a pillar HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1139 of 1395

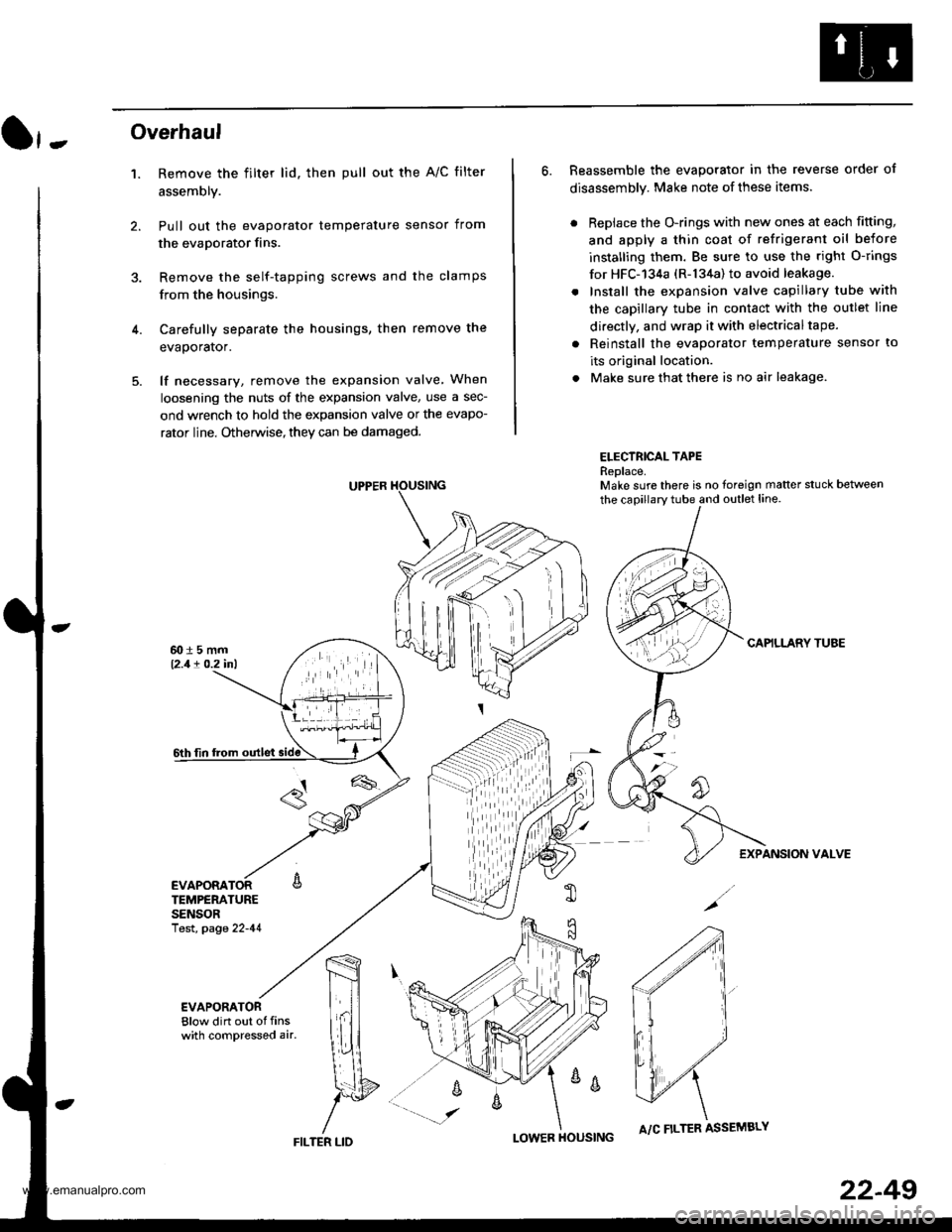

}-Overhaul

1. Remove the filter lid. then pull out the A/C filter

assembly.

Pull out the evaporator temperature sensor from

the evaporator fins.

Remove the self-tapping screws and the clamps

from the housings.

Carefully separate the housings, then remove the

evaporator.

lf necessary, remove the expansion valve When

loosening the nuts of the expansion valve, use a sec-

ond wrench to hold the expansion valve or the evapo-

rator line. Otherwise, they can be damaged.

6. Reassemble the evaporator in the reverse order of

disassembly. Make note of these items.

. Replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil before

installing them. Be sure to use the right O-rings

for HFC-'134a (R-134a) to avoid leakage.

. Install the expansion valve capillary tube with

the capillary tube in contact with the outlet line

directly, and wrap it with electricaltape.

. Reinstall the evaporator temperature sensor to

its original location.

. Make sure that there is no air leakage.

ELECTRICAL TAPEReplace.Make sure there is no foreign matter stuck between

the capillary tube and outlet line.

CAPILLARY TUAE

EXPANSION VALVE

4.

TEMPERATURESENSORlest, page 22-41

,m

\!{

YFILTER LID

;

I-OWER HOUSINGA/C FILTER ASSEMBLY

22-49

www.emanualpro.com

Page 1148 of 1395

A/C System Service

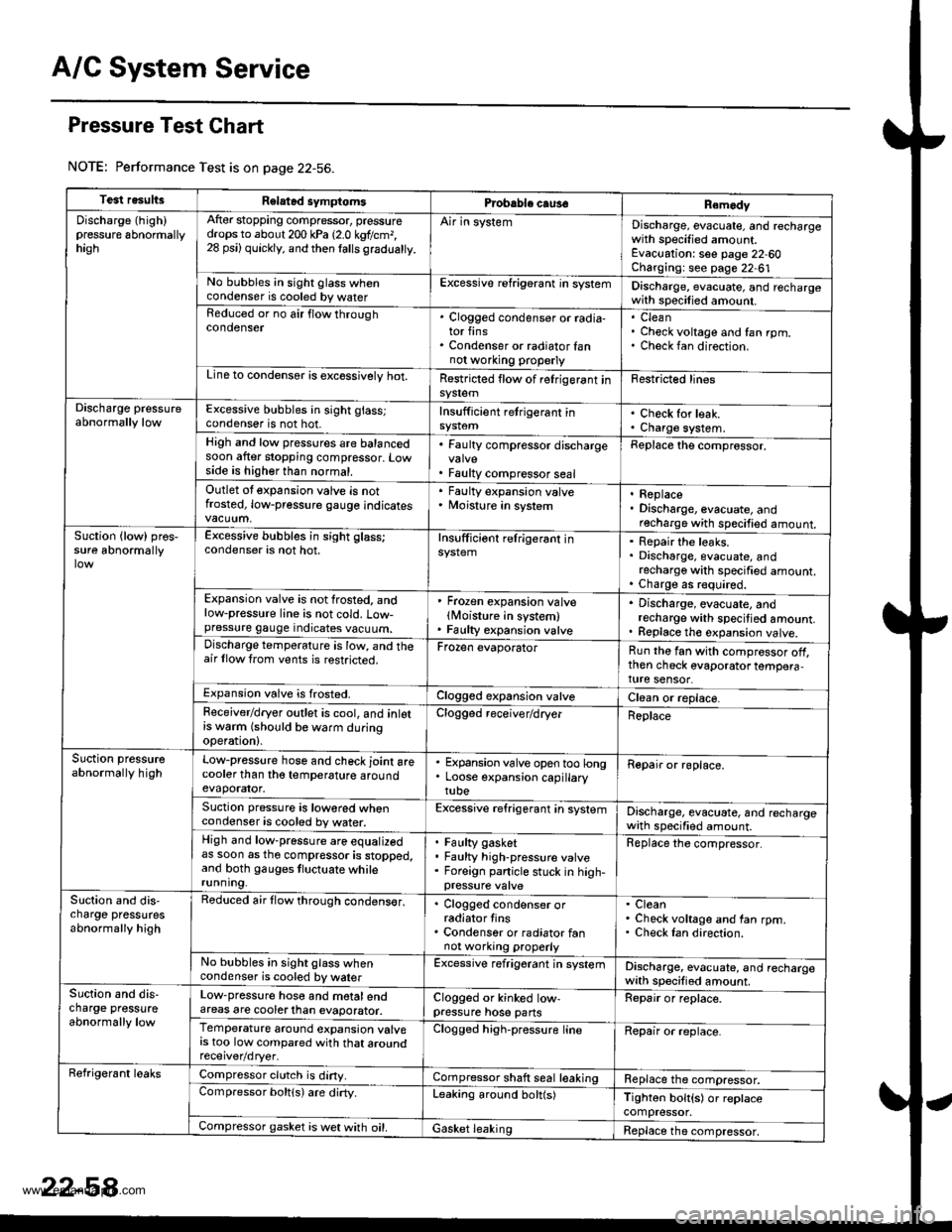

Pressure Test Chart

NOTE: Performance Test is on page 22-56.

Test resultsRelatad symptomsPrcbable caus€Remody

Discharge (high)pressure 6bnormallyhagh

After stopping compressor, pressuredrops to about 200 kPa 12.0 kgtlcm,,28 psi) quickly, and then lalls gradualty.

Air in systemDischarge, evacuate, and rechargewith specified amount.Evacuation: see page 22-60Charging: see page 22-61No bubbles in sight glass whencondenser is cooled by waterExcessive refrigerant in systemDischarge, evacuate, and rechargewith specilied amount.Reduced or no air flow throughcondenser. Clogged condenser or radia-tor fins. Condenser or radiator fannot wo.king properly

CleanCheck voltage and fan rpm.Check fan direction.

Line to condensor is excossivelv hot.Restricted flow of relrigerant insy$emFestricted lines

Discharge pressureabnormally lowExcessive bubbles in sight glass;condenser is not hot.Insufficient retrigerant inCheck for leak.Charge system.High and low pressures are balancedsoon after stopping compressor. Lowside is higher than normal.

. Faulty compressor discharge

. Faulty compressor seal

Replace the comprossor.

Outlet ot expansion valve is notfrosted, low-pressure gauge indicates

' Faulty expansion valve. Moisture in system. Replace. Discharge, evacuate, andrecharge with specified amount.Suction {low) pros,sure abnormallyExcessive bubbles in sight glass;condenser is not hot.Insufficiont relrigerant inRepair the leaks.Discharge, evacuate, andrecharge with specified amount.Charge as r€quired.Expansion valve is not frosted, andlow-pressure line is not cold. Low-pressure gauge indicates vacuum.

' Frozen expansion valvelMoisture in system). Faulty expansion valve

. Discharge, evacuate, andrecharge with specitied amount.. Replace th€ expansion valve.Discharge temperature is low, and theair llow trom vents is restricted.Frozen evaporatorRun the fan with compressor off,then check evaporator tempera,ture sensor.Expansion valve is frosted.Clogged expansion valveClean or replace.Feceiver/dryer outlet is cool, and inlotrs w6rm (should be warm duringoperation).

Clogged receiver/dryerReplace

Suction pressureabnormally highLow-pressure hose and check joint arecooler than tho temperature aroundevaporator.

. Expansion valve open too long. Loose expansion capillarytube

Repair or roplace.

Suction pressure is lowored whencondenser is cooled by water.Excessive refrigerant in systemDischarge, evacuate, and rechargewath specified amount.High and low-pressure are equalizedas soon as tho compressor is stopped,and both gauges tluctuate whilerunning.

Faulty gasketFaulty high-pressure valveForeign panicle stuck in high-

Replace the compressor.

Slction and dis,charge pressutesabnormally high

Reduced air flow through condens€r,. Clogged condenser orradiator tins. Condenser or radiator fannot working properly

CleanCheck voltage and fan rpm.Check Ian direction.

No bubbles in sight glass whencondenser is cooled by walerExcessive refrigerant jn systemDischarge, evacuate, and rechargewith specified amount.Suction and dis-charge pressureabnormally low

Low-pressure hose and motalendareas are cooterlhan evaporator.Clogged or kinked low-pressure hose pansRepair or replace.

Temperature around expansion valvers too low compared with that aroundClogged high-pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny.Compressor shaft seal leakingReplace the compressor.Compressor boltls) are dirty.Leaking around bolt(s)Tighton bolt{s) or replacecompressor.Compressor gasket is wet with oil.Gasket leakingReplace the compressor,

www.emanualpro.com

Page 1186 of 1395

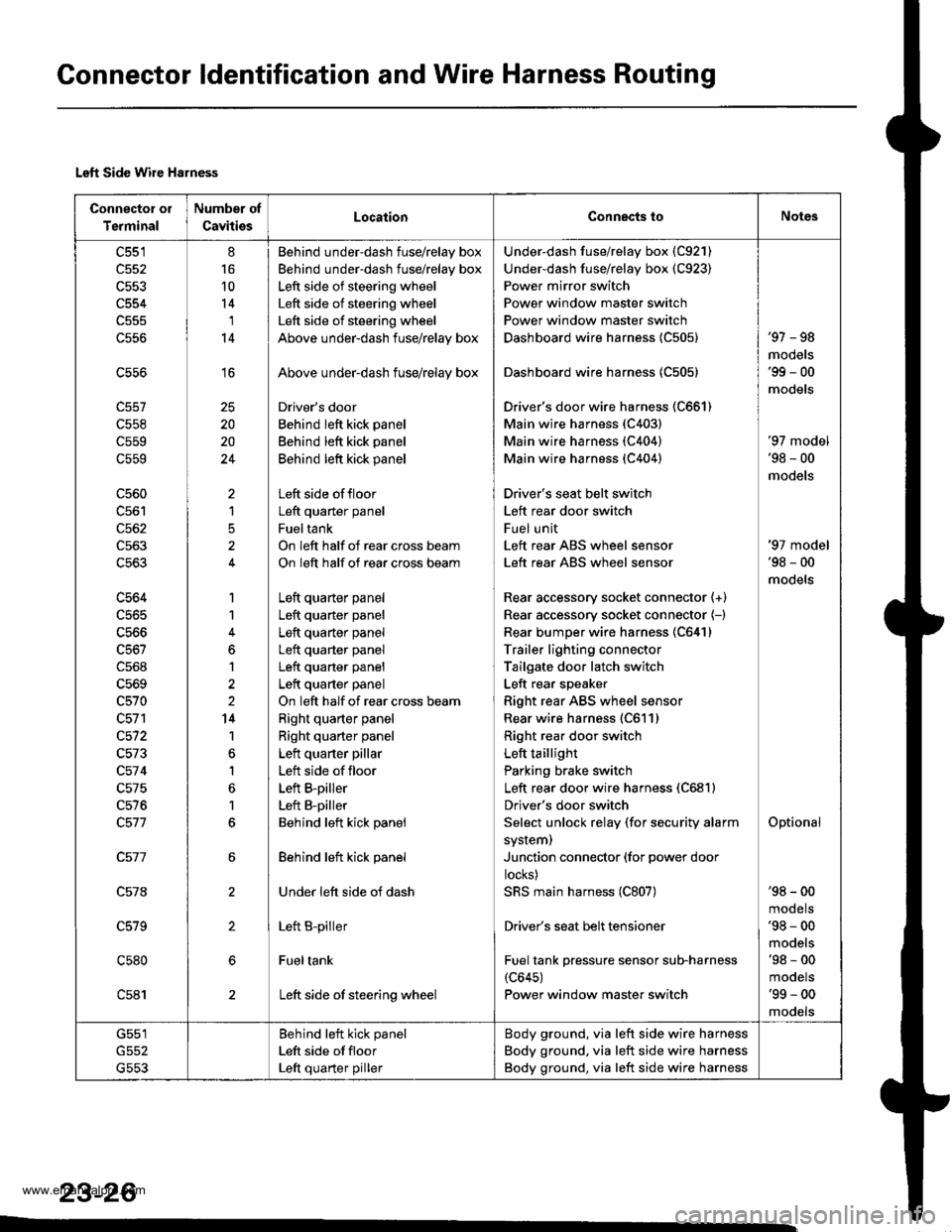

Connector ldentification and Wire Harness Routing

Left Side Wire Harness

Connector oI

Terminal

Number of

CavitiesLocaiionConnects toNot6s

c551

c552

c554

c556

c558

c559

c559

c560

c562

c563

c563

c564

c565

c566

c568

c569

c570

c572

c573

c57 4

c575

c576

c578

c579

c580

c581

8

16

10

14'I

14

16

20

20

24

)

1

5

1

1

6

1

2

14

1

1

6

1

6

Behind under-dash fuse/relay box

Behind under-dash fuse/relay box

Left side of steering wheel

Left side of steering wheel

Left side of steering wheel

Above under-dash fuse/relay box

Above under-dash fuse/relay box

Driver's door

Behind left kick panel

Behind left kick panel

Behind left kick panel

Left side offloor

Left quaner panel

Fueltank

On left half of rear cross beam

On left half of rear cross beam

Left quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

On left half of rear cross beam

Right quarter panel

Right quarter panel

Left quarter pillar

Left side of floor

Left B-piller

Left B-piller

Behind left kick panel

Behind left kick panel

Under left side of dash

Left B-piller

Fueltank

Left side of steering wheel

Under-dash fuse/relay box (C921)

Under-dash fuse/relay box (C923)

Power mirror switch

Power window master switch

Power window master switch

Dashboard wire harness {C505)

Dashboard wire harness 1C505)

Driver's door wire harness (C661)

Main wire harness (C403)

Main wire harness (C404)

Main wire harness (C404)

Driver's seat belt switch

Left rear door switch

Fuel unit

Left rear ABS wheel sensor

Left rear ABS wheel sensor

Rear accessory socket connector {+}

Rear accessory socket connector (-)

Rear bumper wire harness 1C641)

Trailer lighting connector

Tailgate door latch switch

Left rear speaker

Right rear ABS wheel sensor

Rear wire harness (C611)

Right rea. door switch

Left taillight

Parking brake switch

Left rear door wire harness (C681)

Driver's door switch

Select unlock relay (for security alarm

system)

Junction connector (for power door

locks)

SRS main harness (C807)

Driver's seat belt tensioner

Fuel tank pressure sensor sub-harness(c645)

Power window master switch

'97 - 98

mooets'99 - 00

models

'97 model'98 - 00

models

Optional

'97 model'98 - 00

models

'98 - 00

mooets'98 - 00

models'98 - 00

mooets'99 - 00

mooets

G551

G553

Behind left kick panel

Left side ot floor

Left quarter piller

Body ground, via left side wire harness

Body ground, via left side wire harness

Body ground, via left side wire harness

23-26

www.emanualpro.com

Page 1301 of 1395

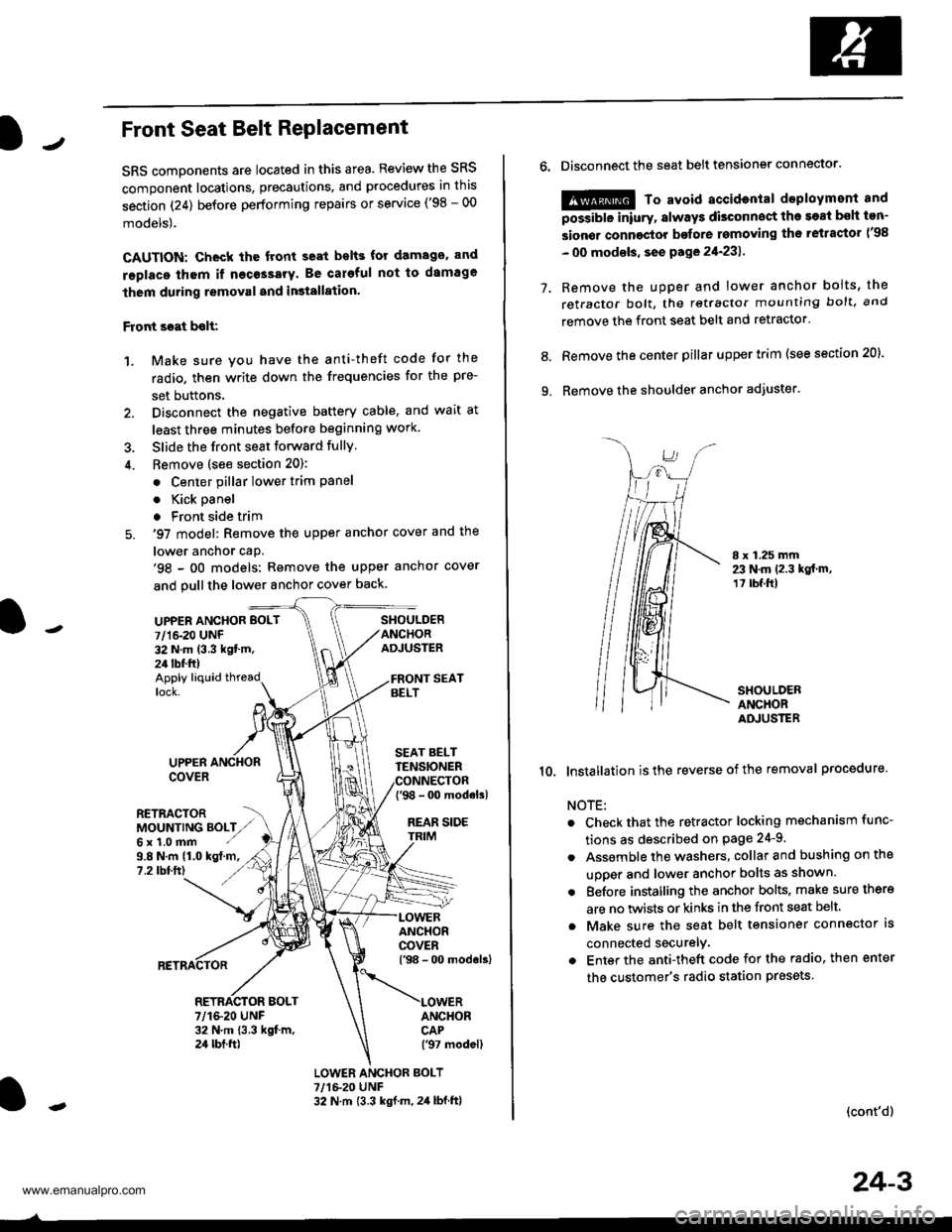

JFront Seat Belt RePlacement

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in this

section (24) before performing repairs or service ('98 - 00

models).

CAUTION: Check the front seat bslts for damago. and

replaco thom if necessary. Be careful not to damage

them during removal and in3tallation'

Front scat bolt:

1. Make sure you have the anti-theft code for the

radio, then write down the frequencies for the pre-

set buttons.

2. Disconnect the negative battery cable, and wait at

least three minutes before beginning work.

3. Slide the front seat forward fully.

4. Bemove (see section 20):

. Center pillar lower trim Pane

. Kick oanel

. Front side trim

5. '97 model: Remove the upper anchor cover and the

lower anchor caP.'98 - oO models: Remove the upper anchor cover

and pull the lower anchor cover back.

UPPEN ANCHOR BOLT

7/1&20 UNF32 N.m (3.3 kgt'm.24 tbf.ft)

SHOULDERANCHORADJUSTER

Apply liquid threadlock.

9.8 N.m (1.0 kgt.m,?.2 tbtft)

UPPERCOVER

RETRACTORMOUNTING BOLTZ,,Gx1.0mm ./

SEAT BELTTENSIONER

{'98 - 0o modols)

REAR SIDE

ANCHORCOVERl'98 - 00 models)

ANCHORCAP('97 modell

RETRACTOR BOLT7/1&20 UNF32 N.m 13.3 kgt m,24 tbt.ft)

LOWER ANCHOR BOLT?,/1&20 UNF32 N.m {3.3 kgf.m, 2,1 lbf.ftl

o.Disconnect the seat belt tensiongr connector.

@ To avoid accidontal deployment and

possibte inlury, always disconnect the soat bsh ton-

sion€r connoctor bofore rsmoving th6 retractor l'98

- 00 modsls, se€ pa ge 21-231 .

Remove the uDDer and lower anchor boits, the

retractor bolt, the retractor mounting bolt, and

remove the front seat belt and retractor.

Remove the center pillar upper trim (see section 20).

Remove the shoulder anchor adjuster.

7.

9.

8.

I x 1.25 mm23 N.m 12.3 kgt.m,1? tbf.ft)

SHOULDERANCHORADJUSTER

10. lnstallation isthe reverse of the removal procedure.

NOTE:

Check that the retractor locking mechanism func-

tions as described on Page 24-9.

Assemble the washers, collar and bushing on the

uooer and lower anchor bolts as shown.

Eefore installing the anchor bolts, make sure there

are no twists or kinks in the front seat belt.

Make sure the seat belt tensioner connector ls

connected securelv.

Enter the anti-theft code for the radio, then enter

the customer's radio station presets

(cont'd)

24-3

www.emanualpro.com

Page 1321 of 1395

Precautions/Procedures

Disconneeting the Airbag Connectors and the Seat Belt Tensioner

Connectors (cont'd)

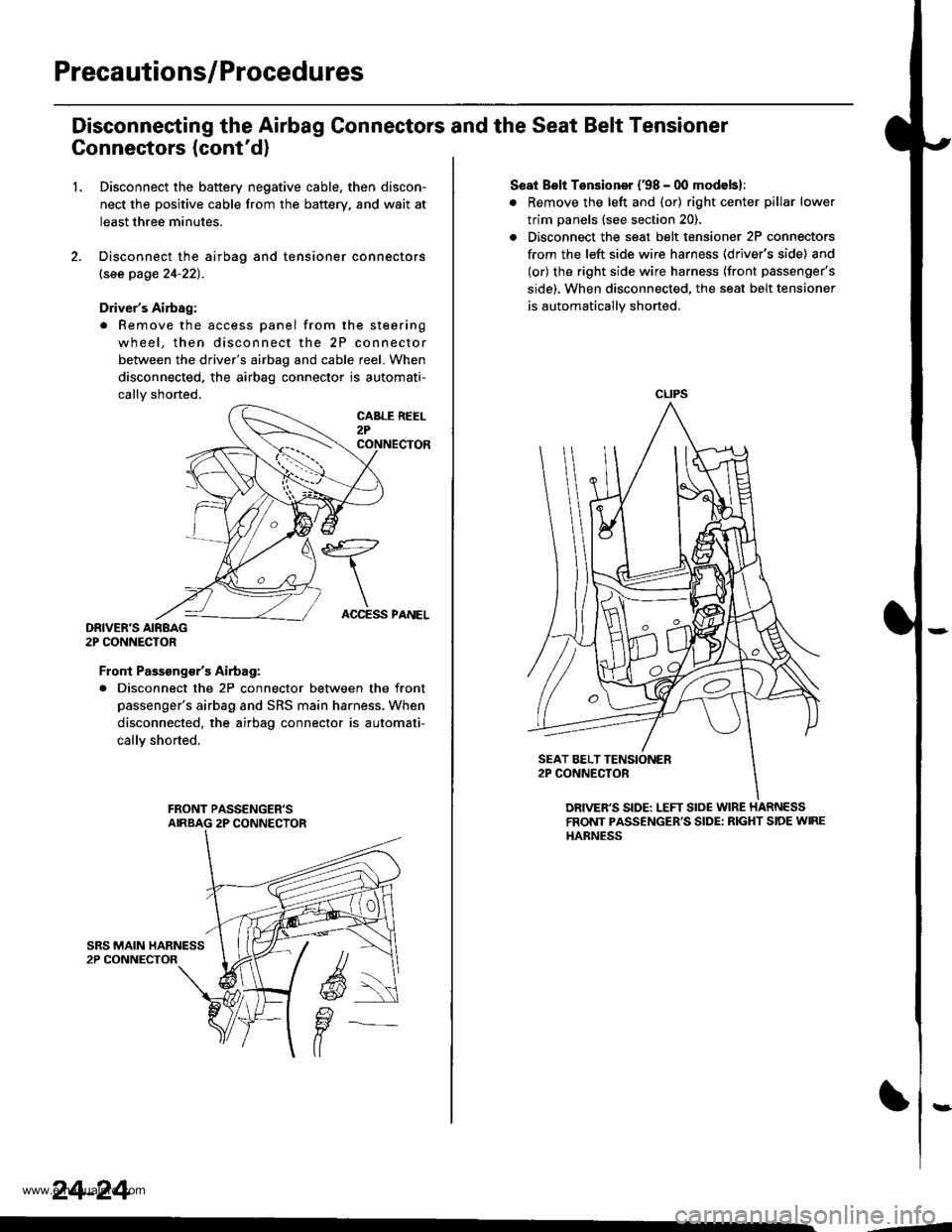

1.Disconnect the battery negative cable, then discon-

nect the positive cable from the battery. and wait at

least three minutes.

Disconnect the airbag and tensioner connectors

lsee page 24-22).

Driver's Airbag:

. Remove the access panel from the steering

wheel, then disconnect the 2P connector

between the driver's airbag and cable reel. When

disconnected, the airbag connector is automati-

callv shorted.

DRIVER'S AIRBAG2P CONNECTOR

Front Passsng€/sAirtag:

. Disconnect the 2P connector between the front

passenger's airbag and SRS main harness. When

disconnected. the airbag connector is automati-

callY shorted.

24-24

ACCESS PANEL

Seat Bslt Tensioner (38 - 00 modebl:

. Remove the left and (or) right center pillar lower

trim panels (see section 20).

. Disconnect the seat belt tensioner 2P connectors

from the left side wire harness (driver's side) and

(or) the right side wire harness (front passenger's

side). When disconnected. the seat belt tensioner

is automatically shorted.

CLIPS

DRIVER'S SIDE: LEFT SloE WIRE HARNESSFRONT PASSENGER'S SIDE: RIGHT SIDE WIREHARNESS

,--4

www.emanualpro.com

Page 1392 of 1395

SRS Unit

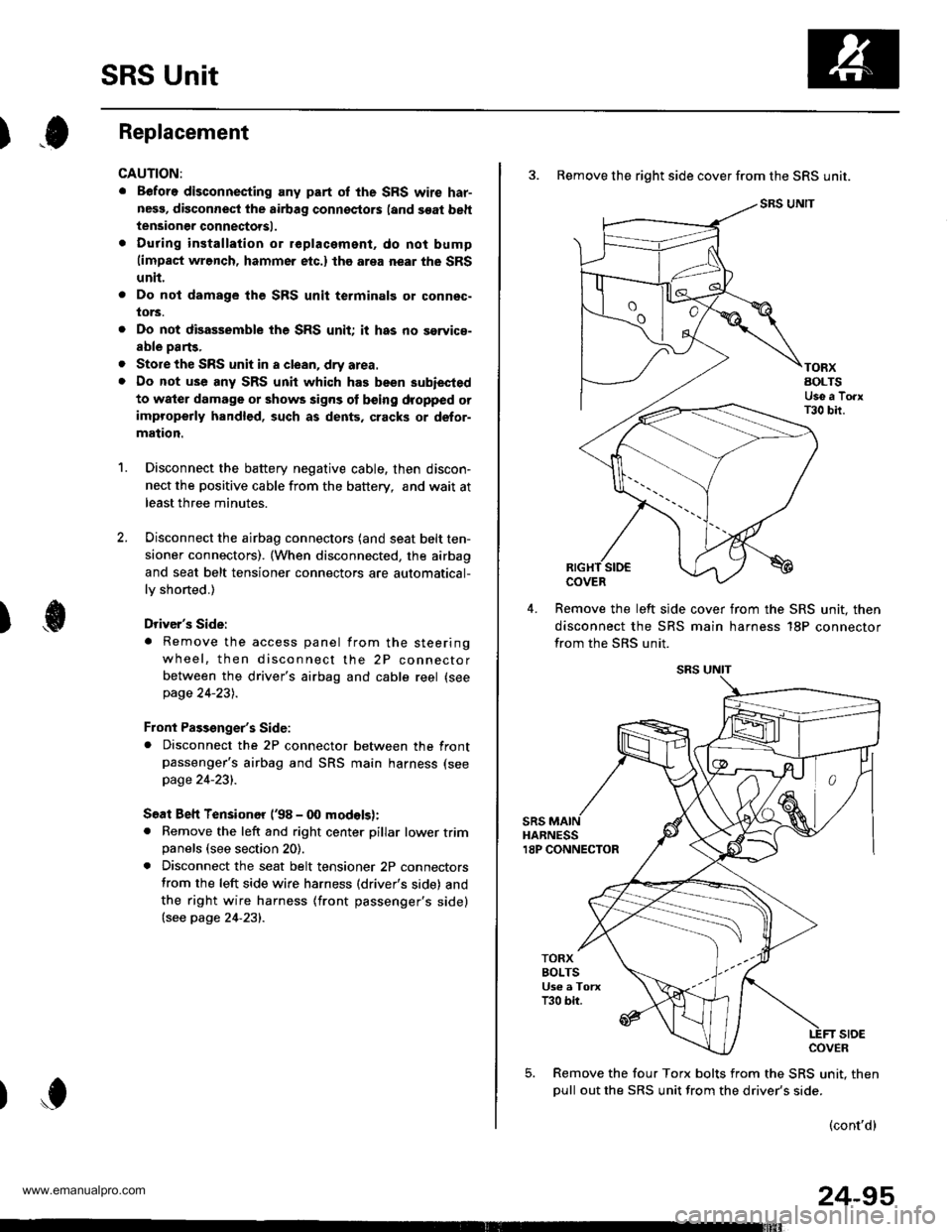

).0Replacement

CAUTION:

. Before disconnecting any part of the SRS wire har-

nesg, disconnect the airbag connoctors (and soat beh

tensioner connectorsl.

. During installation or replacament, do not bump(impact wrench, hammer etc.) the area near the SRS

unit.

Do not damage the SFS unit terminalg or connsc-

lors.

Do not disassemble the SRS unit it has no saryice-

able parts,

Store the SRS unit in a clean, dry area.

Do not use any SRS unit which has been subiected

to water damage or shows signs ot being dropped orimproperly handlgd, such as dents, cracks or defor-

mation.

Disconnect the battery negative cable, then discon-

nect the positive cable from the battery, andwaitat

least three minutes.

Disconnect the airbag connectors (and seat belt ten-

sioner connectors). (When disconnected, the airbag

and seat belt tensioner connectors are automatical-

ly shorted.)

Driver's Side:

. Remove the access panel from the steering

wheel, then disconnect the 2P connector

between the driver's airbag and cable reel (see

page 24-231.

Front Passenger's Side:. Disconnect the 2P connector between the frontpassenger's airbag and SRS main harness (see

page 24-231.

Soat Beh Tensionor ('98 - 00 modelsr:. Remove the left and right center pillar lower trimpanels (see section 20).

. Disconnect the seat belt tensioner 2P connectors

from the left side wire harness (driver's side) and

the right wire harness (front passenger's side)(see page 24'231.

2.

a

a

'1.

)

)o

24-95

3. Remove the right side cover from the SRS unit.

SRS UNIT

TORXAOLTSUse a TorxT30 bir.

COVER

Remove the left slde cover from the SRS unit. then

disconnect the SRS main harness 18P connector

from the SRS unit.

sRsHARNESS18P CONNECTOR

TORXBOLTSUs€ a TorxT30 bir.

stoECOVER

Remove the four Torx bolts from the SRS unit. then

oull out the SRS unit from the driver's side.

(cont'd)

www.emanualpro.com

Page 1393 of 1395

SRS Unit

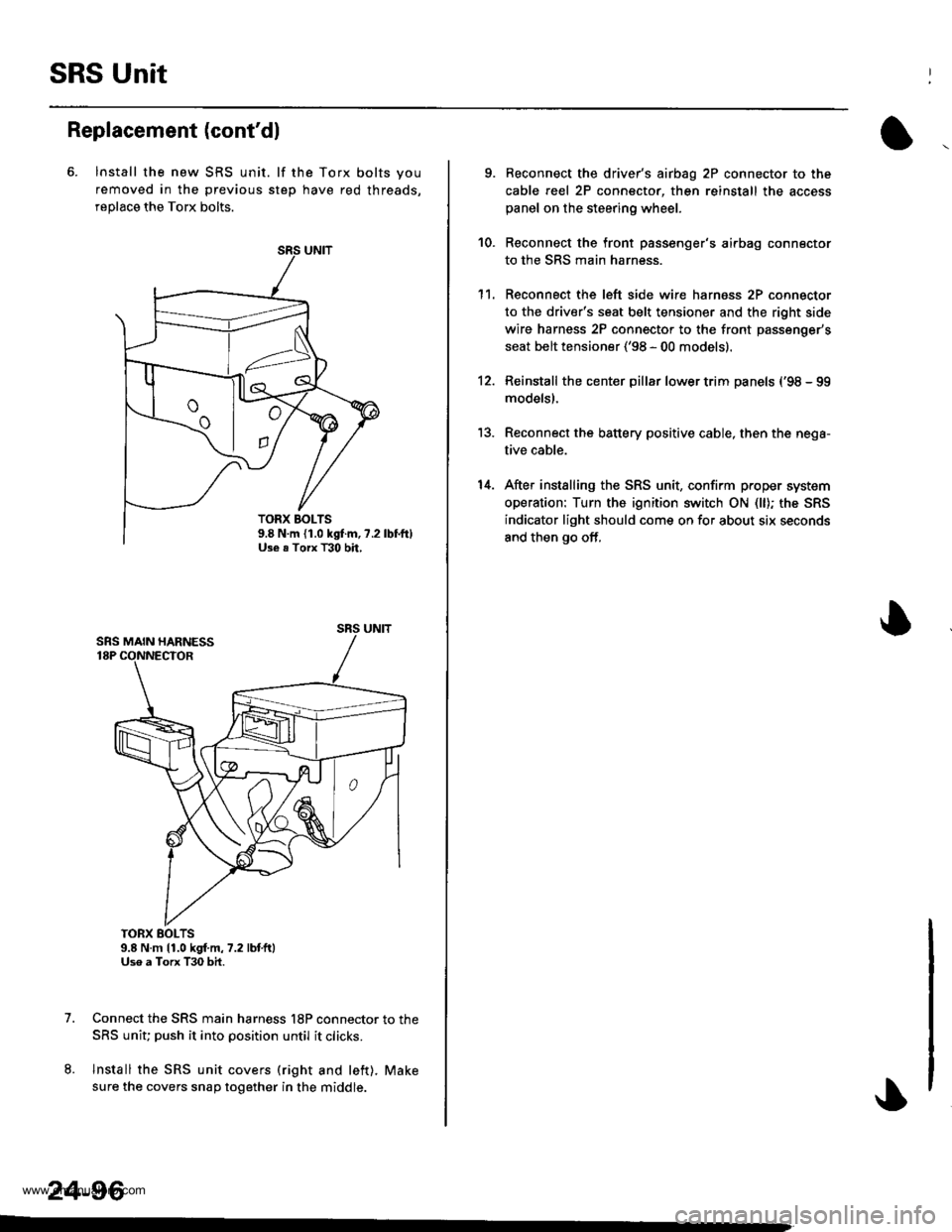

Replacement (cont'dl

6. lnstall the new SRS unit. lf the Torx bolts you

removed in the previous step have red threads,

replace the Torx bolts.

TORX BOLTS9.8 N.m 11.0 kgf.m,7.2 lbtft)Uso a Torx T30 bit.

Connect the SRS main harness l8P connector to the

SRS uniu push it into position until it clicks.

Install the SRS unit covers (right and left). Make

sure the covers snap together in the middle.

7.

8.

TORX BOLTS9.8 N.m {1.0 kgf.m, ?.2Use . Torx T30 bh,

SRS UNIT

24-96

-

9. Reconnect the driver's aibag 2P connector to the

cable reel 2P connector, then reinstall the access

panel on the steering wheel.

Reconnect the front passenger's airbag connector

to the SRS main harness.

Reconnect the left side wire harness 2P connector

to the driver's seat belt tensioner and the right side

wire harness 2P connector to the front passenger's

seat belt tensioner ('98 - 00 models).

Reinstall the center pillar lower trim panels {'98 - 99

modelsl.

Reconnect the battery positive cable, then the nega-

tive cable.

After installing the SRS unit, confirm proper system

operation: Turn the ignition switch ON (ll); the SRS

indicator light should come on for about six seconds

and then go off,

10.

1't.

12.

13.

14.

www.emanualpro.com

Page 1394 of 1395

Airbag/Seat Belt Tensioner

)Disposal

)

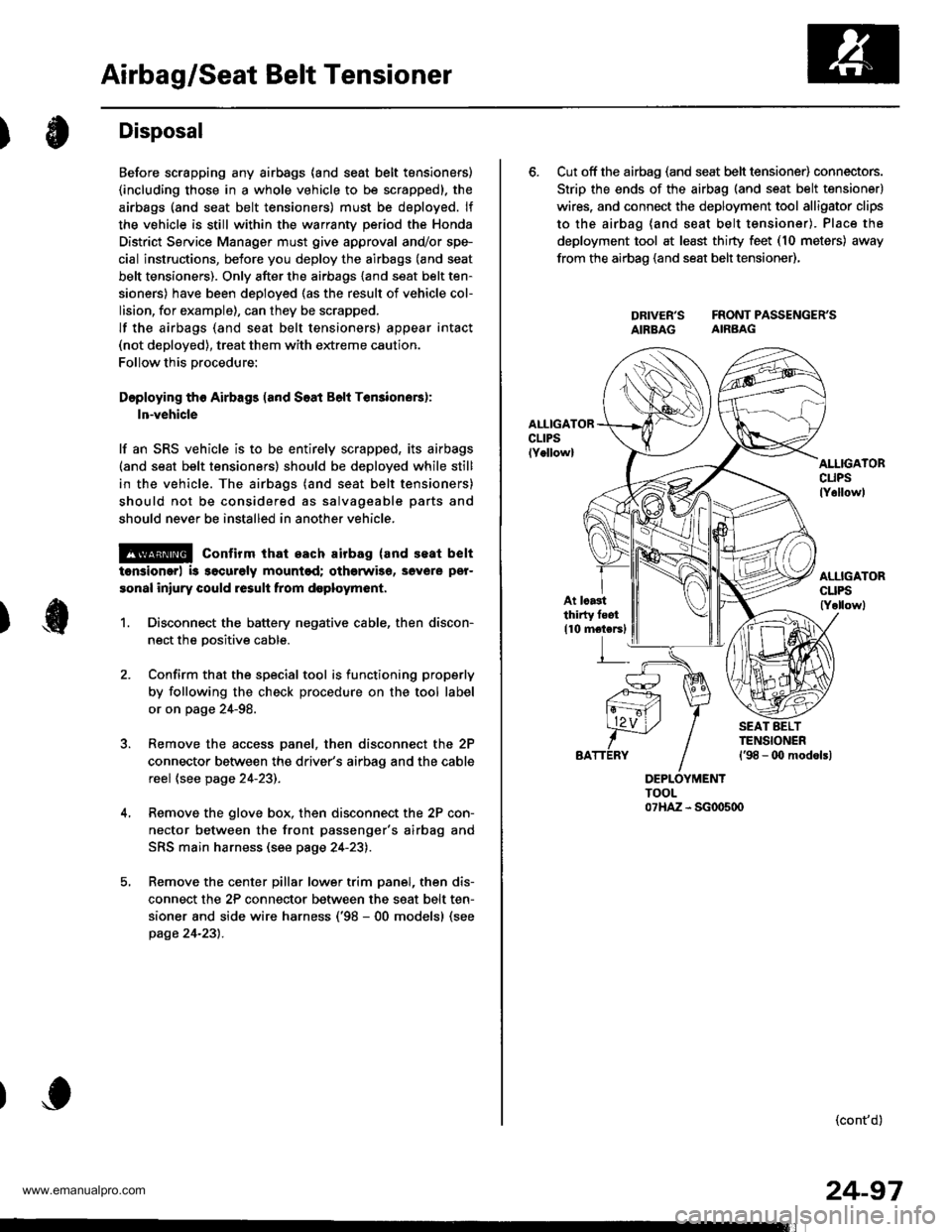

Before scrapping any airbags {and seat belt tansioners)

(including those in a whole vehicle to be scrappedl. the

airbags (and seat belt tensioners) must be deployed. lf

the vehicle is still within the warrantv oeriod the Honda

District Service Manager must give approval and/or spe-

cial instructions, before you deploy the airbags (and seat

belt tensioners). Only after the airbags {and seat belt ten-

sioners) have been deployed (as the result of vehicle col-

lision, for example), can they be scrapped.

lf the airbags (and seat belt tensioners) appear intact

(not deployed), treat them with extreme caution.

Follow this procedure:

Doploying tho Airbags (and Soat B6li Ten3ione6):

ln-vehicle

lf an SRS vehicle is to be entirely scrapped, its airbags(and seat belt tensioners) should be deployed while still

in the vehicle. The airbags (and seat belt tensioners)

should not be considered as salvageable parts and

should never be installed in another vehicle.

@ confirm that each airbag {and seat belt

tonsiongr) i3 ggcurely mountod; othgrwise, severe per-

sonal iniury could result from d6ploym6nt,

1. Disconnect the battery negative cable, then discon-

nect the oositive cable.

Confirm that the special tool is functioning properly

by following the check procedure on the tool label

or on page 24-98.

Remove the access panel, then disconnect the 2P

connector between the driver's airbag and the cable

reel (see page 24-23).

Remove the glove box, then disconnect the 2P con-

nector between the front passenger's airbag and

SRS main harness (see page 24-23).

Remove the center pillar lower trim panel, then dis-

connect the 2P connector between the seat belt ten-

sioner and side wire harness ('98 - 00 models) (see

page 24-231.

6. Cut off the airbag (and seat belt tensioner) connectors.

Strip the ends of the airbag (and seat belt tensioner)

wires. and connect the deployment tool alligator clips

to the airbag (and seat belt tensioner). Place the

deployment tool at least thirty feet (10 meters) away

from the airbao (and seat belt tensioner),

DRIVER'S FRONTPASSENGER'SAIBBAG AIRBAG

AI.IIGATORcuPslY6llowl

At lcastthirty feot

110 motersl

(cont'd)

24-97

www.emanualpro.com