4WD HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 707 of 1395

1.Remove the control lever mounting bolt trom the

torque converter side of the torque converter hous-

ing. (4WD)

Remove the ATF feed pipes from the servo body,

secondary valve body, lock-up valve body, and main

valve body.

For '97 - 98 models:

Remove the two bolts securing the ATF strainer and

servo detent base, then remove the strainer and the

base.

For'99 - 00 models;

Remove the ATF strainer {one bolt).

4. For'97 - 98 models:

Remove the seven bolts securing the servo body,

then remove the servo body and separator plate'

For'99 - 00 models:

Remove the eight bolts securing the servo body,

then remove the servo body and separator plate'

5. Bemove the three bolts securing the secondary

valve body, then remove the secondary valve body'

stop shaft bracket, and separator plate.

6. Remove the eight bolts securing the ATF lubrication

plate and lock-up valve body, then remove the ATF

lubrication plate, lock-up valve body' and separator

plate.

7. Remove the one bolt securing the regulator valve

body, then remove the regulator valve body'

8. Remove the stator shaft and stop shaft.

9. Remove the detent spring from the detent arm, then

remove the control shaft from the torque converter

houslng.

10. Remove the detent arm and detent arm shaft from

the main valve body.

11. Remove the five bolts securing the main valve

body, then remove the main valve body.

When removing the main valve body, do not let the

eight check balls fall out.

12. Remove the ATF pump driven gear shaft, then

remove the ATF PumP gears.

13. Remove the main separator plate with two dowel

prns.

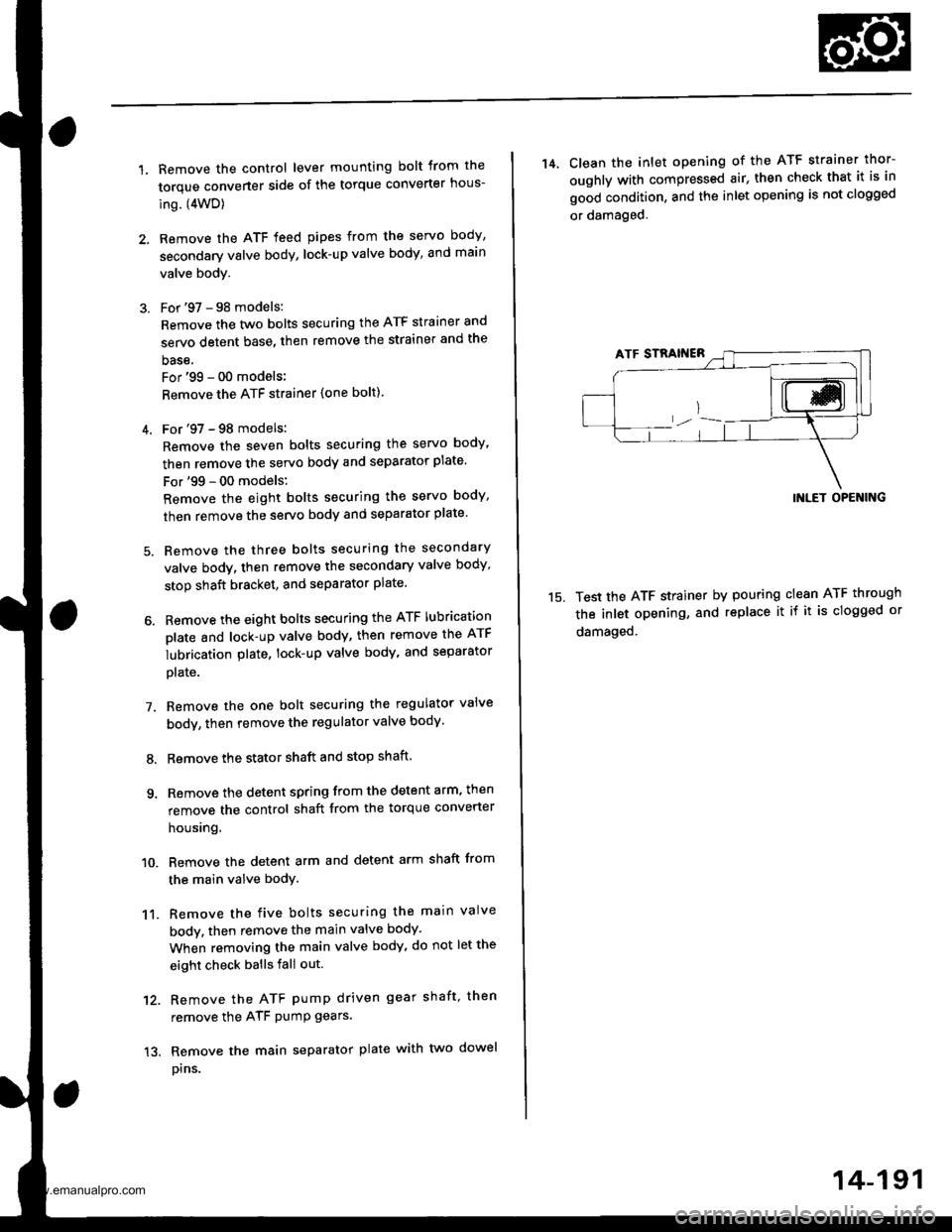

14, Clean the inlet opening of the ATF strainer thor-

oughly with compressed air, then check that it is in

good condition, and the inlet opening is not clogged

or damaged.

15.

INLET OPENING

Test the ATF strainer by pouring clean ATF through

the inlet opening, and replace it if it is clogged or

damaged.

14-191

www.emanualpro.com

Page 740 of 1395

Differential

Differential Carrier Replacement

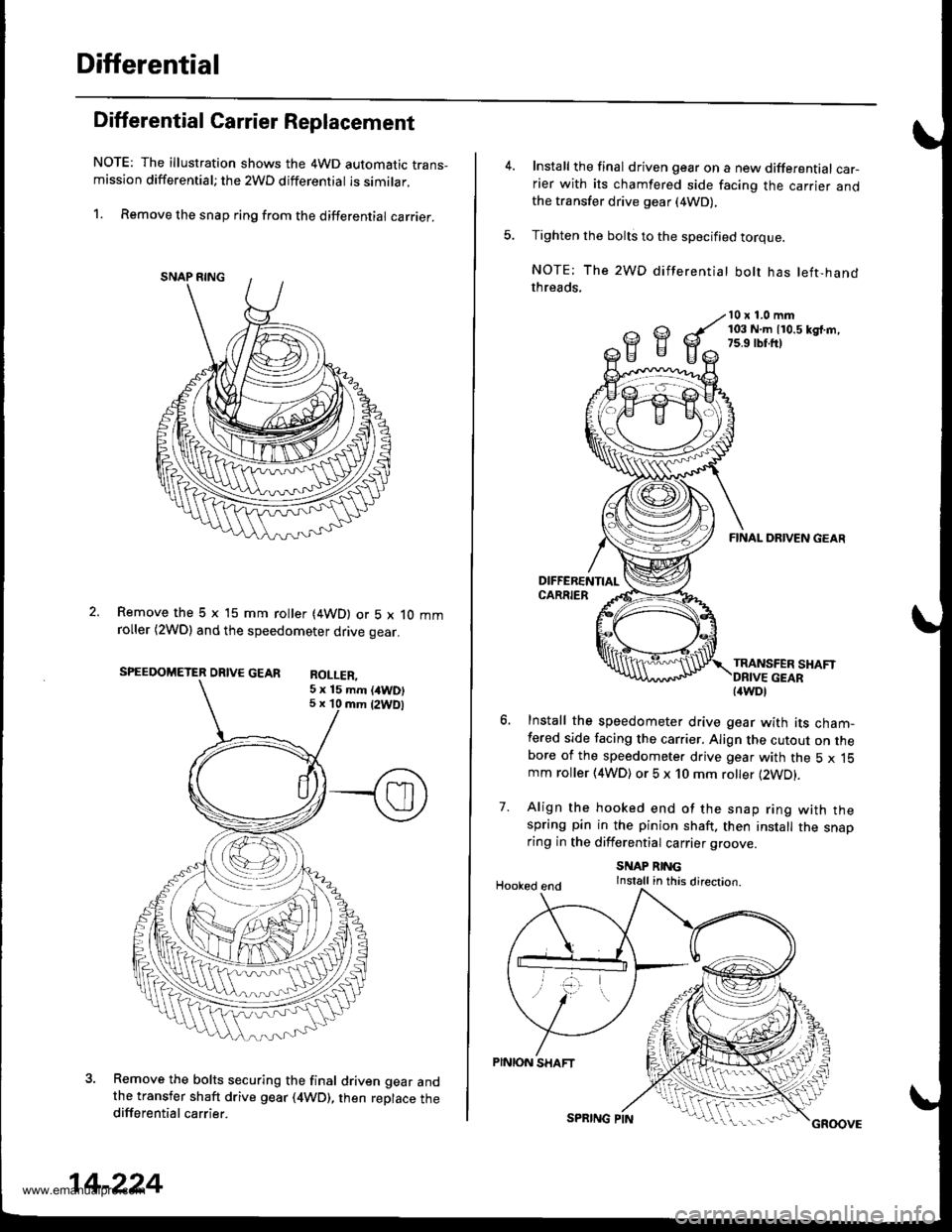

NOTE: The illustration shows the 4WD automatic trans-mission differential; the 2WD differential is similar.

1. Remove the snap ring from the differential carrier.

Remove the 5 x 15 mm roller (4WD) or 5 x 10 mmroller (2WDl and the speedometer drive gear.

SPEEDOMETER DRIVE GEAR RoI I FP

Remove the bolts securing the final driven gear andthe transfer shaft drive gear (4WD), then replace thedifferential carrier.

5 x 15 mm (/tWD)5 x 10 mm {2WDl

14-224

SPRING PINGROOVE

Install the final driven gear on a new differential car-rier with its chamfered side facing the carrier andthe transfer drive gear (4WD),

Tighten the bolts to the specified torque.

NOTE: The 2WD differentiat bolt has left-handthreads,

10 x 1.0 mm103 N.m 110.5 kd.m,7s.9 rbr.ft)

7.

FINAL DRIVEN GEAR

TRANSFER SHAFT

Install the speedometer drive gear with its cham-fered side facing the carrier. Align the cutout on thebore of the speedometer drive gear with the 5 x 15mm roller (4WD) or 5 x 10 mm roller (2WD).

Align the hooked end of the snap ring with thespring pin in the pinion shaft. then install the snaoring in the differential carrier groove

SNAP RINGInstall in this direction.Hooked end

PINION SHAFT

{4WDl

www.emanualpro.com

Page 766 of 1395

Transmission

Reassembly

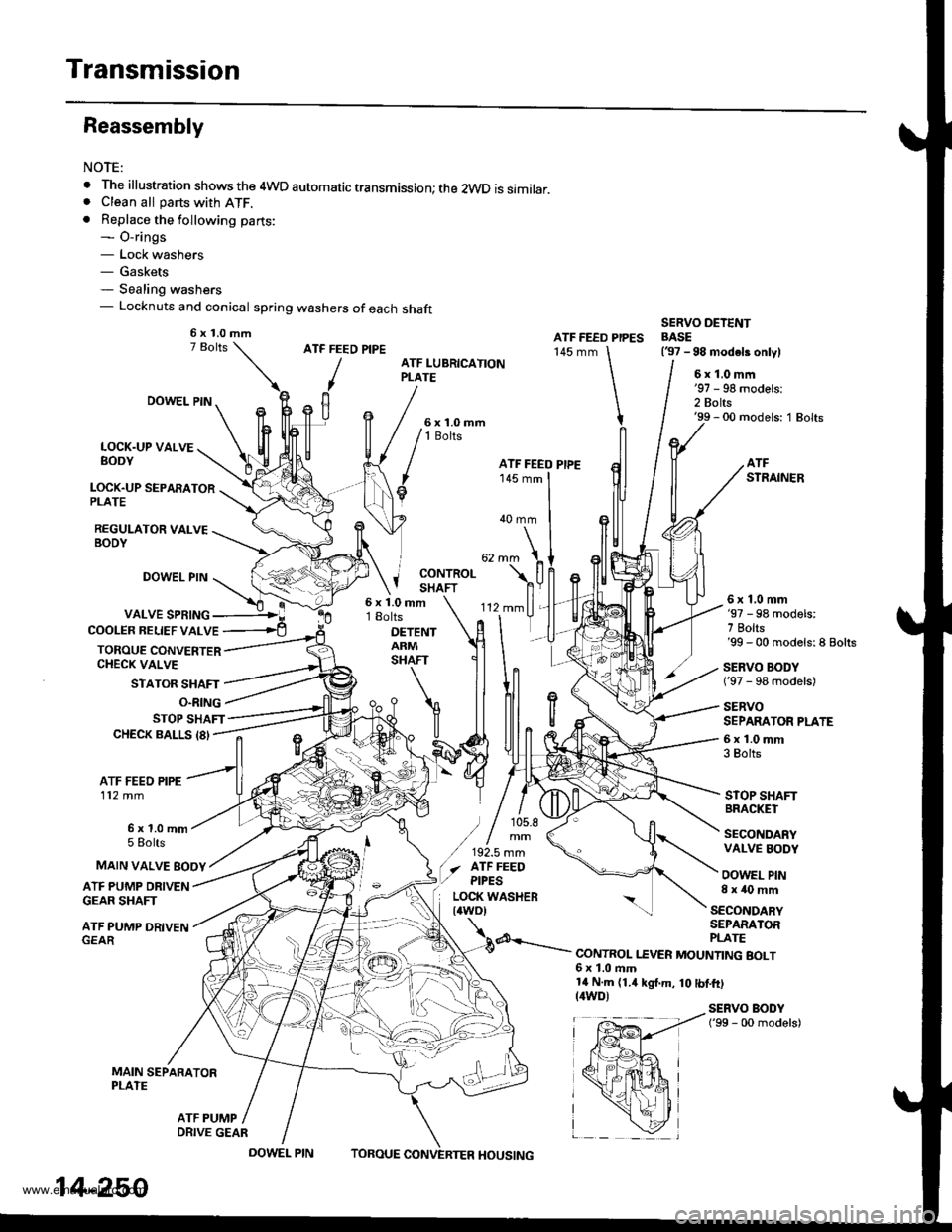

NOTE:

. The illustration shows the 4WD automatic transmission; the 2WD is similar.. Clean all parts with ATF.. Replace the following parts:- O-rings- Lock washers- Gaskets- Sealing washers- Locknuts and conical spring washers of each shaft

ATF FEED PIPE

/

ATF FEED PIPES145 mm

SERVO DETENTBASE(37 -98 modeb onlylATF LUBRICATIONPLATE6x1.0mm

2 Bolts'99 - 00 models: 1 Bolts

LOCK.UP VALVEBODY

LOCK.UP SEPARATORPLATE

REGULATOR VALVEBODY

DOWEL PIN

DOWEL PIN

VALVE SPRING

STATOR SHAFT

'-

'112mmll,

rlT

ATFSTRAINER

40 mm

j coNrRoLI SHAFT

COOLER BELIEF VALVE

TOROUE CONVERTERCHECK VALVE

6x1.0mm18olts

DETENTARMSHAFT

6x1,0mm'97 - 98 models:7 Bolts'99 - 00 models:8 Bolts

SERVO BODY('97 - 98 models)

SERVOSEPARATOR PLATE

6x1.0mm3 Bolts

STOP SHAFTBRACKET

SECONDARYVALVE BODY

OOWEL PIN8x40mm

O.RING

STOP SHAFTCHECK BALLS 18'

ATF FEED PIPE112 mm

6x1.0mm5 Eolts

ATF PUMP DRIVENGEAR SHAFT

ATF PUMP DRIVEN

MAIN SEPARATORPLATE

MAIN VALVE EOOY

SECONDARYSEPARATOR

d---.- PLATE--.- CONTROL I.EVER MOUNTING BOLT6x1.0ftm14 N.m (1.4 kgt.m, 10 tbf.ft)(4WD)SERVO BODY('99 - 00 models)

ATF PUMP

6x1.0mm

ATF FEEO PIPE

) / 105.8

/,,!.,::(./ afF FEEO,/ ptpEs

EP,---!ir{+*a r

fpffi4 i

x*hi

_ \zl

14-250

DRIVE GEAR

DOWEL PINTOBOUEHOUSING

www.emanualpro.com

Page 768 of 1395

Transmission

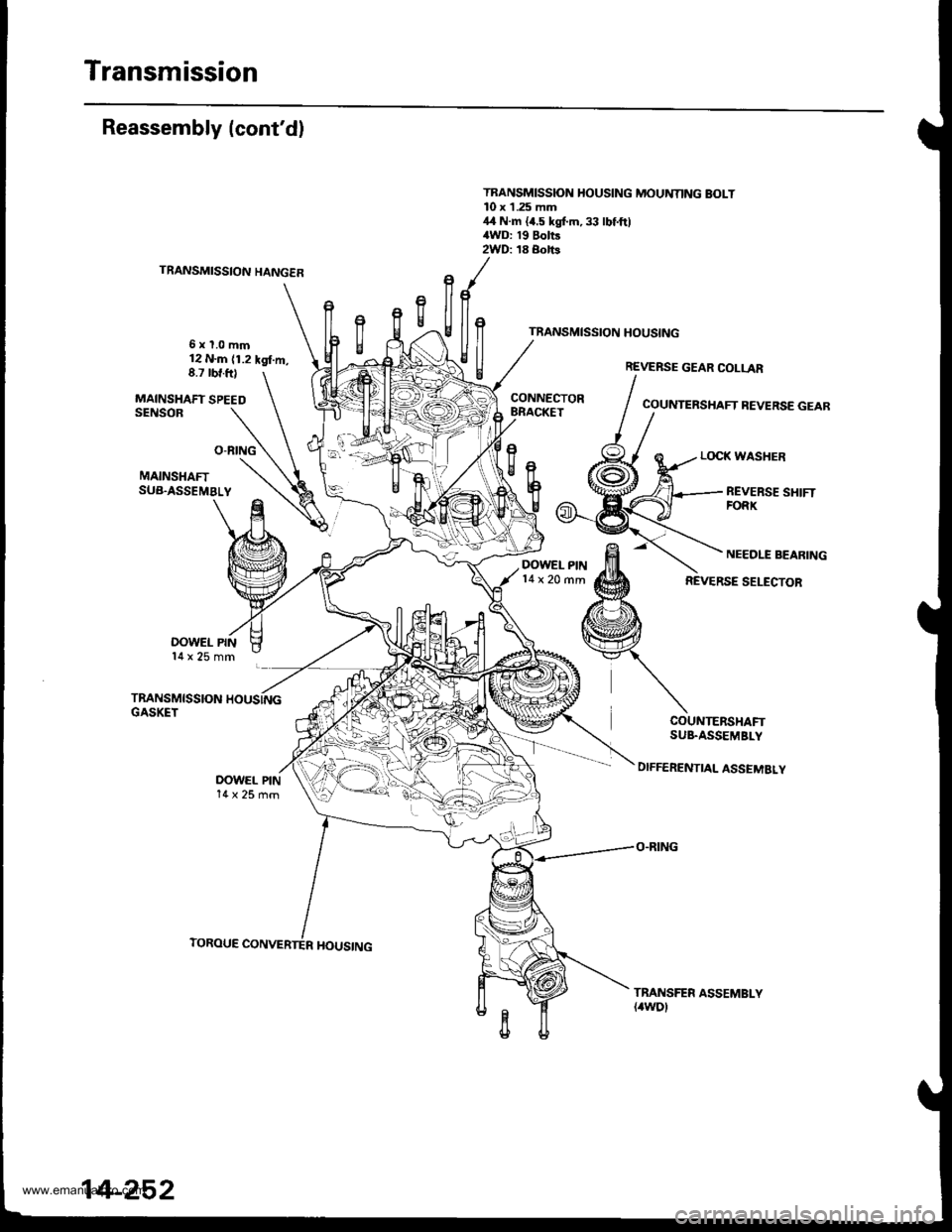

Reassembly (cont'd)

TRANSMISSION HANGER

6xl.0mm12 N.m (1.2 kgl.m,8.7 rbt.ft)

MAINSHAFT SPEEDSENSOB

TRANSMISSION HOUSING MOUNNNG BOLT10 x L254,1 N.m {/4WD: 192WD: 18

t

f,

llf, l

gil /

COUNTERSHAFT BEVERSE GEAB

LOCK WASHER

MAINSHAFTSUB.ASSEMBLY

OOWEL PIN14x25mm

TRANSMISSION HOUSINGGASKET

DOWEL PIN14x25mm

REVERSE SHIFTFORK

DOWEL PIN14 x 20 rnm

NEEDLE BEARING

REVERSE SELECTOR

COUNTERSHAFTSUB.ASSEMBLY

DIFFERENTIAL ASSEMBLY

TRANSFES ASSEMBLY(4wDl

14-252

www.emanualpro.com

Page 769 of 1395

17.

18.

19.

20.

21.

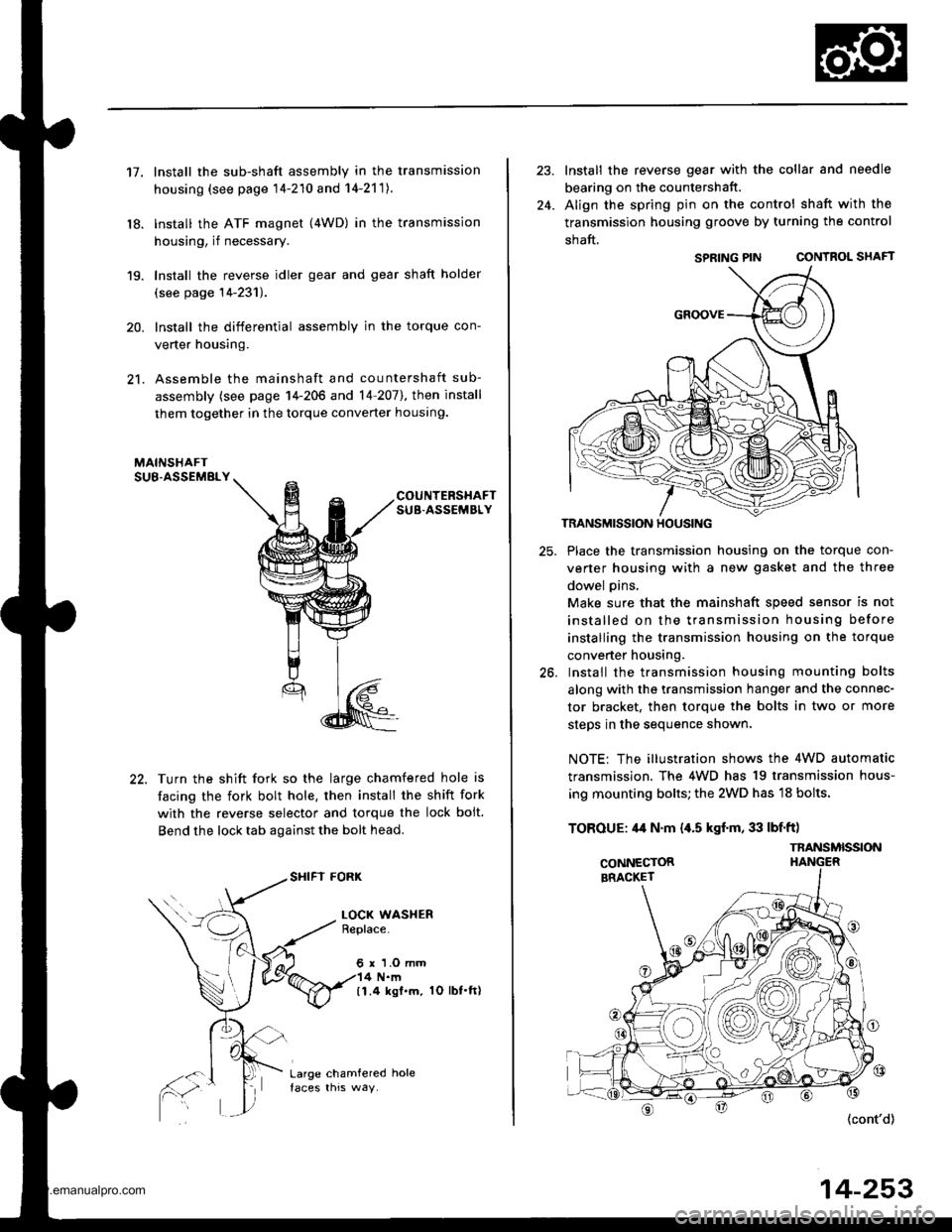

Install the sub-shaft assembly in the transmission

housing (see page 14-210 and 14-2'111.

lnstall the ATF magnet (4WD) in the transmission

housing, if necessary.

Install the reverse idler gear and gear shaft holder

(see page 14-231).

Install the differential assembly in the torque con-

verter housing.

Assemble the mainshaft and countershaft sub-

assembly (see page 14-206 and 14 207],, then install

them together in the torque converter houslng.

COUNTERSHAFTSUB-ASSEMBLY

Turn the shift fork so the large chamfered hole is

facing the fork bolt hole. then install the shift fork

with the reverse selector and torque the lock bolt.

Bend the lock tab against the bolt head.

SHIFI FORK

LOCK WASHERBeplace.

6 r 'l.O mm4 N.m(1.4 ksl.m. 1O lbt.ft)

Large chamfered hole

24.

Install the reverse gear with the collar and needle

bearing on the countershatt.

Align the spring pin on the control shaft with the

transmission housing groove by turning the control

shaft.

SPRING PIN CONTROL SHAFT

TRANSMISSION HOUSING

25. Place the transmission housing on the torque con-

verter housing with a new gasket and the three

dowel pins,

Make sure that the mainshaft speed sensor is not

installed on the transmission housing before

installing the transmission housing on the torque

converter housing.

26. Install the transmission housing mounting bolts

along with the transmission hanger and the connec-

tor bracket, then torque the bolts in two or more

steos in the seouence shown.

NOTE: The illustration shows the 4WD automatic

transmission. The 4WD has 19 transmission hous-

ing mounting bolts; the 2WD has 18 bolts.

TOROUE: 44 N.m {,[.5 kgf.m, 33 lbf'ft)

{cont'd)

14-253

SPRING PIN

TNANSMISSION

www.emanualpro.com

Page 772 of 1395

Transmission

Reassembly lcont'd)

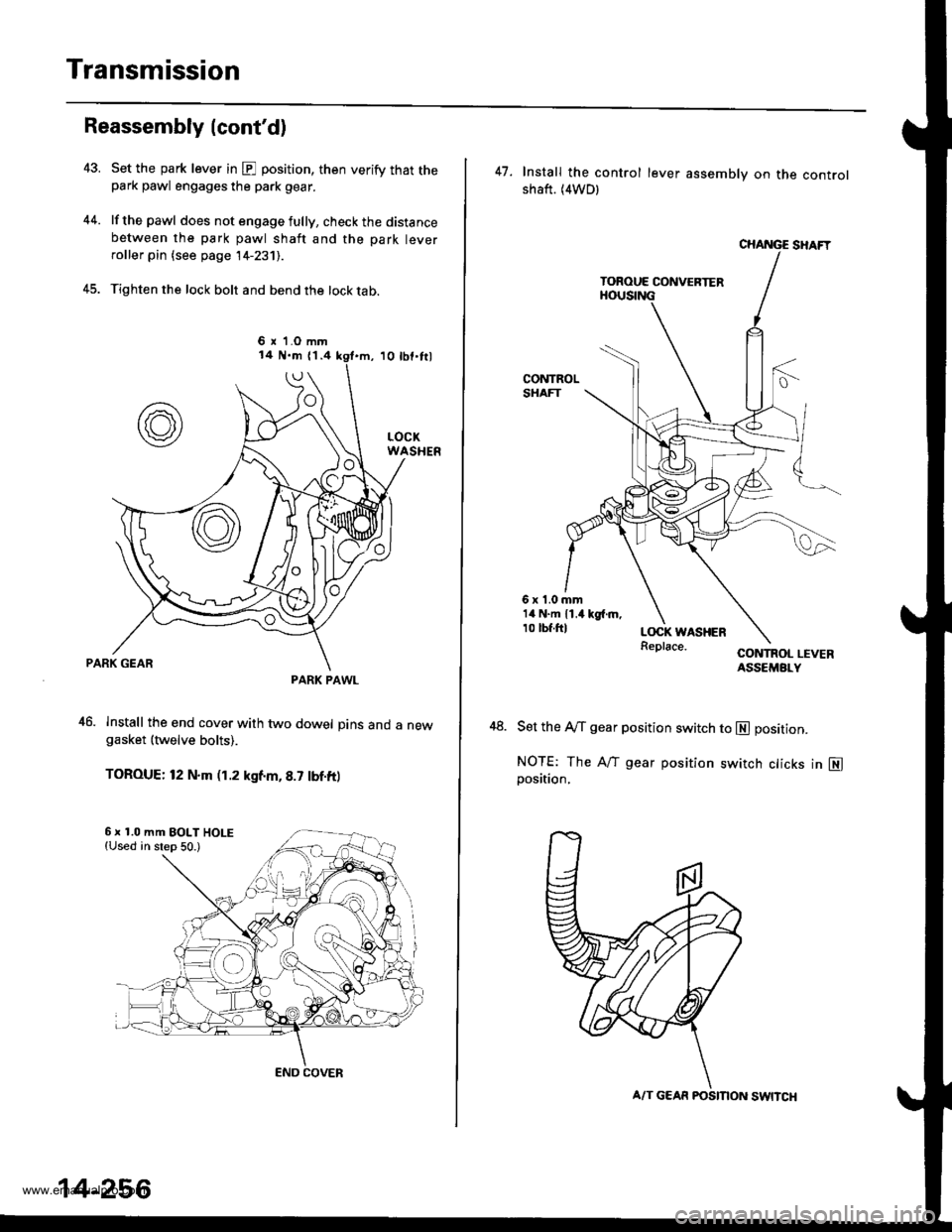

44.

Set the park lever in @ position, then verify that thepark pawl engages the park gear.

lf the pawl does not engage fully, check the distancebetween the park pawl shaft and the park leverroller pin (see page 14-231).

Tighten the lock bolt and bend the lock tab.

1o tbf'frl

PARK GEAR

46. Install the end cover with two dowel pins and a newgasket {twelve bolts).

TOROUE: 12 N.m (1.2 kgf.m, 8.7 tbf.ft)

6 r 1.O mm

PARK PAWL

6 x 1.0 mm EOLT HOLE{Used in step 50.)

END COVER

14-256

A/T GEAR FOSMON SWNCH

47. Install the control lever assemblv on the controlshaft. (4WDl

6x1.0mm14 N.m 11.4 kg{.m,10 tbf.ftl

48.

CONTROL LEVERASSEMBLY

Set the A/f gear position switch to E] position.

NOTE: The Aff gear position switch cticks in N]position,

www.emanualpro.com

Page 773 of 1395

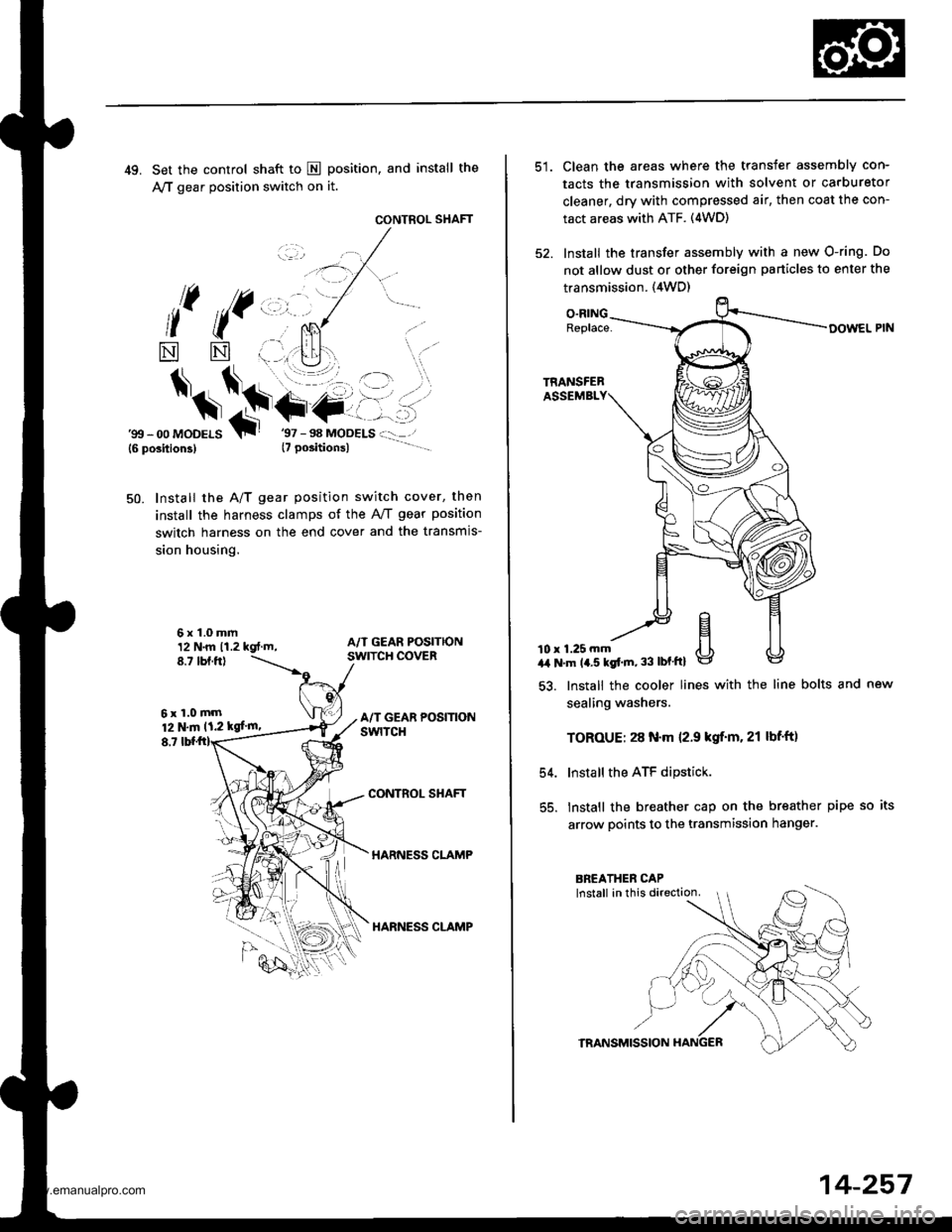

49. Set the control shaft to E position, and install the

A,/T gear position switch on it.

CONTROL SHAFT

l( ((,,, ,.

*

$*\.t+-

NN

6x1.0mm12 N.m 11.2 kgt.m,8.7 tbf.ftl

6xl.0mm12 N.m 11.2 kgf'm,

8,7

'gtt - 00 MoDELS{6 position3}T

Install the A/T gear position switch cover, then

install the harness clamps of the AviT gear position

switch harness on the end cover and the transmis-

sion housing.

50.

CONTROL SHAFT

HARNESS CLAMP

HARNESS CLAMP

Clean the areas where the transfer assembly con-

tacts the transmission with solvent or carburetor

cleaner, dry with compressed air, then coat the con-

tact areas with ATF. (4WD)

Install the transfer assembly with a new O-ring. Do

not allow dust or other foreign particles to enter the

transmission. {4WD)

O.RINGReplace-

10 r 1.25 mma,a N'm 14.5 kgt'm, 33 lbf'ftl

54.

55.

lnstall the cooler lines with the line bolts and new

sealing washers.

TOROUE: 28 N.m 12.9 kgif'm. 21 lbf'ft)

Install the ATF dipstick.

lnstall the breather cap on the breather pipe so its

arrow points to the transmission hanger.

TRANSMISSION

14-257

www.emanualpro.com

Page 777 of 1395

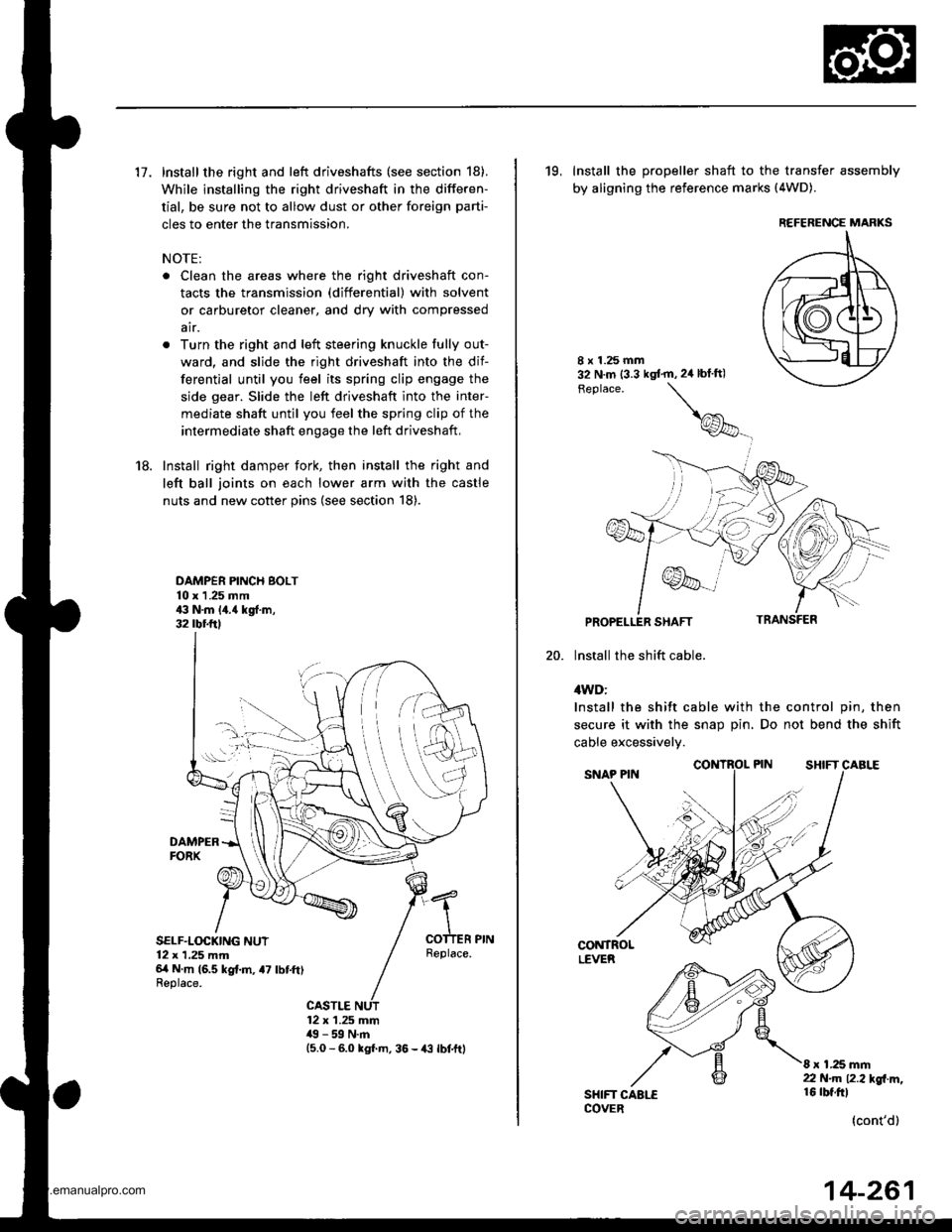

17. Install the right and left driveshafts (see section 18).

While installing the right driveshaft in the differen-

tial, be sure not to allow dust or other foreign parti-

cles to enter the transmission.

NOTE:

. Clean the areas where the right driveshaft con-

tacts the transmission (differential) with solvent

or carburetor cleaner, and dry with compressed

air.

. Turn the right and left steering knuckle fully out-

ward, and slide the right driveshaft into the dif-

ferential until you feel its spring clip engage the

side gear. Slide the left driveshaft into the inter-

mediate shaft until you feel the spring clip of the

intermediate shaft engage the left driveshaft,

18. Install right damper fork, then install the right and

left ball joints on each lower arm with the castle

nuts and new cotter pins (see section 18).

DAMPER PINCH BOLT10 x 1 .25 mm43 N.m 14.{ kgf.m,32 rbr.ftl

DAMPERFORX

SELF.LOCKING NUT12 x 1,25 mm6/t N m (6.5 kg{.m, a7 lbtft)Replace.

Replace.

CASTLE12 x 1.25 mm49 - 59 N.m15.0 - 6.0 kgl m, 36 - {3 lbtftl

19, Install the propeller shaft to the transfer assembly

by aligning the reference marks (4WD).

20.

8 x 1.25 mm32 N.m (3.3 kgt'm,2ir blft)

Feplace.

\

@_

PROPELLER SHAFT

lnstall the shift cable.

4WD:

Install the shift cable with the control pin, then

secure it with the snap Din. Do not bend the shift

cable excessivelv.

CONTROLLEVER

SHIFT CAALECOVER

8 x 1.25 mm22 N.m 12.2l'gl m,16 rbt.ftl

(cont'd)

REFERENCE MARKS

14-261

www.emanualpro.com

Page 789 of 1395

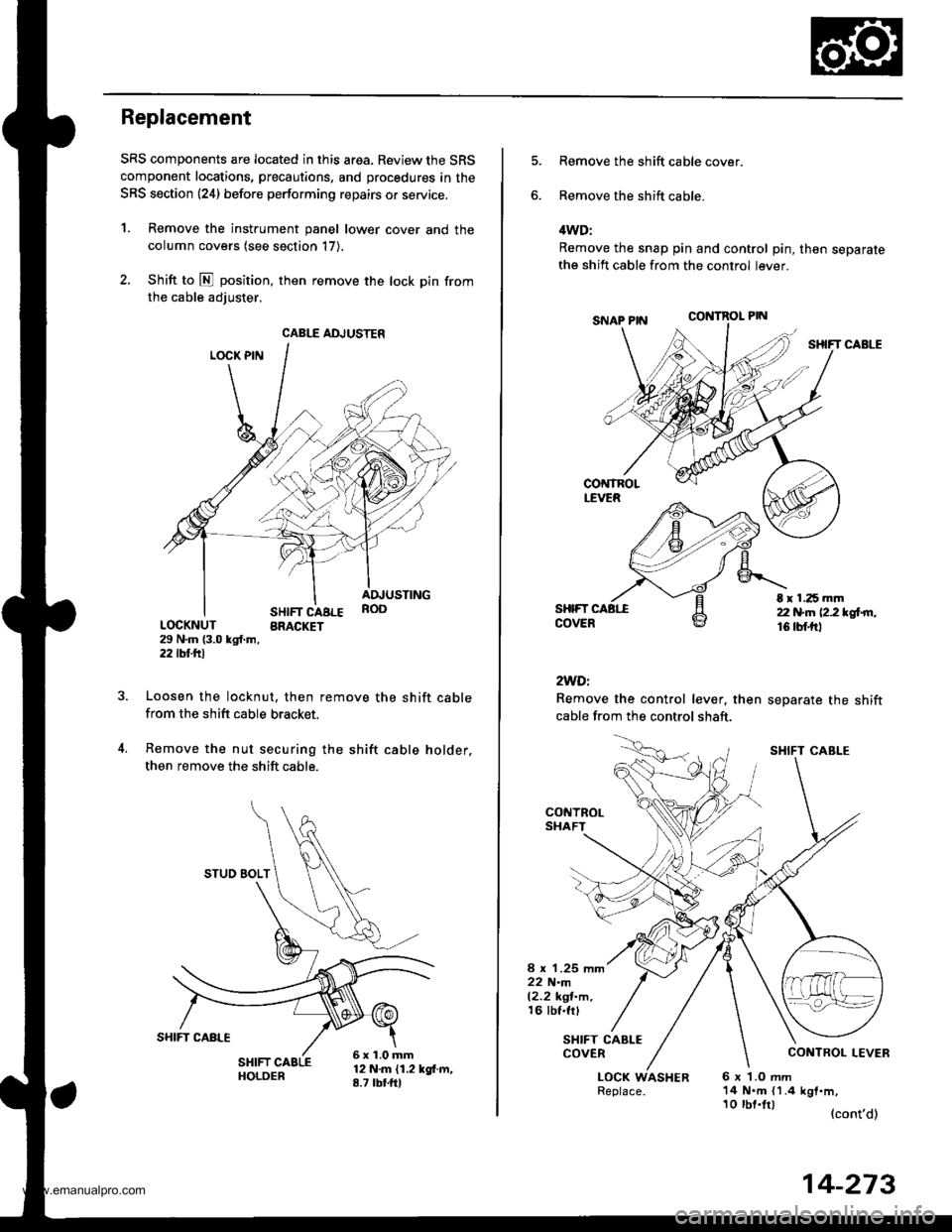

Replacement

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section {24} before performing repairs or service.

1. Remove the instrument panel lower cover and the

column covers (see section 17).

2. Shift to E position, then remove the lock pin from

the cable adiuster.

LOCK PIN

SHIFT CABLEBRACKET

ADJUSTINGROO

LOCKNUT29 N.m {3.0 kgl.m,2j2lbf.trl

Loosen the locknut, then remove the shift cablefrom the shift cable bracket.

Remove the nut securing the shift cable holder,

then remove the shift cable.

12 N.m {1.2 kgf.m,8.7 tbtfrl

CABLE ADJUSTER

STUO BOLT

6x1.0mm

Remove the shift cable cover.

Remove the shift cable.

4WD:

Remove the snap pin and control pin, then separatethe shift cable from the control lever.

CONTROL PIN

SHIFT CABLE

SHIFTCOVER

2WDi

Remove the control lever, then

cable from the control shaft.

separate the shift

t r 1.25 mm22 N.n 12.2 *glrn.16 tbf.trl

CONTROLSHAFT

8 x 1.25 mm22 N.m12.2 kgl-m,16 tbf.frl

SHIFT CABLECOVER

LOCK WASHER6x LOmm14 N.m {1.4 kgf.m,

(cont'd)

SHIFT CABI-E

10 tbt.lrl

14-273

www.emanualpro.com

Page 791 of 1395

Differential

Rear Differential

Special Tools .......... ...........15-2

Description

Rear Differential ................................. 15-4

Hydraulic Flow ............ ,.. 15-6

Real-time 4WD-Dual Pump System

Troub|eshootin9 ................................. 15-10

Rear Differential Assembly

Troubleshooting ................................. 15-13

Maintenance

Differential Fluid ........... . 15-14

Rear Differential Assembly

lllustrated Index .......... .. 15-15

Removal/lnstallation .... 15-16

Differential Carrier Assembly

Leak Repair .................... 15-18

OilSeals

Replacement ...,................................... 15-19

Rear Differential Assembly

Disassembly ..........,......., 15-20

Reassembly .................... 15-23

www.emanualpro.com