Electrical HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 13 of 1395

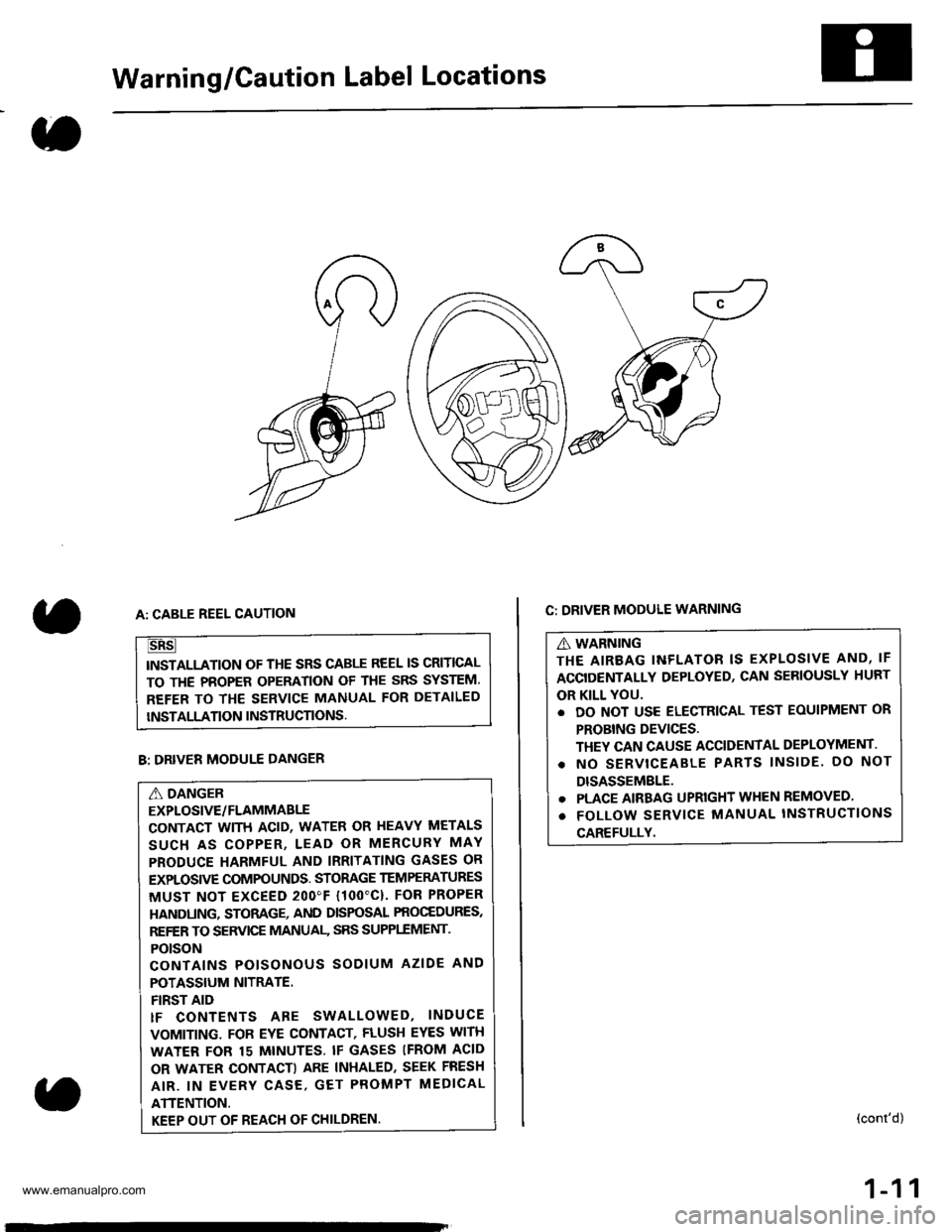

Warning/Caution Label Locations

C: DRIVER MODULE WARNING

A WARNING

THE AIREAG INFLATOR IS EXPLOSIVE AND, IF

ACCIDENTALLY DEPLOYED, CAN SERIOUSLY HURT

OR KILL YOU.

. DO NOT USE ELECTRICAL TEST EOUIPMENT OR

PROBING DEVICES.

THEY CAN CAUSE ACCIDENTAL DEPLOYMENT.

. NO SERVTCEABLE PARTS lNSlDE. DO NOT

DISASSEMBLE.

. PLACE AIRBAG UPRIGHT WHEN REMOVED

. FOLLOW SERVICE MANUAL INSTRUCTIONS

CAREFULLY.

A: CABLE REEL CAUTION

TNSTALLATION OF THE SRS CABLE REEL IS CRITICAL

TO THE PBOPER OPERATION OF THE SRS SYSTEM.

REFER TO THE SERVICE MANUAL FOR DETAILED

INSTALLATION INSTRUCTIONS.

(cont'd)

1-11

B: DRIVER MODULE DANGER

A DANGER

EXPLOSIVE/FLAMMABLE

CONTACT WITH ACID, WATER OR HEAVY METALS

SUCH AS COPPER, LEAD OR MERCURY MAY

PRODUCE HARMFUL AND IRRITATING GASES OR

EXPLOSIVE COMPOUNDS. STOMGE TEM PERATURES

MUST NOT EXCEED 2OO"F {1OO'C}. FOR PROPER

HANDUNG, STORAGE, AND DISPOSAL PROCEDURES.

REFER TO SERVICE MANUAI- SRS SUPPI.EMENT,

POTSON

CONTAINS POISONOUS SODIUM AZIDE AND

POTASSIUM NITRATE.

FIRST AID

tF CONTENTS ARE SWALLOWED, INDUCE

VOMITING. FOR EYE CONTACT, FLUSH EYES WITH

WATER FOR 15 MINUTES. IF GASES IFROM ACID

OR WATER CONTACTI ARE INHALED, SEEK FRESH

AIR. IN EVERY CASE, GET PROMPT MEDICAL

ATTENTION.

KEEP OUT OF REACH OF CHILDREN

www.emanualpro.com

Page 14 of 1395

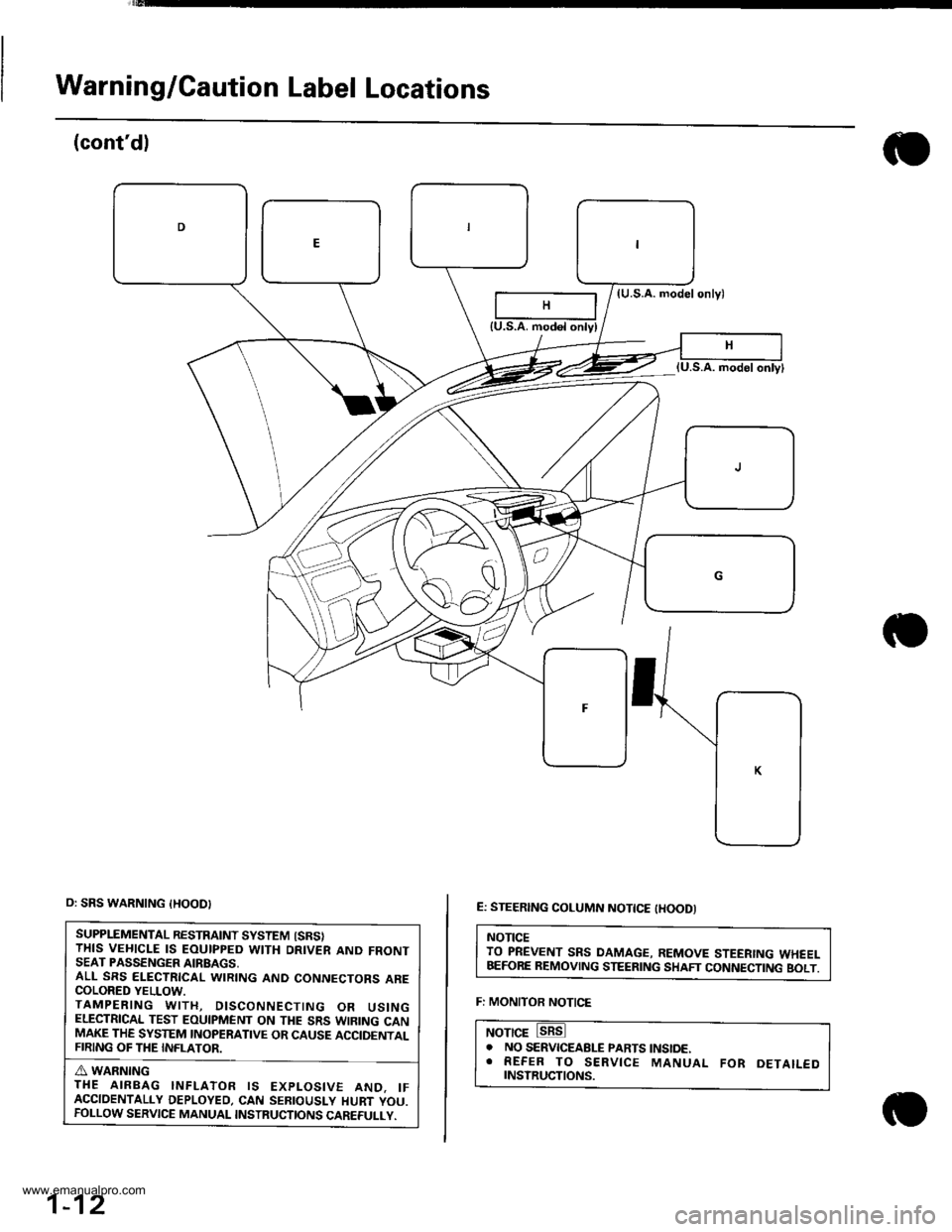

Warning/Caution Label Locations

(cont'dl

(U.S.A. modelonlyl

E: STEERING COLUMN NOTTCE tHOODI

NOTICETO PREVENT SRS DAMAGE, REMOVE STEERING WHEELBEFORE REMOVING STEERING SHAFT CONNECTING BOLT.

F: MONITOR NOTICE

NOTICE. NO SERVICEABLE PARTS tNStoE.. REFER TO SERVICE MANUAL FoR DETAILEDrNsrRucTtoNs.

{U.S.A. modol onlyl

o: SRS WARNING {HOOD}

SUPPLEMENTAL RESTRAINT SYSTEM {SRSITHIS VEHICLE IS EOUIPPED WITH DRIVER AND FRONTSEAT PASSENGER AIRBAGS,ALL SRS ELECTRICAL WIRING AND CONNECTORS ARECOLORED YELLOW.TAMPERING WITH, DISCONNECTING OR USINGELECTRICAL TEST EOUIPMENT ON THE SRS WIRING CANMAKE THE SYSTEM INOPERATIVE OR CAUSE ACCIDENTALFIRING OF THE INFLATOR.

A WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND. IFACCIDENTALLY DEPLOYED, CAN SEBIOUSLY HURT YOU.FOLLOW SERVICE MANUAL INSTRUCTIONS CAREFULLY.

1-12

www.emanualpro.com

Page 15 of 1395

G: FRONT SEAT PASSENGER AIRBAG MODULE DANGEN

A DANGEREXPLOSIVE/FLAMMABLECONTACT WITH ACID, WATER. OR I{EAVY METALS SUCH

AS COPPER. T.EAD. OR MERCURY MAY PRODUCE HARMFUL

AND IRRITATING GASES OR EXPLOSIVE COMPOUNDS.

STORAGE TEMPERATURES MUST NOT EXCEED 2OO"F

IlOO'C). FOR PROPER HANDLING, STORAGE, AND

DISPOSAL PROCEDURES REFER TO THE SERVICE MANUAL,

SRS SUPPLEMENT.POTSONCONTAINS POTSONOUS SODIUM AZIDE ANO POTASSIUM

NITRATE.FIRST AIDIF CONTENTS ARE SWALLOWED, INDUCE VOMITING. FOR

EYE CONTACT, FLUSH EYES WITH WATER FOR 15

MINUTES. IF GASES (FROM ACID OR WATEN CONTACT)

ARE INHALEO. SEEK FRESH AIR. IN EVERY CASE, GET

PROMPT MEDICAL ATTENTION.KEEP OUT OF REACH OF CHILDREN.

A WARNINGTHE AIRBAG INFLATOR IS EXPLOSIVE AND, IF

ACCIDENTALLY DEPLOYED, CAN SERIOUSLY HURT OR

KILL YOU.. DO NOT USE ELECTRICAL TEST EOUIPMENT OR

PROBING DEVICES,THEY CAN CAUSE ACCIDENTAL DEPLOYMENT.. NO SERVICEABI-E PARTS lNSlDE. DO NOT DISASSEMBII.

. PLACE AIRBAG UPRIGHT WHEN REMOVEO.

. FOLLOW SERVIC€ MANUAL INSTRUCTIONS CAREFULLY

H: PASSENGER INFORMATION lU S.A. modell

{U.S.A.'97 model}

AIEBAG SEE OTHER SIDE,

{U.S.A.'98 - 00 modelsl

AIRBAG WARNINGFLIP VISOR OVER.

l: SRS INFORMATION

lU.s.A.'97 model ilcanada '97 - 00 mod€ls I

CAUTIONTO AVOID SERIOUS INJURY:. FOR MAXIMUM SAFEW PROTECTION lN ALL TYPES OF

CRASHES, YOU MUST ALWAYS WEAR YOUR SAFETY

8ELT.o OO NOT INSTALL REARWARD-FACING CHILO SEATS lN

ANY FRONT PASSENGER SEAT POSITION.. DO NOT SIT OR LEAN UNNECESSARILY CLOSE TO THE

AIRBAG.. DO NOT PLACE ANY OBJECTS OVER THE AIRBAG OR

BETWEEN THE AIRBAG AND YOURSELF.. SEE THE OWNER'S MANUAL FOR FURTHER

INFORMATION AND EXPLANATIONS. THE SRS MUST BE INSPECTED TEN YEARS AFTER lT lS

INSTALLED.. THE DATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

lU.S.A.'98 - 00 models)

WARNINGDEATH OR SERIOUS INJURY CAN OCCUR'

. CHILDREN 12 ANO UNDER CAN BE KILLED BY THE

AIRBAG.. THE BACK SEAT lS THE SAFEST PLACE FOR CHILDREN.

. NEVER PUT A REAR-FACING CHILD SEAT lN THE

FRONT.o SIT AS FAR BACK AS POSSIBLE FROM THE AIRBAG

. ALWAYS USE SEAT BELTS AND CHll-D RESTRAINTS.

. THE SRS MUST BE TNSPECTED TEN YEAnS AFTER lT lS

INSTALLED.. THE OATE OF INSTALLATION lS SHOWN ON THE

DRIVER'S DOORJAMB.

J: FRONT PASSENGER AIRBAG WARNING

lU.S.A.'98 - 00 models)

WARNINGCHILDREN CAN BE KILLED OR INJURED 8Y THE

PASSENGER AIRBAG.THE BACK SEAT IS THE SAFEST PLACE FOR CI{ILDREN 12

AND UNDER.MAKE SURE ALL CHILDREN USE SEAT BELTS OR CHILD

SEATS.

K: FRONT SEATBELT TENSIONER WARNING

WABNINGEXPLOSIVE MATERIAL INSIDEYOU CAN BE SERIOUSLY HURT OR BURNED,

. DO NOT TAMPER OR DISASSEMBLENO SERVICEABLE PARTS INSIDE.. REFER TO SERVICE MANUAL FOR COMPLETE

INSTRUCTIONS.

(cont'd)

1-13

www.emanualpro.com

Page 27 of 1395

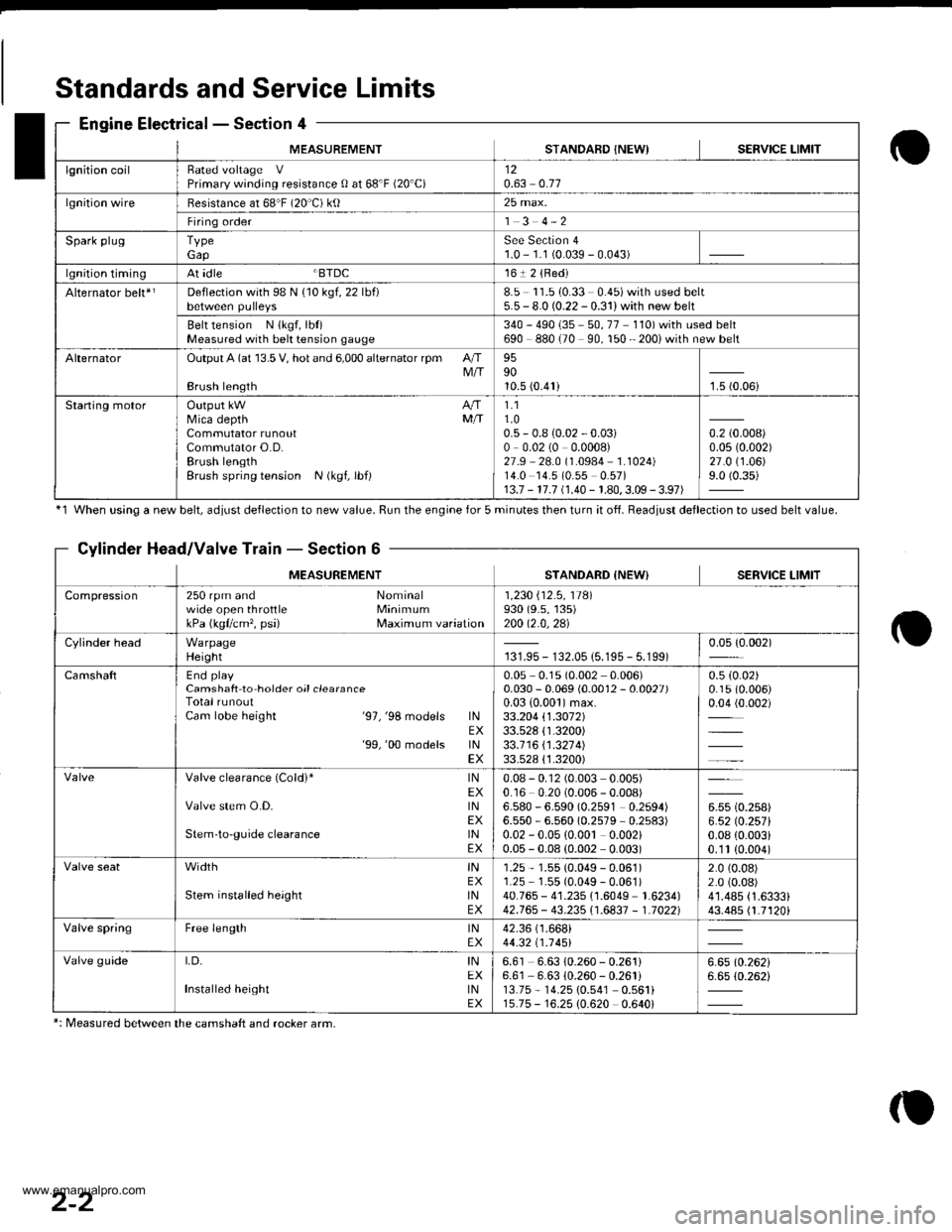

MEASUREMENTSTANDAFD INEWISERVICE LIMIT

lgnition coilRated voltage VPrimary winding resistance 0 at 68'F (20'C)120.63 0.77

lgnition wireBesistance at 68"F (20 C) ktl25 max.

Firing order1 3 4-2

Spark plugTypeGapSee Section 41.0 - 1.1 (0.039 - 0.043)

lgnition timingAt idle BTDC161 2 {Red)

Alternator belt*rDeflection with 98 N {10 kgf, 22 lbf)8.5 11.510.33 0.45)with used belt5.5 - 8.0 (0.22 - 0.31) with new belt

Belt tension N {kgf, lbt)Measured with bek tension gauge340 - 490 {35 - 50, 77 110) with used belt690 880 (70 90, 150 - 200i with new belt

AlternatorOutput A (at 13.5 V, hot and 6,000 alternator rpm AIIM/IBrush length

959010.5 (0.41)1.5 (0.06i

Staning motorOutput kW A/fMica depth MfiCommutator runoutCommutator O.D.Brush lengthBrush spring tension N (kgf, lbf)

1.11.00.5 - 0.8 {0.02 - 0.03)0,0.02 (0 0.0008)27.9 28.0 (1.0984 1.1024)14.0 14.5 (0.55 0.57)13.7 - 17.7 (1.40 - 1.80,3.09 - 3.97)

0.2 (0.008)

0.0s (0.002)

27.0 (1.06)

9.0 (0.35)

Standards and Service Limits

Engine Electrical - Section 4

'1 When using a new belt, ddiust deflection to new value. Run the engine for 5 minutes then turn it of{. Beadiust deflection to used belt value.

Cylinder Head/Valve Train - Section 6

MEASUREMENTSTANDARD {NEW} SERVICE LIMIT

Compression250 rpm and Nominalwide open throttle MinimumkPa (kgflcm'�, psi) Maximum variation

1 ,230 i'12 .5 , 11Al930 (9.s, 135)200 12.0,2al

Cylinder headWarpageHeight131.95 - 132.05 {5.195 - 5.199)0.05 {0.002)

CamshaftEnd playCamshaft to hoider oil clearanceTotal runoutCam lobe height '97,'98 models lNEX'99,'00 models lNEX

0.05 0.1s (0.002 0.006)0.030 - 0.069 (0.0012 - 0.0027)0.03 {0.001)max.33.204 \1.3072133.528 {1.3200)33.1 16 \1 .321 4)33.528 {'1.3200)

0.5 (0.02)

0.15 (0.006)

0.04 (0.002)

Valve clearance (Cold)* lNEXValve stem O.D. lNEXStem'to-guide clearance lNEX

0.08 - 0.12 (0.003 0.005)0.16 0.20 (0.006 - 0.008)6.580 - 6.590 (0.2591 0.2594)6.550 - 6.560 (0.2579 0.2s83)0.02 - 0.05 {0.00t 0.002)0.05 - 0.08 (0.002 0.003)

u* to.rutt6.52lO.257l0.08 {0.003i0.'1t (0.004)

width tNEXStem installed height lNEX

1.25 - 1.55 (0.049 - 0.061)1.25 1.55 (0.049 - 0.061)40.765 - 41.235 {1.6049 1.6234)42.765 - 43.235i'1.6837 - 1.70221

2.0 (0.08)

2.0 (0.08)

41.485 {1.6333}43.485 {1.7120i

Valve springFree length lNEX42.36 (1.668i

44.32 t1 .1 451

Valve guideI,D, INEXInstalled height tNEX

6.61 6.63 10.260 - 0.261)6.61 6.63 {0.260 - 0.261i13.75 - 14.25 10.541 0.561i15.75 - 16.25 {0.620 0.640i

6.6510.26216.65 (0.262i

*: Measured between the camshaft and rocker arm,

2-2

www.emanualpro.com

Page 38 of 1395

--

-

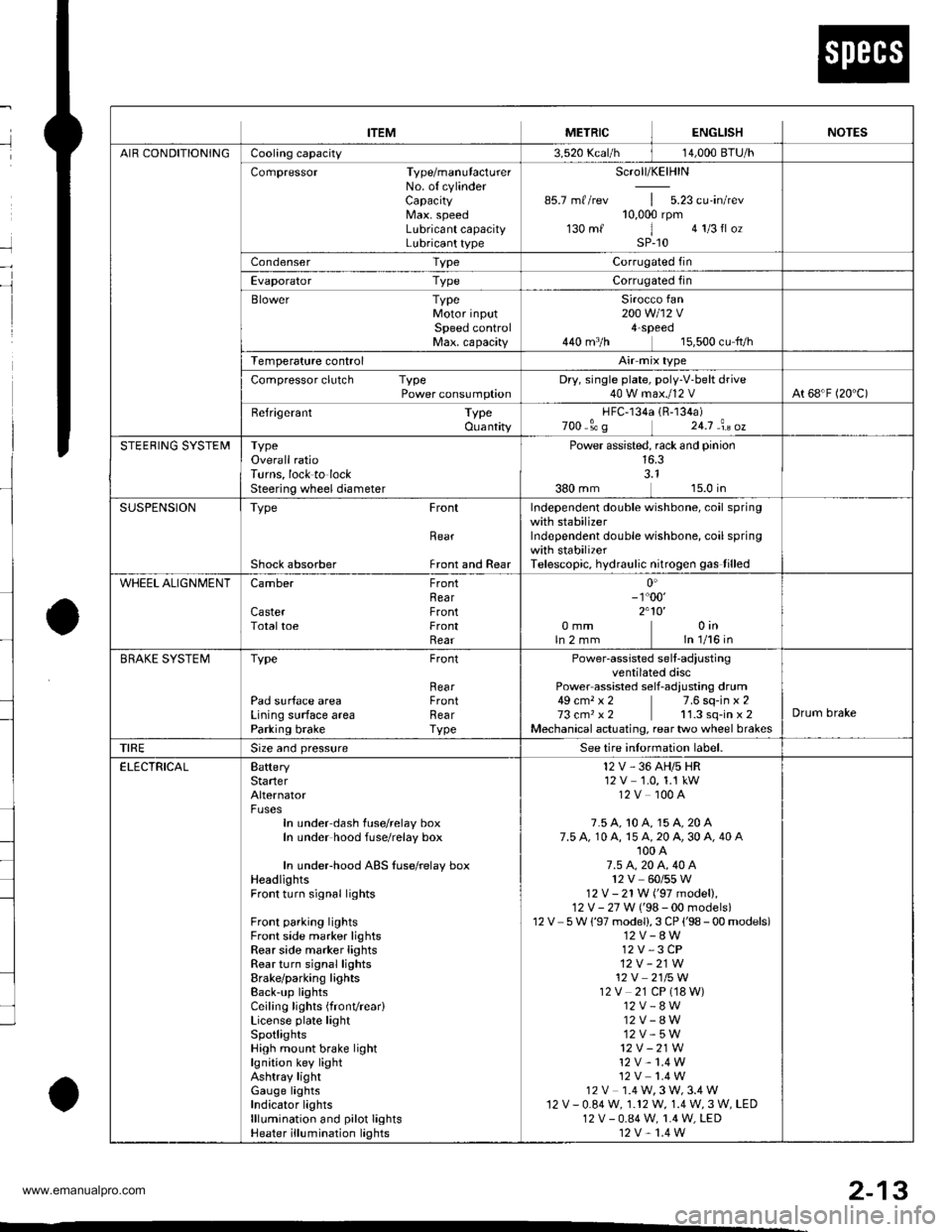

METRICITEMENGLISHNOTES

AIR CONDITIONINGCooling capacity3,520 Kcal/h j 14,000 BTU/h

Compressor Type/manutacturerNo. of cylinderCaPacityMax. speedLubricant capacityLubricant type

Scroll/KElHlN

85.7 mf/rev | 5.23 cu'in/rev10,000 rpm130mf 1 algIlozsP-10

Condenser TypeCorrugated fin

Evaporator TypeCorrugated fin

Blower TypeMotor inputSpeed controlMax. capacity

Sirocco fan200 w 112 v4-Speeo440 m3/h 15,500 cu fvh

Temperature control

Compressor clutch TypePower consumptionDry, single plate, poly-V-belt drive40 W max./12 VAt 68'F (20 C)

Befrigerant TypeOuantity

HFC-134a 1R-134a)zoo o' g 24j an oz

STEERING SYSTEMTypeOverall ratioTurns, lock to lockSteering wheel diameter

Power assisted, rack and pinion

SUSPENSIONType Front

Bear

Shock absorber Front and Rear

Independent double wishbone, coil springwith stabilizerIndependent double wishbone, coil springwith stabilizerTelescopic, hydraulic nitrogen gas tilled

WHEEL ALIGNMENTCamber

CasterTotaltoe

FronthearFrontFrontRear0inln 1/16 in0mmln2mm

0'- r"00'2.10'�

BRAKE SYSTEMTvpe

Pad surface areaLining surface areaParking brake

Front

RearFrontRearTvpe

Power-assisted selt-ad,ustingventilated discPower assisted self-adiusting drum49 cm, x 2 7.6 sq-in x 273 cm, x2 11.3 sq-in x 2Mechanical actuating, rear two wheel brakes

Drum brake

TIRESize and pressureSee tire inlormation label.

ELECTRICALBafteryStarterAlternator

In under-dash fuse/relay boxIn under hood fuse/relay box

In underhood ABS fuse/relay boxHeadlightsFront turn signal lights

Front parking lightsFront side marker lightsRear side marker lightsRear turn signal lightsErake/parking lightsBack-up lightsCeiling lights {fronvrear)License plate lightSpotlightsHigh mount brake lightlgnition key lightAshtray lightGauge lightsIndicator lightslllLrmination and pilot IightsHeater illumination lights

12 V, 36 AH/s HR12V 1.0, 1.1 kW12V 100A

7.5 A, 10 A, 15 A, 20 A7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A'100 A7.5 4,20 A. 40 A12V 60/55 W12 V- 21 W ('97 model),12 V - 27 W ('98-00 models)12V 5 W {'97 model),3 CP ('98 - 00 models)12V-8W12 V,3 CP12V-21W12 V 2115 W12V 21 CP (18 W)12V-8W12V-8W12V-5W12V -21W

12 V- 1.4 W12V 1.4 W12 V 1.4 W,3 W,3.4 W12V-0.84W, 1.12 W, 1.4 W,3 W, LED12 V - 0.84 W, 1.4 W, LED12 V,1.4 W

2-13

www.emanualpro.com

Page 51 of 1395

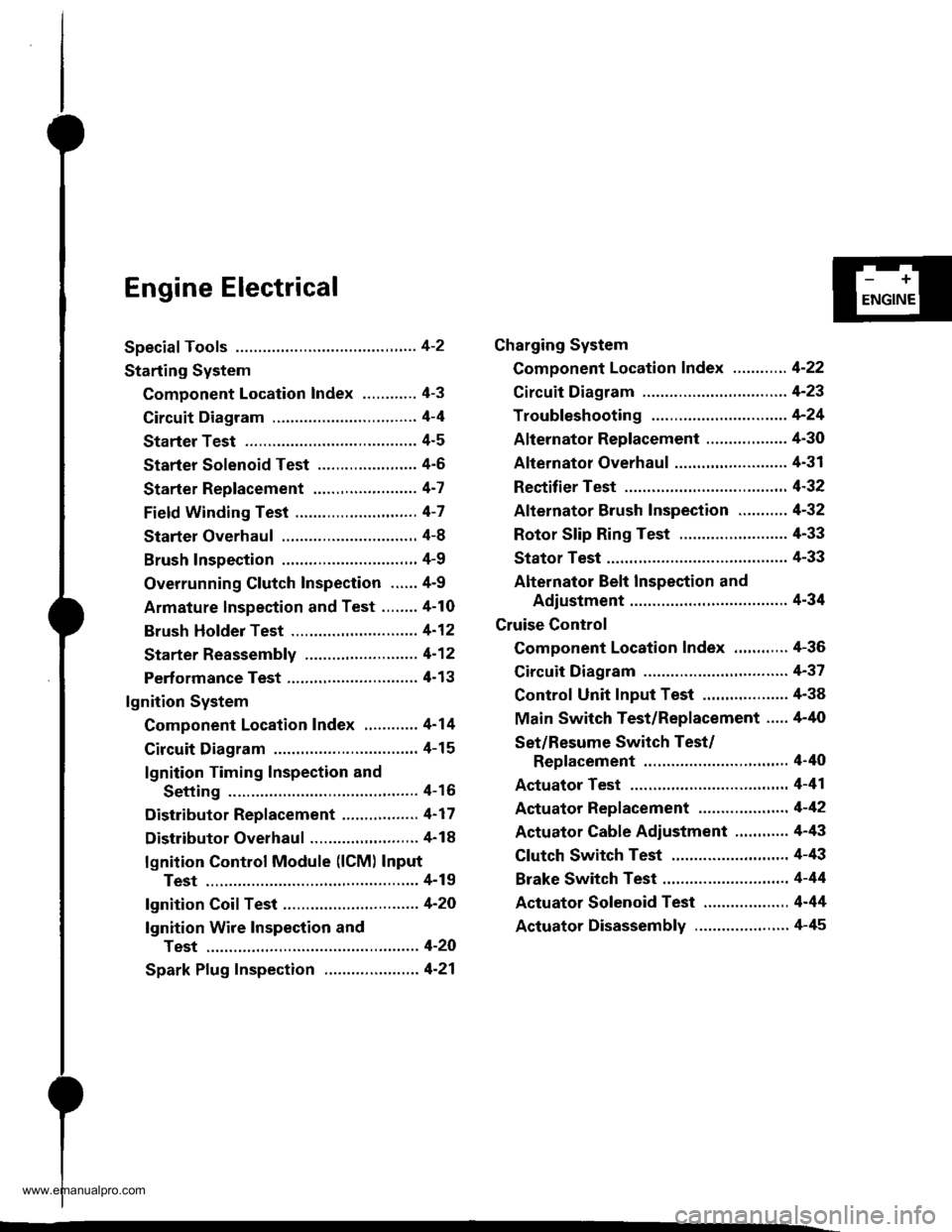

Engine Electrical

Speciaf Tools ............. 4-2

Starting System

Component Location Index ............ 4-3

Circuit Diagram ................................ 4-4

Starter Test ........... 4-5

Starter Solenoid Test ...................... 4'5

Starter Replacement ....................... 4-7

Field Winding Test ........................... 4-7

Starter Overhaul ............................,. 4-8

Brush Inspection ...........................,., 4-9

Overrunning Glutch Inspection ...... 4-9

Armature lnspection and Test ........4-10

Brush Holder Test ............................ 4-12

Starter Reassemb|y ......................... 4-1 2

Perf ormance Test ............................. 4- 1 3

lgnition System

Component Location Index ............ 4-14

Circuit Diagram ................................ 4-15

lgnition Timing Inspection and

Setting .......................................... 4-16

Distributor Replacement ........,........ 4-17

Distributor Overhaul .............,,......... 4-18

lgnition Control Module (lCM) Input

Test ..............................,................ 4-19

fgnition Coil Test .............................. 4-2O

lgnition Wire Inspection and

Test ............................................... 4-20

Spark Plug Inspection ..................... 4-21

-+

ENGINE

Charging System

Component Location Index ............ 4-22

Circuit Diagram ....................,........... 4-23

Troubleshooting .............................. 4-24

Alternator Replacement ..........,....... 4-30

Alternator Overhaul .......,,................ 4-31

Rectifier Test .........4-32

Alternator Brush Inspection ........... 4-32

Rotor Slip Ring Test ........................ 4-33

Stator Test ............. 4-33

Alternator Belt Inspection and

Adiustment ........4-34

Gruise Control

Component Location Index .,,,........ 4-36

Circuit Diagram ................................ 4-37

Control Unit Input Test ................... 4-38

Main Switch Test/Replacement ..... 4-40

Set/Resume Switch Test/

Replacement .......................,........ 4'40

Actuator Test ....,,., 4-41

Actuator Replacement ...............,.... 4-42

Actuator Cable Adiustment ............ 4-43

Clutch Switch Test .......................... 4-43

Brake Switch Test .................. .......... 4-44

Actuator Solenoid Test .............. ...,. 4-44

Actuator Disassembly ..................... 4-45

www.emanualpro.com

Page 194 of 1395

Radiator

Engine Coolant Refilling and Bleeding (cont'dl

Mix the recommended antifreeze with an equal

amount of water in a clean container.

NOTE:

. Always use Genuine Honda Antifreeze/Coolant.

Using a non-Honda coolant can result in corro-s\on, ca

sng t\e coo\

g sys\em \o ma\lunct\on

o. fail.

For best corrosion protection, the coolant con-

centration must be maintained year-round at50% minimum. Coolant concentrations less than

50% may not provide sufficient protection against

corrosion or freezing. Coolant concentrationsgreater than 60% will impair cooling efficiency

and are not recommended.

Do not use additional rust inhibitors or anti-rustproducts; they may not be compatible with the

coolant.

Engine Coolant Refill Capacity Iincluding 0.6 / 10.63US $, 0.53 lmp qtl for hoater and ressrvoirl:

A/T: 3.9 f {4.1 US $, 3.4 lmp qtl

M/T: 1.O t 14.2 US $, 3.5 lmp qrl

10-6

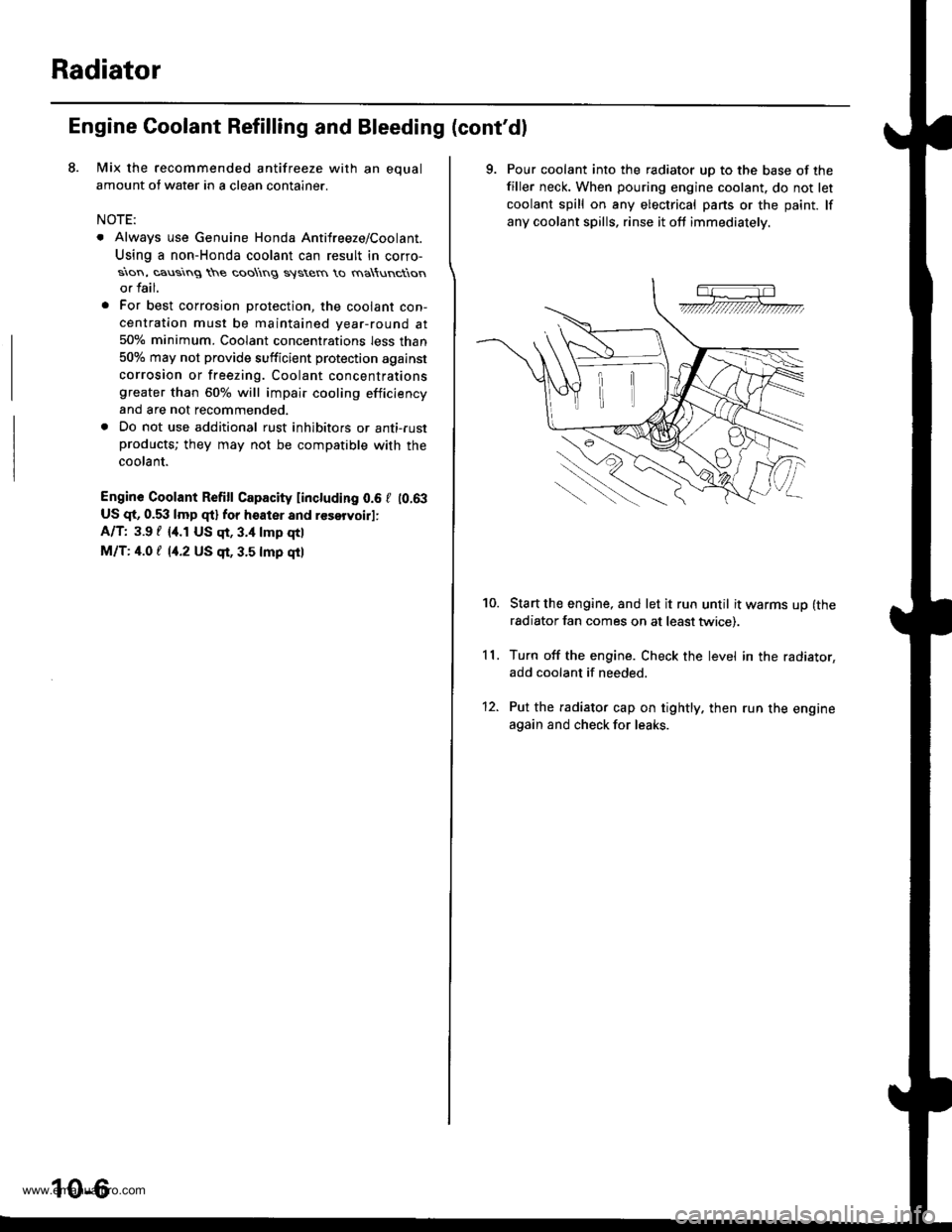

9. Pour coolant into the radiator uD to the base of the

filler neck. When pouring engine coolant. do not let

coolant spill on any electrical pans or the paint. lf

any coolant spills, rinse it oft immediately.

Start the engine, and let it run until it warms up (the

radiator fan comes on at least twice).

Turn off the engine. Check the level in the radiator,

add coolant if needed.

Put the radiator cap on tightly. then run the engine

again and check for leaks.

11.

10.

12.

www.emanualpro.com

Page 204 of 1395

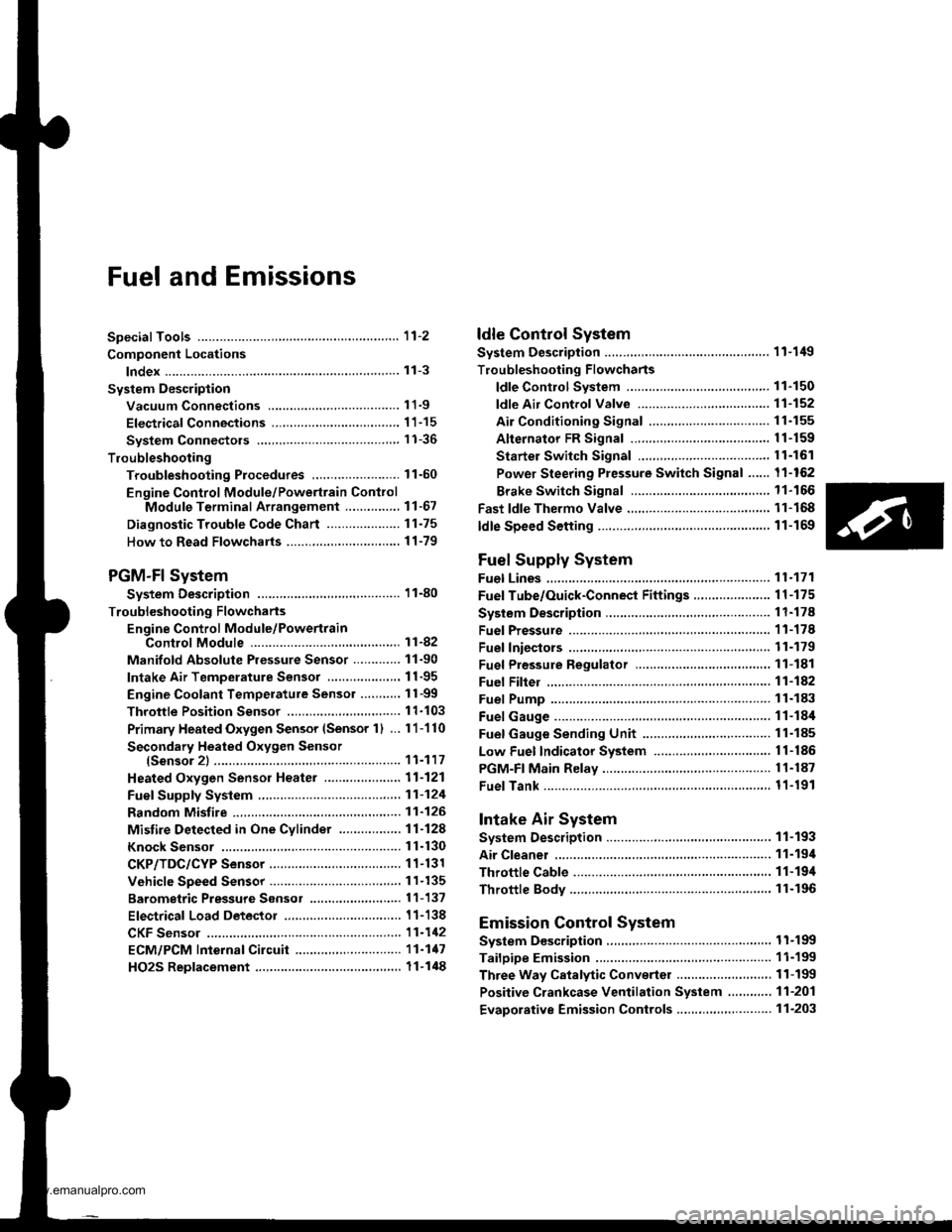

Fuel and Emissions

Special Tools ...................... 11-2

Component Locations

lndex ...................... ....,.... 11-3

Svstem Description

Vacuum Connections ...........,....,.,................. 1 1-9

Electrical Connections ................................... 1 1-15

System Connectors .,.,,.,............................,.,. 1 1-36

Troubleshooting

Troubleshooting Procedures,.,..................... 11-60

Engine Control Module/Powertrain ConttolModule Terminal Arrangement .............., 11-67

Diagnostic Trouble Code Chart .................... 1 t-75

How to Read Flowcharts .......,.....,.,............... I 1-79

PGM-Fl System

System Description .................,.,.,,,............... 1 1-80

Troubleshooting Flowcharts

Engine Control Module/PowertrainControl Module ........11-52

Manifold Absolute Pressure Sensor ............. 11-90

Intake Air Temperature Sensor .................... 1 1-95

Engine Coolant Temperature Sensor .,..,.,.... 1 1-99

Throttle Position Sensor ...........,.....,.,.,..,...... I 1'103

Primary Heated Orygen Sensor (Sensor 1) ... 11-110

Secondary Heated Oxygen Sensor{Sensor 2l .................. 1 1-117

Heated Oxygen Sensor Heater ..................... 11-121

Fuef Supply System ......11-124

Random Misfire ,....,.,..... 11-126

Mistire Detected in One Cylinder .....-........... 11-128

Knock Sensor ................ 11-130

CKP/TDC/CYP Sensor .................................... 1 1-131

Vehicle Speed Sensor ...............................,.... 1 1-135

Barometric Pressure Sensor .....,...,...,.,,........ 1 1-137

Electrical Load Detector ...,.,.......................... 1 1-138

CKF Sensor ................,.,, '11-112

ECM/PCM lnternaf Circuit ............................. 11'117

HO2S Replacement .,.,.,. 11-148

ldle Control System

System Description ............ 11-149

Troubleshooting Flowcharts

ldle Control System ...... 11-150

fdle Air Control Valve ......................,............. 11-152

Air Conditioning Signal ................................. I 1-155

Alternator FR Signal ...................................... 1 1-159

Starter Switch Si9na1 .................................... t l-161

Power Steering Pressure Switch Signal ...... 11-162

Brake Switch Si9na1 ...................................... 11-166

Fast ldle Thermo Valve .,.,.............................,.,.,. 11-168

ldle speed setting .............. 11-169

Fuel Supply System

Fuel Lines ............................ 11-171

Fuef Tube/Ouick-Conneci Fittings ..................... 11 -175

System Description ............ 11-178

Fuel Pressurg ...................... 11-178

Fuel Iniectors ................,..... 11-179

Fuel Pressure Re9u1ator .............................,.,...., f 1-181

Fuef Fifter ....,.,.,.,,,,.,............11-142

Fuel Pump ........................... 11-183

Fuel Gauge .......................... 11-184

Fuel Gauge Sending Unit ................................... I 1-185

Low Fuel Indicator System ...........,.,..,............... 1 1-185

PGM-FI Main Relay ............. 11-187

Fue|Tank................ ............. 11-191

Intake Air System

System Description ............ 11-193

Air Cleanel ,.,.,..................... 11-194

Throttle Cable ..................... 11-194

Throttle Body........ .............. 11-196

Emission Control System

System D$cription ...,....,.,. 11-199

Tailpipe Emission ............... 11-199

Three Way Catalytic Converter ..................,.,...,, 11-199

Positive Crankcase Ventilation System .,.,,,,.,.., 11-2O1

Evaporative Emission Controls .........,.,.,............ 11-203

www.emanualpro.com

Page 206 of 1395

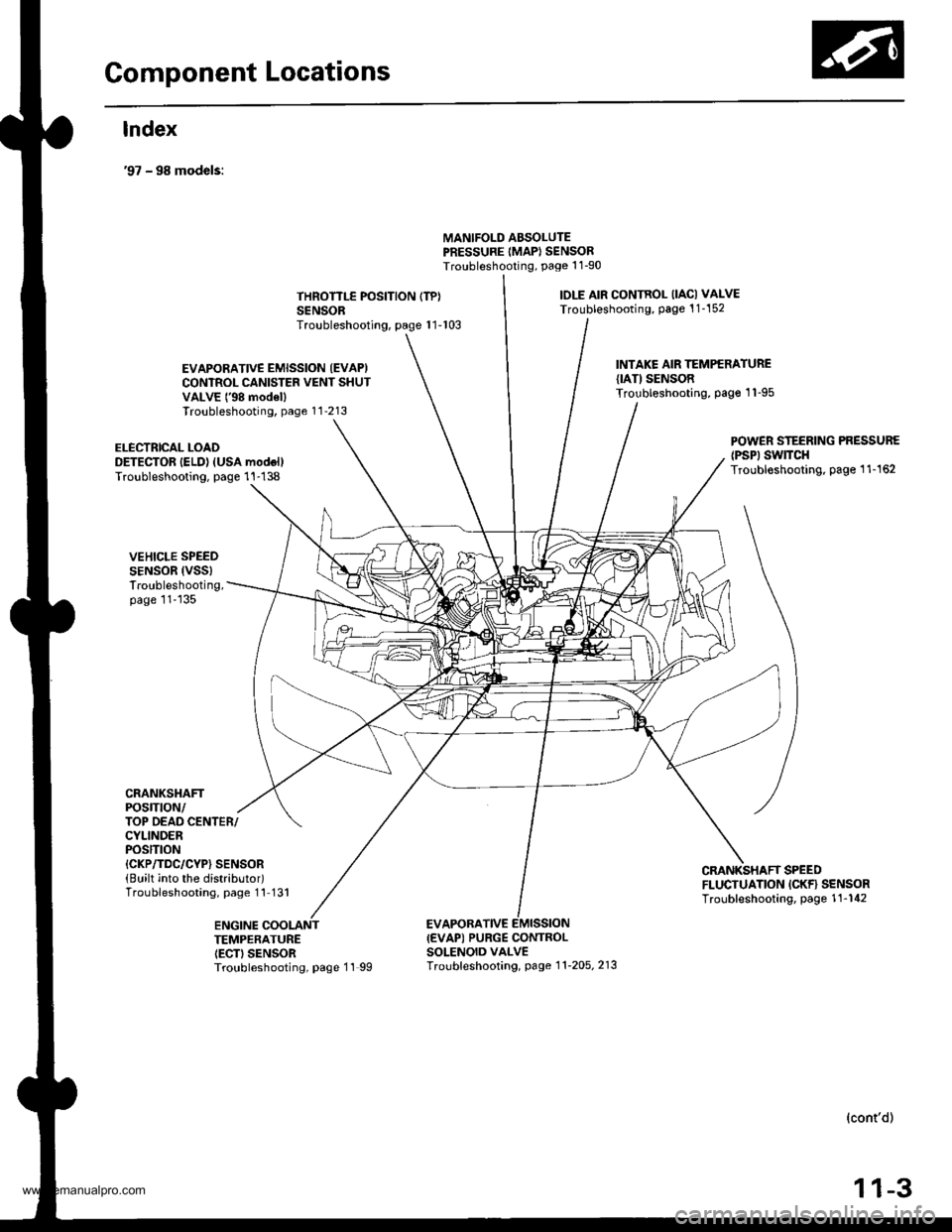

Component Locations

lndex

'97 - 98 models:

MANIFOLD ABSOLUTEPRESSURE IMAP} SENSORTroubleshooting, Page 1 1-90

THROTTLE POSITION (TP}

SENSORTroubleshooting, page 1 1-103

toLE AtR CONTROL llAcl VAI-VE

Troubleshooting, page 1 1-152

EVAPORATIVE EMISSION (EVAP)

CONTROL CANISTER VENT SHUTVALVE t'98 mod€llTroubleshooting, page 11'213

INTAKE AIR TEMPERATUREIIATI SENSORTroubleshooting. page 1 'l -95

ELECTRICAL LOADDETECTOR IELD) (USA modol)Troubleshooting, page 1 1-138

VEHICLE SPEEDSENSOR (VSS)

Troubleshooting,page 11'135

CRANKSHAFTPOSTTtON/

POWER STEERING PRESSURElPsPl swtrcHTroubloshooting, page 1 1-162

TOP OEAD CENTER/CYLINDERPOStTtON{CKP/TDC/CYP} SENSOR(Built into the distributor)Troubleshooting, page 1 l-131

CMNKSHAFT SPEEDFLUCTUATION ICKF} SENSORTroubleshooting. page 1'!-142

ENGINE COOLANTTEMPERATUREIECTI SENSORTroubleshooting, page 11 99

EVAPORATIVEI€VAP) PURGE CONTROLSOLENOID VALVETroubf eshooting, page 1 1'2o5, 213

(cont'd)

11-3

www.emanualpro.com

Page 207 of 1395

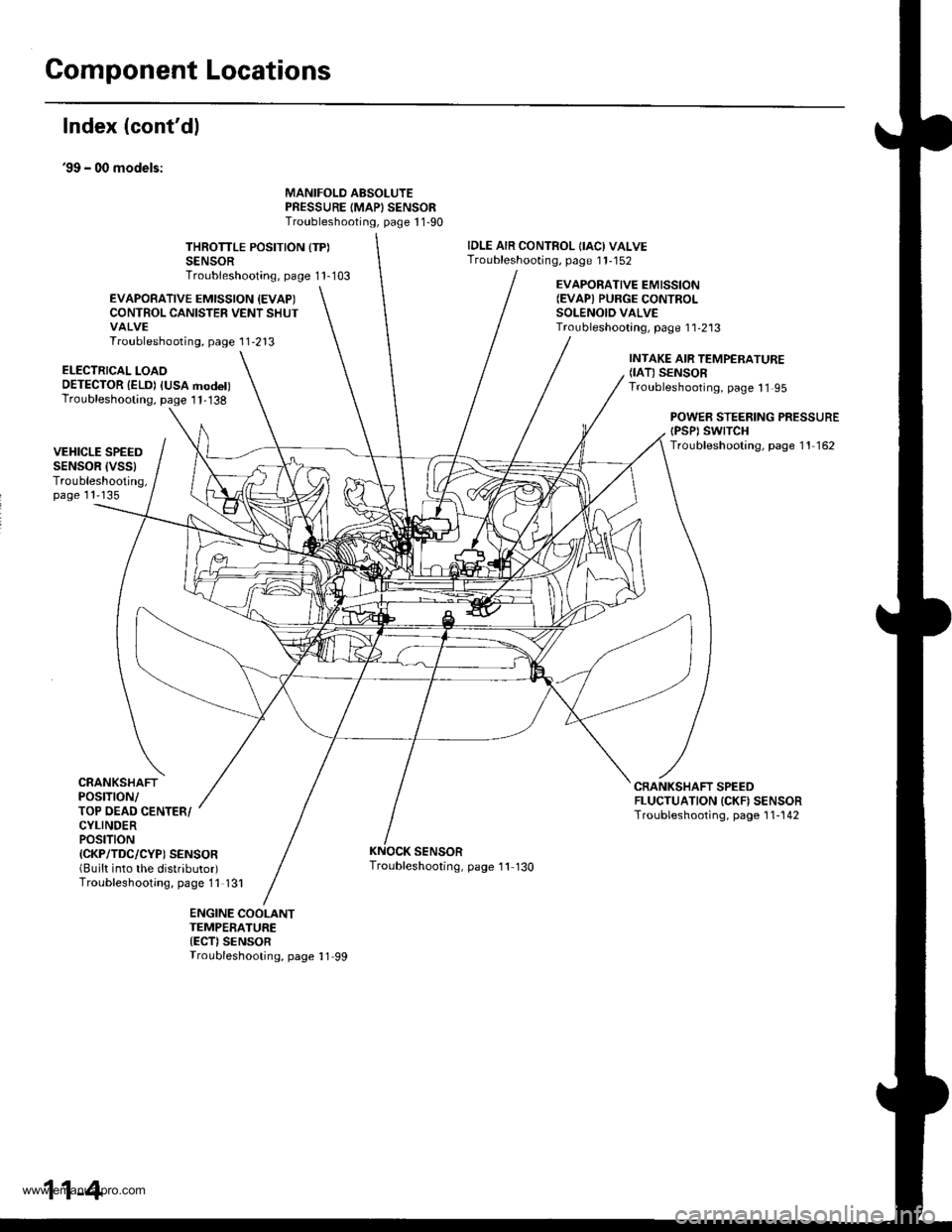

Component Locations

Index (cont'dl

39 - 00 models:

MANIFOLD ABSOLUTEPRESSURE IMAPISENSORTroubleshooting, page 1 1-90

THROTTLE POSITION {TP)SENSORTroubleshooting, page 1 1-103

IDLE AIR CONTROL OACI VALVETroubleshooting, page 1 1-152

EVAPOBATIVE EMISSION {EVAPICONTROL CANISTER VENT SHUTVALVETroubleshooting, page 1 1-213

EVAPORATIVE EMISSION(EVAPI PURGE CONTROI-SOLENOID VALVETroubleshootang, page 1 1-2'13

ELECTRICAL LOAOOETECTOR {ELD) IUSA modet)Troubleshooting, page I 1-138

INTAKE AIR TEMPERATURE(IAT) SENSORTroubleshooting, page 11 95

POWEB STEERING PRESSUREtPsPt swtTcHTroubleshooting, page 11 162VEHICLE SPEEDSENSOR IVSSITroubleshooting,page 11'135

CRANKSHAFTPOSTTTON/TOP OEAD CENTER/CYLINDERPOStTtON{CKP/TDC/CYP) SENSOR(Built into the distributor)Troubleshooting, page 11 131

CRANKSHAFT SPEEDFLUCTUATION ICKN SENSORTroubleshooting, page 1 1-142

SENSORTroubleshooting, page '11 130

ENGINE COOLANTTEMPERATURE{ECT)SENSORTroubleshooting, page 11 99

11-4

www.emanualpro.com