Brake pedal HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 658 of 1395

A/T Gear Position Indicator

1.

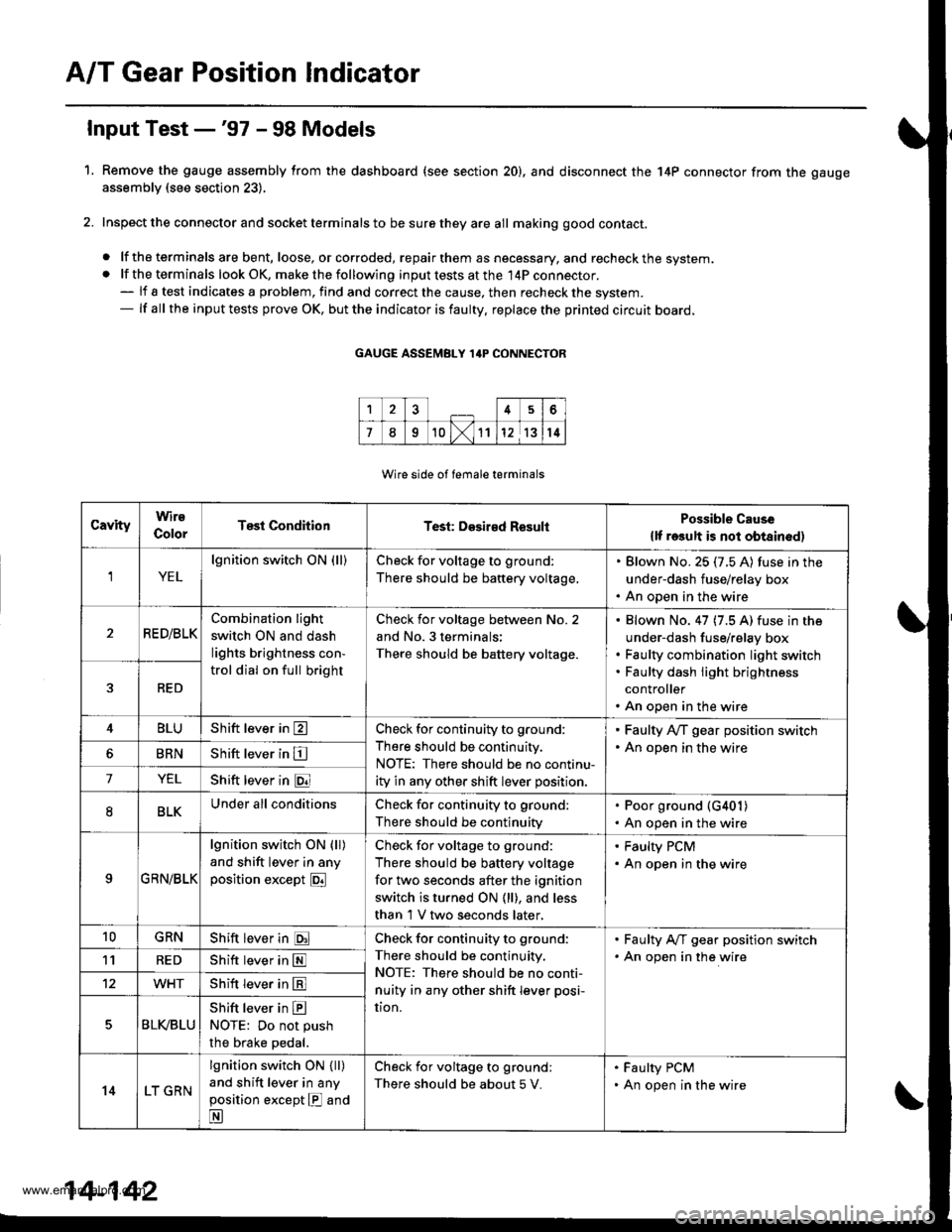

f nput Test -'97 - 98 Models

Remove the gauge assembly from the dashboard (see section 20). and disconnect the 14P connector from the gauge

assemblv (see section 23),

Inspect the connector and socket terminals to be sure they are all making good contact.

. lf the terminals are bent, loose, or corroded, repairthem as necessary, and recheck the system.. lf the terminals look OK, make the following input tests at the 14P connector.- lf I test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, but the indicator is faulty. replace the printed circuit board,

GAUGE ASSEMBLY 14P CONNECTOR

Wire side of female terminals

CavityWirs

ColorTest ConditionTest: Desir€d ResultPossible Cause

{lf rosult is not obtainod)

YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage,

. Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box. An open in the wire

RE D/BLKCombination light

switch ON and dash

lights brightness con-

trol dial on full bright

Check for voltage between No. 2

and No. 3 terminals;

There should be battery voltage.

Blown No. 47 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination Iight switch

Faulty dash iight brightness

controller

An open in the wire

RED

4BLUShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no continu-

ity in any other shift lever position.

' Faulty Ay'T gear position switch. An open in the wireBRNShift lever in E

7YELShift lever in @

8BLKUnder all conditionsCheck for continuity to ground:

There should be continuity

. Poor ground {G401). An open in the wire

9GRN/BLK

lgnition switch ON {ll)

and shift lever in any

position except E

Check for voltage to ground:

There should be battery voltage

for two seconds after the ignition

switch is turned ON {ll), and less

than 1 V two seconds later,

' Faulty PCM. An open in the wire

10GRNShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no conti-

nuity in any other shift lever posi-

UOn.

. Faulty A,ff gear position switch. An open in the wire1'lREDShift lever in @

12WHTShift lever in E

BLVBLU

Shift lever in ENOTE: Do not push

the brake pedal.

14LT GRN

lgnition switch ON { ll)

and shift lever in any

position except E and

E

Check for voltage to ground:

There should be about 5 V.

. Faulty PCM. An open in the wire

14-142

www.emanualpro.com

Page 659 of 1395

L

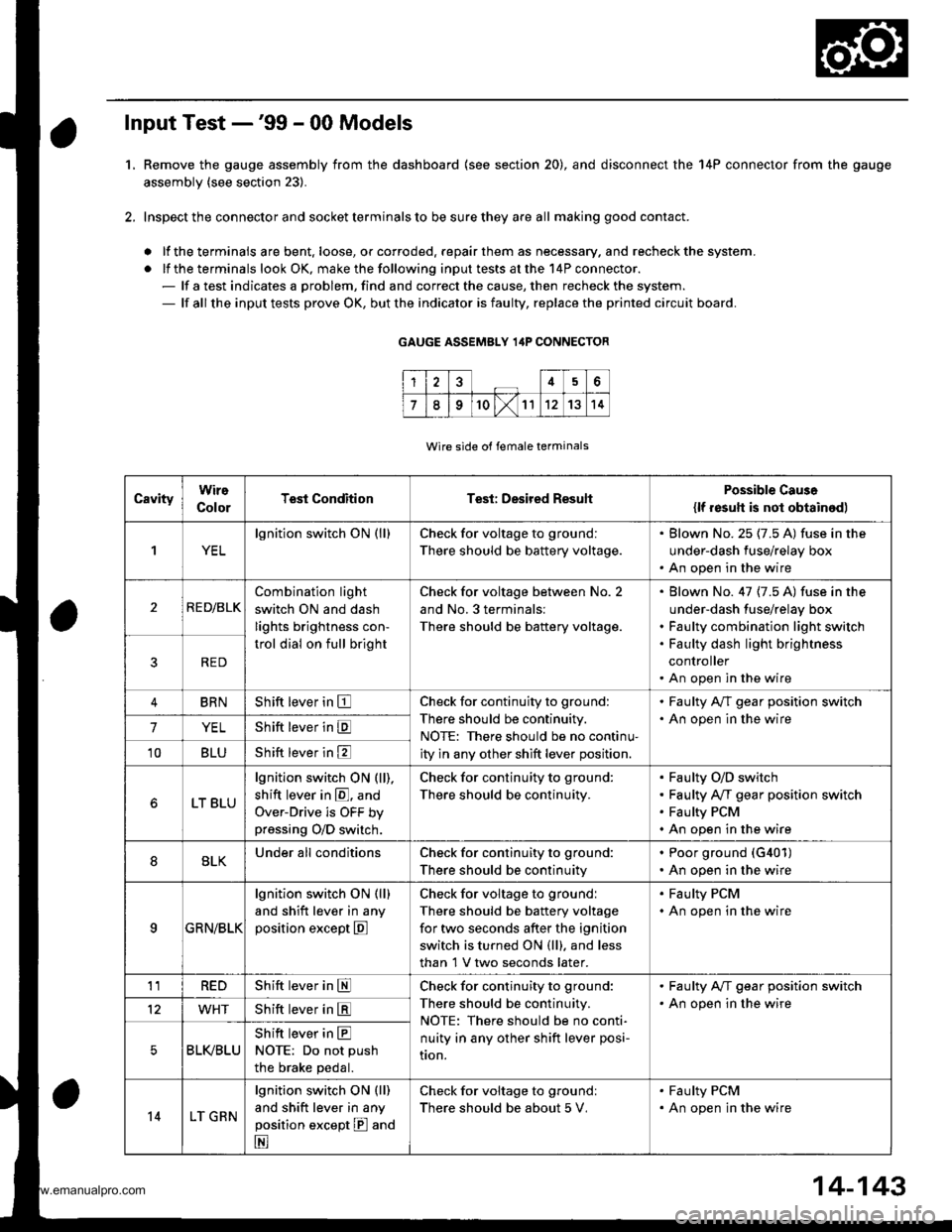

Input Test -'99 - 00 Models

Remove the gauge assembly from the dashboard {see section 20), and disconnect the 14P connector from the gauge

assembly (see section 23).

Inspect the connector and socket terminals to be sure they are all making good contact.

a lf the terminals are bent. loose, or corroded. repair them as necessary. and recheck the system.

. lf the terminals look OK, make the following input tests at the 14P connector.- lf a test indicates a problem, find and correct the cause, then recheck the system.- lf all the input tests prove OK, but the indicator is faulty, replace the printed circuit board.

GAUGE ASSEMBLY 14P CONNECTOR

Wire side of female terminals

CavityWire

ColorTest ConditionTest: Desired ResuhPossible Caus6

{lf resutt is not obtainod)

1YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

. Blown No.25 (7.5 A) fuse in the

under-dash fuse/relay box. An open in the wire

2RE D/BLK

Combination light

switch ON and dash

lights brightness con-

trol dial on full bright

Check for voltage between No. 2

and No.3 terminals:

There should be battery voltage.

Blown No. 47 {7.5 A) fuse in the

under-dash fuse/relay box

Faulty combination light switch

Faulty dash light brightness

controller

An open in the wire

5RED

BRNShift lever in ECheck for continuity to ground:

There should be continuity.

NOTE: There should be no continu-

ity in any other shift lever position.

. Faulty A/T gear position switch. An open in the wire7YELShift lever in E

'10BLUShift lever in E

LT BLU

lgnition switch ON (ll),

shift lever in E. and

Over-Drive is OFF bypressing O/D switch.

Check for continuity to ground:

There should be continuity.

Faulty O/D switch

Faulty A/T gear position switch

Faulty PCM

An open in the wire

8BLKUnder all conditionsCheck for continuity to ground:

There should be continuity

. Poor ground (G401)

. An open in the wire

9a:FI\|/Et| ta

lgnition switch ON (ll)

and shift lever in any

position except E

Check for voltage to groundl

There should be battery voltage

for two seconds after the ignition

switch is turned ON (ll). and less

than 1 V two seconds later.

. Faulty PCM. An open in the wire

11REDShift lever in SCheck for continuity to ground:

There should be continuity.

NOTE: There should be no conti-

nuity in any other shift lever posi-

Iton.

. Faulty A/T gear position switch. An open in the wire12WHTShift lever in E

BLI(BLU

Shift lever in ENOTE: Do not push

the brake pedal.

14LT GRN

lgnition switch ON (ll)

and shift lever in any

position except E and

E

Check for voltage to groundl

There should be about 5 V,

. Faulty PCM. An open in the wire

14-143

www.emanualpro.com

Page 660 of 1395

Interlock System

Interlock Control Unit Input Test

SRS components are located in this area. Review the SRS component locations, precautions, and procedures in the SRS

section (24) before performing repairs or service.

'1. Remove the instrument panel lower cover (see section 20).

2. Disconnect the 8P connector from the interlock control unit.

3. Inspect the connector and connector terminals to be sure they are all making good contact.

. lf the terminals are bent, loose, or corroded, repair them as necessary, and recheck the system

. lf the terminals look OK, make the following input tests at the connector.

- lf a test indicates a problem, find and correct the cause, then recheck the system

- lf all the input tests prove OK, substitute a known-good control unit, and recheck the system. lf the check is OK,

the control unit must be faulty; replace it.

NOTE: lf the shift lock solenoid clicks when the ign ition switch is tu rned ON (ll) while pressing the brake pedal withthe

shift lever in E position, the shift lock system is OK. lf the shift lever cannot be shifted from E position. test the A/T

gear position switch.

14-144

www.emanualpro.com

Page 661 of 1395

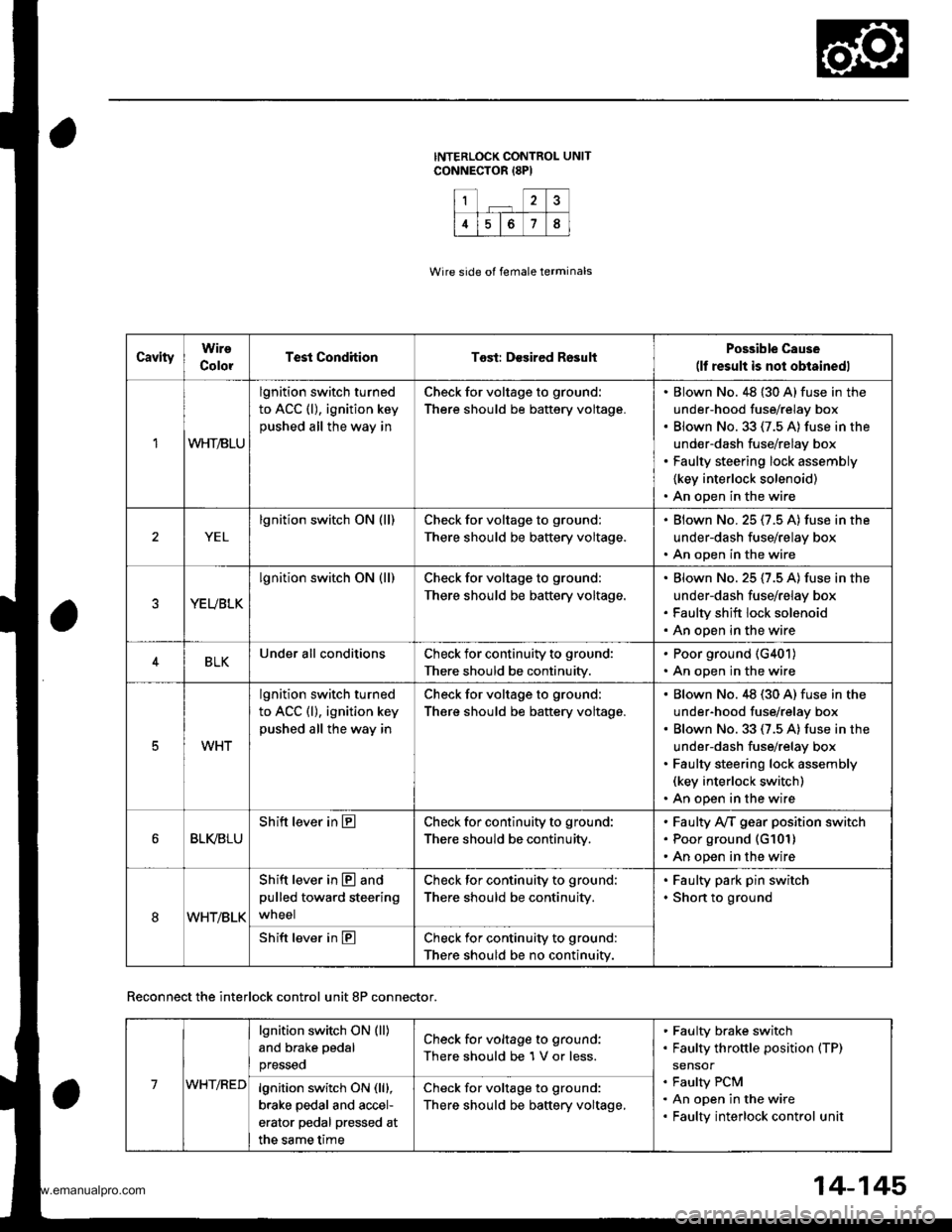

1?

4678

CavityWire

ColorTest CondhionTost: Desired RosultPossible Cause(lf result is not obtainedl

1WHT/BLU

lgnition switch turned

to ACC (l), ignition key

pushed all the way in

Check for voltage to ground:

There should be battery voltage.

Blown No. 48 {30 A} fuse in the

under-hood fuse/relay box

Blown No.33 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty steering lock assembly

{key interlock solenoid)

An open in the wire

YEL

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

Blown No.25 (7.5 A) fuse in the

under-dash fuse/relay box

An open in the wire

YEUBLK

lgnition switch ON (ll)Check for voltage to ground:

There should be baftery voltage.

Blown No. 25 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty shift lock solenoid

An open in the wire

4BLKUnder all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401)

. An open in the wire

5WHT

lgnition switch turned

to ACC (l), ignition key

pushed all the way in

Check for voltage to ground:

There should be battery voltage.

Blown No.48 (30 A) fuse in the

under-hood fuse/relay box

Blown No. 33 (7.5 A) fuse in the

under-dash fuse/relay box

Faulty steering lock assembly(key interlock switch)

An open in the wire

BLI(BLU

Shift lever in ECheck for continuity to ground:

There should be continuity,

Faulty Ay'T gear position switch

Poor ground (G101)

An open in the wire

8WHT/BLK

Shift lever in @ and

pulled toward steering

wneel

Check for continuity to ground:

There should be continuity.

Faulty park pin switch

Shon to ground

Shift lever in ECheck for continuity to ground:

There should be no continuity.

Wire side of female terminals

Reconnect the interlock control unit 8P connector.

14-145

7WHT/RED

lgnition switch ON (ll)

and brake pedal

presseo

Check for voltage to ground:

There should be 1 V or less.

Faulty brake switch

Faulty throttle position (TP)

sensor

Faulty PCM

An open in the wire

Faulty interlock control unit

lgnition switch ON (lll,

brake pedal and accel-

erator pedal pressed at

the same time

Check for voltage to ground:

There should be baftery voltage,

www.emanualpro.com

Page 673 of 1395

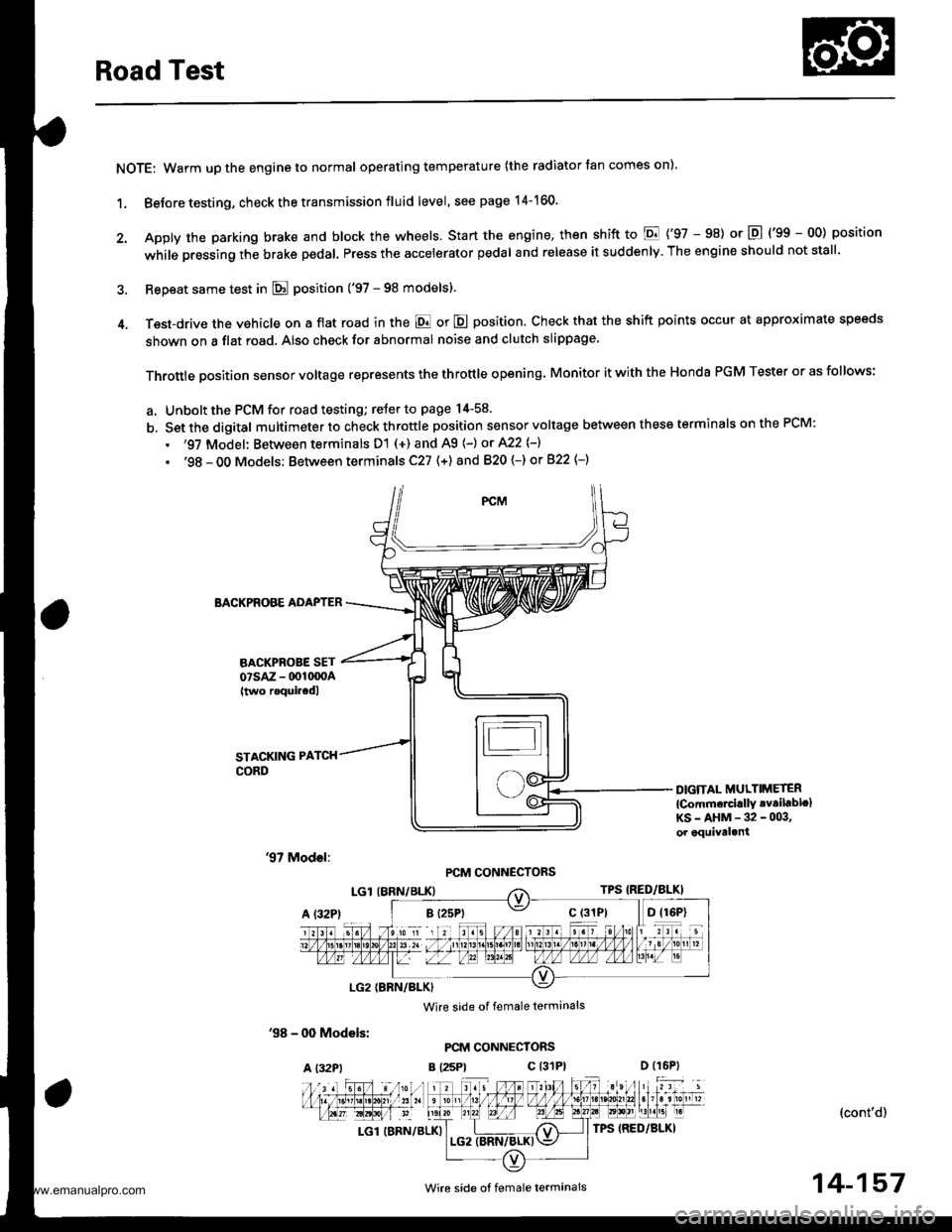

Road Test

NOTE: Warm up the engine to normal operating temperature (the radiator tan comes on).

1. Before testing, check the transmission fluid level, see page 14-160.

2. Apply the parking brake and block the wheels. start the engine, then shift to E {'97 - 98) or E {'gg - 00) position

while pressing the brake pedal. Press the accelerator pedal and release it suddenly. The engine should not stall.

3. Repeat same test in E position ('97 - 98 models).

4. Test-drive the vehicle on a flat road in the E or E position. Check that the shift points occur at approximate speeds

shown on a flat road. Also check for abnormal noise and clutch slippage.

Throttle position sensor voltage represents the throttle opening. Monitor it with the Honda PGM Tester or as follows:

a. Unbolt the PCM for road testing; reJer to page 14-58.

b. Set the digital multimeter to check throttle position sensor voltage between these terminals on the PCM:

. '97 Model: Between terminals D'! (+) and A9 (-) or A22 {-}

. '98 - OO Models; Between terminals C27 (+) and 820 (-) or 822 {-)

BACKPROBE ADAPTER

BACKPROBE SETorsAz - 001moA(two roquircdl

STACKING PATCH

CORD

DIGiTAL MULTIMETER

{Comm€rcirllY .vailablc}KS-AHM-32-003,or equival.nt

'97 Model:PCM CONNECTORS

'98 - 0O Models:

A l32Pt

Wire side of female terminals

PCM CONNECTORS

B {25Pt c l31P}

(cont'd)

LGl (BRN/BLK)

'. //B 1 l'o ti , jl. to a 2r / / 11111t1.t nait la t1 t213tr / t6t, tl / / / / 1 3 / 10n v

t-'a:IM-&E -Llfiffi-fl)\"".'E

Wire side ot female termanals14-157

www.emanualpro.com

Page 675 of 1395

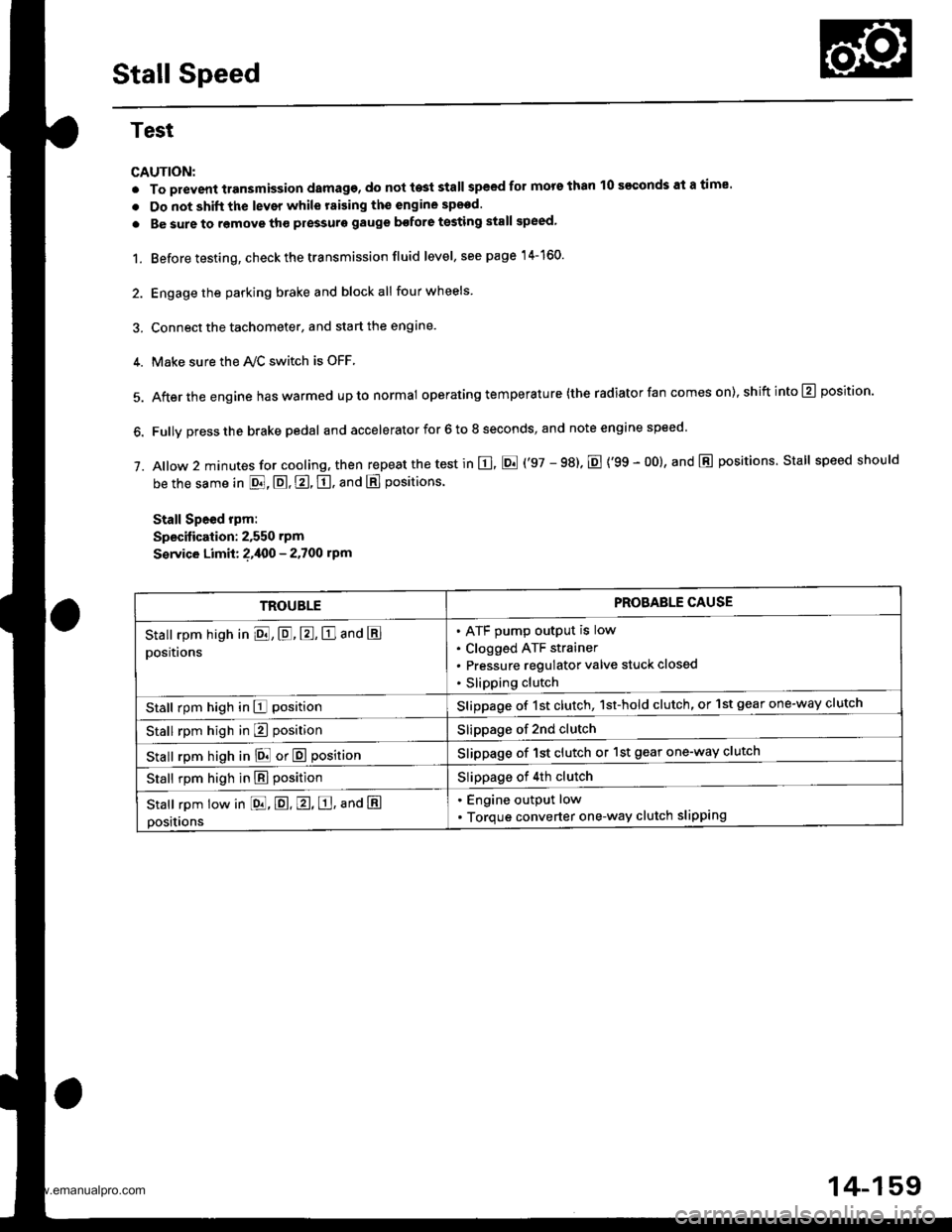

Stall Speed

Test

CAUTION:

. To prevent transmission damage, do not te3t stall speed for mors than 10 s€€onds at a time'

. Do not shift the lever while raising th€ engine spsed.

. Be sure to remove tho pressuro gauge bofore testing stall speed,

1. Before testing, check the transmission fluid level, s€e page 14-160.

2. Engage the parking brake and block all four wheels

3. Connect the tachometer, and start the engane.

4. Make sure the Ay'C switch is OFF

5. After the engine haswarmed upto normal operating temperature (the radiator fan comes on),shiftinto@ position.

6. Fully press the brake pedal and accelerator for 6 to 8 seconds, and note engine speed '

j. A|ow 2 minutes for cooling, then repeat the test in E, E ('97 - 98). E {'99 - 00}, and E positions. Stall speed should

be the same in E, E, E, tr. and E positions

Stall Speed rpm:

Specitication: 2,550 rpm

S€rvice Limit: ?,400 - 2.700 rpm

TROUBLEPROBAELE CAUSE

Stall rpm high in El, E, E, E and E

positions

ATF pump output is low

Clogged ATF strainer

Pressure regulator valve stuck closed

Slipping clutch

Stall rpm high in E positionSlippage of 1st clutch, 1st-hold clutch, or 1st gear one-way clutch

Stall rpm high in E positionSlippage of 2nd clutch

stall rpm high in E! or E positionSlippage of 1st clutch or 1st gear one-way clutch

Stall rpm high in E positionSlippage of 4th clutch

Stall rpm low in [dd, E. E, E, ana E

positions

. Engine output low

. Torque converter one-way clutch slipping

14-159

www.emanualpro.com

Page 925 of 1395

Brakes

Special Tools ............. 19-2

Component Locations

lndex ................ ...... 19-3

Inspection and Adlustment

Brake System Rubber Parts

and Brake Booster ..........,,,.......... 19-4

Brake Pedal ............ 19-5

Parking Brake ........ 19-6

Bleeding ................. 19'7

Brake System Indicator ................... 19-8

Front Brake Pads

Inspection and Replacement .......... 19-9

Front Brake Disc

Disc Runout Inspection ................... 19-11

Disc Thickness and

Parallelism Inspection ........,........ 19-1 1

Front Brake Caliper

Disassembly/Reassembly ............... 19-12

Master Cylinder/Brake Booster

Removal/lnstallation ....................... 19-13

Master Cylinder

Inspection/Disassembly .............. 19-14

Pushrod Clearance Adiustment ...... 19-14

Brake Booster Inspection ...,.,,,,....... 1 9-1 5

Rear Drum Brakes

Inspection .............. 19-15

Brake Shoes

Replacement ..... 19-r 8

Wheel Cylinder Replacement ......... 19-20

Brake Hoses/Lines

Inspection/Torque Specifications ... 19-21

Hose Replacement ....,...,............. ..,,, 19-22

Parking Brake Cable

Inspection and Replacement .......... 19-23

www.emanualpro.com

Page 928 of 1395

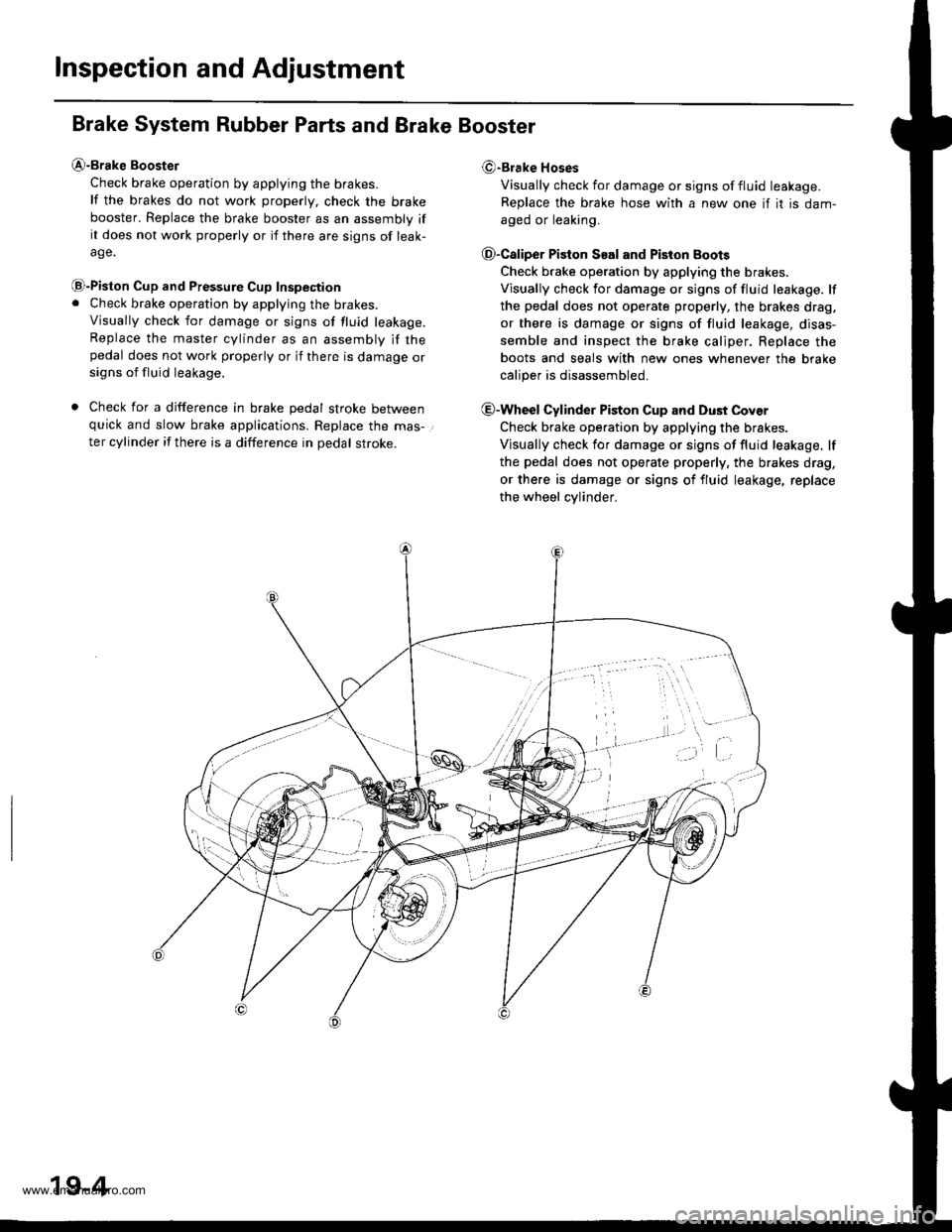

Inspection and Adjustment

Brake System Rubber Parts and Brake Booster

@-Brake Booster

Check brake operation by applying the brakes.

lf the brakes do not work properly, check the brake

booster. Replace the brake booster as an assembly ifit does not work properly or if there are signs of leak-

age.

@-Piston Cup and Pressure Cup Inspection. Check brake operation by applying the brakes.

Visually check for damage or signs of tluid leakage.Replace the master cylinder as an assembly if thepedal does not work properly or if there is damage orsigns of fluid leakage.

. Check for a difference in brake pedal stroke betweenquick and slow brake applications. Replace the mas-.

ter cylinder if there is a difference in pedal stroke.

(9-Brake Hoses

Visually check for damage or signs of fluid leakage.

Replace the brake hose with a new one if it is dam-

aged or leaking.

O-Caliper Piston S€al and Piston Boots

Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage. lf

the pedal does not operate properly, the brakes drag,

or there is damage or signs of fluid leakage, disas-

semble and inspect the brake caliper. Replace the

boots and seals with new ones whenever the brake

caliper is disassembled.

@-Wheel Cylinder Piston Cup and Dust Cover

Check brake operation by applying the brakes.

Visually check for damage or signs of fluid leakage. lf

the pedal does not operate properly, the brakes drag,

or there is damage or signs of fluid leakage, replace

the wheel cvlinder.

19-4

www.emanualpro.com

Page 929 of 1395

Brake Pedal

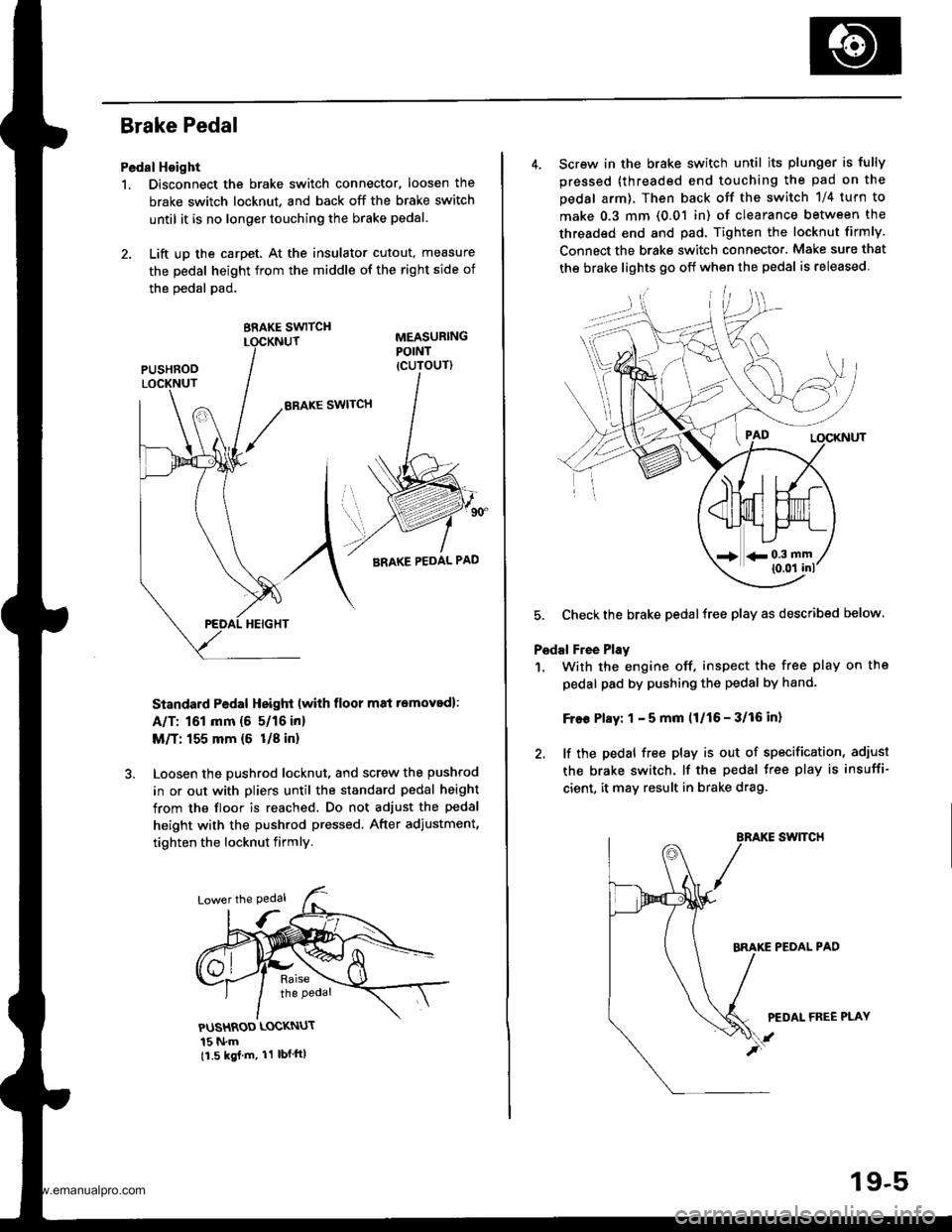

Pedal Hoight

1. Disconnect the brake switch connector, loosen the

brake switch locknut, and back off the brake switch

until it is no longer touching the brake pedal.

2. Lift up the carpet, At the insulator cutout, measure

the pedal height from the middle of the right side of

the oedal pad.

BRAKE SWITCH

ERAKE SWITCH

Standard Pedal Height (with floor m8i removed):

A/T: 161 mm (5 5/16 in)

M/T: 155 mm {6 U8 in}

Loosen the pushrod locknut, and screw the pushrod

in or out with pliers until the standard pedal height

from the floor is reached. Do not adjust the pedal

height with the pushrod pressed. After adiustment,

tighten the locknut firmly.

PUSHROD LOCKNUT

15 N.m11.5 kgj m, 11 lbf ftl

4. Screw in the brake switch until its plunger is fully

pressed (threaded end touching the pad on the

pedal arm), Then back otf the switch 1/4 turn to

make 0.3 mm (0.01 in) of clearance between the

threaded end and pad. Tighten the locknut firmly.

Connect the brake switch connecto.. Make sure that

the brake lights 90 off when the pedal is released

5. Checkthe brake pedalfree play as described below

Pedal Free Play

1. With the engine off. inspect the free play on the

pedal pad by pushing the pedal by hand-

Free Play: 1 - 5 mm (1/16 - 3/16 in)

2. lf the pedal free play is out of specification, adiust

the brake switch. lf the pedal free play is insuffi-

cient, it may result in brake drag.

swtTcH

PEOAL PAD

PEDAL FREE PLAY

19-5

www.emanualpro.com

Page 931 of 1395

Bleeding

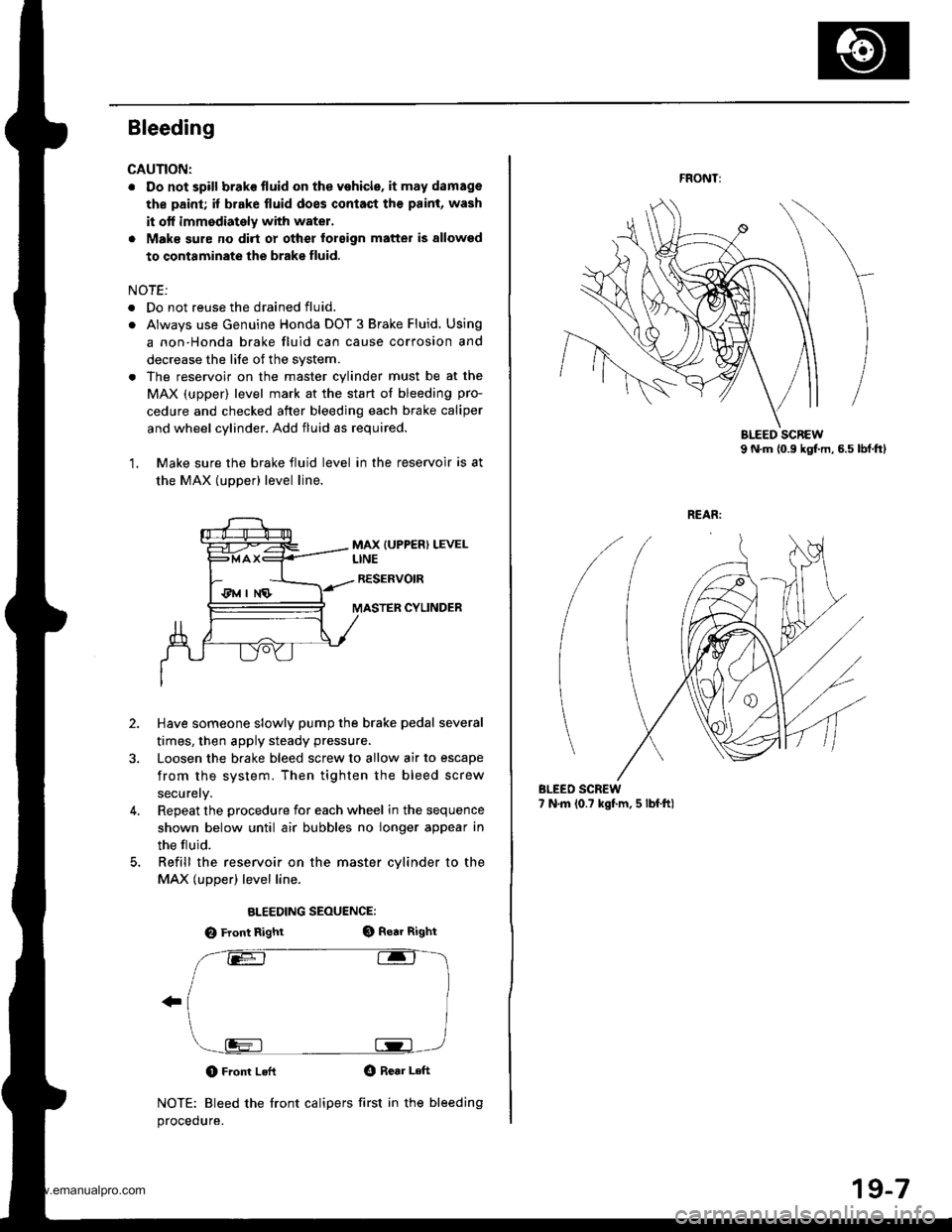

CAUNON:

. Do not spill brake tluid on the vehicle. it may damage

the paint; if brake fluid does contaqt th€ paint, wash

it otf immodiately with water.

. Maks sure no dirt oy other forsign matter is allowsd

to contaminate the brake fluid.

NOTE:

. Do not reuse the drained fluid.

. Always use Genuine Honda DOT 3 Brake Fluid. Using

a non-Honda brake fluid can cause corrosion and

decrease the life of the svstem.

. The reservoir on the master cylinder must be at the

MAX (upper) level mark at the start of bleeding pro-

cedure and checked after bleeding each brake caliper

and wheel cylinder. Add fluid as required.

1, Make sure the brake fluid level in the reservoir is at

the MAX (uDDer) level line.

MAX {UPPER) LEVELLINE

RESERVOIR

MASTER CYLINDER

2.

3.

Have someone slowly pump the brake pedal several

times, then apply steady pressu.e.

Loosen the brake bleed screw to allow air to escape

from the system. Then tighten the bleed screw

securely.

Repeat the procedure for each wheel in the sequence

shown below until air bubbles no longer appear in

the tluid.

Refill the reservoir on the master cvlinder to the

MAX (upper) level line.

ALEEDING SEOUENCE:

O Front RightGt Rear Right

O Front LeflO Rear Left

NOTE: Bleed the front calipers first in the bleeding

procedure.

4.

FRONT:

BLEEO SCREW7 N.m (0.? kgf.m, 5 lbf.ftl

19-7

www.emanualpro.com