Rack HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 98 of 1395

Engine RemovaUlnstallation

Removal

@a Make sure iacks and safety stands are placed properly

and hoist brackets are attached to the correct oosi-

tions on the engine.

. Make sure the vehicle will not roll oft stands and fall

while you are working under it.

NOTEI

. Use fender covers to avoid damaging painted sur-

faces.

o To avoid damage. unplug the wiring connectors care-

fully while holding the connector portion.

lvlark all wiring and hoses to avoid misconnection.

Also, be sure that they do not contact other wiring or

hoses, or interfere with other parts.

Secure the hood in the open position.

Disconnect the battery negative terminal first, then the

positive terminal.

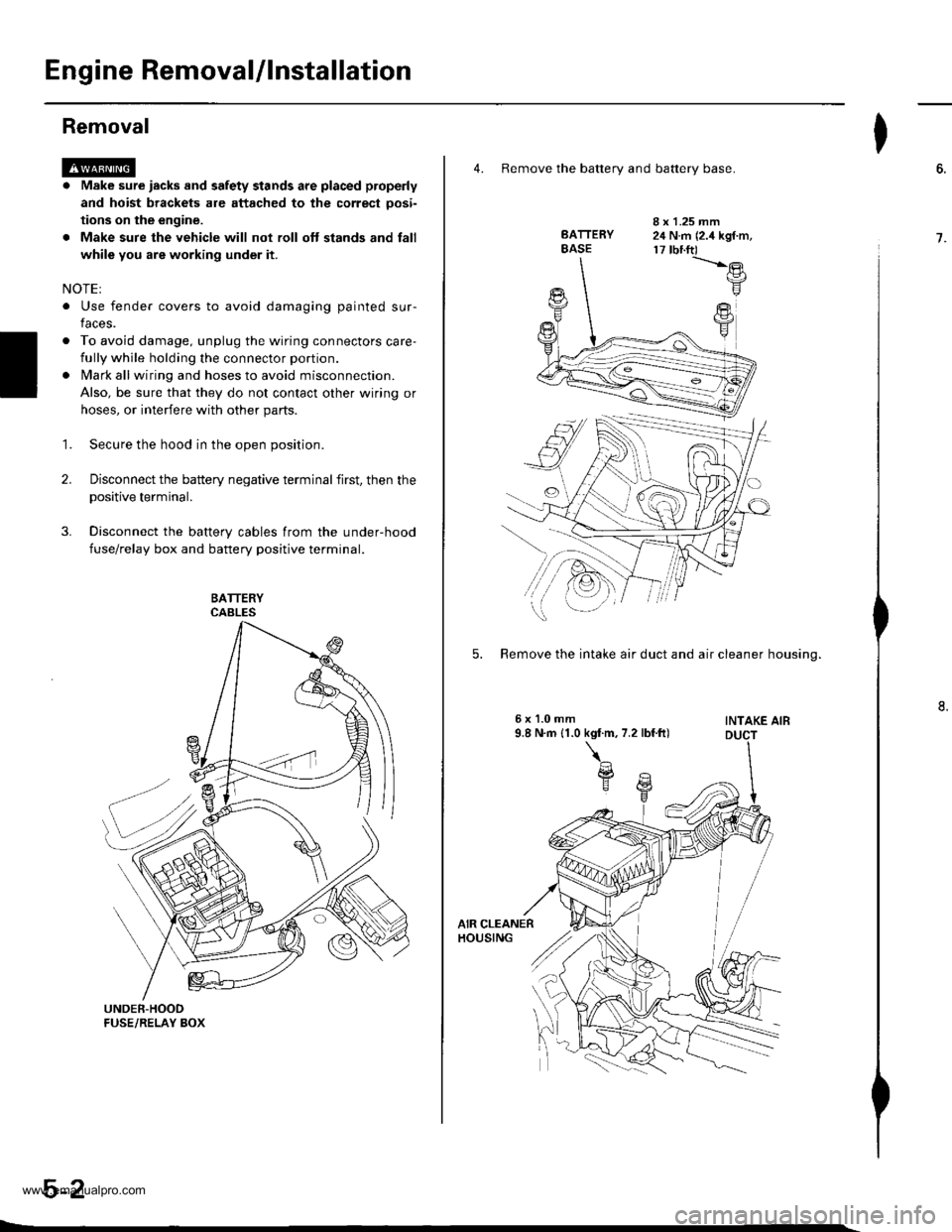

Disconnect the battery cables from the under-hood

fuse/relay box and battery positive terminal.

1.

2.

4. Remove the batterv and batterv base.

BATTERYBASE

I x 1.25 mm24 N.m (2.4 kgf.m,17 tbnft)-t'.-e

F

FY

5. Remove the intake air duct and air cleaner housino.

INTAKE AIB

I

6.

7.

www.emanualpro.com

Page 100 of 1395

Engine Removal/lnstallation

Removal (cont'dl

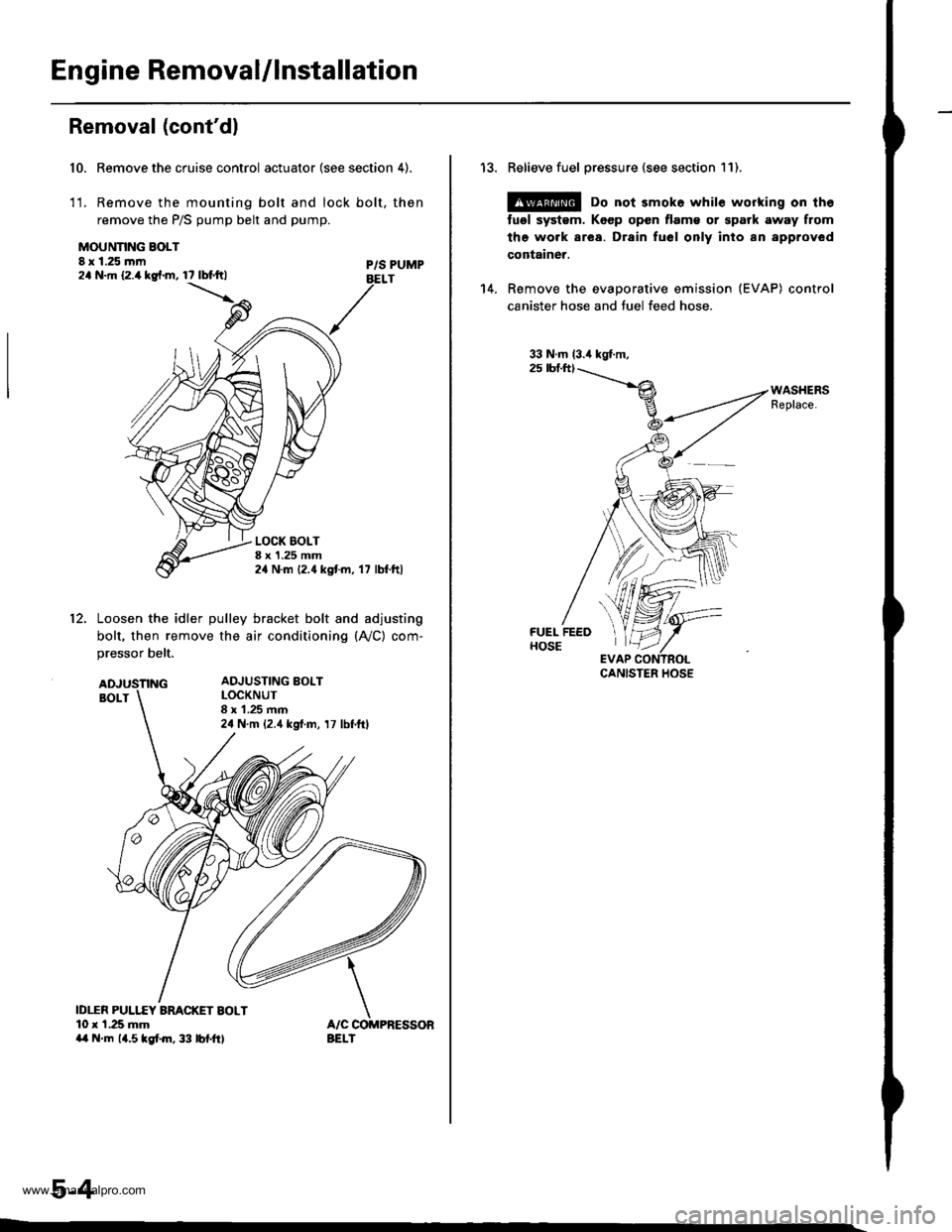

Remove the cruise control actuator (see section 4).

Remove the mounting bolt and lock bolt, then

remove the P/S pump belt and pump.

10.

1t.

MOUNNNG BOLT8 x 1.25 mm2a N.m 12.4 kg{.m, 17 lbtftlP/S PUMPBELT

LOCK BOLTI x 1.25 mm24 N.m {2.4 kgtm, '17 lbf.ftl

12.Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (A,/C) com-

pressor belt.

ID1TR PULI.f,Y ARACKET BOLT10 r 1.25 mma{ N.m 14.5lgtm,33 lbf.ft)

ADJUSTING BOLTLOCKNUT8 x 1.25 mm24 N.m {2.4 kgf.m, 17 lbf.ftl

5-4

13. Relieve fuel pressure {see section 11).

@ Do not 3mok6 whil€ working on th6

tugl systsm. Koep open flam€ or spark away from

the work area. Drain fuel only inlo an approved

container.

14. Remove the evaporative emission (EVAP) control

canister hose and tuel feed hose.

33 N.m (3.4 kgt.m,2s tbf.ft)

,%l

*ryft'fltr

\'t,f

EVAP CCCANISTER HOSE

www.emanualpro.com

Page 102 of 1395

Engine Removal/lnstallation

Removal (cont'd)

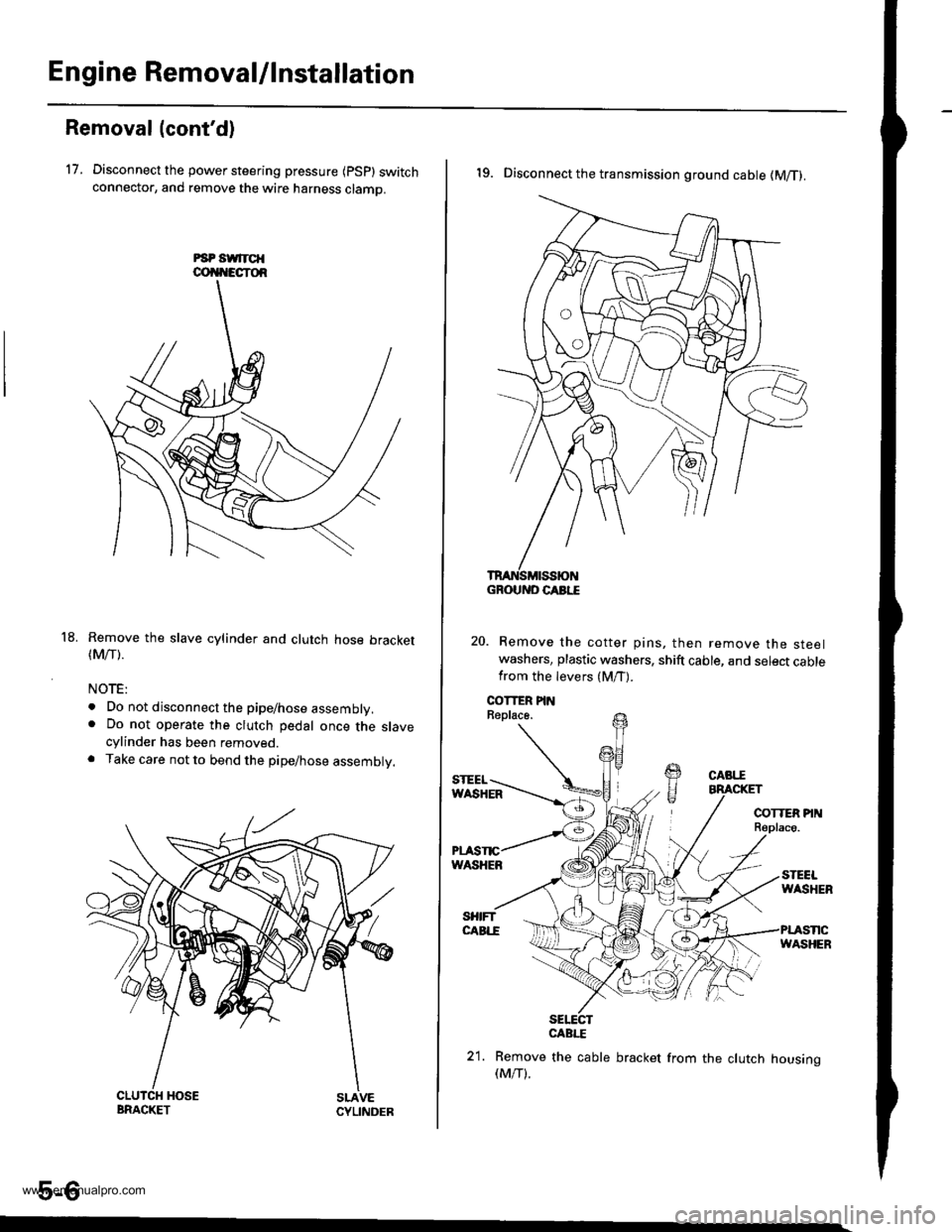

17. Disconnect the power steering pressure {psp} switchconnector, and remove the wire harness clamo.

Remove the slave cylinder and clutch hose bracket(Mrr).

NOTE:

. Do not disconnect the pipe/hose assembly.. Do not operate the clutch pedal once the slavecylinder has been removed.. Take care not to bend the pipe/hose assembly.

5-6

18.

19. Disconnect the transmission ground cable (M/T).

Remove the cotter pins, then remove the steelwashers, plastic washers, shift cable, and select cablefrom the levers (M/T).

sElEcrCABI."E

21. Remove the cable bracket from the clutch housing(M/T).

GROUND CABI."E

www.emanualpro.com

Page 107 of 1395

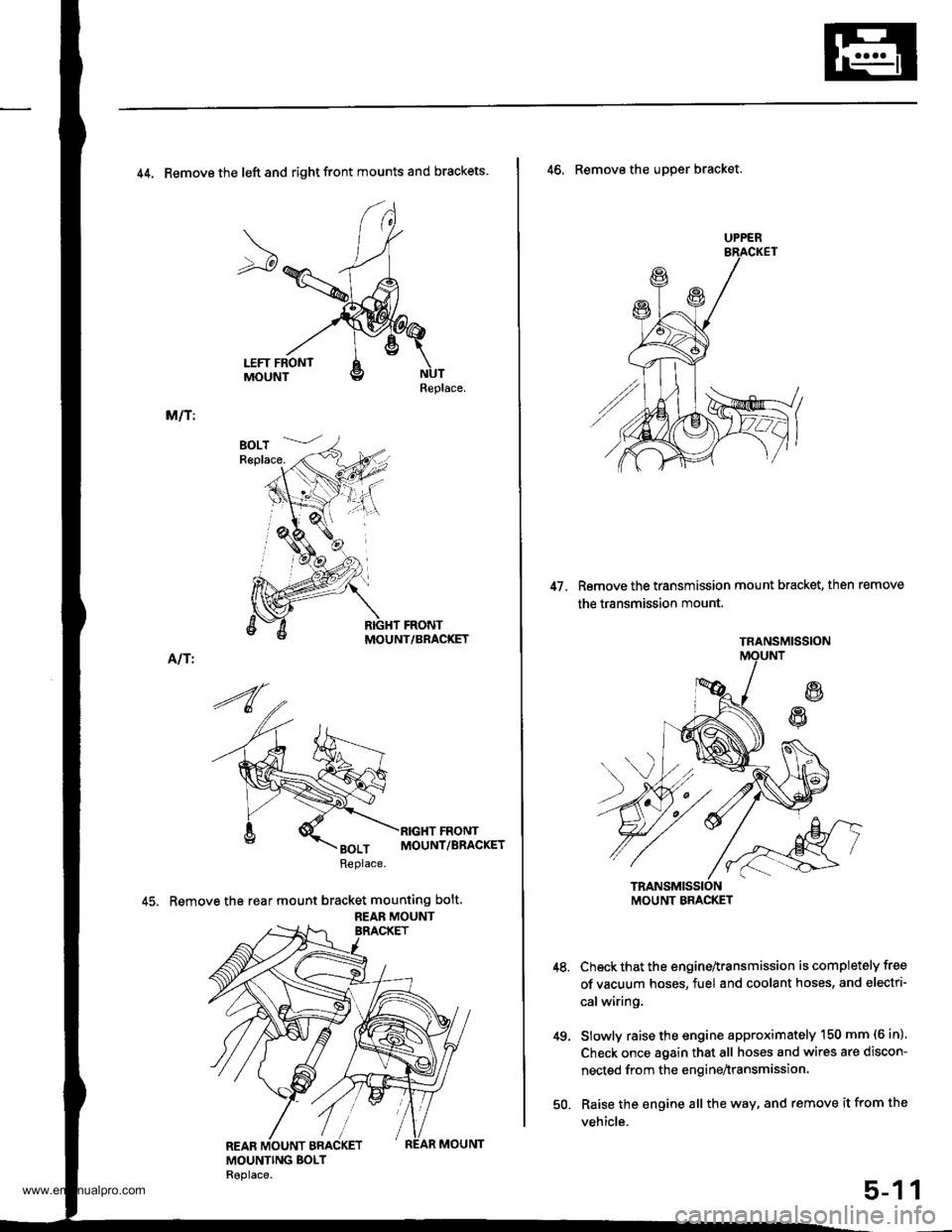

44. Remove the left and right front mounts and brackets

Replace.

M/T:

MOUNT/BRACKET

Alf I

45. Remove the rear mount bracket mounting bolt.

REAB MOUNT

UPPER

47. Remove the transmission mount bracket, then remove

the transmission mount.

46. Remove the uDper bracket.

Check that the engine^ransmission is completely free

of vacuum hoses, fuel and coolant hoses, and electri-

calwiring.

Slowly raise the engine approximately 150 mm (6 in)'

Check once again that all hoses and wires are discon-

nected from the enginenransmission.

Raise the engine all the way, and remove it from the

vehicle.

49.

1

TRANSMISSION

MOUNT BMCKET

50.

5-1

www.emanualpro.com

Page 108 of 1395

En gine Removal/lnstallation

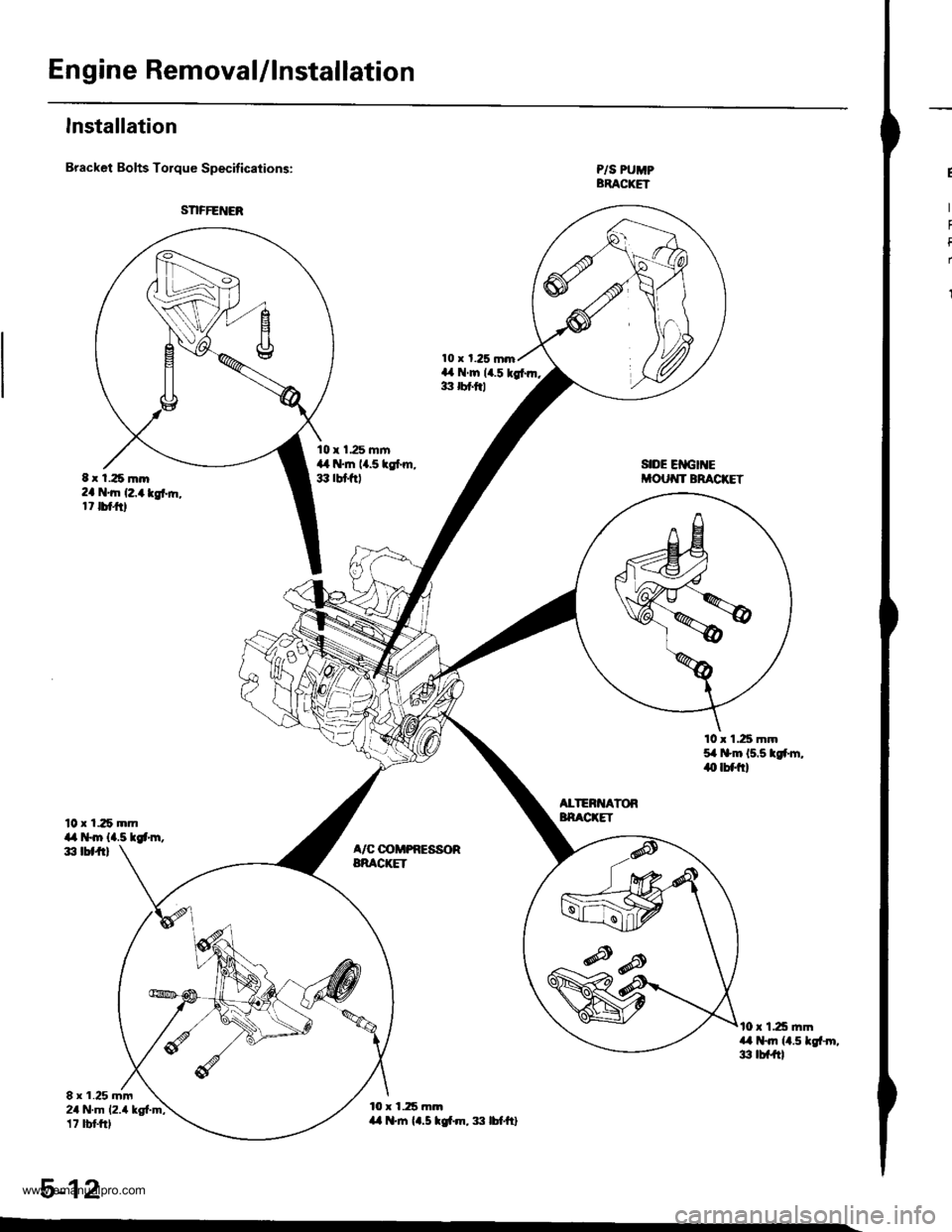

Installation

Bracket Bolts Torque Specifications:

10 x 125 mmil,a t*m {4.5 tgt'm,d, tbtft)

8 r 1.25 mm24 N.m 12.4 kg{.m;17 tbt frl

10 x 1.25 mrn,L il.tn {1.5 tgt m, :|:l lbf'ft}

P/S PUMPBRACKET

SIDE EIIGII{Ei'OUT{T BRACKET

10 x 1.25 mm54 t$m 15.5 tgfm,iO lbflrl

ALTERI{ATORBNACKET

A/C @MPRESSORBRACIGT

t0 r 125 ]nma,l t+Jn ll.5 lgf-rn,3 tbf{tl

5-12

t t 1.25 m.D2a 'tn (2,4 kgt ft,17 tbtftl

www.emanualpro.com

Page 109 of 1395

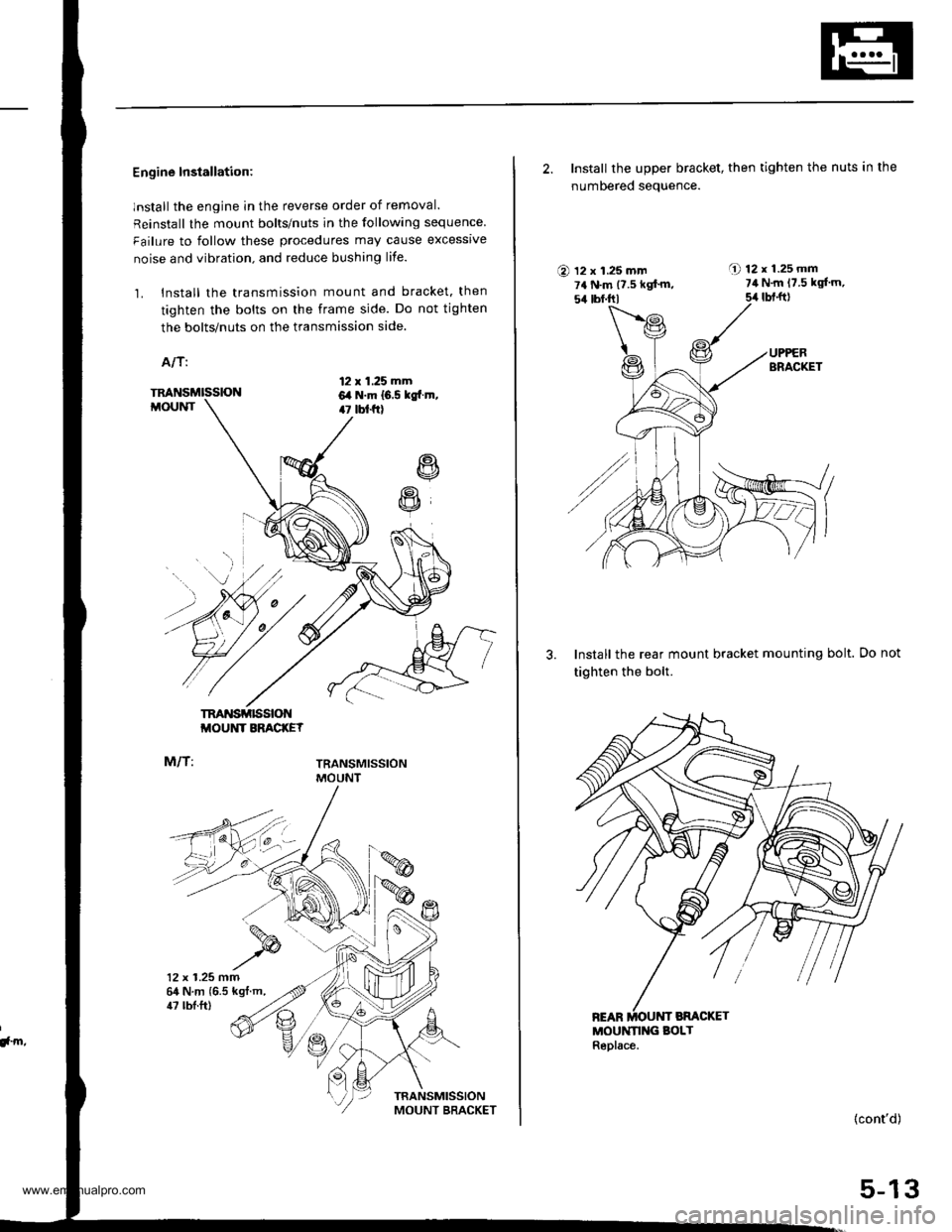

Engine Installation:

lnstall the engine in the reverse order of removal.

Reinstall the mount bolts/nuts in the following sequence

Failure to follow these procedures may cause excessrve

noise and vibration. and reduce bushing life.

1. Install the transmission mount and bracket. then

tighten the bolts on the frame side. Do not tighten

the bolts/nuts on the transmission side.

A/T:

12 x 1.25 mm6,a N.m 16.5 kgtr.m,47 tbt f0

R

R

TM'{SMISSIONMOUNT

M/T:

TRANSMISSIONMOUNT BRACKEY

TRANSMISSIONMOUNT

12 x 1.25 mm64 N.m {6.5 kgt.m,

!, m,

47 tbl.ft)

2. Install the upper bracket, then tighten the nuts in the

numbered seauence.

O 12 x 1.25 mm7a N.m {7.5 kgf'm,54 tbf.trl

A 12r1.25mm7il N.m 17.5 kgl'm,

5,r lbt.ft)

3. Install the rear mount bracket mounting bolt.

tighten the bolt.

MOUNN G BOLTReplace.

Do not

(cont'd)

5-13

www.emanualpro.com

Page 110 of 1395

En gine RemovaUlnstallation

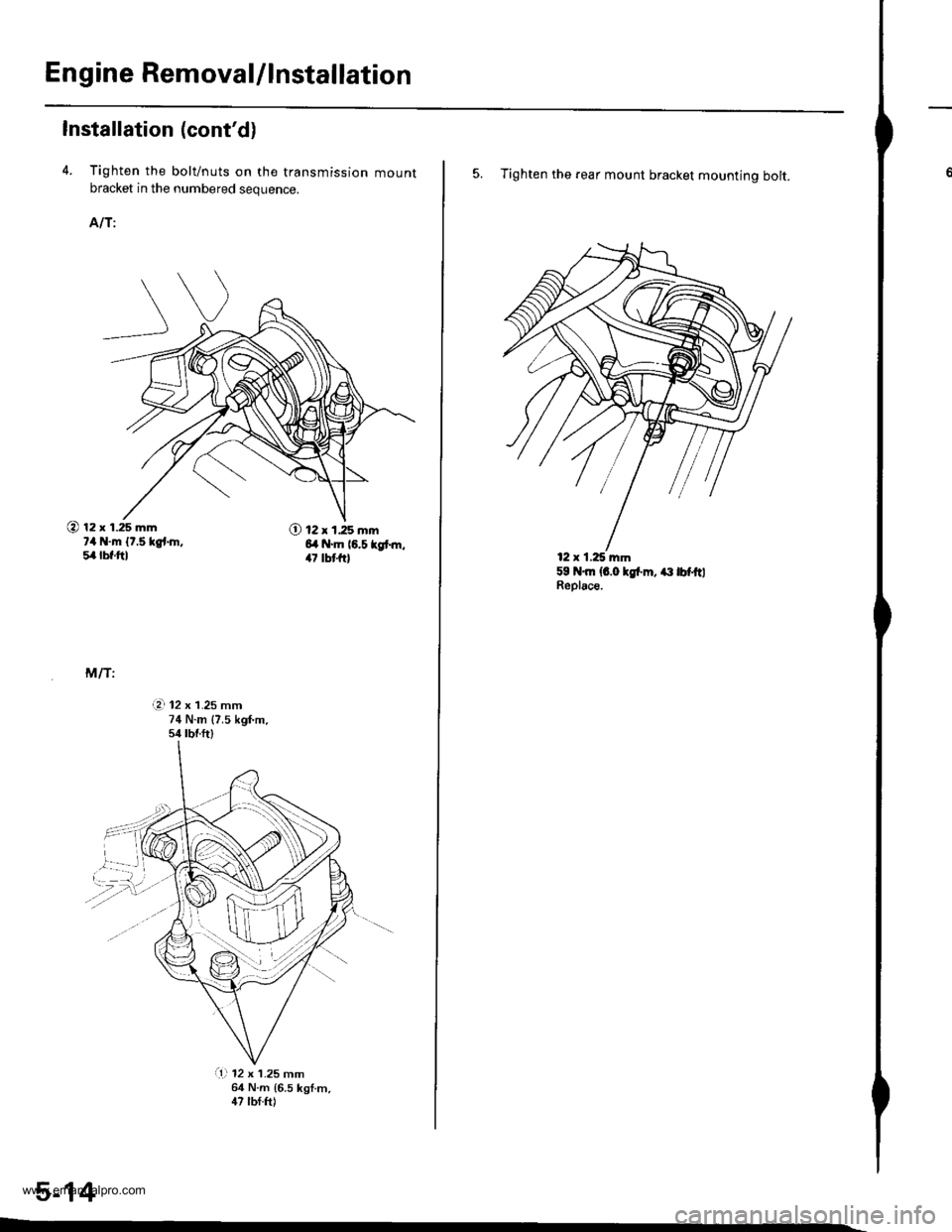

Installation (cont'd)

4. Tighten the bolt/nuts on the transmission mountbracket in the numbered sequence.

AIT:

@ 12 x 1.25 mm?4 N.m {t.5 kgt.h,5,4lbf.ftl

O 12 x 1.25 mm6l .m (6.5 kgt m,47 tbt{r}

M/T:

i?. 12 x 1.25 mm74 N.m {7.5 kgf'm.s/r tbr.ftl

,,.....\.L}

@'...,'..4:

a1l 12 x 1.25 mm64 N.m {6.5 kgf.m,47 lbf.ft)

5-14

5. Tighten the rear mount bracket mounting bolt.

59 N.m {6.0 lgl'm, ait lbf.ftlReplace.

12 x 1.25 mm

www.emanualpro.com

Page 111 of 1395

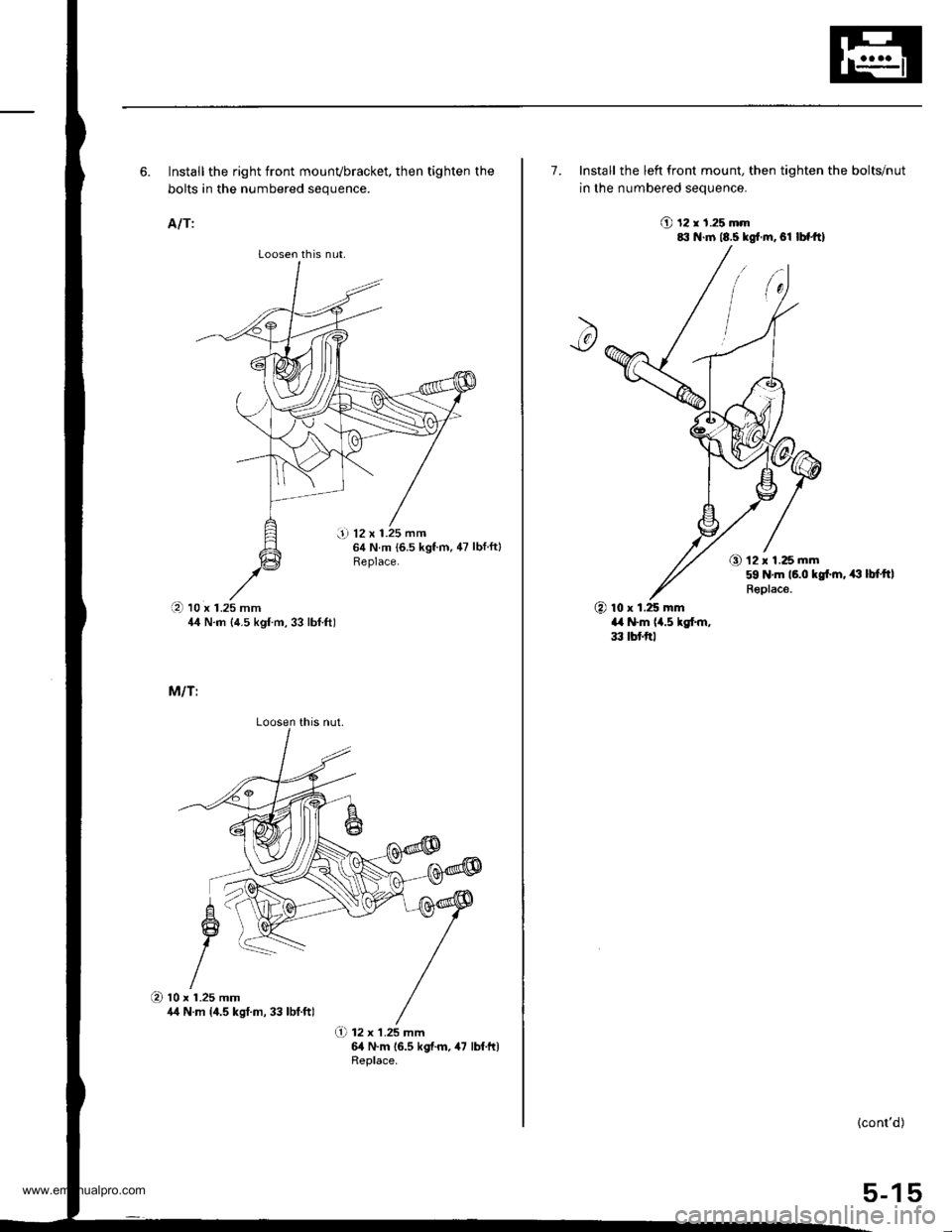

Loosen th is nut,

i! 12 x 1.25 mmg N.m {6.5 kgf.m, 47 lbf.ftlReplace.

6. Install the right front mounvbracket, then tighten the

bolts in the numbered sequence.

A/T:

(D to x t.zs mm44 N.m {4.5 kgf m, 33 lbf.ft)

M/T:

O 12 x 1.25 mm64 N.m 16.5 kgf.m. 47 lbf.ft)Replace.

Loosen this nut.

O 10 x r.25 mm4/t N.m 14.5 kgt.m, 33 lbf.ft)

7. Install the left front mount, then tighten the bolts/nut

in the numbered seouence.

O t2 r 1.25 mm8il N.m 18.5 kgt.m, el |bfftl

O 12 x 1.25 mm59 N.m 16.0 kgt ln, ,€ lbfttl

Replace.

@ lo x 1.25 mma,a N.m 14.5 kgf.m,33 tbf.trl

{cont'd)

5-15

www.emanualpro.com

Page 113 of 1395

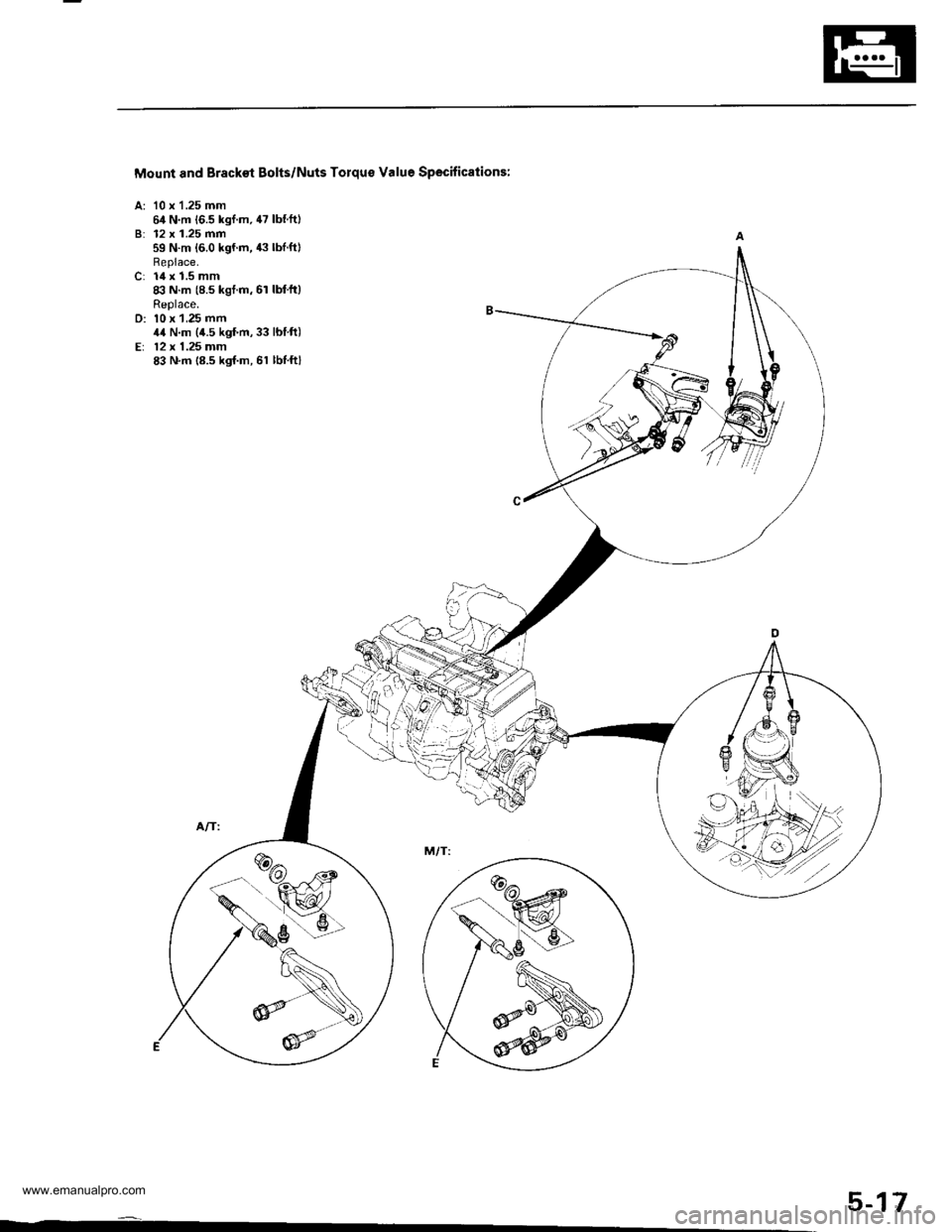

Mount and Brackst Bolts/Nuts Torqus Value Specitications:

A: '10 x 1.25 mm64 N.m 16.5 kgI.m, 47 lb{.ftlB: 12 x 1.25 mm59 N.m 16.0 kgf.m, 43 lblft)Replace.C: 14 x 1.5 mm8:l N.m (8.5 kgt.m, 6r lbl'ft)Replace.D: 10 x 1,25 mm,t4 N.m (4.5 kgf'm,33 lbIft)Er 12 x 1.25 mm83 N.m 18.5 kgf.m, 61 lbl.ftl

5-17

www.emanualpro.com

Page 123 of 1395

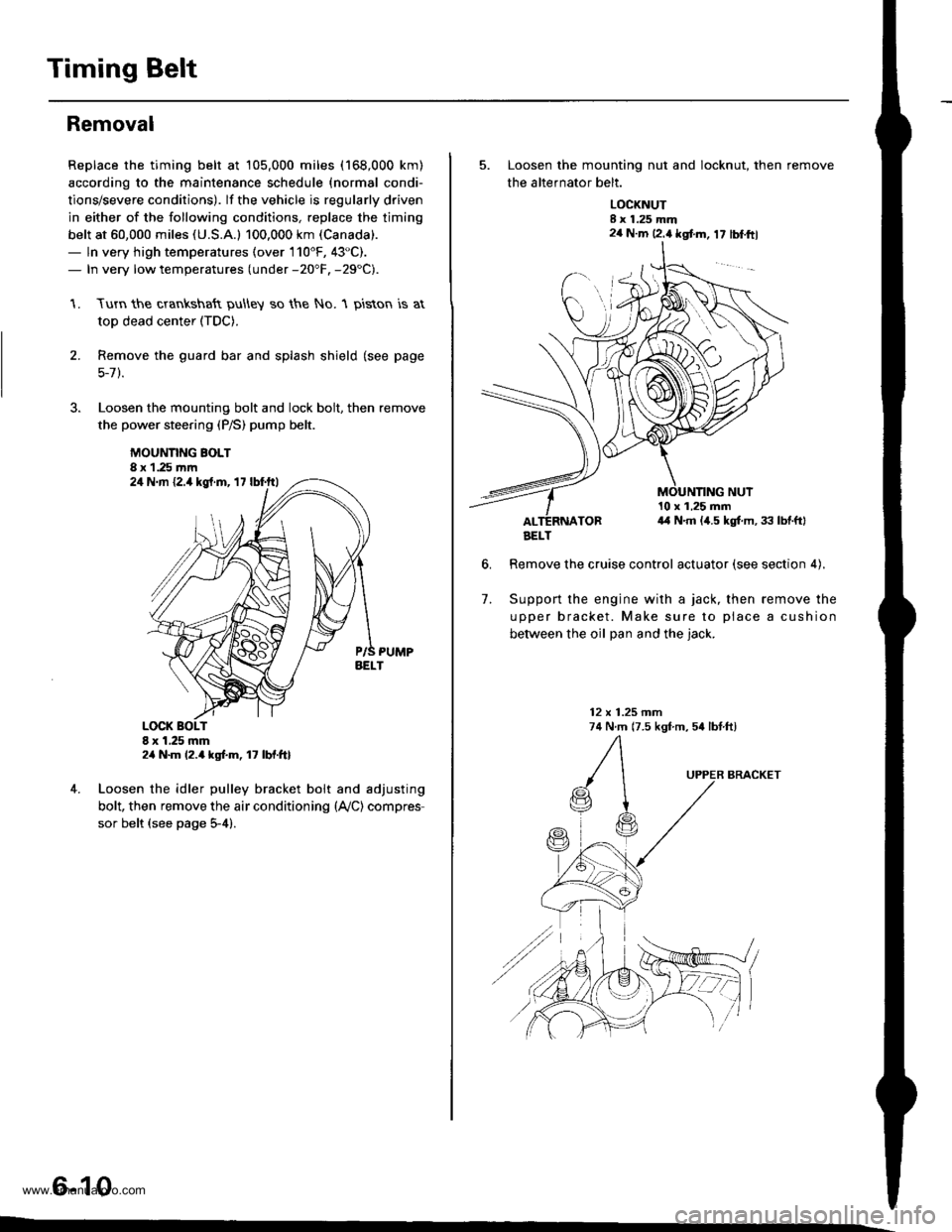

Timing Belt

Removal

Replace the timing belt at 105,000 miles (168,000 km)

according to the maintenance schedule {normal condi-

tions/severe conditions). lf the vehicle is regularly driven

in either of the following conditions, replace the timing

belt at 60,000 miles (U.S.A.l 100.000 km (Canada).

- ln very high temperatures (over 110'F, 43"C).- In very low temperatures (under -20"F. -29"C).

Turn the crankshaft pu\ley so the No. 1 piston is at

top dead center (TDC).

Remove the guard bar and splash shield (see page

5-7 ).

Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt.

MOUNNNG BOLT8 x 1.25 rnm

1.

2.

,l

4. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (lVC) compres

sor belt (see page 5-4).

6-10

24 N.m {2.4 kgt.m, 17 lbf.ftl

24 N.m 12.4 kgf.m, lt lbf.ftl

5. Loosen the mounting nut and locknut, then remove

the altefnator belt.

LOCKNUTI x 1.25 mm2a N.m 12.4 kgt m, 17 lblftl

6.

10 x 1,25 mm4,1 N.m (,1.5 kgt m, 33 lbtftl

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil Dan and the iack.

12 x 1.25 mm74 N.m (7.5 kgf m, 54 lbtftl

7.

BRACKET

AELT

www.emanualpro.com