prop shaft HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 448 of 1395

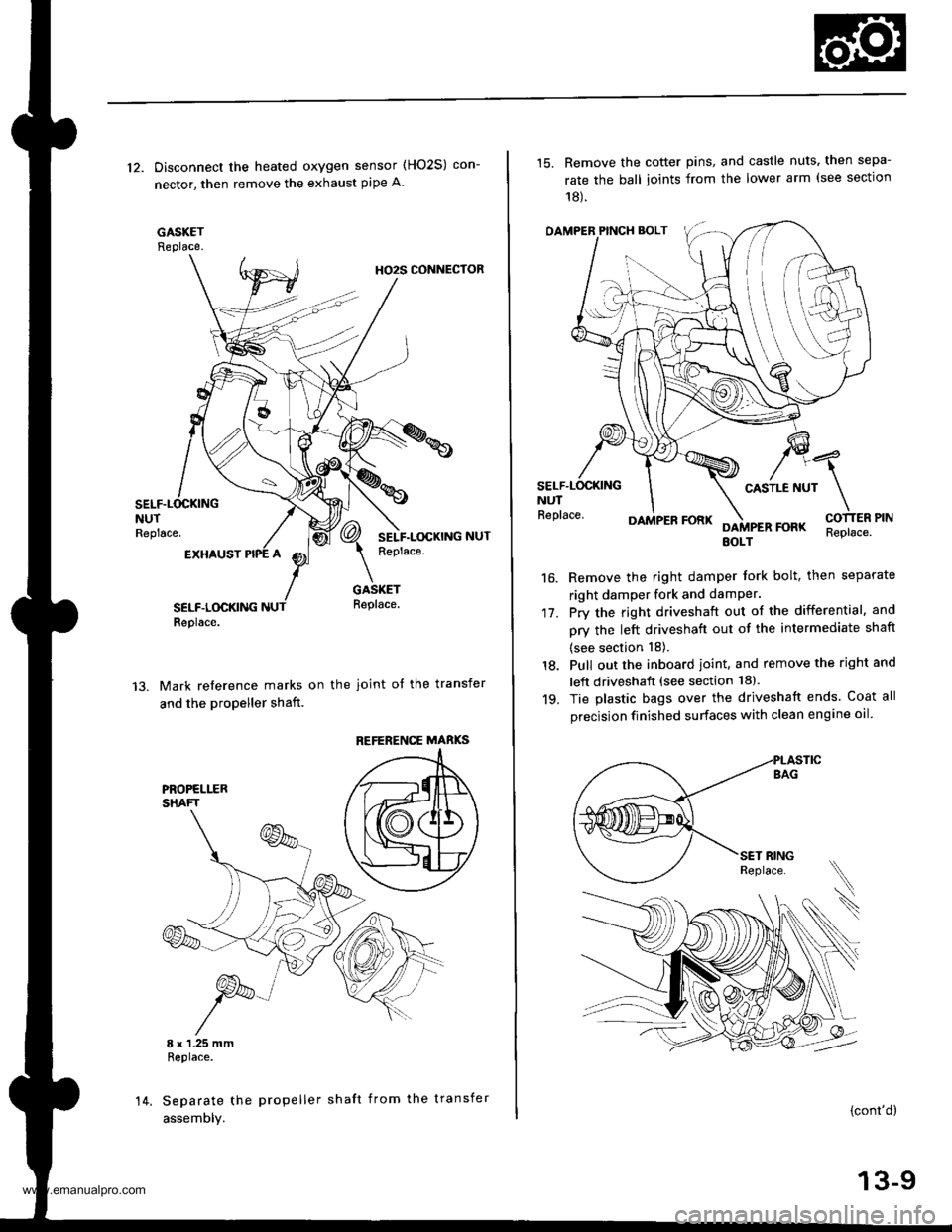

12. Disconnect the heated oxygen sensor (HO2S) con-

nector, then remove the exhaust pipe A.

GASKETReplace.

HO2S CONNECTOR

NUTReplace.

EXHAUST

SELF.LOCKINGReplace.

GASKETReplace.

Mark reference marks on the joint of the transfer

and the propeller shaft.

8 x 1.25 mmReplace.

Separate the propeller shaft from the transfer

assemDly.

REFERENCE MABKS

14.

15. Remove the cotter pins, and castle nuts. then sepa-

rate the ball ioints from the lower arm (see sectlon

18).

OAMPER PINCH BOLT

CASTLE NUTNUTReplace.

17.

16.

DAMPER FORKFOFKEOLTReplace.

Remove the right damper tork bolt, then separate

right damper fork and damPer.

Pry the right driveshaft out of the differential, and

pry the left driveshaft out of the intermediate shaft

(see section 18).

Pull out the inboard ioint, and remove the right and

left driveshaft (see section 18).

Tie plastic bags over the driveshatt ends. Coat all

precision finished surfaces with clean engine oil

18.

19.

\

{cont'd}

13-9

www.emanualpro.com

Page 503 of 1395

Mainshaft Thrust Clearance

Adjustment

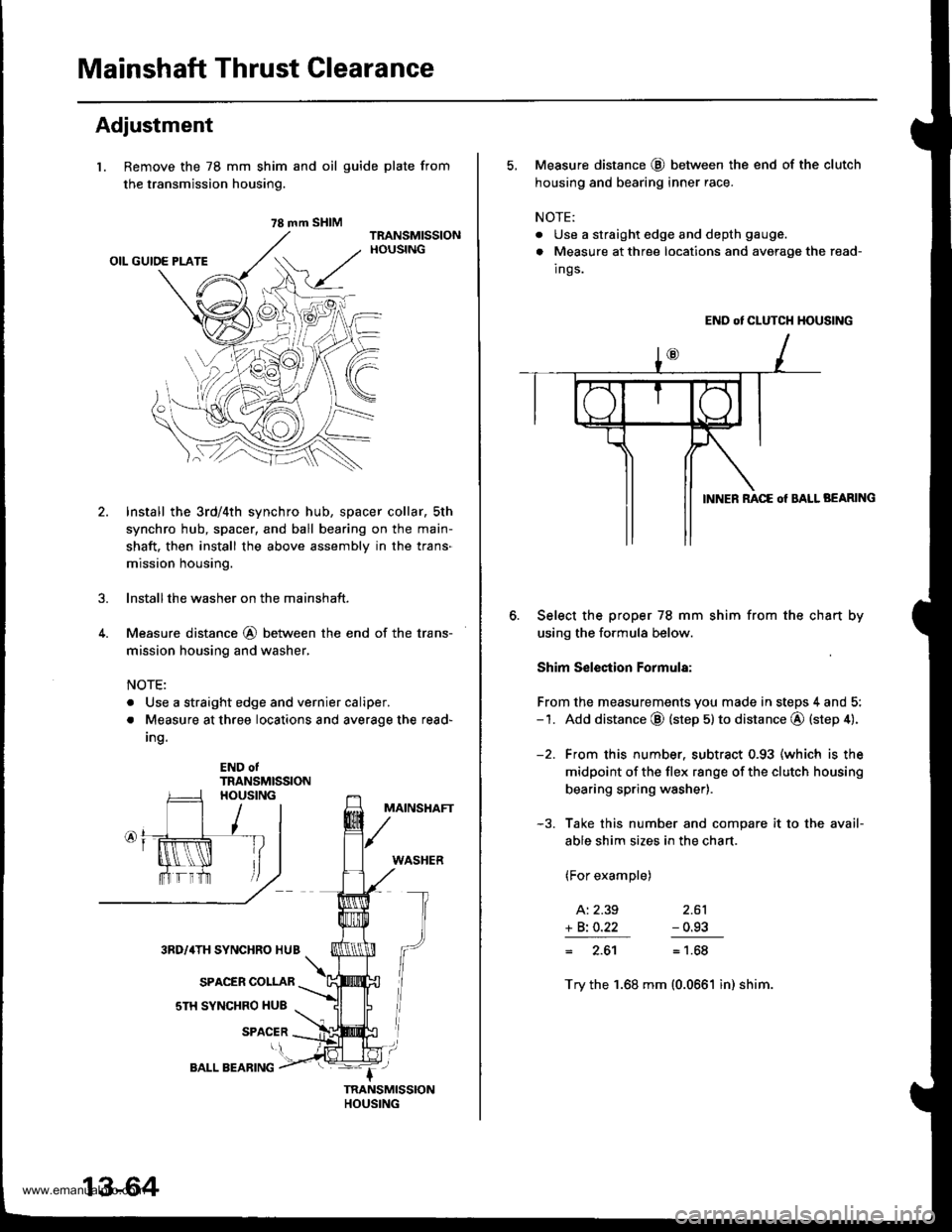

l. Remove the 78 mm shim

the transmission housing.

4.

and oil guide plate from

Install the 3rd/4th synchro hub, spacer collar, sth

synchro hub, spacer, and ball bearing on the main-

shaft. then install the above assembly in the trans-

mission housing.

lnstallthe washer on the mainshaft.

Measure distance @ between the end of the trans-

mission housing and washer,

NOTE:

. Use a straight edge and vernier caliper.

. Measure at three locations and average the read-

Ing.

END otTRANSMISSION

MAINSHAFT

WASHER

3RD/4TH SYNCHRO HUB

SPACER COLLAR

sTH SYNCHRO HUB

SPACER

78 mm SHIM

13-64

BALL BEARING

5, Measure distance @ between the end of the clutch

housing and bearing inner race.

NOTE:

. Use a straight edge and depth gauge.

. Measure at three locations and avorage the read-

Ings.

END ot CLUTCH HOUSING

BEARING

Select the proper 78 mm shim from the chan by

using the formula below.

Shim S€lection Formula:

From the measurements you made in steps 4 and 5:-1. Add distance @ (step 5) to distance @ (step 4).

-2. From this number. subtract 0.93 (which is the

midpoint of the flex range of the clutch housing

bearing spring washer).

-3. Take this number and compare it to the avail-

able shim sizes in the chart.

(For example)

A: 2.39 2.61

+ Bi O.22 - 0.93

= 2.61= 1.68

Try the 1.68 mm (0.0661 in) shim.

www.emanualpro.com

Page 504 of 1395

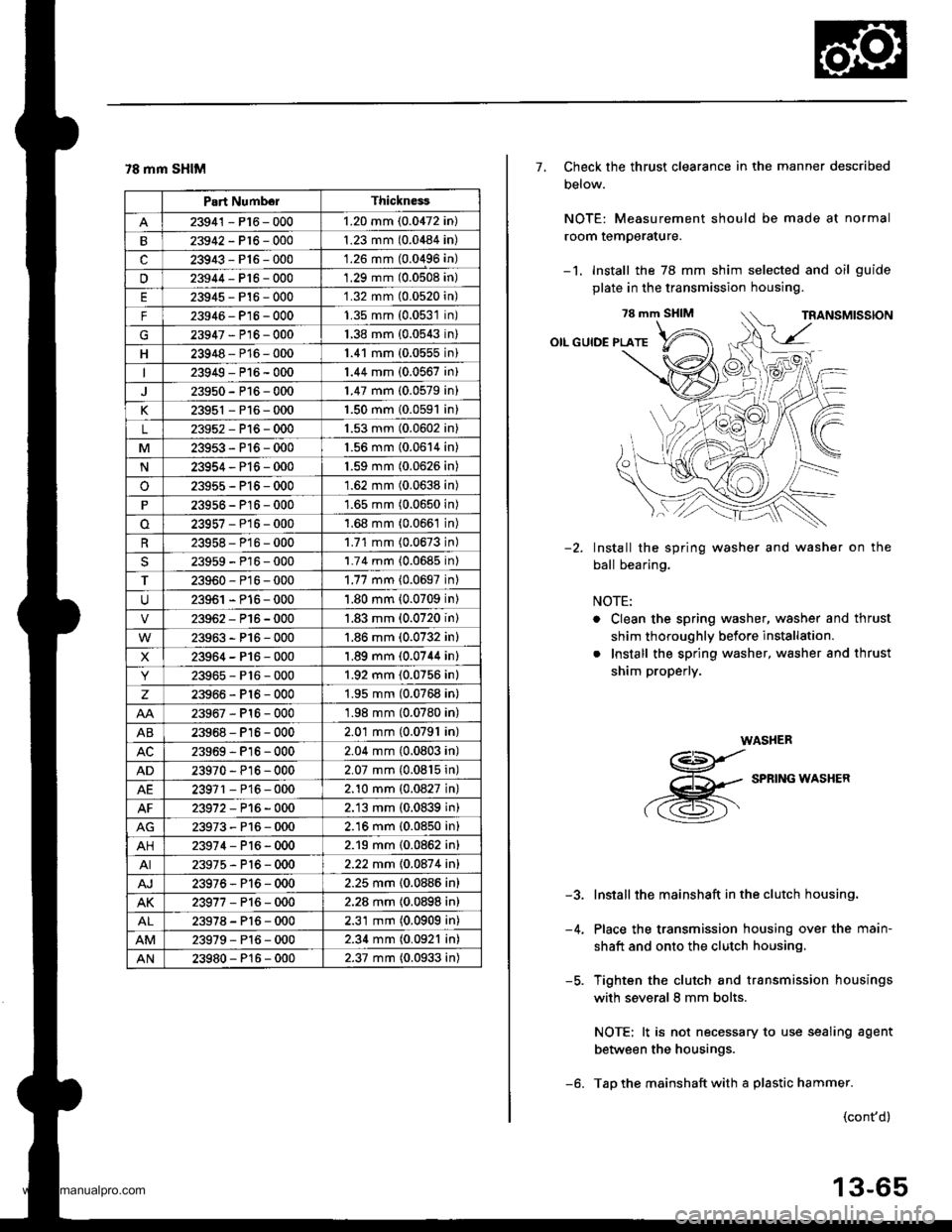

78 mm SHIM

Part NumborThickness

23941 - P16 - 0001.20 mm (0.0472 in)

23942-P16-0001.23 mm (0.0484 in)

c23943-P16-000'1.26 mm (0.0496 in)

u23944-Pt6-0001.29 mm (0.0508 in)

23945-P16-0001.32 mm (0.0520n)

F23946- P16 - 0001.35 mm (0.0531n)

G23947-P16-0001.38 mm {0.0543n)

H23948-P16-0001.41 mm (0.0555n)

23949-P16-0001.44 mm (0.0567 in)

23950-P16-0001.47 mm (0.0579 in)

K23951 - P16 - 0001.50 mm {0.0591 in}

L23952-Pl6-0001.53 mm (0.0602 in)

M23953-P16-0001.56 mm (0.0614 in)

N23954-P16-0001.59 mm (0.0626 in)

o23955-P15-0001.62 mm (0.0638 in)

23956 - P16 - 0001.65 mm (0.0650 in)

23957-P16-0001.68 mm (0.066't in)

23958- P16 - 0001.71 mm (0.0673 in)

23959-P16-0001.74 mm {0.0685 in)

T23960-P16-0001.77 mm {0.0697 inl

23961 - P16 - 0001.80 mm (0.0709 in)

23962-P16-0001.83 mm (0.0720 in)

23963-P16-000'1.86 mm (0.0732 in)

X23964-P16-0001.89 mm (0.0744 in)

23965-P16-0001.92 mm (0.0756 in)

z23966-Pl6-0001.95 mm (0.0768 in)

23967-Pl6-0001.98 mm (0.0780 in)

AB23968-P16-0002.01 mm (0.0791 in)

23969-Pl6-0002.04 mm (0.0803 in)

AD23970 - Pl6-0002.07 mm {0.0815 in)

AE23971 - P16 - 0002.10 mm {0.0827 in}

23972-P16-0002.13 mm (0.0839 in)

23973-P16-0002.16 mm (0.0850 in)

AH23974-P16-0002.19 mm (0.0862 in)

AI23975-P16-0002.22 mm 10.087 4 inl

AJ23976-Pl6-0002.25 mm {0.0886 in}

AK23977-P16-0002.28 mm {0.0898 in)

23978-Pl6-0002.31 mm (0.0909 in)

23979-Pl6-0002.34 mm (0.0921 in)

AN23980-P16-0002.37 mm (0.0933 in)

7, Check the thrust clearance in the manner described

Delow.

NOTE: Measurement should be made at normal

room temperature.

-1. Install the 78 mm shim selected and oil guide

plate in the transmission housing.

78 mm SHIM

OIL GUIDE PLATE

Install the spring washer and washer on the

ball bearing.

NOTE:

. Clean the spring washer, washer and thrust

shim thoroughly before installation.

. Install the spring washer, washer and thrust

shim properly.

WASHER

g

,-g

SPRTNG*ASHER

Install the mainshaft in the clutch housing.

Place the transmission housing over the main-

shaft and onto the clutch housing.

Tighten the clutch and transmission housings

with several 8 mm bolts.

NOTE: lt is not necessary to use sealing agent

between the housings.

Tap the mainshaft with a plastic hammer.

-2.

-5.

(cont'd)

13-65

www.emanualpro.com

Page 513 of 1395

Transmission Assembly

Installation (cont'dl

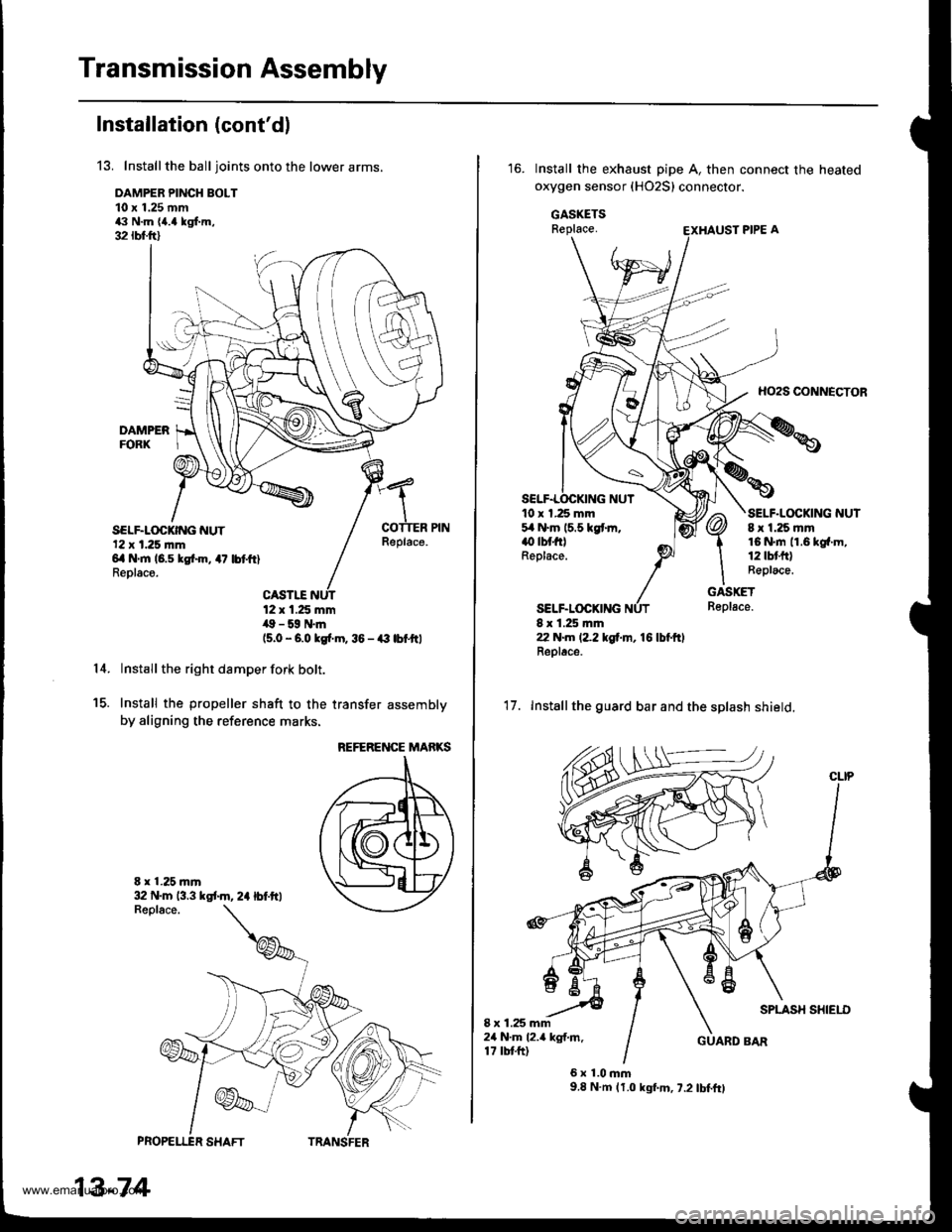

13. Installthe balljoints onto the lower arms.

DAMPER PINCH BOLT10 x 1.25 mm43 N.m {a.a kgf.m,32 rbfft)

SELF.LOCKING NUT'12 x 1.25 |nm6il N'm 16.5 kgtin, 47 lbtftlReolace.

Replace.

14.

PROPELI"ER SHAFT

13-74

12 x 1.25 mm,19 - 59 N.m(5.0 - 6.0 kgi.m, 36 - € lbfttl

Install the right damper fork bolt.

Install the propeller shaft to the transfer assembly

by aligning the reference marks.

E x 1.25 mr'|

15.

REFERENCE MARKS

32 N.m 13.3 kst m, 2a lbf.ftl

TRANSFER

Install the exhaust pipe A, then connect the heated

oxygen sensor (HO2S) connector.

GASKETSReplace.

HO2S CONNECTOR

10 x 1.25 mm5,1N.m 15.5 kgtm.() tbt filReplace.

SELF.LOCKING

SELF.LOCKING NUT8 x 1.25 mm16 N.rn 11.6 kg{.m,12lbtfr)Replace.

GASKETReplace.

8 x 1.25 rr|ln22 N.m (2.2 tgf.m, 16 lbl.ftlReplac6.

'17. Installthe guard bar and the splash shield.

SPLASH SHIEI.I)I x 1.25 mm24 N.m l2.a kgf.m.17 tbtft)GUARD BAR

6x1.0mm9.8 N.m (1.0 kgf.m, 7.2 lbf.ft)

www.emanualpro.com

Page 543 of 1395

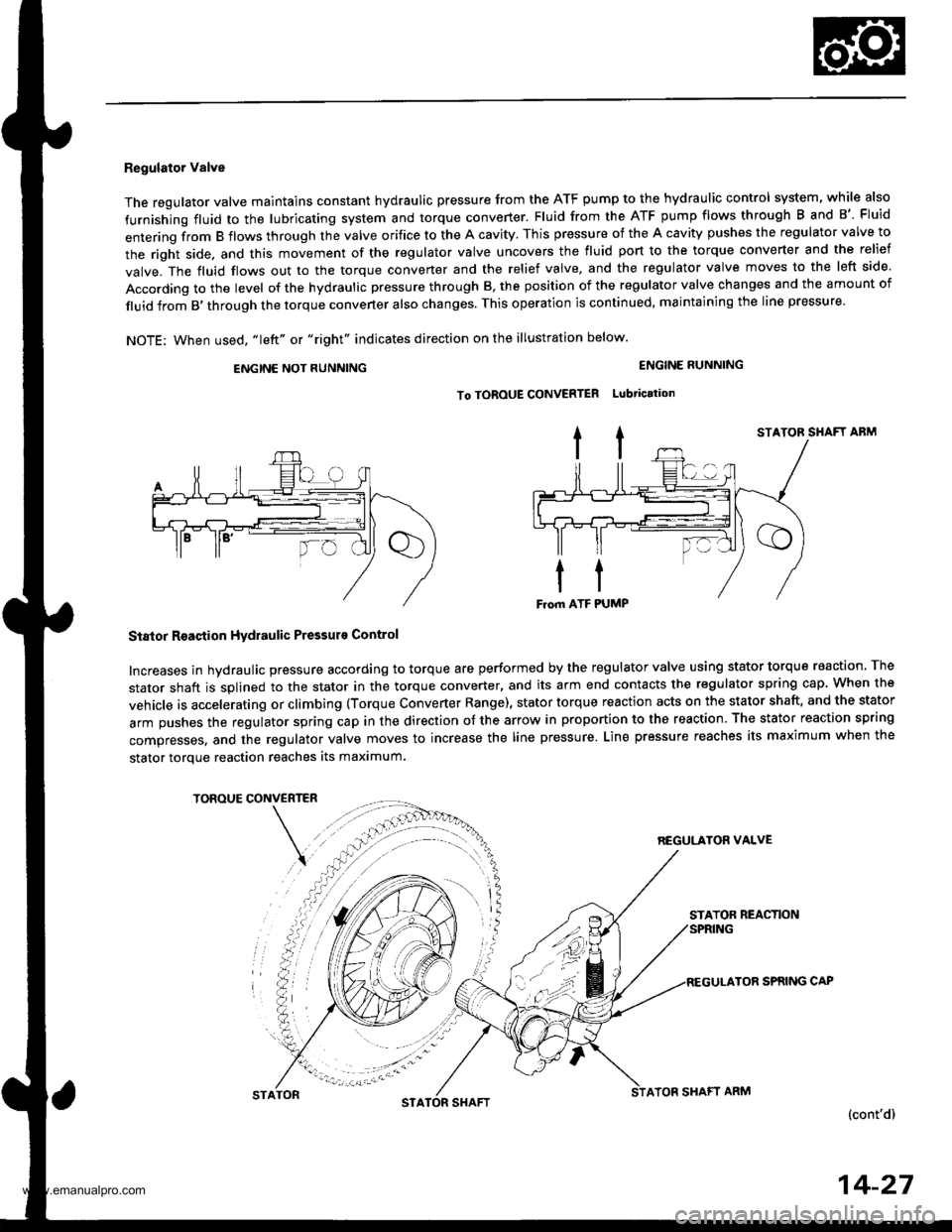

Regulator Valve

The regulator valve maintains constant hydraulic pressure from the ATF pump to the hydraullc control system, while also

furnishing fluid to the lubricating system and torque converter. Fluid from the ATF pump flows through B and B'. Fluid

entering from B flows through the valve orifice to the A cavity. This pressure of the A cavity pushes the regulator valve to

the right side. and this movement of the regulator valve uncovers the fluid port to the torque converter and the relief

valve. The fluid flows out to the torque converter and the relief valve, and the regulator valve moves to the left side.

According to the level of the hydraulic pressure through B, the position of the regulator valve changes and the amount of

fluid from B,through the torque converter also changes. This operation is continued, maintaining the line pressure.

NOTE; When used, "|eft" or "right" indicates direction on the illustration below.

ENGINE NOT RUNNING

STATOR SHAFT ABM

Stator Reaction Hydraulic Pressurs Control

Increases in hydraulic pressure according to torque are performed by the regulator valve using stator torque reaction. The

stator shaft is splined to the stator in the torque converter, and its arm end contacts the regulator spring cap When the

vehicle is accelerating or climbing (Torque Converter Range), stator torque reaction acts on the stator shaft, and the stator

arm pushes the regulator spring cap in the direction of the arrow in proportion to the reaction. The stator reaction spring

compresses, and the regulator valve moves to increase the line pressure. Line pressure reaches its maximum when the

stator torque reaction reaches its maximum.

TOROUE CONVERTER

REGULATON VALVE

STATOR REACTION

TOR SPRING CAP

(cont'd)

ENGINE RUNNING

To TOROUE CONVERTER Lubtication

STATONSTASHAFTATOF SHAFT ARM

14-27

www.emanualpro.com

Page 560 of 1395

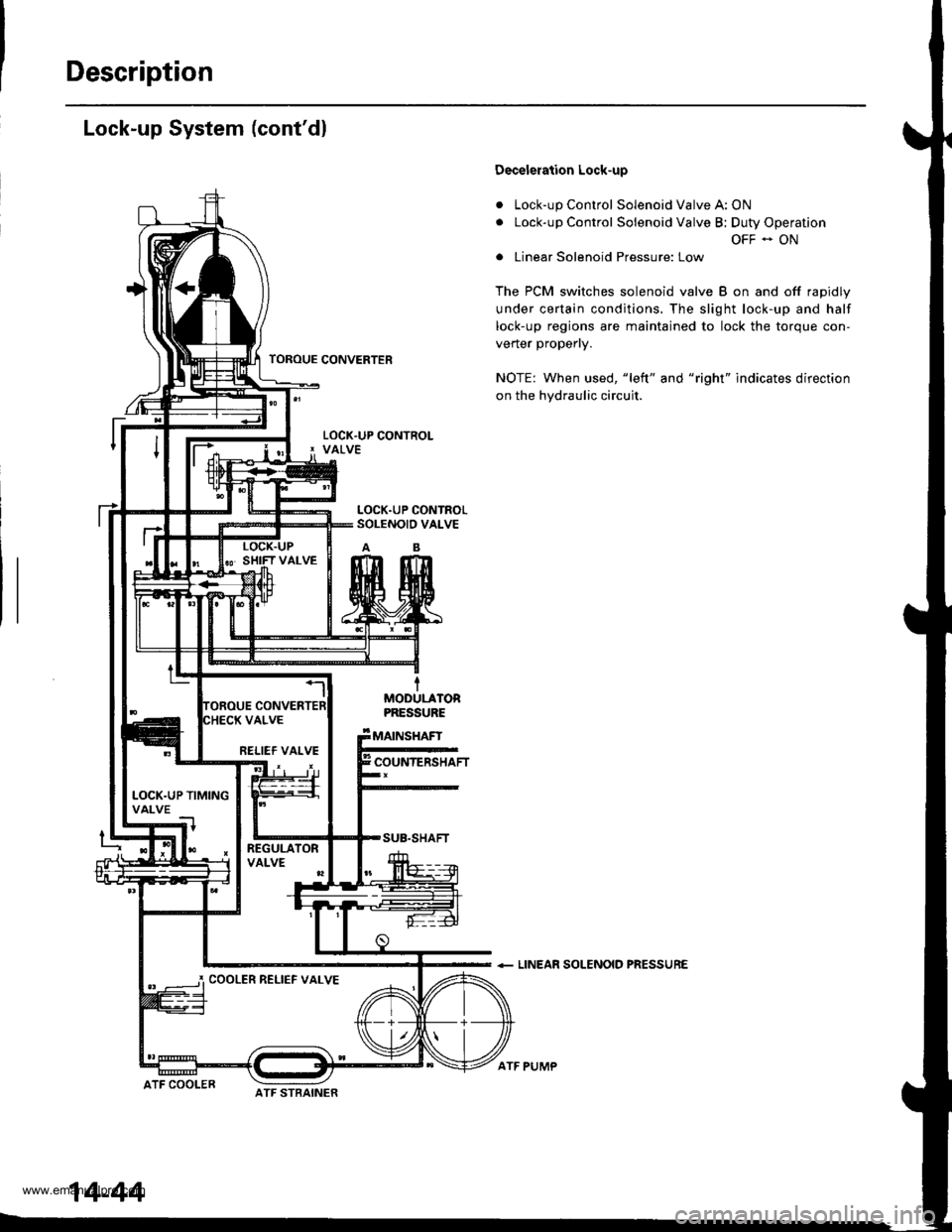

Description

Lock-up System (cont'dl

a

a

Decelelation Lock-up

Lock-up Control Solenoid Valve A: ON

Lock-up Control Solenoid Valve B; Duty Operation

OFF - ON

Linear Solenoid Pressure: Low

The PCM switches solenoid valve B on and off rapidly

under certain conditions. The slight lock-up and half

lock-up regions are maintained to lock the torque con-

vener propeny.

NOTE: When used, "left" and "right" indicates direction

on the hydraulic circuit.

+ LINEAR SOLENOID PRESSURE

TOROUE CONVERTER

tMOOULATORPRESSURE

MAINSHAFT

COUNTERSHAFT

SUB.SHAFT

ATF COOLER

RELIEF VALVE

LOCK.UP TIMINGVALVE

COOLER RELIEF VALVE

14-44

ATF STBAINER

ATF PUMP

www.emanualpro.com

Page 592 of 1395

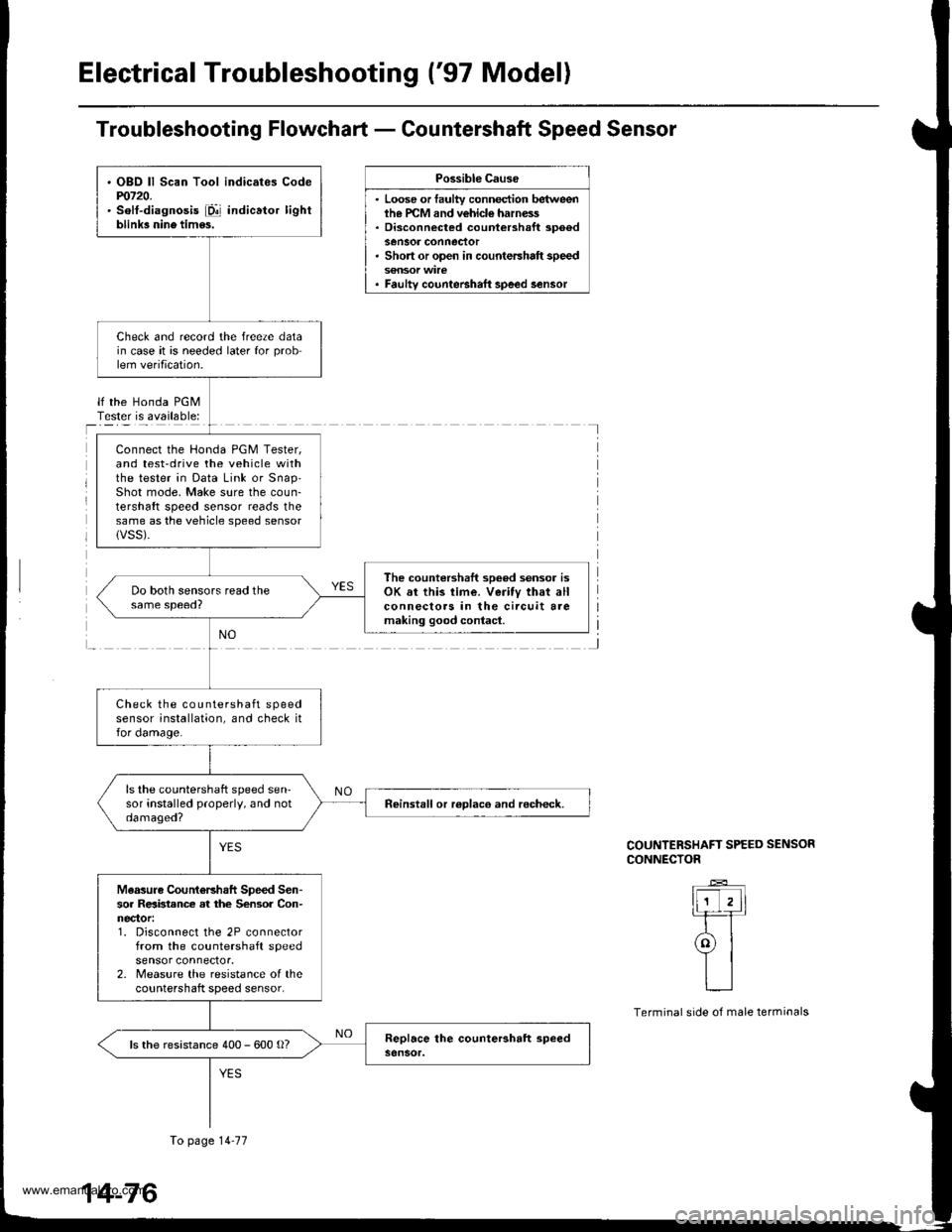

Electrical Troubleshooting ('97 Model)

Troubleshooting Flowchart - Countershaft Speed Sensor

Possible Cause

. Loose or faulty connection betweenih€ PCM and vehicle harness. Disconnected countershaft spoedsensor conneclor. Short or open in countershaft speed

. Faulty counteBhaft speed lensor

lf the Honda PGMTester is available:I

J

COUNTERSHAFT SPEED SENSOR

CONNECTOR

ll-'T,ll-rT

ral

YIL__l

Terminal side of male terminals

. OBO ll Scan Tool indicates Codem720.' solt-diagnosis iD!' indicator lightblink3 nine tim6s.

Check and record the freeze datain case it is needed later for problem verification.

Connect the Honda PGM Tester,and test-drive the vehicle withthe tester in Data Link or snap'Shot mode, Make sure the coun-tershaft speed sensor reads thesame as the vehicle speed sensorlVSS).

The countershaft sooed sensor isOK sr this time. Veritv that allconnecloas in the circuit aremaking good contacl.

Check the countershaft speedsensor installation, and check itfor damage.

ls the countershaft speed sen-sor installed properly, and notdamaged?neinstall or roDlaco and recheck.

Measuro CountoBhaft Speed Sen-sor Relbtance at the Sensor Con-nector:1. Disconnect the 2P connectorfrom the countershaft speedsensor connector.2. Measure the resistance of thecountershaft speed sensor.

ls the resistance 400 - 600 o?

To page 14-77

14-76

www.emanualpro.com

Page 594 of 1395

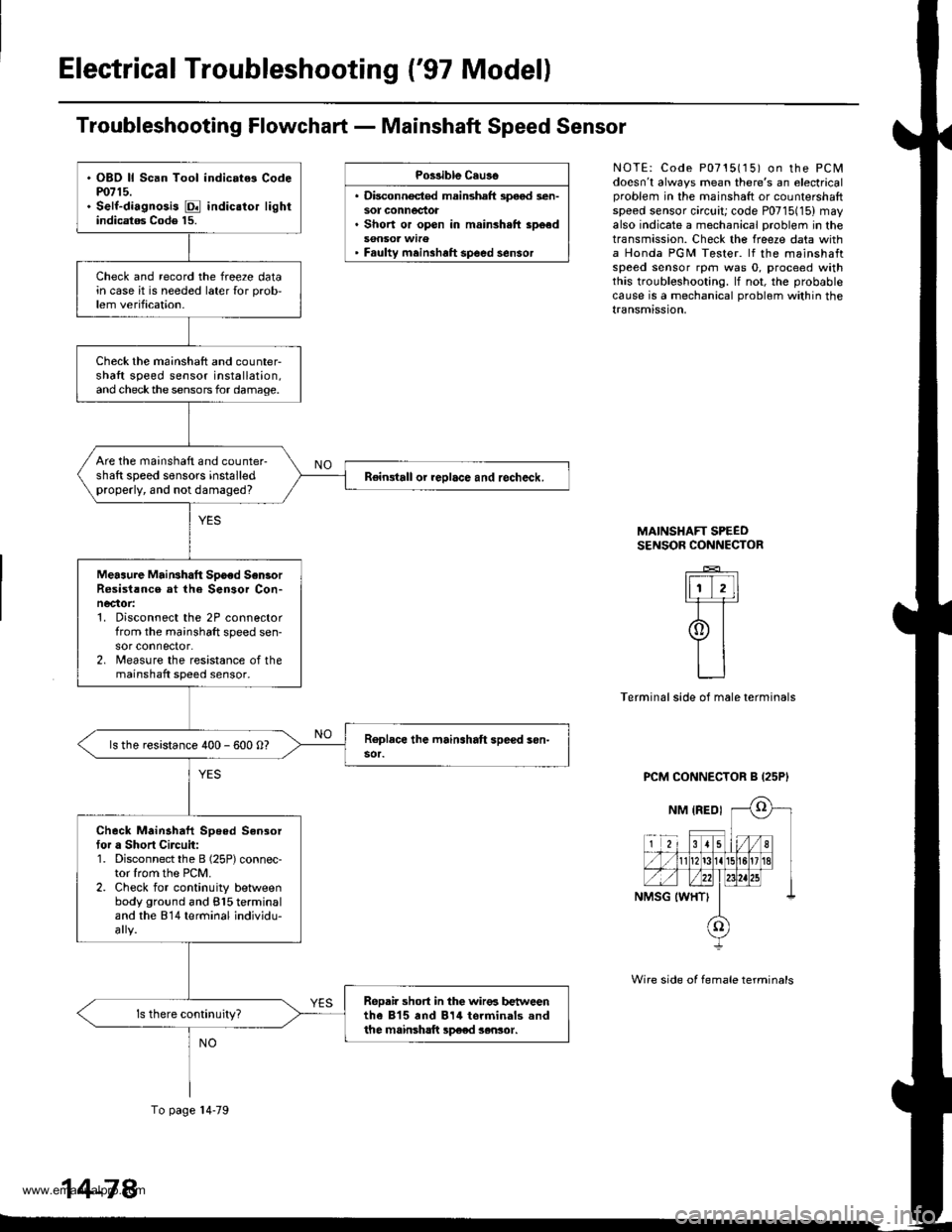

Electrical Troubleshooting {'97 Model)

Troubleshooting Flowchart - Mainshaft Speed Sensor

Po$ible Cau3o

. Disconnocted mainshaft speod sen-sot connectot. Short or open in mainsh.ft sp6ed

' Faulty meinshaft spoed sensor

NOTE: Code P0715115) on the PCMdoesn't always mean there's an electricalproblem in the mainshaft or counlersharlspeed sensor circuit; code P0715(15) mayalso indicate a mechanical problem in thetransmission. Check the freeze data witha Honda PGM Tester. lf the mainshaftspeed sensor rpm was 0, proceed withthis troubleshooting. lf not, the probablecause is a mechanical problom within thetransmission,

MAINSHAFT SPEEOSENSOR CONNECTOR

_E_

ItiT,ll-F=r

9t

LJ

Terminal side of male terminals

PCM CONNECTOR B {25P'

Wire side of female terminals

. OBD ll Scan Tool indic.t6 Codem715.. Self-diagnosis E indic.tor lightindicatag Code 15.

Check and record the freeze datain case it is needed later {or prob,lem verification.

Check the mainshaft and counter-shaft speed sensor installation,and checkthe sensors for damage.

Are the mainshaft and counter-shaft speed sensors installedproperly, and not damaged?Reingtall or reolace and recheck.

Meaaure MaiNhatt Spoed Sen3orR6sist!nce at the Sensor Con-necaor:1. Disconnect the 2P connectorfrom the mainshaft speed sen-sor connector.2. lreasure the resistance of themainshaft speed sensor.

ls the resistance 400 - 600 O?

Check Mainahaft Speed Sensortor a Short Circuit:1. Disconnect the B (25P) connec-tor lrom the PCM.2. Check for continuity betlveenbody ground and 815 terminaland the 814 terminal individu-

ReDair short in the wir€6 b€t reenthe 815 and 814 torminals andthe mainsh!ft sp€ed sensor.

To page l4-79

14-78

www.emanualpro.com

Page 628 of 1395

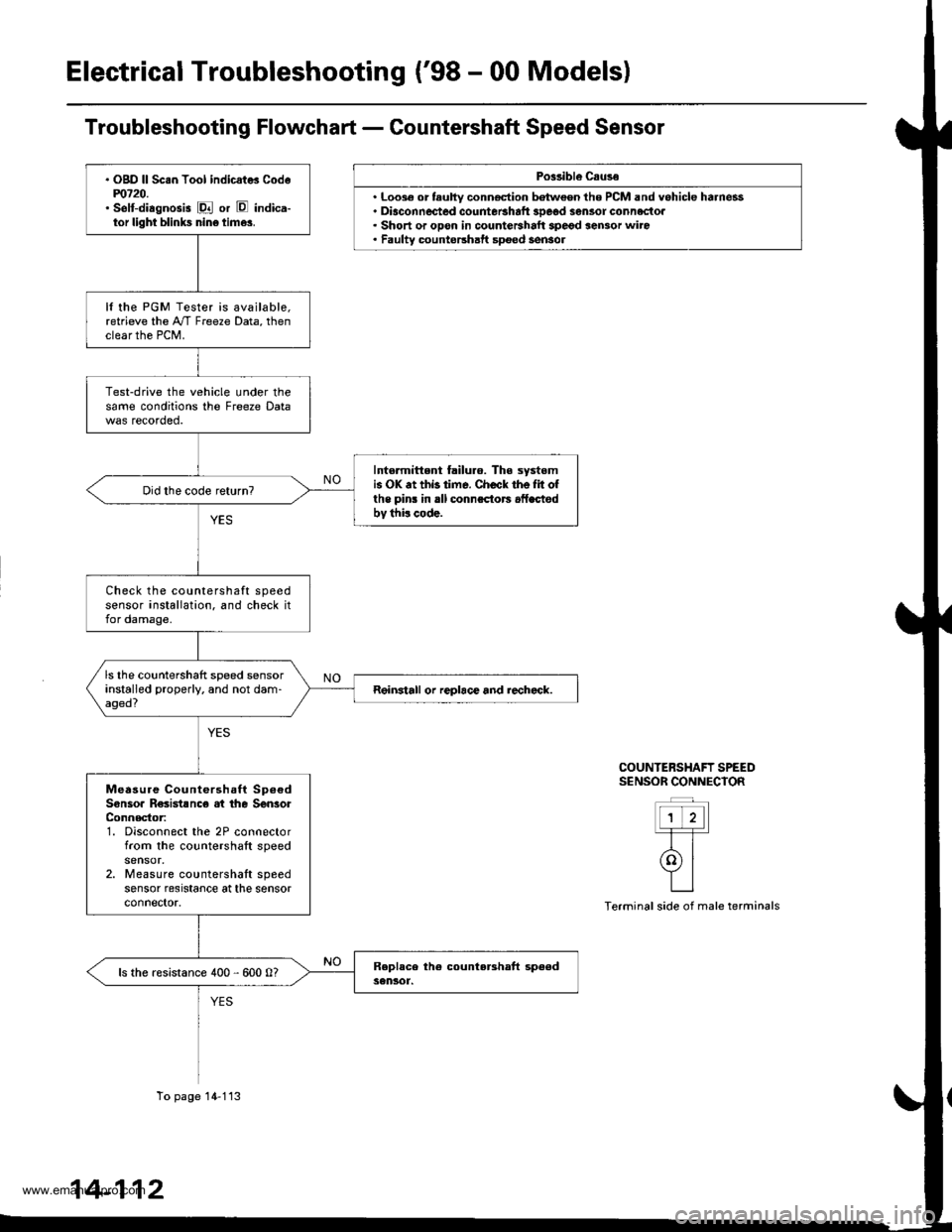

Electrical Troubleshooting ('98 - 00 Models)

Po$ibl€ Csuse

. Loo3€ or tauhy conn€ction batween the PCM and vehicle harness. Diaconnected countetshaft 3Deod sensor connectoa. Short or opon in countershalt spegd sensor wiro. Faulty countershatt spoed sensol

COUNTERSHAFT SPEEDS€NSOR CONNECIOR

ttt'l-T-T-

rolYILI

Terminal side of male terminals

. OgD ll Sc.n Tool indicat* Codem720.' selt-diagnosis E or E indica-tor light blinks nin6 time3.

It the PGM Tester is available,retrieve the A"/T Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freeze Data

Intormittent failuro. The systomis OK .t thb time. Check the Iit ofthe pins in rll connsctors .fLctodbv thi! code.

Check the countershaft speedsensor installation. and check itfor damage.

ls the countershaft speed sensorinstalled properly. and not dam-aged?Reinstall or replace and rechcck.

Measure Countershaft Sp6€dSonsoa R€sistsnc€ at the SenlorConnector:1. Disconnect the 2P connectorfrom the countershaft speed

2. Measure countershaft speedsensor resrstance at the sensorconnector.

ls the resistance 400 - 600 0?

To page 14-113

14-112

www.emanualpro.com

Page 630 of 1395

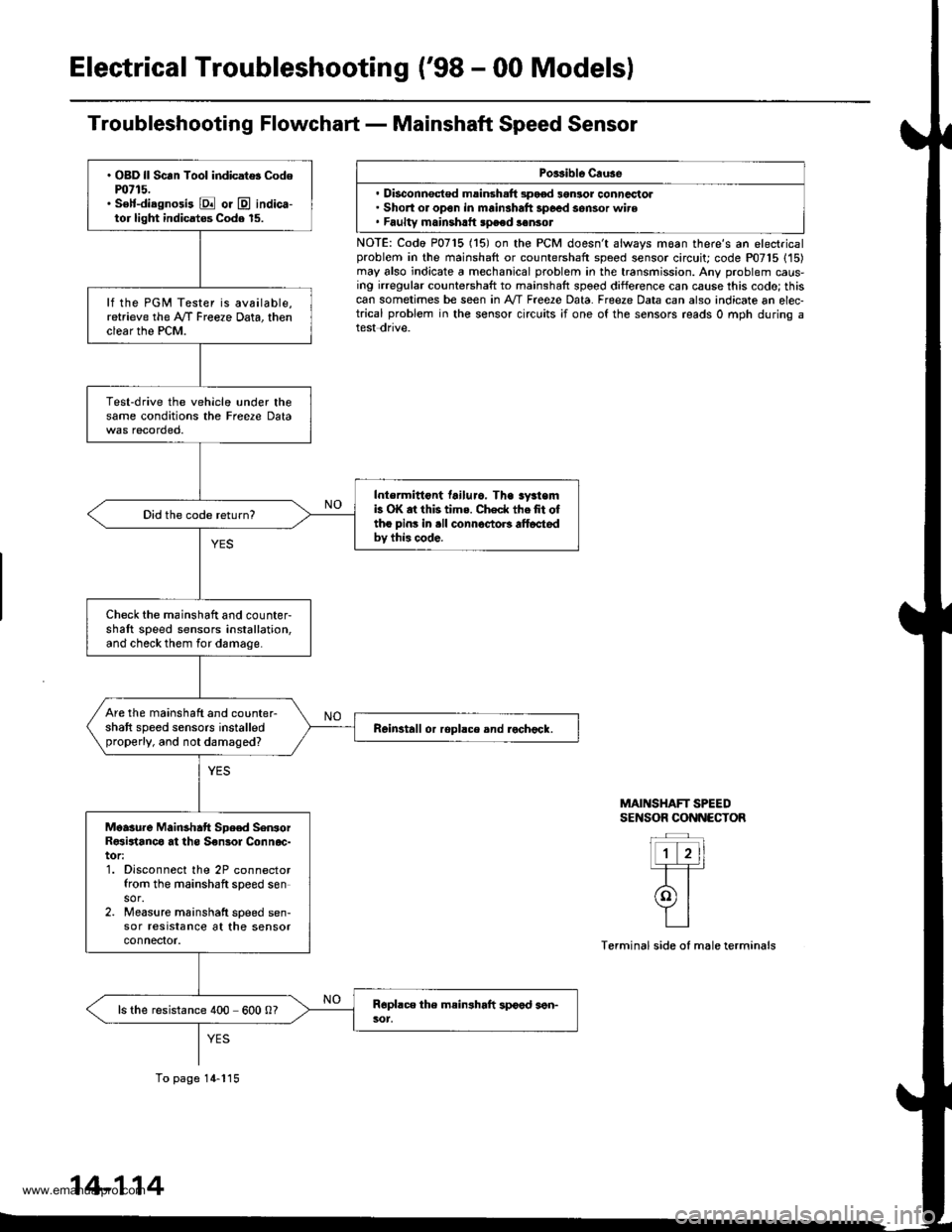

Electrical Troubleshooting ('98 - 00 Modelsl

Troubleshooting Flowchart - Mainshaft Speed Sensor

Porsible Cruse

. Disconnsct€d msinsh.ft 3pood 3gnlor conncctol. Short or open in mainshaft 3poed sensor wire. Faultv mainshrtt speed sonsot

NOTE: Codo P0715 (15) on the PCM doesn't always moan there's an electricalproblem in the mainshaft or countershaft speed sensor circuit; code P07'15 (15)may also indicate a mechanical problem in the transmission. Any problem caus-ing irregular countershaft to mainshaft spoed difference can cause this codo; thiscan sometimes be seen in A'/T Free2e Data. Freeze Data can also indicate an elec-trical problem in the sensor circuits ;f one of the sensors reads 0 mph during atest dnve.

MAINSHAFT SPEEDSENSOR CONNECTOR

Terminal side of male terminals

. OBD ll Scan Tool indicat$ Codem715.. S€lf-diagnosi3 E or @ indica-tor light indicatos Code 15.

lf the PGM Tester is available,retrieve the A/f Freeze Data, thenclear the PCM.

Test-drive the vehicle under thesame conditions the Freere Data

Intermittont tailuro. Tha sy3temb OK at this tims. Check thefit oftho pins in .ll connoctoB alt6ctedbv this code.

Did the code return?

Check the mainshaft and counter-shaft speed sensors installation,and check them for damage.

Are the mainshaft and counter-shaft speed sensors installedproperly, and not damaged?Reinstall or ropllce and rochock.

Moasure Mainshatt Spe€d SenrorR€sirtanco at ths S€nsol Connoc-tor:1. Disconnect the 2P connectorfrom the mainshaft speed sensor.2. Measure mainshatt speed sen-sor resrstance at the sensorconnefior.

ls the resistance 400 600 0?

To page 14-115

14-114

www.emanualpro.com