engine HONDA CR-V 1998 RD1-RD3 / 1.G Service Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 99 of 1395

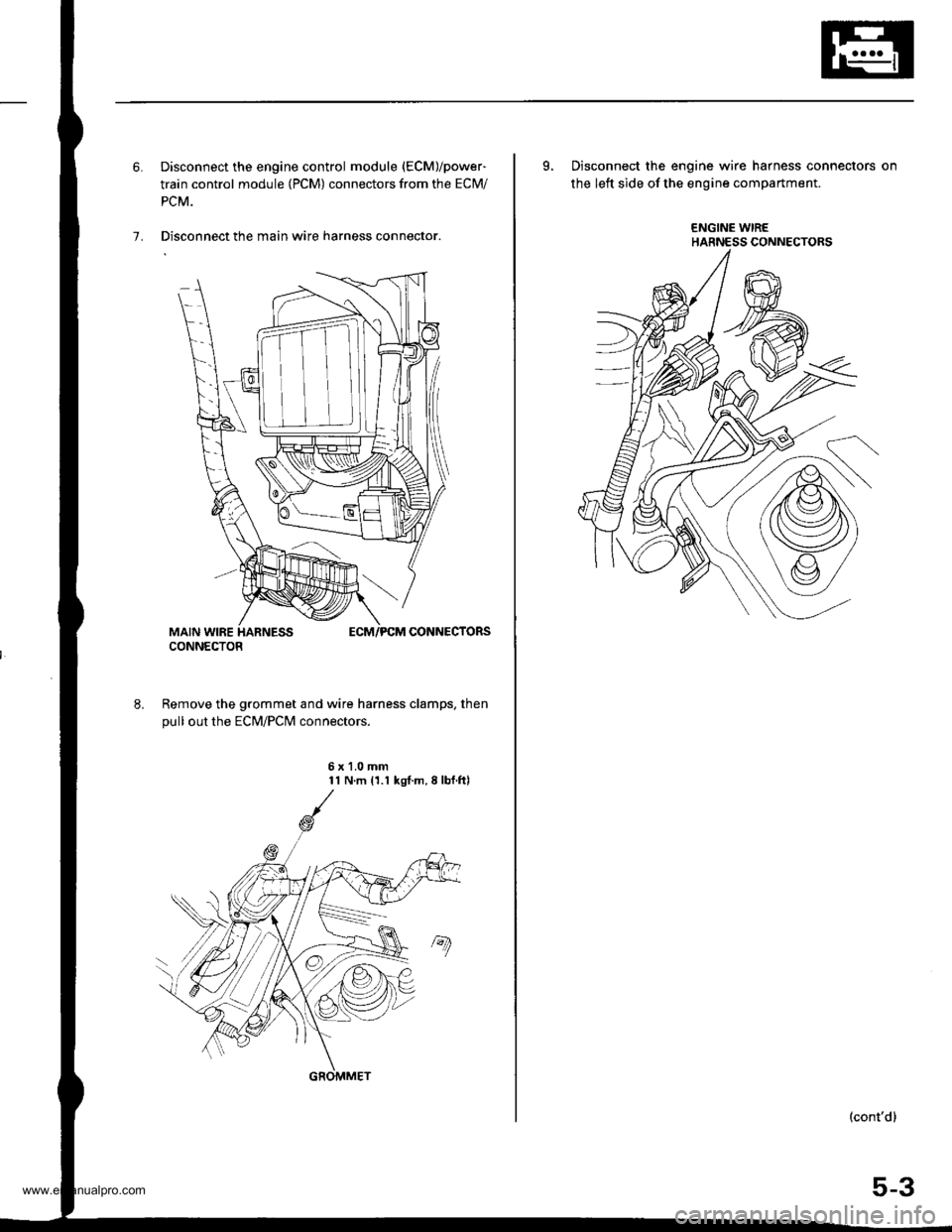

6. Disconnect the engine control module (ECM)/power-

train control module (PCM) connectors from the ECM/

PCM.

7. Disconnect the main wire harness connector.

Remove the grommet and wire harness clamps, then

pull out the EcM/Pclvl connectors.

6x1.0mm11 N.m 11.1 kgl.m,8lbf.ftl

CONNECTOR

GROMMET

L Disconnect the engine wire harness connectors on

the left side of the engine compartment.

ENGINE WIREHARNESS CONNECTORS

(cont'd)

5-3

www.emanualpro.com

Page 100 of 1395

Engine Removal/lnstallation

Removal (cont'dl

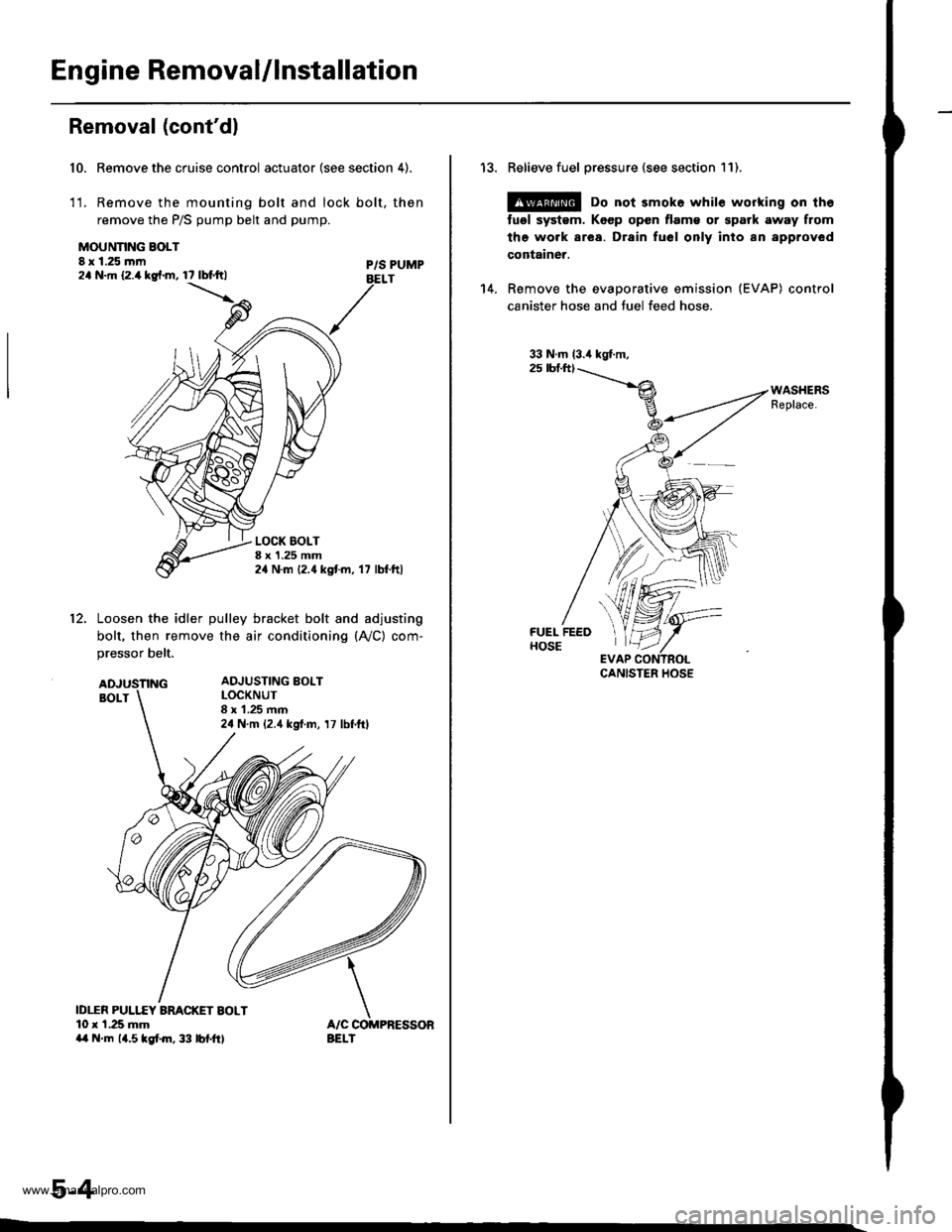

Remove the cruise control actuator (see section 4).

Remove the mounting bolt and lock bolt, then

remove the P/S pump belt and pump.

10.

1t.

MOUNNNG BOLT8 x 1.25 mm2a N.m 12.4 kg{.m, 17 lbtftlP/S PUMPBELT

LOCK BOLTI x 1.25 mm24 N.m {2.4 kgtm, '17 lbf.ftl

12.Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (A,/C) com-

pressor belt.

ID1TR PULI.f,Y ARACKET BOLT10 r 1.25 mma{ N.m 14.5lgtm,33 lbf.ft)

ADJUSTING BOLTLOCKNUT8 x 1.25 mm24 N.m {2.4 kgf.m, 17 lbf.ftl

5-4

13. Relieve fuel pressure {see section 11).

@ Do not 3mok6 whil€ working on th6

tugl systsm. Koep open flam€ or spark away from

the work area. Drain fuel only inlo an approved

container.

14. Remove the evaporative emission (EVAP) control

canister hose and tuel feed hose.

33 N.m (3.4 kgt.m,2s tbf.ft)

,%l

*ryft'fltr

\'t,f

EVAP CCCANISTER HOSE

www.emanualpro.com

Page 102 of 1395

Engine Removal/lnstallation

Removal (cont'd)

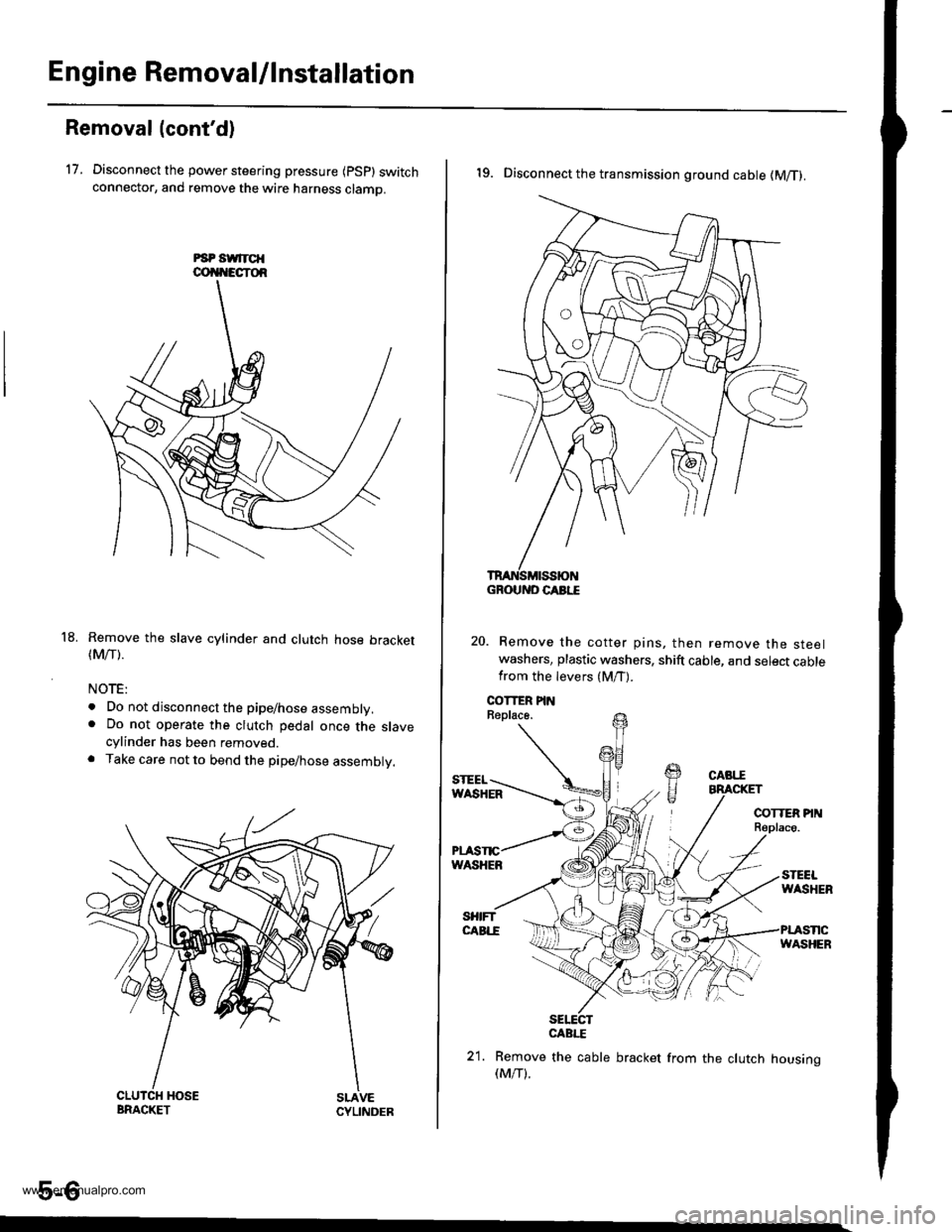

17. Disconnect the power steering pressure {psp} switchconnector, and remove the wire harness clamo.

Remove the slave cylinder and clutch hose bracket(Mrr).

NOTE:

. Do not disconnect the pipe/hose assembly.. Do not operate the clutch pedal once the slavecylinder has been removed.. Take care not to bend the pipe/hose assembly.

5-6

18.

19. Disconnect the transmission ground cable (M/T).

Remove the cotter pins, then remove the steelwashers, plastic washers, shift cable, and select cablefrom the levers (M/T).

sElEcrCABI."E

21. Remove the cable bracket from the clutch housing(M/T).

GROUND CABI."E

www.emanualpro.com

Page 103 of 1395

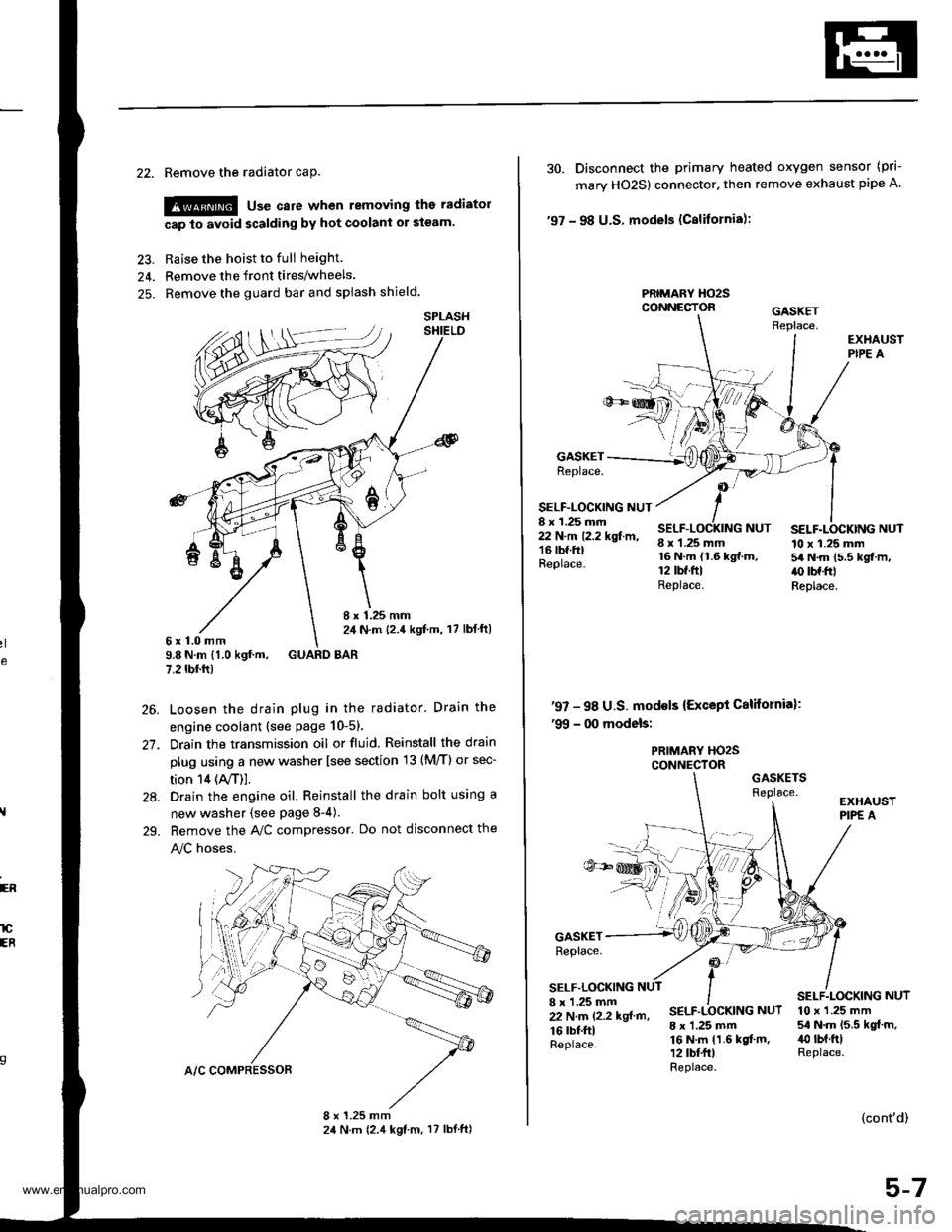

22. Remove the radiator caP.

!@ use care when removing the radiatol

cap to avoid scalding by hot coolani or steam.

23. Raise the hoist to full height

24. Remove the front tires/wheels.

25. Remove the guard bar and splash shield.

8 x 1.25 mm2,1 N.m {2.4 kgf,m, 17 lbl ft)6x1.0mm9.8 N.m {1.0 kgf.m, GUARD BAR7.2 tbf.rr)

Loosen the drain plug in the radiator. Drain the

engine coolant (see page 10-51.

Drain the transmission oil or fluid. Reinstall the drain

plug using a new washer lsee section 13 (M/T) or sec-

tion 14 (ly'T)].

Drain the engine oil. Reinstall the drain bolt using a

new washer {see page 8-4).

Bemove the A,/C compressor. Do not disconnect the

!y'C hoses.

SPLASH

26.

27.

28.

29.

ER

lCEB

30. Disconnect the primary heated oxygen sensor (prl-

mary HO2S) connector. then remove exhaust pipe A

'97 - 98 U.S. models (Cslifornia):

PRIMARY HO2SCONNECTOR

GASKETReplace.

SELF-LOCKING NUT8 x 1.25 mm22 N.m 12.2 kgf.m,16 lbf.ftlReplace.

8 x 1.25 mm16 N.m {1.6 kgf.m.12 tbt.ftlReplace.

SELF.LOCKING NUT10 x 1.25 mm54 N.m 15.5 kgf.m,.() tbf.frlReplace.

NUT

'97 - 98 U.S. mod€ls {Except California):'99 - 00 models:

PRIMARY HO2SCONNECTORGASKETSReplace.

GASKETReplace.

SELF.LOCKING8 x 'l.25 mm22 N.m (2.2 kgf m,

16 rbf.ftlReplace.

SELF.LOCKING NUT

8 x 1.25 mm16 N.m 11.6 kgf.m,12 tbt fr)Replace.

10 x 1.25 mm54 N.m 15.5 kgt.m,40 rbt.ftlReplace.

{cont'd)

5-7

www.emanualpro.com

Page 104 of 1395

Engine RemovaUlnstallation

OOI{TROL PI

Removal (cont'dl

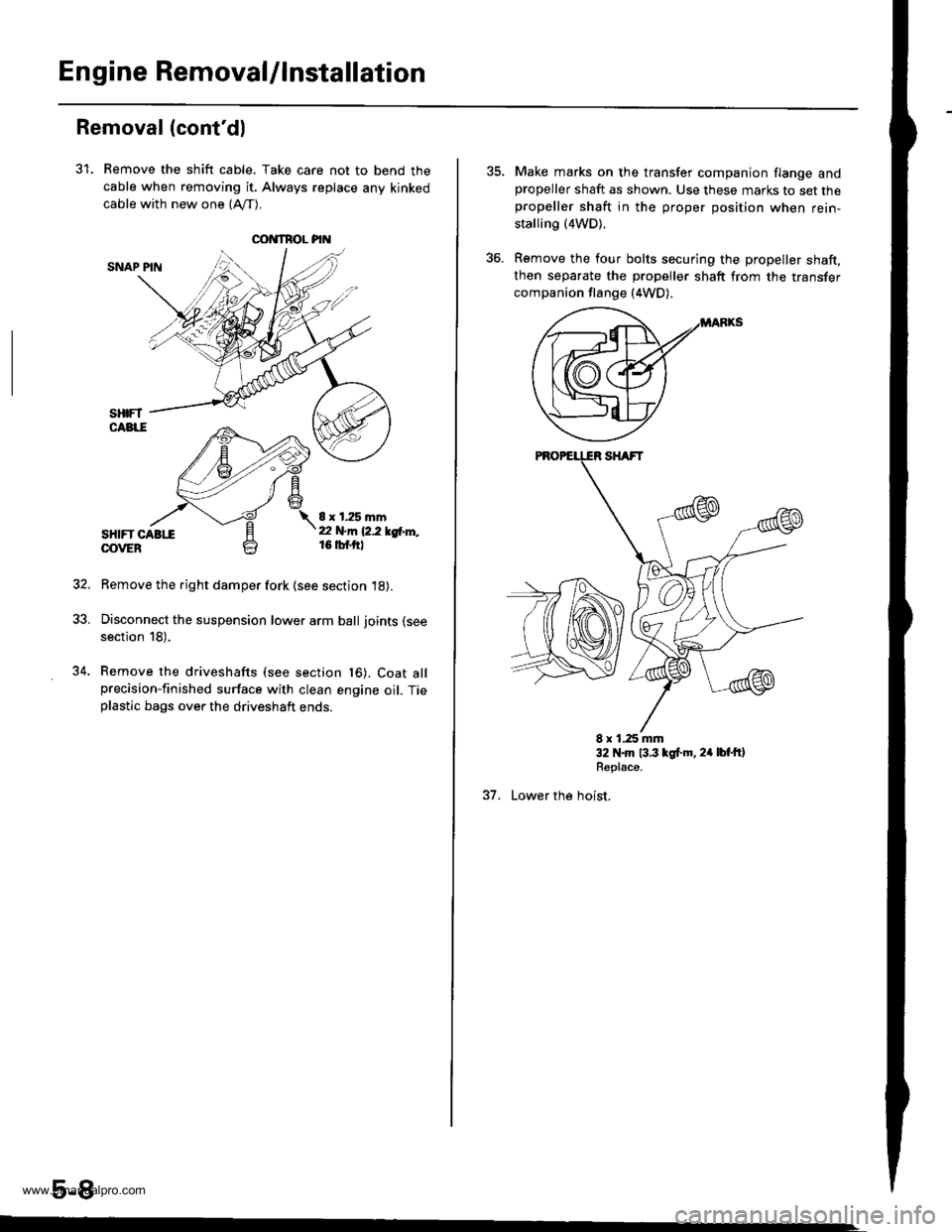

31. Remove the shift cable. Take care not to bend the

cable when removing it. Always replace any kinked

cable with new one (Afl-).

SNAP PIN

sHtFT CABttOOVEB

8 x 1.25 mmt2 N.m 12.2 lgtr'l'',,16 tbf.ftl

Remove the right damper fork (see section 18).

Disconnect the suspension lower arm ball joints (see

section 18),

Remove the driveshafts (see section t6). Coat allprecision-finished surface with clean engine oil. Tieplastic bags over the driveshaft ends.

5-8

34.

Make marks on the transfer companion flange andpropeller shaft as shown. Use these marks to set thepropeller shaft in the proper position when rein-

stalling (4WD).

Remove the four bolts securing the propeller shaft,then separate the propeller shaft from the transfer

companion flange (4WD).

E x 1.25 mm32 N.m 13.3 lgt.m, 24 lbt'ftlRepl€ce.

37. Lower the hoist,

www.emanualpro.com

Page 106 of 1395

Engine RemovaUlnstallation

Removal (cont'dl

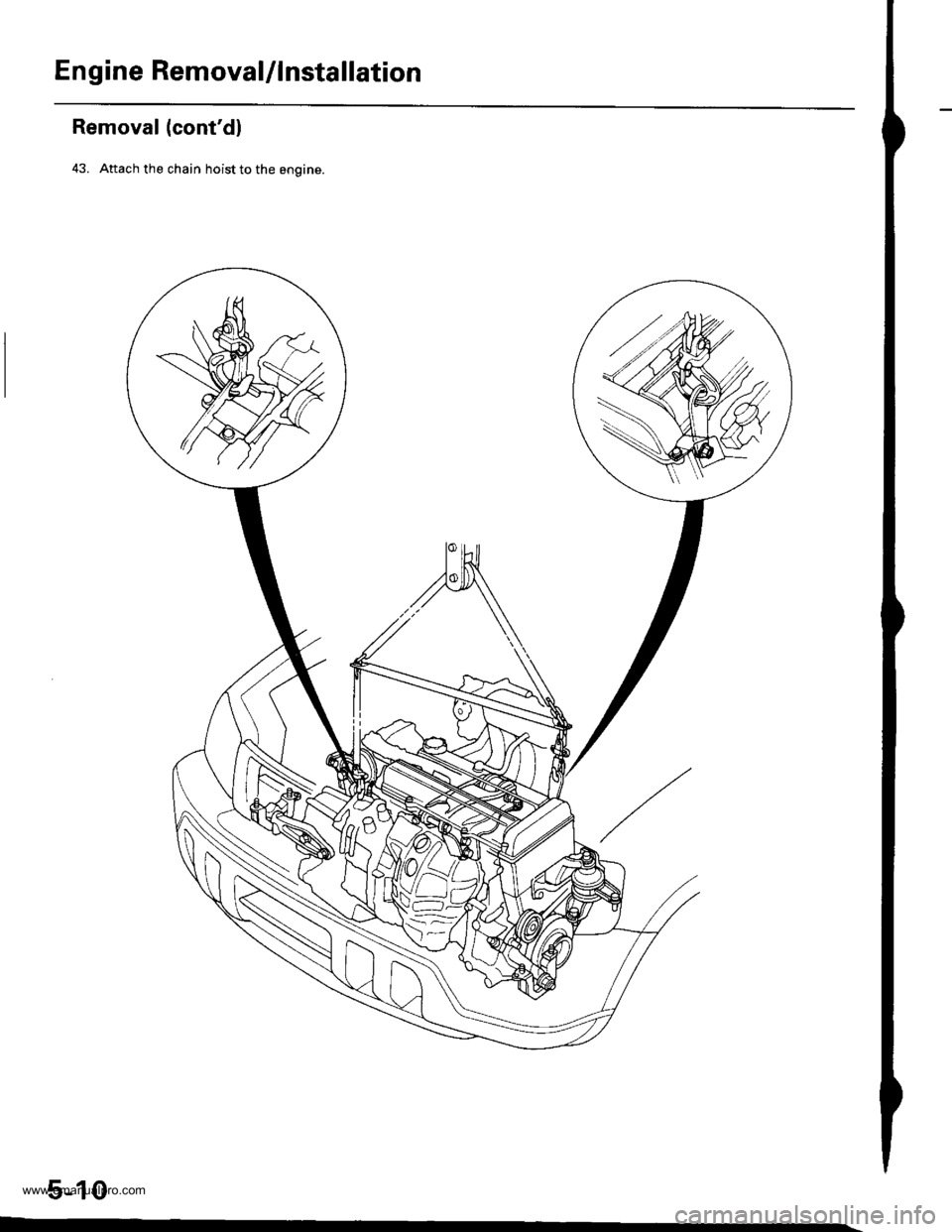

43. Attach the chain hoist to the engine.

5-10

www.emanualpro.com

Page 107 of 1395

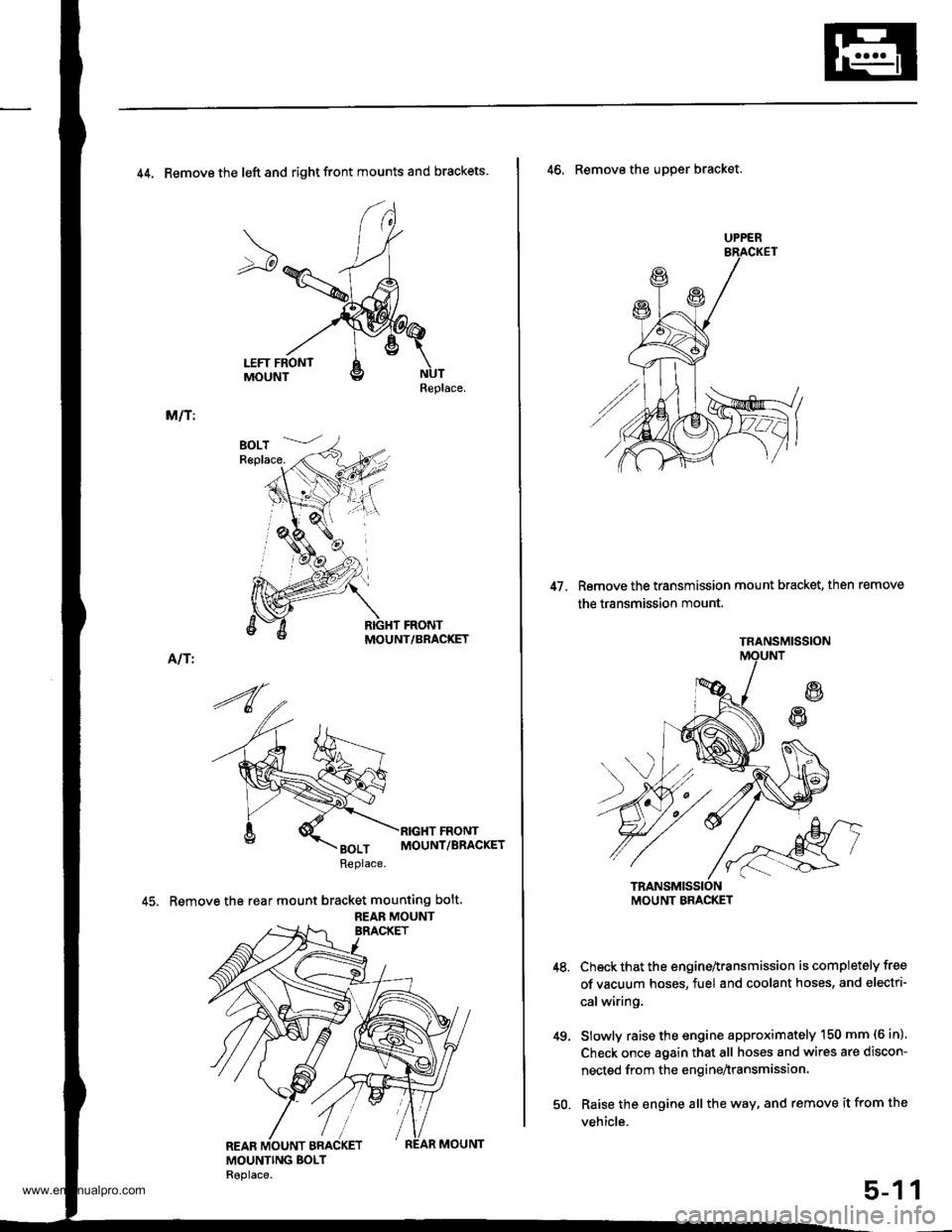

44. Remove the left and right front mounts and brackets

Replace.

M/T:

MOUNT/BRACKET

Alf I

45. Remove the rear mount bracket mounting bolt.

REAB MOUNT

UPPER

47. Remove the transmission mount bracket, then remove

the transmission mount.

46. Remove the uDper bracket.

Check that the engine^ransmission is completely free

of vacuum hoses, fuel and coolant hoses, and electri-

calwiring.

Slowly raise the engine approximately 150 mm (6 in)'

Check once again that all hoses and wires are discon-

nected from the enginenransmission.

Raise the engine all the way, and remove it from the

vehicle.

49.

1

TRANSMISSION

MOUNT BMCKET

50.

5-1

www.emanualpro.com

Page 109 of 1395

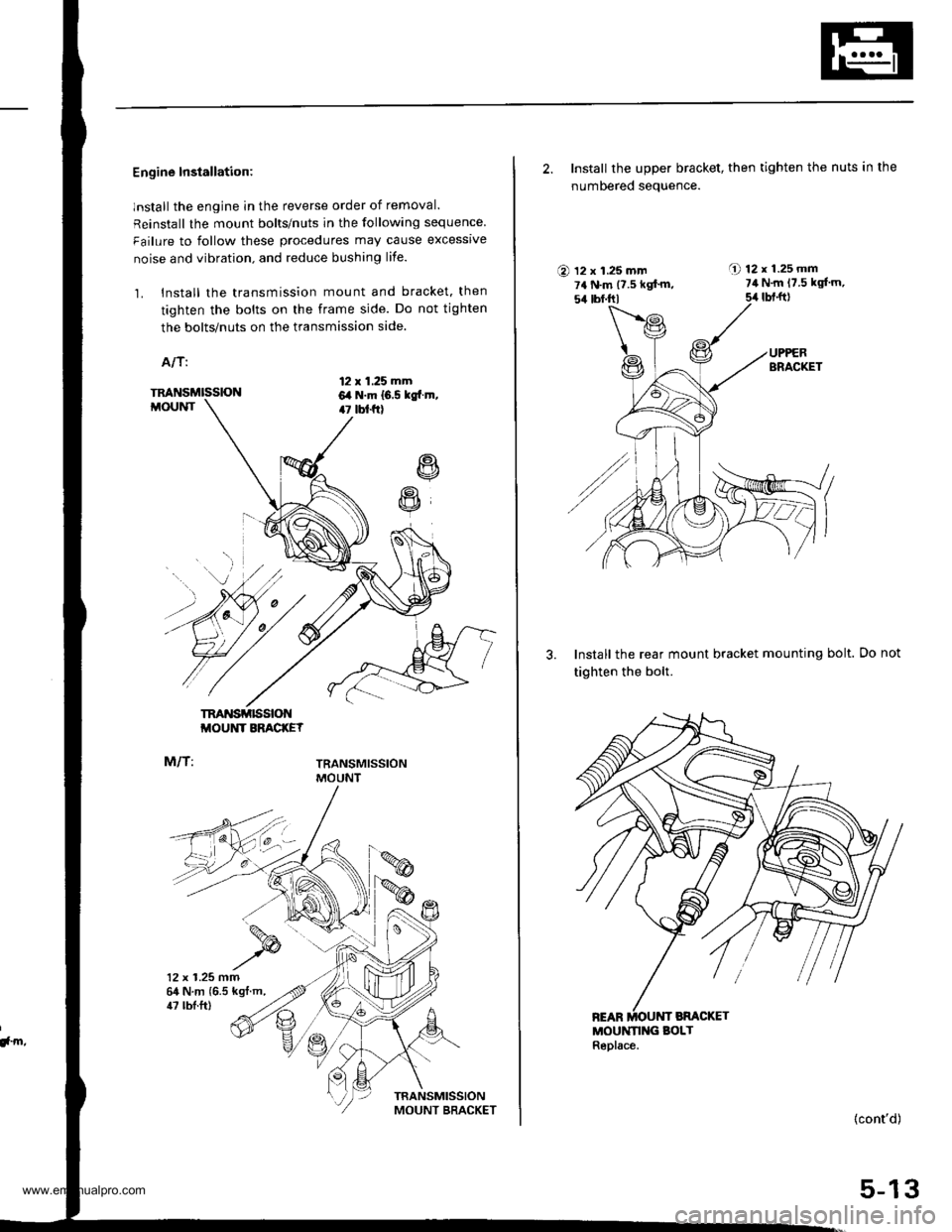

Engine Installation:

lnstall the engine in the reverse order of removal.

Reinstall the mount bolts/nuts in the following sequence

Failure to follow these procedures may cause excessrve

noise and vibration. and reduce bushing life.

1. Install the transmission mount and bracket. then

tighten the bolts on the frame side. Do not tighten

the bolts/nuts on the transmission side.

A/T:

12 x 1.25 mm6,a N.m 16.5 kgtr.m,47 tbt f0

R

R

TM'{SMISSIONMOUNT

M/T:

TRANSMISSIONMOUNT BRACKEY

TRANSMISSIONMOUNT

12 x 1.25 mm64 N.m {6.5 kgt.m,

!, m,

47 tbl.ft)

2. Install the upper bracket, then tighten the nuts in the

numbered seauence.

O 12 x 1.25 mm7a N.m {7.5 kgf'm,54 tbf.trl

A 12r1.25mm7il N.m 17.5 kgl'm,

5,r lbt.ft)

3. Install the rear mount bracket mounting bolt.

tighten the bolt.

MOUNN G BOLTReplace.

Do not

(cont'd)

5-13

www.emanualpro.com

Page 112 of 1395

Engine Removal/lnstallo cton

Installation (cont'd)

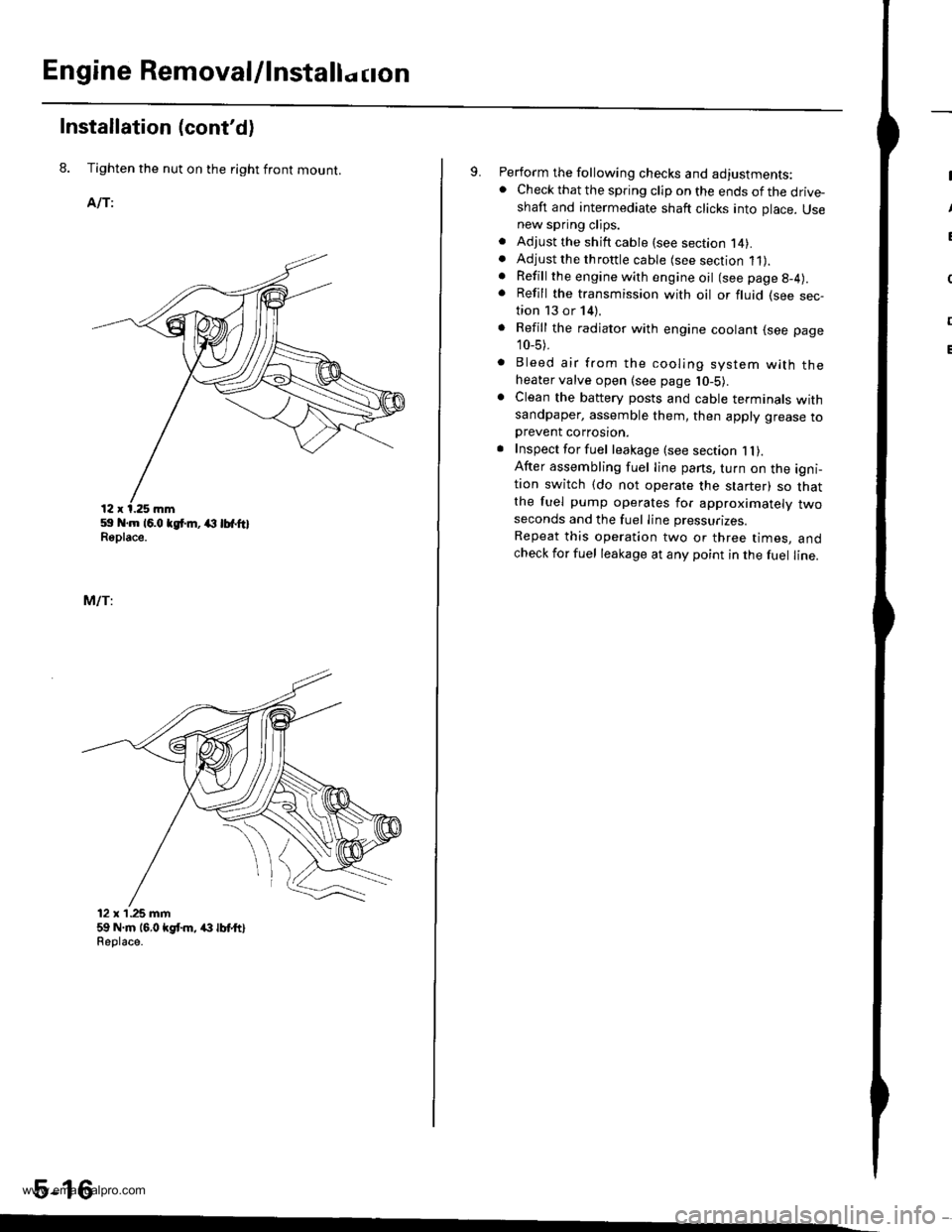

8. Tighten the nut on the right front mount.

AlTi

59 .m 16.0 tgt m, (l lbfftlReplace.

MlTi

12 x'1.25 mm59 N.m 16,0 kgt m, /(} lbt ttlReolace.

5-16

9. Perform the following checks and adjustments:. Check that the spring clip on the ends of the drive-shaft and intermediate shaft clicks into place. Usenew spring clips.. Adjust the shift cable (see section l4).. Adjust the throttle cable (see section 11).. Refill the engine with engine oil (see page g-4).

. Refill the transmission with oil or fluid (see sec-tion 13 or 14).

. Refill the radiator with engine coolant (see page

10_5).

. Bleed air from the cooling system with theheater valve open (see page l0-5).. Clean the battery posts and cable terminals withsandpaper, assemble them, then apply grease toDrevent corrosron.. Inspect for fuel leakage (see section 1l).After assembling fuel line pans, turn on the igni-tion switch (do not operate the starter) so thatthe fuel pump operates for approximately twoseconds and the fuel Iine pressurizes.

Repeat this operation two or three times, andcheck for fuel leakage at any point in the fuel line.

www.emanualpro.com

Page 122 of 1395

1.

2.

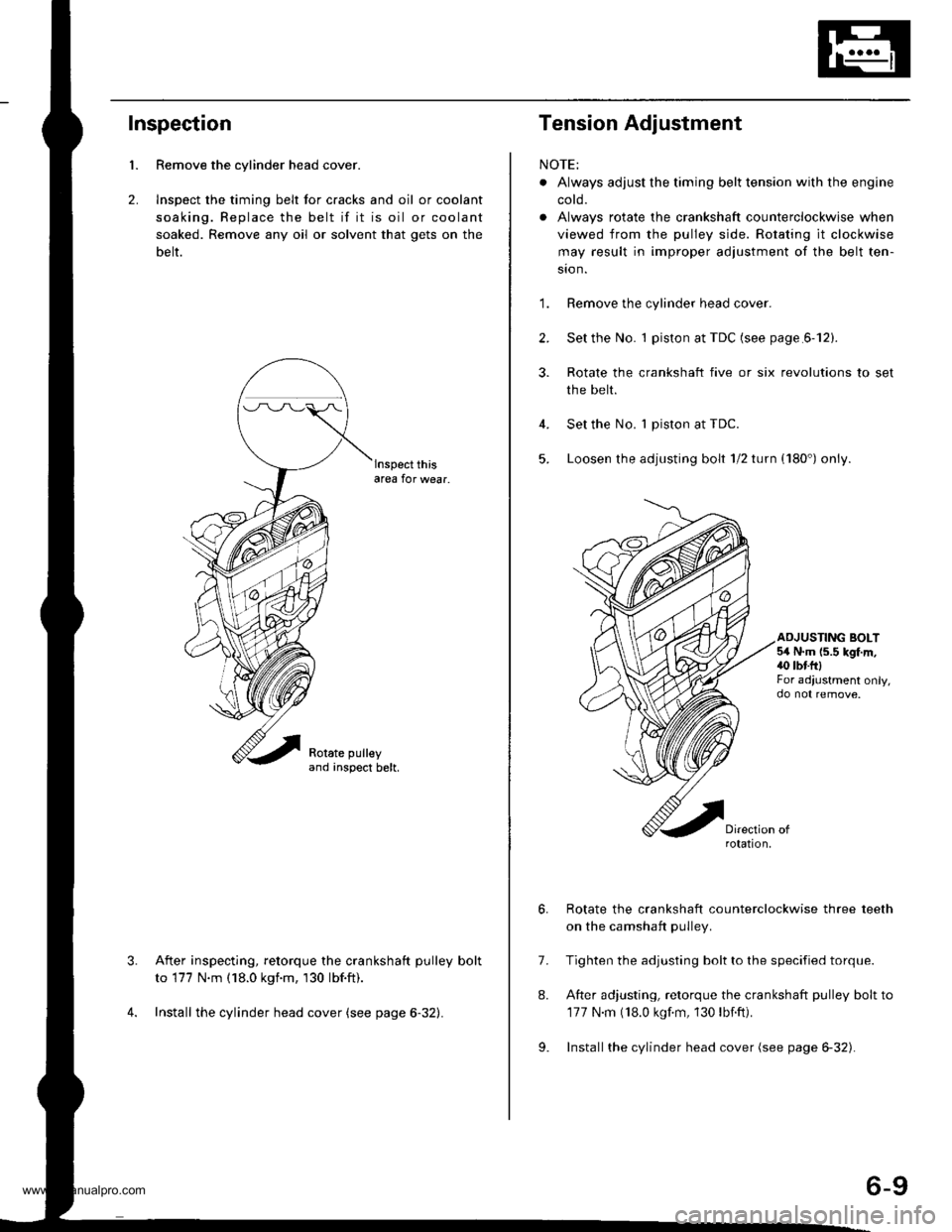

Inspection

Remove the cylinder head cover.

lnspect the timing belt for c.acks and oil or coolant

soaking. Replace the belt if it is oil or coolant

soaked. Remove any oil or solvent that gets on the

belt.

lnspect thisarea for wear.

After inspecting, retorque the crankshaft pulley bolt

to 177 N.m (18.0 kgnm, 130 lbf.ft).

Install the cylinder head cover (see page 6-32).

3.

Tension Adjustment

NOTE:

. Always adjust the timing belt tension with the engine

coto.

. Always rotate the crankshaft counterclockwise when

viewed from the pulley side. Rotating it clockwise

may result in improper adiustment of the belt ten-

sion.

'1. Remove the cylinder head cover

2. Set the No. 1 piston at TDC (see page.6-12).

3. Rotate the crankshaft five or six revolutions to set

the belt.

Set the No. 1 piston at TDC.

Loosen the adjusting bolt 1/2 turn (180') only.

4.

5.

ADJUSTING BOLT5,4 N.m (5.5 kgf.m,40 tbtftlFor adiustment only,

7.

8.

Rotate the crankshaft counterclockwise three teeth

on the camshaft pulley.

Tighten the adjusting bolt to the specified torque.

After adjusting, retorque the crankshaft pulley bolt to

177 N.m (18.0 kgf.m, 130 lbf.ft).

Installthe cylinder head cover (see page 6-32).9.

rotation,

6-9

www.emanualpro.com