Idle HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 282 of 1395

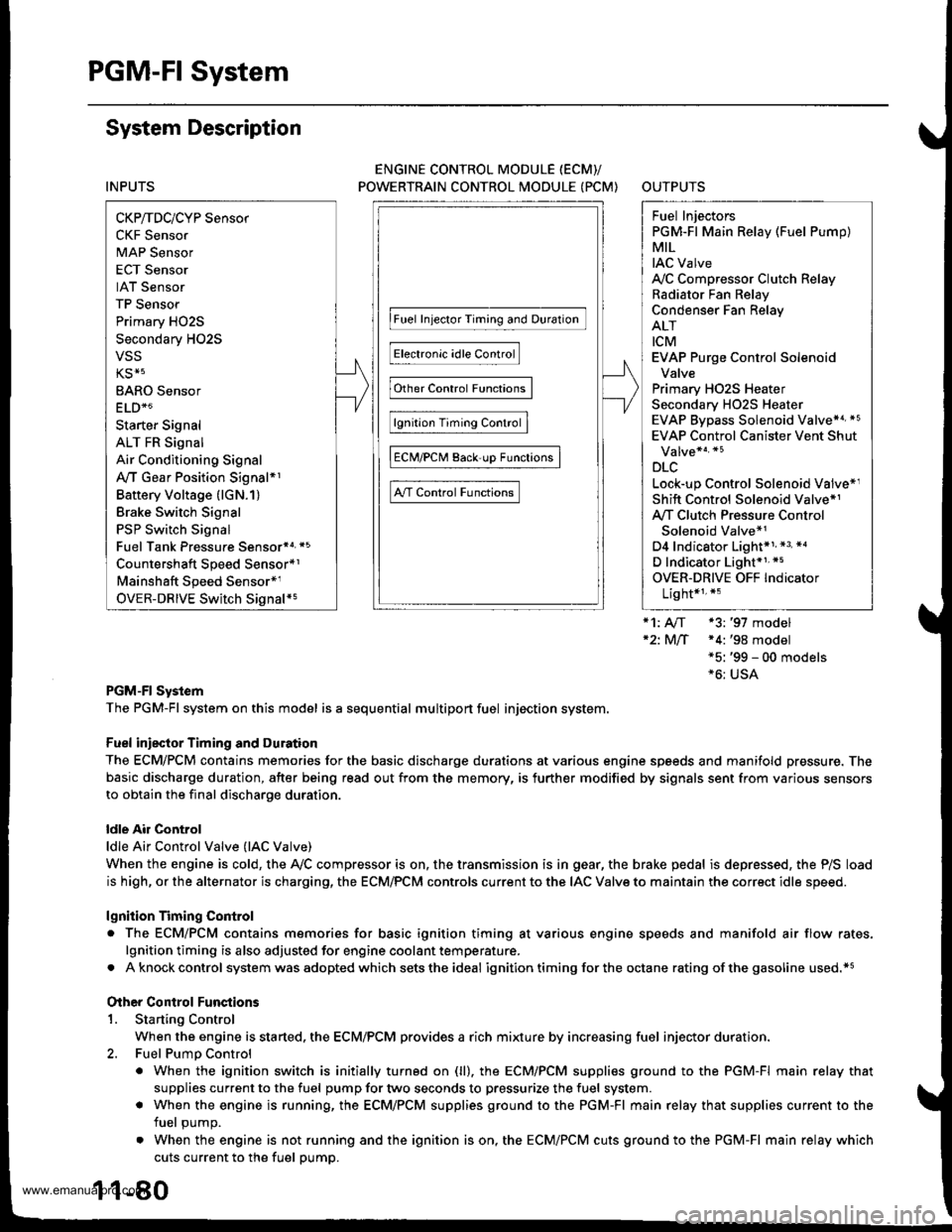

PGM-FI System

System Description

INPUTS

CKP/TDC/CYP Sensor

CKF Sensor

MAP Sensor

ECT Sensor

IAT Sensor

TP Sensor

Primary HO2S

Secondary H02S

vss

KS*5

BARO Sensor

ELD*6

Starter Signal

ALT FR Signal

Air Conditioning Signal

Ay'T Gear Position Signal*1

Baftery Voltage (lGN.1)

Brake Switch Signal

PSP Switch Signal

Fuel Tank Pressuae Sensor*4. *5

Countershaft Speed Sensor*1

Mainshaft Speed Sensor*r

OVER-DRIVE Switch Signal*s

ENGINE CONTROL MODULE (ECM)/

POWERTRAIN CONTROL MODULE (PCM) OUTPUTS

|iuel 1"j""- Th,rhg ""d Drrafr";-l

Et*-.nt"tdt"cont.orl

to,r*,c;;trffi;]

l.----.---:. .Lrgnrnon |lmrng Lonrror I

Ecir/PcM B*k',p Fr""il]

m;"t-ll-r*'io*l

Fuel Injectors

PGM-Fl Main Relay (Fuel Pump)

MIL

IAC Valve

Ay'C Compressor Clutch Relay

Radiator Fan Relay

Condenser Fan Relay

ALT

tcM

EVAP Purge Control Solenoid

Valve

Primary HO2S Heater

Secondary H02S HeaterEVAP Bypass Solenoid Valve*a *5

EVAP Control Canister Vent Shut

DLC

Lock-up Control Solenoid Valve*l

Shift Control Solenoid Valve*1

Ay'T Clutch Pressure Control

Solenoid Valve*1

D4 Indicator Light'1 *3, *a

D Indicator Light,l *5

OVER-DRIVE OFF Indicator

Lighl*t *:

*1: A/T {3:'97 model'2: M/f +4:'98 model*5: '99 - 00 models"6: USA

PGM-Fl System

The PGM-Fl system on this model is a sequential multiport fuel injection system.

Fuel iniecior Timing and Duration

The ECM/PCM contains memories for the basic discharge durations at various engine speeds and manifold pressure. The

basic discharge duration, after being read out from the memory, is further modified by signals sent from various sensors

to obtain the final discharge duration.

ldle Air Control

ldle Air Control Valve (lAC Valve)

When the engine is cold, the Ay'C compressor is on, the transmission is in gear, the brake pedal is depressed, the P/S load

is high, or the alternator is charging, the ECM/PCM controls current to the IAC Valve to maintain the correct idle speed.

lgnition Timing Control

o The ECM/PCM contains memories for basic ionition timing at various engine speeds and manifold air flow rates.

lgnition timing is also adjusted for engine coolant temperature.

. A knock control system was adopted which sets the ideal ig nition timing for the octane rating of the gasoline used.*s

Other Control Funstions

1. Starting Control

When the engine is started. the ECM/PCM provides a rich mixture by increasing fuel injector duration.

2. Fuel Pump Control

. When the ignition switch is initially turned on (ll). the ECMiPCM suppli€s ground to the PGM-FI main relay that

supplies current to the fuel pump for two seconds to pressurize the fuel system.

. When the engine is running, the ECM/PCM supplies ground to the PGM-FI main relay that supplies current to the

fuel oumo.

. When the engine is not running and the ignition is on, the ECM/PCM cuts ground to the PGM-FI main relay which

cuts current to the fuel pump.

1 1-80

www.emanualpro.com

Page 283 of 1395

Fuel Cut-off Control

. During deceleration with the throttle valve closed, current to the fuel injectors iscutoffto improvefuel economyat

speeds over 970 rpm ('97 - 98 models), 920 rpm ('99 - 00 modelsl.

. Fuel cut-off action also takes place when engine speed exceeds 6,500 rpm ('97 - 98 models), 6900 rpm ('99 - 00

models), regardless of the position of the throttle valve, to protect the engine from over-rewing.

With Ay'T model. the PCM cuts the fuel at engine speeds over 5,000 rpm when the vehicle is not moving.*'�

4,./C Comoressor Clutch Relav

When the ECM/PCM receives a demand for cooling from the air conditioning system, it delays the compressor from

being energized, and enriches the mixture to assure a smooth transition to the Ay'C mode.

Evaporative Emission (EVAP) Purge Control Solenoid Valve

When the engine coolant temperature is above 154"F (68'C), the ECM/PCM controls the EVAP purge control solenoid

valve which controls vacuum to the EVAP purge control canister,

Alternator Control

The system controls the voltage generated at the alternator in accordance with the electrical load and driving mode.

which reduces the engine load to improve the fuel economy.

PCM Fail-saf e/Back-up Functions

1. Fail-safe Function

When an abnormality occurs in a signal from a sensor, the ECM/PCM ignores that signal and assumes a pre-pre

grammed value for that sensor that allows the engine to continue to run.

2. Back-up Function

When an abnormality occurs in the ECM/PCM itself, the fuel injectors are controlled by a back-up circuit independent

of the system in order to permit minimal driving.

3. Self-diagnosis Function IMalfunction Indicator Lamp (MlL)l

When an abnormality occurs in a signal from a sensor, the ECM/PCM supplies ground for the MIL and stores the DTC

in erasable memory. When the ignition is initially turned on {ll), the ECM/PCM supplies ground for the MIL for two

seconds to check the MIL bulb condition.

4. Two Trio Detection Method

To prevent false indications, the Two Trip Detection Method is used for the HO2S*1, fuel metering-related. idle control

system, ECT sensor and EVAP control system self-diagnostic functions. When an abnormality occurs, the ECM/PCM

stores it in its memory. When the same abnormality recurs after the ignition switch is turned OFF and ON (ll) again,

the ECM/PCM informs the driver by lighting the MlL. However, to ease troubleshooting, this function is cancelled

when you jump the service check connector, The MIL will then blink immediately when an abnormality occurs.

5. Two (or Three) Driving Cycle Detection Method {'97 model)

A "Driving Cycle" consists of starting the engine, beginning closed loop operation, and stopping the engine. lf misfir-

ing that increases emissions or EVAP control system malfunction is detected during two consecutive driving cycles.

or TWC deterioration is detected during three consecutive driving cycles, the ECM/PCM turns the MIL on. However, to

ease troubleshooting, this function is cancelled when you jump the service check connector. The MIL will then blink

immediately when an abnormality occurs.

*1: '97 - 98 models*2: '99 - 00 models

5.

www.emanualpro.com

Page 294 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Owners Guide

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (contd)

[tn,t nn-] The scan tool indicates Diagnostic Trouble Code (DTC) P0108: A high voltage (low vacuum) problem in the|jg Manifold Absolute HONDA CR-V 1998 RD1-RD3 / 1.G Owners Guide

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (contd)

[tn,t nn-] The scan tool indicates Diagnostic Trouble Code (DTC) P0108: A high voltage (low vacuum) problem in the|jg Manifold Absolute](/img/13/5778/w960_5778-293.png)

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (cont'd)

[tn,t nn-] The scan tool indicates Diagnostic Trouble Code (DTC) P0108: A high voltage (low vacuum) problem in the|jg Manifold Absolute Pressure (MAP) sensor.

MAP SENSOR 3P CONNECTOR IC131I

Wire side of female terminals

vcclIYEL/RED}

PCM CONNECTOR D I16PI

JUMPER WIRE

sGlIGRN/WHTI

Wire side of lemale termin6ls

1

(To page 11,93)': '98 - 00 models

1-92

tcRN/wHrll IIRED/GRN|

The MIL has boen reported on.DTC m108 is slored.

Problem veritication:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on, thenlet it idle.2. Check the MAP with the scantool.

Intermittent tailuro, system i3 OKat this time. Check tor ooor con-nections or loose wires at C131IMAP s6nsor) snd the ECM/rcM.

ls 101 kPa {760 mmHg,30 in.Hg),2.9 V or higher indicated?

Check Ior an open in the MAPsensor:1. Turn the ignition switch OFF.2. Disconnect the MAP sensor3P connector.3. lnstall a jumper wire betweenthe MAP sensor 3P connectorterminals No.3 and No.2.4. Turn the ignition switch ON {ll).5. Check the MAP with the scantool.

ls 10'l kPa (760 mmHg,30 in.Hg),2.9 V or higher indicated?

Check for an open in wire (SGlliDel:1. Remove the jumper wire.2. Measure voltage between theMAP sensor 3P connector ter-minals No. 1 and No- 2.

R6p.ir open in the wire betwoenthe ECM/PCM (D12, CTrl and theMAP sensor.

ls there approx. 5 V?

Check for an open in the wire(MAP line):1. Turn the ignition switch OFF.2. lnstall a iumper wire on thePCM connectors between D3and D12.3. Turn the ignition switch ON (ll).4. Check the MAP wirh the scantool.

Ropair opon in the wire betweenthe PCM {D3, .nd the MAP son-3('t.

ls 101 kPa 1760 mmHg, 30 in.Hg),2.9 V or higher indicated?

YES

www.emanualpro.com

Page 296 of 1395

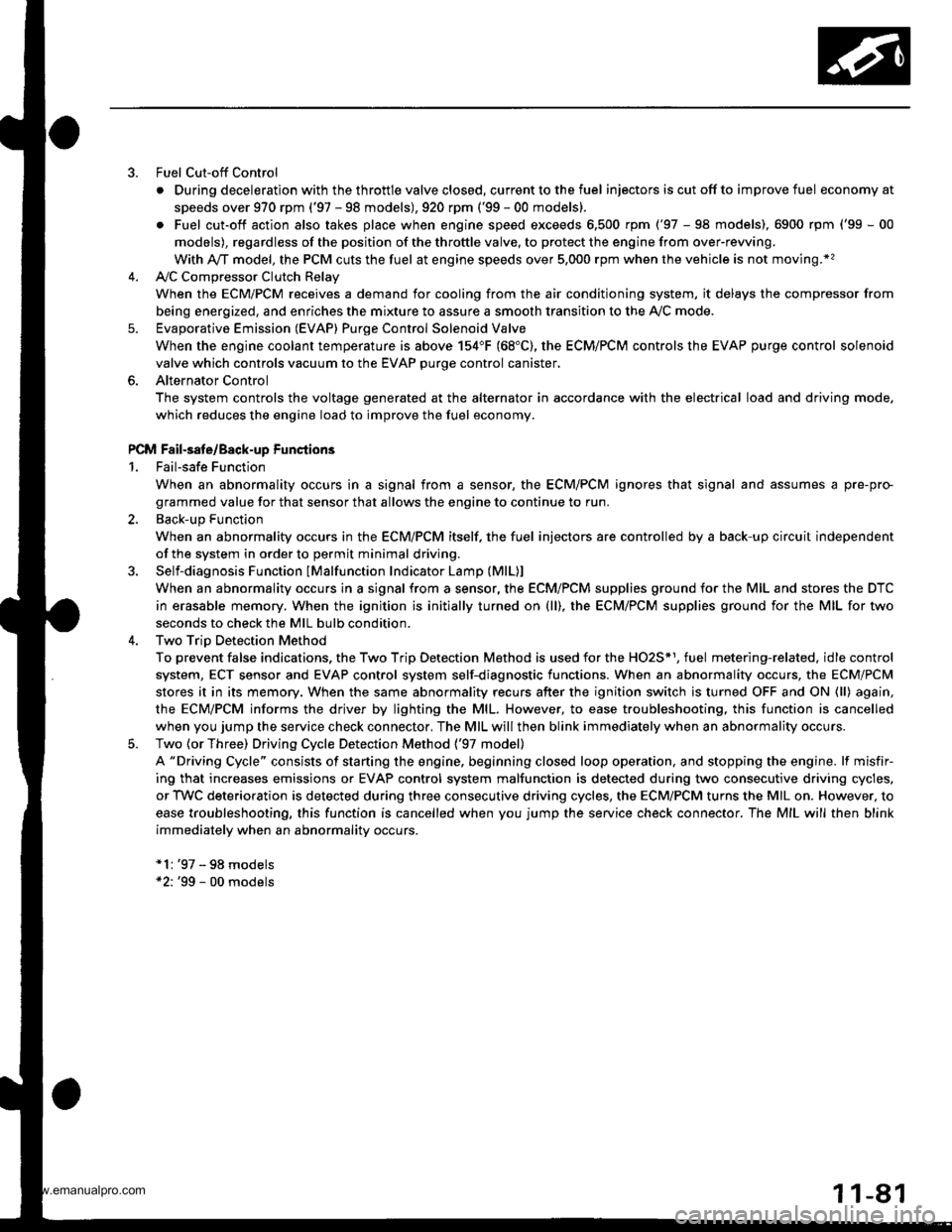

PGM-FI System

Manifold Absolute Pressure (MAP) Sensor (cont'dl

The scan tool indicates Diagnostic Trouble Code (DTC) P1128: Manifold Absolute pressure (MAp) lower thanexoected.

The scan tool indicates Diagnostic Trouble Code (DTC) P'l129: Manifold Absolute Pressure (MAP) higher thanexpected.

l

- The MIL has be6n r€ported on.- DTC Pl128 is stored.

Problom verification:1. Turn the ignition switch ON 1lli.2. Check the MAP with the scantool,

ls 54.1 kPa (406 mmHg, 16.0 in.Hg),1.61 V or higher indicated?I to.mittent failure, 3ydom i! OKal thbtimc,

- The MIL has boen reportod on.- DTC Pl129 is stored.

Problem veritication:1. Start the engine. Hold theengine at 3,000 rpm with noload lin Park or neutral) untilthe radiator fan comes on,then Iet it idle.2. Check the MAP with the scantool,

ls 43.3 kPa (325 mmHg, 12.8 in.Hg),'1.32 V or less indicated?Intarmittani fuilure, systom i3 OKat this time.

11-94

www.emanualpro.com

Page 301 of 1395

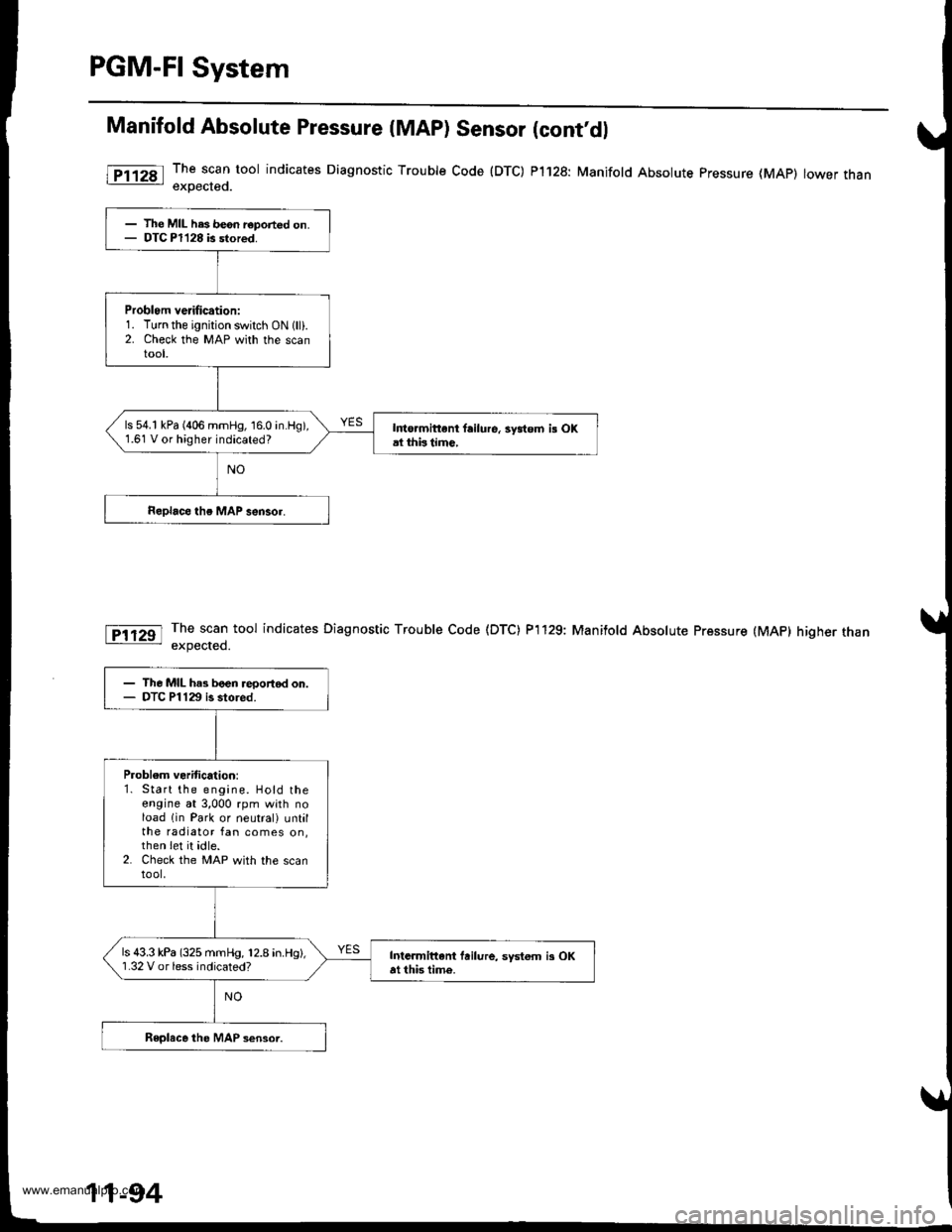

Engine Goolant Temperature (ECTI Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0116: A range/performance problem in the Engine

Coolant Temperature (ECT) Sensor circuit.

The ECT Sensor is a temperature dependant resistor (thermistor). The resistance of the thermistor decreases as the engine

coolant temperature increases as shown below

RESISTANCEtk0l

NOTE: lf DTC P0117 and/or P0118 are stored at the same

bleshoot DTC P0116.

Possible Cause

a ECT sensor deterioration

. Malfunction in the thermostat and cooling system

Troubleshooting Flowchart

-4 32 68 r0a r a0176 212 2aE {'r)-2O O 20 ito tO .o ! t2O I c)

ENGINE COOLANT TEMPERATURE

time as DTC P0116, troubleshoot those DTCS first, then trou-

THERMISTON

- The MIL has be€n roported on.- DTC P01'16 is stored.

Probl6m verification:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on,then let it idle.2. With the scan tool, check theECT.

Intermittent failure, sYstem b OKat this tim6. Check lhe thermo-stat and the cooling 5y3tom.

ls 176 - 200'F (80 - 93"C) or0.4-0.TVindicated?

Check the thermostat and the

cooling system. It th€y are OK,reolace the ECT seNor.

(cont'd)

1 1-99

www.emanualpro.com

Page 313 of 1395

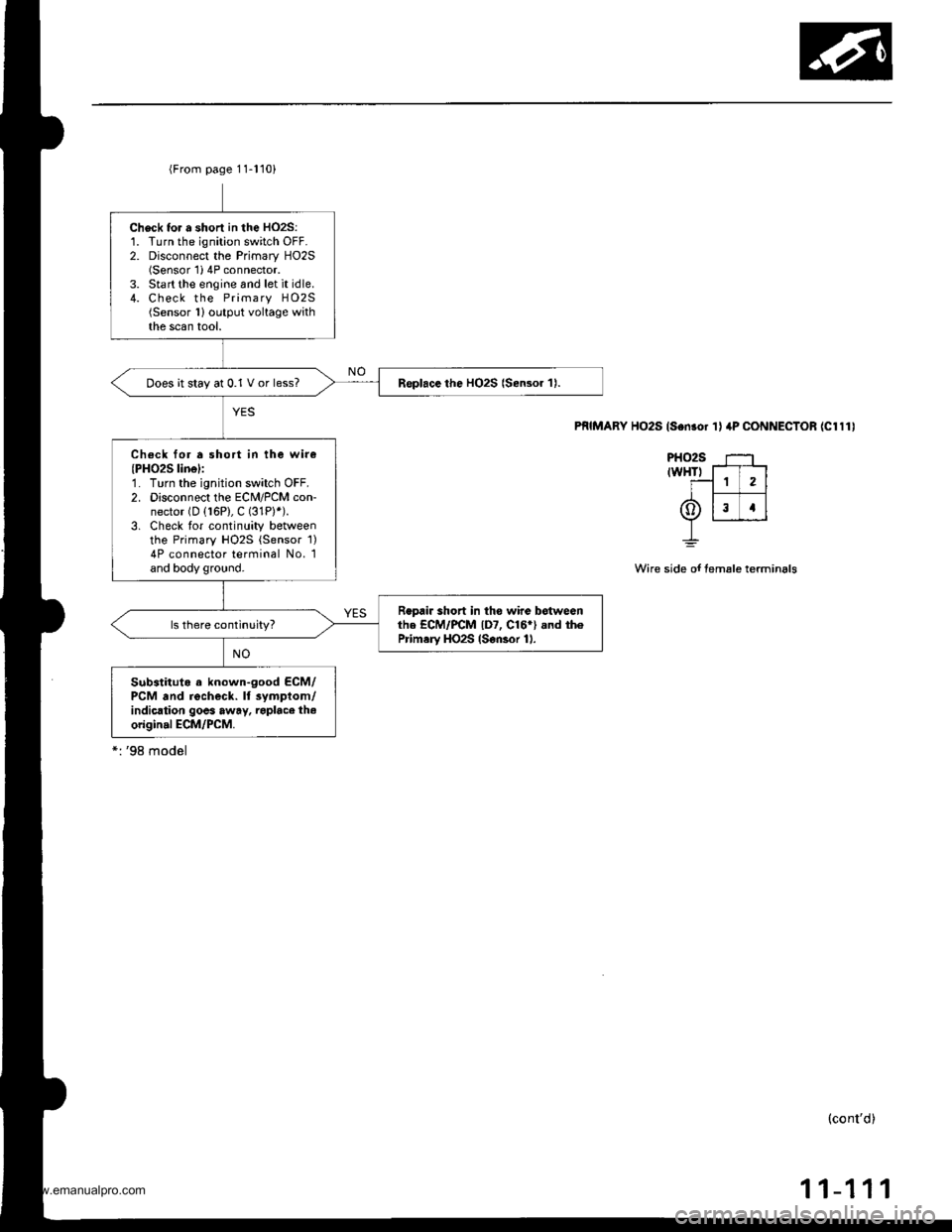

{From page 11-110}

Check tor a shorl in the HO2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor'1i 4P connector.3. Start the engine and let it idle.4. Check the Primary HO2S(Sensor 1)output voltage withthe scan tool.

Replace the HO2S {Sensor 1).Does it stay at 0.1 V or less?

Check for a short in the wir€(PH02S linel:1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector (D (16P), C (31P)*).

3. Check tor continuity betweenthe Primary HO2S {Sensor 1)4P connector terminal No. 1and body ground.

Repair short in tho wire botwesnthe ECM/PCM lD7, C16*) .nd th6Prim.ry HO2S (S€nsor 11.

Substituto a known-good ECM/PCM and recheck. ll 3ympiom/indication goes away. raplace th.origin.l ECM/PCM.

PRIMARY HO2S ls.n.or 'l I 4P CONNECTOR (Cl111

PHO2S ---'trwHTr T-T-l

T-1 1 2l

6tlr rlY r___J_J

L

Wire side of temale terminals

(cont'd)

11-111

www.emanualpro.com

Page 314 of 1395

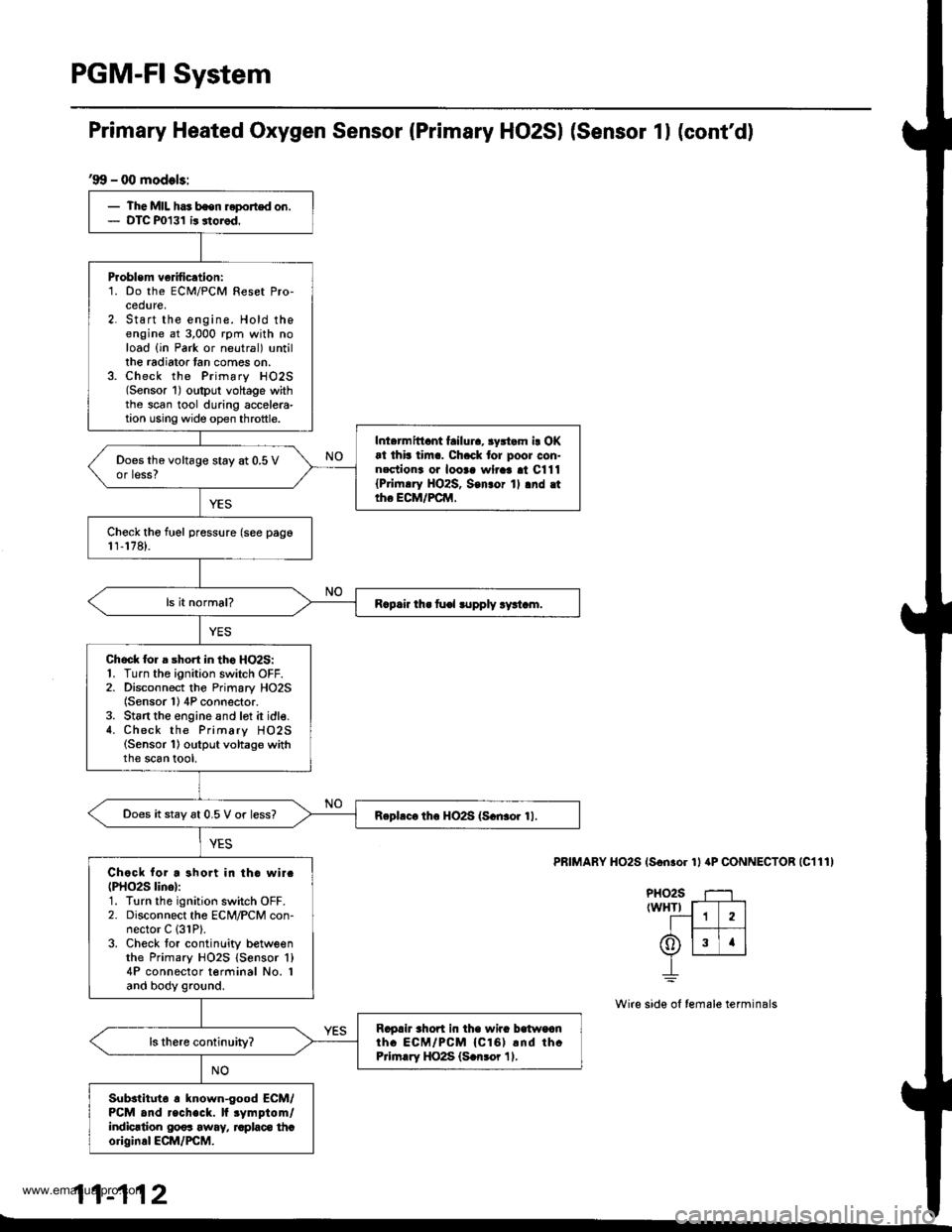

PGM-FI System

'99 - 00 models:

- The MIL has bsen reported on.- DTC P0131 ir storod.

Problem ve fication:1. Do the ECM/PCM Reset Pro-cedure,2. Start the engine. Hold theengine at 3,000 rpm with noload {in Park or neutral) untillhe radiator tan comes on.3. Check the Primary HO2S(Sensor 1) oltput voltage withthe scan tool during accelera-tion using wide op€n throttle.

Inl.rmittant failura, 3yrtam i! OKat thb tim.. Ch.ck tor poor con-nectiona oa looaa wlraa al C111{Pri|n.ry HO2S, Son3or 1l .nd .ttho ECM/FCM,

Does the voltage stay at 0.5 Vor less?

Check tho fuel pressure (see pago1r,178).

R.p.ir th. fu€l lupply ry!t.m.

Chock lor a short in tho HO2S:1. Turn the ignition switch OFF.2. Disconnect the Primary HO2S(Sensor 1) 4P connector.3. St6rt the engine and lot it idle.4. Check the Primary HO2S(Sensor 1) output voltage withthe scan tool,

Does it stay 6t 0.5 V or less?Rephc. th6 HO2S (S.n3or 11.

Chock for a short in tho wirc(PHO2S lino):1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector C (31P).

3. Check tor continlity betweenthe Primary HO2S {Sensor 'l}

4P connector terminal No. Iand body ground.

Ragah rhort in tha wira balwoanth. ECM/PCM {Cl61 rnd thcPrirn.ry HO2S (S.n3or 11.

Substltut6 a known-good ECM/PCM and recheck. lf rymptom/indicrtion 00os away, raplaco thcoriginal ECM/PCM.

Primary Heated Oxygen Sensor (Primary HO2SI (Sensor 1l (cont'd)

PRIMARY HO2S (Son.or 1l aP CONNECTOR |C111)

PHO2S T--1rwHTr f-T---]

--1 1 2lI t--- 1t6)lslrlv L__r__J

_L

Wire side ol female terminals

11-112

www.emanualpro.com

Page 331 of 1395

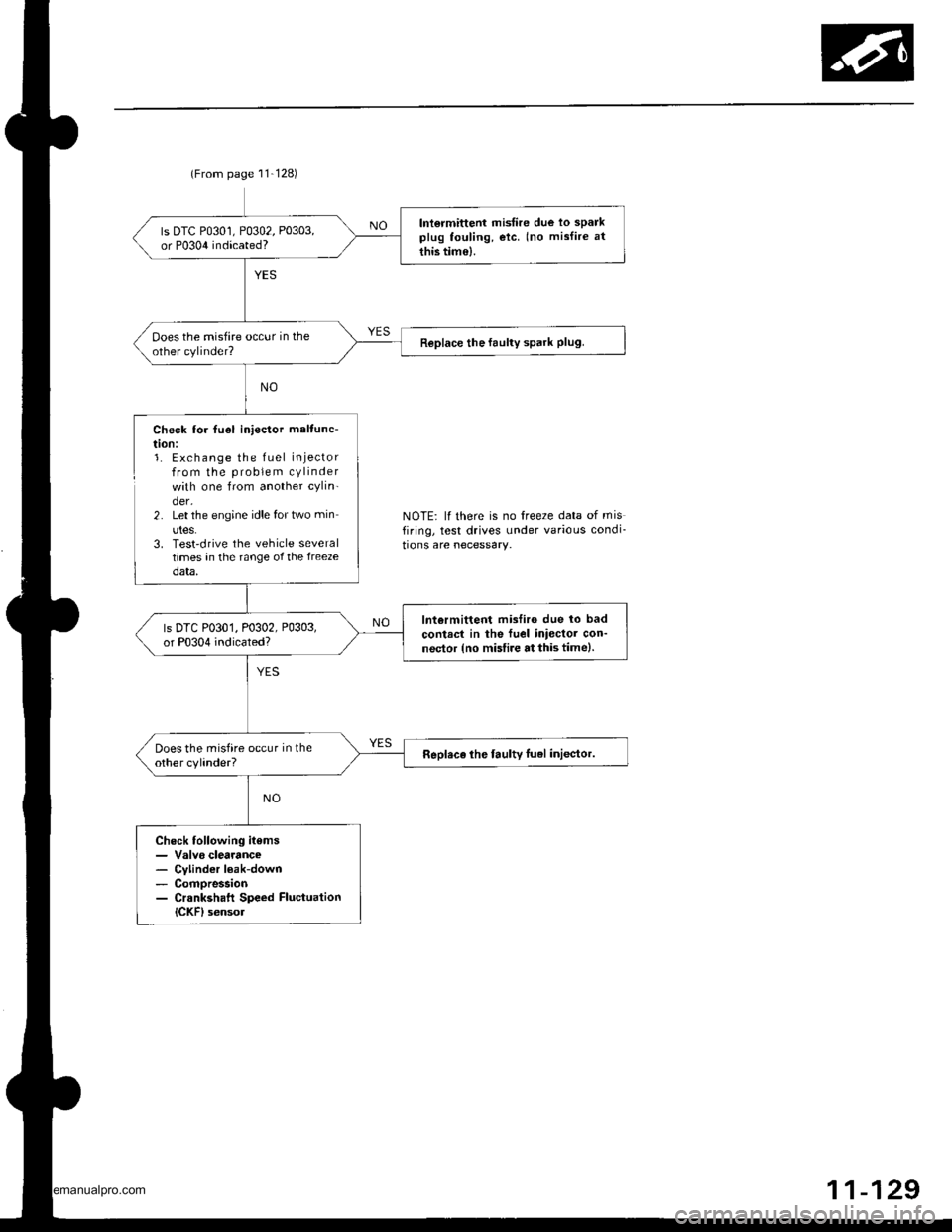

(From page 11-128)

lntormittent misfire due lo sparkplug fouling, etc. (no mislire at

this tim€).

ls DTC P0301, P0302, P0303,or P0304 indicated?

ooes the misfire occur in theother cylinder?Replace the faulty spark Plug.

Check lor fuel iniector maltunc-

t|on:1. Exchange the fuel injectorfrom the problem cylinderwith one from another cylin-der.2. Let the engine idle for two min

utes.3. Test'drive the vehicle severaltimes in the range of the freezedata,

lntermittent misfiro due lo bad

contrct in the fuel iniector con-nector {no misfire at this time).

ls DTC P0301, P0302, P0303,or P0304 indicated?

Does the misfire occur in theother cylinder?Replace lhe faulty luel inlector.

Check following items- Valvo clearance- Cvlinder l€ak-down- Compression- Crsnkshaft Speed FluctuationICKF) sensol

NOTE: lf there is no freeze data of misfiring, test drives under various condi_

tions are necessary.

11-129

www.emanualpro.com

Page 332 of 1395

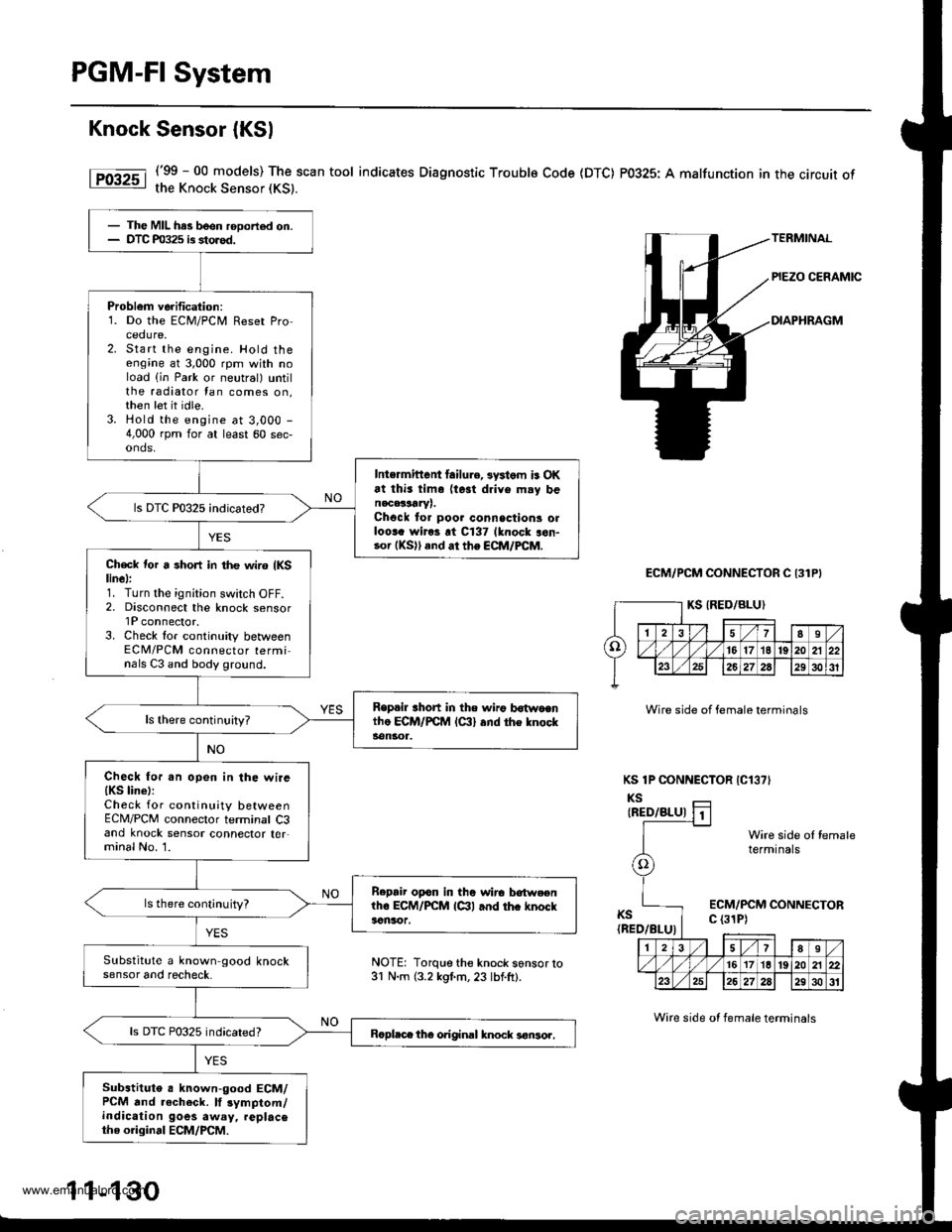

PGM-FI System

Knock Sensor {KSl

('99 - 00 models) The scan tool indicates Diagnostic Troublo Code (DTC) P0325: A malfunction in the circuit ofthe Knock Sensor (KS).

ECM/PCM CONNECTOR C 131P}

Wire side of female terminals

KS 1P CONNECTOR IC13?'

KSIRED/BLU)

KS(BED/BLU)

Wire side ol femaletermtnals

ECM/PCM CONNECTORc (31P)

- The MIL has been rooorted on.- DTC m325 is storod.

Problem verification:1. Do the ECM/PCir, Reset Procedure,2. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator tan comes on,then let it idle.3. Hold the engine at 3,000 -

4,000 rpm for at least 60 sec-onds,

Intermittent lailu.e, 3ystom is OKat thi3 tim. (te3t drive m.y benacalLrYr.Chock to. poor connsctions olloora wiros rt C137 lknock aon-.o. (KS)) and ar the ECM/FCM.

Ch€ck tor a short in the wir6 {KSlinel:1. Turn the ignition switch OFF.2, Disconnect the knock sensorlP connector.3. Check lor continuity betweenECM/PCM connector terminals C3 and body ground.

Replil rhort in the n irg b6{wocntho ECM/PCM lc:ll and the knocks€ngr1.

Check fo..n open in the wire{KS line):Check for continuity betweenECM/PCM connector terminal C3and knock sensor connector ter,minal No. 1.

B.pair opon in the wirc lrotweenlho ECM/PCM lctl and thc knockacnsor.

ls there cont;nuity?

Substitute a known-good knocksensor and recheck.

ls DTC P0325 indicated?Bcpl.ce the original knock 3€nsor,

Substituto a known-good ECM/PCM and .echeck. lf 3ymptom/indication goes away, replacethe original ECM/PCM.

NOTE: Torque the knock s6nsor to31 N.m (3.2 kgl.m, 23 lbf.ft).

1 1-130

Wire side ot female terminals

www.emanualpro.com

Page 339 of 1395

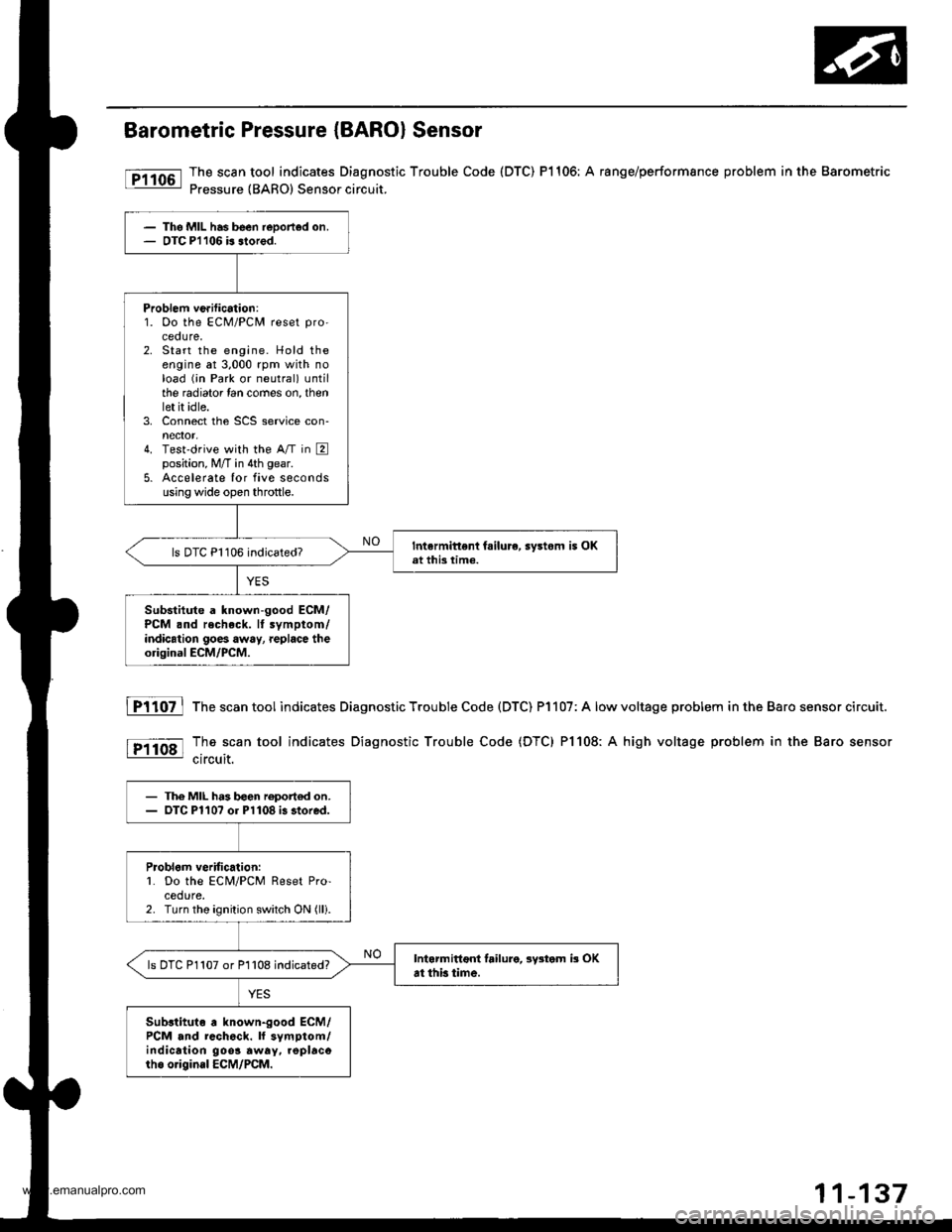

Barometric Pressure (BARO) Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P1106: A range/performsnce problem in the Barometric

Pressure {BARO) Sensor circuit.

The MIL has been reDorted on.OTC Pl106 b slored.

Problem ve.ification:1. Oo the ECM/PCM reset pro'

ceoure.2. Start the engine. Hold theengine at 3,000 rpm with noload (;n Park or neutral) untilthe radiator lan comes on, thenlet it idle.3. Connect the SCS service con-nector,4. Test'drive with the A/T in Eposition, M/T in 4th gear.

5. Accelerate Ior five secondsusing wide open throttle.

Intermittent fsilure, sy3tom i5 OKat this time.ls DTC P1106 indicated?

Substitute a known-good ECM/PCM .nd recheck. It symptom/indication goes away, replace theorigioal ECM/PCM.

fTiloz l

tP11o8l

The scan tool indicates Diagnostic Trouble Code (DTC) P1107: A low

The scan tool indicates Diagnostic Trouble Code (DTC) Pl108: A

circuit.

voltage problem in the Baro sensor circuit.

high voltage problem in the Baro sensor

- The MIL h.3 b€en roport€d on.- OTC Pl10? or Pl108 i3 stored.

Problom veritic.lion:L Do the ECM/PCM Reset Pro-cedure.2. Turn the ignition switch ON (lli.

Intarmittoni failure, lystom b OKat thb time.ls DTC P1107 or P1108 indicated?

Sub3tituto a known-good ECM/PCM and rcch6ck. ll symptom/indication 9oo3 away. .oplacorho o.igin.l ECM/PCM.

www.emanualpro.com