Mil HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 108 of 1395

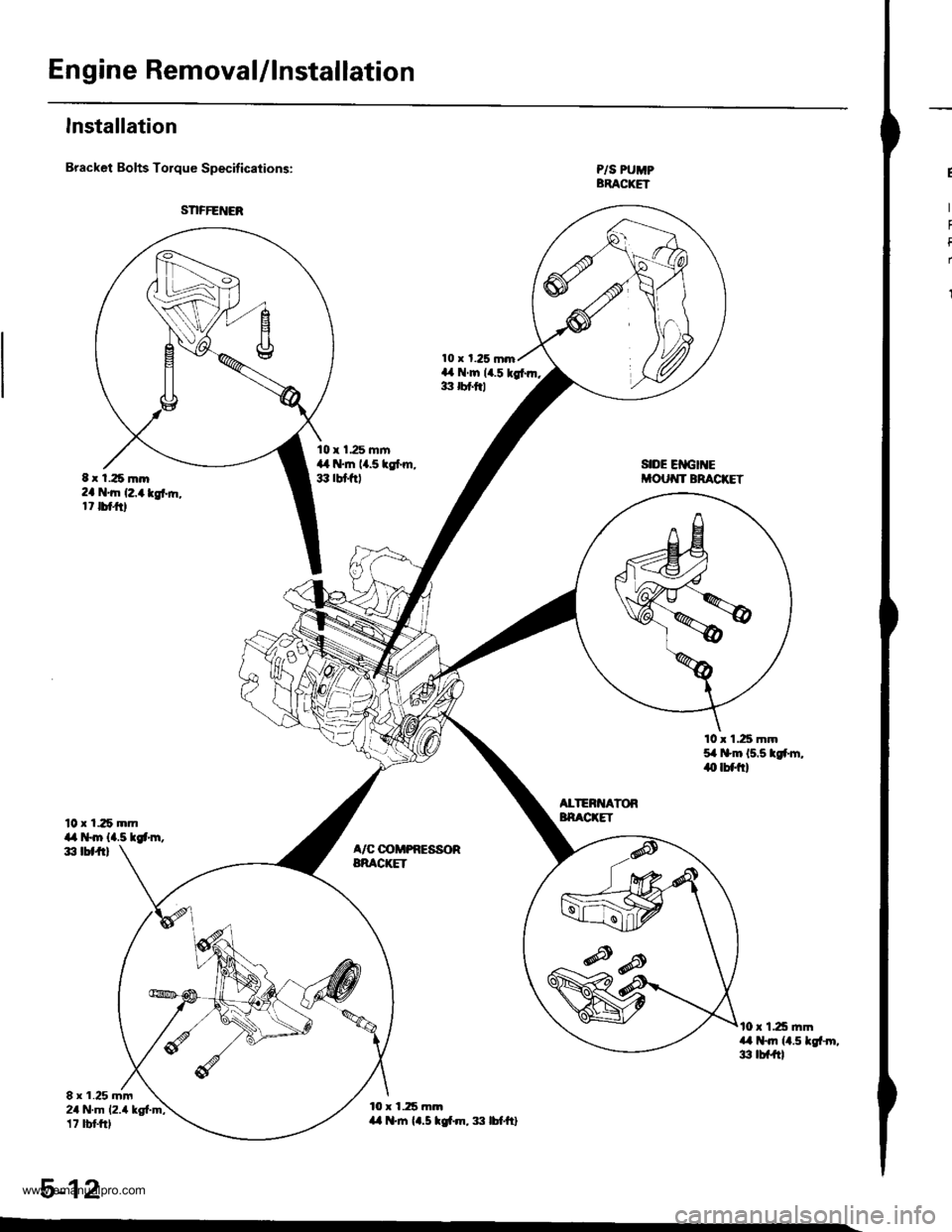

En gine Removal/lnstallation

Installation

Bracket Bolts Torque Specifications:

10 x 125 mmil,a t*m {4.5 tgt'm,d, tbtft)

8 r 1.25 mm24 N.m 12.4 kg{.m;17 tbt frl

10 x 1.25 mrn,L il.tn {1.5 tgt m, :|:l lbf'ft}

P/S PUMPBRACKET

SIDE EIIGII{Ei'OUT{T BRACKET

10 x 1.25 mm54 t$m 15.5 tgfm,iO lbflrl

ALTERI{ATORBNACKET

A/C @MPRESSORBRACIGT

t0 r 125 ]nma,l t+Jn ll.5 lgf-rn,3 tbf{tl

5-12

t t 1.25 m.D2a 'tn (2,4 kgt ft,17 tbtftl

www.emanualpro.com

Page 123 of 1395

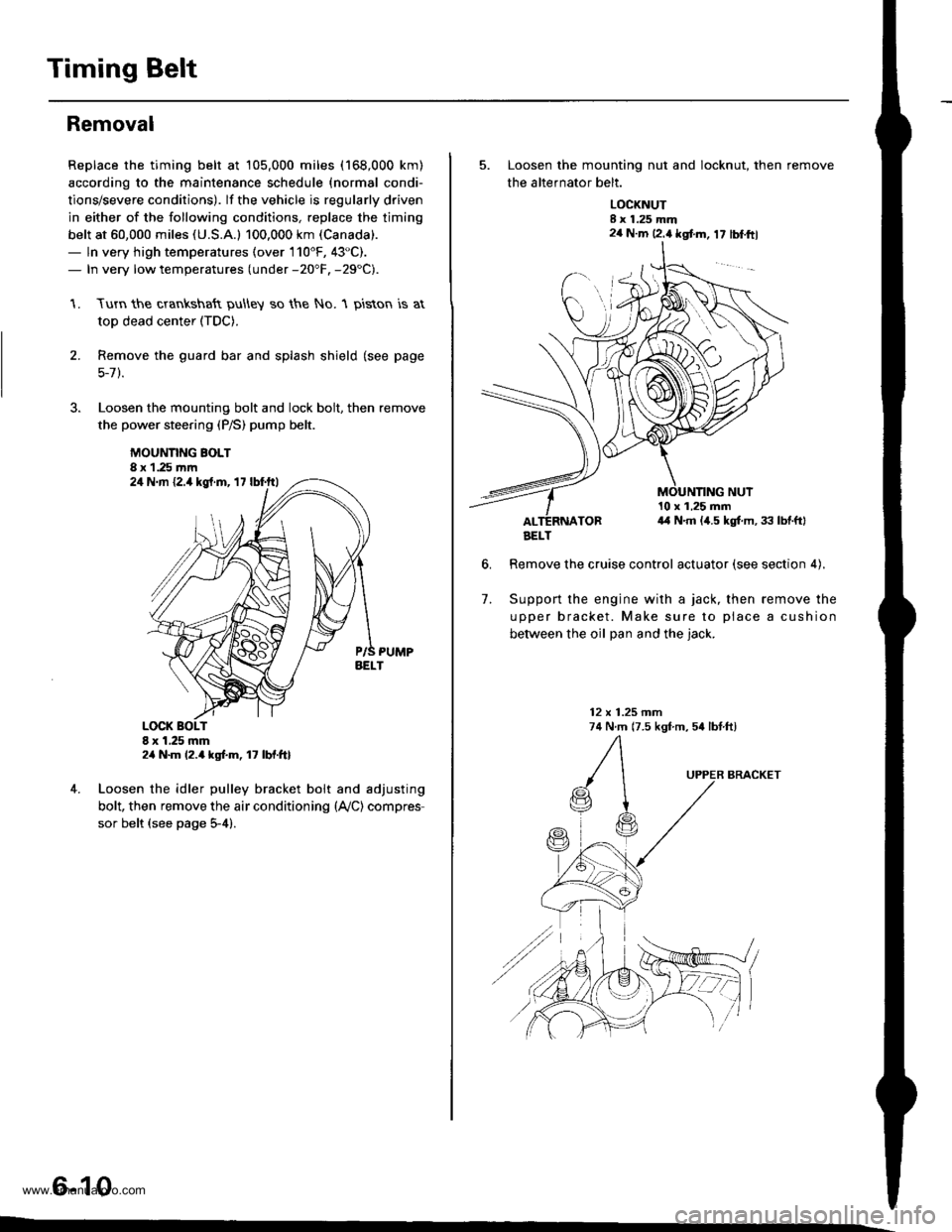

Timing Belt

Removal

Replace the timing belt at 105,000 miles (168,000 km)

according to the maintenance schedule {normal condi-

tions/severe conditions). lf the vehicle is regularly driven

in either of the following conditions, replace the timing

belt at 60,000 miles (U.S.A.l 100.000 km (Canada).

- ln very high temperatures (over 110'F, 43"C).- In very low temperatures (under -20"F. -29"C).

Turn the crankshaft pu\ley so the No. 1 piston is at

top dead center (TDC).

Remove the guard bar and splash shield (see page

5-7 ).

Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt.

MOUNNNG BOLT8 x 1.25 rnm

1.

2.

,l

4. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (lVC) compres

sor belt (see page 5-4).

6-10

24 N.m {2.4 kgt.m, 17 lbf.ftl

24 N.m 12.4 kgf.m, lt lbf.ftl

5. Loosen the mounting nut and locknut, then remove

the altefnator belt.

LOCKNUTI x 1.25 mm2a N.m 12.4 kgt m, 17 lblftl

6.

10 x 1,25 mm4,1 N.m (,1.5 kgt m, 33 lbtftl

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil Dan and the iack.

12 x 1.25 mm74 N.m (7.5 kgf m, 54 lbtftl

7.

BRACKET

AELT

www.emanualpro.com

Page 174 of 1395

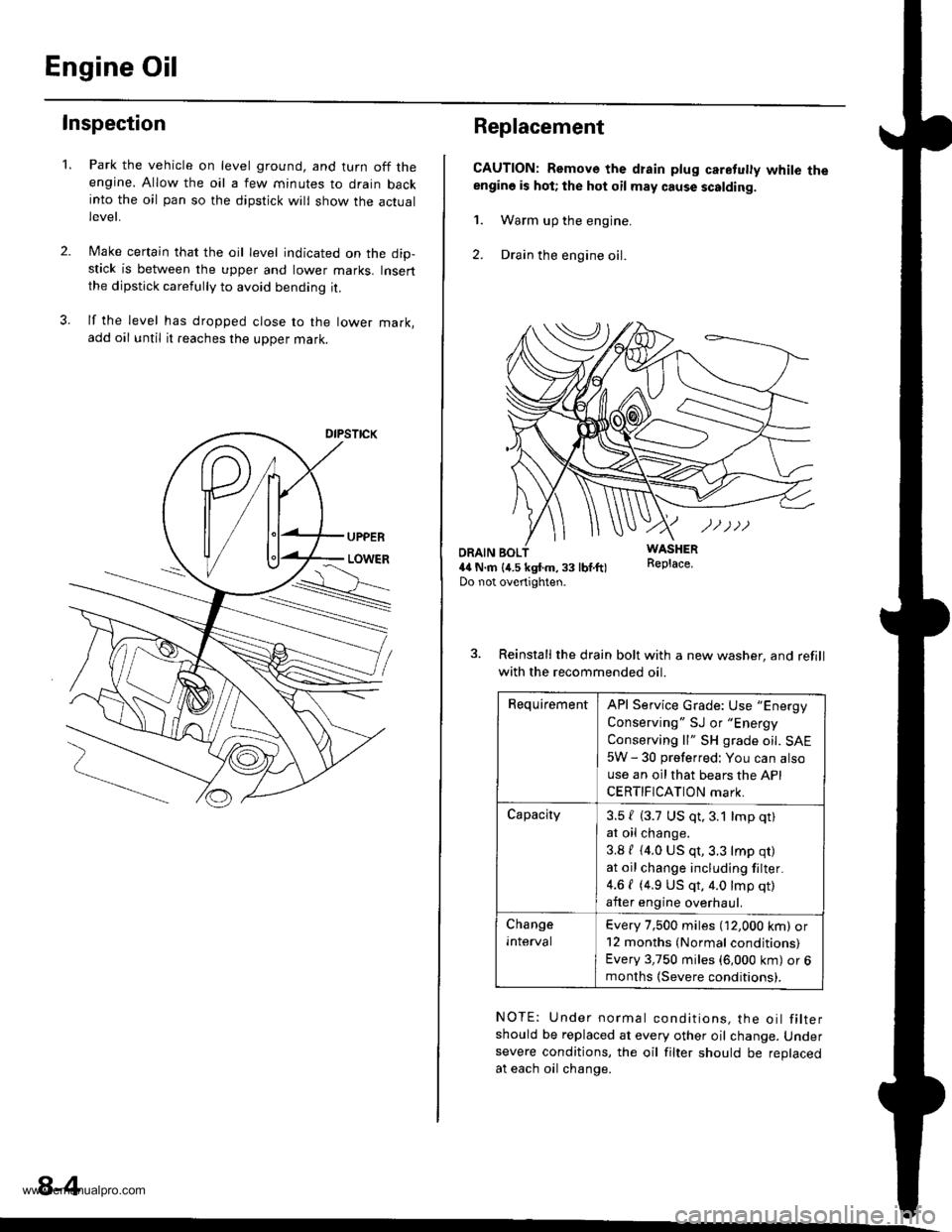

Engine Oil

Inspection

2.

1.Park the vehicle on level ground, and turn off theengine. Allow the oil a few minutes to drain backinto the oil pan so the dipstick will show the actuallevet,

Make certain that the oil level indicated on the dip-stick is between the upper and lower marks. Insertthe dipstick carefully to avoid bending it.

lf the level has dropped close to the lower mark,add oil until it reaches the upper mark.

8-4

Replacement

CAUTION: Remove the drain plug caretuly white theengino is hot; the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHERR€place.ORAIN BOL4il N.m {4.5 kgtm,33 lbf.ft)Do not overtighten.

3. Reinstall the drain bolt with a new washer, and refill

with the recommended oil.

RequirementAPI Service Grade: Use "Energy

Conserving " SJ or "Energy

Conserving ll" SH grade oil. SAE

5W - 30 preferred: You can also

use an oil that bears the API

CERTIFICATION mark.

Capacity3.5 { (3.7 US qt,3.1 lmp qt)

at oil change.

3.8 / (4.0 US qt,3.3 lmp qr)

at oil change including filter.

4.6 { (4.9 US qt, 4.0 lmp qt)

after engine overhaul.

Change

Inlerval

Every 7,500 miles (12,000 km) or12 months (Normal conditions)

Every 3,750 miles (6,000 km) or 6months (Severe conditions).

NOTE: Under normal conditions, the oil filtershould be replaced at every other oil change. Undersevere conditions, the oil filter should be replacedat each oil change.

www.emanualpro.com

Page 262 of 1395

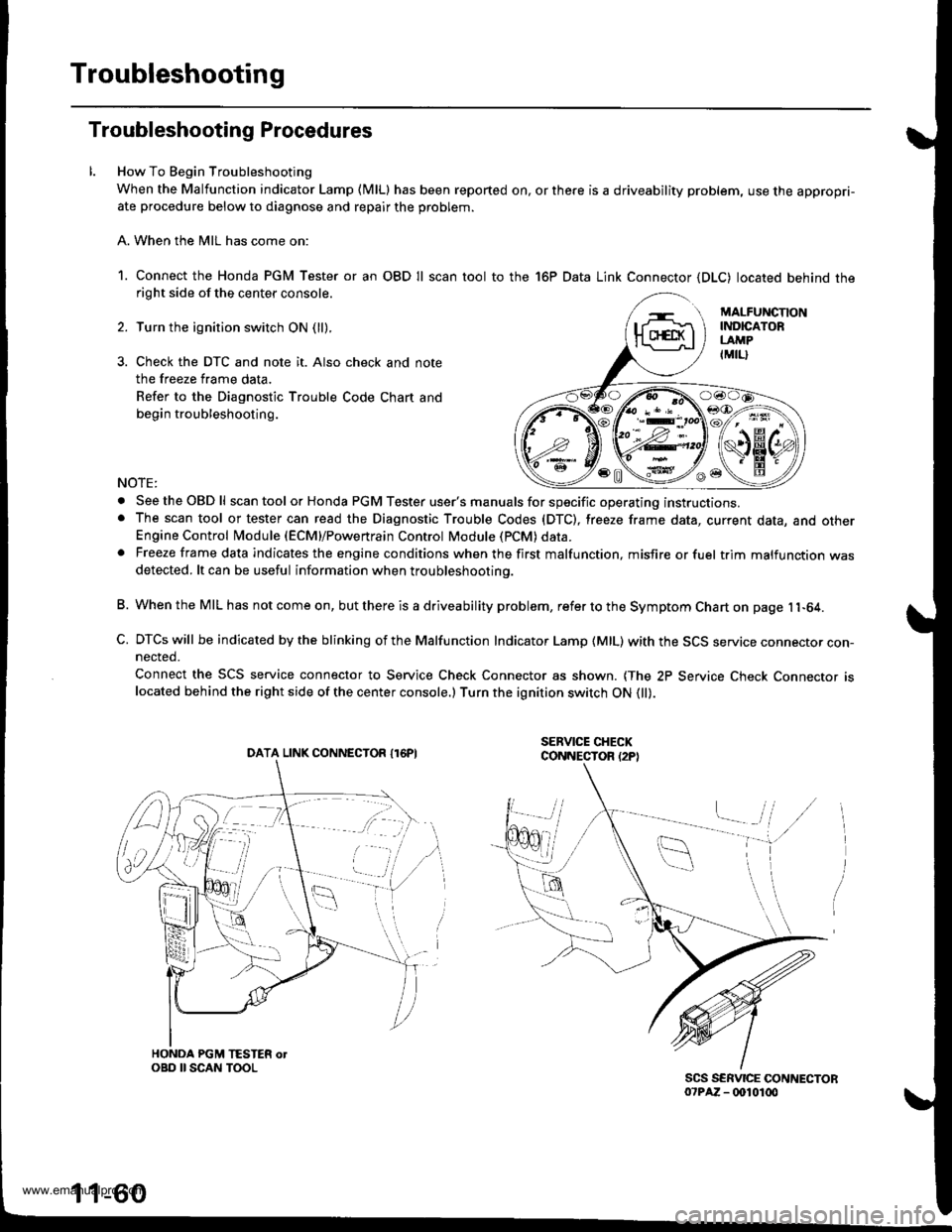

Troubleshooting

Troubleshooting Procedures

How To Begin Troubleshooting

When the Malfunction indicator Lamp (MlLl has been reported on, or there is a driveability problem, use the appropri-ate procedure below to diagnose and repair the problem.

A. When the MIL has come on:

1. Connect the Honda PGM Tester or an OBD Il scan tool to the 16P Data Link Connector (DLC) located behind theright side of the center console.

Turn the ignition switch ON (ll).

Check the DTC and note it. Also check and note

the freeze frame data.

Refer to the Diagnostic Trouble Code Chart and

begin troubleshooting.

NOTE:

. SeetheOBDll scan tool or Honda PGM Tester user's manuals for specific operating instructions.. The scan tool or tester can read the Diagnostic Trouble Codes (DTC), freeze frame data, current data, and otherEngine Control Module (ECM}/Powertrain Control Module (PCM) data.. Freeze frame data indicates the engine conditions when the first malfunction, misfire or fuel trim malfunction wasdetected. lt can be useful information when troubleshootino.

B. When the MIL has not come on, but there is a driveability problem, refer to the Symptom Chart on page 11-64.

C. DTCs will be indicated by the blinking of the Malfunction Indicator Lamp {MlL) with the SCS service connector con-nected.

Connect the SCS service connector to Service Check Connector as shown. {The 2P Service Check Connecror rslocated behind the right side of the center console.) Turn the ignition switch ON 0l).

DATA LINK CONNECTOR I16PI

1 1-60

www.emanualpro.com

Page 263 of 1395

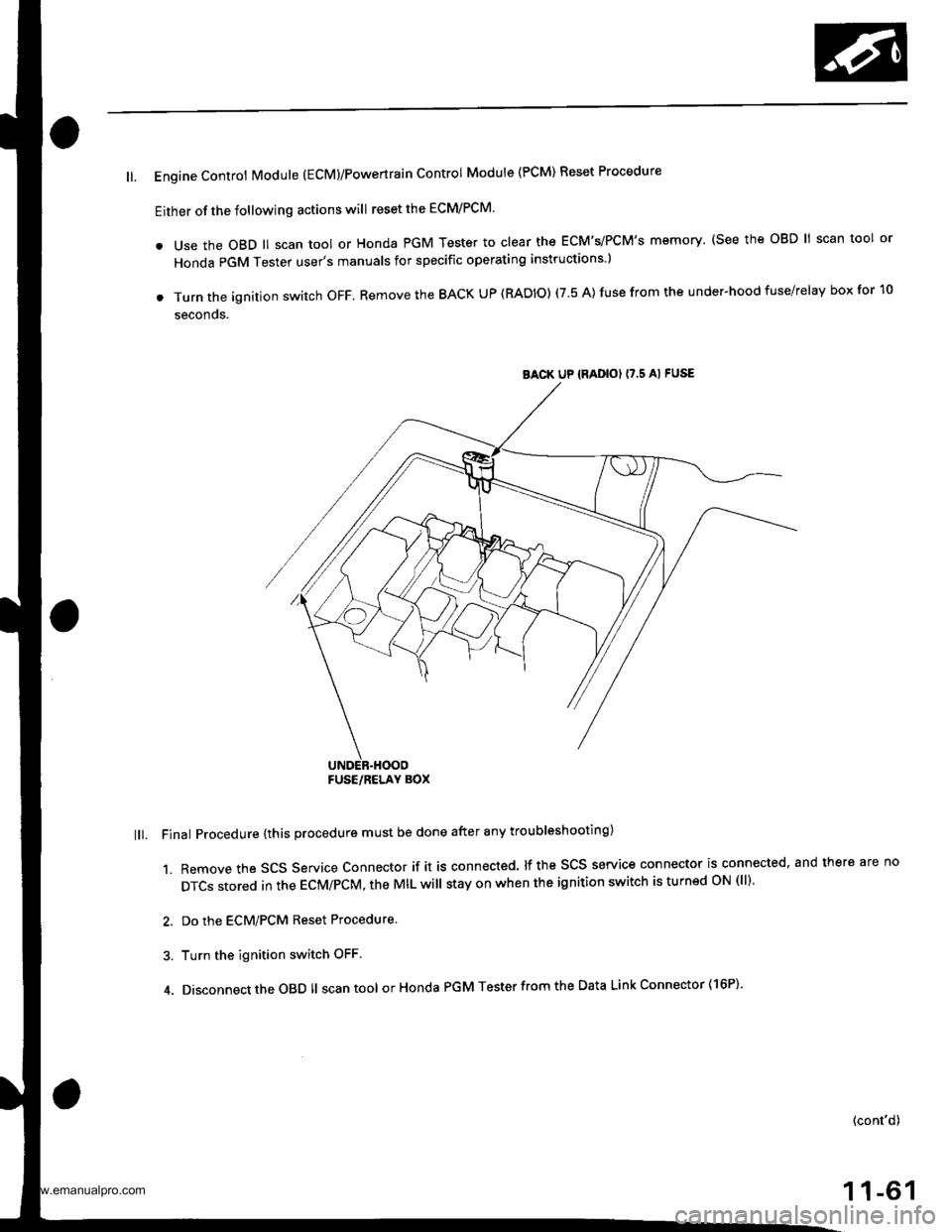

ll. Engine Controt Module (EcM)/Powertrain Control Module {PCM) Reset Procedure

Either of the following actions will reset the ECM/PCM.

. use the oBD ll scan tool or Honda PGM Tester to clear the ECM'�s/PCM'�s memory. (see the oBD ll scan tool or

Honda PGM Tester user's manuals for specific operating instructions )

. Turn the ignition switch oFF. Remove the BACK UP (RADIO) (7.5 A) fuse from the under-hood fuse/relay box for 10

seconos.

lll. Final Procedure {this procedure must be done after any troubleshooting)

1. Remove the SCS Service Connector if it is connected. lf the SCS service connector is connected. and there are no

DTCS stored in the ECM/PCM, the MIL will stay on when the ignition switch is turnsd oN (ll).

2. Do the ECM/PCM Reset Procedure.

3. Turn the ignition switch OFF

4. Disconnect the OBD ll scan tool orHonda PGM Tester from the Data Link Connector ( 16P)'

(cont'd)

1 1-61

BACK UP {RADIOI I7,5 AI FUSE

FUSE/RELAY BOX

www.emanualpro.com

Page 266 of 1395

Troubleshooting

Troubleshooting Procedures (cont'dl

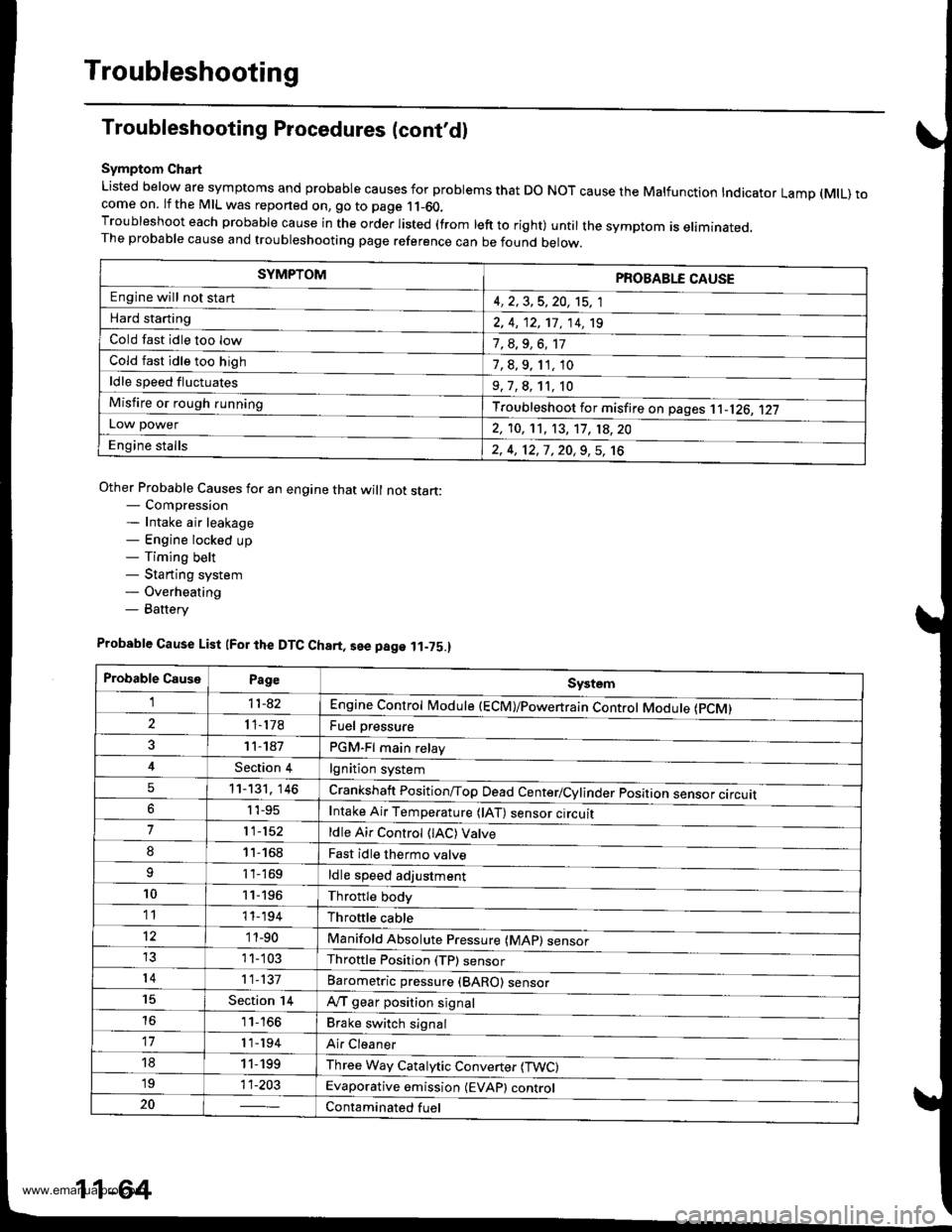

Symptom Chart

Listed below are symptoms and probable causes for problems that DO NOT cause the Malfunction Indicator Lamp (MlL) tocome on. lf the MIL was reported on, go to page 11-60.Troubleshoot each probable cause in the order listed (from left to right) until the symptom is eliminated,The probable cause and troubleshooting page reference can be found below.

Other Probable Causes for an engine that will not start:- Compression- Intake air leakage- Engine locked up- Timing belt- Starting system- Overheating- Battery

SYMPTOMPROBABLE CAUSE

Engine will not sta rt4, 2,3,5,20, 't5, 1

Hard starting2, 4, 12,17, 14, 't9

Cold fast idle too low7, a,9, 6, 17

Cold fast idle too high7,8,9,11,10

ldle speed fluctuates9,7,8, 't1, 10

Misfire or rough runningTroubleshoot for misfire on pages '11-126, 1|21LOl/\/ power2, 10,11, 13, '17, 18,20

Engine stalls2, 4, 12,1,20,9,5, 't6

Probable Cause List (For the DTC Ch8rt, see page ll-75.)

Probable CausePageSystem

Engine controt ruoaute (ecvtffi'I11-42

I 1-178Fuel oressure

PGM-Fl main relav

lgnition system

Crankshatt Position/Top Dead Center/Cylinder position sensor circuit

Intake Air Temperature (lAT) sensor ctrculr

ldle Air Control (lAC) Vatve

Fast idle thermo valve

ldle speed adjustment

Throttle body

Throftle cable

Manifold Absolute P."""rr"ffi

Throftle Position (TP) sensor

Barometric pressur" (gnno-

Ay'T gear position signal

Brake switch signal

Air Cleaner

Three Way Catalytic Converter (TWC)

Evaporative emission (EVAP) control

Contaminated fuel

1 1- 187

Section 4

5't1-'t31,146

6I '�t-95

711-152

81'l-168

1 1- 169

1011-196'1111-'194

12'1 'l -90

1 1- 103

1411-137

15Section 14

161 1- 166

17r 1-194

181 1,199'1911-203

20

11-64

www.emanualpro.com

Page 269 of 1395

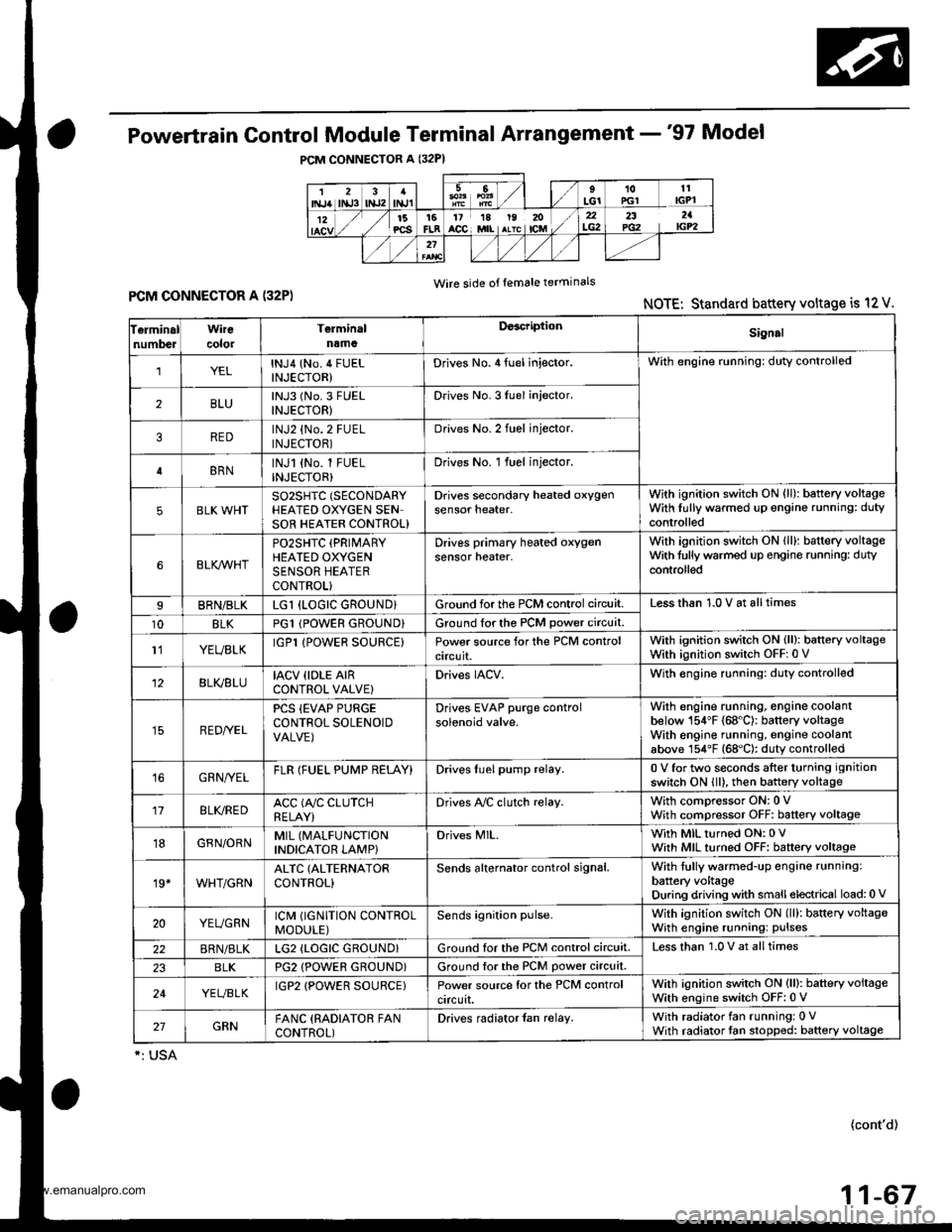

Powertrain Control Module Terminal Arrangement -'97 Model

FCM CONNECTOR A (32P)NOTE: Standard battery voltage is 12 V.

Wire side of lemale terminals

f€rminalnumlreJWirecolor

Telminalnama

DescriptionSignal

YELlNJ4 (No.4 FUELINJECTOR)Drives No. 4 {uel injector.With engine running: duty controlled

2BLUlNJ3 (No.3 FUELINJECTOR)Drives No. 3luel injector.

REDlNJ2 {No.2 FUELINJECTOR)Drives No.2 tuel injector.

BRNlNJl (No. l FUELINJECTOR)Drives No. 1 fuel injector.

5BLK WHTSO2SHIC (SECONDARY

HEATED OXYGEN SENSOR HEATER CONTROL)

D ves secondary heated oxygensensor heater.With ignition switch ON {ll): battery voltageWith fully warmed up engino running: dutycontrolled

6BLKAr'YHT

PO2SHTC (PRIMARY

HEATED OXYGENSENSOR HEATERCONTROL}

Drives primary heated oxygensensor heater,With ignition switch ON lll): battery voltagewith fully warmed up engine running: dutycontroll6d

I8RN/BLKLGl (LOGIC GROUND}Ground forthe PCM control circuit.Less than 1.0 V at all times

10BLKPG1 lPOWER GROUND}Ground for the PCM power circuit.

l1YEUELKIGPl lPOWER SOURCE}Power source for the PCM controlcircuit.

With ignition switch ON (ll): battery voltageWith ignition switch OFF: 0 V

12BLI(BLUIACV {IDLE AIRCONTROL VALVE}Drives IACV.With €ngine running: duty controlled

REDryEL

PCS (EVAP PURGECONTFOL SOLENOIDVALVE)

Drives EVAP purge controlsolenoid valve.

With engine running, engine coolantbelow 154'F (68"C): battery voltageWith engine running, engine coolantabove 154"F (68"C): duty controlled

16GRN/VELFLR (FUEL PUMP RELAY)Drives Iuel pump relay.0 V for two seconds after turning ignition

switch ON lll), then battery voltage

118LI(REDACC (A,/C CLUTCHRELAY}Drives Ay'C clutch relay.With comoressor ON: 0 VWith compressor OFF: baftery voltage

18GRN/ORNMIL (MALFUNCTION

INDICATOR LAMP}Drives MlL.With MIL turned ON: 0 VWith MIL turned OFF: baftery voltage

19*WHT/GRNALTC (ALTERNATOR

CONTROL}Sends alternator control signal.With tully warmed-up engine running:

battery voltageDuring driving with smallelectrical load:0 '

20YEUGRNICM (IGNITION CONTROLMODULE)Sends ignition pulse.With ignition switch ON (ll): baftery voltageWith engine running: pulses

22BRN/BLKLG2 (LOGIC GROUND}Ground tor the PCM control circuit.Less than 1.0 V at alltimes

23BLKPG2 {POWER GROUND}Ground lor the PCM power circuit.

24YEUBLKIGP2 {POWER SOURCE}Power source for the PCM controlcircuit.

With ignition switch ON (ll): battery voltage

With engine switch OFF: 0 V

27GRNFANC (RADIATOR FANCONTROL)Drives radiator {an relay.With radiator fan running: 0 VWith radiator fan stopped: baftery voltage

*: USA

{cont'd)

11-67

www.emanualpro.com

Page 273 of 1395

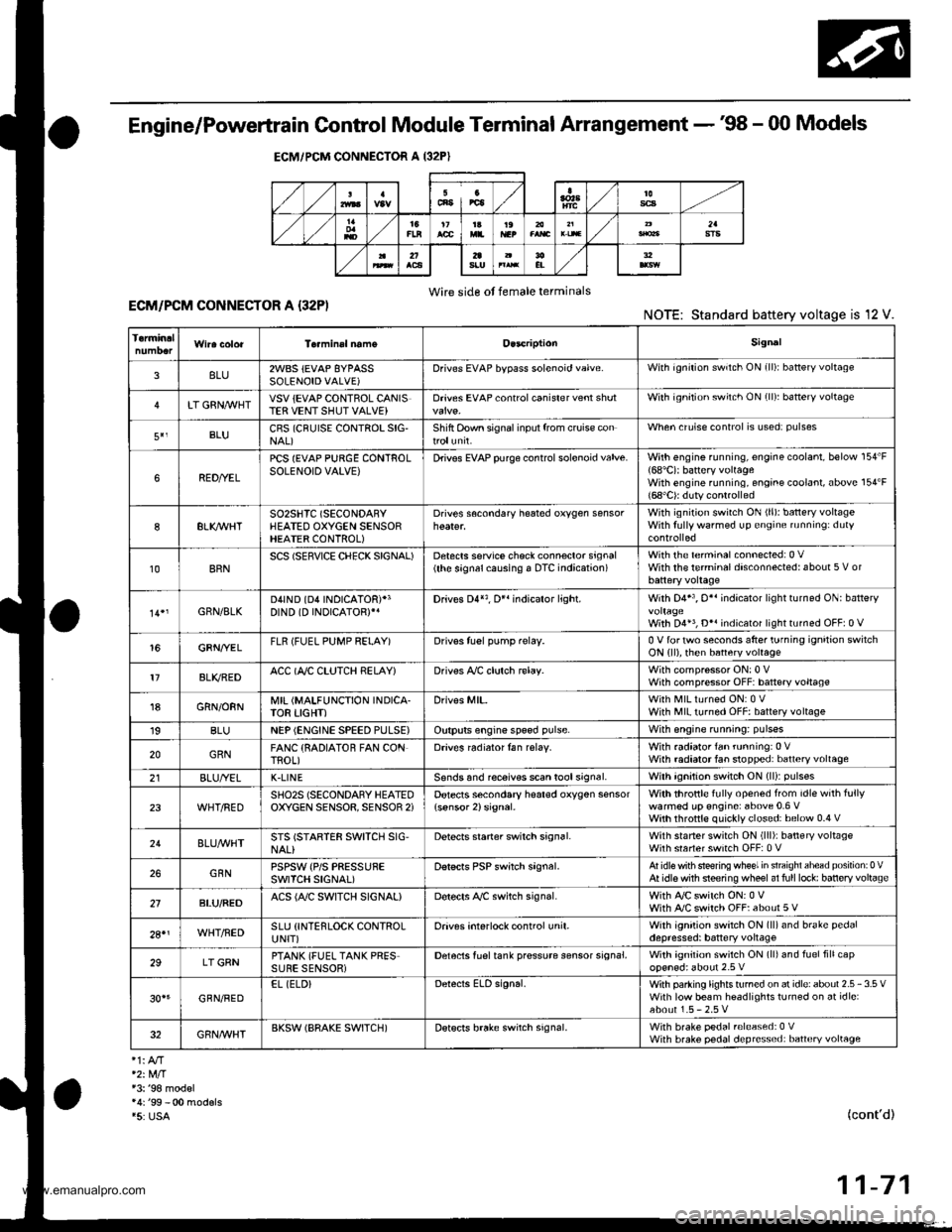

Engine/Powertrain Control Module Terminal Arrangement - 38 - 00 Models

ECM/PCM CONNECTOR A (32P}

,/./5aIsca

,/ l,/t5ItsTs

n2ls!uCI

Wire side ot female terminalsECM/FCM CONNECTOR A {32P)NOTE: Standard baftery voltage is '12 V.

D93criptionSignal

3BLU2WBS {EVAP BYPASSSOLENOID VALVE)Drives EVAP bvoass solonoid valve.With ignirion switch ON {ll)r battery voltage

LT GRNMHTVSV {EVAP CONTROL CANISTEB VENT SHUT VALVE)D.ives EVAP controlcanisler vent shutWith ig^ition switch ON (ll): battery voltage

5',BLUCRS (CRUISE CONTROL SIG'NAL)Shift Oown signalinputfrcm cruise conWhen cruise control is used: pulses

6RED/YEL

PCS (EVAP PURGE CONTROLSOLENOID VALVE)Drives EVAP purge controlsolonoid valve.With engins running, engine coolant, below 154'F(68'C)r battery voltageWith engine running, engine coolant, above 154"F{6a'C}r duty conl.olled

8ELIOWHTSO2SHTC (SECONDARVHEATED OXYGEN SENSORHEATER CONTROL)

Drives sacondary heated oxygen sensorWith ignition switch ON (ll): banery voltageWith fully warmed up engine running: duty

10BRNSCS (SERVICE CHECX SIGNAL)Detects seNics check conneclor signal(he signalcausing a DTC indicatjon)with rhe lerminal connected:0 vWith the rerminaldisconnectedrabout 5 v or

l4'rGRN/8LKD4IND (D4INDICATOR)+3DIND (D INDICATORTIDrives D4*3. Dr'indicaior light.W,rh 04' , O" indrcator light turned O batter,

With D4*3, D*. indicator light turned OFFr0 V

16GRNI/ELFLR (FUEL PUMP RELAY)Drivss fusl pump relay.0 V for iwo seconds after ru'nin9 ign'lion swilchON lll), then banery voltage

17AL|(/REDACC (I/C CLUTCH RELAY}Drives l,/C clurch rclay.With compressor ONr0 VWith compressor OFF: battery voltage

18GRN/ORNMIL (MALFUNCTION INDICA.TOR LIGHT)Driv€s MlL.With MlLturned ON:0 VWith MIL turned OFF: battery voltage

19BLUNEP (ENGINE SPEED PULSE)Outputs engine spsed pulse.With sngine runnin9: pulses

20GRNFANC {RADIATOR FAN CONTROL)Drives r6diator fan rslay.With radaator fan running:0 VWith radaatorfan stopped: battery vollage

218LU/t/ELK-LINESends and receiv€s scan toolsignal.With ignition switch ON (ll): p'rlses

23WHT/REDSHO2S (SECONDARY HEATEDOXYGEN SENSOR. SENSOR 2iDetects secondary h€at€d oxygen sensorWith throttle fully opened from idle wilh fullywalmed up engine: above 0.6 Vwith rhrottle quickly closed: below 0-4 V

21BLU/WHTSTS (STARTER SWITCH SIG,NAL}Dotocts srarter switch signal.Whh staner switch ON (lll): batlery voltageWith srarter switch OFF: 0 V

26GBNPSPSW {P/S PsESSUFESWITCH SIGNAL)Detecrs PSP switch signal.At idle with steeing wh€el in stBighl ahead position: 0 VAt idls with nee ng wheel al full lockr banory voltage

2fBLU/BEOACS (Ir'C SWTCH SIGNAL}D€tects ly'C switch signal.With Ay'C switch ON:0 VWith l/C swil€h OFF: about 5 V

2A'\WHT/NEDSLU {INTERLOCK CONTROLUNIT)Orives interlock control unil.With ignilion switch ON (ll)and brake pedaldepressed: battery vohage

29LT GRNPTANK (FUEL TANK PRES'SURE SENSOR)Detocts fueltank pressure sensor signal.With agnition switch ON (ll) and fuel fill capopensd; about 2.5 v

GBN/FEDEL (ELD}Detects ELD signal.Wirh paaing rightstumed on at idle:about 2.5 - 3.5 VWith low beam headlights tumed on at idle:about 1.5-2.5V

GRN/WHTBKSW (BRAKE SWTTCH)Dst€cts brake switch signal.Wirh brake pedal released:0 VWith brake pedal depressed: battery vollage

13: '98 modsl

15: USA(cont'd)

11-71

www.emanualpro.com

Page 282 of 1395

PGM-FI System

System Description

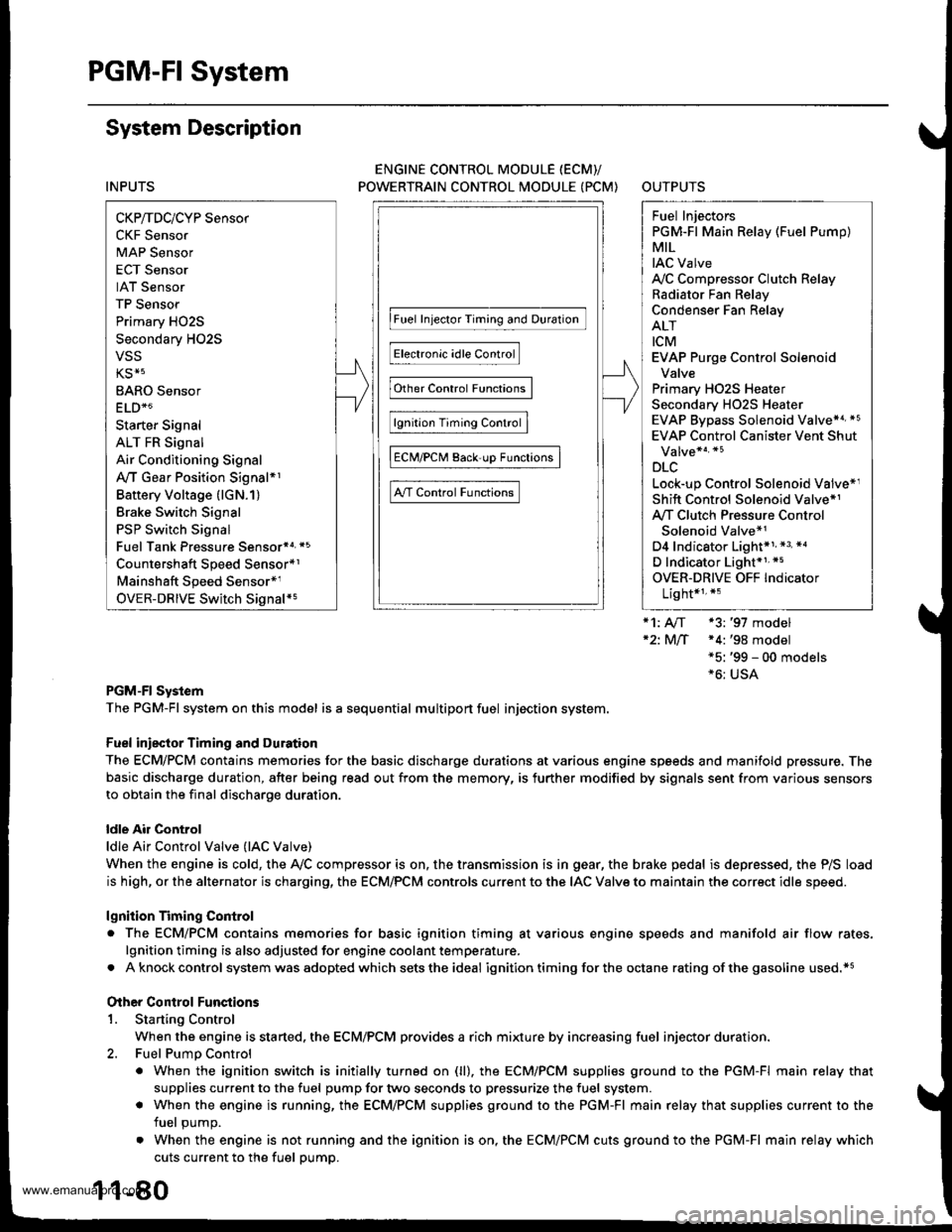

INPUTS

CKP/TDC/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

Primary HO2S

Secondary H02S

vss

KS*5

BARO Sensor

ELD*6

Starter Signal

ALT FR Signal

Air Conditioning Signal

Ay'T Gear Position Signal*1

Baftery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal

Fuel Tank Pressuae Sensor*4. *5

Countershaft Speed Sensor*1

Mainshaft Speed Sensor*r

OVER-DRIVE Switch Signal*s

ENGINE CONTROL MODULE (ECM)/

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

|iuel 1"j""- Th,rhg ""d Drrafr";-l

Et*-.nt"tdt"cont.orl

to,r*,c;;trffi;]

l.----.---:. .Lrgnrnon |lmrng Lonrror I

Ecir/PcM B*k',p Fr""il]

m;"t-ll-r*'io*l

Fuel Injectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

Ay'C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

tcM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S HeaterEVAP Bypass Solenoid Valve*a *5

EVAP Control Canister Vent Shut

DLC

Lock-up Control Solenoid Valve*l

Shift Control Solenoid Valve*1

Ay'T Clutch Pressure Control

Solenoid Valve*1

D4 Indicator Light'1 *3, *a

D Indicator Light,l *5

OVER-DRIVE OFF Indicator

Lighl*t *:

*1: A/T {3:'97 model'2: M/f +4:'98 model*5: '99 - 00 models"6: USA

PGM-Fl System

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel iniecior Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold pressure. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

o The ECM/PCM contains memories for basic ionition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. A knock control system was adopted which sets the ideal ig nition timing for the octane rating of the gasoline used.*s

Other Control Funstions

1. Starting Control

When the engine is started. the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on (ll). the ECMiPCM suppli€s ground to the PGM-FI main relay that

supplies current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM/PCM supplies ground to the PGM-FI main relay that supplies current to the

fuel oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

1 1-80

www.emanualpro.com

Page 283 of 1395

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors iscutoffto improvefuel economyat

speeds over 970 rpm ('97 - 98 models), 920 rpm ('99 - 00 modelsl.

. Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm ('97 - 98 models), 6900 rpm ('99 - 00

models), regardless of the position of the throttle valve, to protect the engine from over-rewing.

With Ay'T model. the PCM cuts the fuel at engine speeds over 5,000 rpm when the vehicle is not moving.*'�

4,./C Comoressor Clutch Relav

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure a smooth transition to the Ay'C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is above 154"F (68'C), the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister,

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode.

which reduces the engine load to improve the fuel economy.

PCM Fail-saf e/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pre

grammed value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self-diagnosis Function IMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the MIL and stores the DTC

in erasable memory. When the ignition is initially turned on {ll), the ECM/PCM supplies ground for the MIL for two

seconds to check the MIL bulb condition.

4. Two Trio Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S*1, fuel metering-related. idle control

system, ECT sensor and EVAP control system self-diagnostic functions. When an abnormality occurs, the ECM/PCM

stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (ll) again,

the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is cancelled

when you jump the service check connector, The MIL will then blink immediately when an abnormality occurs.

5. Two (or Three) Driving Cycle Detection Method {'97 model)

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles.

or TWC deterioration is detected during three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to

ease troubleshooting, this function is cancelled when you jump the service check connector. The MIL will then blink

immediately when an abnormality occurs.

*1: '97 - 98 models*2: '99 - 00 models

5.

www.emanualpro.com