light HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 74 of 1395

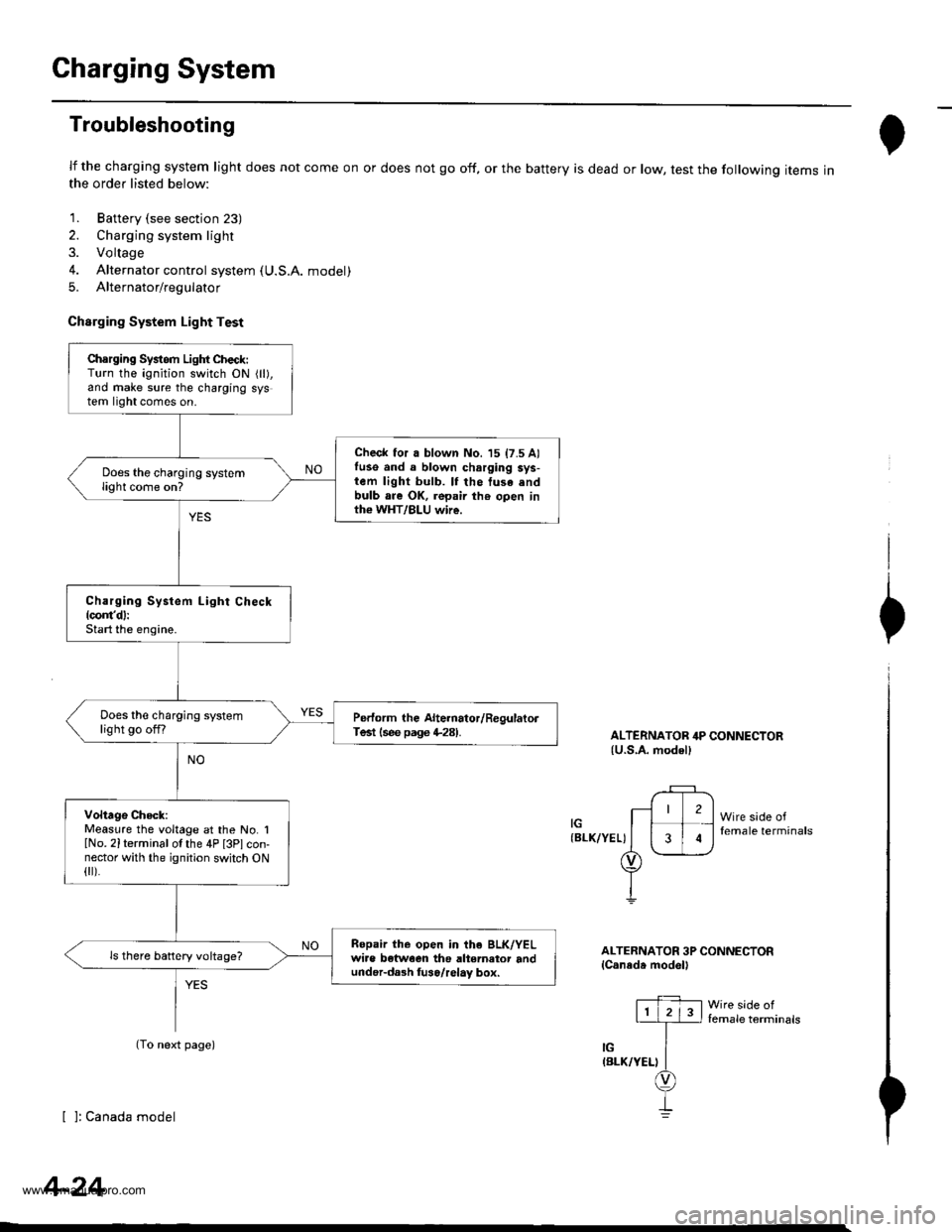

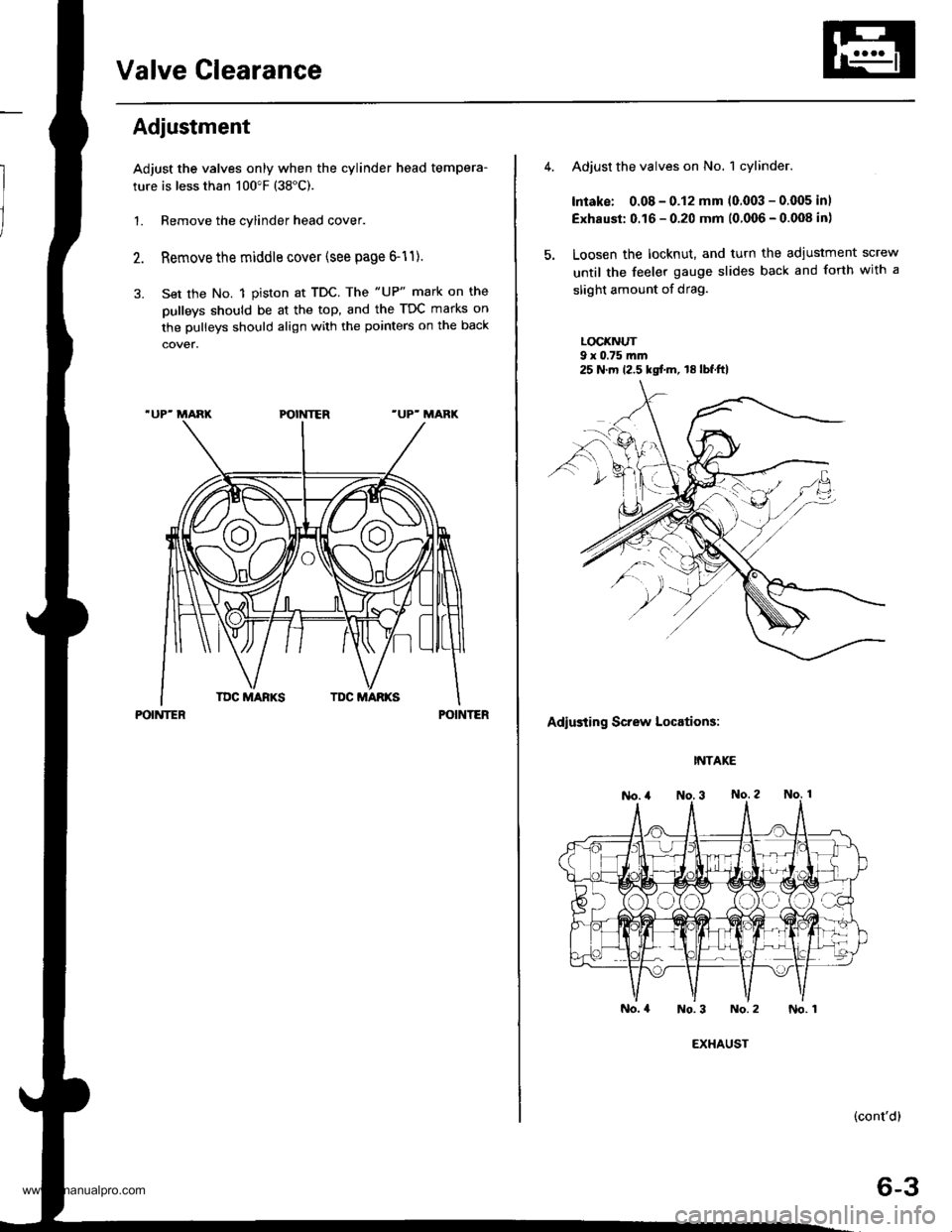

Gharging System

Troubleshooting

lf the charging system light does not come on or does not go off, or the battery is dead or low, test the following items inthe order listed below:

1. Battery (see section 23)

2. Charging system light

3. Voltage

4. Alternator control system (U.S.A. model)

5. Alternator/regulator

Charging System Light Test

ALTERNATOR 4P CONNECTOR{U.S,A. modell

(BLK/YEL)

2

3

Wire sade offemale terminals

I

I

I

ALTERNATOR 3P CONNECTORlCaneda model'

Iemale terminals

[ ]: Canada model

Chsrging Systom Light Check:Turn the ignition switch ON {ll),and make sure the charging system light comes on.

Check for a blown No. 15 17.5 Alfuse and a blown charging sys-tem light bulb. lf the tusa .ndbulb are OK, repair th€ open inth€ WHT/BLU wire.

Does the charging systemlight come on?

Charging System Light Check{com'd}:Start the engine.

Does the charging systemlight go offfPerform the Alte.nator/RegulatorTest lsee page +281.

Voltage Check:Measure the voltage at the No. IlNo. 2iterminal of the 4P [3Plcon-nector with the ignition switch ON{ ).

Ropair the open in the BLK/YELwiae betwoen the altemator andunder-da3h luso/relay box.

ls there battery voltage?

(To next page)

4-24

www.emanualpro.com

Page 75 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

in(From previous page)

Does the charging systemlight come on?

Ch6ck the L circuil:1. Turn the ignition switch OFF.2. Disconnect the 4P [3P] con-nector from the alternator.3. Turn the ignition switch HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

in(From previous page)

Does the charging systemlight come on?

Ch6ck the L circuil:1. Turn the ignition switch OFF.2. Disconnect the 4P [3P] con-nector from the alternator.3. Turn the ignition switch](/img/13/5778/w960_5778-74.png)

in(From previous page)

Does the charging systemlight come on?

Ch6ck the L circuil:1. Turn the ignition switch OFF.2. Disconnect the 4P [3P] con-nector from the alternator.3. Turn the ignition switch ON (ll).

Repair the short to ground in theWHT/BLU wire.

[ ]: Canada model(cont'd)

4-25

www.emanualpro.com

Page 76 of 1395

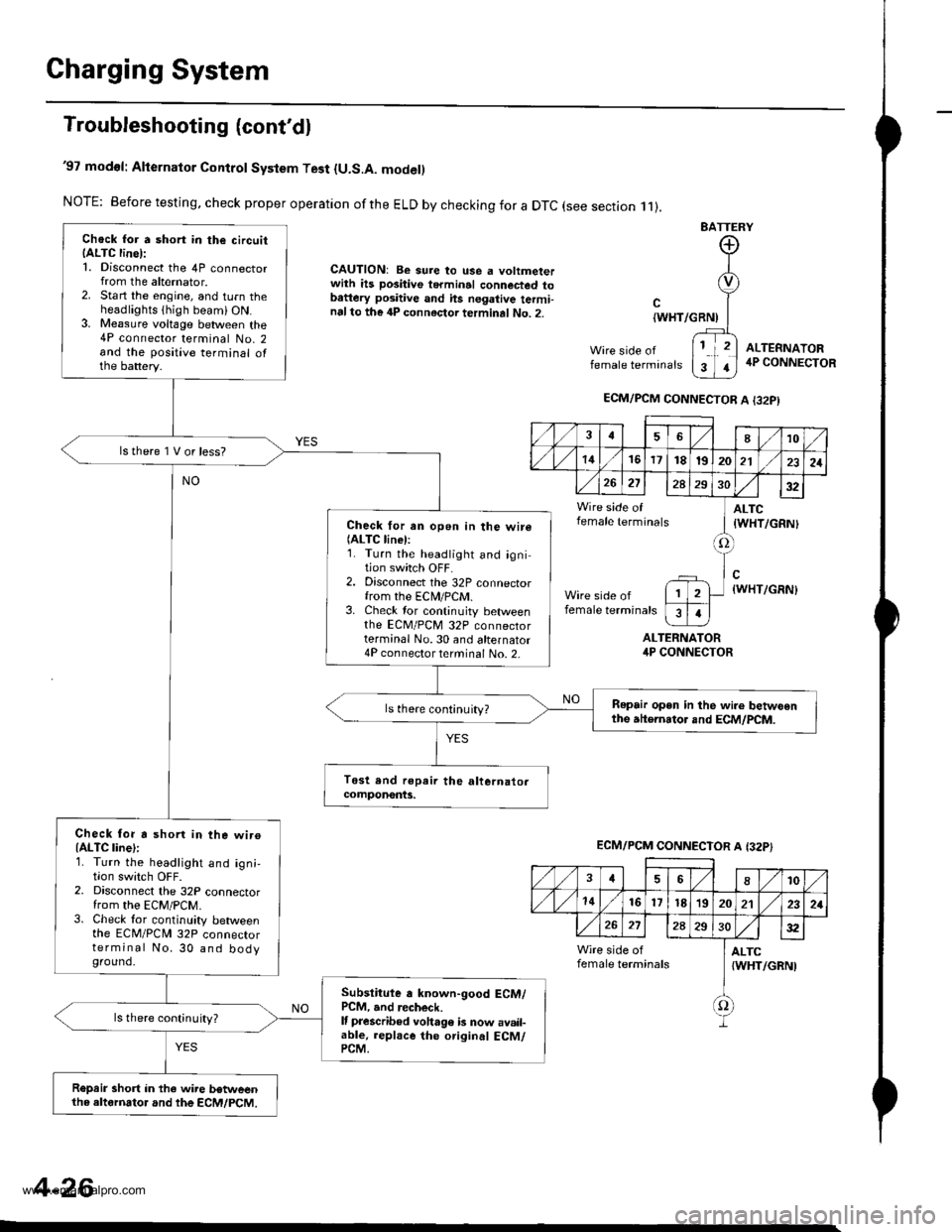

Charging System

Troubleshooting (cont'dl

'97 modol: Alternator Control System Test {U.S.A. model)

NOTE: Before testing, check proper operation ofthe ELD by checking for a DTC (see section .11).

CAUTION: Be sure to use a voltmeterwith ils positive terminal connected tobattery positive and hs negative termi-nalto the 4P connector terminal No. 2.

BATTERY

Wire side offemale terminals

{WHT/GRNI

ALTERNATORirP CONNECTOR

ALTEFNATOR4P CONNECTOR

Chock for a short in the circuitIALTC line):1. Disconnect the 4P connectorfrom the alternator.2. Start the engine, and turn theheadlights thigh beami ON.3. Me8sure voltage between the4P connector terminal No. 2and the positive terminal ofthe battery.

lstherelVorless?

Check for an open in the wire(ALTC linel:1. Turn the headlight and igni-tion switch OFF.2. Disconnect the 32P connectorfrom the ECN4/PCM.3. Check tor continuity betweenthe EcM/PcM 32P connectorterminal No.30 and alternator4P connector terminal No. 2-

Repair open in the wi.e betwoenthe atternator and ECM/PCM.ls there continuity?

Check for a shorl in the wiroIALTC line):1. Turn the headlight and ign;,I|on swrtcn UFF2. Disconnect the 32P connectorfrom the EcM/PcM.3. Check tor continuity betweenthe ECM/PCN4 32P connectorterminal No. 30 and bodyground.

Subslitute a known-good ECM/PCM, and recheck.It prescribed voha96 b now avail-able, replace the original ECM/PCM.

ls there continuity?

R€prir short in the wire betweenthe altornator and the ECM/PCM.

ECM/PCM CONNECTOR A I32PI

,/1./1810

./ l./t4161718t9202121

26272A293032

Wire side of ] ALTCfemale terminals I tWHT/cRNl

tlWHT/GRN)

female terminals

I

1

ECM/PCM CONNECTOR A {32P}

,/ ,/46810

,/1,/1416l7t8'1920212321

272A2S30:t2

Wire side of I ALTCfemale terminals {WHT/GRNI

f)

4-26

www.emanualpro.com

Page 77 of 1395

R'oR

l

u

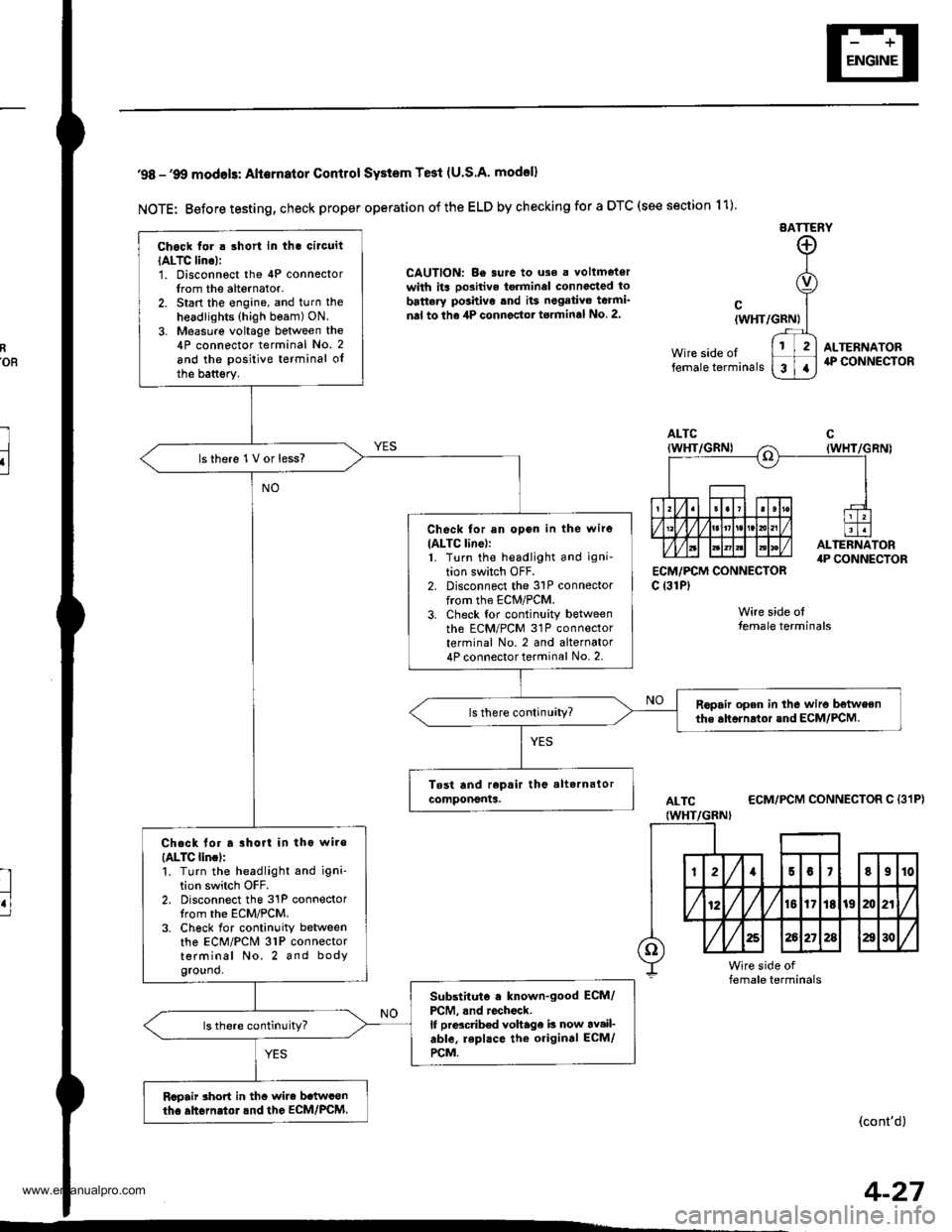

'98 -'9O modols: Alternator Contlol SYstem Te3t (U.S.A' model)

NOTE: Before testing, check proper operation of the ELD by checking for a DTC (see section 11)

EATTERY

CAUTION: Be surc to uso a voltmetorwith its oo3itive torminel connccted to

battery po3hivo tnd its negativo teami'

nal to the 4P connector torminal No 2.

ECM,/PCM CONNECTORc {31P)

Wire side olfemale terminals

cIWHT/GRN)

Wire side oltemale terminals

ALTERNATOR4P CONNECTOR

ALTC

IWHT/GBNI

ECM/PCM CONNECTOR C {31P}

(cont'd)

Chock tor . short in tha circuit

IALTC lino):1. Disconnoct the 4P connectorIrom the alternator.2. Start the engine, and turn the

headlights (high beam) ON.

3. Measure voltage between the4P connector terminal No. 2

and the positive terminal oIthe battsry.

lsthere 1V or less?

Check for an opon in the wire

IALTC line):1. Turn the headlight and igni-

tion switch OFF.2. Disconnect the 31P connectorfrom the ECM/PCM.3. Check tor continuity betweenth6 ECM/PCM 31P connectorterminal No. 2 and alternator4P connector terminal No. 2.

Ropair open in the wiro betweenthe ahornrtor and ECM/PCM.

Chack lor a rhort in tho wire

{ALTC lincl:'!. Turn the headlight and igni'tion switch OFF.2. Disconnect the 31P connectorIrom the ECM/PCM.3. Ch6ck for continuity betweenthe ECM/PCM 31P connectorterminal No. 2 and bodyground.

Substituto . known-good ECM/

PCM, .nd rochock.lf prdcdb€d voltage b now av.il-able, repl.ce the original ECM/

rcM.

Rcpair rhort in thc wire b.twconth. ahGrn.tol.nd the EcM/PcM.

4-27

www.emanualpro.com

Page 86 of 1395

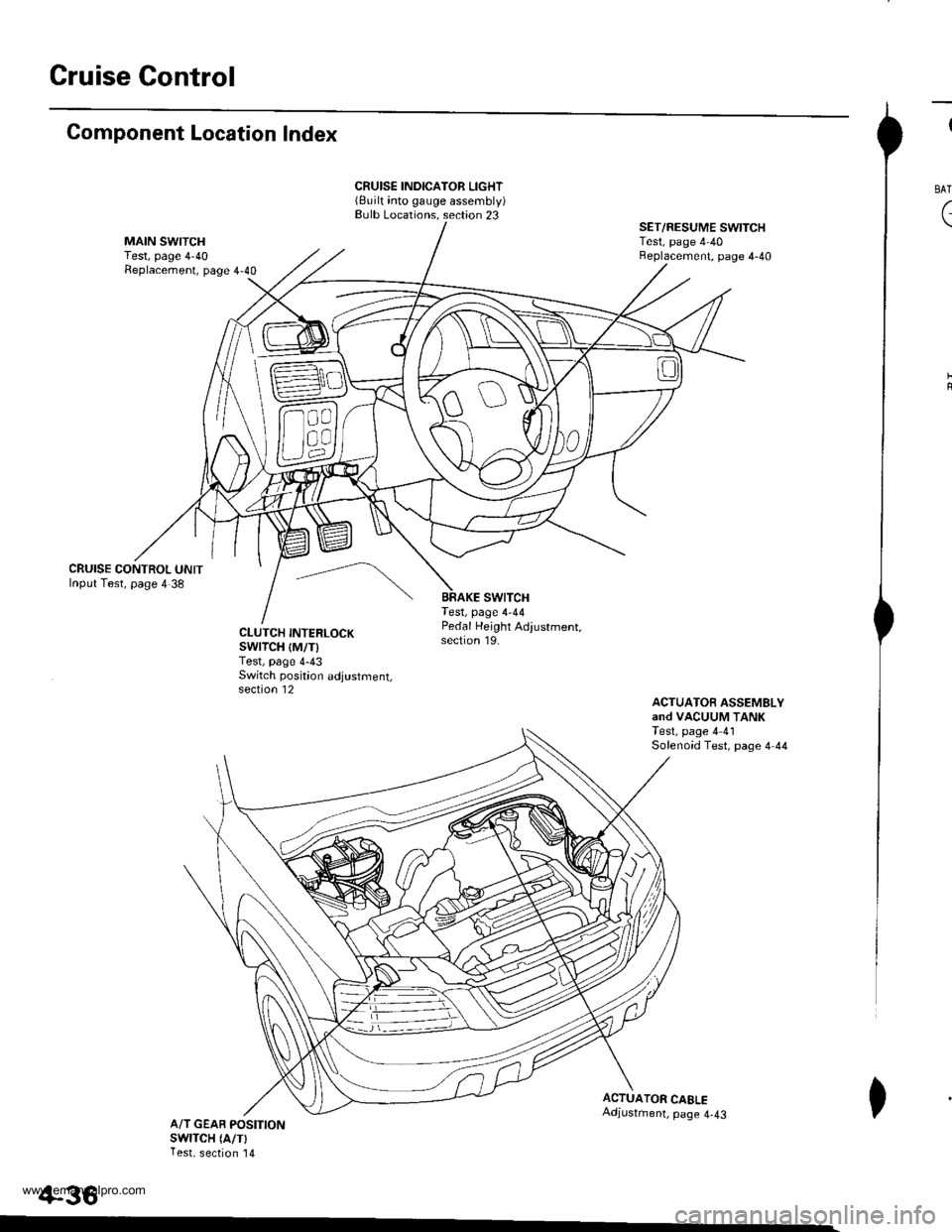

Gruise Control

Component Location Index

CRUISE CONTROL UNITInput Test, page 4 38

CRUISE INDICATOR LIGHT(Built into gauge assembly)Bulb Locations. section 23

swtTcHTest, page 4-44

SET/RESUME SWITCHTest, page 4 40Beplacement, page 4-40

ACTUATOfi ASSEMBLYand VACUUM TANKTest, page 4 41Solenoid Test, page 4 44

CLUTCH INTERLOCKswrTcH {M/T)Test, page 4-43Switch poskion adjustment,section 12

Pedal Height Adjustment,section 19.

ACTUATOR CAELEAdjustment, page 4-43A/T GEAB POSITIONswlTcH (A/TlTest, section '14

+36

I

BAT

(

I

www.emanualpro.com

Page 87 of 1395

UNDER.OASH FUSARELAY BOX

INDICATORLIGHT(0.84W)

lPIOSET

526712813

CRUISE CONTROT UNLT 10

11114

COMEINATONL GH'I SWITCH

f7

IRED/BLK

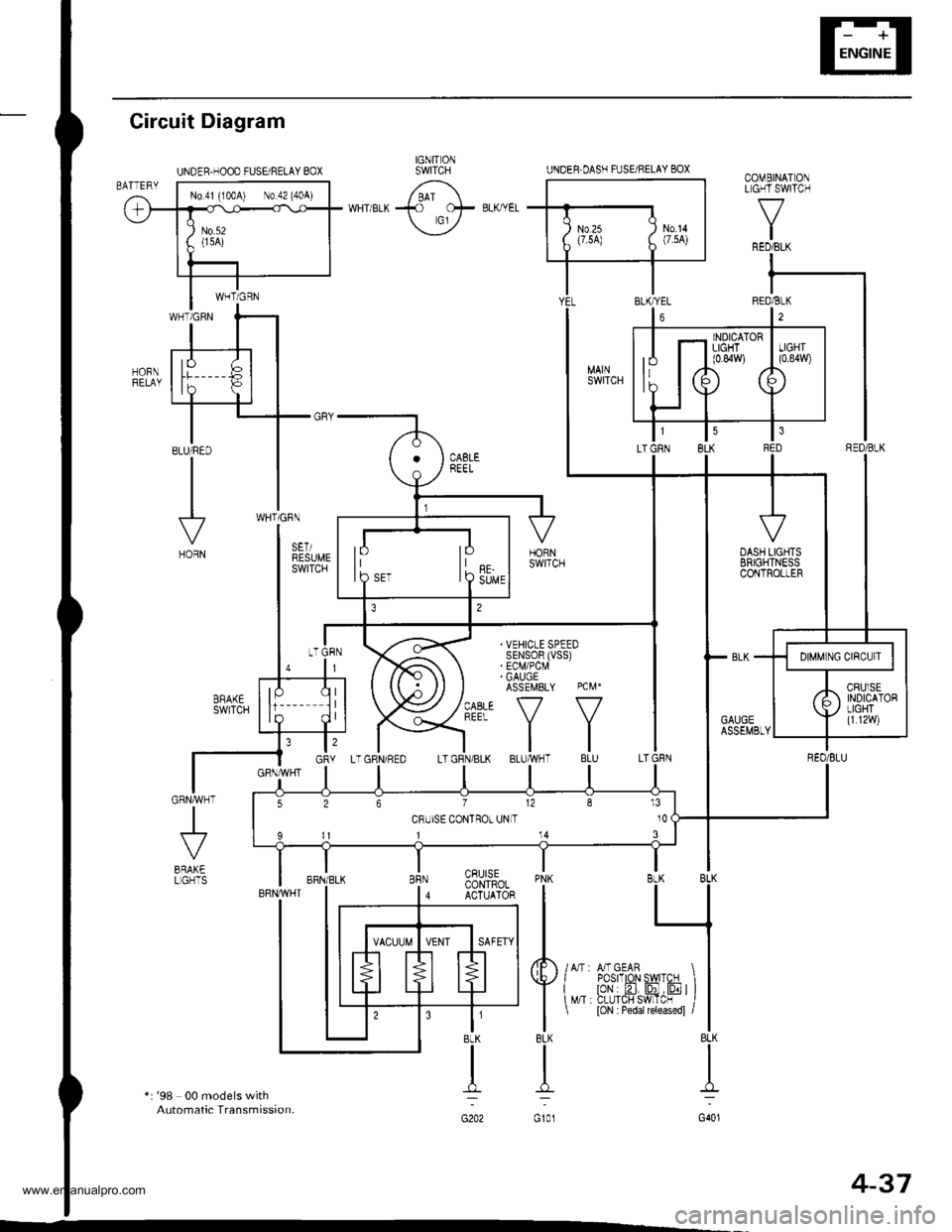

Gircuit Diagram

*: '98 00 models withAutomatic Transmission.

J

BRAK€LGHTSPNK BLK BLK

I L_l

tl

4F /lr,mcern I I

Y{"^ i?tr'.flffi'JF ) l

I

t loN : Pedar rereasedl /l

8LK BLK

TI

G101 G401

CRUISECONTROLACTUATOR

t'BLK

n:

G202

IGNIT ONSWITCHUNDER.HOOD FUSEi RELAY BOX

No 41 (100A) No 42 (404)

4-37

www.emanualpro.com

Page 89 of 1395

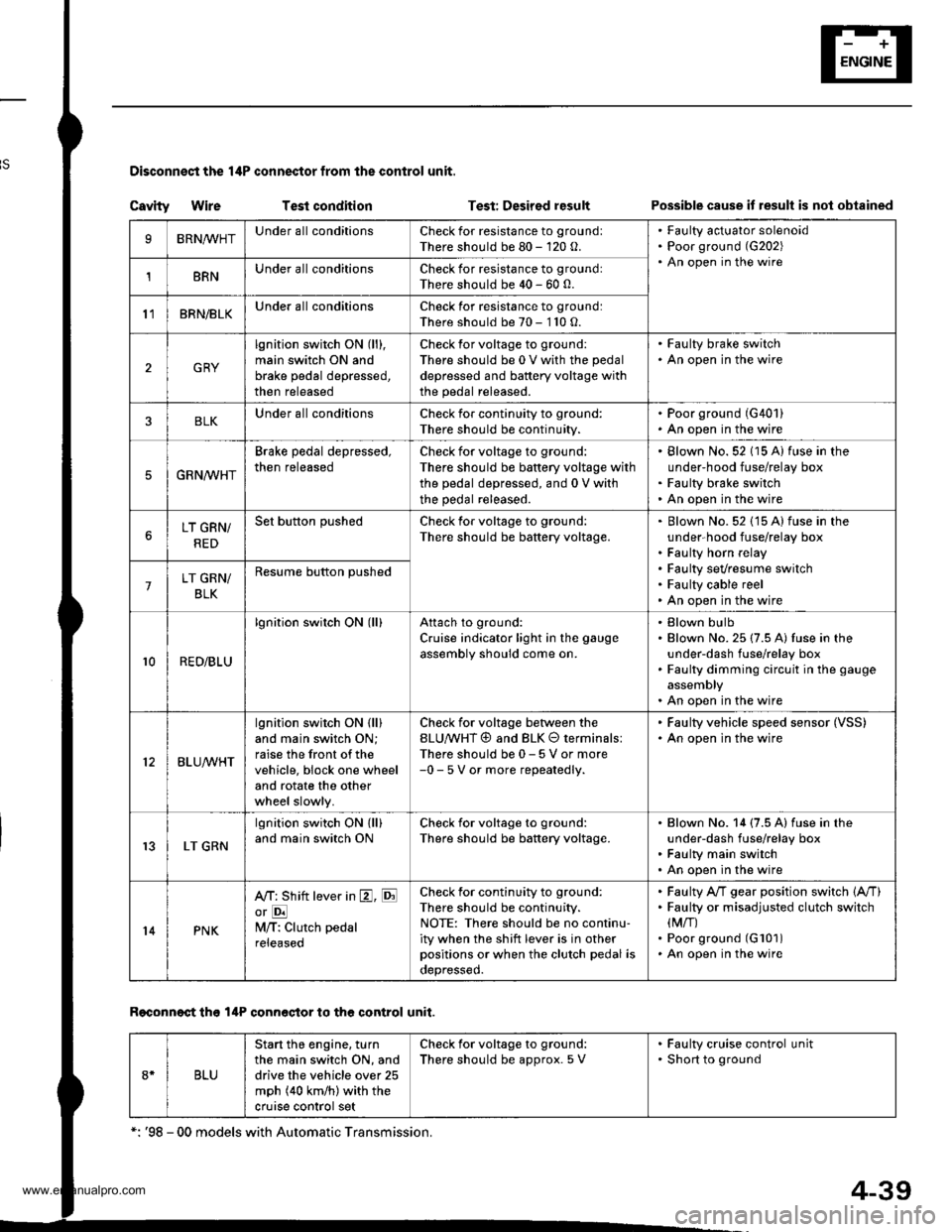

Disconnest the lilP connector from the control unit.

Csvity WireTest condition

R€conn€ct tho 14P connGctor to the control unit.

Test: Desired resultPossible cause it result is not obtained

BRNAr'VHTUnder all conditionsCheck for resistance to groundl

There should be 80 - 120 o.

Faulty actuator solenoid

Poor ground (G202)

An open in the wire1BRNUnder all conditionsCheck for resistance to groundl

There should be 40 - 60 0.

11BRN/BLKUnder all conditionsCheck for resistance to ground:

There should be 70 - 110 O.

2GRY

lgnition switch ON (ll),

main switch ON and

brake pedal depressed,

then released

Check for voltage to ground:

There should be 0 V with the pedal

depressed and battery voltage with

the pedal released.

. Faulty brake switch. An open in the wire

BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401). An open in the wire

5GRNMHT

Brake pedal depressed,

then released

Check for voltage to ground:

There should be battery voltage with

the pedal depressed, and 0 V with

the pedal released.

Blown No.52 1'15 Alfuse in the

under-hood fuse/relay box

Faulty brake switch

An open in the wire

LT GRN/

RED

Set button pushedCheck for voltage to ground:

There should be battery voltage.Blown No. 52 {'15 A} fuse in the

under-hood fuse/relay box

Faulty horn relay

Faulty sevresume switch

Faulty cable reel

An open in the wire7LT GRN/

BLK

Resume button pushed

10RED/BLU

lgnition switch ON lll)Attach to ground:

Cruise indicator light in the gauge

assembly should come on.

Elown bulbBlown No. 25 (7.5 A) tuse in theunder-dash fuse/relay box

Faulty dimming circuit in the gauge

assembly

An open in the wire

ELU^r'r'HT

lgnitjon switch ON {ll}and main switch ON;

raise the front of the

vehicle, block one wheel

and rotate the other

wheel slowly.

Check for voltage between the

ELUA/VHT @ and BLK O terminalsl

There should be 0 - 5 V or more-0 - 5 V or more repeatedly.

Faulty vehicle speed sensor (VSS)

An open in the wire

r3LT GRN

lgnition switch ON {ll}and main switch ONCheck for voltage to ground:

There should be battery voltage.

Blown No. 14 (7.5 A) fuse in theunder-dash fuse/relay box

Faulty main switch

An open in the wire

l4PNK

A'/T: Shift lever in E, EotE

lvl/T: Clutch pedal

releaseo

Check for continuity to ground:

There should be continuity.NOTE: There should be no continu-

ity when the shift lever is in otherpositions or when the clutch pedal is

oepresseo.

Faulty A/f gear position switch 1A,/TlFaulty or misadjusted clutch switch

fi{/r)Poor ground (G101)

An open in the wire

BLU

Start tho engine. turnthe main switch ON, anddrive the vehicle over 25

mph (40 km/h)with the

crurse control set

Check for voltage to ground:

There should be approx.5 V

. Faulty cruise control unit. Shod to ground

*: '98 - 00 models with Automatic Transmission.

4-39

www.emanualpro.com

Page 91 of 1395

n-

n-

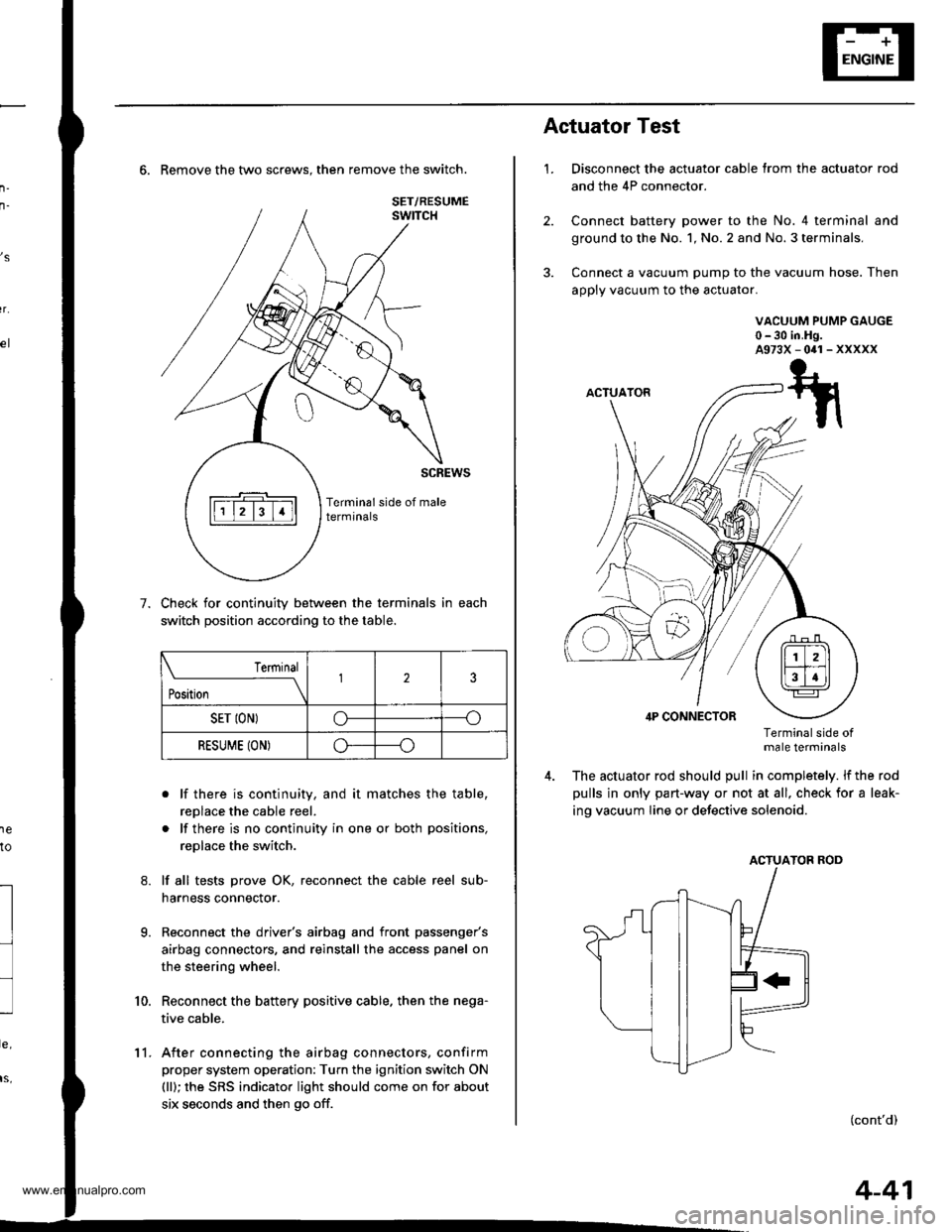

6. Remove the two screws. then remove the switch.

Check for continuity between the terminals in each

switch position according to the table.

. lf there is continuity, and it matches the table,

replace the cable reel.

. lf there is no continuity in one or both positions,

replace the switch.

lf all tests prove OK, reconnect the cable reel sub-

harness connector.

Reconnect the driver's airbag and front passenger's

airbag connectors, and reinstall the access panel on

the steering wheel.

Reconnect the battery positive cable. then the nega-

tive cable.

After connecting the airbag connectors, confirm

proper system operation: Turn the ignition switch ON

(ll); the SRS indicator light should come on for about

six seconds and then go off.

,s

r.

1e

to

7.

l

9.

10.

SET/RESUME

Terminal

t*,r*

-__\l23

SET ION)o----o

RESUME (ON)o----o

11.

4-41

1.

Actuator Test

Disconnect the actuator cable trom the actuator rod

and the 4P connector.

Connect battery power to the No. 4 terminal and

ground to the No. 1, No. 2 and No. 3 terminals,

Connect a vacuum pump to the vacuum hose. Then

apply vacuum to the actuator.

VACUUM PUMP GAUGE0-30 in.Hg.A973X-041-XXXXX

Terminalside otmale terminals

The actuator rod should pull in completely. lf the rod

pulls in only part-way or not at all, check for a leak-

ing vacuum Iine or defective solenoid.

ACTUATOB ROD

(cont'd)

www.emanualpro.com

Page 94 of 1395

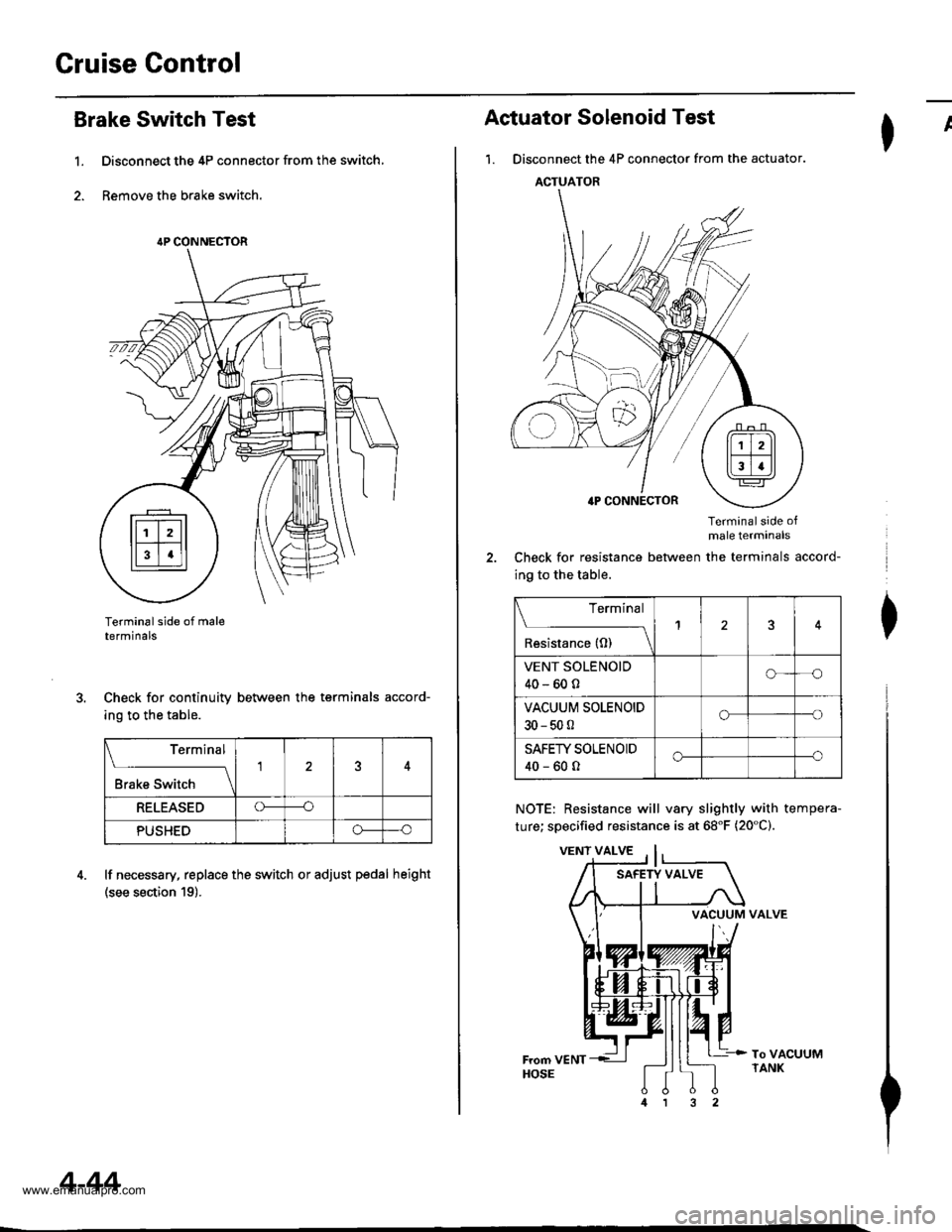

Cruise Control

Brake Switch Test

1. Disconnect the 4P connector from the switch,

2. Remove the brake switch.

Terminal side of maletermtnals

Check for continuity between the terminals accord-

ing to the table.

lf necessary, replace the switch or adjust pedal height

(see section 19).

{P CONNECTOR

Terminal

;;;;-t

15

RELEASEDO----o

PUSHEDo--o

4-44

ACTUATOR

Actuator Solenoid Test

1. Disconnect the 4P connector from the actuator.

Terminalside ofmale terminals

Check for resistance between the terminals accord-

ing to the table.

NOTE: Resistance will vary slightly with tempera-

ture; specified resistance is at 68"F (20"C).

VALVE

I

I

I

To VACUUMTANK

Terminal

il',",""*(t)

_\13

VENT SOLENOID

40-600o--o

VACUUM SOLENOIDo---o

30-500

SAFEW SOLENOID

40-600o----o

VACUUM

www.emanualpro.com

Page 116 of 1395

Valve Clearance

Adiustment

Adjust the valves only when the cylinder head tempera-

ture is less than 100"F (38"C).

1. Remove the cylinder head cover.

Remove the middle cover (see page 6-11).

Set the No. 1 piston at TDC. The "UP" mark on the

pulleys should be at the top, and the TDC marks on

the pulleys should align with the pointers on the back

POINTERPOINTER

Adjust the valves on No. 1 cylinder.

Intake: 0.08 - 0.12 mm (0.003 - 0.005 inl

Exhaust: 0.16 - 0.20 mm (0.006 - 0.008 in)

Loosen the locknut, and turn the adiustment screw

until the feeler gauge slides back and forth with a

slight amount of drag.

LOCI(NUT9 x 0.75 m.n

Adiusting Screw Locations:

INTAKE

No.4 No.3 No.2

(cont'd)

6-3

25 N.m 12.5 kgf.m, 18lbf.ft)

EXHAUST

No. 1

www.emanualpro.com