Hub HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 33 of 1395

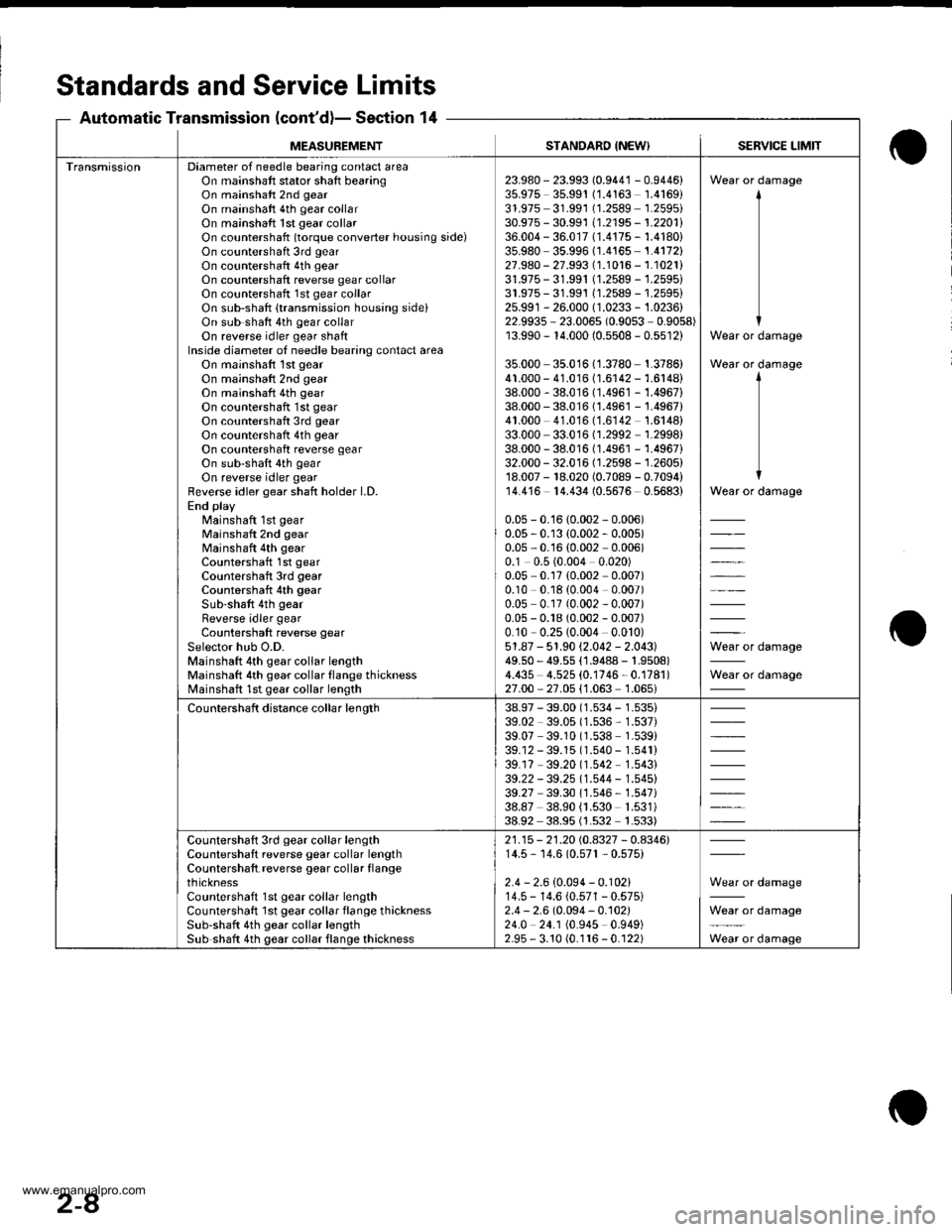

Standards and ServiceLimits

Section 14Automatic Transmission (cont'd)-

MEASUBEMENTSTANDARD {NEW}SERVICE LIMIT

TransmissionDiameter of needle bearing contact areaOn mainshaft stator shaft bearingOn mainshaft 2nd gear

On mainshaft 4th gear collarOn mainshaft 1st gear collarOn countershatt (torque converter housing side)On countershaft 3rd gear

On countershaft 4th gearOn countershaft reverse gear collarOn countershaft 1st gear collarOn sub-shaft {transmission housing sideiOn sub shaft 4th gear collarOn reverse idler gear shaftInside diameter of needle bearing contact areaOn mainshaft 1st gear

On mainshaft 2nd gearOn mainshaft 4th gear

On countershaft 1st gear

On countershaft 3rd gear

On countershaft 4th gear

On countershaft reverse gearOn sub-shaft 4th gear

On reverse idler gearfleverse idler gear shaft holder l.D.End playMainshaft 1st gearMainshaft 2nd gearMainshaft 4th gearCountershaft 1st gearCountershaft 3rd gearCountershaft 4th gear

Sub-shaft 4th gear

Reverse idler gearCountershaft reverse gear

Selector hub O.D.Mainshaft 4th gear collar lengthMainshaft 4th gear collar flange thicknessMainshaft 1st gear collar length

23.980- 23.993 (0.9441 - 0.9446)35.975 35.99'! (1.4163 1.4169)31.975 31.991 (1.2589 1.2595i30.975 - 30.991 11.2195 - 1.2201l'36.004 - 36.017 (1.4175 - 1.4180)35.980 35.996 (1.4165 1.4172)27.980 - 27.993 (1.1016 - 1.1021i31.975- 31.991 (1.2589 -'�j.2595i

31.975- 31.991 (1.2589 - 1.2595)25.991 - 26.000 (1.0233 - 1.0236)22.9935 - 23.006s (0.9053 0.9058)13.990 - r4.000 (0.5508 - 0.5512)

35.000 35.016 (1.3780 1.3786)41.000 - 41.016 (1.6142 - 1.6148)38.000 - 38.016 (1.4961 -'�1.4967)

38.000 - 38.016 (1.496'1 - 1.4967)41.000 41.016 (1.6142 1.6148)33.000 - 33.016 (1.2992 1.2998)38.000 - 38.016 (1.4961 - 1.4967)32.000 - 32.016 (1.2598 - 1.2605)18.007 - 18.020 (0.7089 - 0.7094)14.416 14.434 (0.5676 0.5683)

0.05 - 0.16 {0.002 - 0.006)0.05 - 0.13 (0.002 - 0.005)0.05,0.'16 (0.002 0.006)0.1 0.5 (0.004 0.020)0.05 0.17 {0.002 0.007)0.10 0.18 (0.004 0.007)0.0s 0.17 (0.002 - 0.007)0.05 - 0.18 (0.002 - 0.007)0.10,0.25(0.004 0.010)51.87 - 51.90 (2.042 - 2.043)49.50 - 49.55 (1.9488 - |.9508)4.435 4.525 (0.1746-0.1781)

27.00,27.05 {1.063'1.065i

Wear or damage

Wear or damage

Wear or damage

Wear or damage

il*=lo'. d"'.n"n"

Wear or damage

Countershaft distance collar length38.97 - 39.00 (1.534 - 1.535)39.02 39.05 (1.536, 1.537)39.07 39.10 (1.538 1.539)39.12 - 39.15 (1.540 - 1.541)39.17 - 39.20 (1.542 * 1.543)39.22 - 39.25 11.544 - 1.545)39.27 39.30 1'1.546 - 1.547i38.87 38.90 {1.530 1.531)38.92 38.95 (1.s32 1.533)

Countershaft 3rd gear collar lengthCountershaft reverse gear collar lengthCountershaft reverse gear collar flangethicknessCountershaft 1st gear collar lengthCountershaft lst gear collar flange thicknessSub-shaft 4th gear collar lengthSub shatt 4th gear collar flange thickness

21.15 - 21.20 rc.4327 - 0.4346)14.5, 14.6 (0.57't , 0.575)

2.4 - 2.6 (0.094 - 0.102)14.5 - 14.6 (0.571 - 0.575)2.4 - 2.6 (0.094 - 0.102)24.0 24.1 (0.945 0.949)2.95 - 3.10 (0.116 - 0.122)

Wear or damage

Wear or damage

Wear or damage

2-8

www.emanualpro.com

Page 461 of 1395

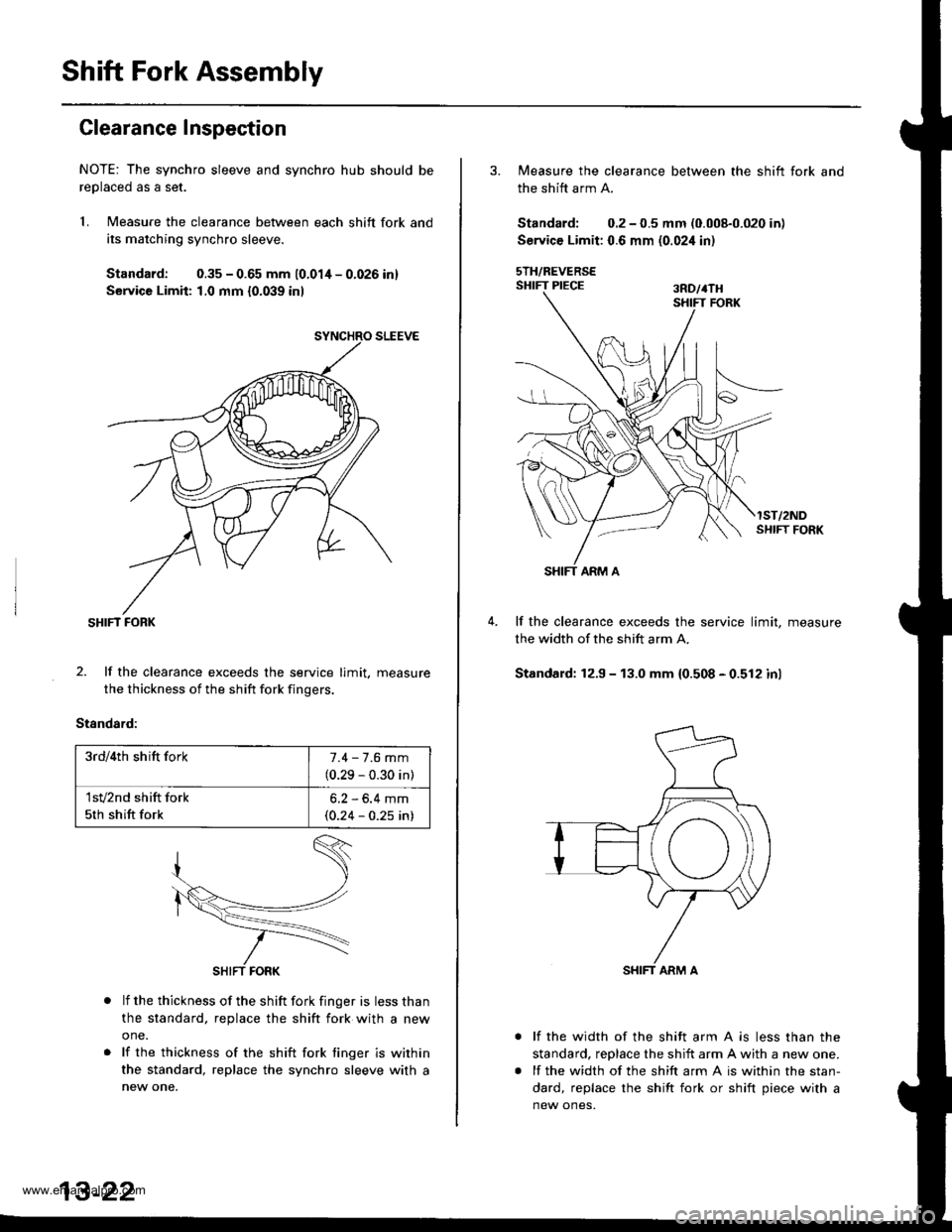

Shift Fork Assembly

Clearance Inspection

NOTE: The synchro sleeve and synchro hub should be

reolaced as a set.

1. Measure the clearance between each shift fork and

its matching synchro sleeve.

Standard: 0.35 - 0.65 mm 10.01/t - 0.026 inl

Service Limit: 1,0 mm {0.039 inl

SHIFT FORK

2. lf the clearance exceeds the service limit. measure

the thickness of the shift fork fingers.

Standard:

lf the thickness of the shift fork finger is less than

the standard, replace the shift fork with a new

one.

lf the thickness of the shift fork tinger is within

the standard, replace the synchro sleeve with a

new one.

3rd/4th shift fork7.4 - 7.6 mm

(0.29 - 0.30 in)

1sv2nd shift fork

5th shift fork

6.2 - 6.4 mm(0.24 - 0.25 in)

3. Measure the clearance between the shift fork and

the shift arm A.

Standard; 0.2 - 0.5 mm (0.008-0.020 in)

Service Limit: 0.6 mm (0.02i1 in)

sTH/REVERSESHIFT PIECE ran,rru

lST/2NDSI{IFT FORK

lf the clearance exceeds the service limit, measure

the width of the shift arm A.

Standard: 12.9 - 13.0 mm 10.508 - 0.512 inl

lf the width of the shift arm A is less than the

standard, reDlace the shift arm A with a new one.

lf the width of the shift arm A is within the stan-

dard, replace the shift fork or shift piece with a

new ones.

www.emanualpro.com

Page 462 of 1395

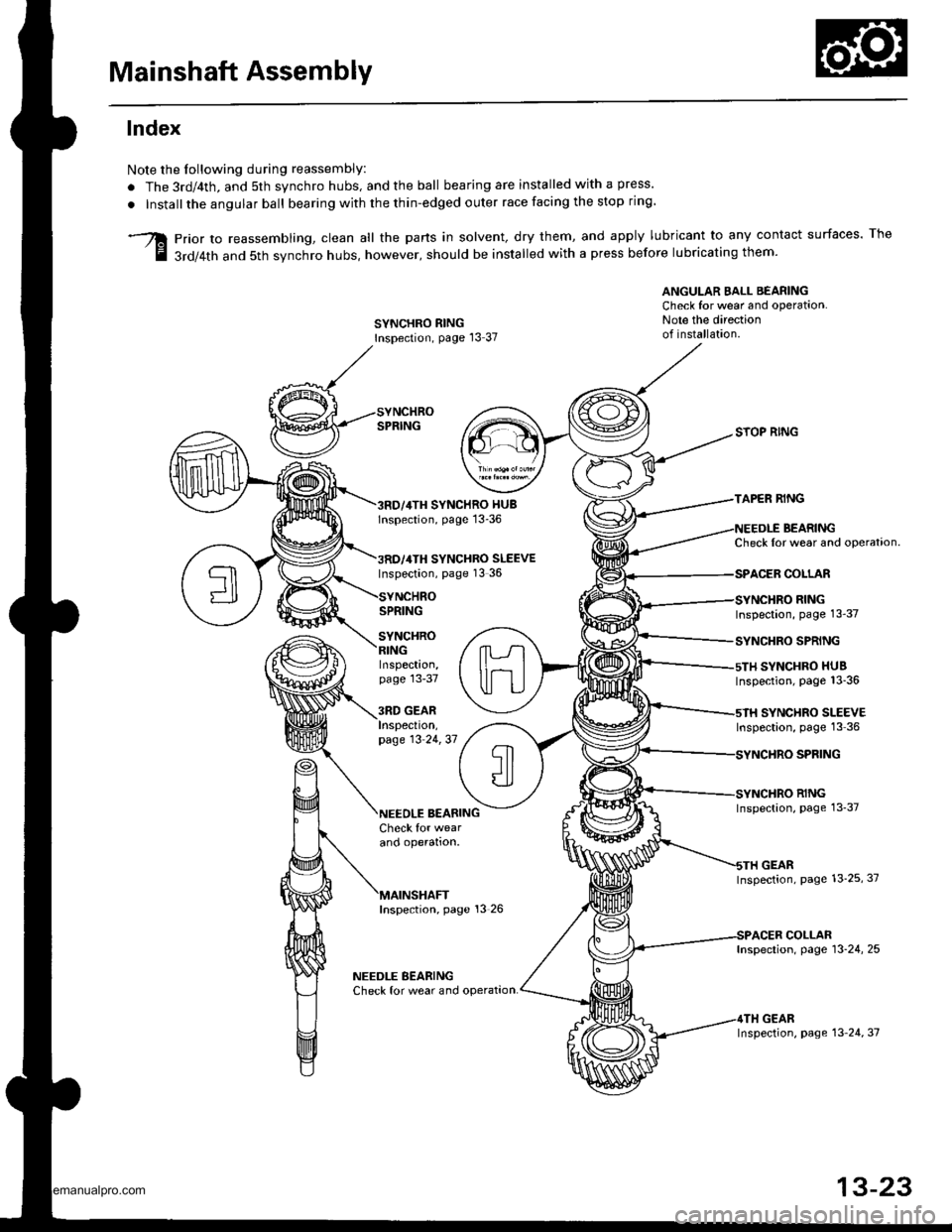

Mainshaft Assembly

lndex

Note the Iollowing during reassembly:

. The 3rd/4th, and 5th synchro hubs, and the ball bearing are installed with a press.

. Installthe angular ball bearing with the thin-edged outer race facing the stop ring

prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact surfaces. The

3rd/4th and 5th svnchro hubs, however, should be installed with a press before lubricating them'

ANGULAR EALL BEARINGCheck for wear and operation.Note the directionof installation.SYNCHRO RINGInspection, page l3 37

SYNCHRO HUBlnspection, page 13-36

SYNCHRO SLEEVEInspection, page 13 36

SPRING

SYNCHRO

SYOP RING

TAPER RING

BEARINGCheck Ior wear and operataon.

COLLAR

RINGInspection, page 13-37

SYNCHRO SPRING

SYNCHRO HUBInspection, page 13_36

SYNCHRO SLEEVEInspection, page 13 36

SPFING

RINGInspection, page 13_37

GEARInspection, page 13_25, 37

COLLARInspection, page 13-24, 25

GEARInspection, page 13 24, 37

Inspection,page 13-37

3RD GEARInspeclton,page 13 24,37

BEARINGCheck for wearano operalton.

Inspection, page 13 26

NEEDLE BEARINGCheck for wear and operat,on.

13-23

www.emanualpro.com

Page 463 of 1395

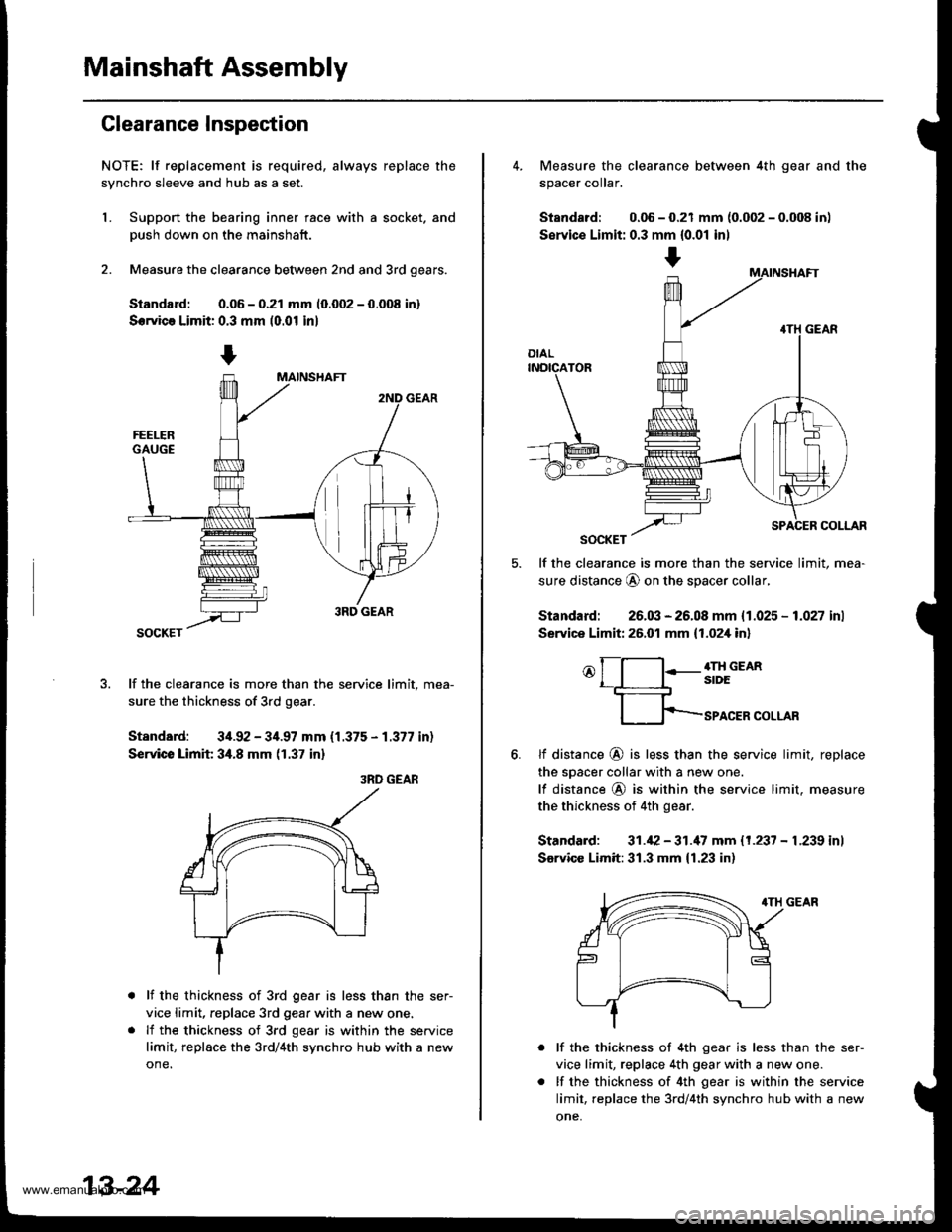

Mainshaft Assembly

Clearance Inspection

NOTE; lf replacement is required, always replace the

synchro sleeve and hub as a set.

L Support the bearing inner race with a socket. and

Dush down on the mainshaft.

2. Measure the clearance between 2nd and 3rd oears.

Siandard: 0.06 - 0.21 mm 10.002 - 0.008 in)

Servica Limit: 0.3 mm (0.01 in)

lf the clearance is more than the service limit, mea-

sure the thickness of 3rd gear.

Standard: 34.92 - 34.97 mm {1.375 - 1.377 in)

Service Limit 34.8 mm (1.37 in)

3RD GEAR

lf the thickness of 3rd gear is less than the ser-

vice limit, replace 3rd gear with a new one.

lf the thickness of 3rd gear is within the service

limit, replace the 3rd/4th synchro hub with a new

one.

13-24

+

4. Measure the clearance between 4th gear and the

spacer coIar,

Standard: 0.06 - 0.21 mm {0.002 - 0.008 in)

Servic€ Limit: 0.3 mm {0.01 inl

lf the clearance is more than the service limit, mea-

sure distance @ on the spacer collar,

Standard: 26.03 - 26.08 mm {1.025 - 1.027 inl

Service Limit: 26.01 mm {1.02,[ in]

o[-l:-g;;em

fp-rro.ERcoLLAR

6.tf distance @ is less than the service limit, replace

the sDacer collar with a new one.

lf distance @ is within the service limit. measure

the thickness of 4th gear.

Standard: 31.42 - 31.'17 mm 11.237 - L239 inl

Sarvicc Limit:31.3 mm {1.23 in)

lf the thickness of 4th gear is less than the ser-

vice limit, replace 4th gear with a new one.

lf the thickness of 4th gear is within the service

limit, replace the 3rd/4th synchro hub with a new

one,

www.emanualpro.com

Page 464 of 1395

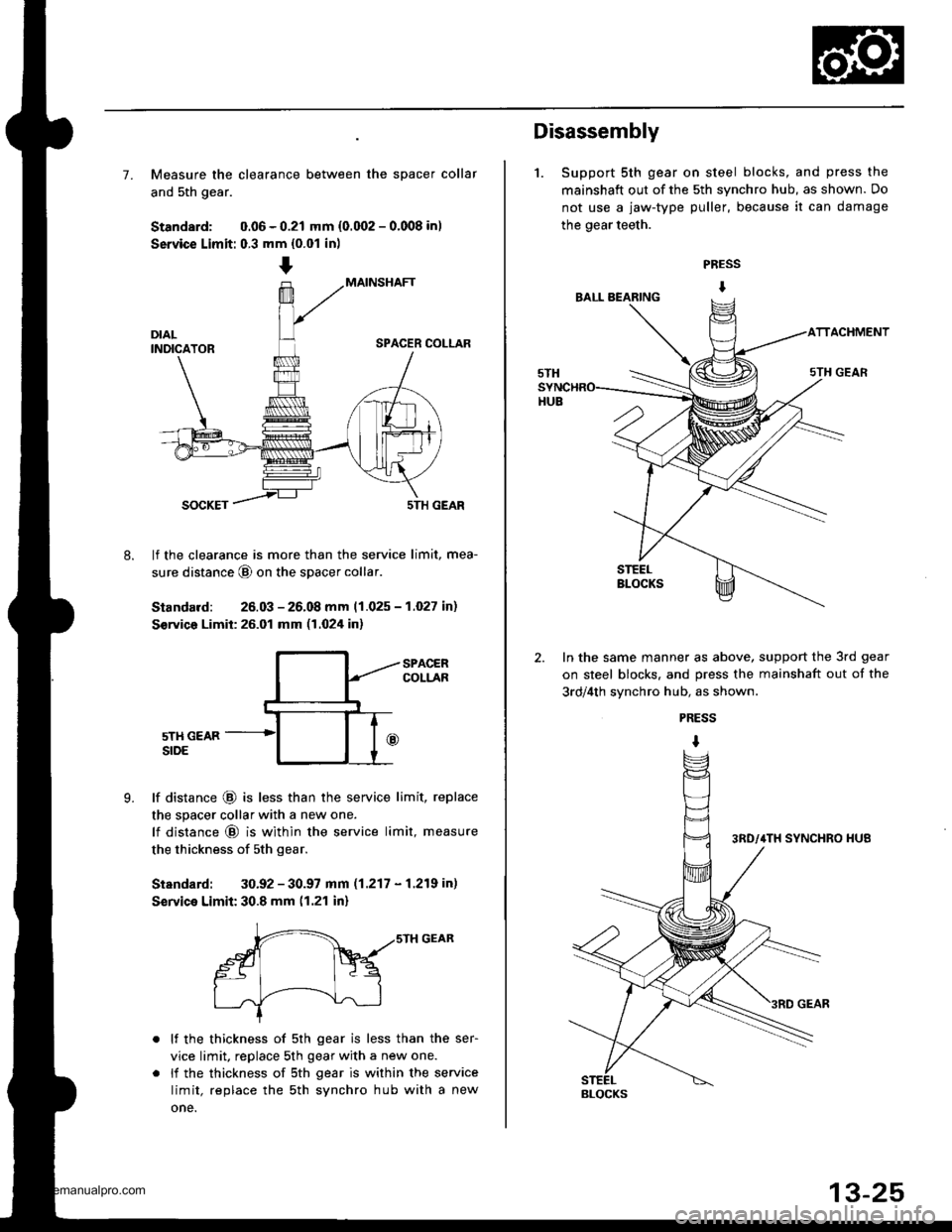

7. Measure the clearance between the spacer collar

and 5th gear.

Standard: 0.06 - 0.21 mm {0.002 - 0.008 in)

Service Limit: 0.3 mm {0.01 in)

MAINSHAFT

SPACER COLLAR

8.

SOCKET5TH GEAR

lf the clearance is more than the service limit, mea-

sure distance @ on the spacer collar

Standard: 26.03 - 26.08 mm 11.025 - 1.027 in)

S€rvico Limit: 26.01 mm (1.024 in)

9.

SPACERCOLLAR

5TH GEARSIDE

lf distance @ is less than the service limit, replace

the spacer collar with a new one.

lf distance @ is within the service limit, measure

the thickness of sth gear.

Standard: 30.92 - 30.97 mm (1.217 - 1.219 in)

Service Limit: 30.8 mm (1.21 in)

r-- ,,srH GEAR

gt Fq

I .J'-----!--\--J-l

lf the thickness of 5th gear is less than the ser-

vice limit, replace 5th gear with a new one.

li the thickness of sth gear is within the service

limit, replace the sth synchro hub with a new

one.

Disassembly

1. Support 5th gear on steel blocks, and press the

mainshaft out of the 5th synchro hub, as shown. Do

not use a jaw-type puller, because it can damage

the gear teeth.

PRESS

I

ACHMENT

In the same manner as above, support the 3rd gear

on steel blocks. and press the mainshaft out of the

3rd/4th svnchro hub, as shown.

PRESS

I

BLOCKS

www.emanualpro.com

Page 466 of 1395

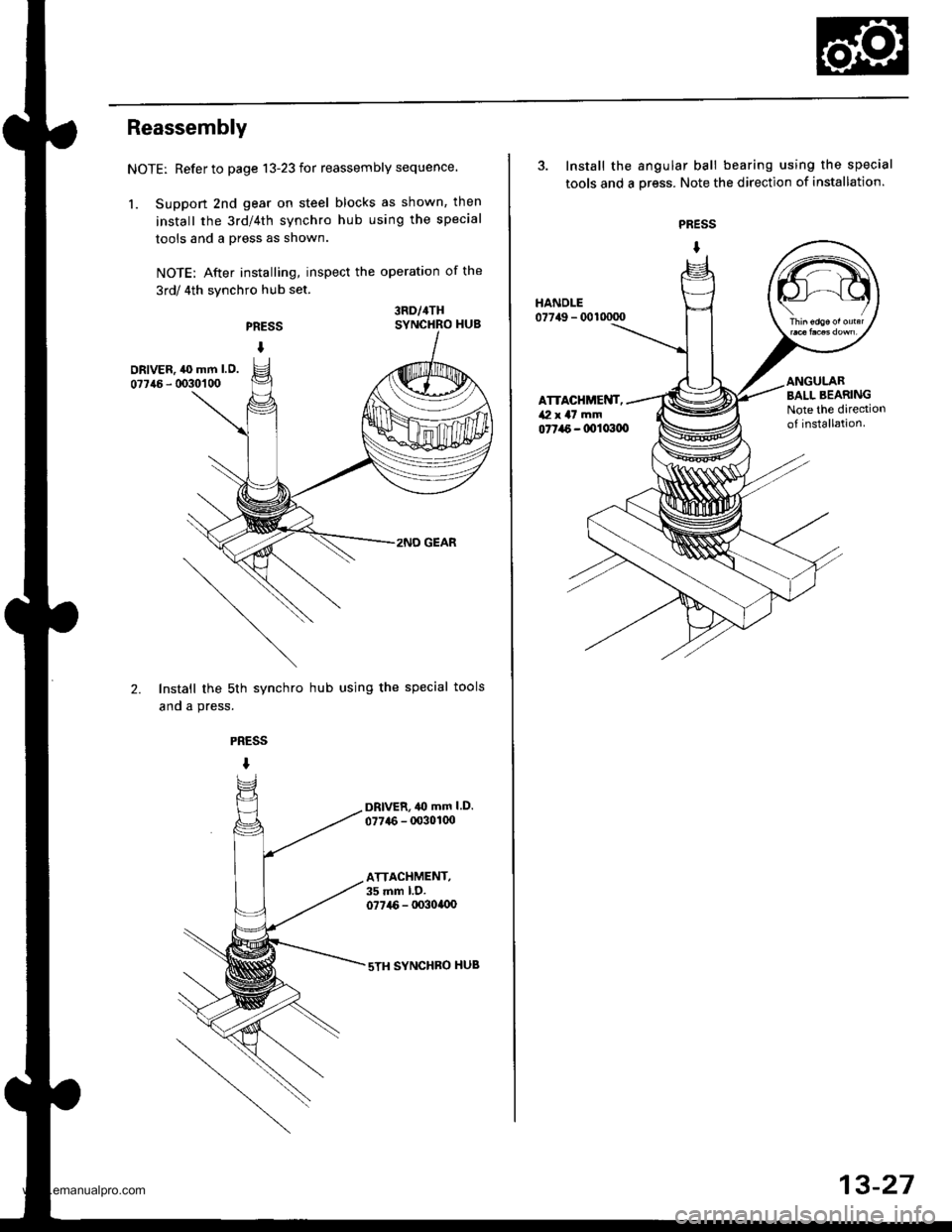

Reassembly

NOTE: Refer to page 13-23 for reassembly sequence.

1. Suppon 2nd gear on steel blocks as shown, then

install the 3rd/4th synchro hub using the special

tools and a press as shown.

NOTE: After installing, inspect the operation of the

3rd/ 4th synchro hub set.

PRESS

I

3RD/4THSYNCHRO HUB

DRIVER, ,l(} mm l.O.

07746 - 0030'�1 00

2.

2NO GEAR

Install the sth synchro hub using the special tools

and a press.

PRESS

I

DRlvER,40 mm l.D.

077{6 - 00301(x)

ATTACHMENT,35 mm l.D.077i16 - lx)3ollx)

sTH SYNCHBO HUB

3. Install the angular ball bearing using the special

tools and a oress. Note the direction of installation.

PRESS

I

077a6 - 0011x100

HANDLE07749 - 0010000

ATTACHMENT,/Vl x a7 mm

BALL BEARINGNote the dirediono{ installation.

13-27

www.emanualpro.com

Page 467 of 1395

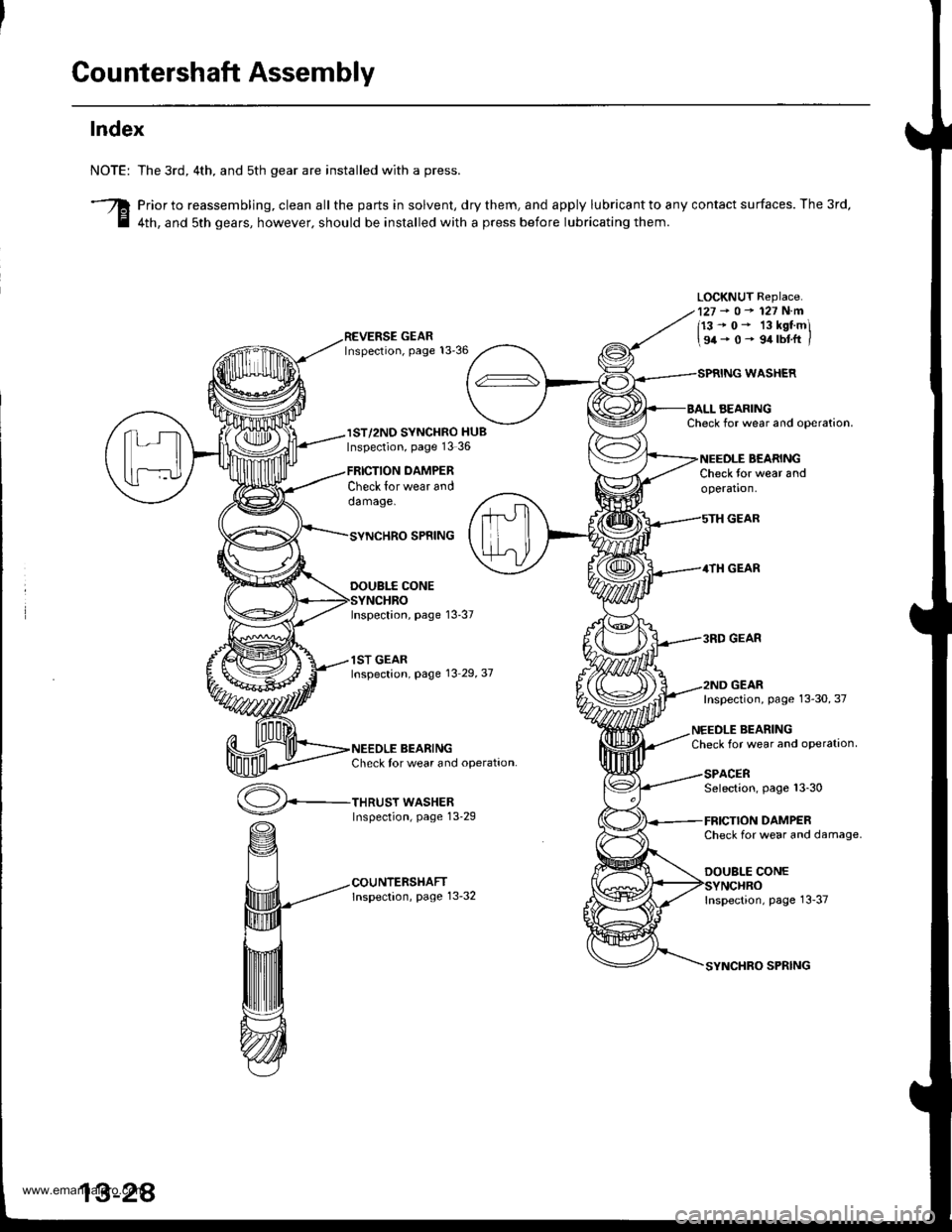

Countershaft Assembly

Index

NOTE:

3

The 3rd, 4th. and sth gear are installed with a press.

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact surfaces. The 3rd,

4th, and sth gears, however. should be installed with a press before lubricating them.

LOCKNUT Replace.127-o-127N.m

113-0- 13kstmi

\94-0- 9.trbtft /

IST/2ND SYNCHRO HUBInspection, page 13 36

Check lor wear anddamage.

THRUST WASHERInspection, page 13-29

DAMPER

WASHER

AEARINGCheck for wear and ooeration.

BEARINGCheck for wear andoperation.

GEAR

4TH GEAR

3RD GEAR

GEAR

SPNING

DOUBI.f CONE

Inspection, page 13-37

1ST GEARInspection, page 13 29,37

BEARINGCheck tor wear and operation.

Inspection, page 13-30, 37

NEEDLE BEARINGCheck for wear and oPeration

SPACERSelection, page 13-30

DAMPERCheck for wear and damage.

DOUBLE CONE

Inspection, page 13-37

SPRING

www.emanualpro.com

Page 468 of 1395

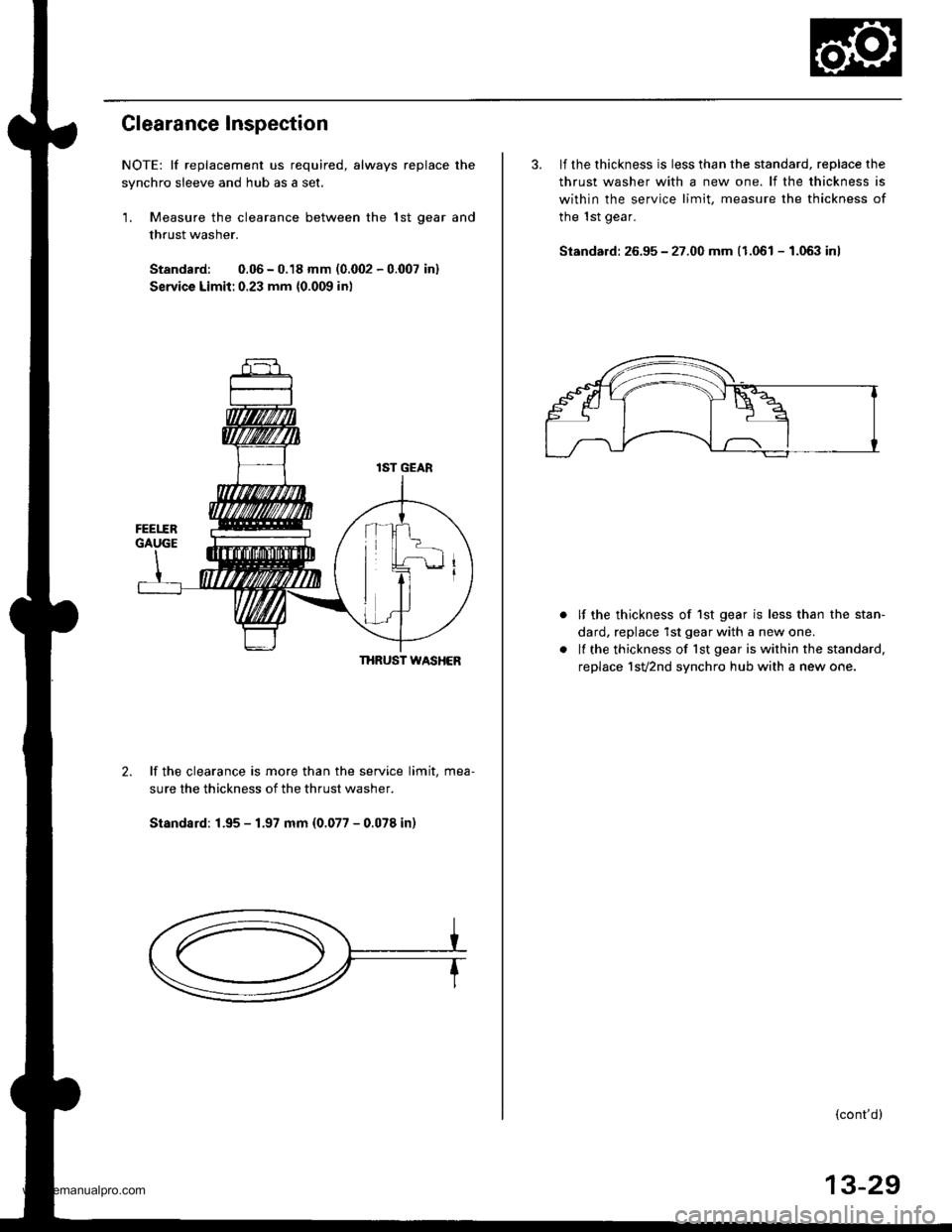

Clearance Inspection

NOTE: lf replacement us required, always replace the

synchro sleeve and hub as a set.

1. Measure the clearance between the lst oear and

thrust washer.

Standard: 0.06 - 0.18 mm (0.@2 - 0.007 in)

Servica Limit:0.23 mm {0.009 in)

THRUST WASHER

2.lf the clearance is more than the service limit, mea-

sure the thickness of the thrust washer.

Standsrd: 1.95 - 1.97 mm (0.077 - 0.078 in)

3. lf the thickness is less than the standard, reDlace the

thrust washer with a new one. lf the thickness is

within the service limit, measure the thickness of

the 1st gear.

Standard: 26.95 - 27.00 mm (1.061 - 1.063 inl

lf the thickness of 1st gear is less than the stan-

dard, replace 1st gear with a new one.

lf the thickness of lst gear is within the standard.

replace 1sv2nd synchro hub with a new one.

{cont'd}

13-29

www.emanualpro.com

Page 469 of 1395

Countershaft Assembly

Clearance Inspection (cont'dl

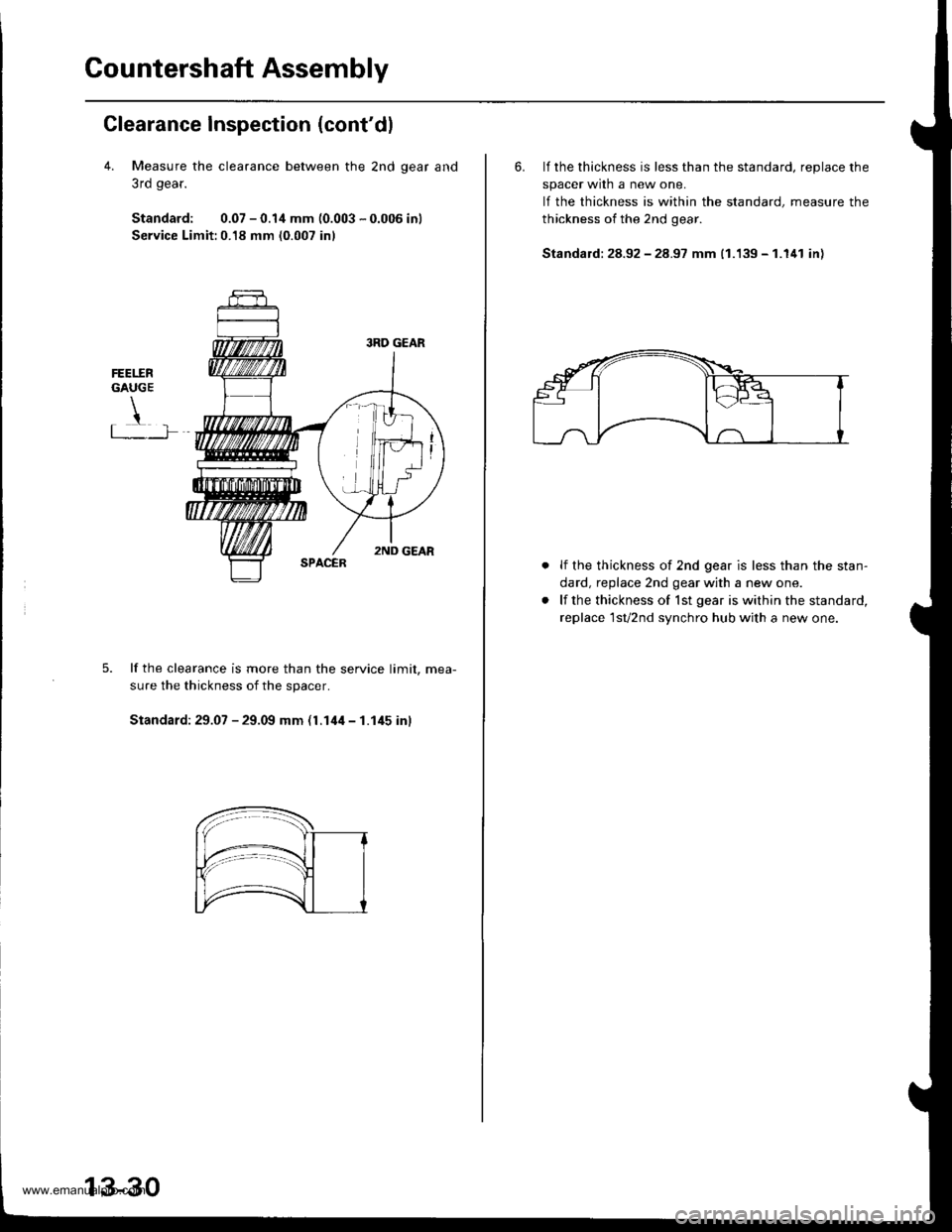

4. Measure the clearance between the 2nd qear and

3rd gear.

Standard: 0.07 - 0.1,1 mm (0.003 - 0.006 inl

Service Limit:0.18 mm (0.007 inl

FEET.ERGAUGE

!t .�-]�

lf the clearance is more than the service limit. mea-

sure the thickness of the spacer.

Standard: 29.07 - 29.09 mm (l.14il - 1.145 inl

13-30

6. lf the thickness is less than the standard, reDlace the

spacer wrln a new one.

lf the thickness is within the standard, measure the

thickness of the 2nd gear.

Standald: 28.92 - 28.97 mm (1.139 - 1.141 in)

lf the thickness of 2nd gear is less than the stan-

dard, replace 2nd gear with a new one.

lf the thickness of lst gear is within the standard,

replace 1sv2nd synchro hub with a new one.

www.emanualpro.com

Page 472 of 1395

Reassembly

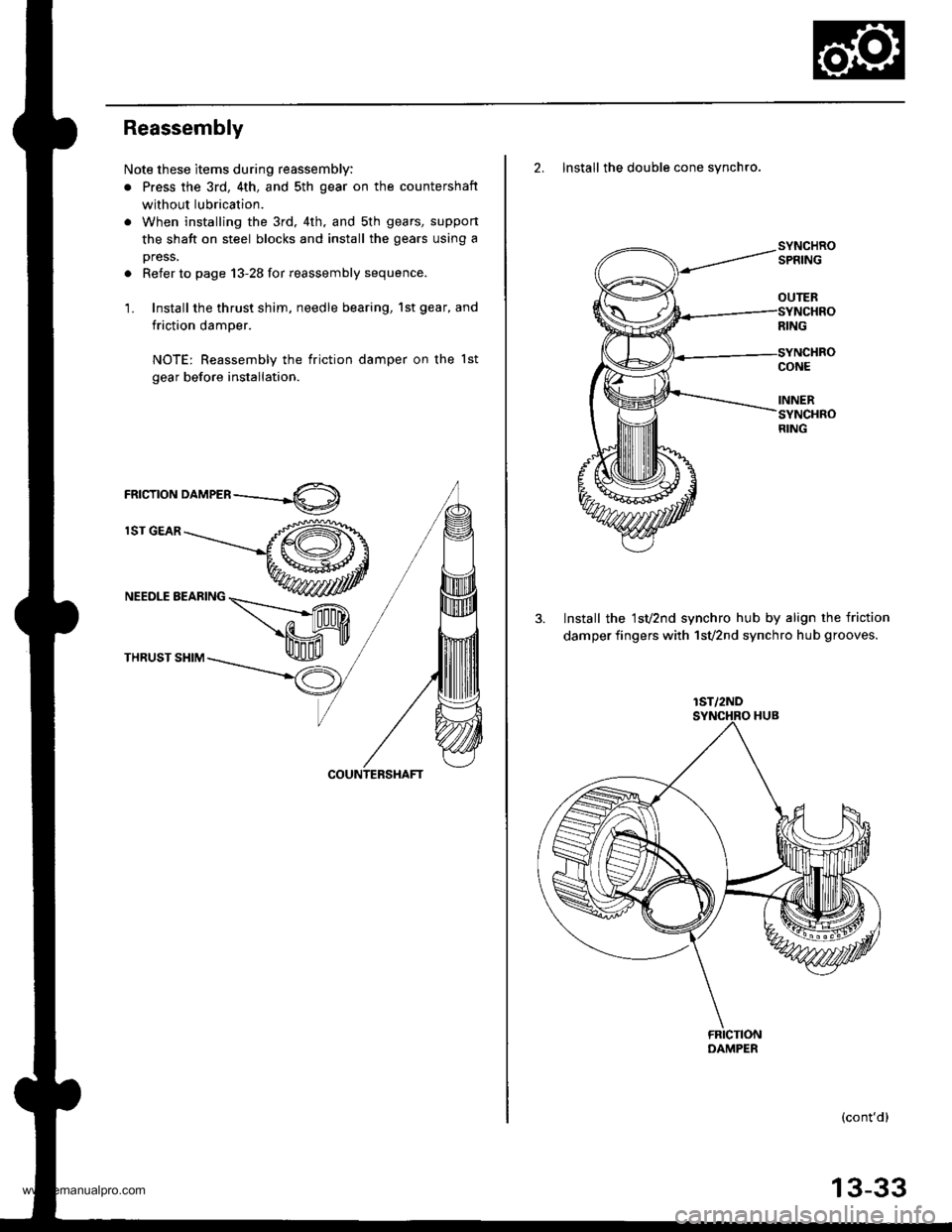

Note these items during reassembly:

. Press the 3rd, 4th, and sth gear on the countershaft

without lubrication.

. When installing the 3rd, 4th. and sth gears, suppon

the shaft on steel blocks and install the gears using a

press.

. Refer to page 13-28 for reassembly sequence.

1. Install the thrust shim, needle bearing, 1st gear, and

friction damper.

NOTE: Reassembly the friction damper on the lst

gear before installation.

rnrcrroru orn,leen ----.-4O)

lST GEAR

NEEDLE BEARING

THRUST SHIM

2. Install the double cone synchro.

3. Install the 1sv2nd synchro hub by align the friction

damper fingers with 1svznd synchro hub grooves.

(cont'd)

OUTER

lST/2ND

13-33

www.emanualpro.com