fuel HONDA CR-V 1998 RD1-RD3 / 1.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 329 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Manual PDF

Misfire Detected in One Cylinder

Ipffi1] Thescantoot indicates Diagnostic Trouble Code (DTC) P0301: Cylinder 1 misfire detected.

lF03O2l 16".""n toot indicates Diagnostic Trouble Code (DTC) P0302; Cy HONDA CR-V 1998 RD1-RD3 / 1.G Manual PDF

Misfire Detected in One Cylinder

Ipffi1] Thescantoot indicates Diagnostic Trouble Code (DTC) P0301: Cylinder 1 misfire detected.

lF03O2l 16".""n toot indicates Diagnostic Trouble Code (DTC) P0302; Cy](/img/13/5778/w960_5778-328.png)

Misfire Detected in One Cylinder

Ipffi1] Thescantoot indicates Diagnostic Trouble Code (DTC) P0301: Cylinder 1 misfire detected.

lF03O2l 16".""n toot indicates Diagnostic Trouble Code (DTC) P0302; Cylinder 2 misfire detected.

I P0303 | fne scan tool indicates Diagnostic Trouble Code (DTC) P0303: Cylinder3 misfire detected.

lF0il04l 16" ""un tool indicates Diagnostic Trouble Code (DTC) PO3O4: Cylinder 4 misfire detected

Description

Misfire detection is accomplished by monitoring the crankshaft speed with the crankshaft speed fluctuation (CKF) sensor

which is attached to the crankshaft.

lf misiiring strong enough to damage the catalyst is detected, the MIL will blink during the time of its occurrence. and DTC

P0301, P0302, P0303 and/or P0304 will be stored. Then, after the misfire has ceased, the MIL will come on.

lf misfiring that increases emissions is detected during two consecutive driving cycles. the MIL will come on, and DTc

P0301, P0302, P0303 and/or P0304 will be stored.

NOTE: lJ some of the DTcs listed below are stored at the same time as a misfire DTc, troubleshoot those DTcs first, then

troubleshoot the misfire DTC.

P0107, P0108, P'n2a, P1129t MAP sensor

Po'17 'l , P0112t Fuel suPP|Y system

P0441: EVAP insufficient Purge flow

P1336, P1337: CKF sensor

P1359, Pl361, P1362: TDC sensor

Pl381, P1382: CYP sensor

Possible Cause

. Fuel injector clogging, fuel leakage, air leakage

. Fuel injector circuit open or shorted

. Spark plug carbon deposits, fouling, malfunction

. lgnition wires open, leaking

. Distributor malfunction

. Compression low

. Valve clearance out of specification

(cont'd)

11-127

www.emanualpro.com

Page 331 of 1395

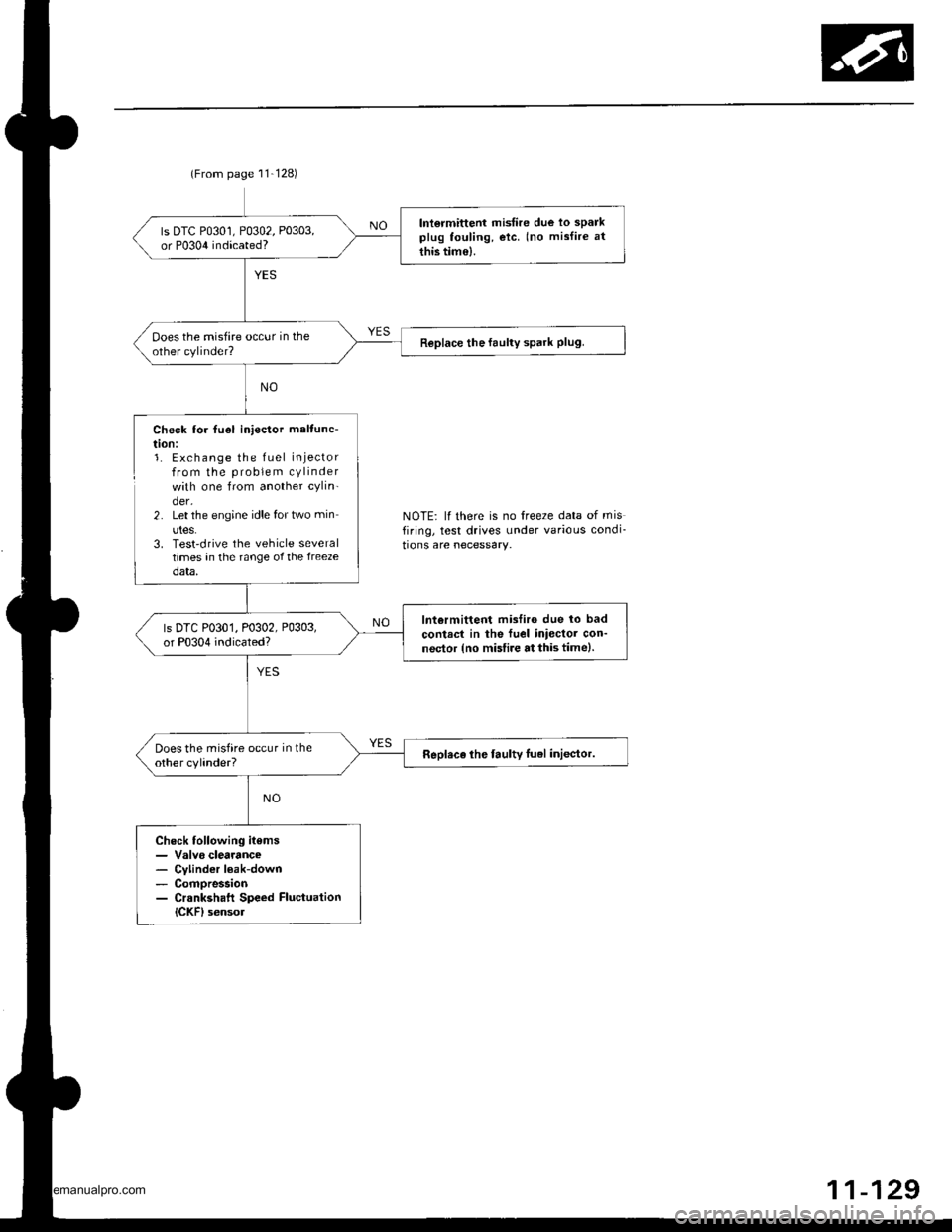

(From page 11-128)

lntormittent misfire due lo sparkplug fouling, etc. (no mislire at

this tim€).

ls DTC P0301, P0302, P0303,or P0304 indicated?

ooes the misfire occur in theother cylinder?Replace the faulty spark Plug.

Check lor fuel iniector maltunc-

t|on:1. Exchange the fuel injectorfrom the problem cylinderwith one from another cylin-der.2. Let the engine idle for two min

utes.3. Test'drive the vehicle severaltimes in the range of the freezedata,

lntermittent misfiro due lo bad

contrct in the fuel iniector con-nector {no misfire at this time).

ls DTC P0301, P0302, P0303,or P0304 indicated?

Does the misfire occur in theother cylinder?Replace lhe faulty luel inlector.

Check following items- Valvo clearance- Cvlinder l€ak-down- Compression- Crsnkshaft Speed FluctuationICKF) sensol

NOTE: lf there is no freeze data of misfiring, test drives under various condi_

tions are necessary.

11-129

www.emanualpro.com

Page 333 of 1395

tro-rsl

1Tffi61

tF136t

fPfa6r-1

tF138tl

I-Pi382l

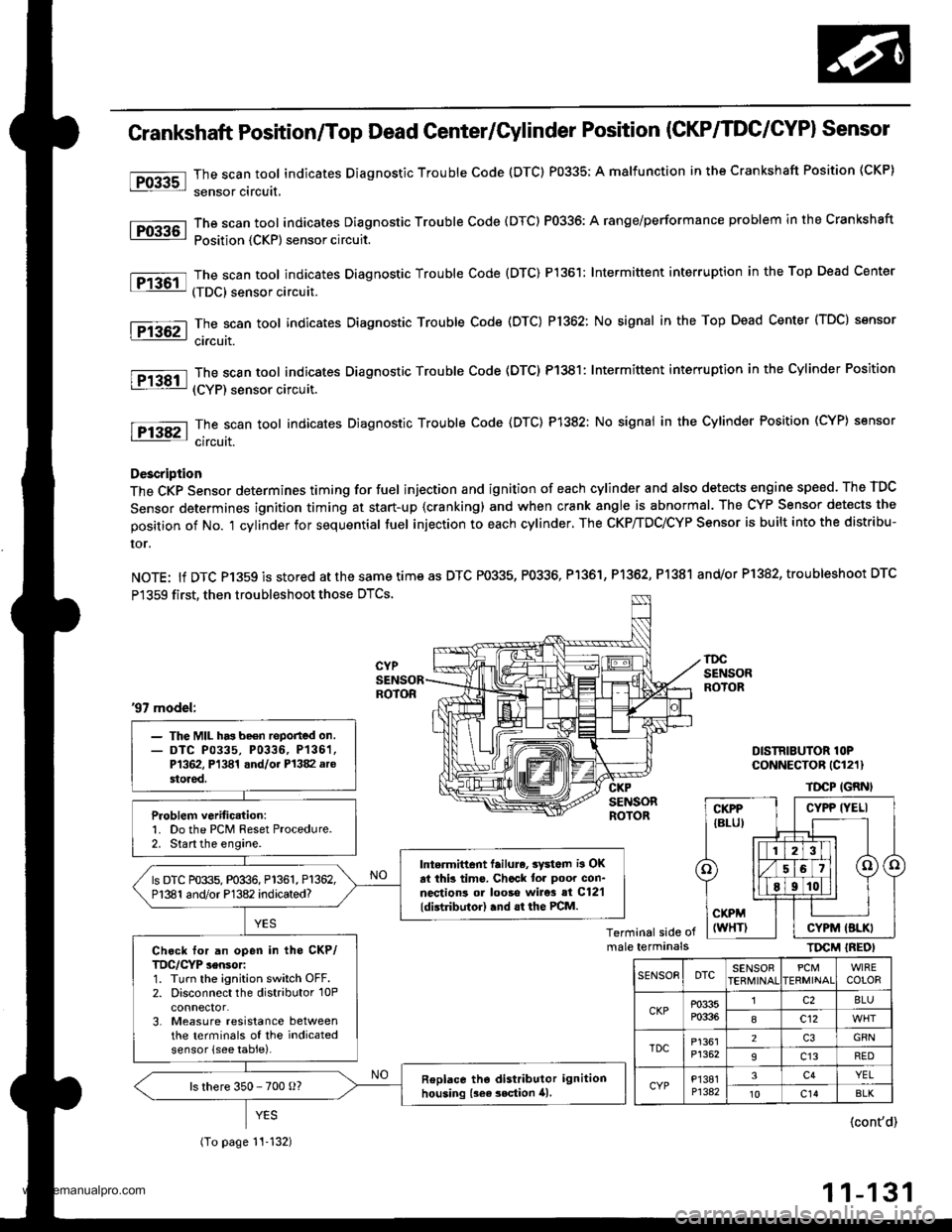

Crankshaft Position/Top Dead Genter/Gylinder Position (CKP/TDC/CYPI Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0335; A malfunction in the Crankshaft Position (CKP)

sensor circuit,

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the Crankshaft

Position {CKP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) P1361: Intermittent interruption in the Top Dead Center

(TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1362: No signal in the Top Dead Center (TDC) sensor

ci.cuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cylinder Position

(CYP) sensor circuit.

The scan toot indicates Diagnostic Trouble Code {DTC) P1382: No signal in the Cylinder Position (CYP} sensor

circuit.

Description

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDC

Sensor determines ignition timing at start-up {cranking) and when crank angle is abnormal. The CYP Sensor detects the

position of No. 't cylinder for sequential fuel injection to each cylinder. The CKP/TDC/CYP Sensor is built into the distribu-

ror.

NOTE: lf DTC P1359 is stored atthesametimeas DTC P0335, P0336, Pl361, P1362, P1381 and/or P1382, troubleshoot DTC

P1359 first, then troubleshoot those DTCS.

DISTRIBUTOR lOPCoNNECTOR (Cl211

TDCP IGRNI

Terminal side ofmale terminalsTIrcM IREOI

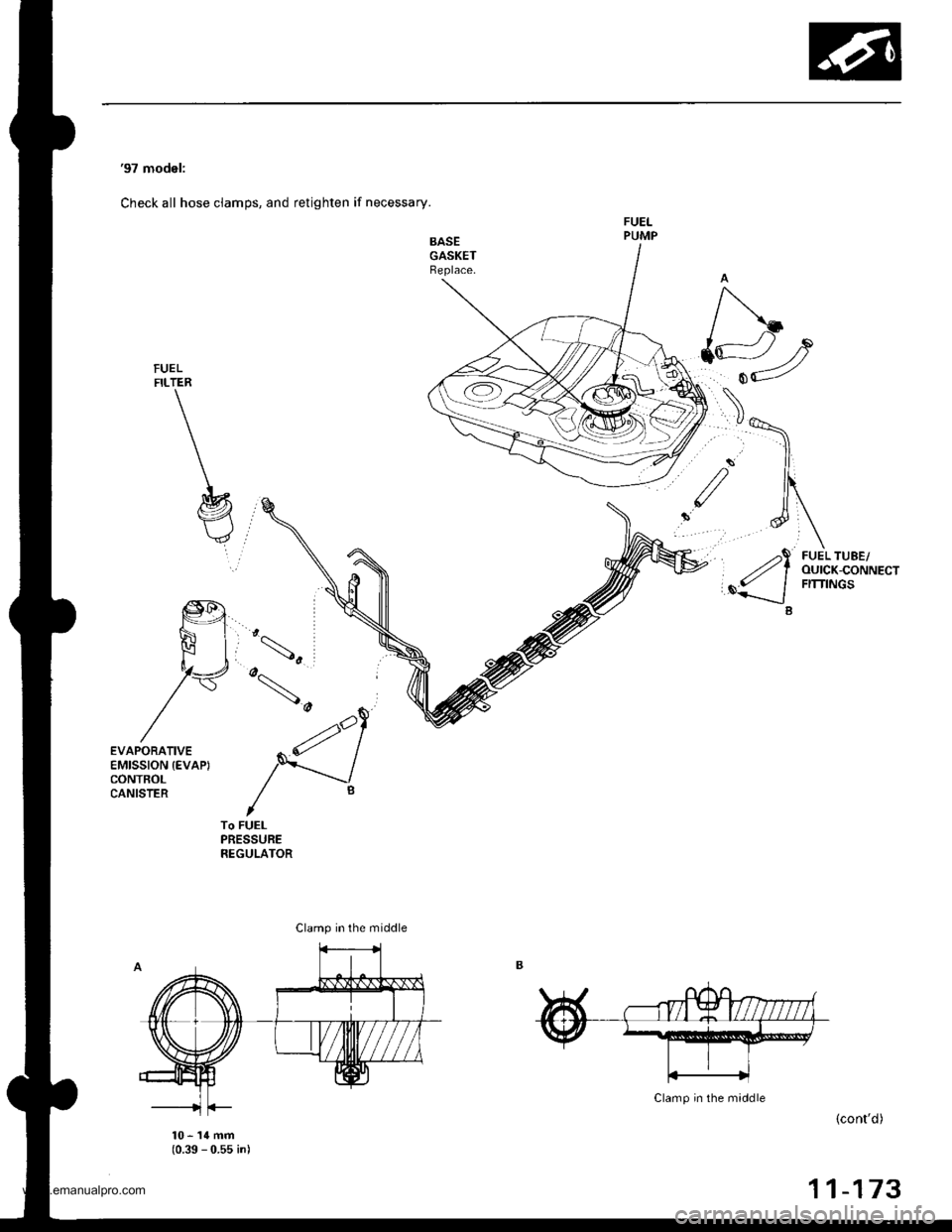

'97 model:

- The MIL has be€n reported on.- DTC P0335, P0336, P136'�1,P1362, Pl341 and/oi P1382 arestored.

Problem verific.tion:1. Do the PCM Reset Procedure.2. Start the engine.

Intermittent lailure, 3yd6m i3 OKat thb tims. Chcck tor poor con-nections ol looso wire3 si C12'l

ldistributor) .nd .t the PCM.

ls DTC P0335, P0336, P1361, P1362,P1381 and/or P1382 indicated?

Ch.ck for an open in tho CKP/TDC/CYP sensor:1. Turn the ignition switch OFF.2. Disconnect the distributor 10Pconnector.3. Measure resistance betweenthe terminals of the indicatedsensor (see table).

Replace tho distributor ignitionhousing {sea 3ection 41.ls there 350 - 700 o?

(To page 11-132)

CYPP IYELI

CYPM (BLKI

SENSOEDTCSENSOBPCMERMINAIWIRECOLOR

CKPP0335P0336

lc28LU

8c12

TDCP1361P1352

2GRN

9c13RED

CYPP'�I381P1342

3c4YEL't0c14BLK

{cont'd)

11-131

www.emanualpro.com

Page 373 of 1395

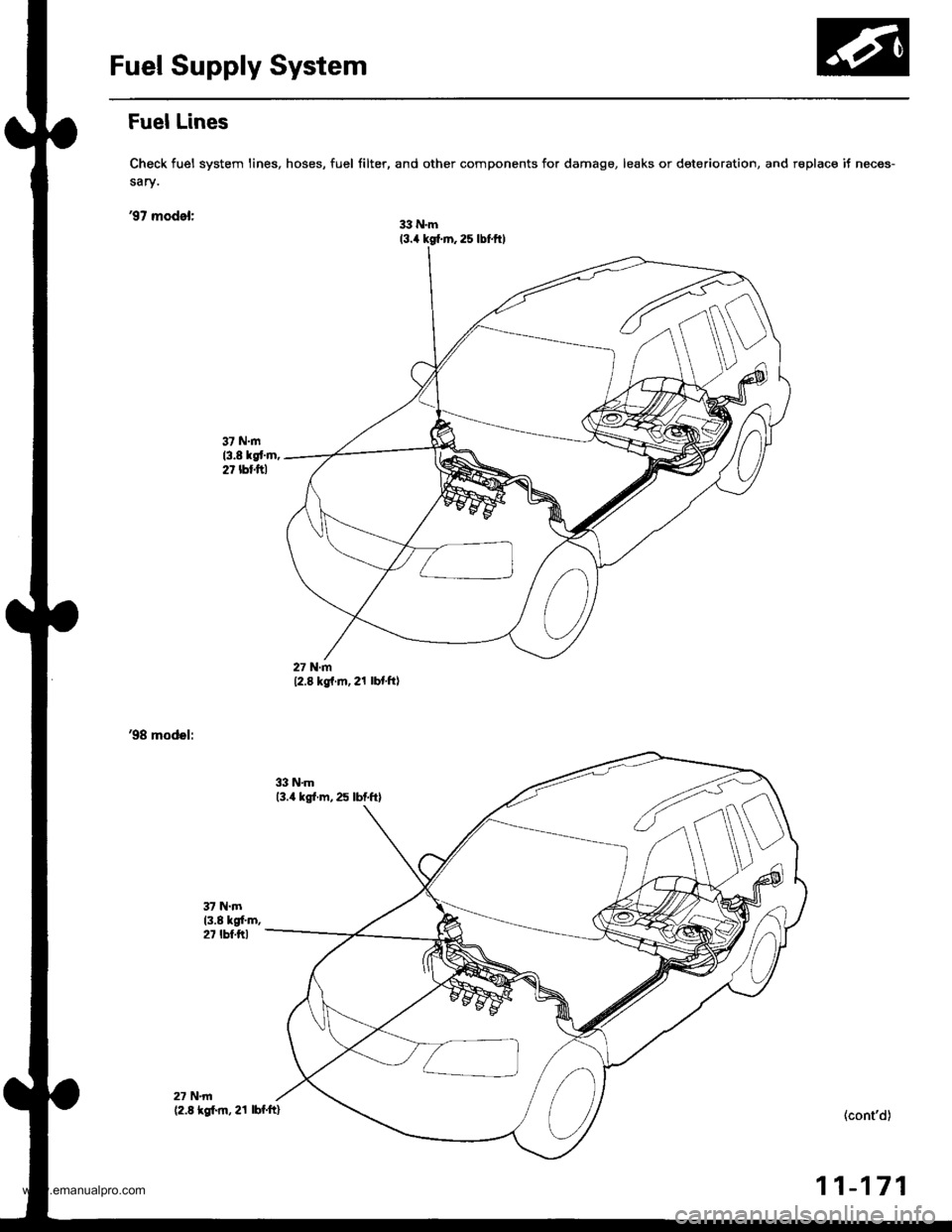

Fuel Supply System

Fuel Lines

Check fuel system lines, hoses, fuel filter, and other components for damage, leaks or det6rioration, and r€place it neces-

sary.

'97 model:33 N.m(3.4 kg(.m, 2s lbf.ftl

27 N.m12.8 kg{.m, 21 lbf.ft)

'98 model:

(cont'd)

11-171

27 N.rn(2.8 kgl.m, 21 lbf.ft)

www.emanualpro.com

Page 374 of 1395

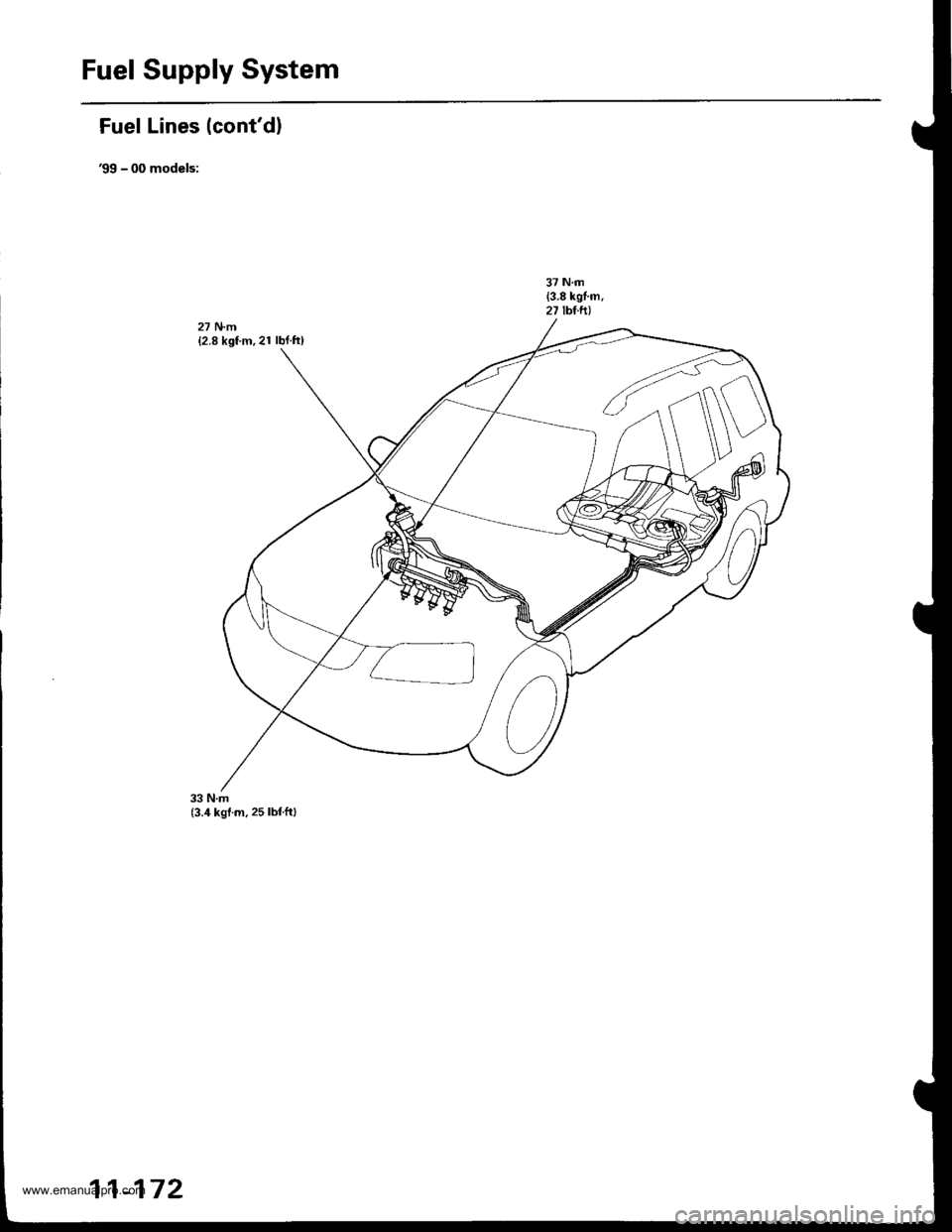

Fuel Supply System

Fuel Lines (cont'dl

'99 - 00 models:

33 N.m(3.4 kgl.m.25lbtftl

11-172

www.emanualpro.com

Page 375 of 1395

'97 model:

Check all hose clamps, and retighten if necessary.

FUELFILTER

/\

{"2

,"1<,, I___--tJ

B

FUEL TUBE/OUICK-CONNECTFITTINGS

EVAPORATIVEEMISSION {EVAP}CONTBOLCANISTER

'^s

,4\-') |Ift q'l I

/'------/

/B,To FUELPRESSUREREGULATOR

10-14mm(0.39 - 0.55 inl

(cont'd)

11-173

Clamp in the middle

www.emanualpro.com

Page 376 of 1395

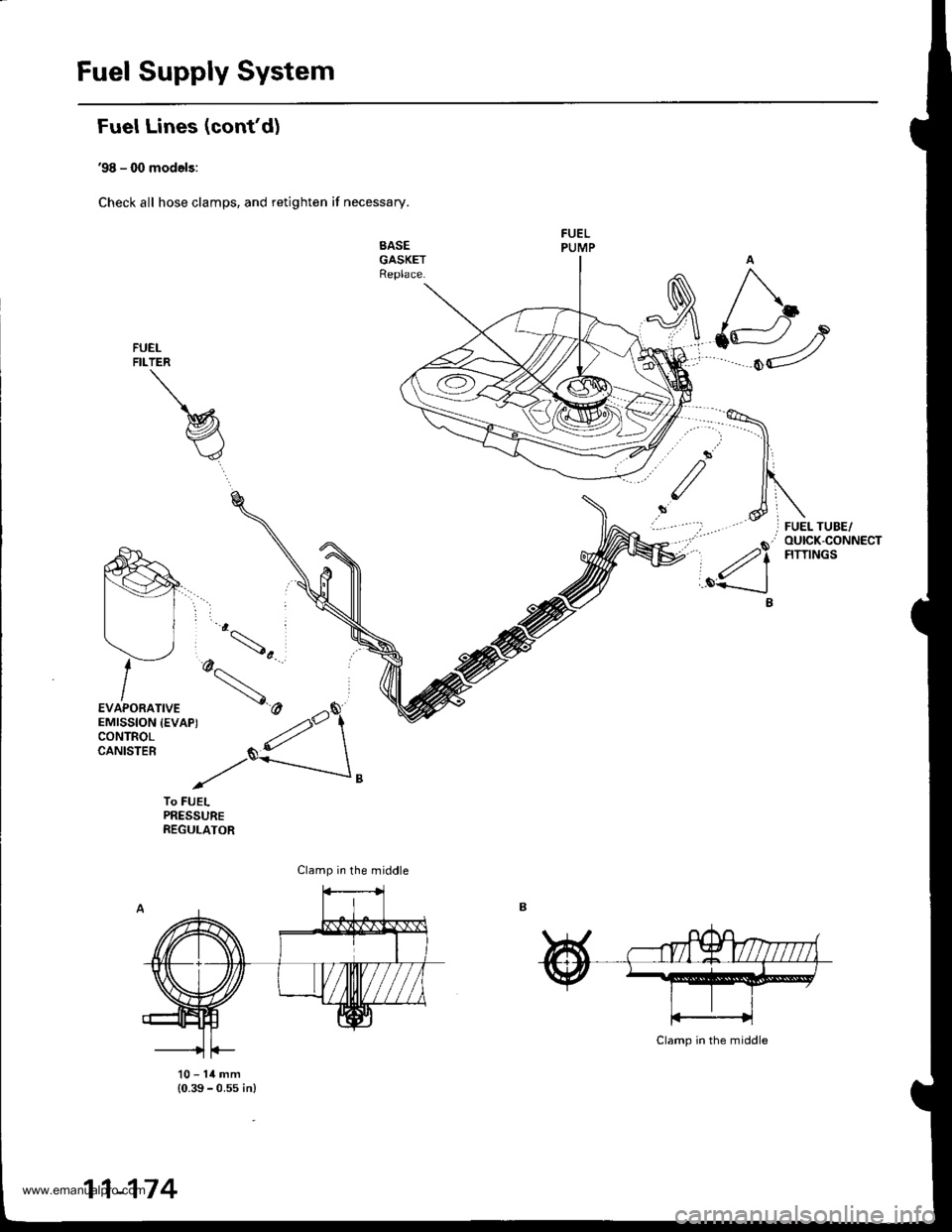

Fuel Supply System

Fuel Lines (confd)

'98 - (X) models:

Check all hose clamps, and retighten if necessary.

SASEGASKETReplace.

FUELFILTER

To FUELPRESSUREREGULATOR

10-14mm(0.39 - 0.ss in)

Clamp in the middle

11-174

www.emanualpro.com

Page 377 of 1395

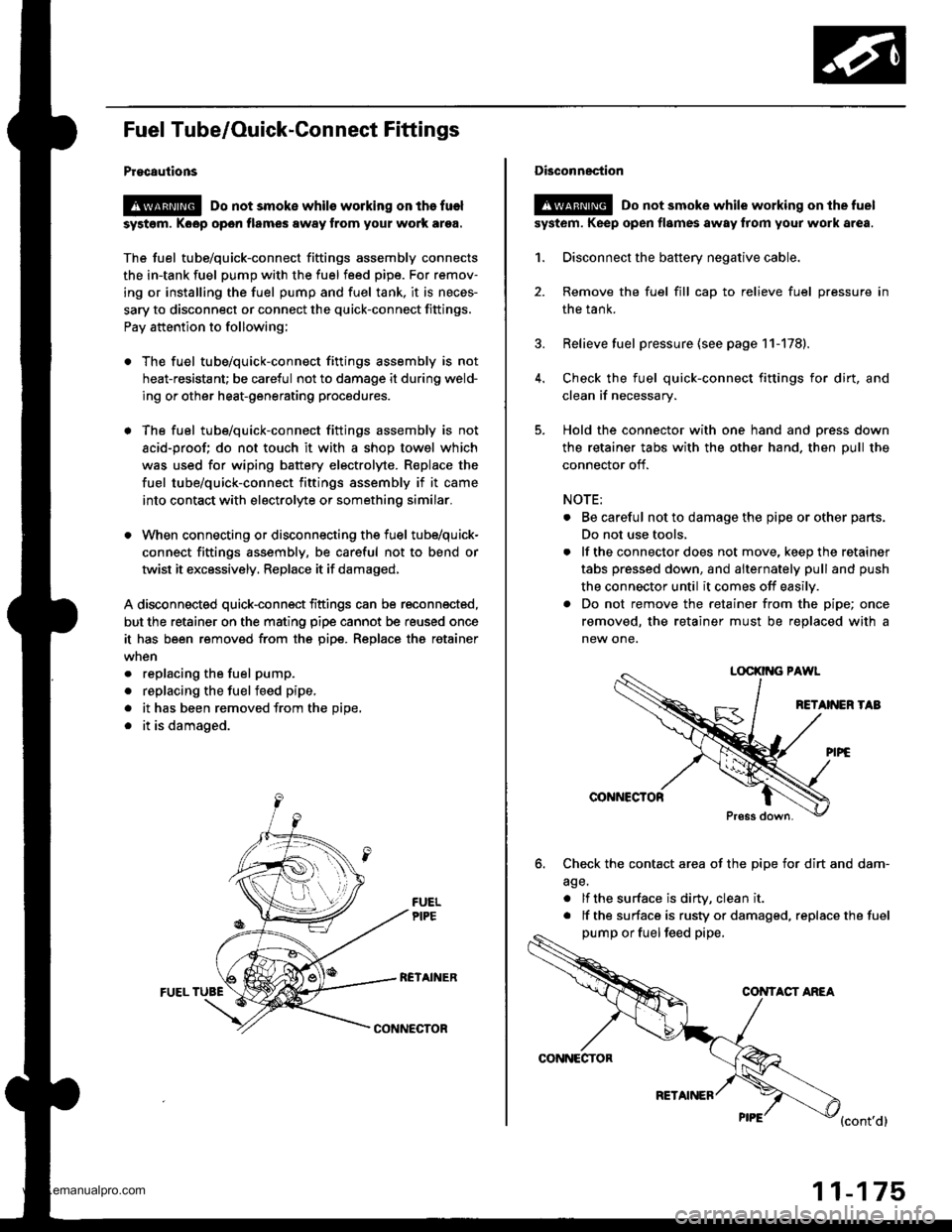

Fuel Tube/Ouick-Gonnect Fittings

Procautions

@ Do not smoke whils working on the fuel

syst6m, Koop open flames away from your work ar9a.

The fuel tube/quick-connect fittings assembly connects

the in-tank fuel pump with the fuel feed pipe. For remov-

ing or installing the fuel pump and fuel tank, it is neces-

sary to disconnect or connect the quick-connect fittings.

Pay attention to following;

. The fuel tube/quick-connect fittings assembly is not

heat-resistant; be careful not to damage it during weld-

ing or other heat-generating procedures.

. The fuel tube/quick-connect fittings assembly is not

acid-proof; do not touch it with a shop towel which

was used for wiping battery electrolyte. R€place the

fuel tube/quick-connect fittings assembly if it came

into contact with electrolyte or somethino similar.

. When connecting or disconnecting the fuel tube/quick-

connect fittings assembly, be careful not to bend or

twist it excessively, Replace it if damaged,

A disconnected quick-connect fittings can be reconnected,

but the retainer on the mating pipe cannot be reused once

it has been removed from the pipe. Replace tha retainer

. replacing the fuel pump.

. replacing the fuelfeed pipe,

. it has been removed from the Dioe,

. it is damaged.

RCTAINERFUEL TUBE

CONNECTOR

CONNECTOR

RETAINER

11-175

Disconnection

!@ Do not smoke while working on the fuel

syst6m. Keep open flames away from your work area.

1. Disconnect the battery negative cable.

2. Remove the fuel fill cap to relieve fuel pressure in

the tank.

3. Relieve fuel pressure (see page 11-178).

4. Check the fuel quick-connect fittings for dirt, and

clean if necessary.

5. Hold the connector with one hand and press down

the retainer tabs with the other hand. then pull the

connector off.

NOTE:

. Be careful not to damage the pipe or other parts.

Do not use tools,

. lf the connector does not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.

. Do not remove the retainer from the pipe; once

removed, the retainer must be replaced with a

new one.

LOCKII{G PAWL

RETANEN TAB

@NNCCTOR

Press down.

6. Check the contact area of the pipe for dirt and dam-

age.

. lf the surface is dirW, clean it

. lf the surface is rusty or damaged, replace the fuel

pump or fuel feed pipe,

CONTACT ANEA

{cont'd}

www.emanualpro.com

Page 378 of 1395

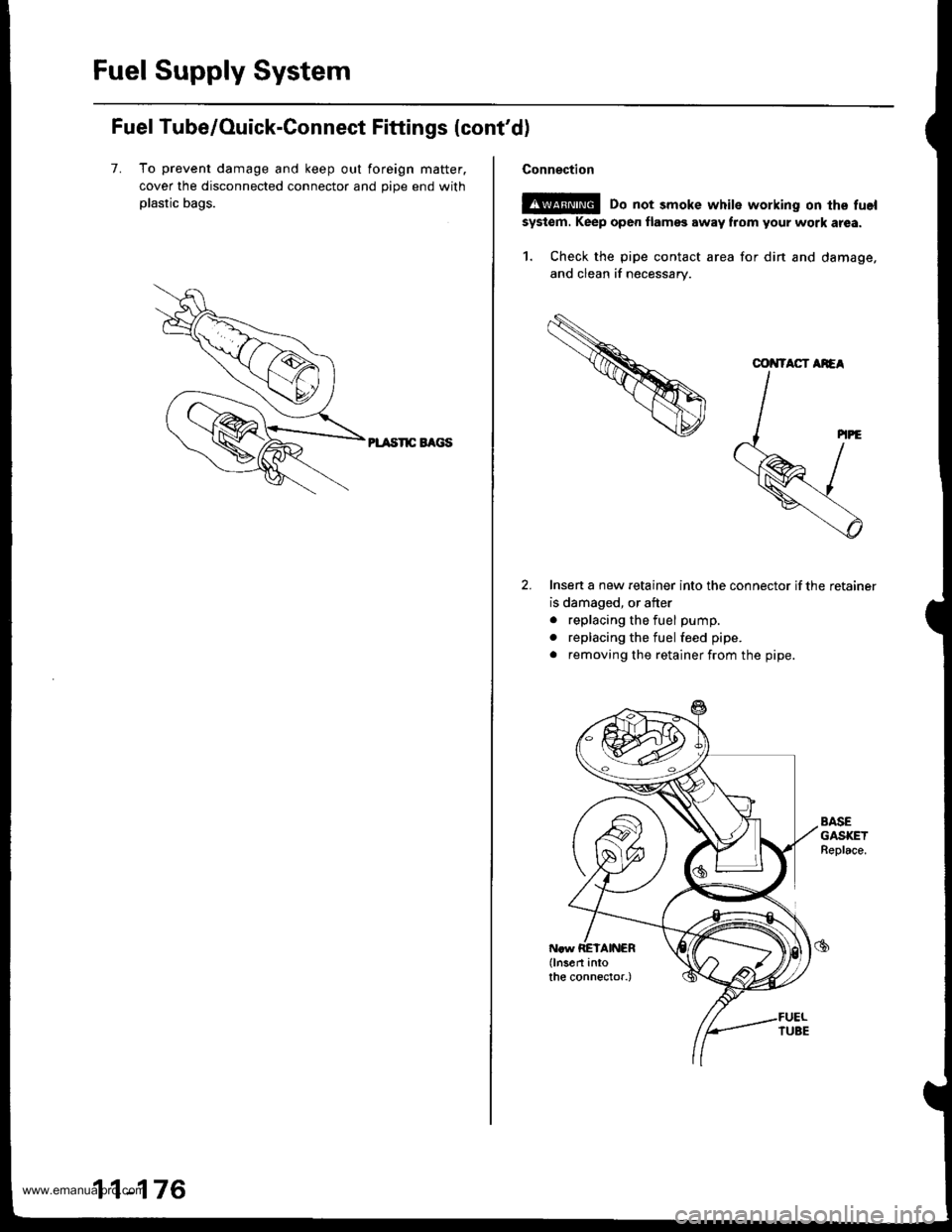

Fuel Supply System

Fuel Tube/Ouick-Connect Fittings {cont'd)

7. To prevent damage and keep out foreign matter.

cover the disconnected connector and oioe end with

plastic bags.

PL TSnC EAGS

11-176

Connection

E!@ Do not smoke white working on the fuel

system. Keep oper flamss away flom your work atea.

1. Check the pipe contact area for din and damage,

and clean if necessary.

Insen a new retainer into the connector if the retainer

is damaged, or after

. replacing the fuel pump.

. replacing the fuel feed pipe.

. removing the retainer from the pipe.

AASEGASKETBeplace.

COiITACT AiEA

www.emanualpro.com

Page 379 of 1395

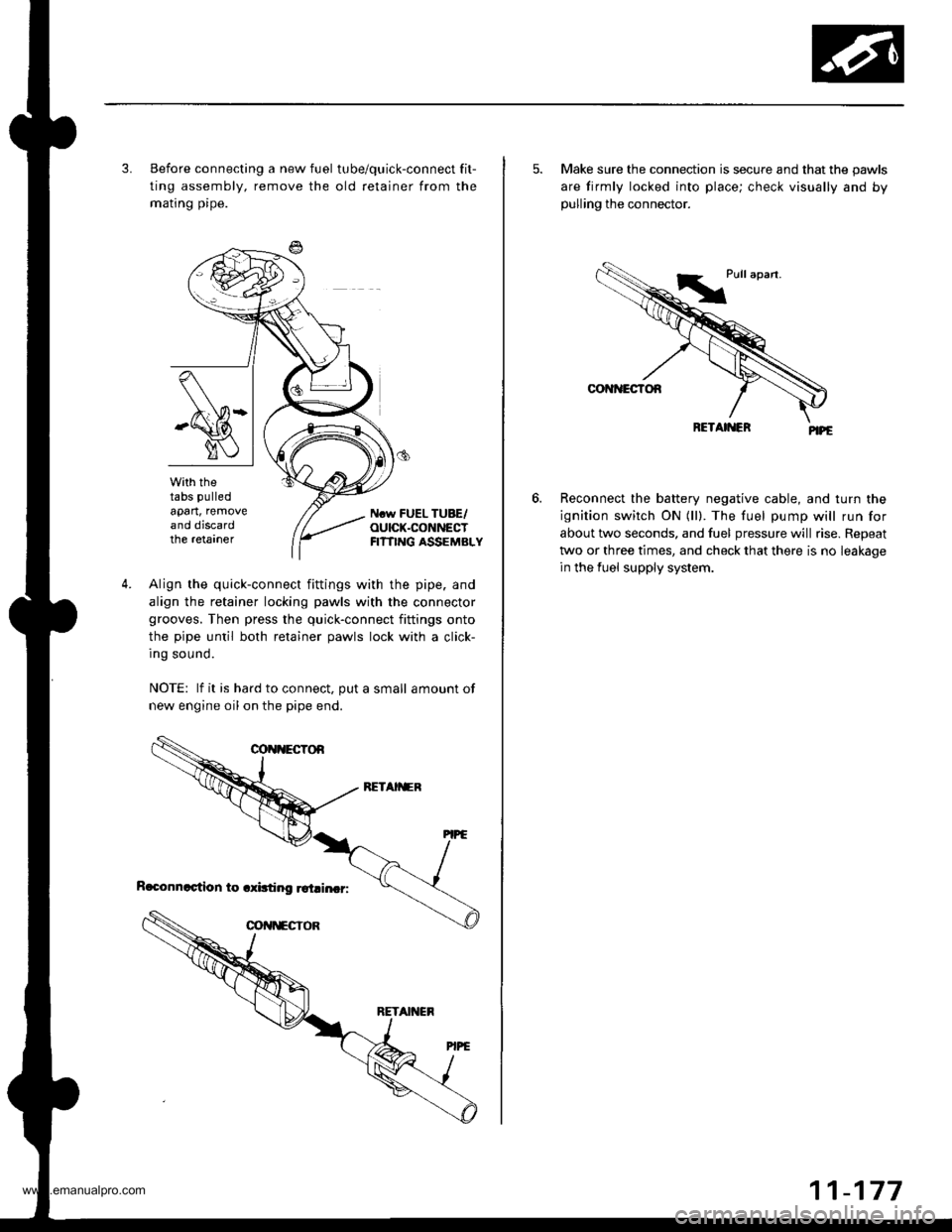

3. Before connecting a new fuel tube/quick-connect fit-

ting assembly, remove the old retainer from the

mating pipe.

with thetabs pulled

apart, removeand discardthe retarner

Ncw FUEL TUBE/OUICK.CONNECTFI?TING ASSEMBLY

4.Align the quick-connect fittings with the pipe. and

align the retainer locking pawls with the connector

grooves. Then press the quick-connect fittings onto

the pipe until both retainer pawls lock with a click-

Ing sound.

NOTE: lf it is hard to connect, put a small amount of

new engine oil on the pipe end.

5. Make sure the connection is secure and that the pawls

are firmly locked into place; check visually and bypulling the connector.

Reconnect the battery negative cable, and turn the

ignition switch ON (ll). The fuel pump will run for

about two seconds, and fuel pressure will rise. Repeat

two or three times, and check that there is no leakage

in the fuel supply system.

6.

www.emanualpro.com