engine HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 565 of 1395

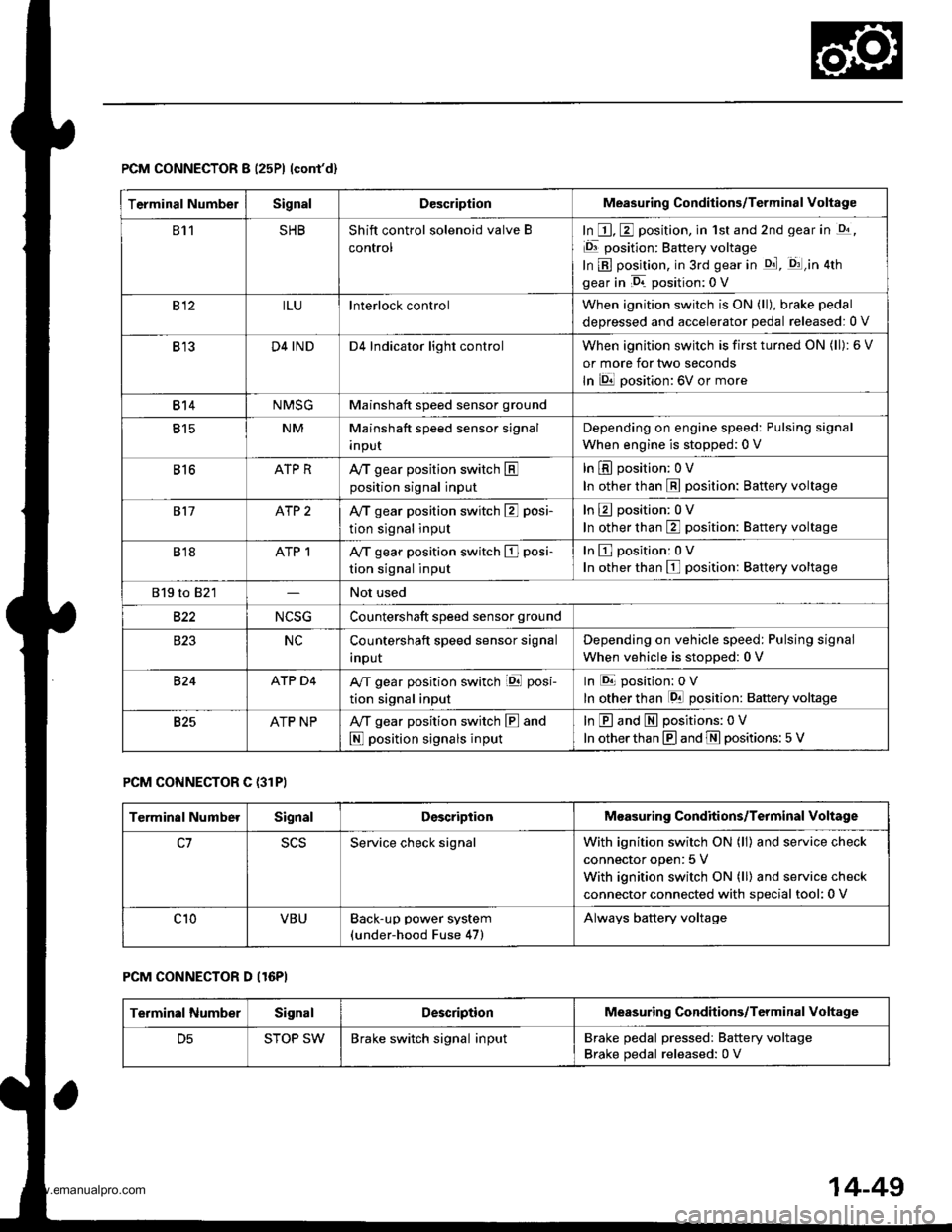

PCM CONNECTOR B (25P) lcont'd)

PCM CONNECTOR C {31PI

PCM CONNECTOR D II6PI

Terminal NumbelSignalDescriptionMeasuring Conditions/Terminal voltage

811SHBShift control solenoid valve B

control

In E, E position, in 1st and 2nd gear in -q,

Er position: Battery voltage

In B position, in 3rd gear in qd, q:l,in atn

gear in D. position: 0 V

812ILUlnterlock controlWhen ignition switch is ON (ll), brake pedal

deDressed and accelerator oedal released:0 V

B13D4 INDD4 Indicator light controlWhen ignition switch is first turned ON (ll): 6 V

or more for tlvo seconds

In lDll position: 6V or more

814NMSGMainshaft speed sensor ground

815NMMainshaft speed sensor signal

InpuI

Depending on engine speed: Pulsing signal

When engine is stopped: 0 V

816ATP RAy'T gear position switch Eposition signal input

In E position; OV

In other than E position: Battery voltage

817ATP 2Ay'T gear position switch E posi-

tion signal input

InEposition:0V

In other than E position: Battery voltage

B18ATP 1A/T gear position switch El posi-

tion signal input

InEposition:0V

In other than E position: Battery voltage

819 to 821Not used

B�22NCSGCountershaft speed sensor ground

NCCountershaft speed sensor signal

Inpur

Depending on vehicle speed: Pulsing signal

when vehicle is stooped: 0 V

824ATP D4A/T gear position switch iql posi-

tion signal input

In E position: 0V

In other than lgal position: Baftery voltage

825ATP NPAy'T gear position switch E and

N position signals input

In E and E positions: 0V

In otherthan @ and ffi positions:5 V

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

SCSService check signalWith ignition switch ON (ll) and service check

connector open: 5 V

With ignition switch ON (ll) and service check

connector connected with special tool: 0 V

c10VBUBack-up power system(under-hood Fuse 47)

Always battery voltage

Terminal NumberSignalDescriptionMeasuring Conditions/Terminal Voltage

STOP SWBrake switch signal inputBrake pedal pressedr Battery voltage

Brake pedal released: 0 V

14-49

www.emanualpro.com

Page 571 of 1395

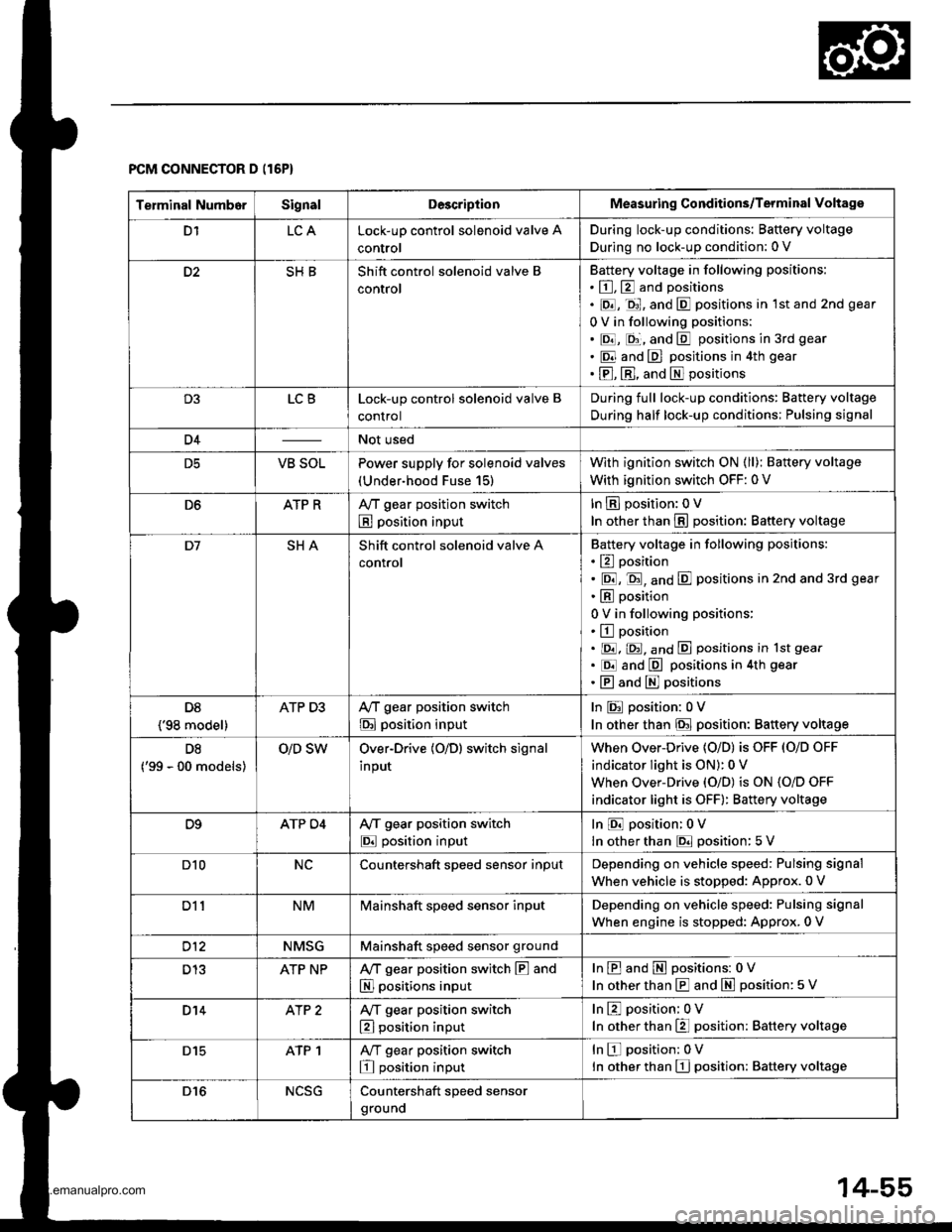

Terminal NumborSignalDescriptionMeasuring Conditions/Terminal Voltage

D1LCALock-up control solenoid valve A

control

During lock-up conditions: Baftery voltage

During no lock-up condition: 0 V

D2SHBShift control solenoid valve B

control

Battery voltage in following positions:

. E, E and positions

. E, -ql, and E positions in lst and 2nd gear

0 V in following positions:

. E, E;, and E positions in 3rd gear

. E and E positions in 4th gear

. E, El, and El positions

D3LCBLock-up control solenoid valve B

control

During full lock-up conditions: Battery voltage

During half lock-up conditions; Pulsing signal

D4Not used

D5VB SOLPower supply for solenoid valves

(Under-hood Fuse 15)

With ignition switch ON (ll); Battery voltage

With ignition switch OFF: 0 V

D6ATP RAy'T gear position switch

B position input

In E position: OV

In other than E position: Baftery voltage

D7SHAShift control solenoid valve A

control

Battery voltage in following positions:

. E position

. E, E, and E positions in 2nd and 3rd gear

. E position

0 V in following positions:

. E position. E. E, and E positions in lst gear

. Erl and E positions in 4th gear

.EandEpositions

D8

{'98 model}

ATP D3Ay'T gear position switch

E position input

In E position: 0V

In other than E position: Baftery voltage

D8

('99 - 00 models)

O/D SWOver-Drive (O/D) switch signal

input

When Over-Drive {O/D) is OFF (O/D OFF

indicator light is ON): 0 V

When Over-Drive {O/D) is ON {O/D OFF

indicator light is oFF): Battery voltage

D9ATP D4A/f gear position switch

E position input

In E position: 0V

In other than E position: 5 V

D10NCCountershaft sDeed sensor inoutDepending on vehicle speed: Pulsing signal

when vehicle is stopped: Approx.0 V

Dl1NMMainshaft speed sensor inputDepending on vehicle speed: Pulsing signal

When engine is stopped: Approx. 0 V

D12NMSGMainshaft speed sensor ground

D13ATP NPA,/T gear position switch E and

El positions input

InEandEpositions: 0V

In other than E and m position: 5 V

D14AlP 2A/T gear position switch

El position input

InE position; 0V

In other than E position: Battery voltage

D15ATP 1A,/T gear position switch

E position input

InEposition:0V

ln other than El position: Battery voltage

D16NCSGCountershaft speed sensor

grouno

PCM CONNECTOR D (16P)

14-55

www.emanualpro.com

Page 599 of 1395

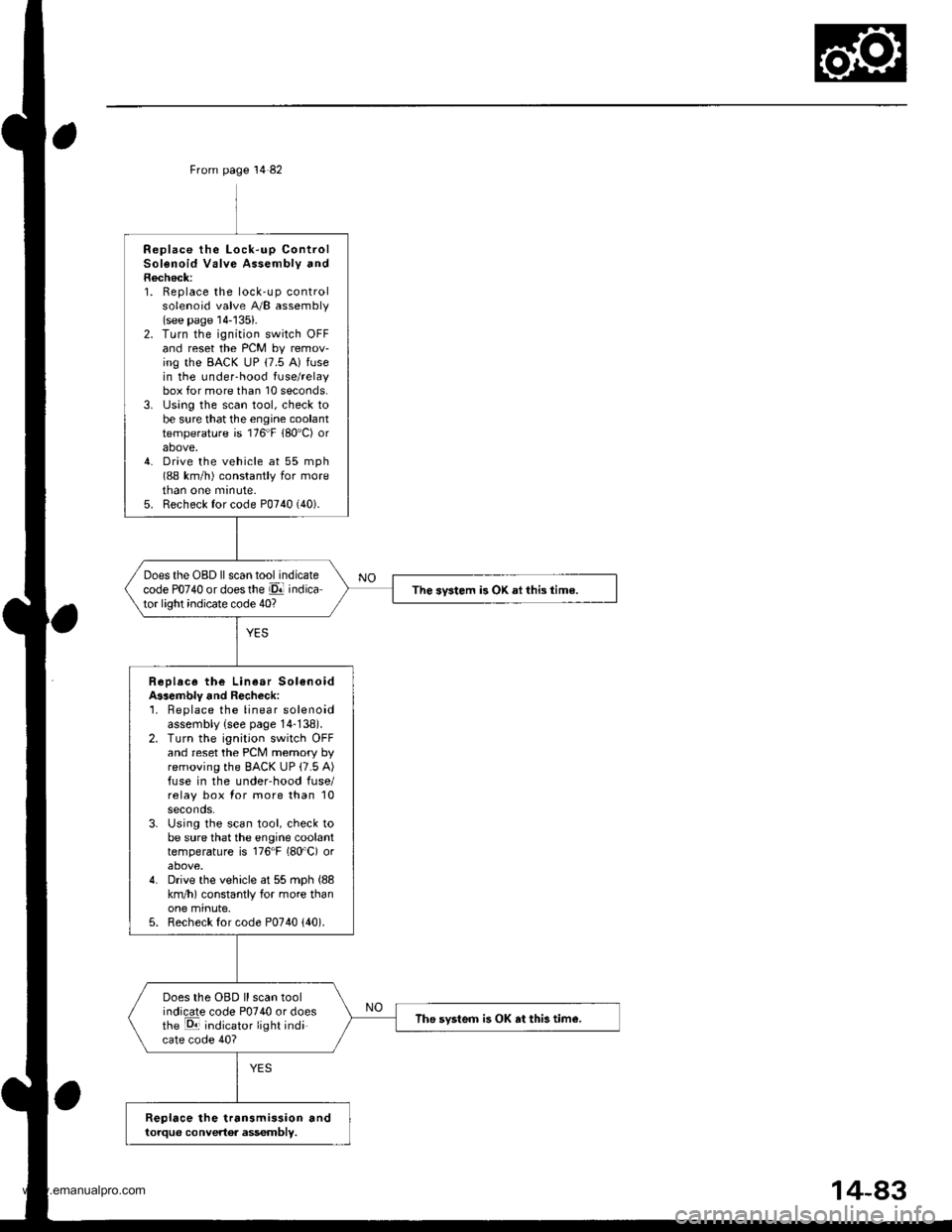

From page 14 82

Replace the Lock-up ControlSolenoid Valve Assembly andRecheck:1. Replace the lock-up controlsolenoid valve A/B assembly(see page 14-'135).2. Turn the ignition switch OFFand reset the PCM by remov-ing the BACK uP (7.5 A) fusein the under-hood fuse/relaybox for more than 10 seconds.3. lJsing the scan tool, check tobe sure that the engine coolanttemperature is 176"F 180'C) orabove,4. Drive the vehicle at 55 mph(88 km/h) constantly for moretnan one mrnute.5. Recheck for code P0740 (40).

Does the OBD ll scan tool indicatecode PO74O or doesthe El indicator light indicate code 40?The svstem is OK ai this time.

Replace the Linear Sol€noidA$embly and Recheck:'1. Beplace the linear solenoidassembly {see page 14-138).2. Turn the ignition switch OFFand reset the PCM memory byremoving the BACK UP (7.5 A)fuse in the underhood fuse/relay box for more than 10seconds.3. Using the scan tool, check tobe sure that the engine coolanttemperature is 176"F (80'C) orabove.4. Drive the vehicle at 55 mph (88

km/h) constantly for more thanone minute,5. Recheck for code P0740 {40).

Does the OBD ll scan toolindicate code P0740 or doesthe E indicator light indicate code 40?

The svsteo is OK at this tim€.

Replace the transmission andtorque convertor assembly.

www.emanualpro.com

Page 636 of 1395

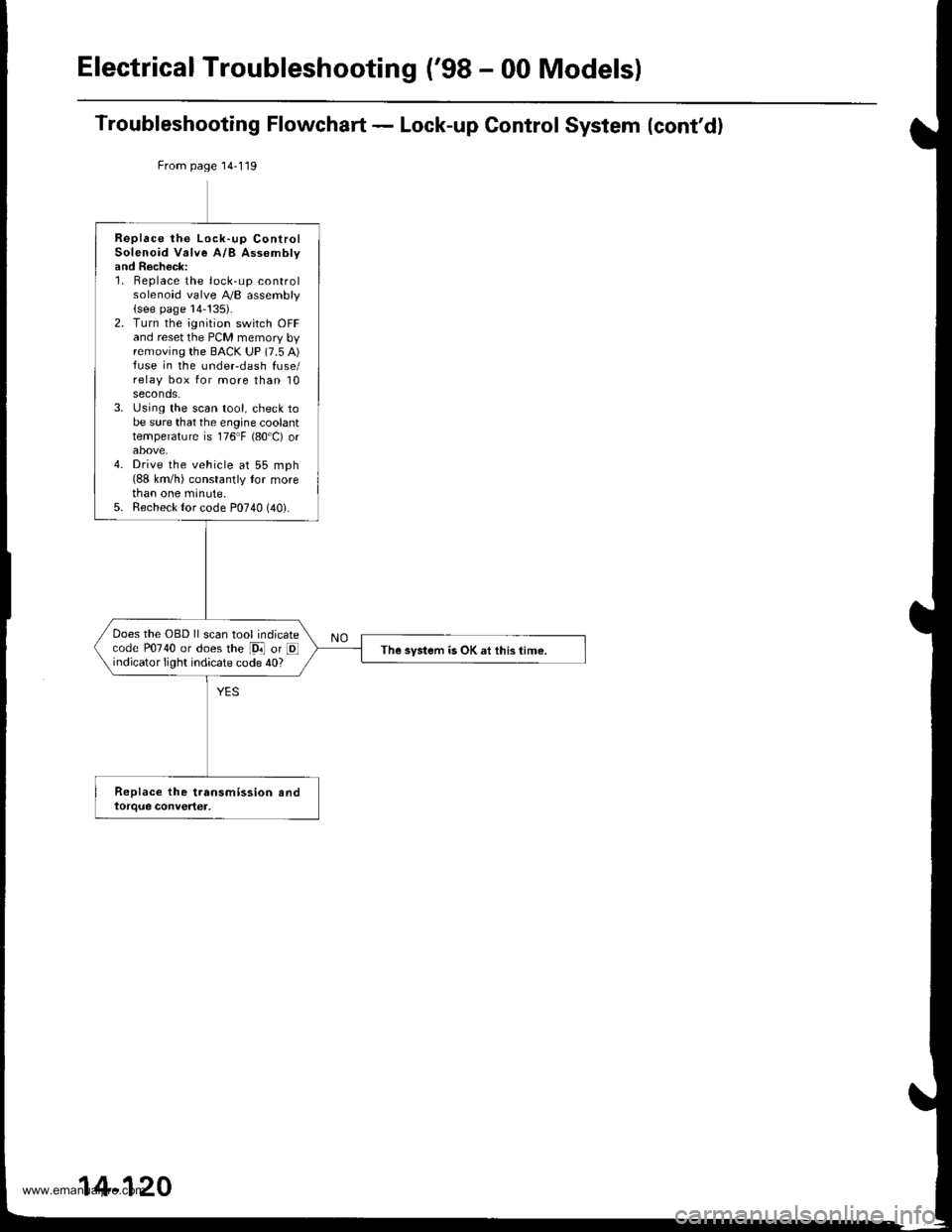

Electrical Troubleshooting ('98 - 00 Models)

Troubleshooting Flowchart - Lock-up Control System (cont'd)

From page 14-119

Replace the Lock-up ControlSolenoid Valve A/B Assomblyand Recheck:1. Replace the lock-up controlsolenoid valve A,/B assembly(see page 14-!35).2. Turn the ignition switch OFFand reset the PCM memory byremoving the BACK UP (7.5 A)fuse in the undeFdash fuse/relay box for more than 10seconds.3. Using the scan tool, check tobe sure that the engine coolanttemperature is 176"F {80'C) orabove.4. Drive the vehicle at 55 mph(88 km/h) constantly tor morethan one minute.5. Recheck {or code P0740 (40i.

Does the OBD ll scan tool indicatecode P0740 or does the [9i] or Eindicator light indicate code 40?The system is OK at this time.

14-120

www.emanualpro.com

Page 657 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

8. Set the control shaft to E] position. then install the

A,/T gear position switch on it.

CONTROL SHAFT

Install the AyT gear position switch cover and har-

ness clamp on the end cover.

Connect the HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

8. Set the control shaft to E] position. then install the

A,/T gear position switch on it.

CONTROL SHAFT

Install the AyT gear position switch cover and har-

ness clamp on the end cover.

Connect the](/img/13/5778/w960_5778-656.png)

8. Set the control shaft to E] position. then install the

A,/T gear position switch on it.

CONTROL SHAFT

Install the Ay'T gear position switch cover and har-

ness clamp on the end cover.

Connect the A,/T gear position switch connector.

then install it on the connector bracket.

Turn the ignition switch ON (ll). Move the shift lever

through all gears, and check the AfI gesr position

switch synchronization with the A/T gear position

indicator.

9.

10.

11.

A/TGEARPOSMON A/T GEAR POSITIONINDICATOR INDICATOR'99 - 00 MODELS '�97 - 98 MOOELS

12, Start the engine. Move the shift lever through all

gears. and verify the following:

. The shift lever cannot be moved to E] position

from E position unless the shift lever is pulled.

. The engine will not start in any position other

than E or E.. The back-up lights come on when the shift lever

is in El position.

14-141

www.emanualpro.com

Page 669 of 1395

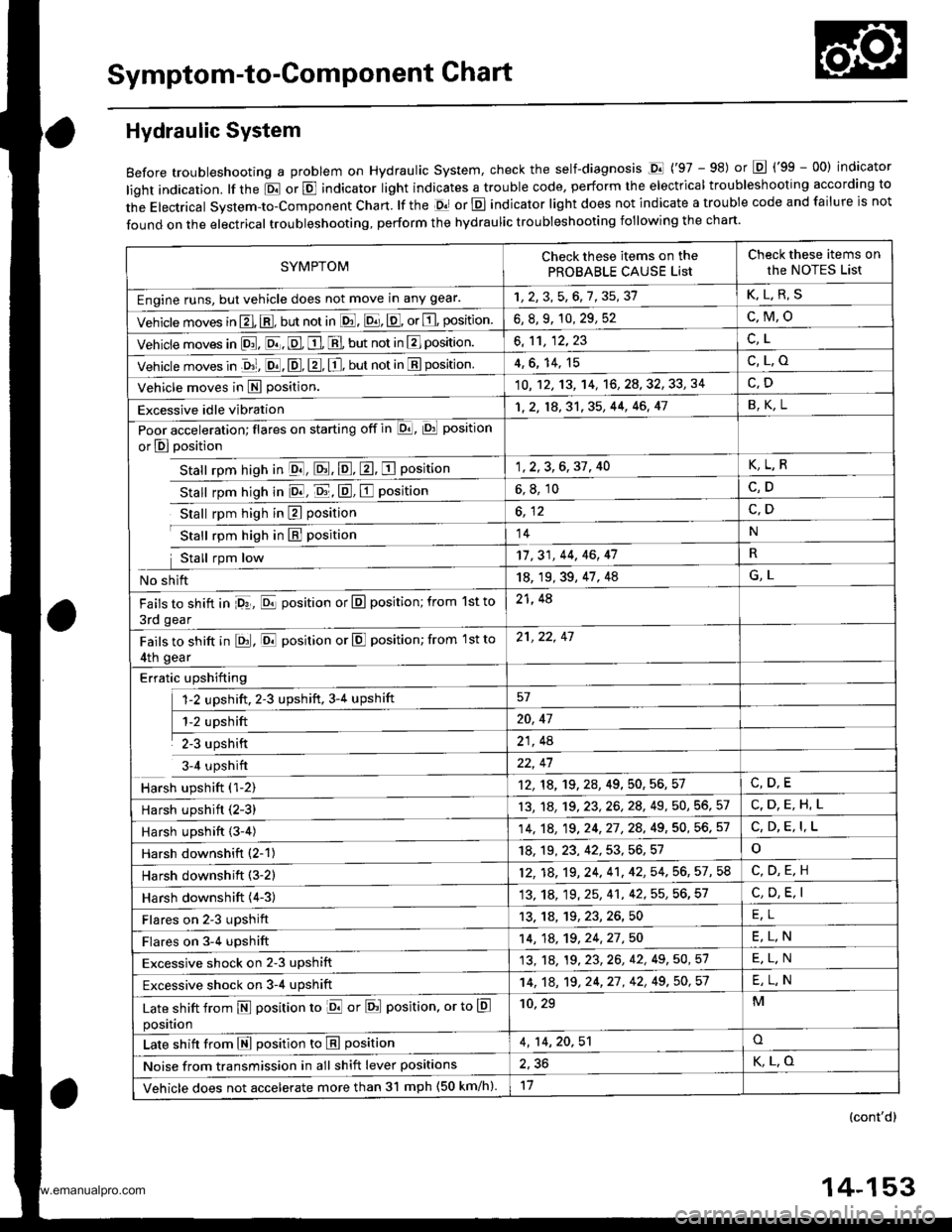

Symptom-to-Component Chart

Hydraulic System

Before troubleshooting a problem on Hydraulic system, check the self-diagnosis Dl ('97 - 98) or Lq ('99 - 00) indicator

light indication. lf the El or E indicator light indicates a trouble code, perform the electrical troubleshooting according to

the Electrical System-to-Component Chart. lf the Ol or E indicator light does not indicate a trouble code and failure is not

found on the electrical troubleshooting, perform the hydraulic troubleshooting following the chart.

SYMPTOMCheck these items on the

PROBABLE CAUSE List

Check these items on

the NOTES List

Engine runs, but vehicle does not move in any gear.1r2FAt?82?K,L.R,S

Vehicle moves in El. @, but not in lE. E, E, or E, position6, 8, 9, 10, 29, 52c,M,o

Vehicle moves in [D!. E, E. E, E, but not in E] position.al

Vehicle moves in .&1, E. E, E, E, but not in E position4,6, 14, 15c,L.o

Vehicle moves in E position.10 , 12, 13, '�l4, '16, 2A, 32, 33, 34

Excessive idle vibration1,2, 18,3'1,35, 44, 46, 41B,K,L

Poor acceleration; flares on starting off in E, Di position

or E position

Stall rpm hish in El, El, E, E, E Position

Stall rpm hiqh in E, E, E, E position

1,2,3,6,37, 40K,L,R

6, 8, 10C,D

Stall rpm high in E positionc,D

Stall rpm high in hl position14N

Stall rpm low17,31, 44, 46, 47R

No shift18, 19, 39, 47, 48G,L

Fails to shift in Pr, E position or E position; from 1st to

3rd gear

21, 48

Fails to shift in EJ, E position or E position; from 1st to

4th gear

21,22, 47

Erratic upshifting

fz upshlft. ,3 ripshlft, 3r. up+ilft57

ffi20, 47

il21, 4A

3-4 upshift22, 47

Harsh upshift ('l-2)12, 18, 19,2A,49, 50, 56, 57

Harsh upshift (2-3)13, 1A, 19,23,26,28, 49, 50, 56, 57C,D.E,H,L

Harsh upshift {3-4)14,1A, 19,24,27,28, 49, 50, 56. 57C, D, E, I,L

Harsh downshitt (2-1)18, 19,23, 42,53,56,51o

Harsh downshift (3-2)12, 18,19,24,41,42, 54. 56, 57, 58

Harsh downshift (4-3)13,'1A, 19, 25, 41, 42, 55, 56, 57C, D, E, I

Flares on 2-3 upshift13,1A,19,23,26,50FI

Flares on 3-4 upshift14, 1A, 19,24,27,50E,L,N

Excessive shock on 2-3 upshift13. '18, 19 , 23, 26, 42, 49 , 50, 51E.L.N

Excessive shock on 3-4 upshift14, 1A, 19,24,27 , 42, 49,50,51E,L,N

Late shift from N position to ld or Erl position. or to E

position

10, 29M

Late shift from E position to E position4, 14,20,51o

Noise from transmission in all shift lever positions2,36K,L.O

Vehicle does not accelerate more than 3l mph (50 km/h).11

(cont'd)

14-153

www.emanualpro.com

Page 670 of 1395

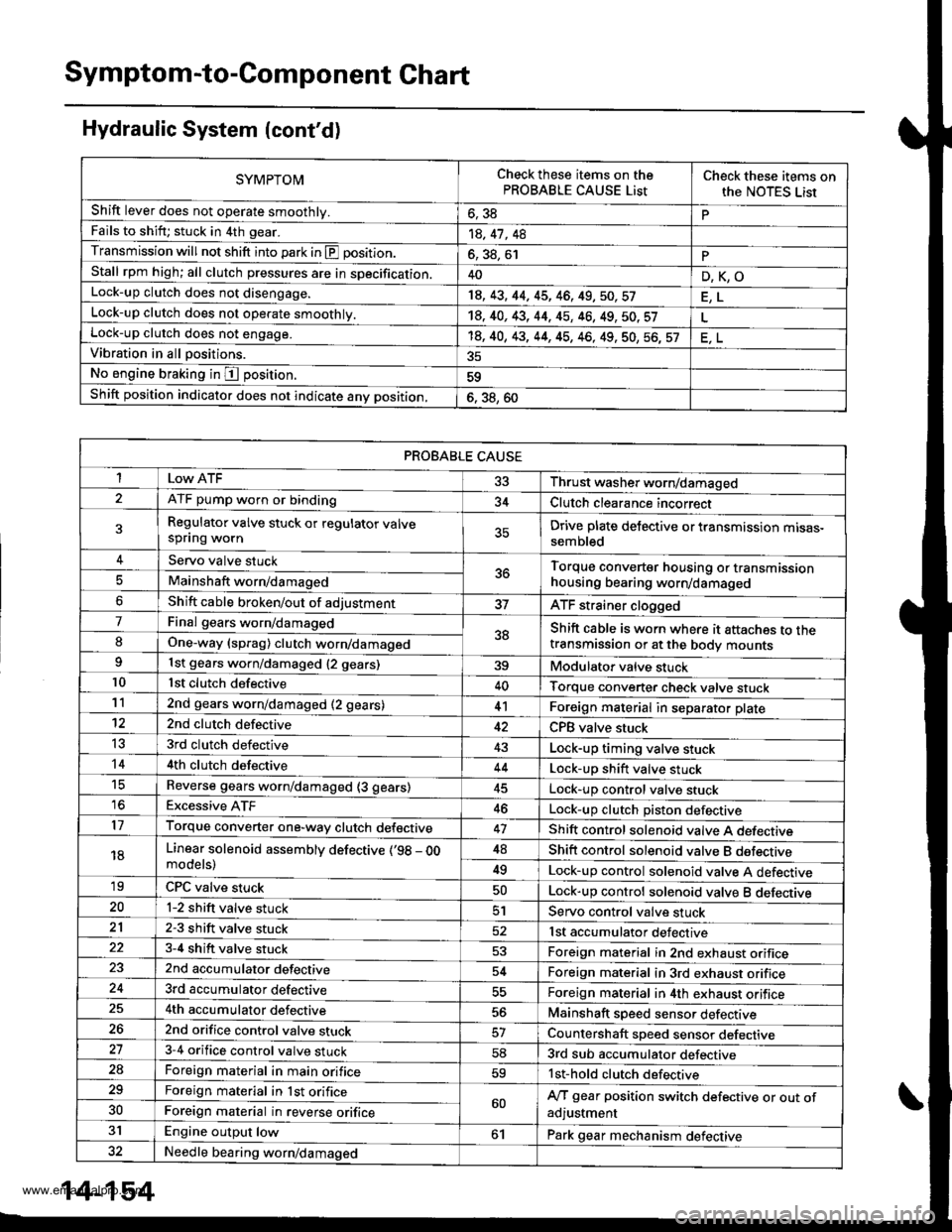

Symptom-to-Component Chart

Hydraulic System (cont'd)

SYMPTOMCheck these items on thePROBABLE CAUSE ListCheck these items onthe NOTES Lisr

Shift lever does not operate smoothly.o, JdPFails to shift; stuck in 4th gear.14, 41 , 48

Transmission will not shift into park in E position.6, 38, 61PStall rpm high; all clutch pressures are in specification.40D,K,OLock-up clutch does not disengage.18, 43, 44, 45, 46, 49,50,57

Lock-up clutch does not operate smoothly.14, 40, 43, 44, 45, 46, 49, 50. 57Lock-up clutch does not engage.'t8, 40, 43, 44, 45, 46, 49, 50, 56, 57Vibration in all positions.

No engine braking in I position.59

Shift position indicator does not indicate anv position,6. 38, 60

PROBABLE CAUSE

I 33 Thrust washer worn/damaged

ATF pump worn or binding34Clutch clearance incorrect

Regulator valve stuck or regulator valvespflng wornDrive plate delective or transmission mtsas-sembled

Servo valve stuck5ttTorque converter housing or transmissionhousing bearing worn/damagedMainshaft worn/damaged

Shift cable broken/out of adjustmentATF strainer clogged

7Final gears worn/damaged38Shift cable is worn where it attaches to thetransmission or at the body mountsIOne-way (sprag) clutch worn/damaged

1st gears worn/damaged {2 gears)39Modulator valve stuck10lst clutch defective40Torque converter check valve stuck112nd gears worn/damaged (2 gears)41Foreign material in separator plate't22nd clutch defectiveCPB valve stuck

t53rd clutch defective43Lock-up timing valve stuck144th clutch defective44Lock-up shift valve stucktcReverse gears worn/damaged (3 gears)Lock-up control valve stuck16Excessive ATF46Lock-up clutch Diston defective17Torque converter one-way clutch defective47Shift control solenoid valve A defecttve

18Linear solenoid assemblv defective (,98 - OOmodels)48Shift control solenoid valve B dsfectrve

49Lock-up control solenoid valve A defective'19CPC valve stuckLock-up control solenoid valve B deleqtve20l-2 shift valve stuck51Servo control valve stuck212-3 shift valve stuck52lst accumulator defective3-4 shift valve stuck53Foreign material in 2nd exhaust orifice2nd accumulator defective54Foreign material in 3rd exhaust orifice3rd accumulator defectiveForeign material in 4th exhaust orifice4th accumulator defective56Mainshaft speed sensor defective262nd orifice control valve stuckCountershaft speed sensor defective273-4 orifice control valve stuck583rd sub accumulator defective2aForeign material in main orifice59lst-hold clutch defective29Foreign material in lst orifice60A/T gear position switch defective or out ofadjustment30Foreign material in reverse orifice

31Engine output low61Park gear mechanism defective32Needle bearing worn/damaged

14-154

www.emanualpro.com

Page 672 of 1395

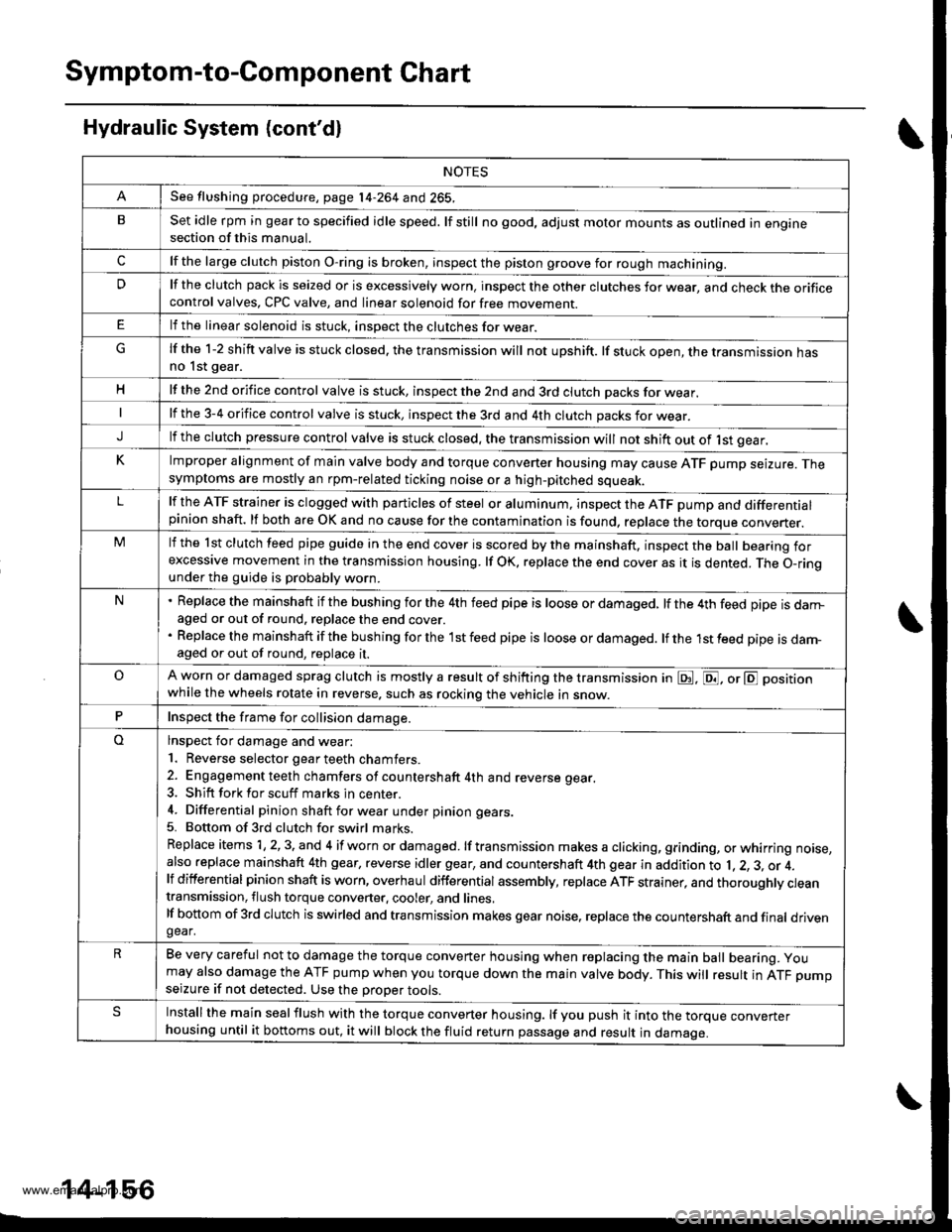

Symptom-to-Com ponent Chart

Hydraulic System (cont'd)

NOTES

See flushing procedure, page l4-264 and 265,

BSet idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

clf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

Dlf the clutch pack is seized or is excessively worn. inspect the other clutches fot wear, and check the orificecontrol valves, CPC valve, and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lf the 1-2 shift valve is stuck closed. the transmission will not upshift. lf stuck open, the transmission hasno lst gear.

Hlf the 2nd orifice control valve is stuck, inspect the 2nd and 3rd clutch Dacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch packs for wear.

Jlf the clutch pressure control valve is stuck closed. the transmission will not shift out of lst gear.

Klmproper alignment of main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

Llf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Mlf the lst clutch feed pipe guide in the end cover is scored by the mainshaft. inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

N' Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged, lf the 4th feed pipe is darrFaged or out of round. replace the end cover.' Replace the mainshaft if the bushing for the l st feed pipe is loose or damaged. lf the 1st feed pipe is dam-aged or out of round, replace it.

oA worn or damaged sprag clutch is mostly a result of shifting the transmission in E!. E, or E positionwhile the wheels rotate in reverse. such as rocking the vehicle in snow.

PInspect the frame for collision damage.

lnspect for damage and wear:

l. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear under pinion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1, 2, 3. and 4 if worn or damaged. lf transmission makes a clicking, grinding, or whirring noise,also replace mainshaft 4th gear, reverse idler gear, and countershaft 4th gear in addition to 1,2, 3, or 4.lf differential pinion shaft is worn, overhaul differential assembly, replace ATF strainer, and thoroughly cjeantransmission, flush torque converter. cooler, and lines,lf bottom of 3rd clutch is swirled and transmission makes gear noise. replace the countershaft and final drivenoear,

Be very careful not to damage the torque converter housing when replacing the main ball bearing. you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the Drooer tools.

SInstall the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

www.emanualpro.com

Page 673 of 1395

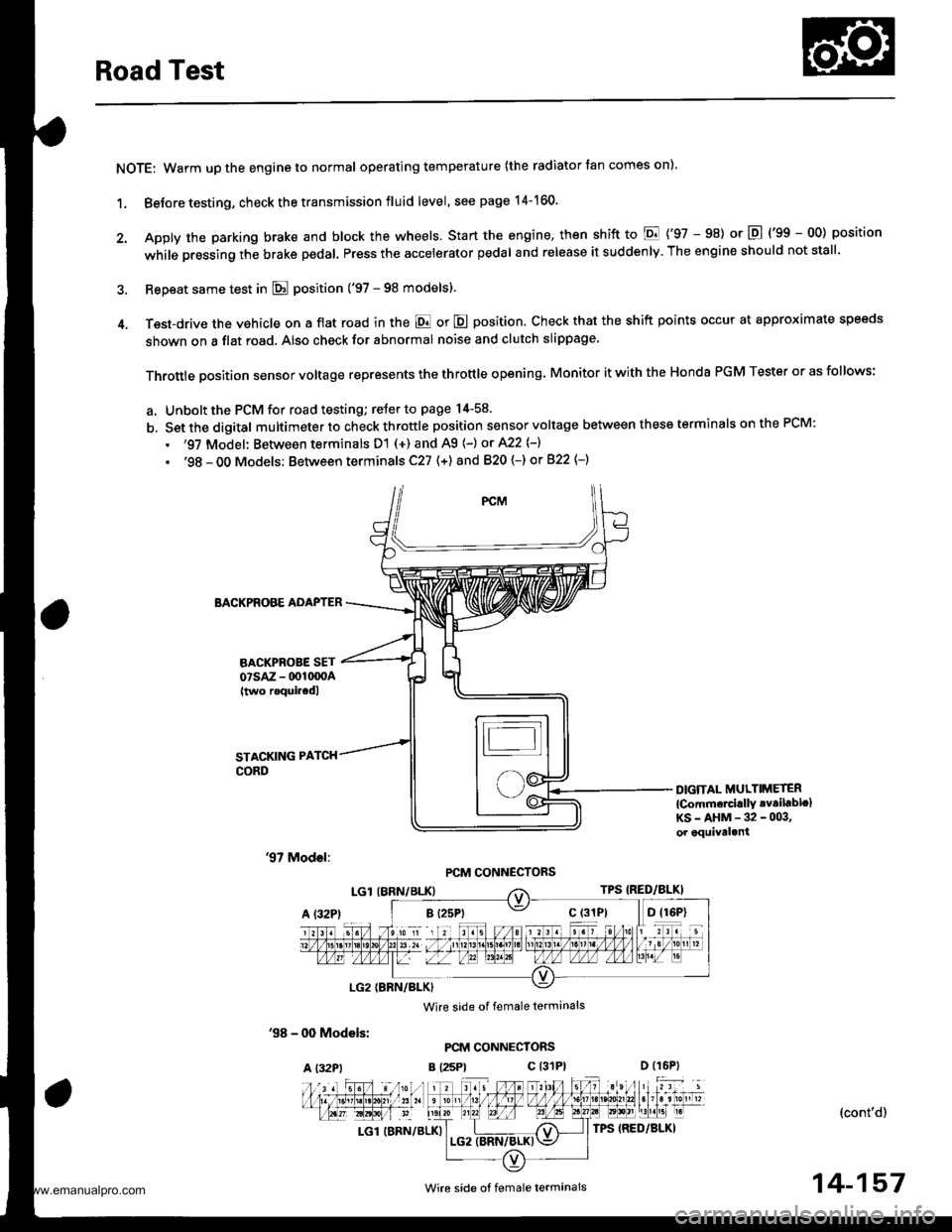

Road Test

NOTE: Warm up the engine to normal operating temperature (the radiator tan comes on).

1. Before testing, check the transmission fluid level, see page 14-160.

2. Apply the parking brake and block the wheels. start the engine, then shift to E {'97 - 98) or E {'gg - 00) position

while pressing the brake pedal. Press the accelerator pedal and release it suddenly. The engine should not stall.

3. Repeat same test in E position ('97 - 98 models).

4. Test-drive the vehicle on a flat road in the E or E position. Check that the shift points occur at approximate speeds

shown on a flat road. Also check for abnormal noise and clutch slippage.

Throttle position sensor voltage represents the throttle opening. Monitor it with the Honda PGM Tester or as follows:

a. Unbolt the PCM for road testing; reJer to page 14-58.

b. Set the digital multimeter to check throttle position sensor voltage between these terminals on the PCM:

. '97 Model: Between terminals D'! (+) and A9 (-) or A22 {-}

. '98 - OO Models; Between terminals C27 (+) and 820 (-) or 822 {-)

BACKPROBE ADAPTER

BACKPROBE SETorsAz - 001moA(two roquircdl

STACKING PATCH

CORD

DIGiTAL MULTIMETER

{Comm€rcirllY .vailablc}KS-AHM-32-003,or equival.nt

'97 Model:PCM CONNECTORS

'98 - 0O Models:

A l32Pt

Wire side of female terminals

PCM CONNECTORS

B {25Pt c l31P}

(cont'd)

LGl (BRN/BLK)

'. //B 1 l'o ti , jl. to a 2r / / 11111t1.t nait la t1 t213tr / t6t, tl / / / / 1 3 / 10n v

t-'a:IM-&E -Llfiffi-fl)\"".'E

Wire side ot female termanals14-157

www.emanualpro.com

Page 674 of 1395

Road Test

(cont'd)

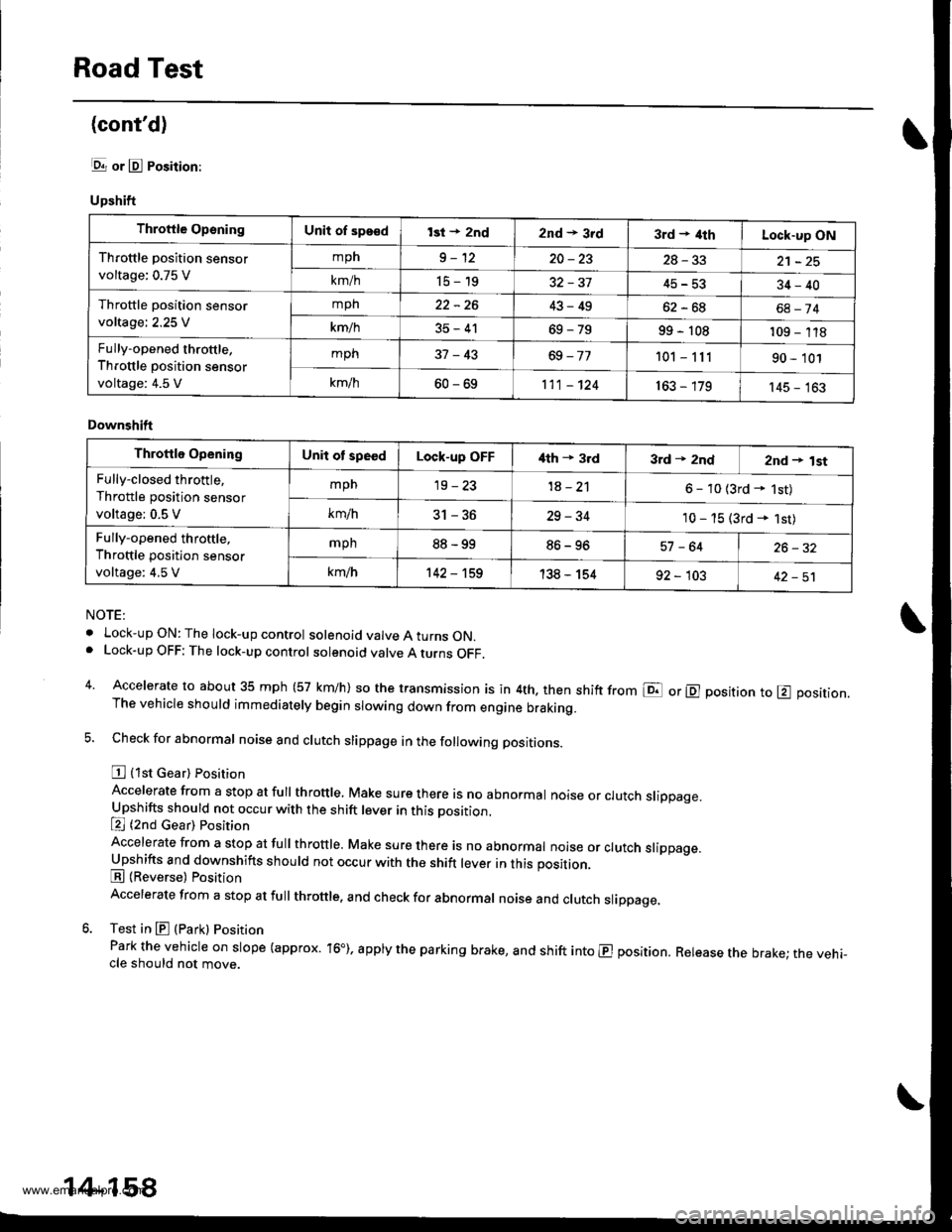

lgrr or E Position:

Upshift

NOTE:

. Lock-upON:The lock-up control solenoid valve A turns ON.. Lock-up OFF: The lock-up control solenoid valve A turns OFF.

4. Accelerate to about 35 mph (57 km/h) so the transmission is in 4th. then shift from E or E position to E position.The vehicle should immediately begin slowing down from engine braking.

5. Check for abnormal noise and clutch slippage in the following positions.

E {1st Gear) Position

Accelerate from a stop at full throttle, Make sure there is no abnormal noise or clutch slippage.Upshifts should not occur with the shift lever in this position.

E (2nd cear) Position

Accelerate from a stop at fuI throttre. Make sure there is no abnormar noise or crutch srippage.Upshifts and downshifts should not occur with the shift lever in this position.

E (Reverse) Position

Accelerate from a stop at full throttle. and check for abnormal noise and clutch slippage.

6. Test in E (Park) Position

Park the vehicle on slope (approx. 16"), apply the parking brake, and shift into E position. Release the brake; the vehi-cle should not move.

Throftle OpsningUnit of sps€dlsi + 2nd2nd * 3rd3rd + ilthLock-up ON

Throttle position sensor

voltage: 0.75 V

mph9-1220-2328-33

km/h15-1945-5334-40

Throttle position sensor

voltage; 2.25 V

mph22-2643-49oz - ott68-74

km/h35-4169-7999 - 108109 - 118

Fully-opened throttle,

Throttle position sensor

voltage: 4.5 V

mph37-43101 - 11190 - 101

k-/h60-69111 - 124163 - 179145 - 163

Downshift

Throttle OpeningUnit ot speedLock-up OFFi{th + 3rd3rd * 2ndznd + lst

Fully-closed throttle,

Throttle position sensor

voltage; 0.5 V

mpn19-231A - 2'l6 - 10 {3rd - 1st)

km/h5t-5D29-3410 - 15 (3rd * 1st)

Fully-opened throttle,

Throttle position sensor

voltage: 4,5 V

mph88-9986-9657 -6426-32

km/h142 - 't59138 - 15492 - 10342-51

14-158

www.emanualpro.com