Back HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 15 of 1395

G: FRONT SEAT PASSENGER AIRBAG MODULE DANGEN

A DANGEREXPLOSIVE/FLAMMABLECONTACT WITH ACID, WATER. OR I{EAVY METALS SUCH

AS COPPER. T.EAD. OR MERCURY MAY PRODUCE HARMFUL

AND IRRITATING GASES OR EXPLOSIVE COMPOUNDS.

STORAGE TEMPERATURES MUST NOT EXCEED 2OO"F

IlOO'C). FOR PROPER HANDLING, STORAGE, AND

DISPOSAL PROCEDURES REFER TO THE SERVICE MANUAL,

SRS SUPPLEMENT.POTSONCONTAINS POTSONOUS SODIUM AZIDE ANO POTASSIUM

NITRATE.FIRST AIDIF CONTENTS ARE SWALLOWED, INDUCE VOMITING. FOR

EYE CONTACT, FLUSH EYES WITH WATER FOR 15

MINUTES. IF GASES (FROM ACID OR WATEN CONTACT)

ARE INHALEO. SEEK FRESH AIR. IN EVERY CASE, GET

PROMPT MEDICAL ATTENTION.KEEP OUT OF REACH OF CHILDREN.

A WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND, IF

ACCIDENTALLY DEPLOYED, CAN SERIOUSLY HURT OR

KILL YOU.. DO NOT USE ELECTRICAL TEST EOUIPMENT OR

PROBING DEVICES,THEY CAN CAUSE ACCIDENTAL DEPLOYMENT.. NO SERVICEABI-E PARTS lNSlDE. DO NOT DISASSEMBII.

. PLACE AIRBAG UPRIGHT WHEN REMOVEO.

. FOLLOW SERVIC€ MANUAL INSTRUCTIONS CAREFULLY

H: PASSENGER INFORMATION lU S.A. modell

{U.S.A.'97 model}

AIEBAG SEE OTHER SIDE,

{U.S.A.'98 - 00 modelsl

AIRBAG WARNINGFLIP VISOR OVER.

l: SRS INFORMATION

lU.s.A.'97 model ilcanada '97 - 00 mod€ls I

CAUTIONTO AVOID SERIOUS INJURY:. FOR MAXIMUM SAFEW PROTECTION lN ALL TYPES OF

CRASHES, YOU MUST ALWAYS WEAR YOUR SAFETY

8ELT.o OO NOT INSTALL REARWARD-FACING CHILO SEATS lN

ANY FRONT PASSENGER SEAT POSITION.. DO NOT SIT OR LEAN UNNECESSARILY CLOSE TO THE

AIRBAG.. DO NOT PLACE ANY OBJECTS OVER THE AIRBAG OR

BETWEEN THE AIRBAG AND YOURSELF.. SEE THE OWNER'S MANUAL FOR FURTHER

INFORMATION AND EXPLANATIONS. THE SRS MUST BE INSPECTED TEN YEARS AFTER lT lS

INSTALLED.. THE DATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

lU.S.A.'98 - 00 models)

WARNINGDEATH OR SERIOUS INJURY CAN OCCUR'

. CHILDREN 12 ANO UNDER CAN BE KILLED BY THE

AIRBAG.. THE BACK SEAT lS THE SAFEST PLACE FOR CHILDREN.

. NEVER PUT A REAR-FACING CHILD SEAT lN THE

FRONT.o SIT AS FAR BACK AS POSSIBLE FROM THE AIRBAG

. ALWAYS USE SEAT BELTS AND CHll-D RESTRAINTS.

. THE SRS MUST BE TNSPECTED TEN YEAnS AFTER lT lS

INSTALLED.. THE OATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

J: FRONT PASSENGER AIRBAG WARNING

lU.S.A.'98 - 00 models)

WARNINGCHILDREN CAN BE KILLED OR INJURED 8Y THE

PASSENGER AIRBAG.THE BACK SEAT IS THE SAFEST PLACE FOR CI{ILDREN 12

AND UNDER.MAKE SURE ALL CHILDREN USE SEAT BELTS OR CHILD

SEATS.

K: FRONT SEATBELT TENSIONER WARNING

WABNINGEXPLOSIVE MATERIAL INSIDEYOU CAN BE SERIOUSLY HURT OR BURNED,

. DO NOT TAMPER OR DISASSEMBLENO SERVICEABLE PARTS INSIDE.. REFER TO SERVICE MANUAL FOR COMPLETE

INSTRUCTIONS.

(cont'd)

1-13

www.emanualpro.com

Page 23 of 1395

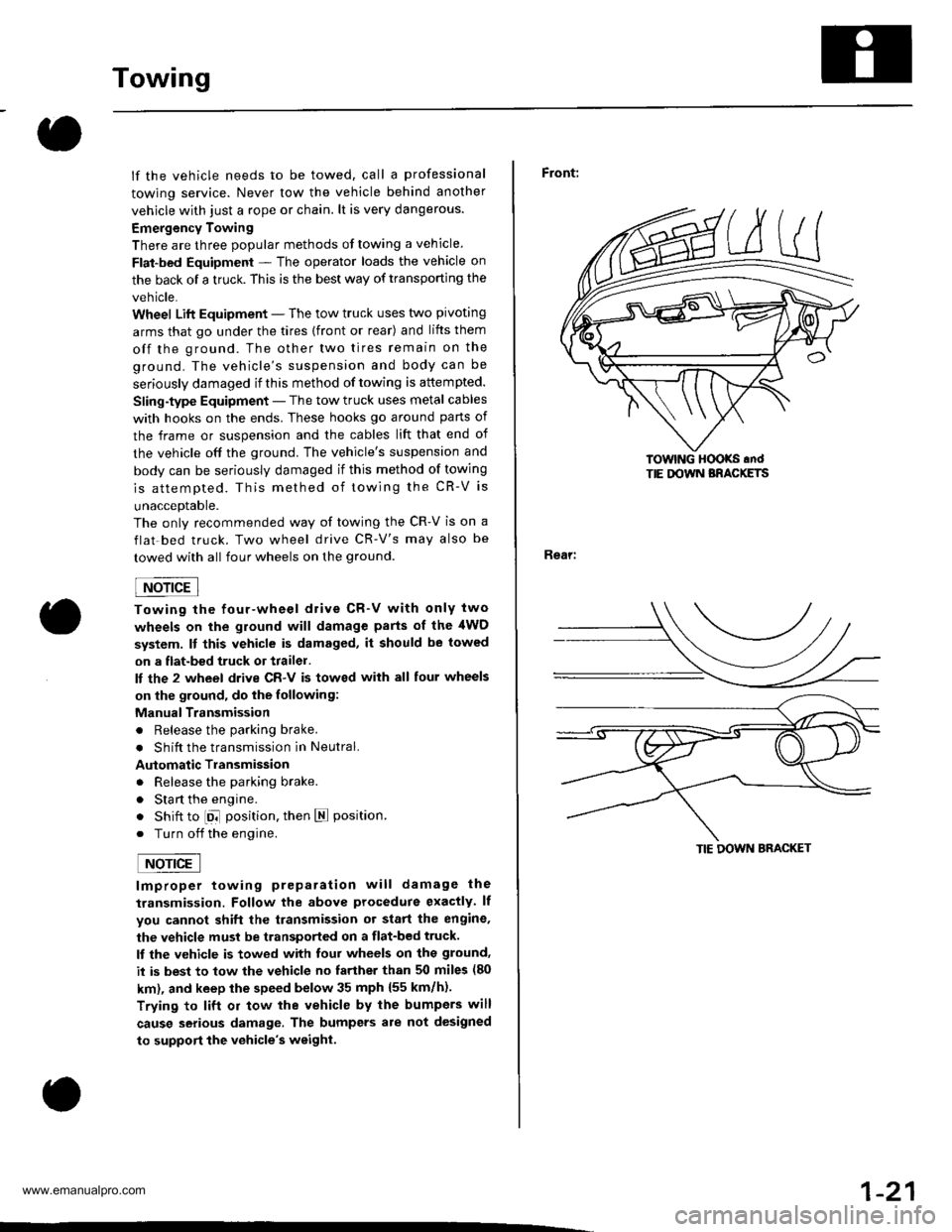

Towing

lf the vehicle needs to be towed, call a professional

towing service. Never tow the vehicle behind another

vehjcle with just a rope or chain. lt is very dangerous.

Emergency Towing

There are three popular methods of towing a vehicle.

Flat-bed Equipment - The operator loads the vehicle on

the back of a truck. This is the best way of transporting the

vehicle.

Wheel Lift Equipment - The tow truck uses tlvo pivoting

arms that go under the tires lfront or rear) and lifts them

off the ground. The other two tires remain on the

ground. The vehicle's suspension and body can be

seriously damaged if this method of towing is attempted.

Sling-type Equipment - The tow truck uses metal cables

with hooks on the ends. These hooks go around parts of

the frame or suspension and the cables lift that end of

the vehicle off the ground. The vehicle's suspension and

body can be seriously damaged if thjs method of towing

is attempted. This methed of towing the CR-V is

unaccePtable.

The onlv recommended way of towing the CR-V is on a

flat-bed truck. Two wheel drive CR-V's may also be

towed with all four wheels on the ground.

Towing the four-wheel dlive CR-v with only two

wheels on the ground will damage parts of the 4wD

system. It this vehicle is damaged, it should be towed

on a flat-bed truck ol trailel.

It the 2 wheel drive CR-v is towed wiih all tour wheels

on the ground, do the following:

Manual Transmission

. Release the parking brake.

. Shift the transmission in Neutral

Automatic Transmission

. Release the parking brake.

. Sta rt the engine.

. Shift to lD.l position. then E position.

. Turn off the engine.

lmproper towing preparation will damage the

transmission. Follow the above procedure exactly. lf

you cannot shift the transmission or start the engine,

the vehicle must be transported on a flat-bed truck.

lf the vchicle is towed with four wheels on the ground,

il is best to tow the vehicle no larther than 50 miles (80

km), and keep the speed below 35 mph {55 km/h).

Trying to lift or tow the vehicle by ihe bumpers will

cause serious damage. The bumpers ale not dosigned

to support the vehicle's weight.

Front:

Rear:

lOwlNG HOOKS .ndTIE DOWN BRACKETS

TIE DOWN BRACKET

1-21

www.emanualpro.com

Page 31 of 1395

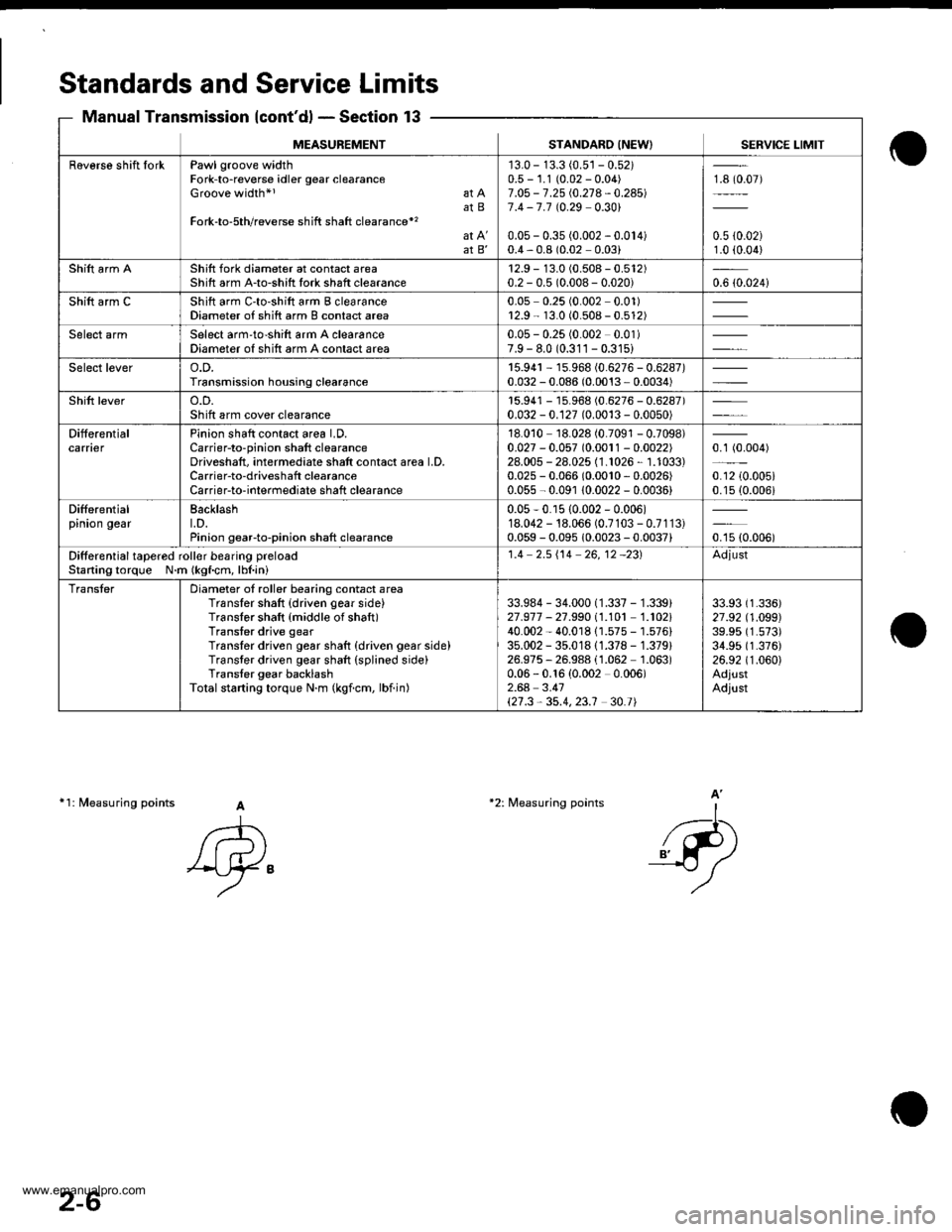

Standards and Service Limits

Manual Transmission {cont'd} - Section 13

11: fuleasuring points A

A

'Ay"

-l-...

_{-P)

A'*2: Measuring points

MEASUREMENTSTANDARO INEW) SERVICE LIMIT

Raverse shift IorkPawl groove widthFork-to-reverse idler gear clearanceGroove width*l at AatBFork-to-5th/reverse shift shaft clearance*'�

at B'

'13.0 - 13.3 (0.5'�j - 0.52)0.5 - 1.1 (0.02 - 0.04)7.O5 - 7.25 i.0.21 4 - 0.24517.4 -7.7 t0.29 0.301

0.05 - 0.35 (0.002 - 0.014)0.4,0.8 (0.02 0.03)

18 (0.07)

0.5 {0.02)1.0 (0.04)

Shift arm AShift fork diameter at contact areaShift arm A-to-shitt tork shaft clearance12.9 - 13.0 (0.508 - 0.512)0.2 - 0.5 (0.008- 0.020)0.6 {0.024i

Shift arm CShift arm C'to-shift arm B clearanceDiameter of shift arm B contact area0.05 0.25 (0.002 0.01)r2.9 - 13.0 (0.508 - 0.512)

Select armSelect arm'to-shift arm A clearanceDiameter of shift arm A contact area0.05 - 0.25 (0.002 0.01)7.9 - 8.0 (0.311 - 0.31s)

Select levero.D.Transmission housing clearance15.94r - 15.968 (0.6276 - 0.6287)0.032 - 0.086 (0.0013 - 0.0034)

Shift levero.D.Sh ift arm cover clearancer5.941 - 15.968 (0.6276 - 0.6287)0.032 - 0.127 (0.0013 - 0.0050)

DifferentialcarnerPinion shaft contact area LD.Carrier-to-pinion shaft clearanceDriveshaft, intermediate shatt contact area LD,Carrier-to-driveshaft clearanceCarrierto-interrnediate shaft clearance

18.010 18.028 (0.7091 - 0.7098)0.027 - 0.057 (0.0011 - 0.0022)28.005 - 28.025 (1.1026, 1.1033)0.025 - 0.066 (0.0010,0.0026)

0.055 - 0.091 10.0022 - 0.0036)

0.1 (0.004)

0.12 {0.005i0.15 (0.006i

Differentialpinion gearBacklasht.D.Pinion gearto-pinion shaft clearance

0.05-0.r5 {0.002 - 0.006)18.042 - 18.066 (0.7103 - 0.7113)0.059 - 0.095 10.0023 - 0.0037)oru ro.ooor

Ditferential tapered roll€r besring preloacStaning torque N.m (kgf.cm, lbl.ini

1.4 2.5i'14 26,12 -231Adjust

TransterDiameter of roller bearing contact areaTransler shaft {driven gear side}Translor shaft {middle of shaft)Transter drive gearTranslor driven gear shaft {driven gear side)Transter driven gear shaft (splined side)Trans{er gear backlashTotalstarting torque N.m (kgicm, lbiin)

33.984 - 34.000 (1.337 - 1.339)21.977 - 27.99011.101 1.102140.002 - 40.01811.575 - 1.576)35.002 - 35.01811.378 - 1.379)26.975, 26.988 (1.062 1.063)0.06 - 0.16 {0.002 0.006)2.64 3.41\21.3,35.4,23.1 30.t|

33.93 (1.336)

27 .92 (1 .O99)39.95 (1.573)

34.95 (1.376)

26.92 (1.060)

AdjustAdjust

2-6

www.emanualpro.com

Page 34 of 1395

2-9

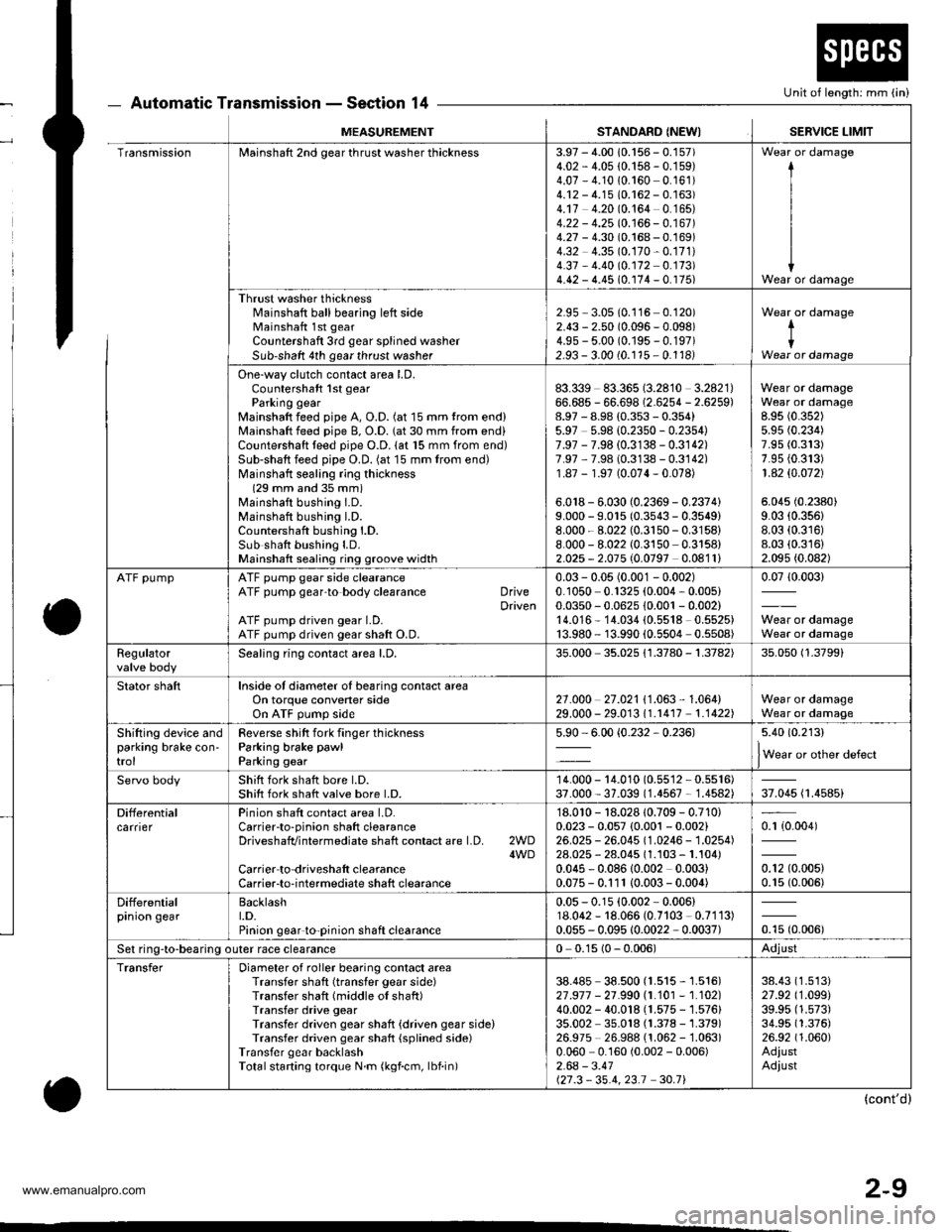

Automatic Transmission - Section 14

o

Unit of length: mm (in)

o

MEASUREMENTSTANDARD (NEWISERVICE LIMIT

TransmissionMainshaft 2nd gear thrust washer thickness3.97 - 4.00 10.156 - 0.157)4.02 - 4.05 {0.158 - 0.159)4.07 - 4.1010.160 0.161)4.12 - 4.15 (0.162 - 0.163)4.17 4.20 (0.164 0.165)4.22 - 4.25 10.166 - 0.167 )4.27 - 4.30 (0.168 - 0.169)4.32 4.35 (0.170-0.171)

4.37 - 4.40 (0.172 0.173)4.42 - 4.45 (0.174 - 0. r75)

I

I

IWear or damage

Thrust washer thicknessl'rainshaft ball bearing left sideMainshaft 1st gear

Countershaft 3rd gear splined washerSub-shaft 4th gear thrust washer

2.95 3.05 (0.116 0.120)2.43 - 2.50 (0.096 - 0.098)4.9s - 5.00 (0.195 - 0.197)2.93 - 3.00 (0.115 - 0.1181

Wear or damage

tIWear or damage

One-way clutch contact area LD.Countershaft 1st gearParking gearMainshaft feed pipe A, O.D. (at 15 mm trom end)Mainshaft feed pipe B, O.D. (at 30 mm from end)Countershaft teed pipe O.D. lat 15 mm from end)Sub-shaft feed pipe O.D. (at 15 mm from end)Mainshatt sealing ring thickness(29 mm and 35 mm)Mainshaft bushing I.D.Mainshaft bushing l.D.Countershaft bushing l.D.Sub shatt bushing LD.Mainshaft sealing ring groove width

83.339 83.365 (3.2810 3.2821)66.685 - 66.698 (2.6254 - 2.6259)8.97 - 8.98 (0.353 - 0.354)5.97 5.98 {0.2350 - 0.2354)7.97 - 7.98 (0.3138 - 0.3142)7.97 ,7.98 (0.3138 - 0.3142)1.87 - 1.97 (0.074-0.078)

6.018 - 6.030 (0.2369 - 0.2374)9.000 - 9.015 (0.3543 - 0.3549)8.000 - 8.022 (0.3150-0.3158)

8.000 - 8.022 (0.3150 0.3158)2.025 - 2.075 (0.0797 0.0811)

Wear or damageWear or damage8.95 (0.352)

5.95 (0.234)

7.95 (0.313)

7.95 {0.313)1 .42 $.O72)

5.045 (0.2380)

9.03 (0.356)

8.03 (0.316)

8.03 (0.316)

2.095 (0.082)

ATF pumpATF pump gear side clearanceATF pump gear'to body clearance DriveDrivenATF pump driven gear LD.ATF pump driven gear shaft O.D.

0.03 - 0.05 (0.001 - 0.002)0.1050 0.1325 (0.004, 0.005)0.0350 - 0.0625 10.001 - 0.002)14.016* 14.034 (0.5518 0.5525)13.980 - 13.990 {0.5504 0.5508)

0.0710.003)

Wear or damageWear or damage

Regulatorvalve bodySealing ring contact area l.D,35.000 35.025 {1.3780 - 1.3782)35.050 (1.3799)

Stator shaftInside of diameter oI bearing contact areaOn torque convener sideOn ATF pump side2't .o00 27 .021 I '1 .063 , 1 .064)29.000 - 29.01311.r417 1.1422)Wear or damageWear or damage

Shifting device andparking brake con'trol

Reverse shitt fork finger thicknessParking brake pawl

Parking gear

5.90 - 6.00 {0.232,0.236)5.40 (0.213)

lWear or other defect

Servo bodyShift fork shatt bore l.D.Shift fork shatt valve bore l.D.14.000 - 14.010 (0.55'�l2 - 0.5516)37.000 - 37.039 (1.4567 - 1.4582)37.045 (1.4585)

DifferentialcarrierPinion shaft contact area LD.Carrierto-pinion shaft clearanceDriveshafvintermediate shaft contact are l.D. 2WD4WDCarrier to driveshalt clearanceCarrier-to-intermediate shaft clearance

'18.010 - 18.028 10.709 - 0.710)0.023 - 0.057 {0.001 - 0.002}26.025 - 26.045 (1.0246 - 1.0254)28.025 - 28.045 (1.103 - 1.104)0.045 - 0.08610.002 0.003)0.075 - 0.111 10.003- 0.004)

0.r {0.004)

0.12 (0.005)

0.15 (0.006)

Differentialprnron gearBacklasht.D.Pinion gear'to-pinion shaft clearance

0.05 - 0.15 (0.002 - 0.006)18.062 - 18.066 (0.7103 - 0.7113)0.055 - 0.095 10.0022 - 0.0037)otu to.oout

Set ring-to-bearing outer race clearance0 0.15 (0 - 0.006)Adjust

TransferDiameter of roller bearing contact areaTransfer shaft (transfer gear side)Transfer shaft (middle of shaft)Transfer drive gearTransfer driven gear shaft {driven gear side)Transfer driven gear shaft {splined side)Transfer gear backlashTotalstarting torque N.m (kgf.cm, lbf.in)

38.485 38.500 (1.515 - 1.516)27 .917 - 21 .990 |.1.101 - 1.102)40.002 - 40.018 (1.575 - 1.576)35.002 35.018 (1.378 - 1.379)26.975 26.988 (1.062 -'�l.063)

0.060 0.160 (0.002 - 0.006)2.64 - 3.41127.3 - 35.4,23.1 30.71

38.43 (1.513)

27.92 (1.099)

39.95 (1.573)

34.95 (1.376)

26.92 (1.060)

AdiustAdiust

(cont'd)

www.emanualpro.com

Page 38 of 1395

--

-

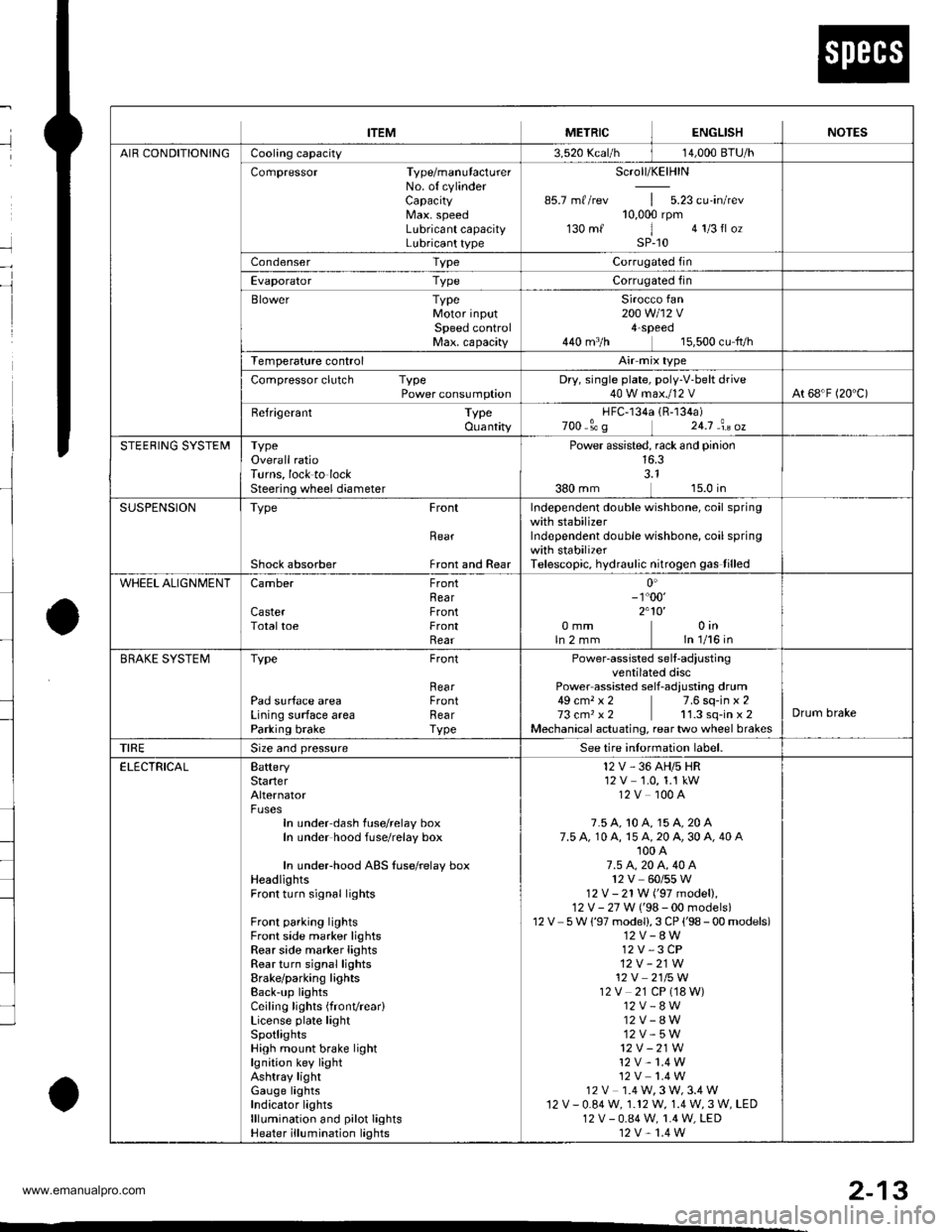

METRICITEMENGLISHNOTES

AIR CONDITIONINGCooling capacity3,520 Kcal/h j 14,000 BTU/h

Compressor Type/manutacturerNo. of cylinderCaPacityMax. speedLubricant capacityLubricant type

Scroll/KElHlN

85.7 mf/rev | 5.23 cu'in/rev10,000 rpm130mf 1 algIlozsP-10

Condenser TypeCorrugated fin

Evaporator TypeCorrugated fin

Blower TypeMotor inputSpeed controlMax. capacity

Sirocco fan200 w 112 v4-Speeo440 m3/h 15,500 cu fvh

Temperature control

Compressor clutch TypePower consumptionDry, single plate, poly-V-belt drive40 W max./12 VAt 68'F (20 C)

Befrigerant TypeOuantity

HFC-134a 1R-134a)zoo o' g 24j an oz

STEERING SYSTEMTypeOverall ratioTurns, lock to lockSteering wheel diameter

Power assisted, rack and pinion

SUSPENSIONType Front

Bear

Shock absorber Front and Rear

Independent double wishbone, coil springwith stabilizerIndependent double wishbone, coil springwith stabilizerTelescopic, hydraulic nitrogen gas tilled

WHEEL ALIGNMENTCamber

CasterTotaltoe

FronthearFrontFrontRear0inln 1/16 in0mmln2mm

0'- r"00'2.10'�

BRAKE SYSTEMTvpe

Pad surface areaLining surface areaParking brake

Front

RearFrontRearTvpe

Power-assisted selt-ad,ustingventilated discPower assisted self-adiusting drum49 cm, x 2 7.6 sq-in x 273 cm, x2 11.3 sq-in x 2Mechanical actuating, rear two wheel brakes

Drum brake

TIRESize and pressureSee tire inlormation label.

ELECTRICALBafteryStarterAlternator

In under-dash fuse/relay boxIn under hood fuse/relay box

In underhood ABS fuse/relay boxHeadlightsFront turn signal lights

Front parking lightsFront side marker lightsRear side marker lightsRear turn signal lightsErake/parking lightsBack-up lightsCeiling lights {fronvrear)License plate lightSpotlightsHigh mount brake lightlgnition key lightAshtray lightGauge lightsIndicator lightslllLrmination and pilot IightsHeater illumination lights

12 V, 36 AH/s HR12V 1.0, 1.1 kW12V 100A

7.5 A, 10 A, 15 A, 20 A7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A'100 A7.5 4,20 A. 40 A12V 60/55 W12 V- 21 W ('97 model),12 V - 27 W ('98-00 models)12V 5 W {'97 model),3 CP ('98 - 00 models)12V-8W12 V,3 CP12V-21W12 V 2115 W12V 21 CP (18 W)12V-8W12V-8W12V-5W12V -21W

12 V- 1.4 W12V 1.4 W12 V 1.4 W,3 W,3.4 W12V-0.84W, 1.12 W, 1.4 W,3 W, LED12 V - 0.84 W, 1.4 W, LED12 V,1.4 W

2-13

www.emanualpro.com

Page 62 of 1395

Starting System

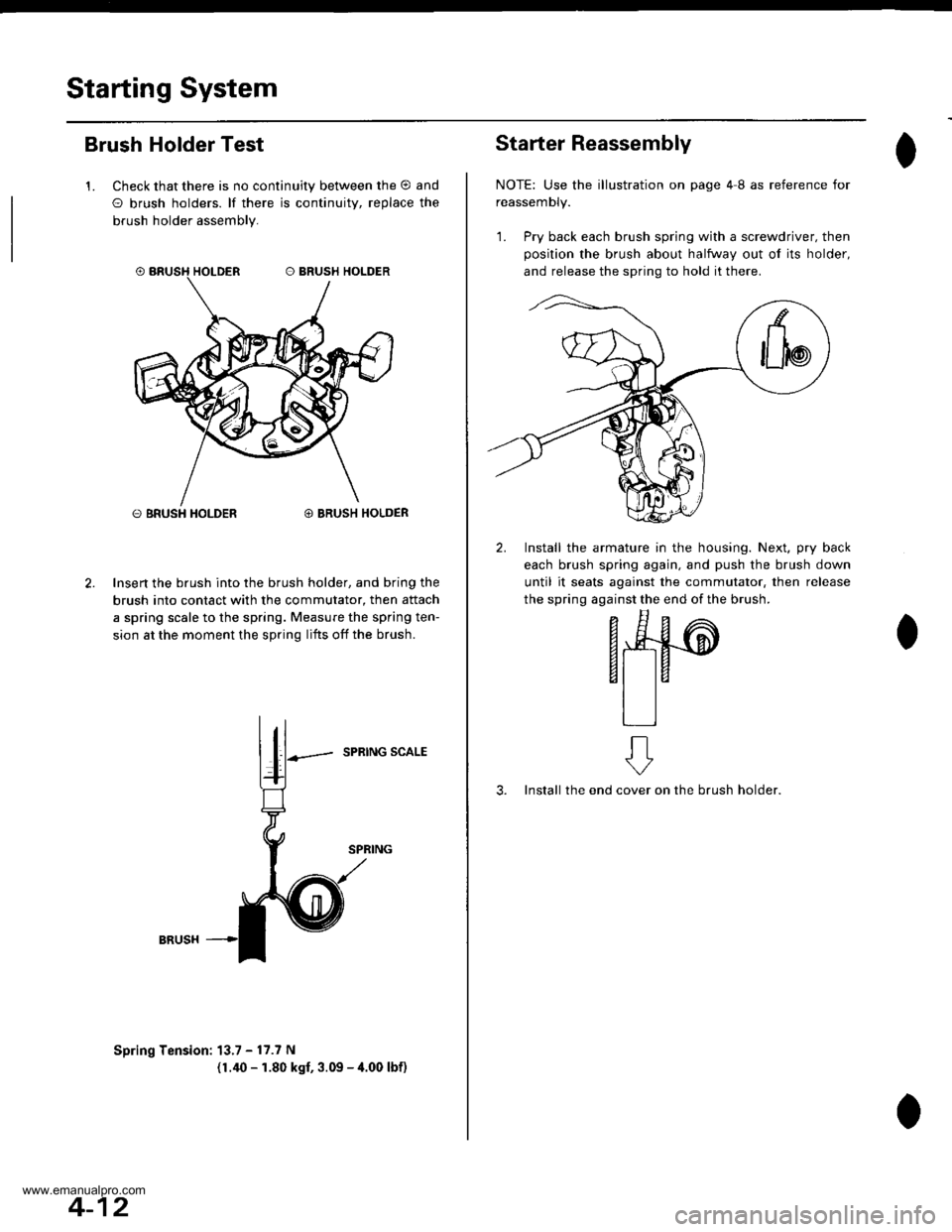

Brush Holder Test

1. Check that there is no continuity between the O and

O brush holders. lf there is continuitv, replace the

brush holder assembly.

O BRUSH HOLDER@ BRUSH HOLDER

Insert the brush into the brush holder, and bring the

brush into contact with the commutator, then attach

a spring scale to the spring. Measure the spring ten-

sion at the moment the spring lifts off the brush.

SPRING SCALE

Spring Tension: 13.7 - 17.7 N

(1.40 - 1.80 kgf, 3.09 - 4.00 lbf)

4-12

Starter Reassembly

NOTE: Use the illustration on page 4I as reference for

reassemDty.

1. Pry back each brush spring with a screwdriver, then

position the brush about halfway out ol its holder,

and release the spring to hold it there.

2. Install the armature in the housing. Next, pry back

each brush spring again, and push the brush down

until it seats against the commutator, then release

the spring against the end of the brush.

- E^

F*4#-@

6t taal la

tlll

3. Install the endon the brush holder.

ft

cover

www.emanualpro.com

Page 79 of 1395

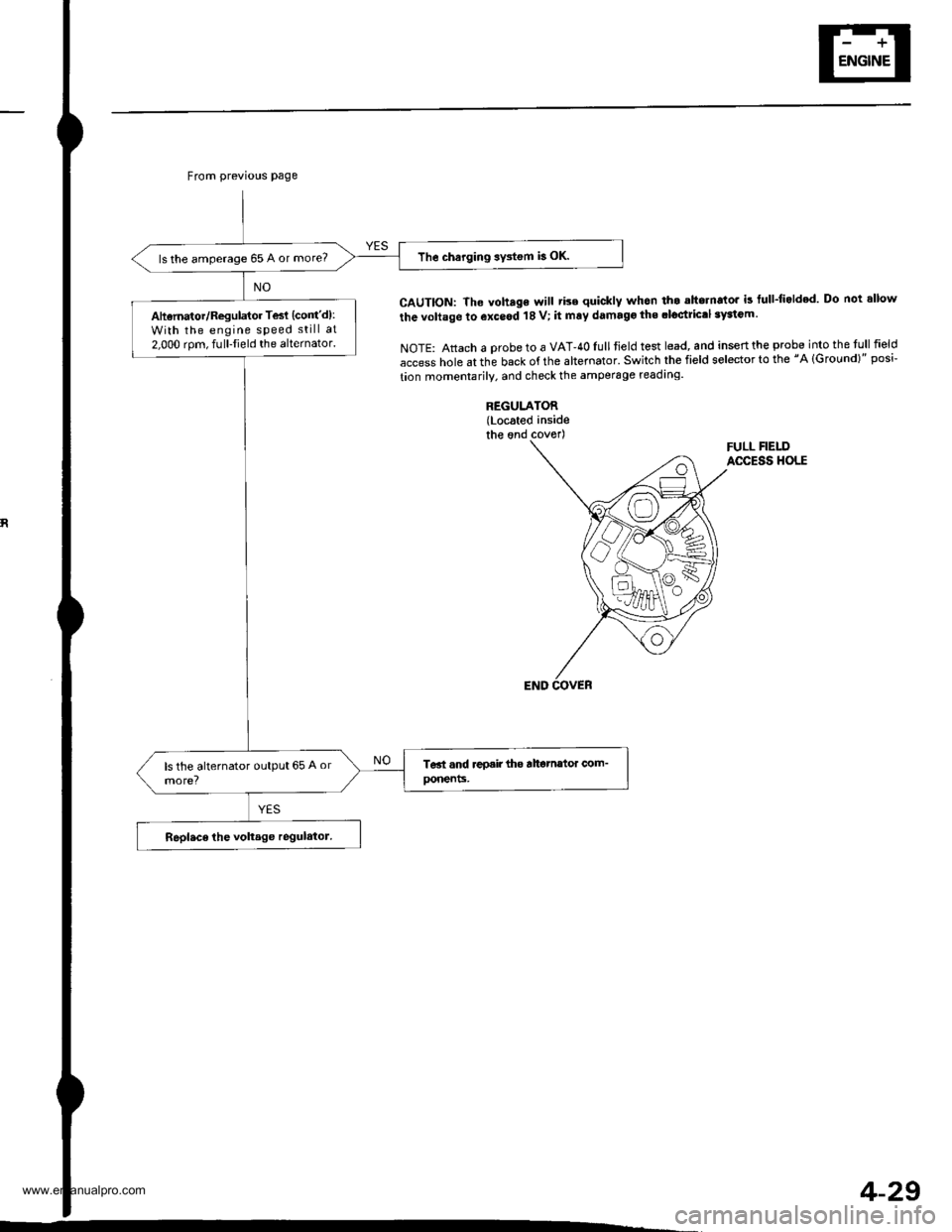

From previous page

The charging sy3tem b OK.ls the amperage 65 A or more?

Aharnator/Regulator Tesl (cont'd):

With the engine speed still at

2.000 rom, fulllield the alternator.

CAUTION: The voh.ge will tise quickly whon th. ahornato. is tull-li.lded Do not allow

the voltage to exceod 18 V; it mry damago the .loctrictl 3yaiGm.

NOTE: Attach a probe to a VAT-40Iull tield test lead, and inseft the probe into the tull field

access hole at the back of the altemator' Switch the field selector to the "A lGround)" posi-

tion momentarily. and check the amperage readrng.

REGULATOR(Located insidethe ond coverlFULL FIELDACCESS HOLE

4-29

www.emanualpro.com

Page 92 of 1395

Cruise Gontrol

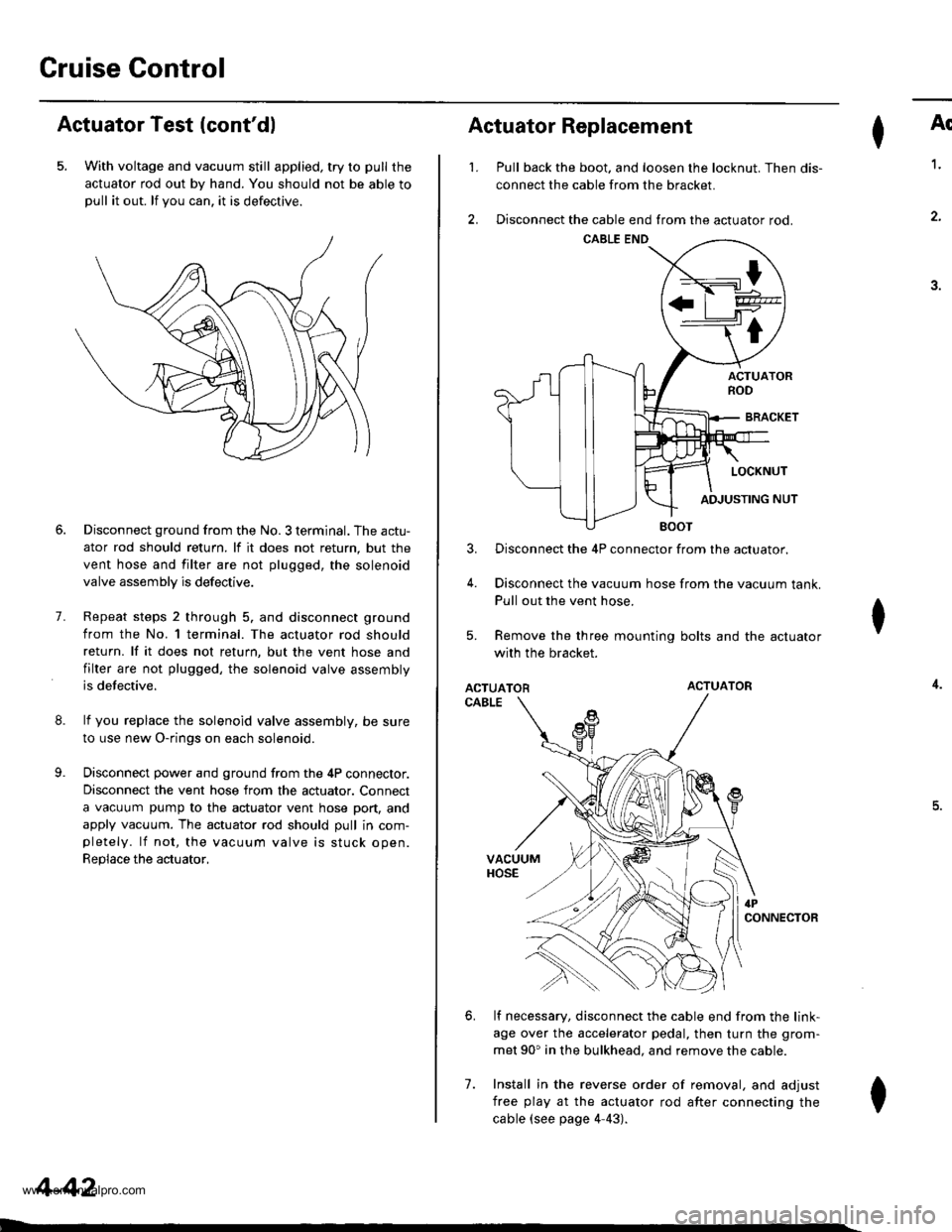

Actuator Test (cont'dl

5. With voltage and vacuum still applied, try to pull the

actuator rod out by hand. You should not be able topull it out. lf you can. it is defectrve.

8.

9.

7.

Disconnect ground from the No. 3 terminal. The actu-

ator rod should return. lf it does not return, but the

vent hose and filter are not plugged, the solenoid

valve assembly is defective.

Repeat steps 2 through 5. and disconnect ground

from the No. l terminal. The actuator rod should

return. lf it does not return, but the vent hose and

filter are not plugged, the solenoid valve assembly

is defective.

lf you replace the solenoid valve assembly, be sure

to use new O-rings on each solenoid.

Disconnect power and ground from the 4P connector.

Disconnect the vent hose from the actuator. Connect

a vacuum pump to the actuator vent hose port, and

apply vacuum. The actuator rod should pull in com-pletely. lf not, the vacuum valve is stuck open.

Replace the actuator,

4-42

I

't.

Actuator Replacement

3.

4.

7.

Ar

Pull back the boot. and loosen the locknut. Then dis-

connect the cable from the bracket.

Disconnect the cable end from the actuator rod.

1.

4.

.J.

Disconnect the 4P connector from the actuator.

Disconnect the vacuum hose from the vacuum tank.

Pull out the vent hose.

Remove the three mounting bolts and the actuator

with the bracket.

ACTUATORACTUATOR

CABLE

lf necessary, disconnect the cable end from the link-

age over the accelerator pedal, then turn the grom-

met 90' in the bulkhead. and remove the cable.

Install in the reverse order of removal, and adjust

free play at the actuator rod after connecting the

cable (see page 4-43).

I

6.

I

www.emanualpro.com

Page 116 of 1395

Valve Clearance

Adiustment

Adjust the valves only when the cylinder head tempera-

ture is less than 100"F (38"C).

1. Remove the cylinder head cover.

Remove the middle cover (see page 6-11).

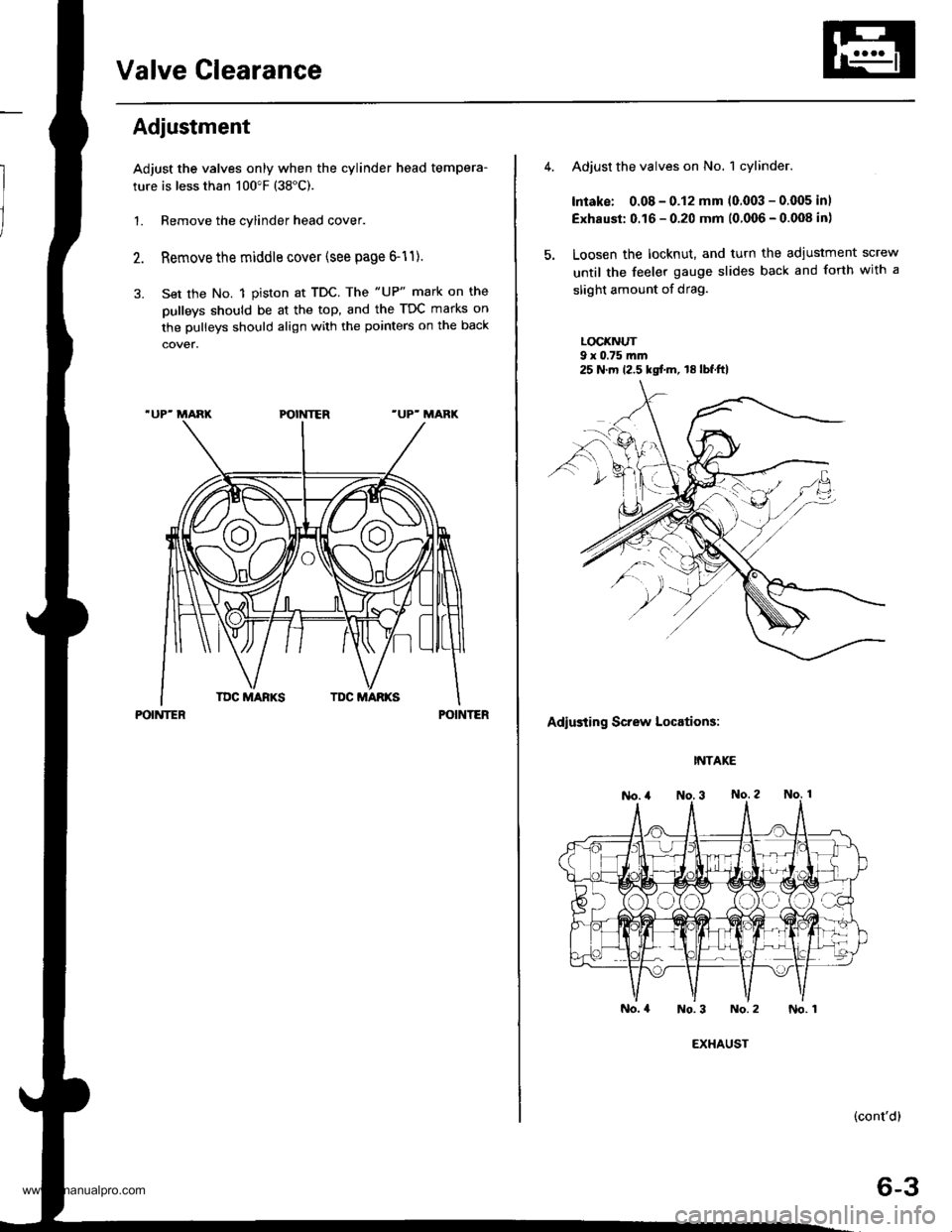

Set the No. 1 piston at TDC. The "UP" mark on the

pulleys should be at the top, and the TDC marks on

the pulleys should align with the pointers on the back

POINTERPOINTER

Adjust the valves on No. 1 cylinder.

Intake: 0.08 - 0.12 mm (0.003 - 0.005 inl

Exhaust: 0.16 - 0.20 mm (0.006 - 0.008 in)

Loosen the locknut, and turn the adiustment screw

until the feeler gauge slides back and forth with a

slight amount of drag.

LOCI(NUT9 x 0.75 m.n

Adiusting Screw Locations:

INTAKE

No.4 No.3 No.2

(cont'd)

6-3

25 N.m 12.5 kgf.m, 18lbf.ft)

EXHAUST

No. 1

www.emanualpro.com

Page 124 of 1395

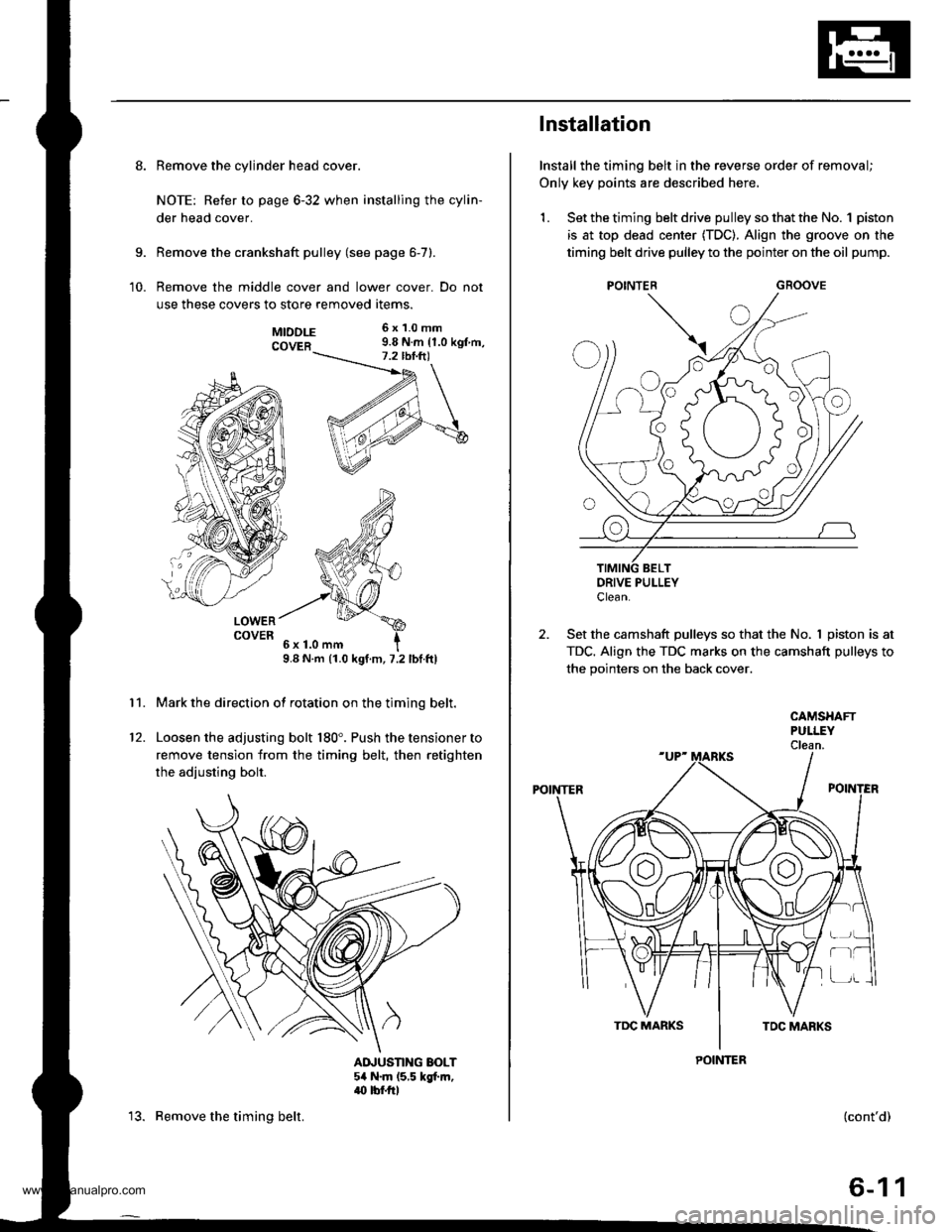

8. Remove the cylinder head cover.

NOTE: Refer to page 6-32 when installing the cylin-

der head cover.

Remove the crankshaft pulley (see page 6-7).

Remove the middle cover and lower cover. Do not

use these covers to store removed items.

9.

10.

11.

MTDDLE 6x1.0mm

COVER 9.8 N.m {1.0 kgt m,

LOWERCOVER

9.8 N.m (1.0 kgt.m, 7.2 lbf.ftl

Mark the direction of rotation on the timing belt.

Loosen the adjusting bolt 180'. Push the tensioner to

remove tension from the timing belt, then retighten

the adiusting bolt.

AINUSTING BOLT54 N.m (5,5 kgt m,.(} tbf.rrl

12.

13. Remove the timing belt.

Installation

Install the timing belt in the reverse order of removal;

Only key points are described here,

1. Set the timing belt drive pulley so that the No. 1 piston

is at top dead center (TDC). Align the groove on the

timing belt drive pulley to the pointer on the oil pump.

GROOVE

DRIVE PULLEYClean.

2. Set the camshaft pulleys so that the No. I piston is at

TDC. Align the TDC marks on the camshaft pulleys to

the pointers on the back cover.

POINTER

CAMSHAFTPULLEYClean.

POINTER

r-t

(cont'd)

6-11

www.emanualpro.com