damper HONDA CR-V 1998 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 921 of 1395

Rear Damper

1.

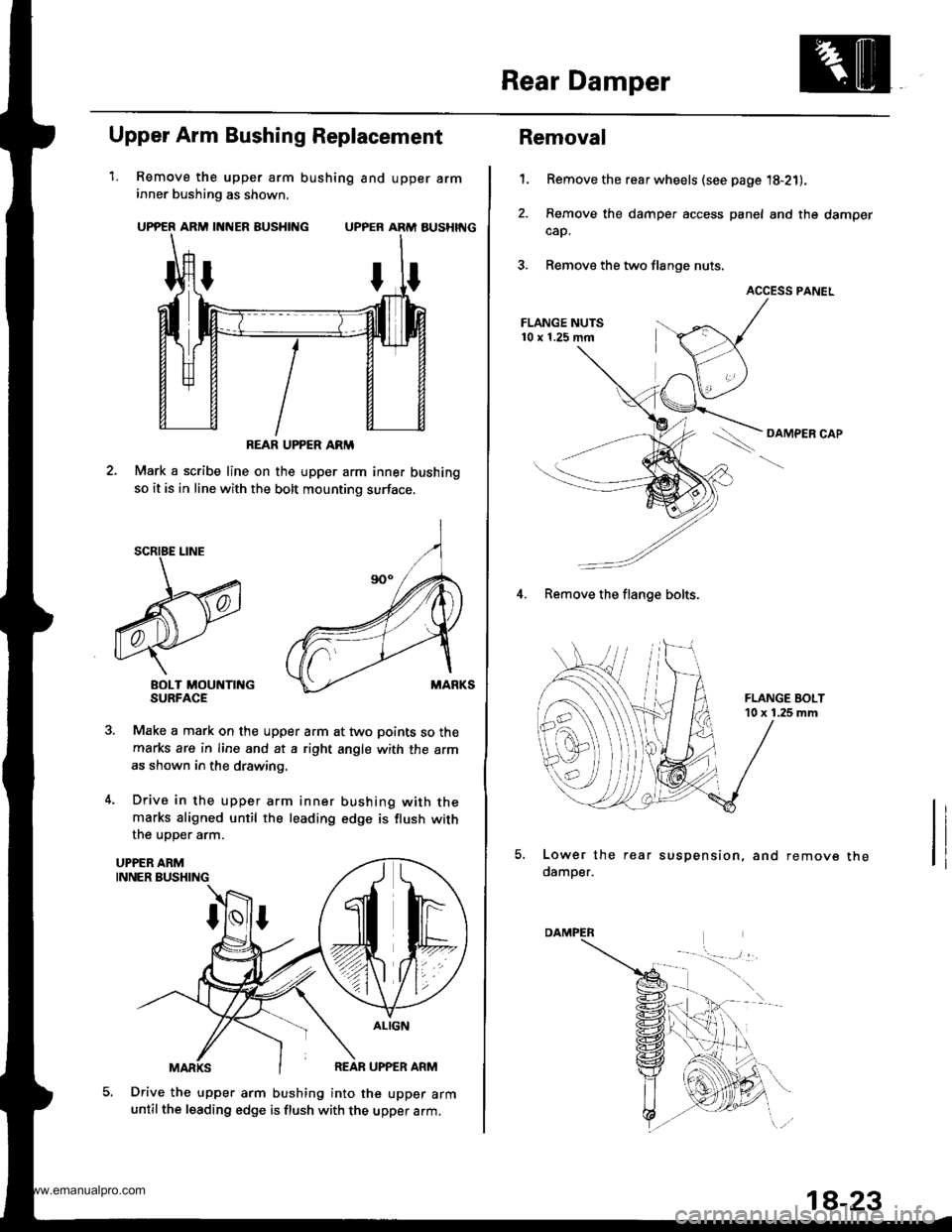

Upper Arm Bushing Replacement

Remove the upper arm bushing and upper arminner bushing as shown.

UPPER ARM INNER BUSHING UPPER ARM AUSHIT{G

Mark a scribe line on the upper arm inner bushing

so it is in line with the bolt mounting surface.

BOLT MOUNTII{GSURFACE

Make a mark on the upper arm at two points so the

marks are in line and at a right angle with the arm

as shown in the drawing.

Drive in the upper arm inner bushing with themarks aligned until the leading edge is flush with

the uoDer arm.

Drive the upper arm bushing into the upper armuntil the leading edge is flush with the upper arm.

REAR UPPER ARM

5.

Removal

Remove the rear wheels (see page '18-21),

Remove the damper access panel and the damper

cap.

Remove the two flange nuts.

ACCESS PANEL

OAMPER CAP

't.

4. Remove the flange bolts.

Lower the rear suspension, and remove

damper.the

1a-23

www.emanualpro.com

Page 922 of 1395

Rear Damper

Disassembly/lnspection

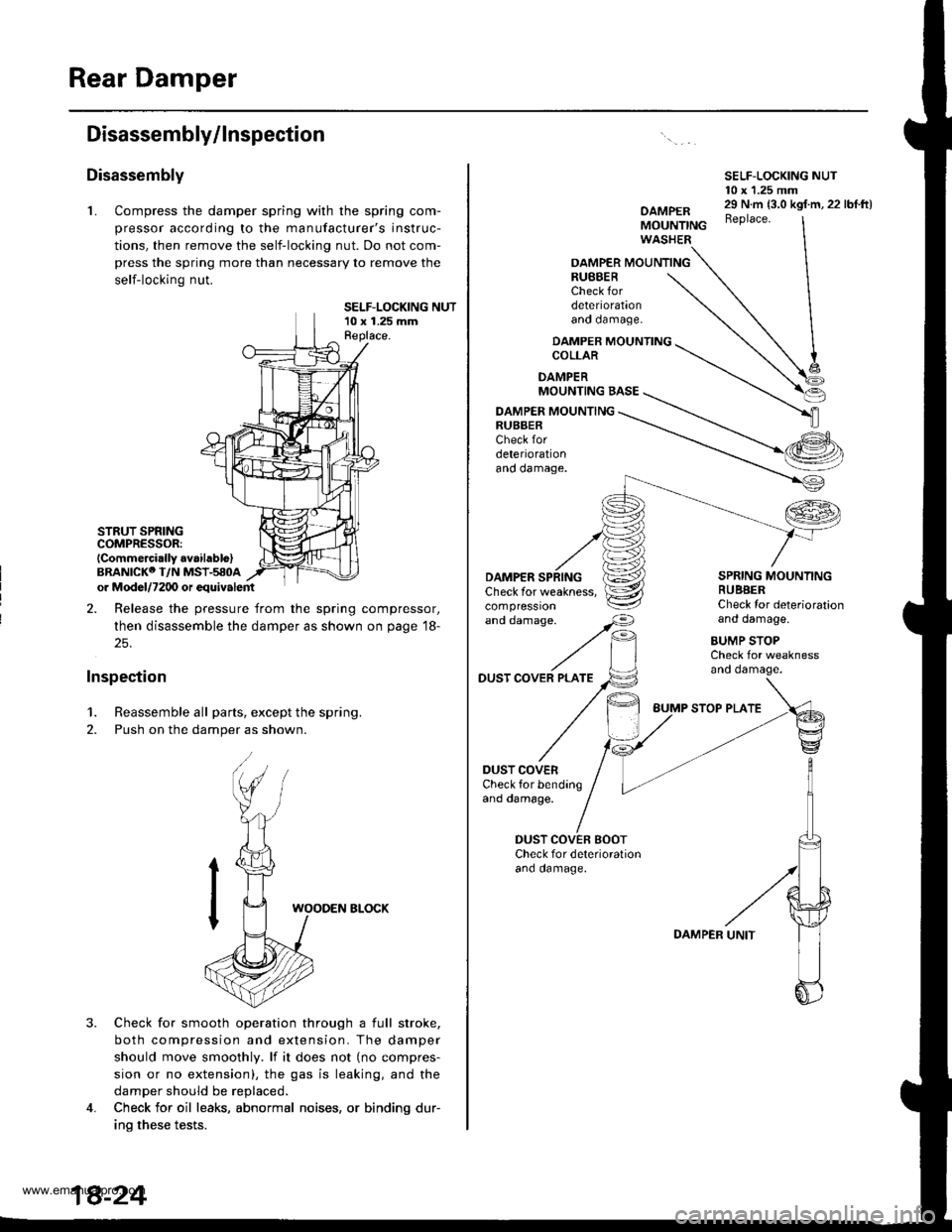

Disassembly

L Compress the damper spring with the spring com-

pressor according to the manufacturer's instruc-

tions, then remove the self-locking nut. Do not com-

press the spring more than necessary to remove the

self-locking nut.

SELF-LOCKING NUT10 x 1.25 mmReplace.

STRUT SPRINGCOMPRESSOR:lCommercirlly avaihblo)BRANICKO I/N MSI-580Aor Mod6l/7200 or equivalent

2. Release the pressure from the spring compressor,

then disassemble the damper as shown on page 18-

25.

Inspection

1. Reassemble all parts, except the spring.

2. Push on the damper as shown.

3.

WOODEN ELOCK

Check for smooth operation through a full stroke,

both compression and extension. The damper

should move smoothly. lf it does not (no compres-

sion or no extension), the gas is leaking, and the

damper should be replaced.

Check for oil leaks, abnormal noises, or binding dur-

ino these tests.

4.

SELF-LOCKING NUT10 x 1.25 mm

OAMPERMOUNTINGWASHER

29 N.m {3.0 kgf.m, 22 lbf.ft)Beplace.

OAMPER MOUNTINGRUBBERCheck fordeteriorationano oamage.

DAMPER MOUNTINGCOLLAR

DAMPERMOUNTING BASE

DAMPER MOUNTINGRUBBERCheck fordeteriorationano oamage.

'"dd"^.s"'

//F,

DAMPERCheck for weakness,compressron

DUST COVER PLATE

DUST COVERCheck for bendingand damage.

SPRING MOUNTINGRUBBERCheck Ior deteriorationand damage.

BUMP STOPCheck for weaknessano oamage.

DUST COVEN BOOTCheck for deterioralionano oamage.

BUMP STOP PLATE

DAMPER

www.emanualpro.com

Page 923 of 1395

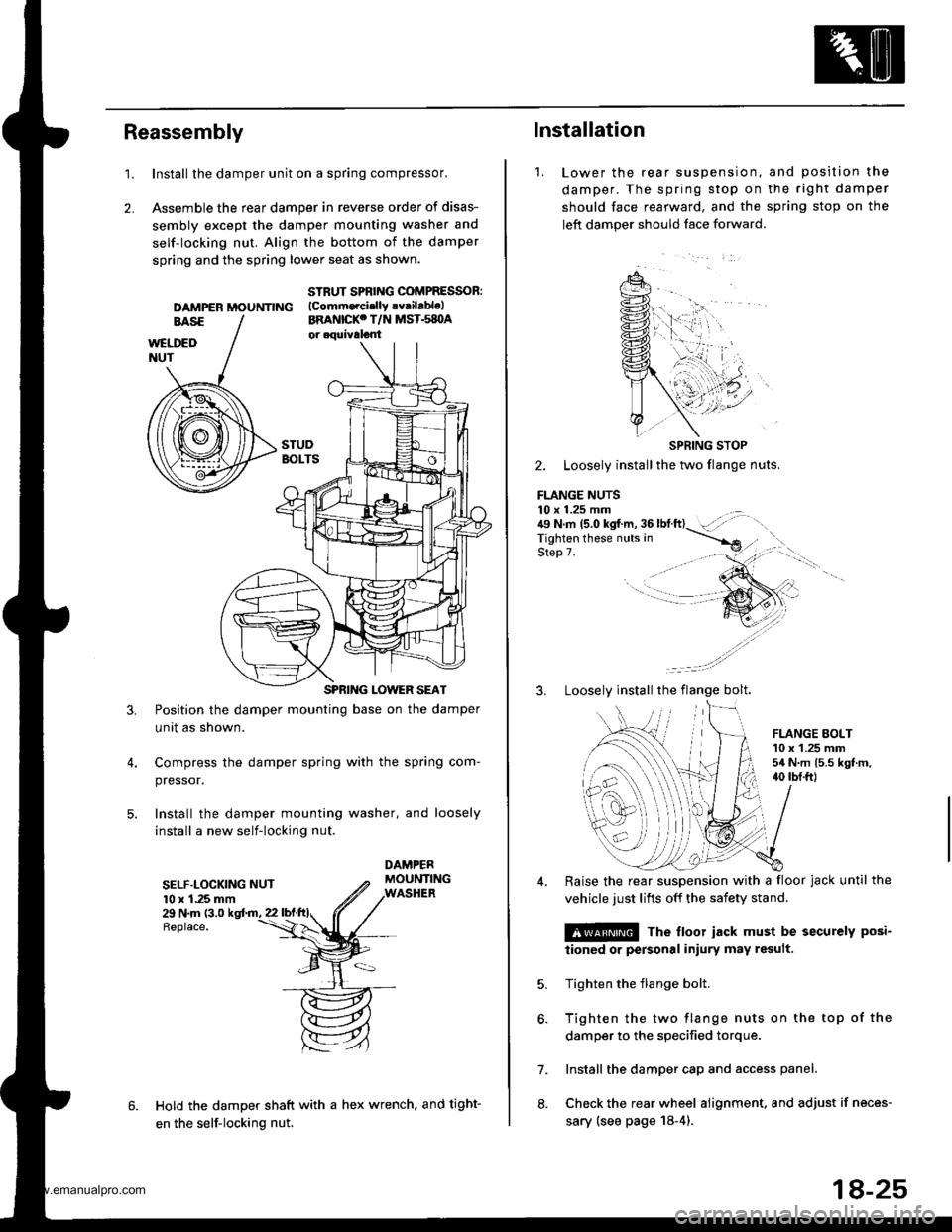

Reassembly

1.Install the damper unit on a spring compressor,

Assemble the rear damper in reverse order of disas-

sembly except the damper mounting washer and

self-locking nut. Align the bottom of the damper

spring and the spring lower seat as shown.

2.

DAMPER MOUNNNG

STRUT SPBING COMPRESSOR:(Commorcislly !v.ilablelBRANICKC T/N MST.s8OA

3.Position the damper mounting base on the damper

unit as shown.

Compress the damper spring with the spring com-

pressor.

Install the damper mounting washer, and loosely

install a new self-locking nut.

SELF.LOCKING NUT10 x 1.25 mm29 N.m (3.0

Replace.

Hold the damper shaft with a hex wrench, and tight-

en the self-locking nut.

1.

lnstallation

Lower the rear suspenston,

damper. The spring stop on

should face rearward, and the

left damper should face forward.

and position the

the right damper

sprang stop on the

SPRING STOP

2. Loosely install the two flange nuts.

FLANGE NUTS10 x 1.25 mm . .:{9 N.m 15.0 kgf.m, 36 lbtft}- :',,-rigf't"n if'"""_nrr. in ----.-*

qla^ 7Step 7.

3. Loosely install the flange bolt.

FLANGE EOLT10 x 1.25 mm54 N.m 15.5 kgt.m,40 tbI.ft)

6.

7.

8.

Raise the rear suspension with a floor jack until the

vehicle just lifts off the safety stand.

@ The floor iack must be securely posi-

iioned or personal iniury may result.

Tighten the flange bolt.

Tighten the two flange nuts on the top of the

damper to the specified torque.

Install the damper cap and access panel.

Check the rear wheel alignment. and adjust if neces-

sary (see page 18-4).

18-25

www.emanualpro.com

Page 1007 of 1395

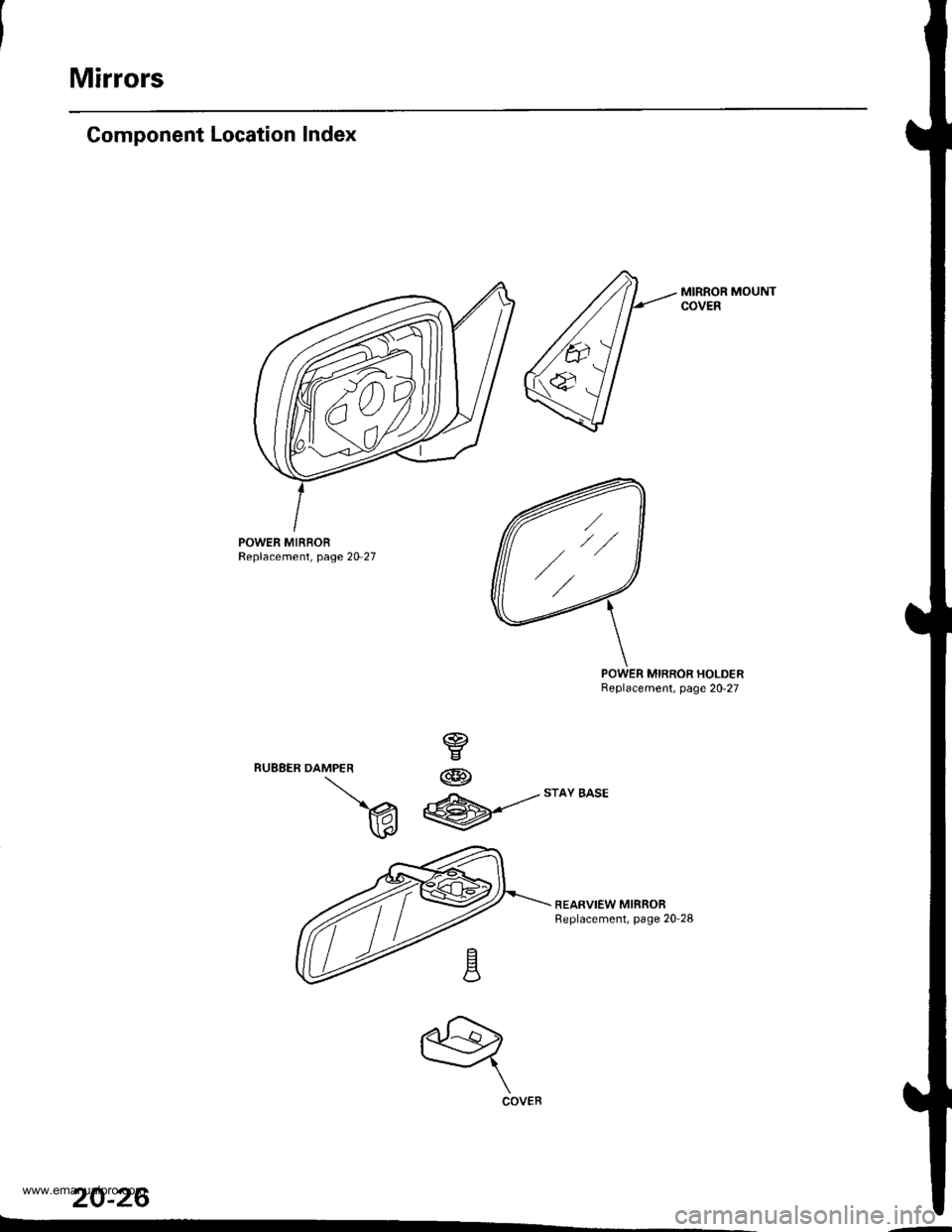

Mirrors

Component Location Index

MIRROR MOUNTCOVEB

POWER MIRBORReplacement, page 20 27

MIRROR HOLDERBeplacement, page 20-27

REARVIEW MIRRORReplacement, page 20-28

20-26

DAMPER

v

W

@

@

w

q

COVER

,//

www.emanualpro.com

Page 1009 of 1395

Mirrors

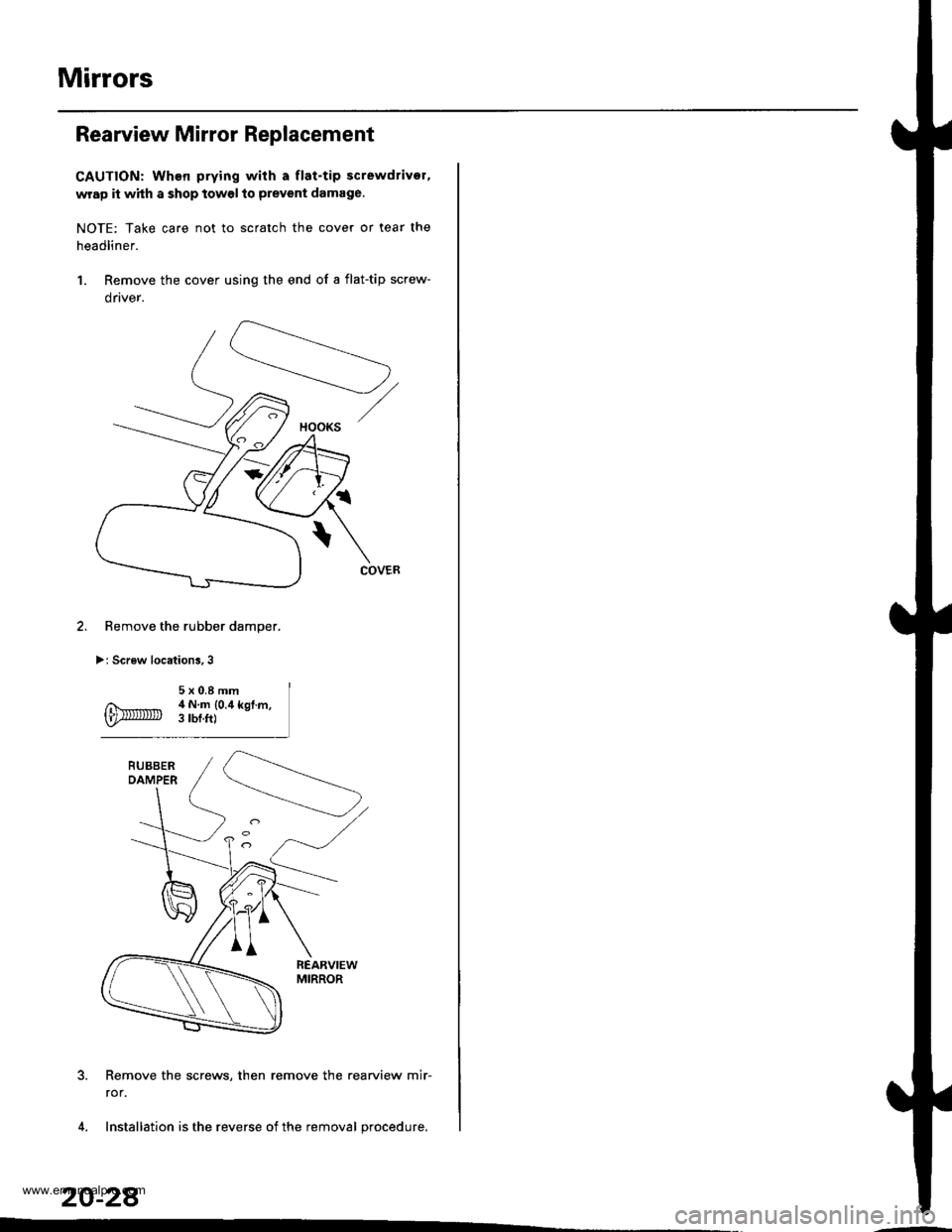

Rearview Mirror Replacement

CAUTION: When prying with a flat-tip screwdrivor,

wrap it whh a shop towel to prevent damage.

NOTE: Take care not to scratch the cover or tear the

headliner.

1. Remove the cover using the end of a flat-tip screw-

drtver.

Remove the rubber damper.

>: Screw locations,3

Remove the screws, then remove the rearview mir-

ror.

Installation is the reverse of the removal procedure.

20-28

HOOKS

www.emanualpro.com

Page 1016 of 1395

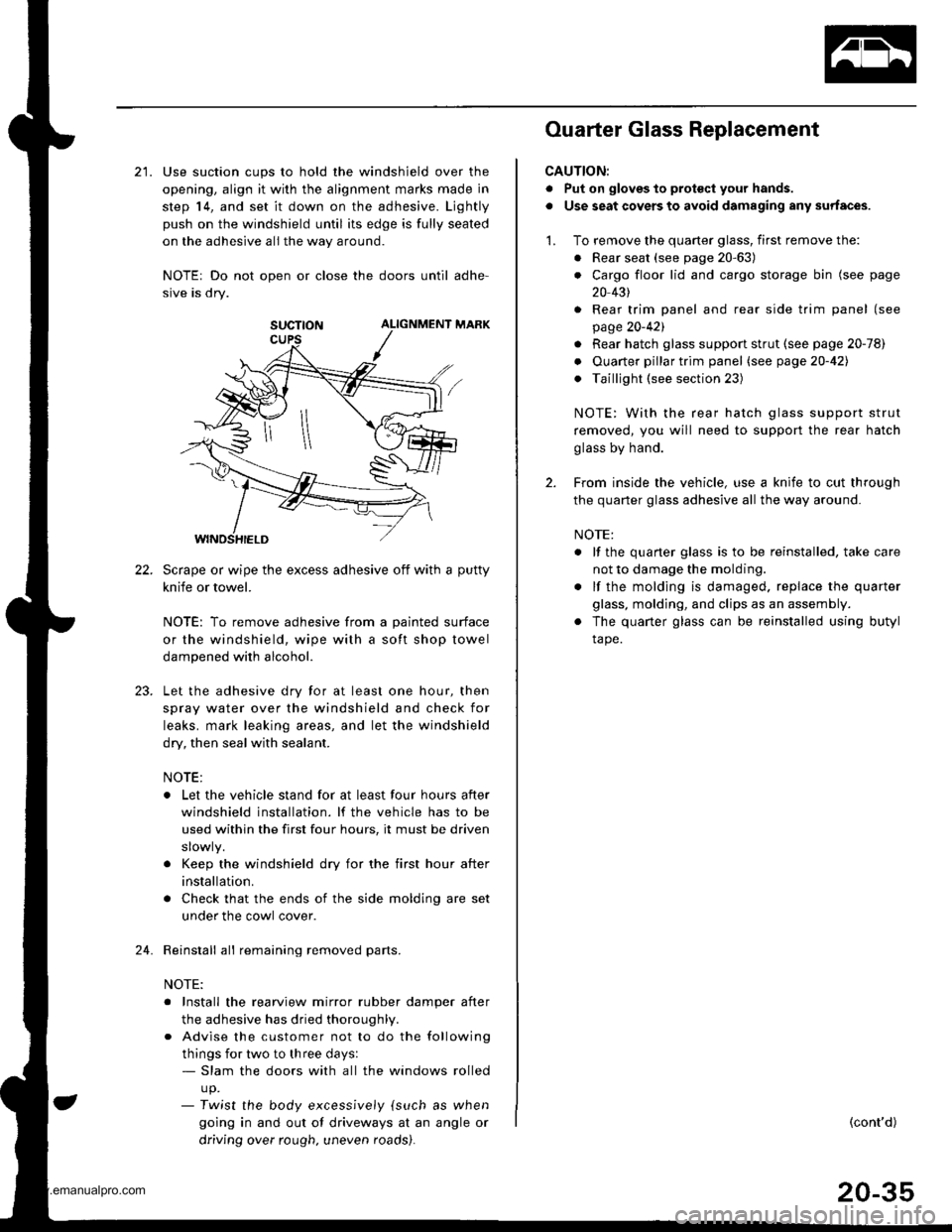

22.

21. Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 14, and set it down on the adhesive. Ljghtly

push on the windshield until its edge is fully seated

on the adhesive all the way around.

NOTEr Do not open or close the doors until adhe-

sive is dry.

SUCTTON ALIGNMENT MARK

Scrape or wipe the excess adhesive off with a putty

knife or towel.

NOTE: To remove adhesive from a painted surface

or the windshield, wipe with a soft shop towel

dampened with alcohol.

Let the adhesive dry for at least one hour, then

spray water over the windshield and check for

leaks. mark leaking areas, and let the windshield

dry, then seal with sealant.

NOTE:

. Let the vehicle stand for at least four hours after

windshield installation. lf the vehicle has to be

used within the first four hours, it must be driven

. Keep the windshield dry for the first hour after

installation.

. Check that the ends of the side molding are set

under the cowl cover.

Reinstall all remaining removed parts.

NOTE:

. Install the rearview mirror rubber damper after

the adhesive has dried thoroughl,.

. Advise the customer not to do the following

things for two to three days:- Slam the doors with all the windows rolled

up.- Twist the body excess,vely {such as when

going in and out of driveways at an angle or

driving over rough. uneven roads).

24.

Ouarter Glass Replacement

CAUTION:

. Put on gloves to prot€ct your hands.

. Use seat covers to avoid damaging any surfaces.

1. To remove the quarter glass, first remove the:

. Rear seat (see page 20-63)

. Cargo floor lid and cargo storage bin (see page

20 431

. Rear trim panel and rear side trim panel (see

page 20-421

. Rear hatch glass support strut (see page 20-78)

. Ouarter pillar trim panel (see page20-421

. Taillight (see section 23)

NOTE: With the rear hatch glass support strut

removed, you will need to support the rear hatch

glass by hand.

2. From inside the vehicle, use a knife to cut through

the quarter glass adhesive all the way around.

NOTE:

. lf the quaner glass is to be reinstalled, take care

not to damage the molding.

. lf the molding is damaged. replace the quarter

glass, molding, and clips as an assembly.

. The quarter glass can be reinstalled using butyl

tape.

(cont'd)

20-35

www.emanualpro.com

Page 1049 of 1395

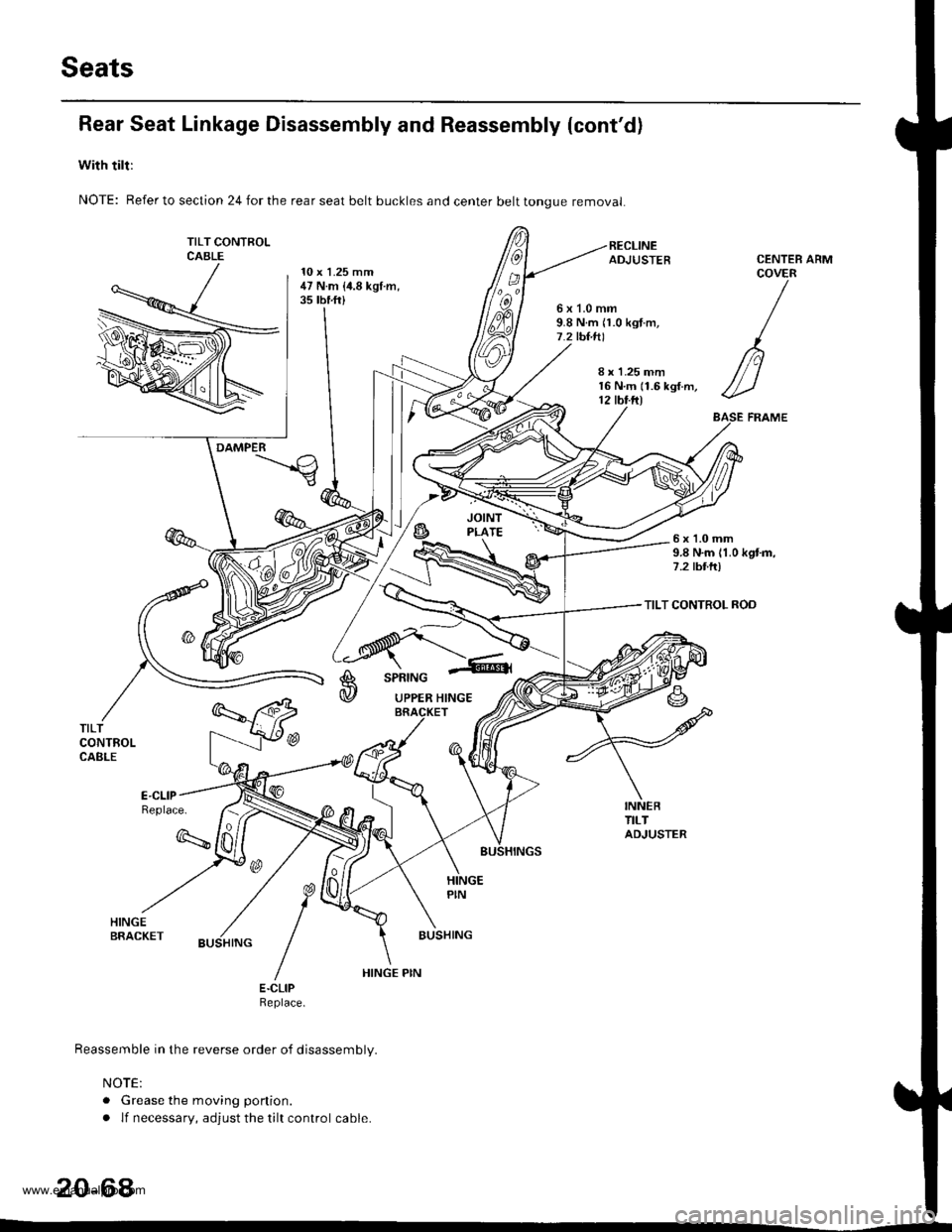

Seats

Rear Seat Linkage Disassembly and Reassembly (cont'd)

with tilt:

NOTE: Refer to section 24 for the rear seat belt buckles and center belt tongue removal

TILT CONTFOLCABLE10 x 1.25 mm47 N.m {i1.8 kgt.m,35 tbf.ft)

ARM

6x1.0mm9.8 N.m n.0 kgt.m,7.2 tbt.tll

CENTEBCOVER

/

n

//-)

ASE FRAME

8 r 1.25 mm16 N.m (1.6 kgf.m,12 tbt.ftl

DAMPER

6x1.0mm9.8 N.m 11.0 kgtm,7.2 tbttr)

TILT CONTROL ROD

A

@

SPRING

UPPER HINGE

TILTCONTROLCABLE

Replace.

q

BUSHING

E.CLIPReptace.

Reassemble in the reverse order of disassembly.

NOTE:

. Grease the moving ponion.

. lf necessary, adjust the tilt control cable.

20-64

HINGE PIN

www.emanualpro.com

Page 1088 of 1395

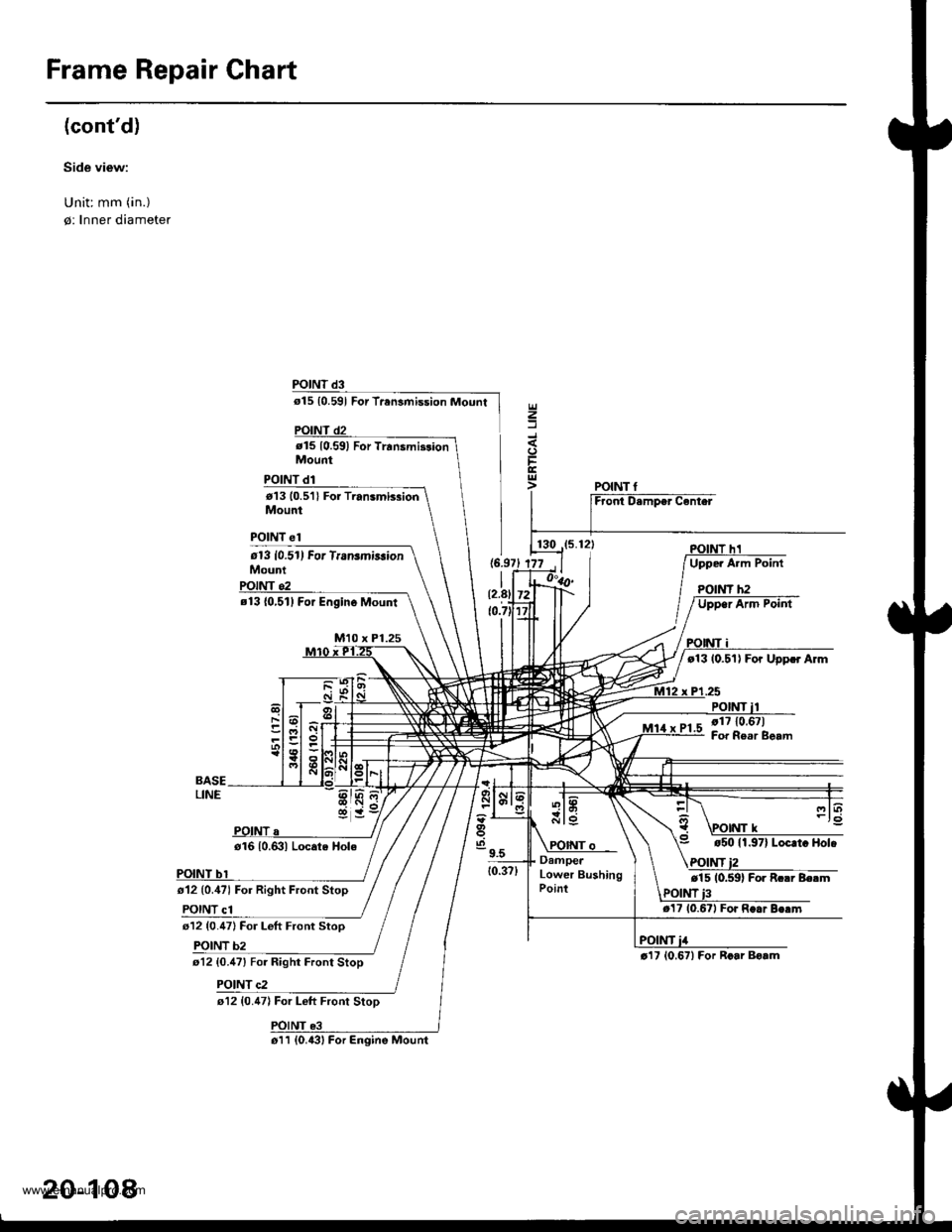

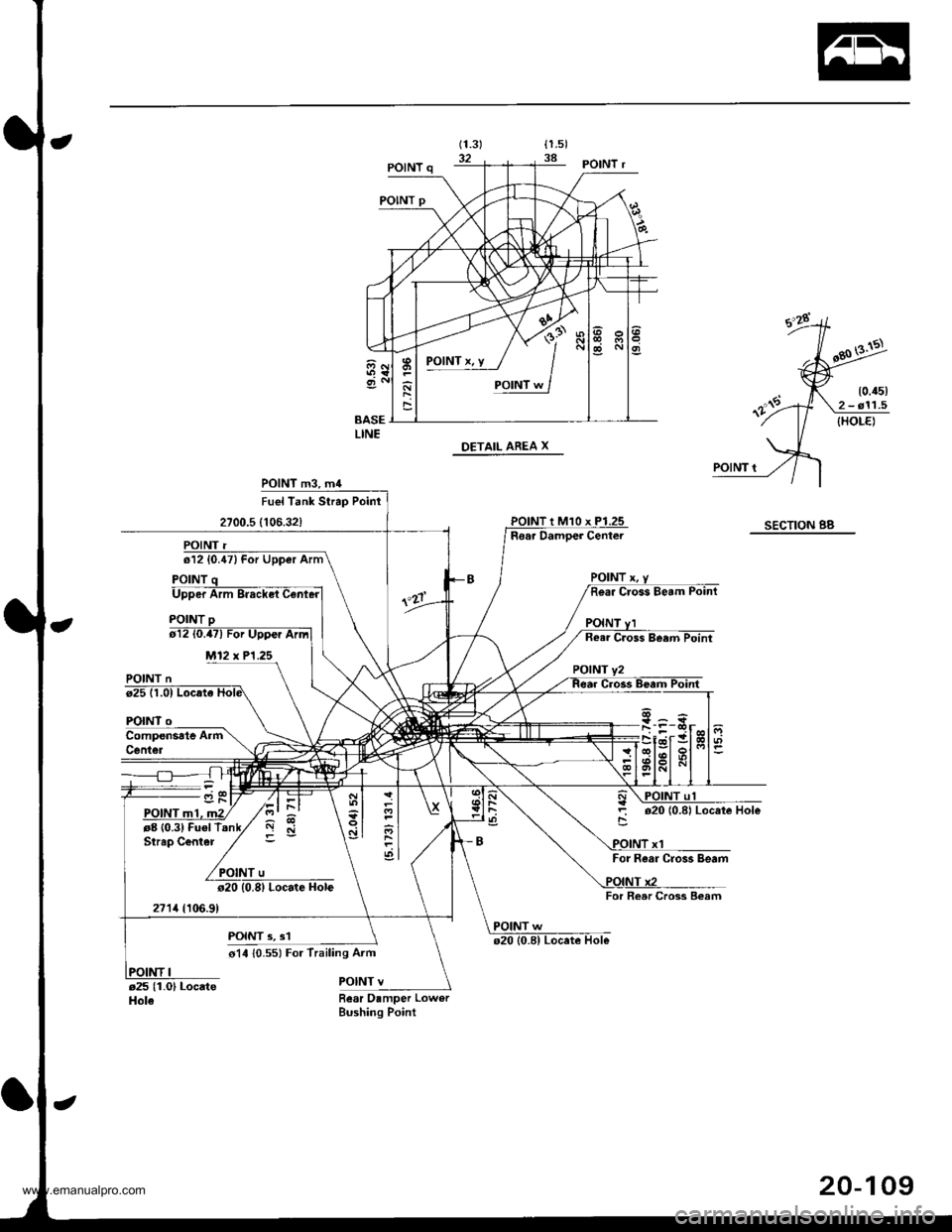

Frame Repair Chart

(cont'd)

Side view:

Unit: mm (in.)

0: Inner diamete.

POINT d3

o15 {0.591 For Trensmission Mount

d15 10.591 For Trrnsmi3donMount

POINT d1

t13 10.5'll For Transmb3ionMount

POINT el

613 10.51) For TransmirsionMouni

z

t13 {0,511 For Engin6 Mount

M10 x Pl.25

t13 10.51) For Uppcr Arm

.25

POINT,1710.67)Fof Re.r Beam

o12 (0.,171 For Right Front Stop

POINT c1

o16 10.631 Locate Hole

612 {0.47} For Left Front Stoo

b2

r12 {0.47) For Left Front StoD

t5011.97| Locrt. Hol.

POINT

t17 10.671 Fo. R..r

r'17 10.671 For Rcar Bo.mt12 {0.47} For Right Front Stop

POINT c2

130POINT h1

DamperLower BushingPoint

o11 (0.{31 For Engine Mount

20-108

www.emanualpro.com

Page 1089 of 1395

POlNTx.y / I

'sad

POINT m3, m4

Upper Arm

M12 x P1.25

Locate Hole

POINT 3, s1

o14 {0.551 For Trailing Aim

POINT v

Fuel Tank Strap Poinr

2700.5 (106.32)SECTION BBRear Damoer Center

POINT n

FOINT

rg (0.3) Fuel TStrap Center

271,1(10,6.9)

o2010.8| Locate Hole

For Rear Cros3 Beam

For Reer Cross Beam

POINT w

Bear Damper LowerBushing Point

I

\-

ql

ol

.df

20-109

www.emanualpro.com