right front mount HONDA CR-V 1998 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 903 of 1395

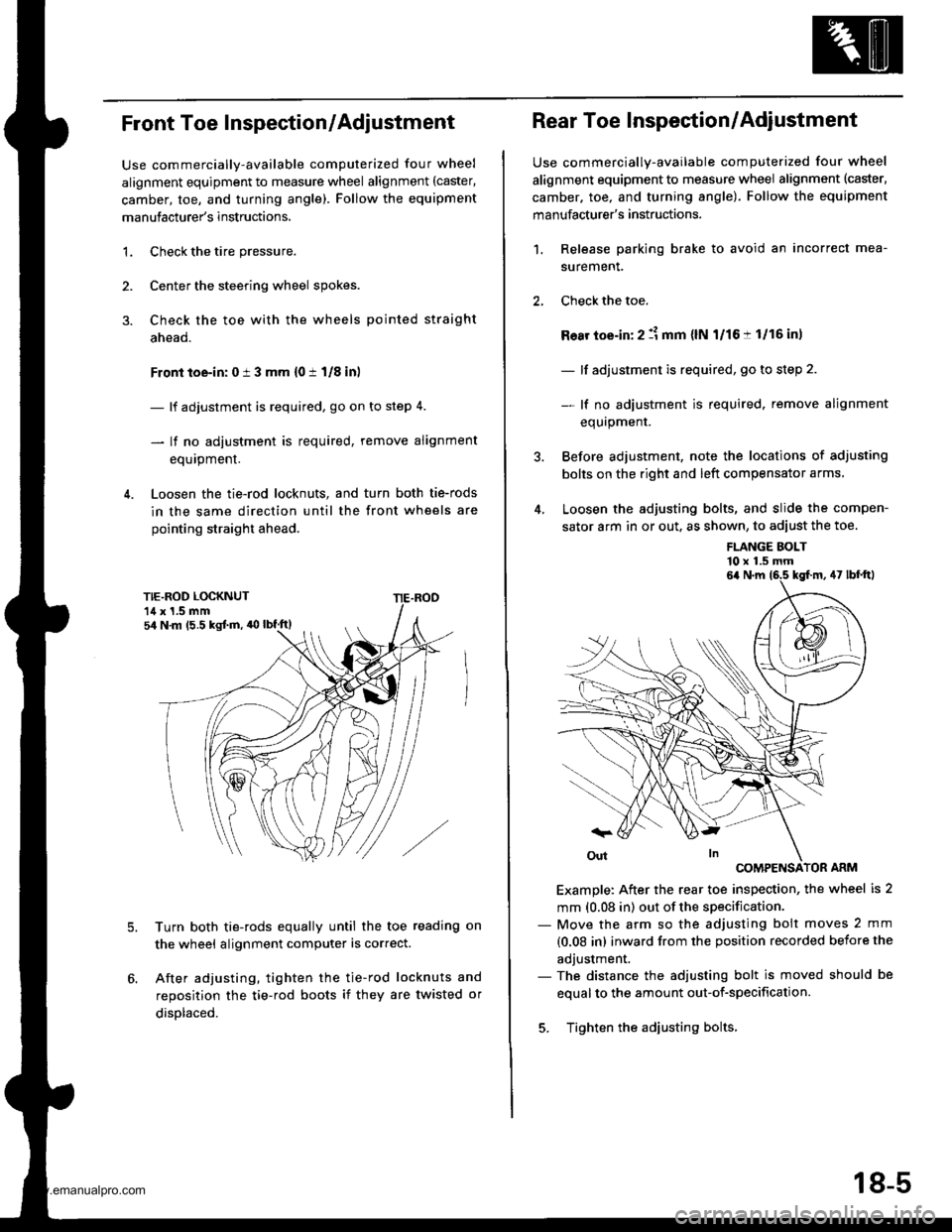

Front Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment (caster,

camber, toe, and turning angle). Follow the equipment

manufacturer's instructions,

3.

1.Check the tire pressure.

Center the steering wheel spokes.

Check the toe with the wheels pointed straight

ahead.

Front toe-in: 0 i 3 mm {0 t 1/8 inl

- lf adjustment is required, go on to step 4.

- lf no adjustment is required, remove alignment

equipment.

Loosen the tie-rod locknuts, and turn both tie-rods

in the same direction until the front wheels are

pointing straight ahead.

5.Turn both tie-rods equally until the toe reading on

the wheel alignment computer is correct.

After adjusting, tighten the tie-rod locknuts and

reposition the tie-rod boots if they are twisted or

displaced.

sir N m (5.5 kgJ.m, 'O lbf.ft)

Rear Toe Inspection/Adjustment

Use commercially-available computerized four wheel

alignment equipment to measure wheel alignment (caster,

camber. toe, and turning angle). Follow the equipment

manufacturer's instructions.

Release parking brake to avoid an incorrect mea-

surement.

Check the toe.

Ro8r toe-in: 2 :1 mm {lN l/16:t 1/16 in,

- lf adjustment is required, go to step 2.

- lf no adiustment is required. remove alignment

equrpmenr.

Before adjustment, note the locations of adjusting

bolts on the right and left compensator arms.

Loosen the adjusting bolts, and slide the compen-

sator arm in or out. as shown, to adiust the toe.

1.

FLANGE BOLT'10 x 1.5 mm

COMPENSATOR ARM

Example: After the rear toe inspection, the wheel is 2

mm (0.08 in) out of the specification.- Move the arm so the adjusting bolt moves 2 mm

{0.08 in) inward from the position recorded before the

adjustment.- The distance the adjusting bolt is moved should be

equal to the amount out-of-specification.

5. Tighten the adjusting bolts.

6a N.m 16.5 kgf.m, 47 lbf'ftl

18-5

www.emanualpro.com

Page 1088 of 1395

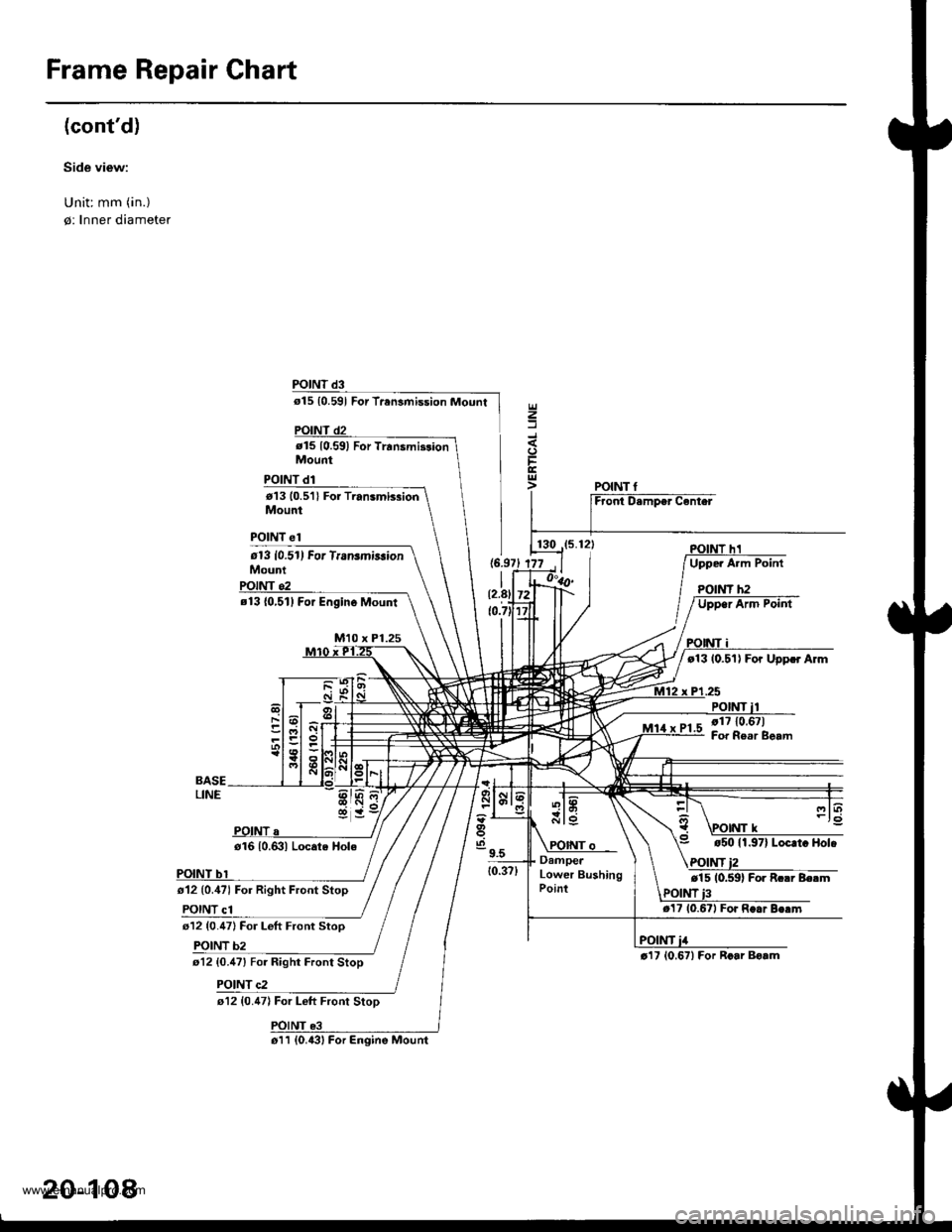

Frame Repair Chart

(cont'd)

Side view:

Unit: mm (in.)

0: Inner diamete.

POINT d3

o15 {0.591 For Trensmission Mount

d15 10.591 For Trrnsmi3donMount

POINT d1

t13 10.5'll For Transmb3ionMount

POINT el

613 10.51) For TransmirsionMouni

z

t13 {0,511 For Engin6 Mount

M10 x Pl.25

t13 10.51) For Uppcr Arm

.25

POINT,1710.67)Fof Re.r Beam

o12 (0.,171 For Right Front Stop

POINT c1

o16 10.631 Locate Hole

612 {0.47} For Left Front Stoo

b2

r12 {0.47) For Left Front StoD

t5011.97| Locrt. Hol.

POINT

t17 10.671 Fo. R..r

r'17 10.671 For Rcar Bo.mt12 {0.47} For Right Front Stop

POINT c2

130POINT h1

DamperLower BushingPoint

o11 (0.{31 For Engine Mount

20-108

www.emanualpro.com

Page 1153 of 1395

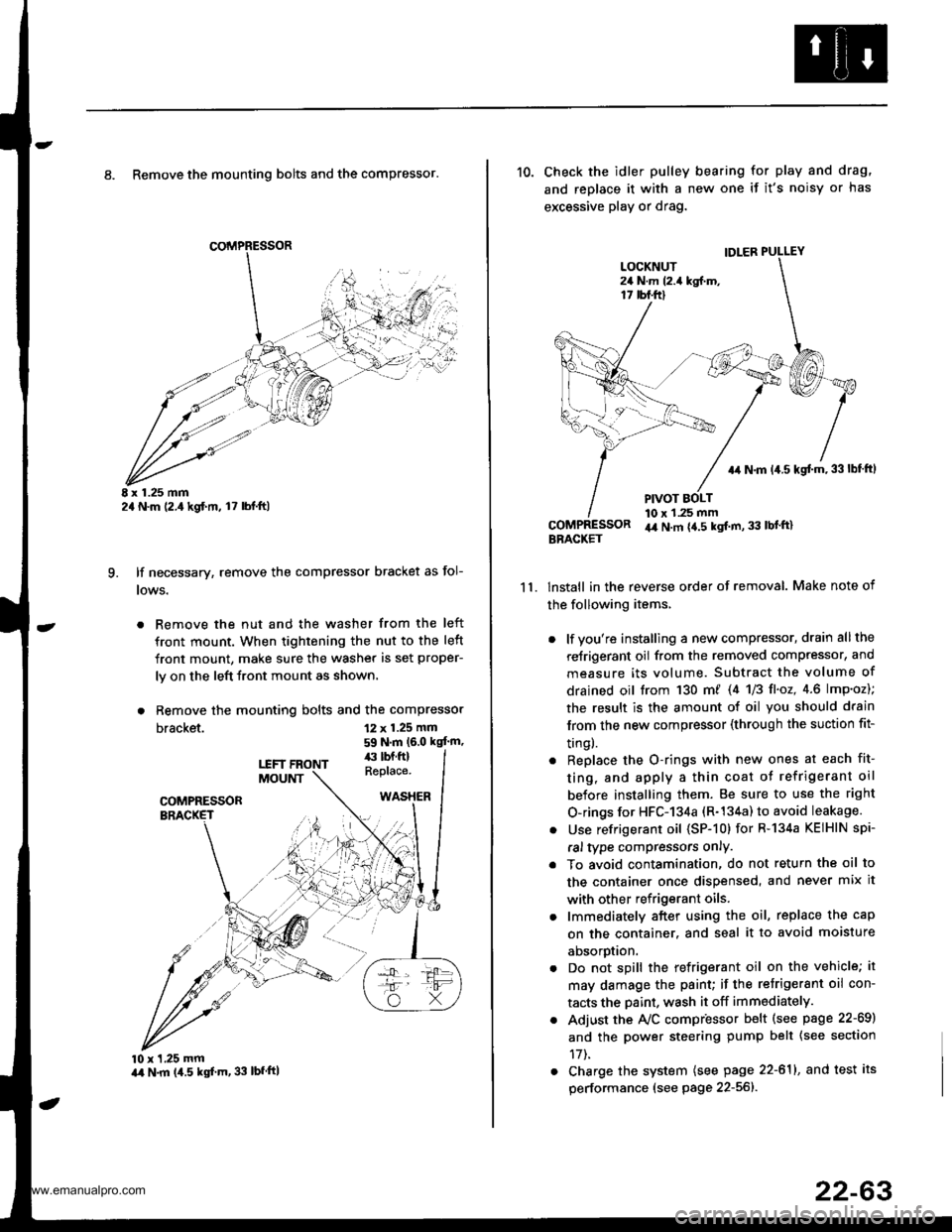

8. Remove the mounting bolts and the compressor.

E x 1.25 mm2a N.m (2.,1kgf.m, l7 lbl.ft)

lf necessary, remove the compressor bracket as fol-

lows.

. Remove the nut and the washer from the left

front mount. When tightening the nut to the left

front mount, make sure the washer is set proper-

ly on the left front mount as shown.

. Remove the mounting bolts and the compressor

bracket.

q

12 x 1.25 mm

59 N.m (6.0 kgt'm,

10 x 1,25 mmart N.m (4.5 kgf'm, 33 lbfftl

11.

10. Check the idler pulley bearing for play and drag,

and replace it with a new one if it's noisy or has

excessive play or drag.

lnstall in the reverse order of removal. Make note of

the following items,

. lf you're installing a new compressor, drain all the

reJrigerant oil from the removed compressor, and

measure its volume. Subtract the volume of

drained oil trom 130 m/ 14 U3 fl'o2,4.6 lmp'oz);

the result is the amount of oil you should drain

lrom the new compressor (through the suction fit-

trngl.

. Replace the O-rings with new ones at each fit-

ting, and apply a thin coat o{ refrigerant oil

before installing them. Be sure to use the right

O-rings for HFC-134a (R-134a) to avoid leakage.

. Use refrigerant oil (SP-10) for R-134a KEIHIN spi-

ral type compressors only.

. To avoid contamination, do not return the oil to

the container once dispensed, and never mix it

with other refrigerant oils.

. lmmediately after using the oil, replace the cap

on the container. and seal it to avoid moisture

aDsorprlon.

. Do not spill the refrigerant oil on the vehicle; it

may damage the paint; if the retrigerant oil con-

tacts the Daint, wash it off immediately.

. Adjust the Ay'C compr'essor b€lt (see psge 22-69)

and the power steering pump belt {see section

17t.

. Charge the system (see page 22-611, and test its

performance (see page 22-56]-.

IDLER PULLEY

+r N.m 14.5 kgt m,33lbf ftl

PIVOT BOLT10 x 1.25 mmir4 N.m {4.5 kgt m, 33 lbl'ft}BBACKET

www.emanualpro.com

Page 1160 of 1395

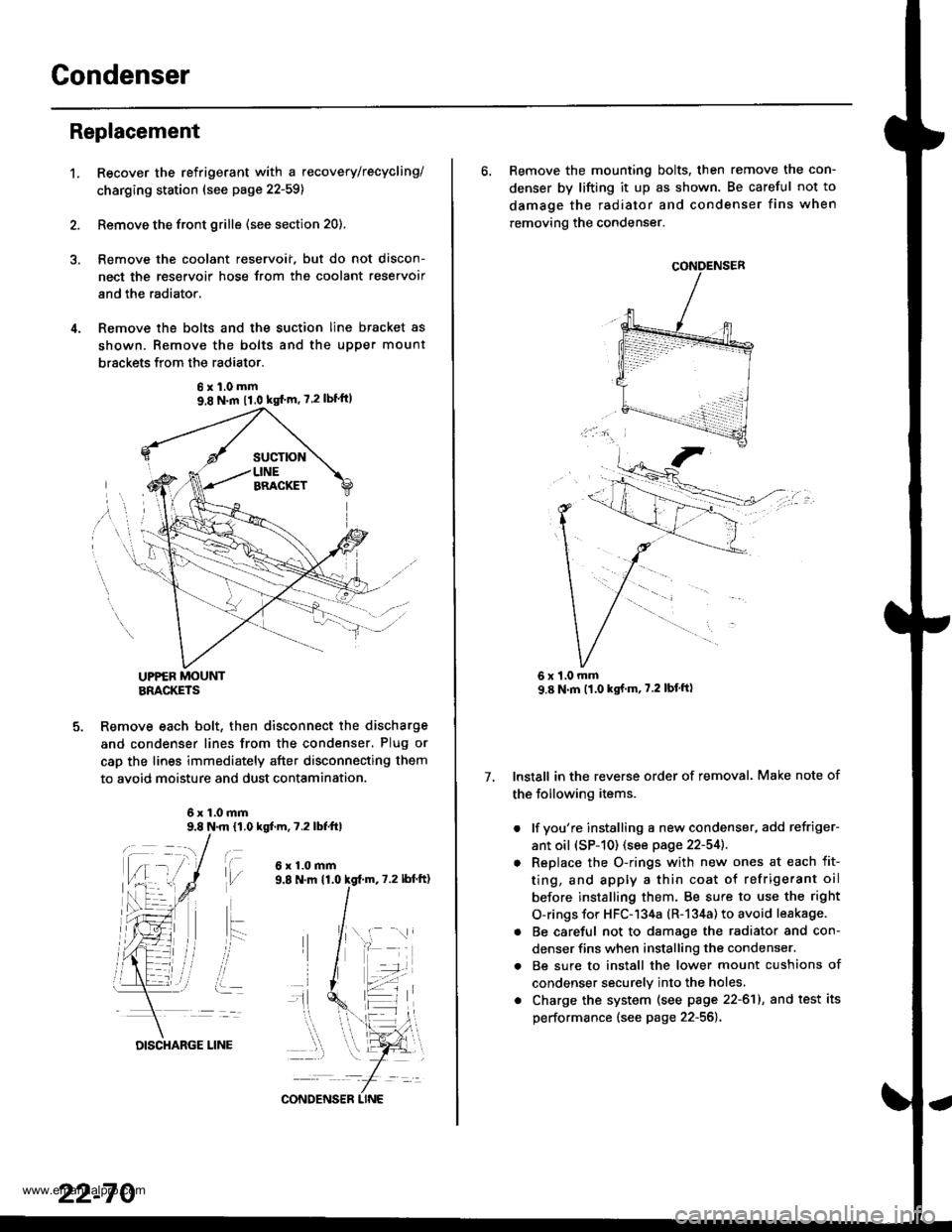

Gondenser

't.

Replacement

Recover the refrigerant with a recovery/recycling/

charging ststion (see page 22-59)

Remove the front grille (see section 20).

Remove the coolant reservoii, but do not discon-

nect the reservoir hose Jrom the coolant reservoir

and the radiator.

Remove the bolts and the suction line bracket as

shown. Remove the bolts and the upper mount

brsckets from the radiator.

UPPER MOUNTBRACKETS

Remove each bolt, then disconnect the discharge

and condenser lines from the condenser, Plug or

cap the lines immediately after disconnecting them

to avoid moisture and dust contamination.

6x1.0mm9.8 N.m 11,0 kgf.m, 7.2 lbfttl

t\,l/

ait- -:

i..

6x1.0mm

6xl.0mm9,8 N.m 11.0 kgf'm' 7.2lbf'ft)

22-70

DISCHARGE LINE

CONDENS€R LINE

6. Remove the mounting bolts, then remove the con-

denser by lifting it up as shown. Be careful not to

damage the radiator and condenser fins when

removing the condenser.

Install in the reverse order of removal. Make note of

the following items.

. lf you're installing a new condenser, add refriger-

ant oil (sP-10) (see page 22-54]..

o Replace the O-rings with new ones at each fit-

ting, and apply a thin coat of refrigerant oil

before installing them. Be sure to use the right

O-rings for HFC-134a (R-134a) to avoid leakage.

. Be careful not to damage the radiator and con-

denser fins when installing the condenser.

. Be sure to install the lower mount cushions of

condenser securely into the holes,

. Charge the system (see page 22-61), and test its

performance (see page 22-56).

7.

1,0 mm

www.emanualpro.com

Page 1171 of 1395

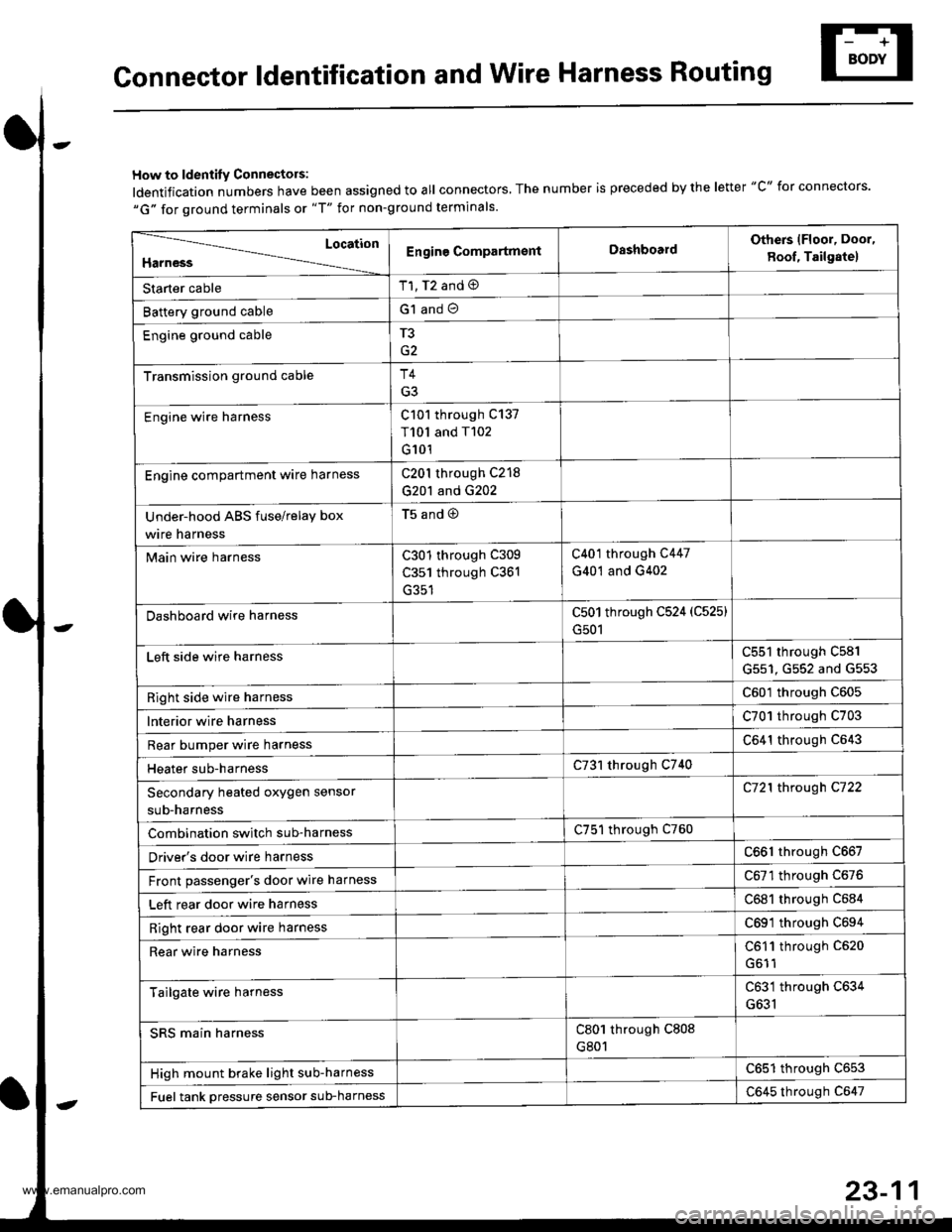

Gonnector ldentification and Wire Harness Routing

How to ldentity Connectors:

ldentification numbers have been assigned to all connectors, The number is preceded by the letter "C" for connectors.

"G" for ground terminals or "T" for non-ground terminals.

Location

HarnessEngine CompartmsntDashboardOthers lFloor, Door,

8oof, Tailgate)

Starter cableT1, T2 and @

Battery ground cableG1 and O

Engine ground cableT3

Transmission ground cableT4

G3

Engine wire harnessC101 through C137

T101 and T102

G101

Engine compartment ware harnessC201 through C218

G201 and G202

Under-hood ABS fuse/relay box

wire harness

t5ano9

Main wire harnessC301 through C309

C351 through C361

C401 through C447

G401 and G402

Dashboard wire harnessC501 through C524 (C525)

G501

Left side wire harnessC551 through C581

G551, G552 and G553

Right side wire harnessC601 through C605

lnterior wire harnessC701 through C703

Rear bumper wire harnessC641 through C643

Heater sub-harnessC731 through C740

Secondary heated oxygen sensor

sub-harness

C721 through C722

Combination switch sub-harnessC751 through C760

Driver's door wire harnessC661 through C667

Front passenger's door wire harnessC6Tl through C676

Left rear door wire harnessC681 through C684

Right rear door wire harnessC69'l through C694

Rear wire harnessC611 through C520

Tailgate wire harnessC631 through C634

G631

SRS main harnessC801 through C808

G801

High mount brake light sub-harnessC651 through C653

Fuel tank oressure sensor sub-harnessC645 through C647

www.emanualpro.com

Page 1188 of 1395

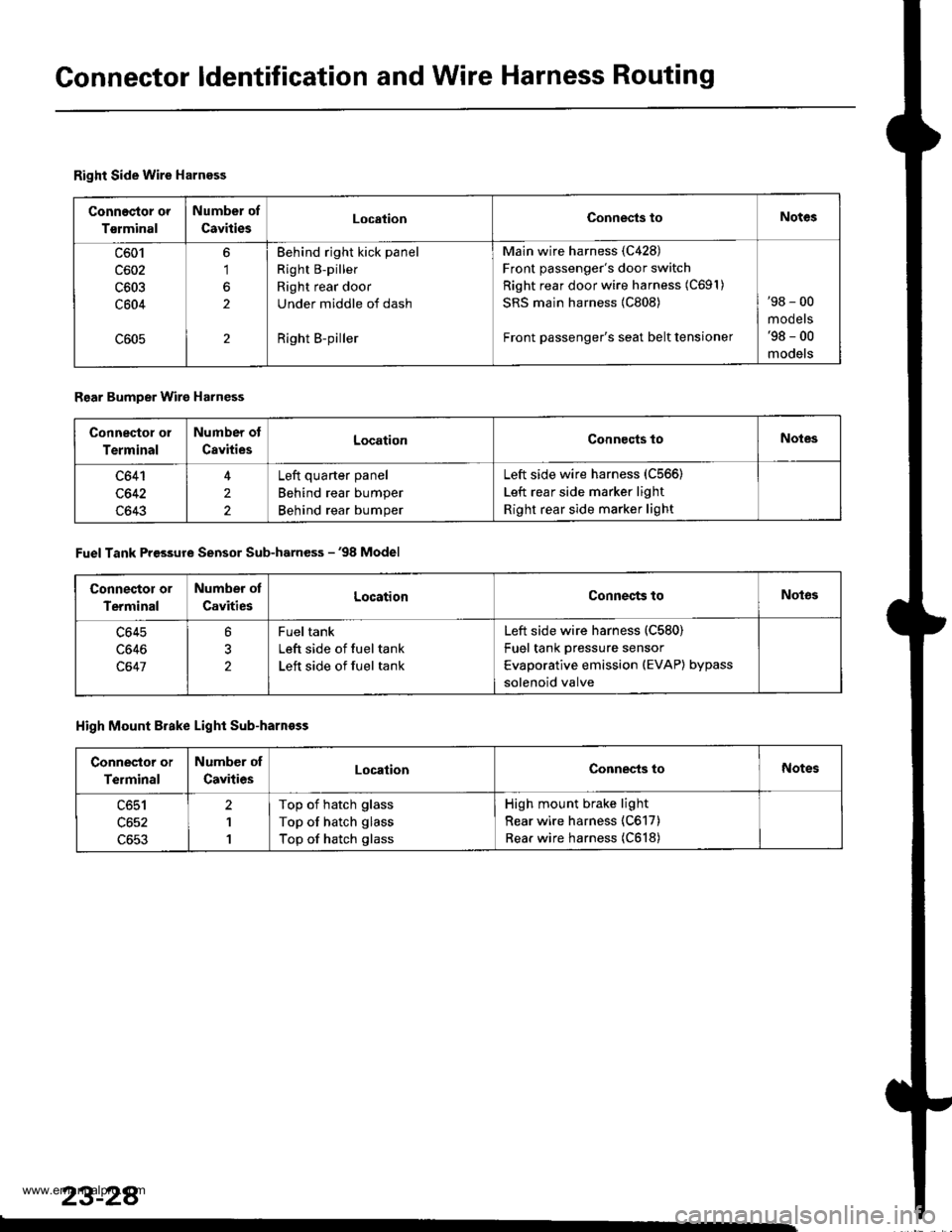

Gonnector ldentification and Wire Harness Routing

Right Side Wire Harness

Connec{or or

Tsrminal

Number of

CavitiesLocationConnests toNotes

c601

c602

c603

c604

6'1

2

2

Behind right kick panel

Right B-piller

Right rear door

Under middle of dash

Right B-piller

Main wire harness (C428)

Front passenger's door switch

Right rear door wire harness (C691)

SRS main harness {C808)

Front passenger's seat belt tensioner

'98 - 00

mooets'98 - 00

models

Rear Bumper Wire Harness

Connector ol

Terminal

Number ot

CavitiesLocationConnocts toNotes

c641

c642

c643

4

2

2

Left quarter panel

Behind rear bumper

Behind rear bumper

Left side wire harness (C566)

Left rear side marker light

Right rear side marker light

Fuel Tank Pressure Sensor Sub-harness - '98 Model

Connector or

Terminal

Number ot

CavitiesLocationConnects toNot63

c645

c646

c647

?

2

Fueltank

Left side of fuel tank

Left side of fuel tank

Left side wire harness (C580)

Fuel tank pressure sensor

Evaporative emission (EVAP) bypass

solenoid valve

High Mount Brake Light Sub-harnoss

Conneslor or

Terminal

Number of

CavitiesLocationConnec-ts toNotes

c651

c652

c653

2

1

1

Top of hatch glass

Top of hatch glass

Top of hatch glass

High mount brake light

Rear wire harness (C617)

Rear wire harness (C618)

23-28

www.emanualpro.com

Page 1262 of 1395

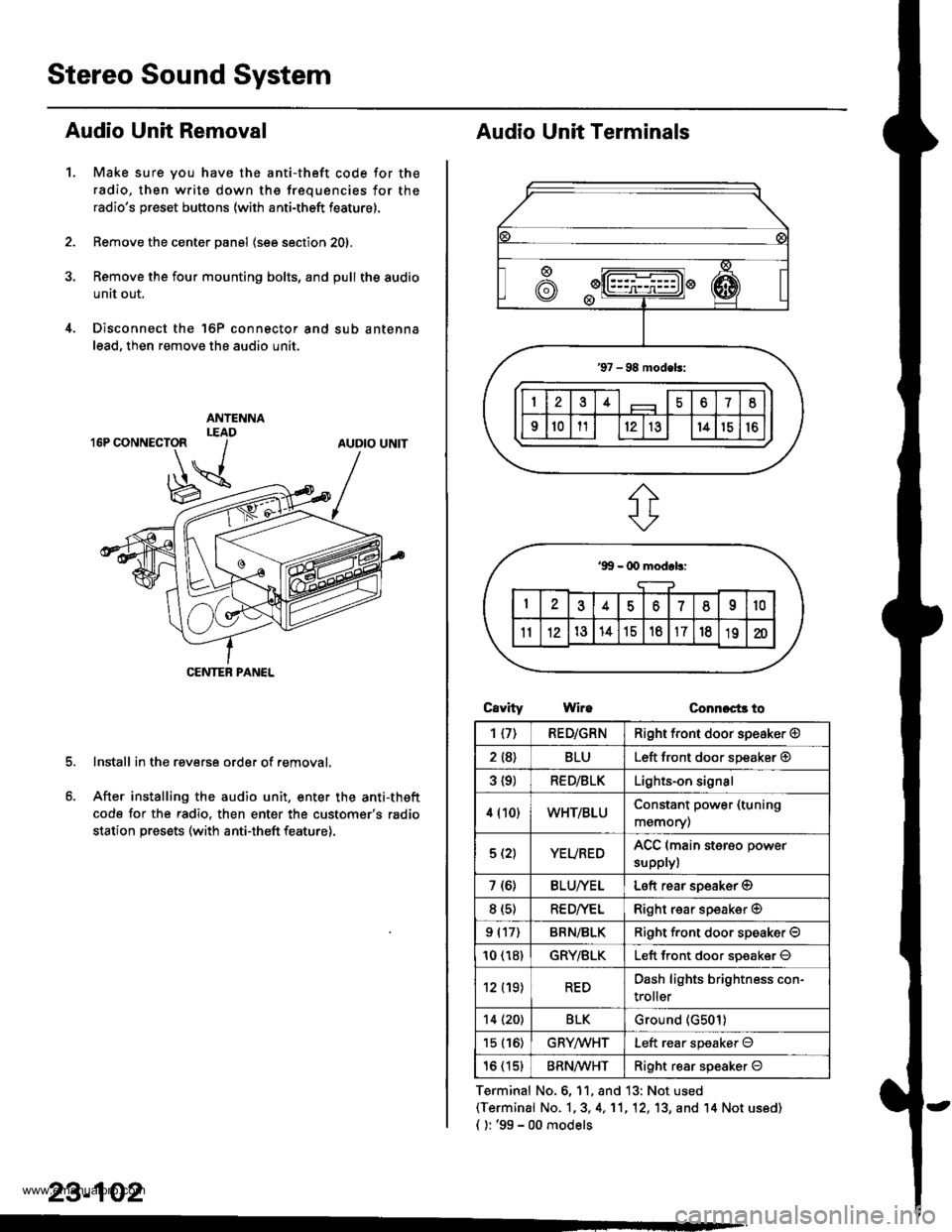

Stereo Sound System

Audio Unit Removal

Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons (with anti-theft feature).

Remove the center panel (see section 201,

Remove the four mounting bolts, and pull the audio

unit out.

Disconnect the 'l6P connector and sub antenna

lead, then remove the audio unit.

Install in the reverse order of removal.

After installing the audio unit, enter the anti-theft

code for the radio. then enter the customer's radio

station presets (with anti-theft feature).

1.

AUDIO UNIT

CENTEB PANEL

23-102

Audio Unit Terminals

CavrtyWireConnoct3 to

Terminal No.6, 11, and 13: Not used(Terminal No. 1,3, 4,'11,12, 13, and '14 Not us6d)

{ ): '99 - 00 models

1{7)RED/GRNRight front door speaker @

2 {8}BLULeft front door speaker @

3 {9)RED/BLKLights-on signal

4 (10)WHT/BLUConstant power (tuning

memory)

5 (2)YEUREDACC (main sterso power

supplyl

7 (6)BLU/YELLeft rear soeaker @

8 (s)RE D/VELRight rear speaker @

9 (17)BRN/BLKRiqht f.ont door speaker O

10 (18)GRY/BLKLeft front door soeaker O

12 (19)REDDash lights brightness con-

troller

14 (20)BLKGround (G501)

15 (16)GRYMHTLeft rear speaker O

16 (15)BRN^ll/HTRight resr speaker O

www.emanualpro.com

Page 1289 of 1395

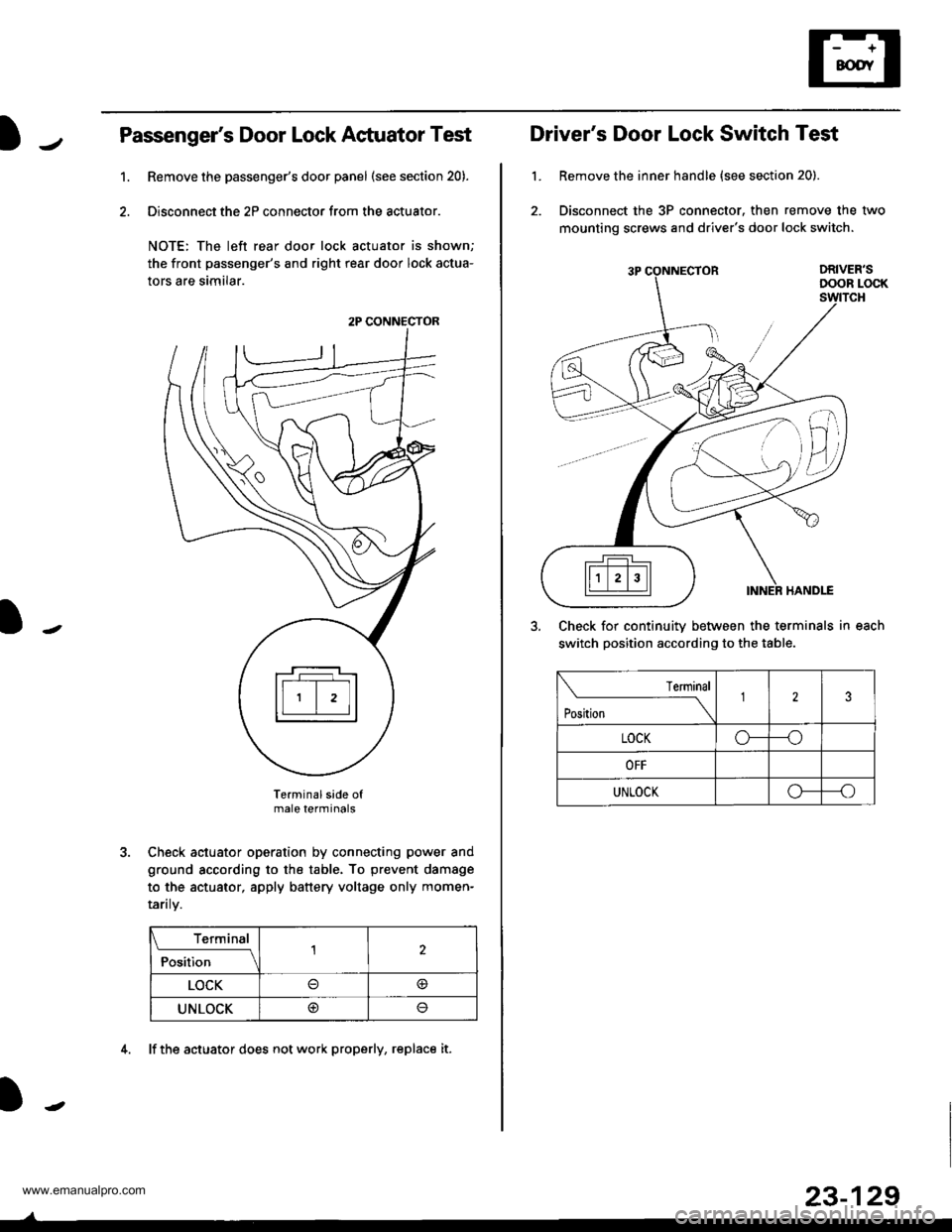

Passenger's Door Lock Actuator Test

Remove the passenger's door panel (see section 20).

Disconnect the 2P connector from the actuator.

NOTE: The left rear door lock actuator is shown;

the front passenger's and right rear door lock actua-

tors are similar.

Terminal side ofmale terminals

Check actuator operation by connecting power and

ground according to the table. To prevent damage

to the actuator, apply battery voltage only momen-

raflry.

Terminal

;;il;--r

,l

LOCK@

UNLOCK@

1.

2P CONNECTOR

4. lf the actuator does not work properly, replace it.

23-129

L

Driver's Door Lock Switch Test

Remove the inner handle {see section 20).

Disconnect the 3P connector. then remove the two

mounting screws and driver's door lock switch.

Check for continuitv between the terminals in each

switch position according to the table.

lermlnal

Position \

123

LOCKo---o

OFF

UNLOCKo--_o

www.emanualpro.com