4-34 HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 51 of 1395

Engine Electrical

Speciaf Tools ............. 4-2

Starting System

Component Location Index ............ 4-3

Circuit Diagram ................................ 4-4

Starter Test ........... 4-5

Starter Solenoid Test ...................... 4'5

Starter Replacement ....................... 4-7

Field Winding Test ........................... 4-7

Starter Overhaul ............................,. 4-8

Brush Inspection ...........................,., 4-9

Overrunning Glutch Inspection ...... 4-9

Armature lnspection and Test ........4-10

Brush Holder Test ............................ 4-12

Starter Reassemb|y ......................... 4-1 2

Perf ormance Test ............................. 4- 1 3

lgnition System

Component Location Index ............ 4-14

Circuit Diagram ................................ 4-15

lgnition Timing Inspection and

Setting .......................................... 4-16

Distributor Replacement ........,........ 4-17

Distributor Overhaul .............,,......... 4-18

lgnition Control Module (lCM) Input

Test ..............................,................ 4-19

fgnition Coil Test .............................. 4-2O

lgnition Wire Inspection and

Test ............................................... 4-20

Spark Plug Inspection ..................... 4-21

-+

ENGINE

Charging System

Component Location Index ............ 4-22

Circuit Diagram ....................,........... 4-23

Troubleshooting .............................. 4-24

Alternator Replacement ..........,....... 4-30

Alternator Overhaul .......,,................ 4-31

Rectifier Test .........4-32

Alternator Brush Inspection ........... 4-32

Rotor Slip Ring Test ........................ 4-33

Stator Test ............. 4-33

Alternator Belt Inspection and

Adiustment ........4-34

Gruise Control

Component Location Index .,,,........ 4-36

Circuit Diagram ................................ 4-37

Control Unit Input Test ................... 4-38

Main Switch Test/Replacement ..... 4-40

Set/Resume Switch Test/

Replacement .......................,........ 4'40

Actuator Test ....,,., 4-41

Actuator Replacement ...............,.... 4-42

Actuator Cable Adiustment ............ 4-43

Clutch Switch Test .......................... 4-43

Brake Switch Test .................. .......... 4-44

Actuator Solenoid Test .............. ...,. 4-44

Actuator Disassembly ..................... 4-45

www.emanualpro.com

Page 80 of 1395

Charging System

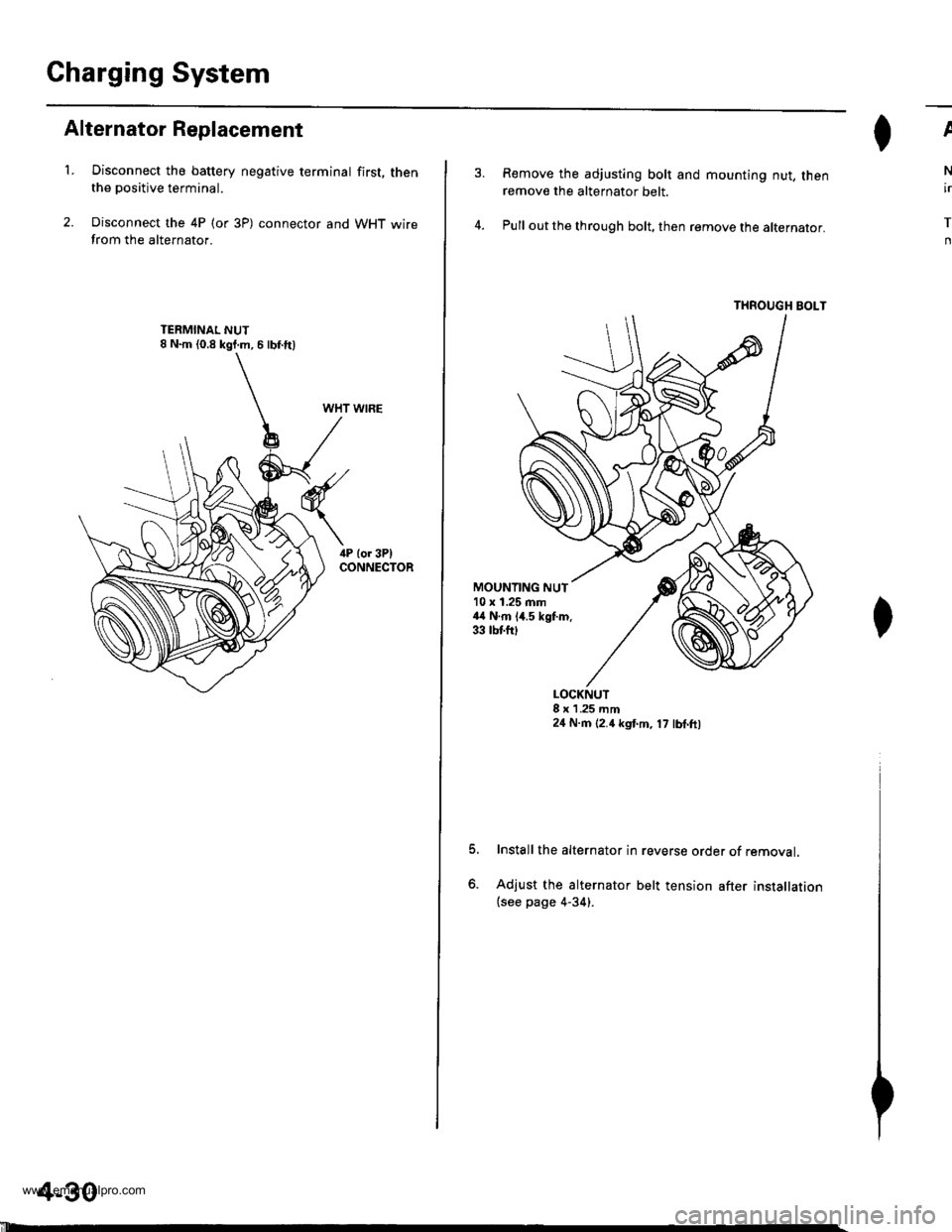

Alternator Replacement

't.Disconnect the battery negative terminal first, thenthe positive terminal.

Disconnect the 4P (or 3P) connector and WHT wirefrom the alternator.

WHT WIRE

4-30

'll

Remove the adjusting bolt and mounting nut, thenremove the alternator belt.

Pull out the through bolt, then remove the alternator.

THROUGH BOLT

ll^I}v

N

ir

T

n

MOUNTING NUT10 x 1.25 mm44 N.m 14.5 kgf.m.33 tbtfttt

o.

LOCKNUT8 x 1 .25 mm24 N.m (2.4 kgt m, 17 lbl.ft,

Install the alternator in reverse order of removal.

Adjust the alternator belt tension after installation(see page 4-34).

www.emanualpro.com

Page 84 of 1395

Charging System

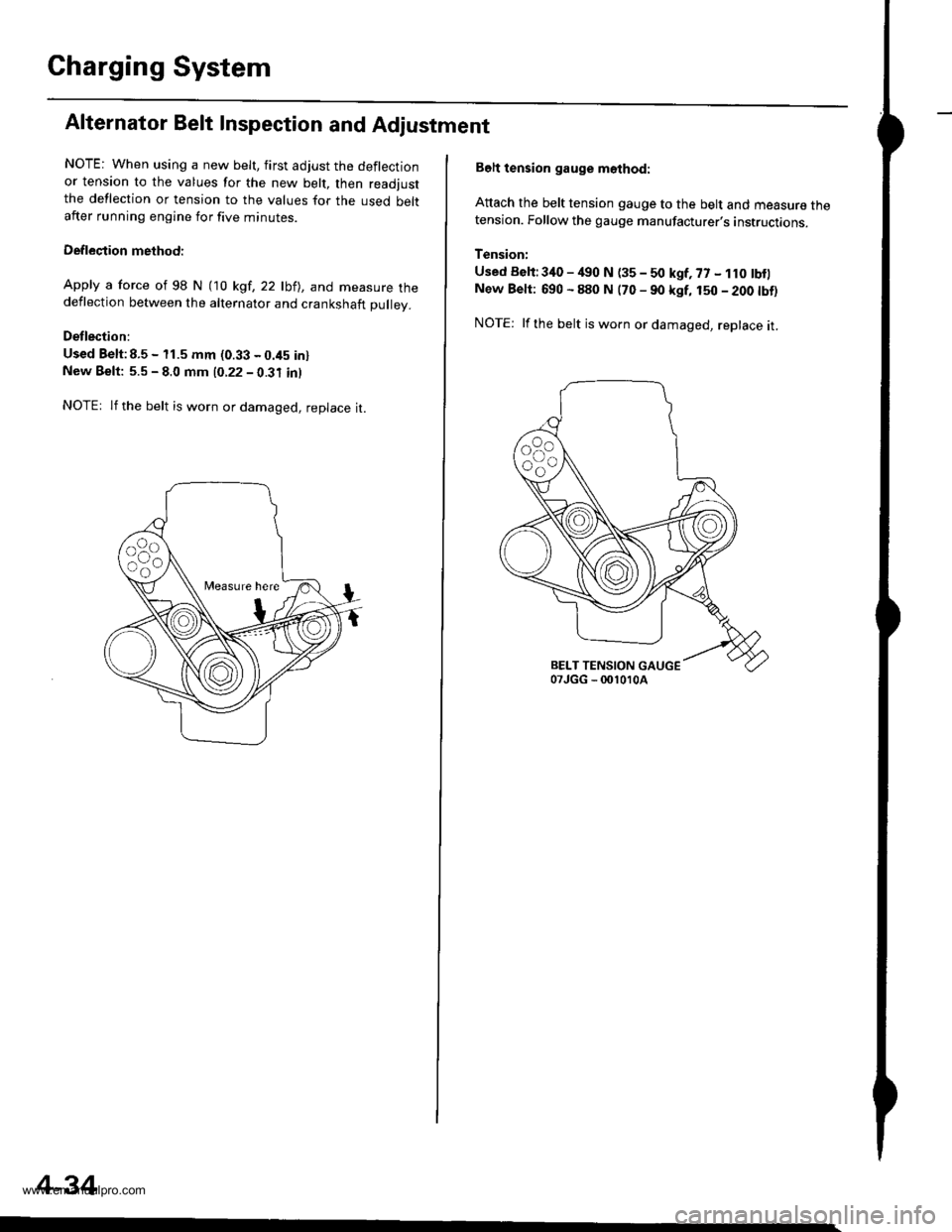

Alternator Belt Inspection and Adjustment

NOTE: When using a new belt, first adjust the deflectionor tension to the values for the new belt, then readjustthe deflection or tension to the values for the used beltafter running engine for five minutes.

Deflection methodi

Apply a force of 98 N (10 kgt,22lbll, and measure thedeflection between the alternator and crankshaft pulley.

Detlection:

Used Belt:8.5 - 11.5 mm (0.33 - 0.45 inlNew Beft: 5.5 - 8.0 mm 10.22 - 0.31 inl

NOTEr lf the belt is worn or damaged, replace it.

Measure here

4-34

Belt tension gauge m6thod:

Attach the belt tension gauge to the belt and measure thetension. Follow the gauge manufacturer's instructions.

Tension:

Used Belt:340 - /€0 N (35 - 50 kgf, 77 - 1r0 tbf)New Belt: 690 - 880 N (70 - 90 kgf, 150 - 200 tbt)

NOTE: lfthe belt is worn or damaged, replace it.

www.emanualpro.com

Page 550 of 1395

Description

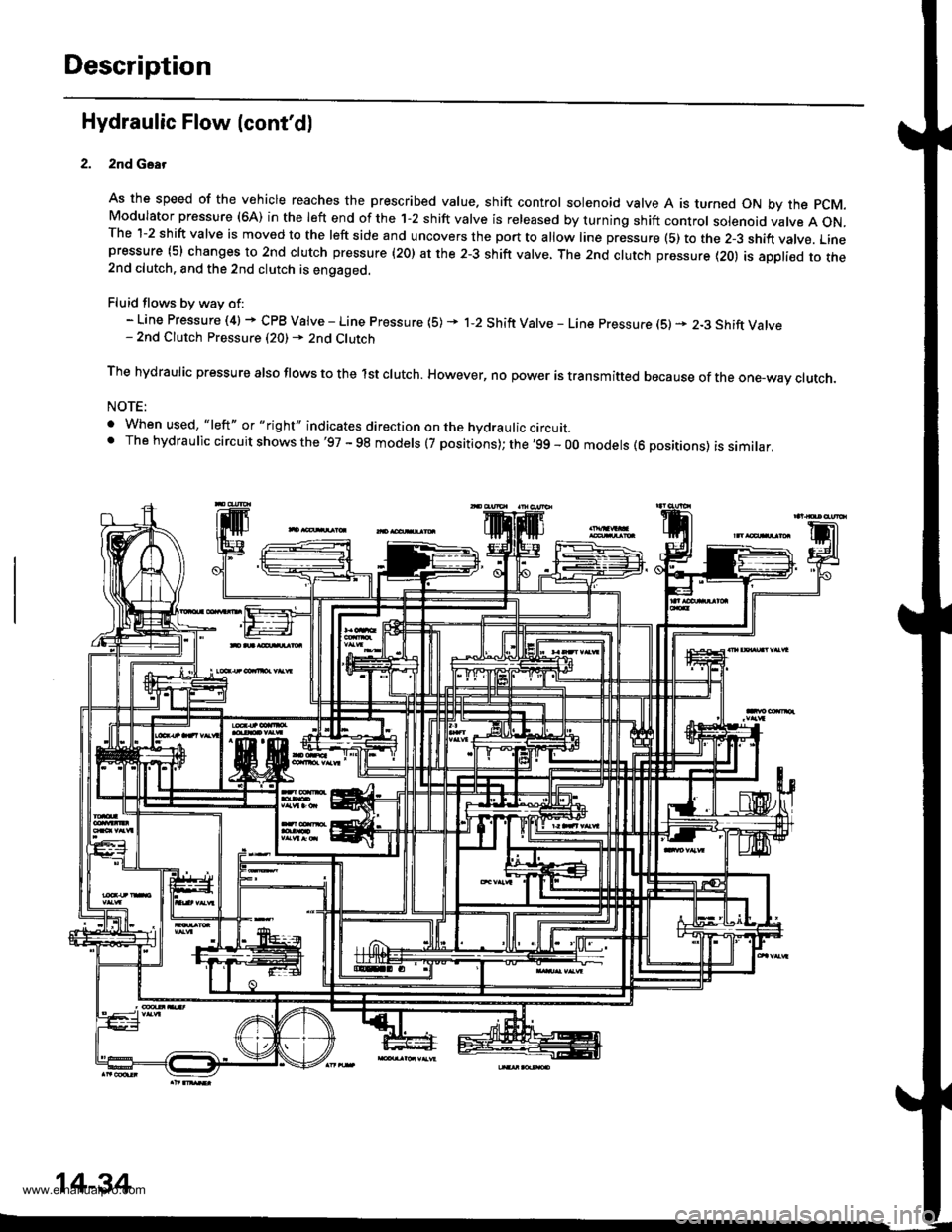

Hydraulic Flow (cont'dl

2nd Gsar

As the speed of the vehicle reaches the prescribed value. shift control solenoid valve A is turned ON by the pCM.Modulator pressure (6A) in the left end of the 1-2 shift valve is released by turning shift control solenoid valve A ON.The 1-2 shift valve is moved to the left side and uncovers the port to allow line pressure (5) to the 2-3 shift vatve. Linepressure (5) changes to 2nd clutch pressure (20) at the 2-3 shift valve, The 2nd clutch pressure {20) is appli€d to the2nd clutch. and the 2nd clutch is engaged.

Fluid flows by way of:- Line Pressure (4) + CPB Valve - Line Pressure (5) * 1-2 Shift Valve - Line pressure (S) * 2-3 Shift Valve- 2nd Clutch Pressure (20) - 2nd Clutch

The hydraulic pressure also flows to the lst clutch. However, no power is transmitted because of the one-wav ctutch.

NOTE:

. When used, "|eft" or "right" indicates direction on the hydraulic circurr_' The hydraulic circuit shows the'97 - 98 models (7 positions); the '99 - 00 models (6 positions) is similar,

14-34

www.emanualpro.com

Page 1326 of 1395

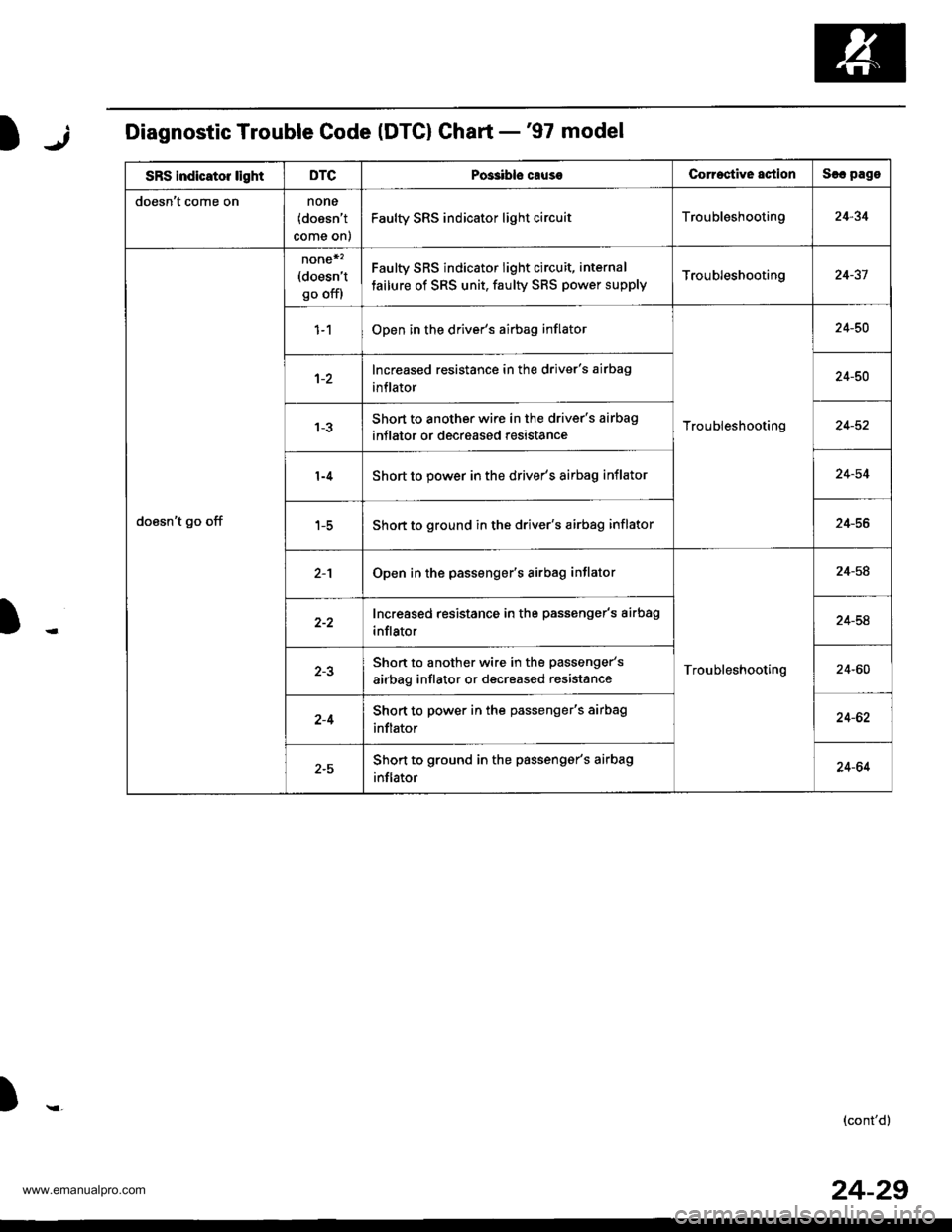

jIDiagnostic Trouble Code (DTG) Ghart -'97 model

SRS indicator lightDTCPos3ibls causeCorroctive actionSlc pago

doesn't come onnone(doesn't

come on)

Faulty SRS indicator light circuitTroubleshooting24-34

doesn't go off

none*'�(doesn't

go off)

Faulty SRS indicator light circuit, internal

tailure of SRS unit, faulty SBS power supplyTroubleshooting24-37

Open in the driver's airbag inflator

Troubleshooting

24-50

Increased resistance in the driver's airbag

inflator24-50

Short to another wire in the driver's airbag

inflator or decreased resistance24-52

Short to power in the driver's airbag inflator24-54

Short to ground in the driver's airbag inflator24-56

Open in the passenger's airbag inflator

Troubleshooting

24-58

Increased resistance in the passenger's airbag

inflator24-54

Shon to another wire in the passenger's

airbag inflator or decreased resistance24-60

2-4Short to power in the passenger's airbag

inflator24-62

2-5Shon to ground in the passengar's airbag

inflator24-64

)r,(cont'd)

24-29

www.emanualpro.com

Page 1328 of 1395

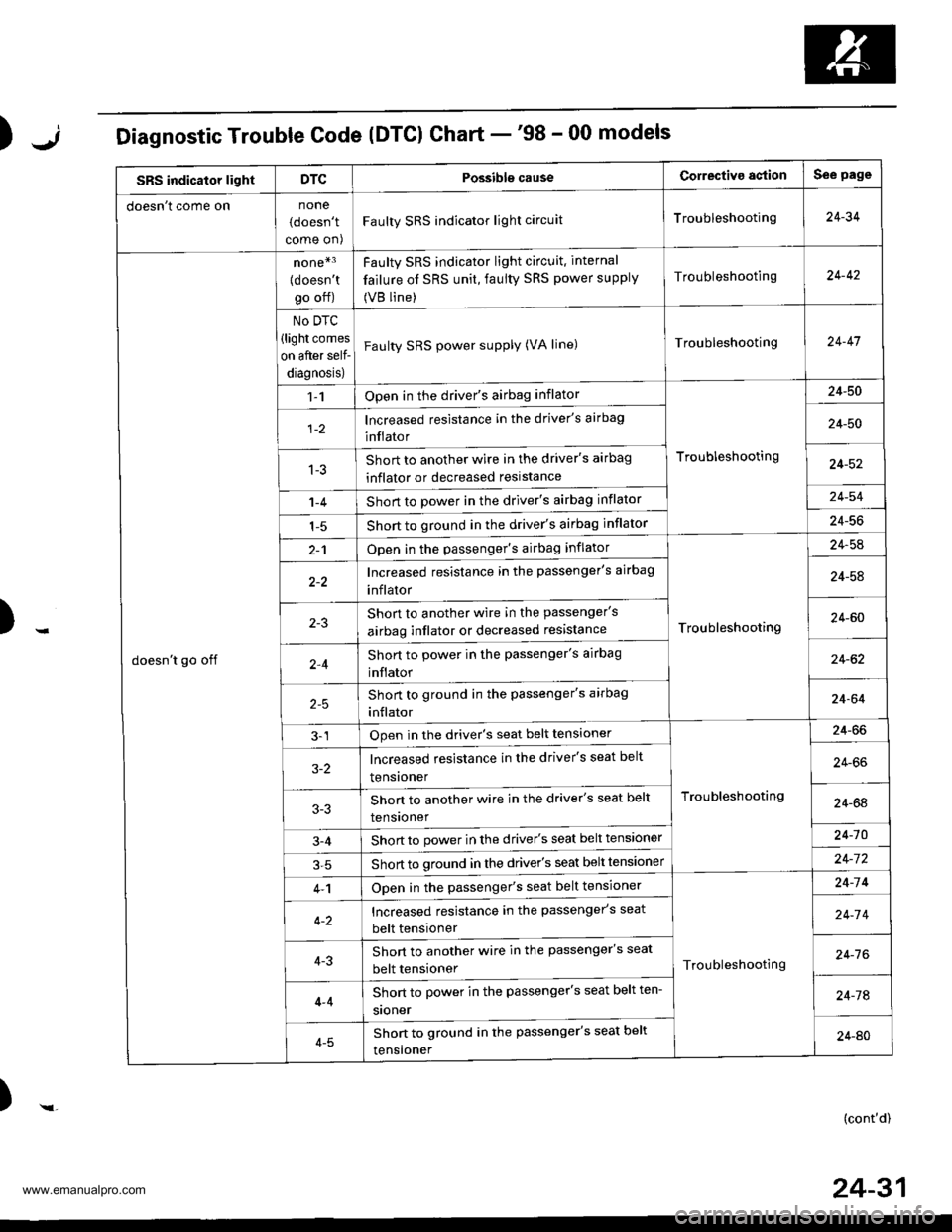

);Diagnostic Trouble Code (DTCI Chart -'98 - 00 models

SRS indicator lightDTCPossibls causeCorrectiva agtionSee page

doesn t come onnone

(doesn't

come on)

Faulty SRS indicator light circuitTroubleshooting24-34

doesn't go off

none*3

{doesn'tgo off)

No DTC

(light comes

on after self-

diagnosis)

Faulty SRS indicator light circuit. internal

failure of SRS unit, faulty SRS power supply

(VB line)

Troubleshooting24-42

Faulty SRS power supply (VA line)Troubleshooting24-47

1-1Open in the driver's airbag inflator

Troubleshooting

24-50

lncreased resistance in the driver's airbag

inflator24-50

1-3Short to another wire in the driver's airbag

inflator or decreased reslstance24-52

1-4Short to power in the driver's airbag inflator24-54

1-5Short to ground in the driver's airbag inflator24-56

2-1Open in the passenger's airbag inflator

Troubleshooting

24-54

Increased resistance in the passenger's airbag

inflator24-58

Shon to another wire in the passenger's

airbag inflator or decreased resistance24-60

2,4Short to power in the passenger's airbag

inflator24-62

Short to ground in the passenger's arrbag

inflator24-64

3-1Open in the driver's seat belt tensioner

Troubleshooting

24-66

3-2lncreased resistance in the driver's seat belt

tensroner24-66

Shon to another wire in the driver's seat belt

tensroner24-64

3-4Short to power in the driver's seat belt tensioner24-10

Short to ground in the driver's seat belt tensloner24-7 2

4-1Open in the passenger's seat belt tensioner

Troubleshooting

24-14

Increased resistance in the passenger's seat

belt tensioner24-7 4

4-3Short to another wire in the passenger's seat

belt tensioner24-7 6

4-4

4-5

Short to power in the passenger's seat belt ten-

sroner24-74

Shon to ground in the passenger's seat belt

tensroner24-AO

)-(cont'd)

24-31

www.emanualpro.com

Page 1331 of 1395

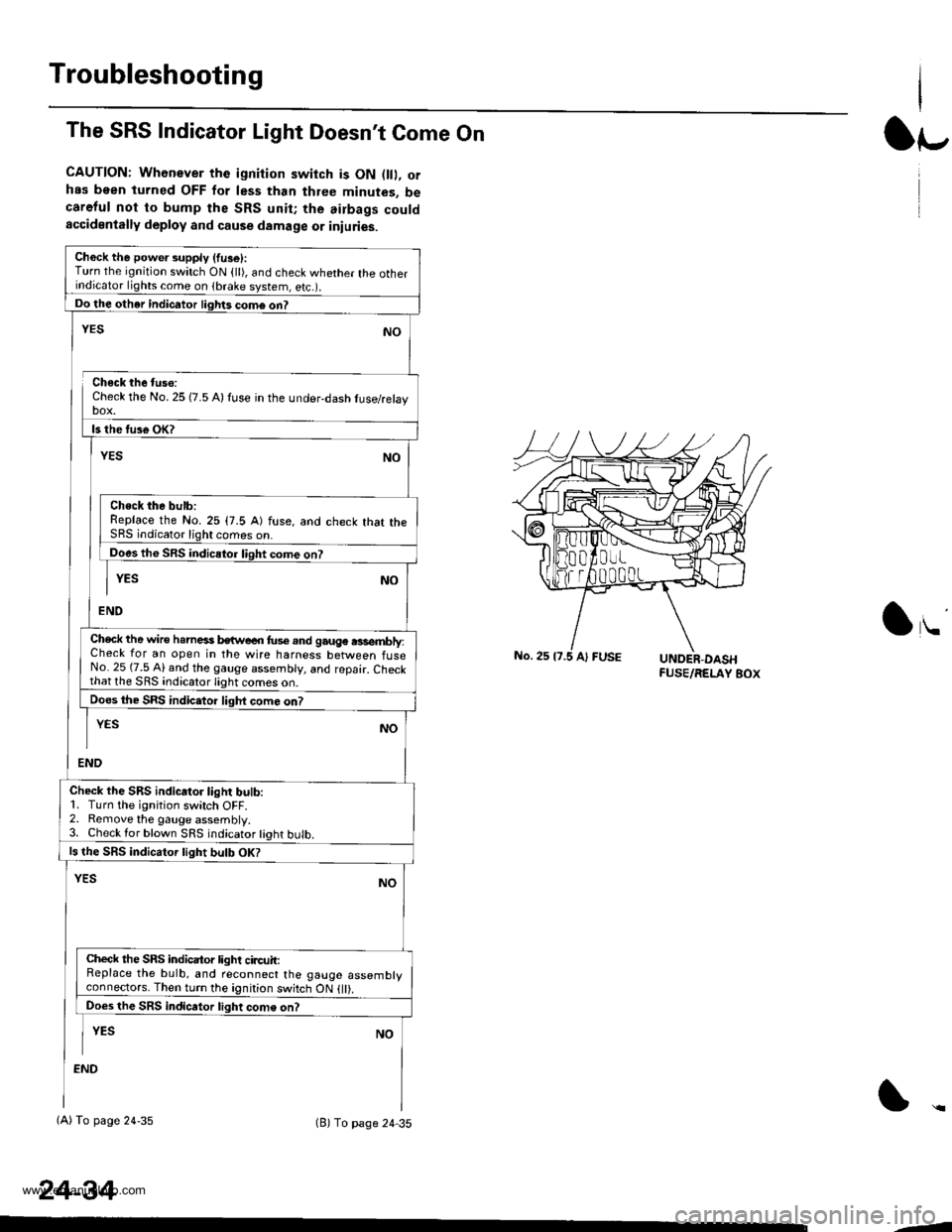

Troubleshooting

The SRS Indicator Light Doesn't Come On

CAUTION: Whenever the ignition switch is ON D, orhas been turned OFF for less than three minutes, becareful not to bump the SRS unit; the airbags couldaccidentally deploy and cause damage or iniuries.

Ch6ck the power supply (fuse):Turn the ignition switch ON {ll), and check whether the otherindicator lights come on (brake system, e(c.r.

Do the other indicator liglrts com6 on?

Check the No. 25 (7.5 A) fuse in the under-dash tuse/relayDOX.

ls the tus€ oK?

NO

Check the bulb:Replace the No.25 (7.5 A) fuse, and check that theSRS indicator light comes on.

Does the SRS indicator liqht come on?

YESNO

END

YES

Check the wire h.rnesi kwe€n fus€.nd gauge .3sembly:Check for an open in the wire harness between fuseNo. 25 (7.5 Al and the gauge assembly, and repair. Checkthat lhe SRS indicato.lighi

Does the SRS indic.tor liqht com6 on?

END

YESNO

Check the SRS indicator light bulb:1. Turn the ignition switch OFF.2. Remove the gauge assembly.3. Check lor blown SRS indicator tight bulb.

ls the SRS indicator tight bulb OK?

YESNO

Check the SRS indicator light circuit:Replace the bulb, and reconnect the gauge assemblyconneclors. Then turn the ignition switch ON {ll).

Does the SRS indicator light come on?

I YEs No

:ND

(A) To page 24-35(B) To page 24 35

24-34

lr-

lu

-J

www.emanualpro.com

Page 1332 of 1395

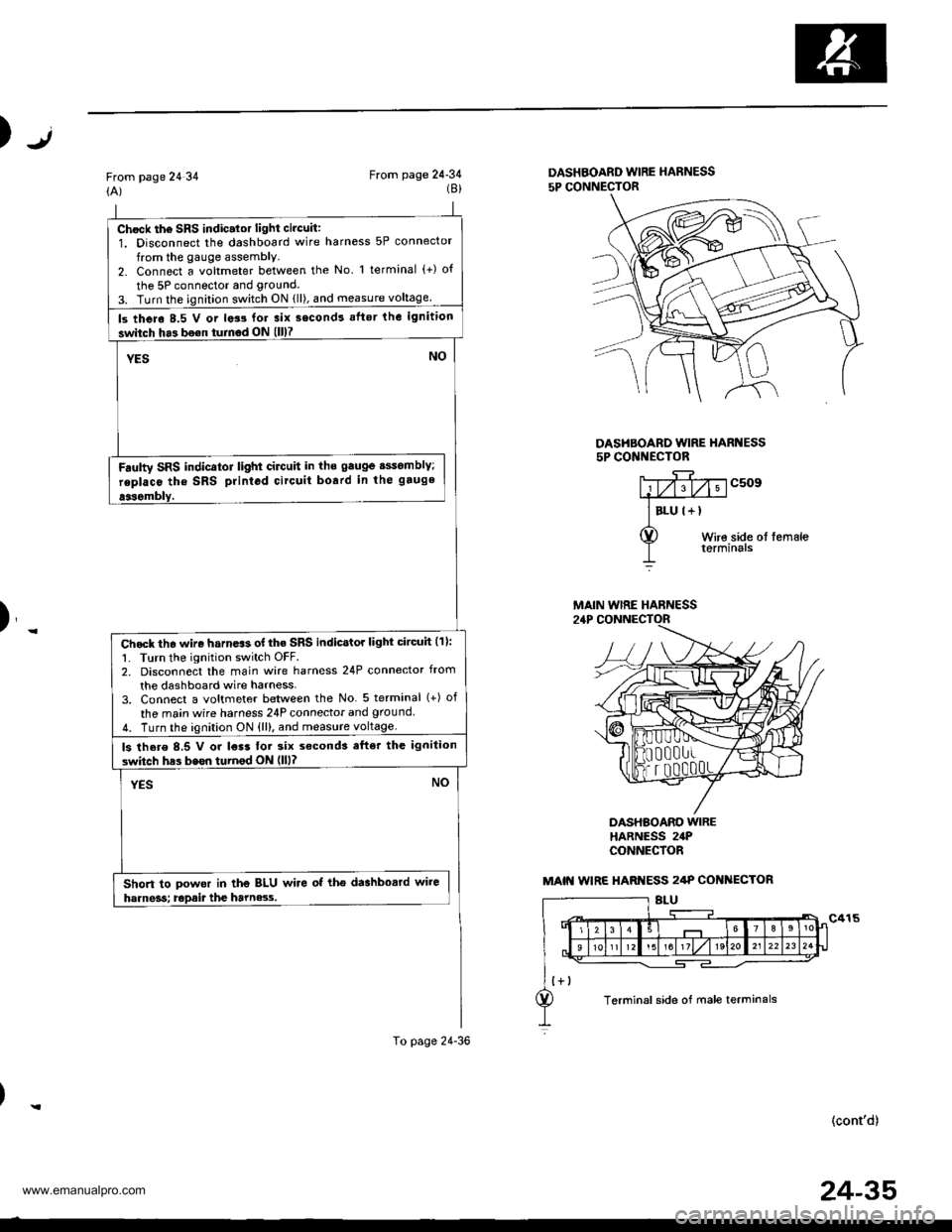

Chock th6 SRS indic.lor light circuit:1. Disconnect the dashboard wire harness 5P connector

from the gauge assembly.2. Connect a voltmeter between the No l terminal (+) o{

the 5P connector and grouncl.

3. Turn the ignition switch ON {ll), and measure voltage

ls thero 8.5 V or lats for 3ix second! aflsr the ignition

switch ha3 bo€n turnod ON (ll)7

YESNO

Fdulty SRS indicator light cilctlit in ths gauge sssomblY;

replaco tho SRS printod circuit board in the gauge

aasombly,

Chock th6 wire harn.$ of the SRS indicstor light circuh (11:

1. Turn the ignition switch OFF.2. Disconnect the main wire harness 24P connector from

the dashboard wire harness-3. Connect a voltmeter between the No 5 terminal (+) of

the ma;n wire harness 24P connecior and ground

4. Turn the ignition ON {ll), and measure voltage.

ls there 8,5 V or l€r3 tor six s€cond3 efter the ignilion

switch has bssn turnod ON llll?

YESNO

Short to powor in the BLU wire of tho dashbosrd wire

harne3s; Epait the harne3.s.

To page 24-36

Jt)

From page 24 34(A)From page 24-34(8)DASHBOARD WIRE HARNESS

5P CONNECTOR

DASHBOARD WIRE HARI{ESS5P CONI{ECTOR

c509

Wire side ol femaleterminals

)_

DASHBOARO WIREHARNESS 24PCONNECfOR

(cont'd)

MAIN WIRE HARNESS

MAIN WIRE HARI{ESS 2/tP COI{ ECTOR

Terminal side of male terminals

24-35

www.emanualpro.com