page 1 HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1304 of 1395

Seat Belts

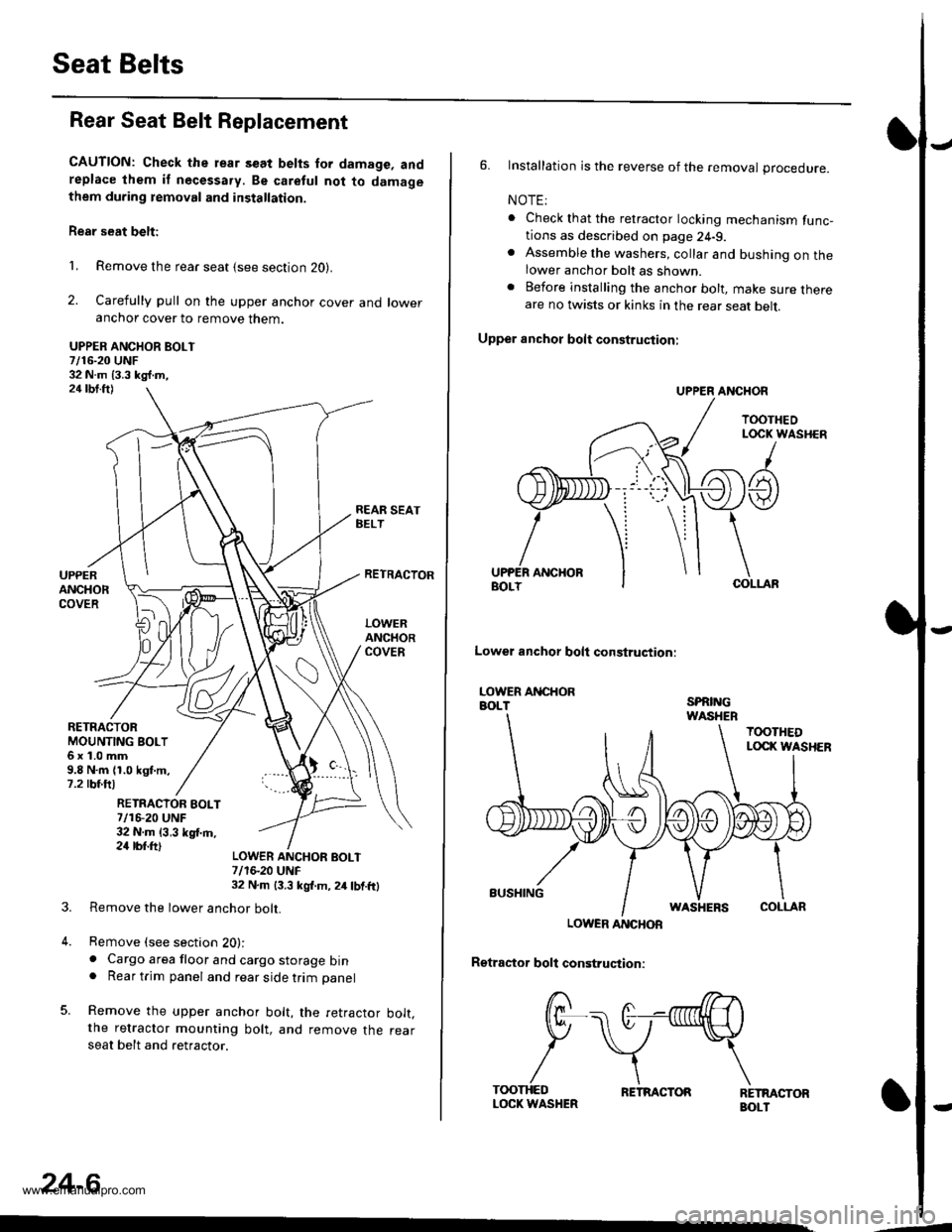

Rear Seat Belt Replacement

CAUTION: Check the rear s€at belts for damage, andreplace lhem if necessa.y. Be caretul not to damagethem during temoval and installation.

Rear seat belt:

1, Remove the rear seat {see section 20}.

2. Carefully pull on the upper anchor cover and loweranchor cover to remove them.

UPPER ANCHOR BOLT7/16-20 UNF32 N.m 13.3 kg{.m,24 tbt.ft)

REAR SEATBELT

RETRACTOBMOUNTING BOLT6x1.0mm9.8 N.m (1.0 kgt.m.7.2 rbf.ftl

UPPERANCHORCOVER

RETRACTOR

LOWERANCHORCOVER

RETRACIOR EOLT7/16-20 UNF32 N.m {3,3 kgf.m,24 rbr.ft)

3.

4.

LOWER ANCHOF BOLT7/1S20 UNF32 N.m 13.3 kgl.m, 2/r lbf.ftl

Remove the lower anchor bolt.

Remove (see section 20):. Cargo area floor and cargo storage bin. Rear trim panel and rear side trim panel

Remove the upper anchor bolt, the retractor bolt.the retractor mounting bolt, and remove the rearseat belt and retractor.

24-6

,--

6. Installation is the reverse of the removal procedure.

NOTE:

. Check that the retractor locking mechanism func-tions as described on page 24-9.. Assemble the washers, collar and bushing on thelower anchor bolt as shown.. Before installing the anchor bolt, make sure thereare no twists or kinks in the rear seat belt.

Upper anchot bolt construction:

UPPER ANCHOR

TOOTHEOLOCK WASHER

/

A t

ANCHORCOLLAF

Lowel anchor bolt construqtion:

LOWER ANCHORBOLTSPRINGWASHEB

TOOTHEDLOCI( WASHER

BUSHINGWASHERSCOLLAR

LOWER ANCHOR

Rgtractor boll construction:

RETMCTORBOLT

/ r>--->.

f/F\-. (t--nnnllH \

P \v*\

/\\T(X)THEDLOCK WASHERRETRACTOR

www.emanualpro.com

Page 1307 of 1395

Inspection

SRS components ale located in this area. Review the

SRS component locations, precautions, and procedures

in this section (24) before preforming repairs or service

('98 - 00 models).

!!!@ To avoid accidontal deployment and possi-

6i6-'rnpry. att"ays aisconnsct th€ seat beh tensioner con-

n€ctor belore removing tho retrastor {.98 - 00 modols, seo

page2+231.

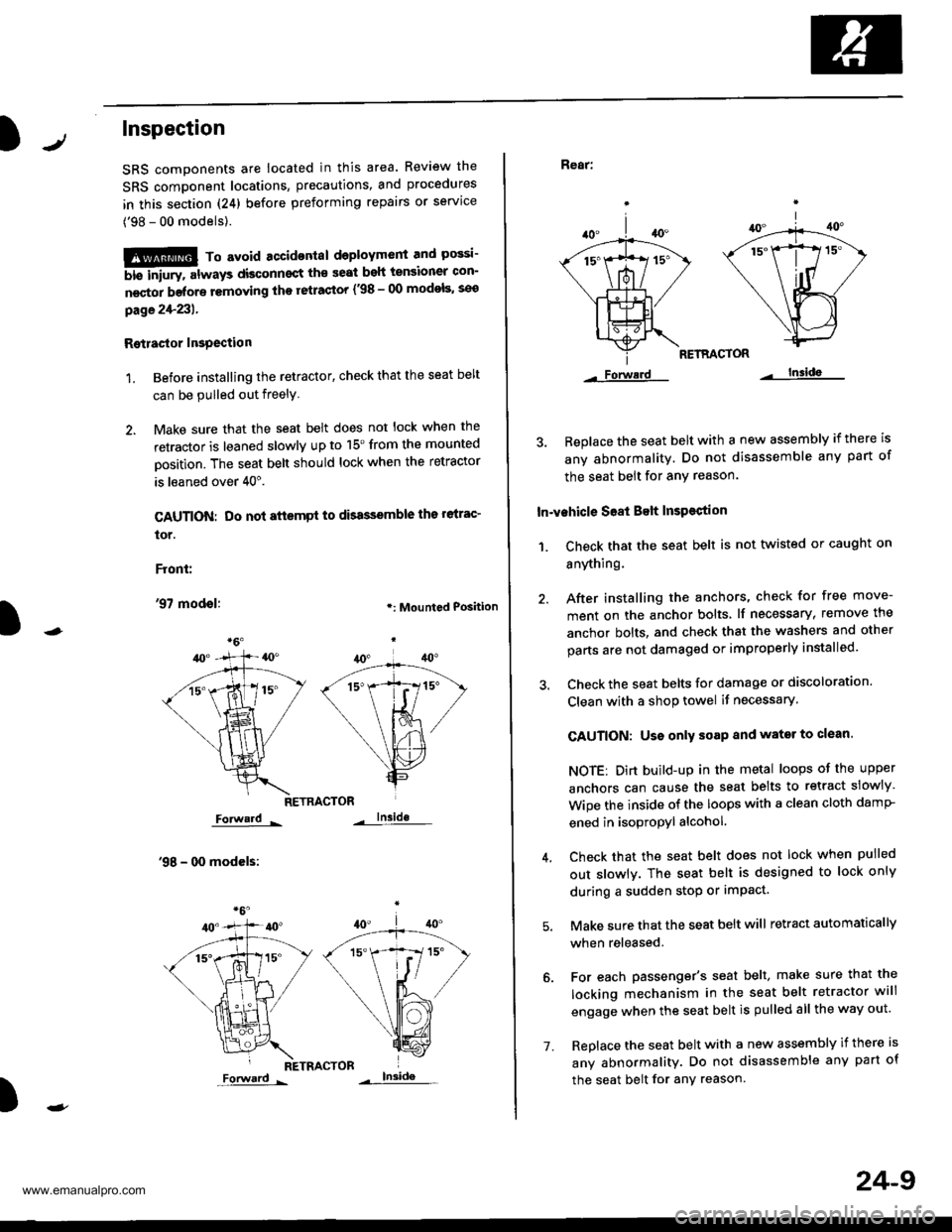

Rgtlastor Insgection

1. Before installing the retactor, check that the seat belt

can be pulled out freely

2. Make sure that the seat belt does not lock when the

retractor is leaned slowly up to 15'from the mounted

Dosition. The seat belt should lock when the retractor

is leaned over 40".

CAUTION: Do not attsmpt to dbassemble ths relrac'

tor.

Front:

'97 modol:.: Mounted Position

RETRACTOR

Forward -

'98 - 00 modcls:

lnside

RETRACTOR

)

Forward -

'1.

24-9

Rear:

RETRACTOR

Forwerd lnsida

3. Beplace the seat belt with a new assembly if there is

any abnormality. Do not disassemble any part of

the seat belt for any reason.

In-vehicle S68t Belt InsPestion

1. Ch€ck that the seat belt is not twisted or caught on

anything.

40.

/A

\|_t-.

*1ix

\/

Lls=

Forwerd

After installing the anchors, check for free move-

ment on the anchor bolts lf necessary, remove the

anchor bolts, and check that the washers and other

parts are not damaged or improperly installed.

Check the seat belts for damage or discoloration.

Clean with a shop towel if necessary.

CAUTION: Uso only soap and wator to clean.

NOTE: Dirt build-up in the metal loops of the upper

anchors can cause the seat belts to retract slowly

Wipe the inside of the loops with a clean cloth damP

ened in isopropyl alcohol.

Check that the seat belt does not lock when pulled

out slowlv. The seat belt is designed to lock only

during a sudden stop or impact.

Make sure that the seat belt will retract automatically

when released.

For each passenger's seat belt, make sure that the

locking mechanism in the seat belt retractor will

engage when the seat belt is pulled all the way out.

Replace the seat belt with a new assembly if there is

any abnormality. Do not disassemble any part of

the seat belt for any reason.

www.emanualpro.com

Page 1311 of 1395

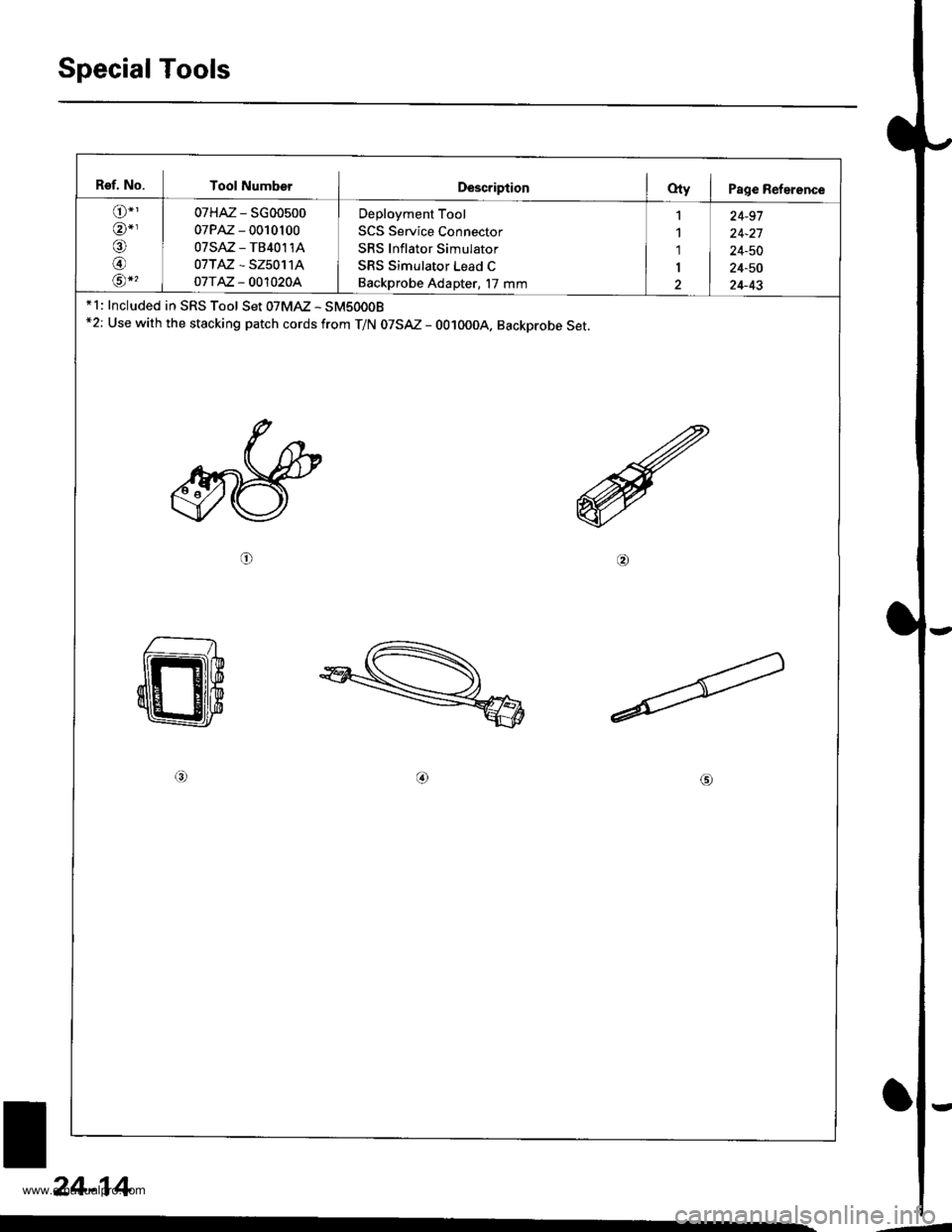

Special Tools

Ref. No. Tool NumberDescriptionOty I Page Reference

o"'

@-,/a\

@rA*,

07HAz - SG00500

07PM - 0010100

07sAz - TB40114

07TAZ - SZ50114

o7T AZ - OO1O20A

Deployment Tool

SCS Service Connector

SRS Inflator Simulator

SRS Simulator Lead C

Backprobe Adapter, l7 mm

1

1'1

I

2

24-91

24-21

24-50

24-50

24-43* 1: Included in SRS Tool Set 07MAZ - SM5000B*2: Use with the stacking patch cords from T/N 07SAZ - 0010004, Backprobe Set.

o@

/no

24-14

.-

www.emanualpro.com

Page 1312 of 1395

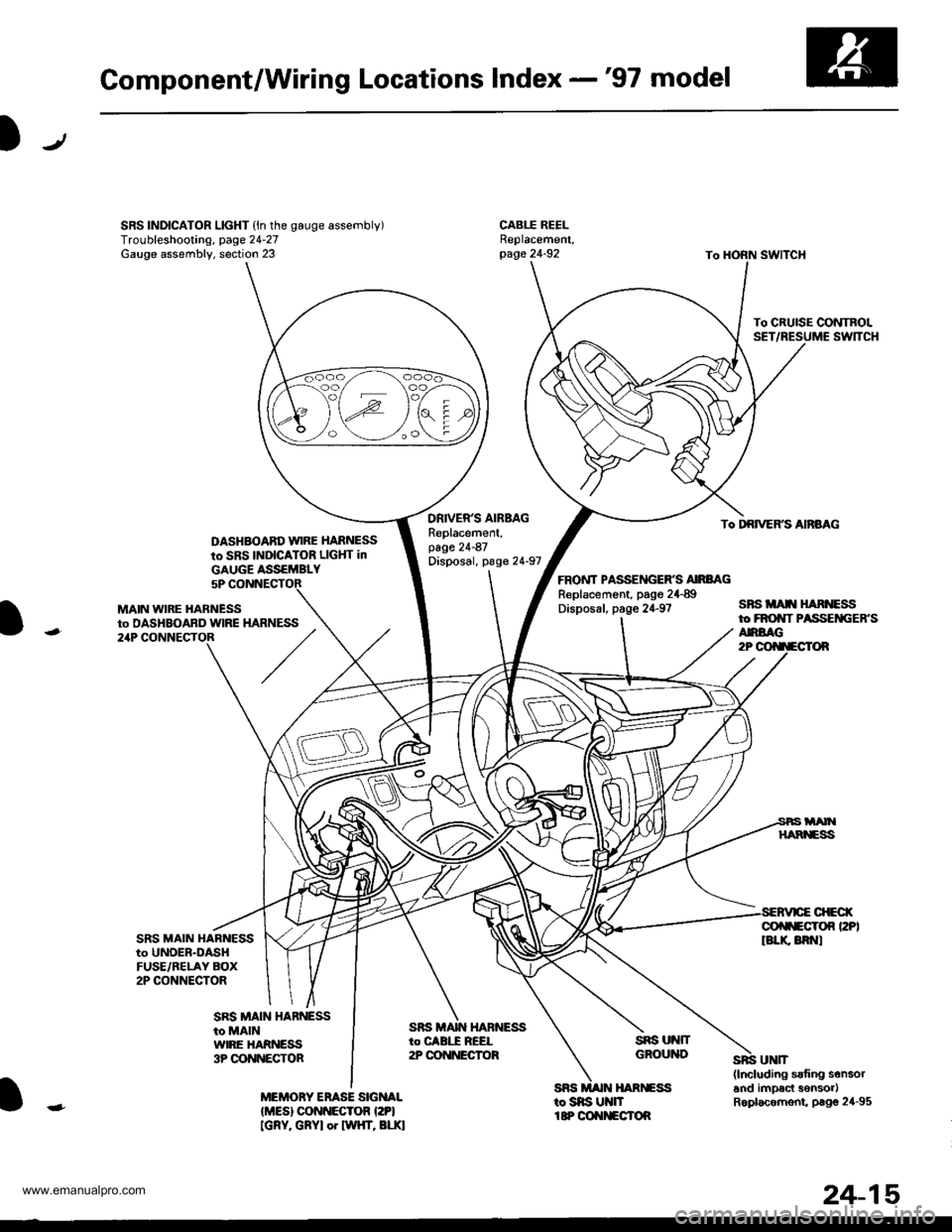

Component/Wiring Locations Index -'97 model

SRS INDICATOR LIGHT (ln the gauge assembly)Troubleshooting, page 24-27Gauge assembly, section 23

DASHBOABD w|RE HARNESS

to SBS INDICATOR LIGHT in

DRIVER'S AIBMGReplacement,page 21-87Disposal, page 24-97

To CRUISE CONTROLSET

To DRIVERS AnBAG

ANBAG2P

sBsitAr[ ] nNEssto FROI|T PASSEiIGEB.S

FRONT PASSEITGER'S AIRBAGReplacement, pago 24{9Disposal, page 24-97

sns ut{fTGROUND

SES MAIN HAR]GSStosns U nItP OOIIITECTOR

MAIN WIRE HABNESSto DASHBOABD wlRE21P

SRS MAIN HABNESSto UNOEB-DASHFUSE/BELAY BOX2P CONNECTOR

GOf$ECrOn PPIlBLr( 8R t

MEMORY ERASE SIGNALIMES) CONNECTOR I2PI[GRY. GRYI or twHT, BLr.l

GAUGE ASSEMBLY5P

HARNESS

SRS MAIN HARNESSto MAINWIRE HARNESS3P OONNECTOR

24-15

www.emanualpro.com

Page 1313 of 1395

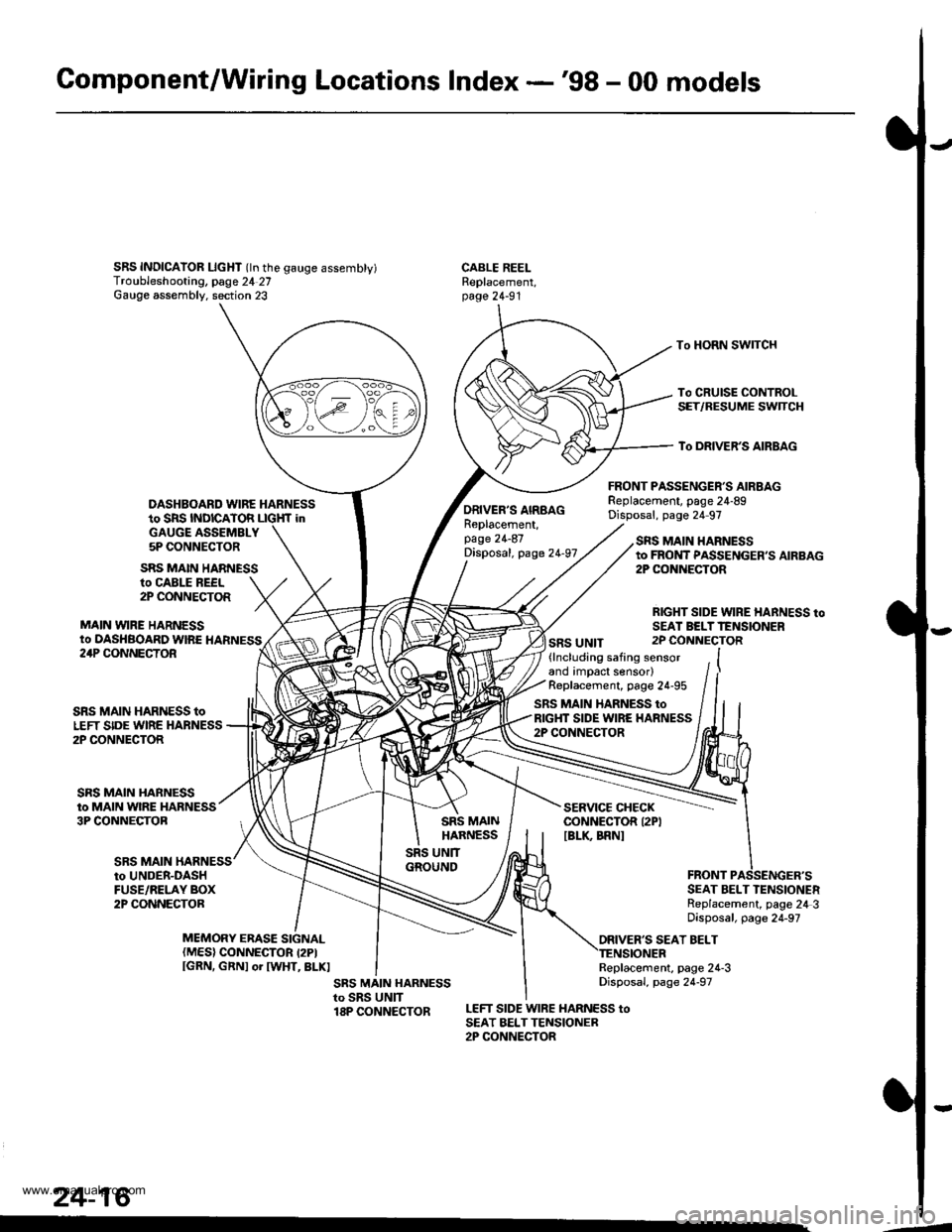

Gomponent/Wiring Locations Index -'98 - 00 models

SRS INDICAIOR LIcHT (ln the gauge assembty)Troubleshooting, page 24 27Gauge assembly. section 23

DASHBOARD WIRE HARNESSto SRS INDICATOR LIGHf inGAUGE ASSEMBLY5P CONNECTOR

FRONT PASSENGER'S AIRBAGReplacement, page 24-89Disposal, page 24 97

CABLE REELReplacement,page 24-91

To HORN SWITCH

To CRUISE CONTROLSET/RESUME SWTCH

To DRIVER'S AIRBAG

ro CABLE REEL2P CONNECTOR

MAIN VYIRE HARNESSto DASHBOARD WIRE HARNESS

SRS MAIN HARNESS

ORIVER'S AIRBAGReplacement,page 24-87Disposal, page 24-97

SRS UNIT

SRS MAIN HARNESSto FROI{T PASSENGER,S AIRBAG2P CONiIECTOR

RIGHT SIDE WIRE HARNESS toSEAI BELTTENSIONER2P CONNECTOR24P CONNECTOR

SRS MAIN

SRS MAIN HARNESS toLEFT SIDE WIRE HARNESS2P CONNECTOR

SRS MAIN HARNESSto MAIN WIRE HARNESS3P CONNECTOB

(lncluding safing sensorand impact sensor)Replacement, page 24-95

SRS MAIN HARNESS toRIGHT SIDE WIRE HARNESS2P CONNECTOR

SERVICE CHECKCONNECTOR I2PIIBLK BRNI

to UNDER-DASHFUSE/RELAY BOX2P CONNECTORSEAT BELT TENSIONERReplacement, page 24 3Disposal, page 24-97

ORIVER'S SEAT BELTMEMORY ERASE SIGNAL(MES) CONNECTOR I2PIIGRN, GRNI or IWHT, BLKIReplacement, page 24-3Disposal, page 24-97

LEFT SIDE WIRE HARNESS toSEAT BELTTENSIONER2P CONNECTOR

24-16

.4

www.emanualpro.com

Page 1316 of 1395

Precautions/Procedures

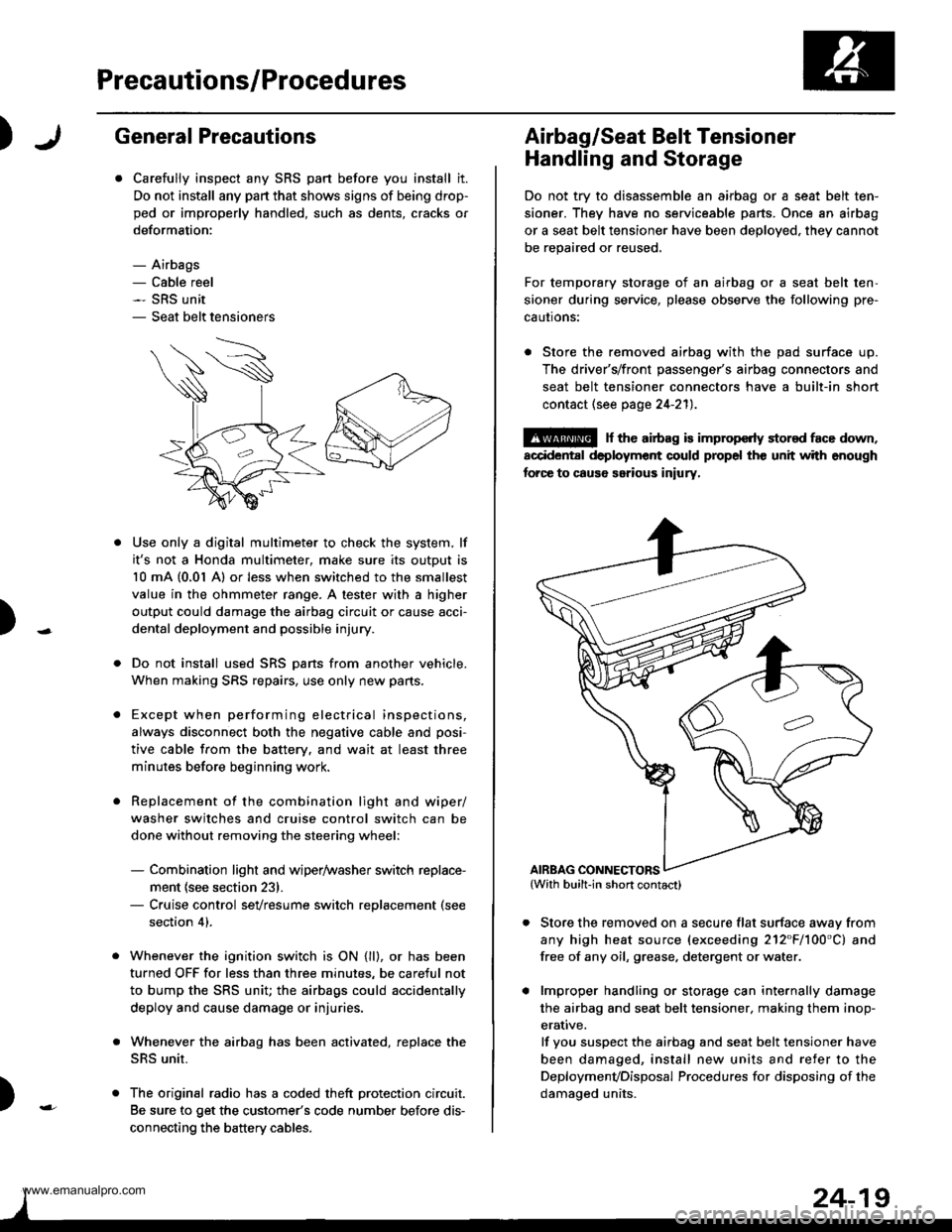

)General Precautions

Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being drop-

ped or improperly handled, such as dents, cracks or

deformation:

- Airbags- Cable reel- SRS unit- Seat belt tensioners

N

)-

Use only a digital multimeter to check the system, lf

it's not a Honda multimeter, make sure its output is

10 mA (0,01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury.

Do not install used SRS Dans from another vehicle,

When making SRS repairs, use only new pans.

Except when performing electrical inspections,

always disconnect both the negative cable and posi-

tive cable from the batterv. and wait at least three

minutes before beginning work.

Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combination light and wiper/washer switch replace-

ment {see section 231.- Cruise control sevresume switch replacement (see

section 41.

Whenever the ignition switch is ON {ll}, or has been

turned OFF for less than three minutes, be careful not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or injuries.

Whenever the airbag has been activated, replace the

SRS unit.

The original radio has a coded theft protection circuit.

Be sure to get the customer's code number before dis-

connecting the battery cables.

)

Airbag/Seat Belt Tensioner

Handling and Storage

Do not try to disassemble an airbag or a seat belt ten-

sioner. They have no serviceable parts. Once an airbag

or a seat belt tensioner have been deployed. they cannot

be repaired or reused.

For temporary storage of an airbag or a seat belt ten-

sioner during service, please observe the following pre-

cautons:

. Store the removed airbag with the pad surface up.

The driver's/front passenger's airbag connectors and

seat belt tensioner connectors have a built-in short

contact (see page 24-211.

@ r th€ airb.g is impropcrty stor€d face down,

accidental deployment could propel the unit with enough

forc€ to caus6 serious iniury,

Store the removed on a secure flat surface awav from

any high heat source (exceeding 212"F/100'C) and

free of any oil, grease. detergent or water.

lmproper handling or storage can internally damage

the airbag and seat belt tensioner. making them inop-

erative.

lf you suspect the airbag and seat belt tensioner have

been damaged, install new units and refer to the

Deploymenvoisposal Procedures for disposing of the

damaoed units.

AIRBAG CONNECTORS

www.emanualpro.com

Page 1321 of 1395

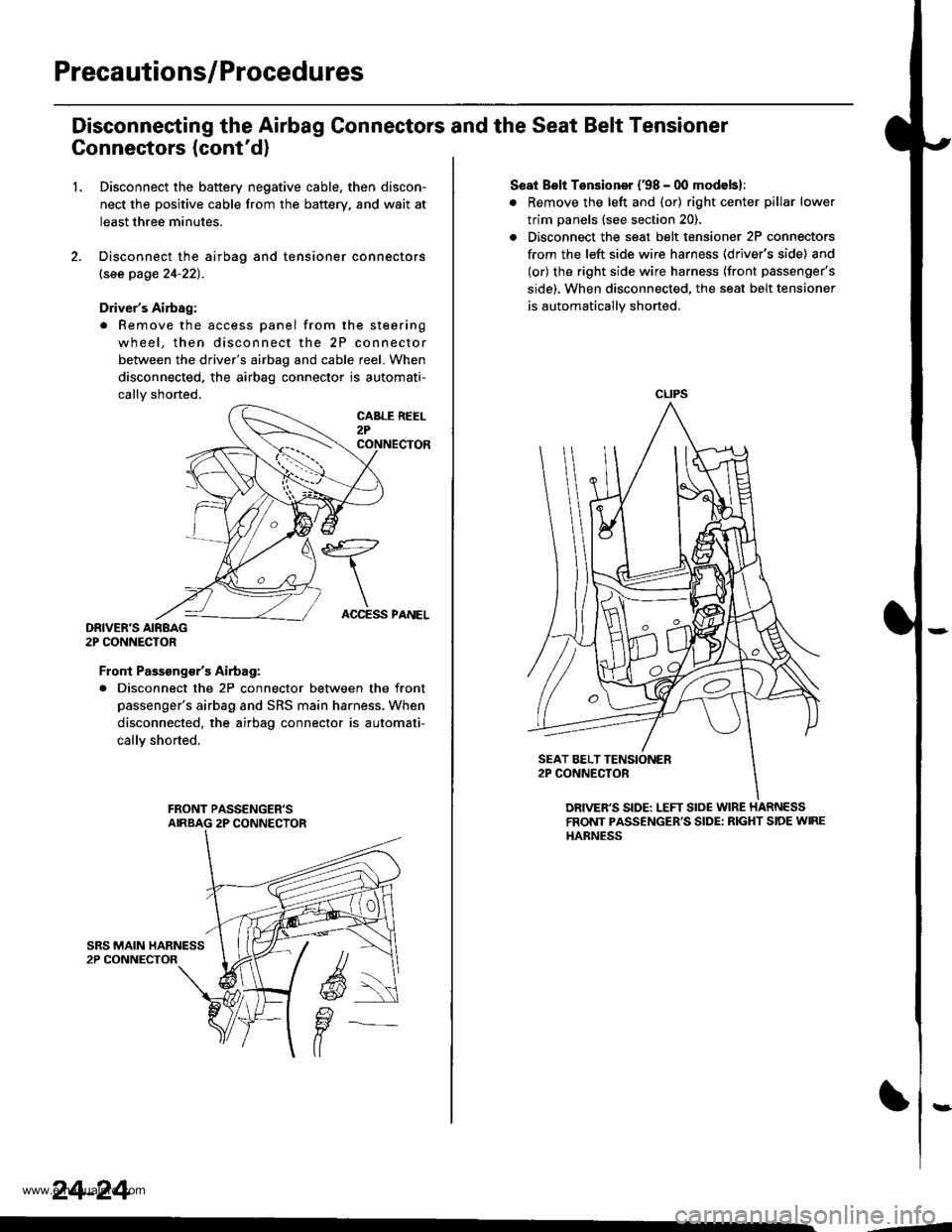

Precautions/Procedures

Disconneeting the Airbag Connectors and the Seat Belt Tensioner

Connectors (cont'd)

1.Disconnect the battery negative cable, then discon-

nect the positive cable from the battery. and wait at

least three minutes.

Disconnect the airbag and tensioner connectors

lsee page 24-22).

Driver's Airbag:

. Remove the access panel from the steering

wheel, then disconnect the 2P connector

between the driver's airbag and cable reel. When

disconnected, the airbag connector is automati-

callv shorted.

DRIVER'S AIRBAG2P CONNECTOR

Front Passsng€/sAirtag:

. Disconnect the 2P connector between the front

passenger's airbag and SRS main harness. When

disconnected. the airbag connector is automati-

callY shorted.

24-24

ACCESS PANEL

Seat Bslt Tensioner (38 - 00 modebl:

. Remove the left and (or) right center pillar lower

trim panels (see section 20).

. Disconnect the seat belt tensioner 2P connectors

from the left side wire harness (driver's side) and

(or) the right side wire harness (front passenger's

side). When disconnected. the seat belt tensioner

is automatically shorted.

CLIPS

DRIVER'S SIDE: LEFT SloE WIRE HARNESSFRONT PASSENGER'S SIDE: RIGHT SIDE WIREHARNESS

,--4

www.emanualpro.com

Page 1322 of 1395

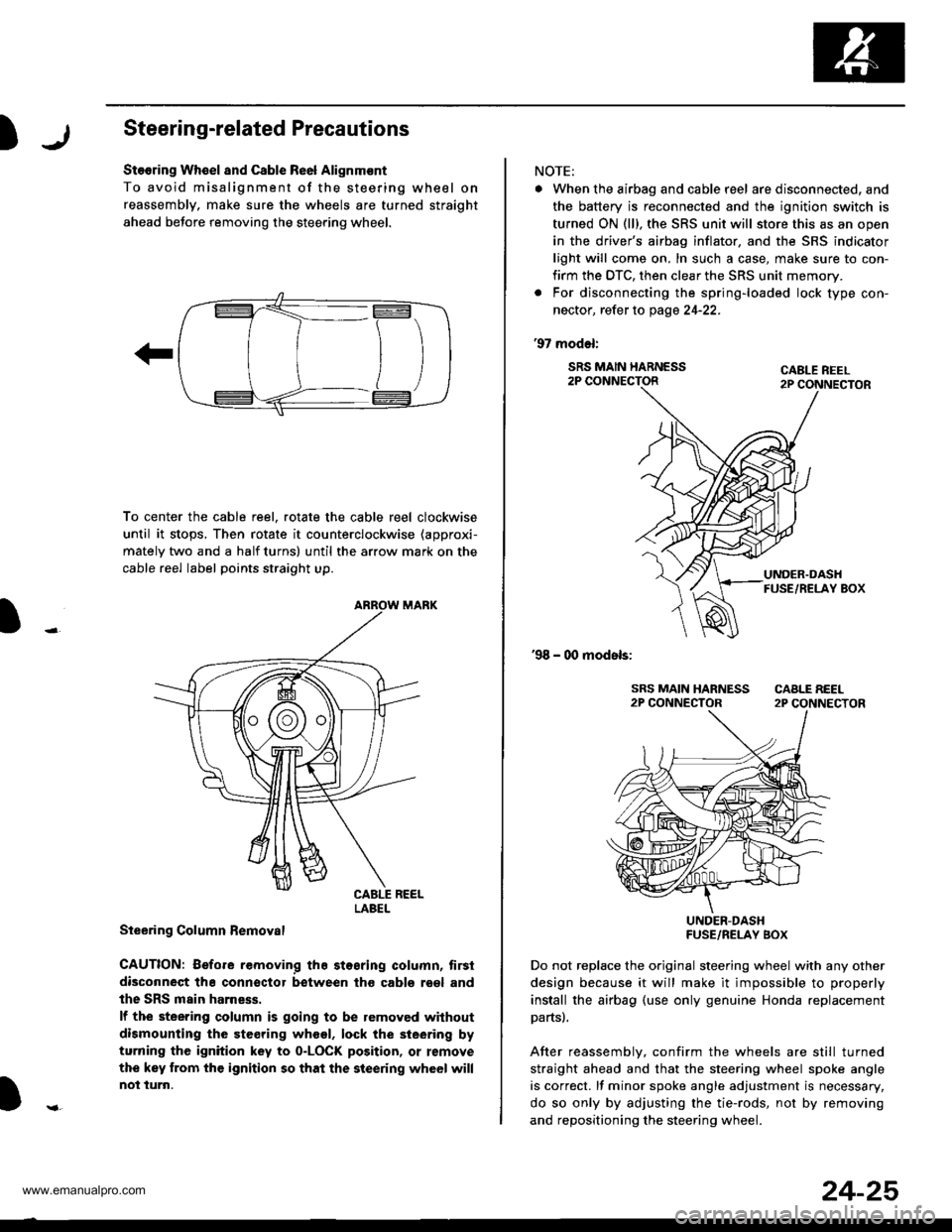

)Steering-related Precautions

Stooring Wh€el and Csble Re6l Alignm€nt

To avoid misalignment of the steering wheel on

reassembly, make sure the wheels are turned straight

ahead beJore removing the steering wheel.

To center the cable reel, rotate the cable reel clockwise

until it stops, Then rotate it counterclockwise (approxi-

mately two and a half turns) until the arrow mark on the

cable reel label points straight up.

Steering Column Bemoval

CAUTION: Before removing the stosring column, tirsi

disconneqt tha connsctor between tho cabls roel and

the SRS main harness.

lf the steering column is going to be removed without

dismounting the steering wheel, lock the sieering by

turning the ignition key to o-LOCK position, or remove

the key trom the ignition so that the steering wheel will

not turn.

LABEL

NOTE:

. When the airbag and cable r6el are disconnected, and

the battery is reconnected and the ignition switch is

turned ON (ll), the SRS unit will store this as an open

in the driver's airbag inflator, and the SRS indicator

light will come on, In such a case, make sure to con-

firm the DTC, then clear the SRS unit memory.

. For disconnecting the spring-loaded lock type con-

nector, refer to page 24-22.

'97 model:

SRS MAIN HARNESS2P CONNECTORCABLE REEL2P CONNECTOR

'98 - 00 models:

UNDER-DASHFUSE/RELAY BOX

Do not replace the original steering wheel with any other

design because it will make it impossible to properly

install the airbag (use only genuine Honda replacement

partsl.

After reassemblv, confirm the wheels are still turned

straight ahead and that the steering wheel spoke angle

is correct. lf minor spoke angle adjustment is necessary,

do so only by adjusting the tie-rods, not by removing

and repositioning the steering whee .

24-25

www.emanualpro.com

Page 1323 of 1395

Troubleshooting

Self-diagnostic Procedures

The self-diagnostic function of the SRS system allows it to locate the causes of system problems and to store this informa-

tion in memory, For easier troubleshooting, this data can be retrieved via a data link circuit.

. When you turn the ignition switch ON (ll). the SRS indicator will come on. lf it goes off after six seconds, the system is

normal.

. lf there is 8n abnormality, the system locates and defines the problem. stores this information in memory, and turns

the SRS indicator light on. The data will remain in the memory even when the ignition switch is turned off or if the bat-

terv is disconnected.

. When you connect the SCS service connector to the service check connector (2P), and turn the ignition switch ON (ll),

the SRS indicator light will indicate the diagnostic trouble code (DTC) by the number of blinks.

. After reading and recording the DTC, proceed with the troubleshooting forthis code.

Precsutions

. Use only a digital multimeter to check the system. lf it's not a Honda multimeter. make sure its output is 10 mA (0.01 A)

or less when switched to the smallest value in the ohmmeter range. A tester with a higher output could damage the

airbag circuit or cause accidental airbag deployment and possible injury.

. Whenever the ignition switch isON (ll). or has been turned OFF for less than three minutes, be careful nottobumpthe

SRS unit; the airbags could accidentally deploy and cause damage or injuries.

. Before you remove the SRS main harness, disconnect the airbag and tensioner connectors (see page 24-23).

. Make sure the battery is sufficiently charged (see section 23). lf the battery is dead or low, measuring values won't be

correct.

. Do not touch a tester probe to the terminals in the SRS unit or harness connectors, and do not connect the terminals

with a jumper wire. Use only the backprobe set and the SCS service connector.

For backprobing spring-loaded lock type con nectors, .efet to page 24-22.

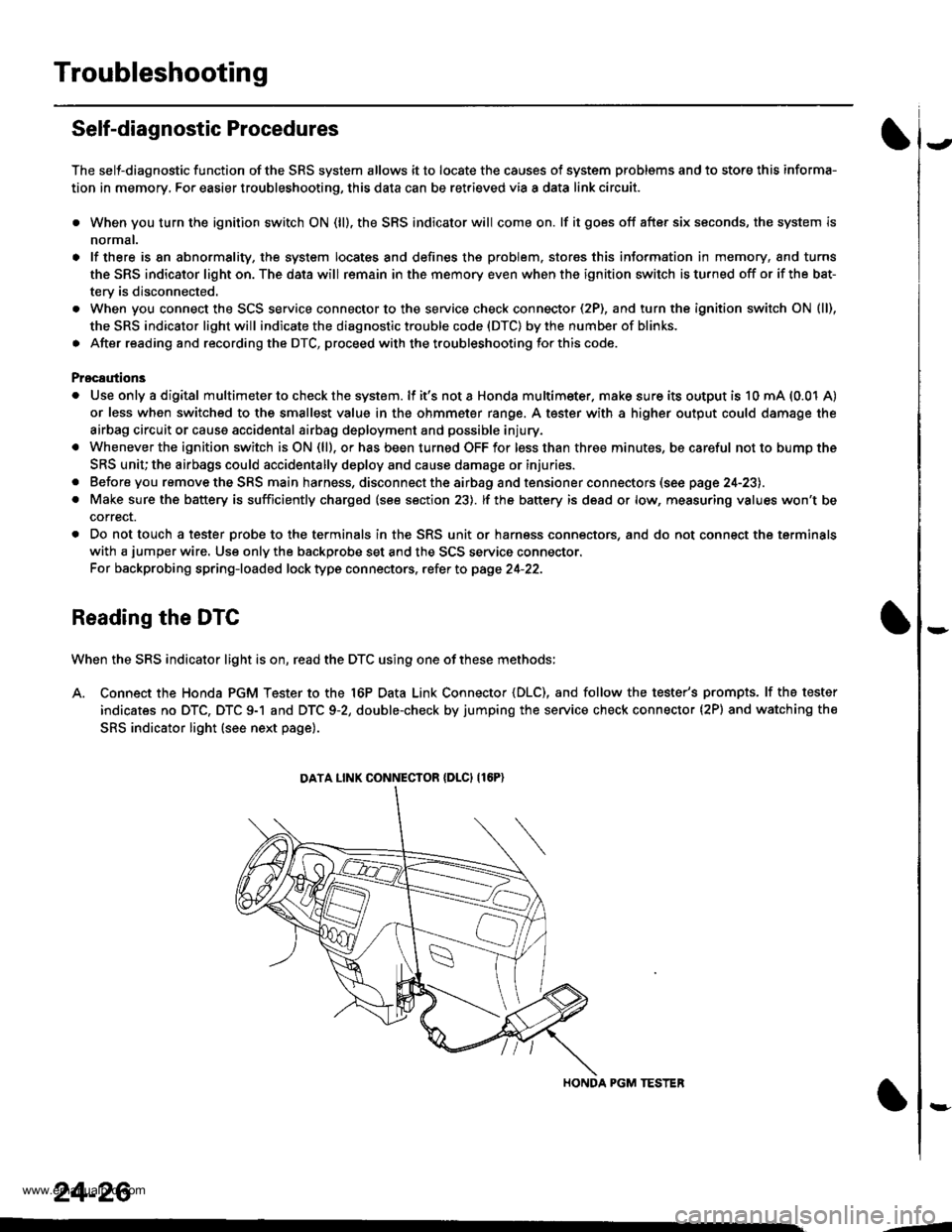

Reading the DTC

When the SRS indicator light is on, read the DTC using one of these methods;

A. Connect the Honda PGM Tester to the 16P Data Link Connector {DLC), and follow the tester's prompts. lf the tester

indicates no DTC, DTC 9-1 and DTC 9-2, double-check by jumping the service check connector (2P) and watching the

SRS indicator light (see next page).

HONDA PGM TESTER

DATA LINK CONNECIOR {DLCI {16P)

24-26

,1

www.emanualpro.com

Page 1327 of 1395

Troubleshooting

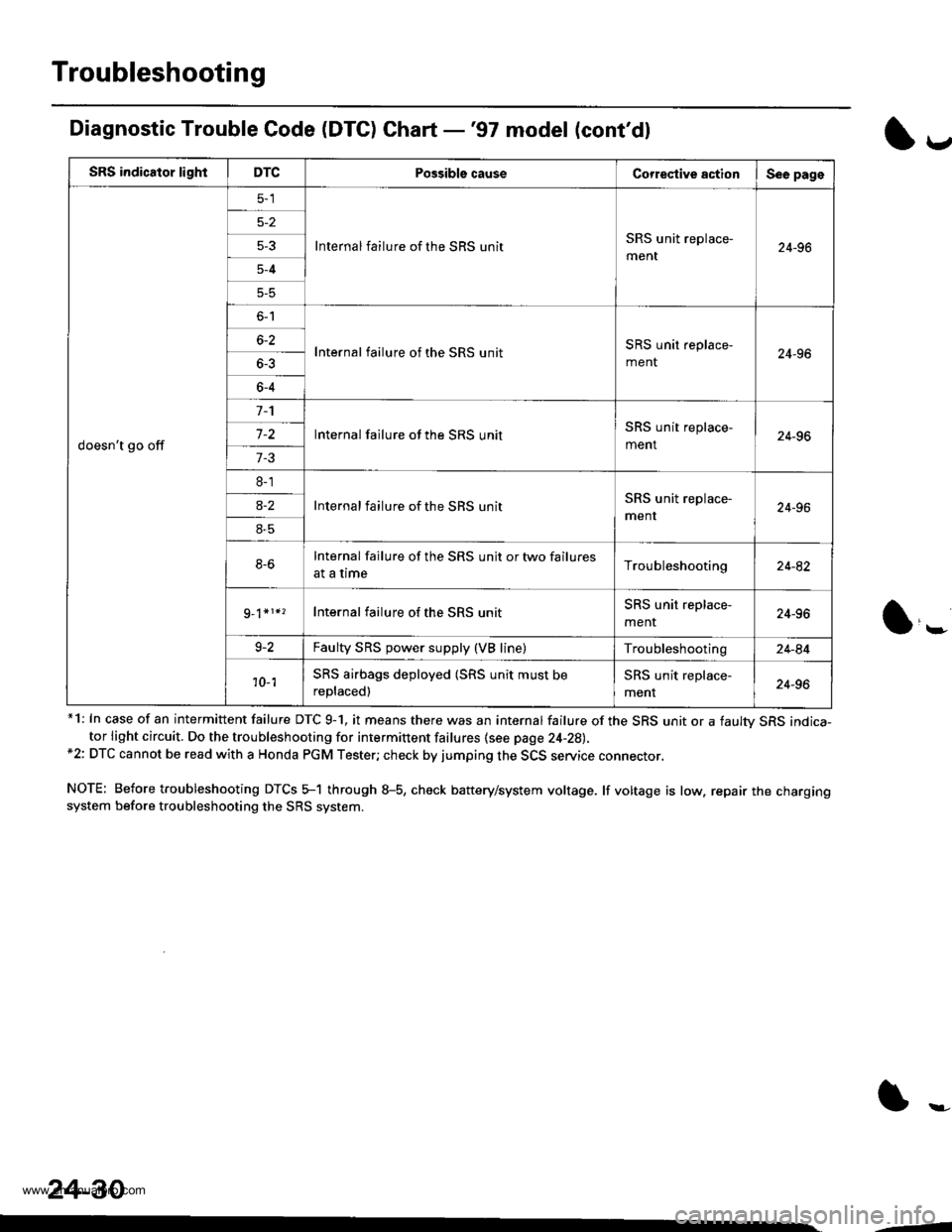

Diagnostic Trouble Code (DTC) Chart -'97 model (cont'dl

*1: In case of an intermittent failure DTC 9-1, it means there was an internal failure of the SRS unit or a faultv SRS indica-tor light circuit. Do the troubleshooting for intermittent failures {see page 24-28),*2: DTC cannot be read with a Honda PGM Tester; check by jumping the SCS service connector.

NOTE: Before troubleshooting DTCS 5-1 through 8-5, check battery/system voltage. lf voltage is low. repair the chargingsystem before troubleshooting the SRS system.

l*

SRS indicator lightDTCPossible causeCorrestive actionSee page

doesn't go off

Internal failure of the SRS unitSRS unit replace-

ment24-965-3

5-4

5-5

o-l

Internal failure of the SRS unitSRS unit replace-

ment24-966-2

6-4

lnternal failure of the SRS unitSRS unit replace-

ment24-967-2

7-3

8-1

Internal failure of the SBS unitSRS unit replace-

menr24-96a-2

8-5

8-6Internal failure of the SRS unit or two failures

at a timeTroubleshooting24-82

Internal failure of the SRS unitSRS unit replace-

menr24-96

9-2Faulty SRS power supply (VB line)Troubleshooting24-84

'10- 1SRS airbags deployed (SRS unit must be

replaced)

SRS unit replace-

ment24-96

24-30

--

www.emanualpro.com