

Three Way Catalytic Convertsr lTwcl:

The Three wav Catalvtic Converter (TWC) is used to

convert hydrocarbons (HC), carbon monoxide (CO), and

oxides of nitrogen (NOx) in the exhaust gas to carbon

dioxide (COr), dinitrogen (Nr) and water vapor,

{cont'd)

1 1-199

www.emanualpro.com

Page 675 of 1395

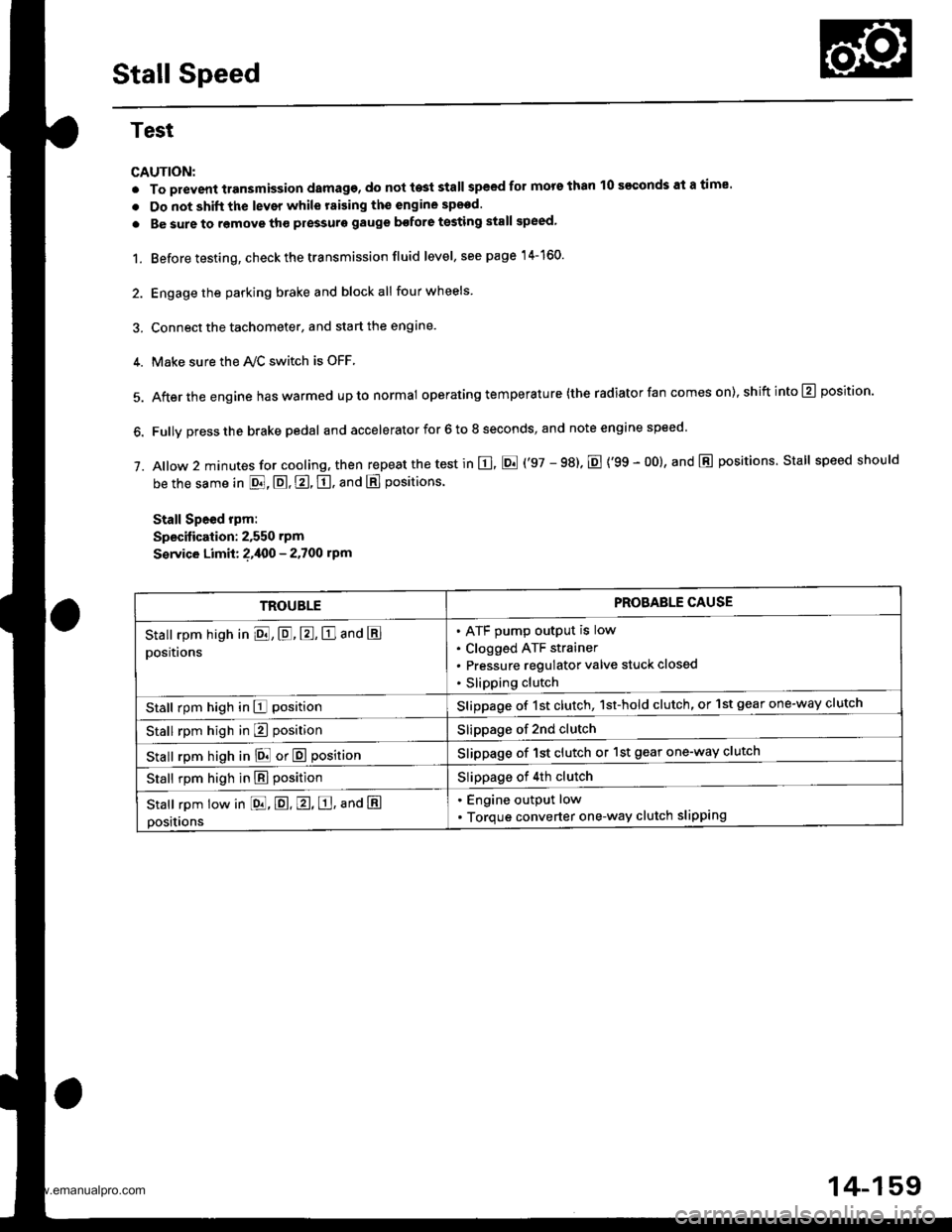

Stall Speed

Test

CAUTION:

. To prevent transmission damage, do not te3t stall speed for mors than 10 s€€onds at a time'

. Do not shift the lever while raising th€ engine spsed.

. Be sure to remove tho pressuro gauge bofore testing stall speed,

1. Before testing, check the transmission fluid level, s€e page 14-160.

2. Engage the parking brake and block all four wheels

3. Connect the tachometer, and start the engane.

4. Make sure the Ay'C switch is OFF

5. After the engine haswarmed upto normal operating temperature (the radiator fan comes on),shiftinto@ position.

6. Fully press the brake pedal and accelerator for 6 to 8 seconds, and note engine speed '

j. A|ow 2 minutes for cooling, then repeat the test in E, E ('97 - 98). E {'99 - 00}, and E positions. Stall speed should

be the same in E, E, E, tr. and E positions

Stall Speed rpm:

Specitication: 2,550 rpm

S€rvice Limit: ?,400 - 2.700 rpm

TROUBLEPROBAELE CAUSE

Stall rpm high in El, E, E, E and E

positions

ATF pump output is low

Clogged ATF strainer

Pressure regulator valve stuck closed

Slipping clutch

Stall rpm high in E positionSlippage of 1st clutch, 1st-hold clutch, or 1st gear one-way clutch

Stall rpm high in E positionSlippage of 2nd clutch

stall rpm high in E! or E positionSlippage of 1st clutch or 1st gear one-way clutch

Stall rpm high in E positionSlippage of 4th clutch

Stall rpm low in [dd, E. E, E, ana E

positions

. Engine output low

. Torque converter one-way clutch slipping

14-159

www.emanualpro.com

Page 1100 of 1395

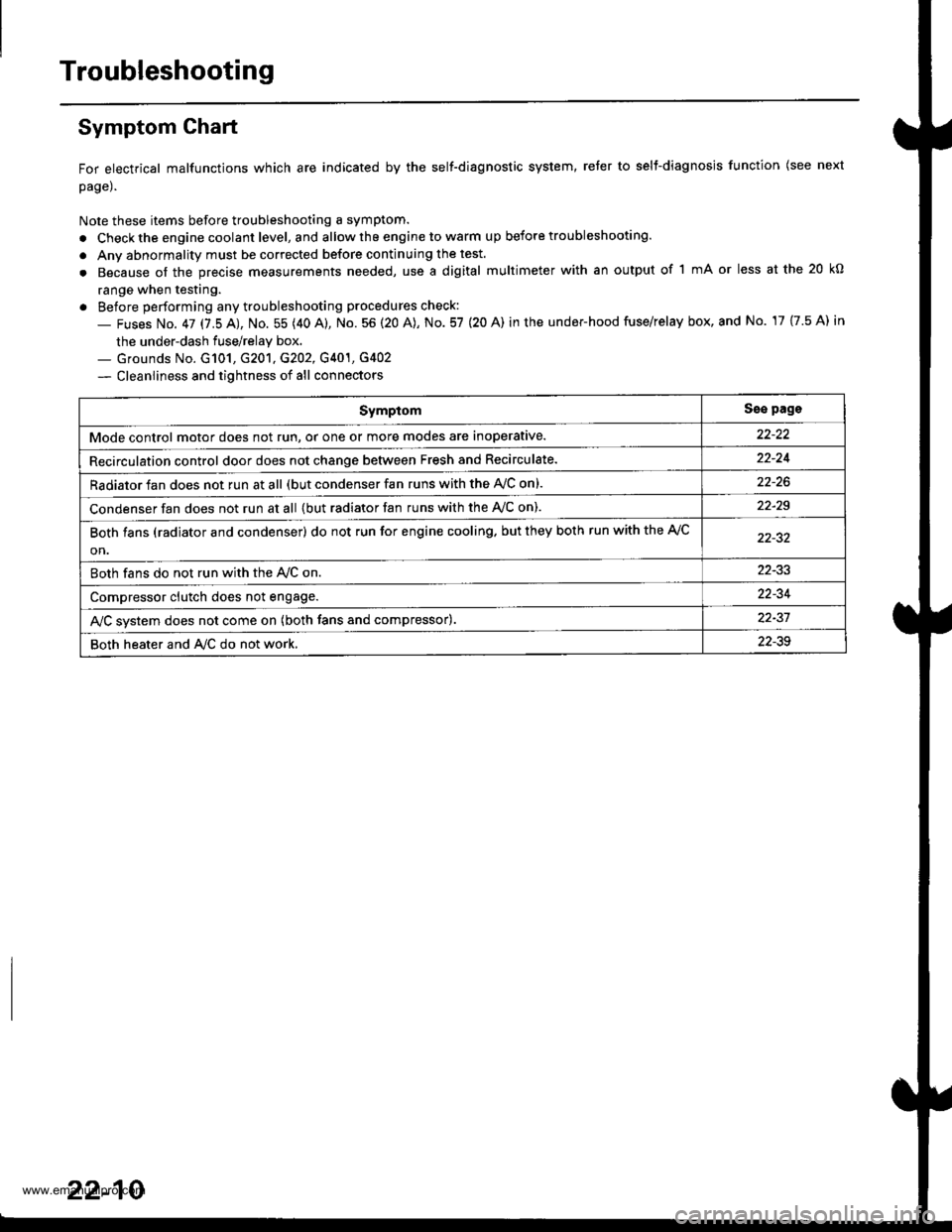

Troubleshooting

Symptom Ghart

For electrical malfunctions which are indicated by the self-diagnostic system, reter to selt-diagnosjs function (see next

page).

Note these items before troubleshooting a symptom.

. Check the engine coolant level, and allow the engine to warm up before troubleshooting.

. Anv abnormality must be corrected before continuing the test.

. Because of the precise measurements needed, use a digital multimeter with an output of 1 mA or less at the 20 kO

range when testing.

. Before performing any troubleshooting procedures check:

- Fuses No. 47 17.5 AJ, No. 55 (40 A), No. 56 (20 A), No. 57 (20 A) in the under-hood fuse/relay box, and No. 17 {7.5 A) in

the under-dash fuse/relay box.._ Grounds No. G101, G201, G202, G401, G4O2

- Cleanliness and tightness of all connectors

SymptomSse pags

Mode control motor does not run, or one or more modes are inoperative.

Recirculation control door does not change between Fresh and Recirculate.22-24

Radiator fan does not run at all (but condenser fan runs with the AVC on).

Condenser fan does not run at all {but radiator fan runs with the Ay'C on).22-29

Both fans (radiator and condenser) do not run for engine cooling. but they both run with the A,/C

on.

Both fans do not run with the Ay'C on22-33

Compressor clutch does not engage.22-34

AJC svstem does not come on (both fans and compressor).22-37

Both heater and A/C do not work,22-39

22-10

www.emanualpro.com