Light on steering wheel HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 38 of 1395

--

-

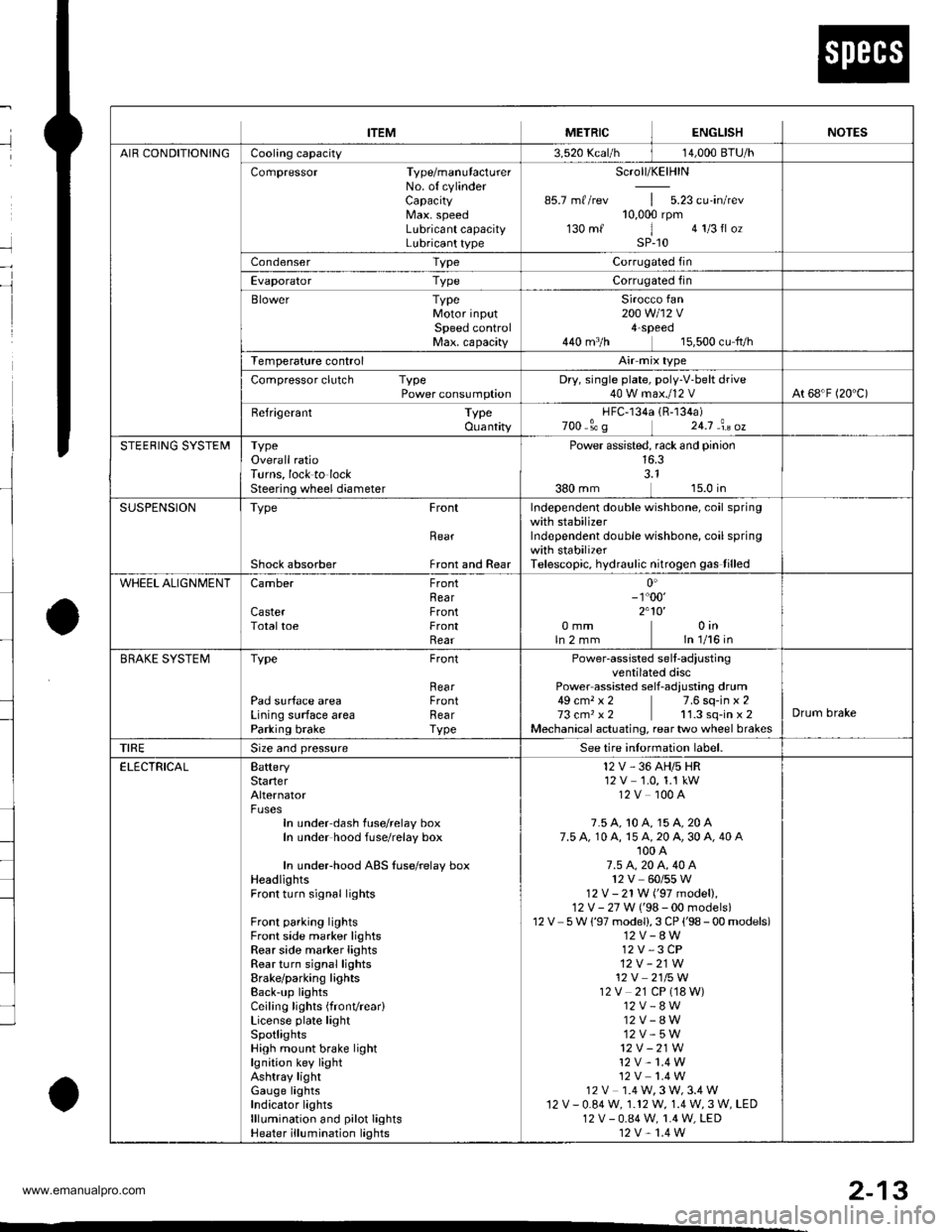

METRICITEMENGLISHNOTES

AIR CONDITIONINGCooling capacity3,520 Kcal/h j 14,000 BTU/h

Compressor Type/manutacturerNo. of cylinderCaPacityMax. speedLubricant capacityLubricant type

Scroll/KElHlN

85.7 mf/rev | 5.23 cu'in/rev10,000 rpm130mf 1 algIlozsP-10

Condenser TypeCorrugated fin

Evaporator TypeCorrugated fin

Blower TypeMotor inputSpeed controlMax. capacity

Sirocco fan200 w 112 v4-Speeo440 m3/h 15,500 cu fvh

Temperature control

Compressor clutch TypePower consumptionDry, single plate, poly-V-belt drive40 W max./12 VAt 68'F (20 C)

Befrigerant TypeOuantity

HFC-134a 1R-134a)zoo o' g 24j an oz

STEERING SYSTEMTypeOverall ratioTurns, lock to lockSteering wheel diameter

Power assisted, rack and pinion

SUSPENSIONType Front

Bear

Shock absorber Front and Rear

Independent double wishbone, coil springwith stabilizerIndependent double wishbone, coil springwith stabilizerTelescopic, hydraulic nitrogen gas tilled

WHEEL ALIGNMENTCamber

CasterTotaltoe

FronthearFrontFrontRear0inln 1/16 in0mmln2mm

0'- r"00'2.10'�

BRAKE SYSTEMTvpe

Pad surface areaLining surface areaParking brake

Front

RearFrontRearTvpe

Power-assisted selt-ad,ustingventilated discPower assisted self-adiusting drum49 cm, x 2 7.6 sq-in x 273 cm, x2 11.3 sq-in x 2Mechanical actuating, rear two wheel brakes

Drum brake

TIRESize and pressureSee tire inlormation label.

ELECTRICALBafteryStarterAlternator

In under-dash fuse/relay boxIn under hood fuse/relay box

In underhood ABS fuse/relay boxHeadlightsFront turn signal lights

Front parking lightsFront side marker lightsRear side marker lightsRear turn signal lightsErake/parking lightsBack-up lightsCeiling lights {fronvrear)License plate lightSpotlightsHigh mount brake lightlgnition key lightAshtray lightGauge lightsIndicator lightslllLrmination and pilot IightsHeater illumination lights

12 V, 36 AH/s HR12V 1.0, 1.1 kW12V 100A

7.5 A, 10 A, 15 A, 20 A7.5 A, 10 A, 15 A, 20 A, 30 A, 40 A'100 A7.5 4,20 A. 40 A12V 60/55 W12 V- 21 W ('97 model),12 V - 27 W ('98-00 models)12V 5 W {'97 model),3 CP ('98 - 00 models)12V-8W12 V,3 CP12V-21W12 V 2115 W12V 21 CP (18 W)12V-8W12V-8W12V-5W12V -21W

12 V- 1.4 W12V 1.4 W12 V 1.4 W,3 W,3.4 W12V-0.84W, 1.12 W, 1.4 W,3 W, LED12 V - 0.84 W, 1.4 W, LED12 V,1.4 W

2-13

www.emanualpro.com

Page 91 of 1395

n-

n-

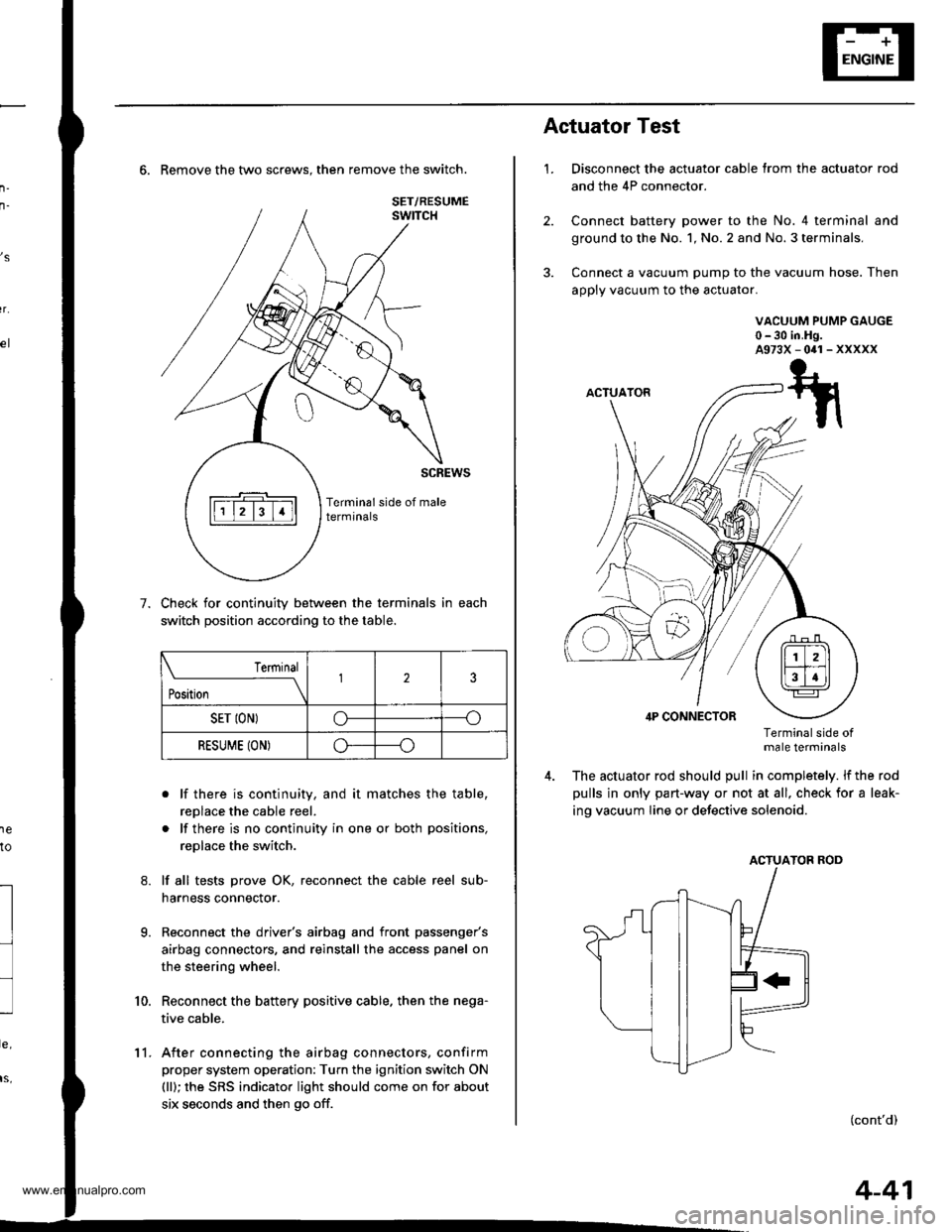

6. Remove the two screws. then remove the switch.

Check for continuity between the terminals in each

switch position according to the table.

. lf there is continuity, and it matches the table,

replace the cable reel.

. lf there is no continuity in one or both positions,

replace the switch.

lf all tests prove OK, reconnect the cable reel sub-

harness connector.

Reconnect the driver's airbag and front passenger's

airbag connectors, and reinstall the access panel on

the steering wheel.

Reconnect the battery positive cable. then the nega-

tive cable.

After connecting the airbag connectors, confirm

proper system operation: Turn the ignition switch ON

(ll); the SRS indicator light should come on for about

six seconds and then go off.

,s

r.

1e

to

7.

l

9.

10.

SET/RESUME

Terminal

t*,r*

-__\l23

SET ION)o----o

RESUME (ON)o----o

11.

4-41

1.

Actuator Test

Disconnect the actuator cable trom the actuator rod

and the 4P connector.

Connect battery power to the No. 4 terminal and

ground to the No. 1, No. 2 and No. 3 terminals,

Connect a vacuum pump to the vacuum hose. Then

apply vacuum to the actuator.

VACUUM PUMP GAUGE0-30 in.Hg.A973X-041-XXXXX

Terminalside otmale terminals

The actuator rod should pull in completely. lf the rod

pulls in only part-way or not at all, check for a leak-

ing vacuum Iine or defective solenoid.

ACTUATOB ROD

(cont'd)

www.emanualpro.com

Page 851 of 1395

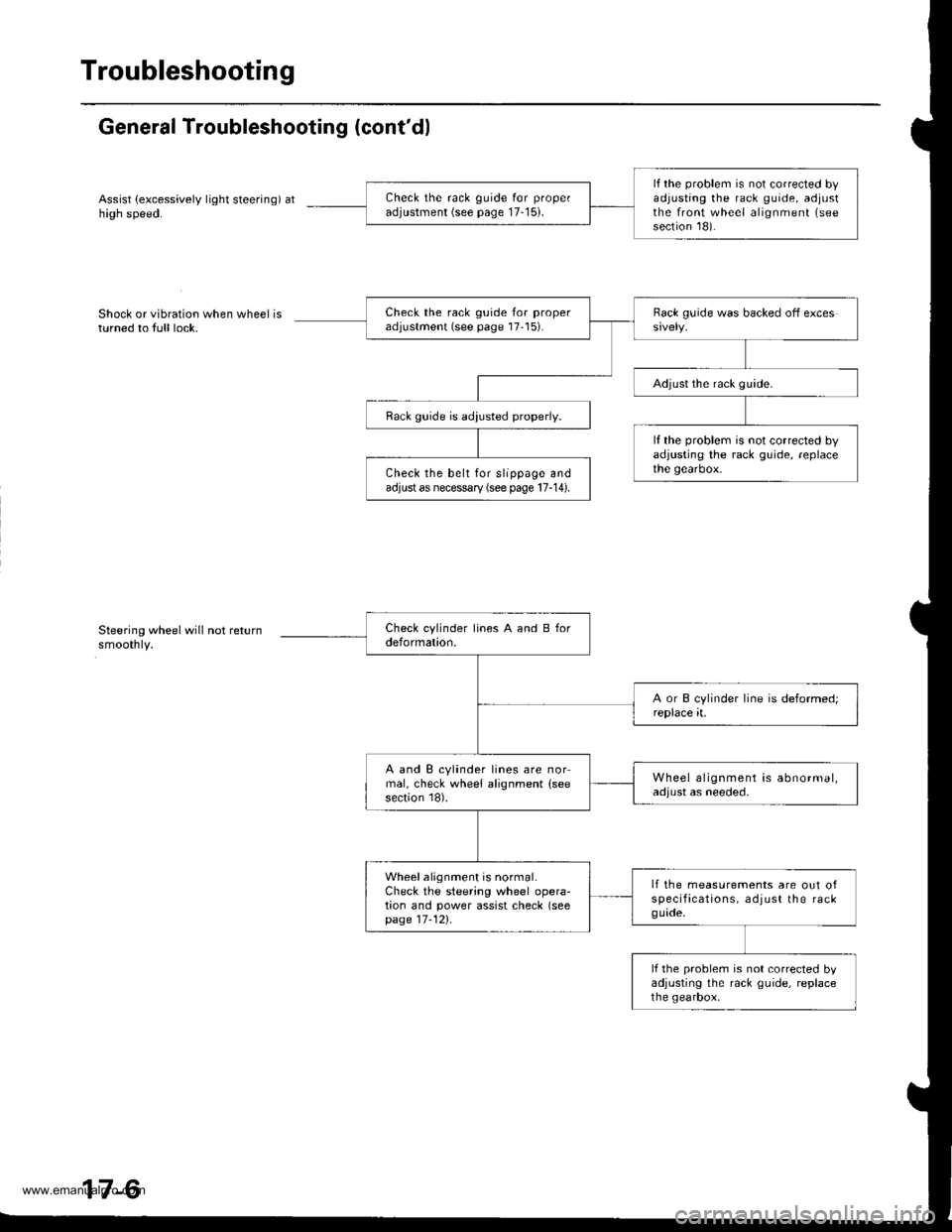

Troubleshooting

General Troubleshooting (cont'dl

Assist (excessively light steering) athigh speed.

Shock or vibration when wheel isturned to full lock.

Steering wheel will not returnsmoothly.

lf the problem is not corrected byadjusting the rack guide, adjustthe front wheel alignment (see

section 18).

Check the rack guide for proper

adjustment (see page 17-15).

Check the rack guide for properadjustment (see page 17'15).

Adjust the rack guide.

Rack guide is adiusted properly.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox.Check the belt for slippage andadjust as necessary (see page 17-14).

A and B cylinder lines are normal, check wheel alignment (see

section 18).

Wheel alignment is abnormal,adjust as needed.

Wheel alignment is normal.Check the steering wheel opera-tion and power assist check (seepage 17-121.

lf the measurements are out ofspecifacations, adjust the rackguade.

lf the problem is not corrected byadjusting the rack guide, replacethe gearbox,

www.emanualpro.com

Page 1184 of 1395

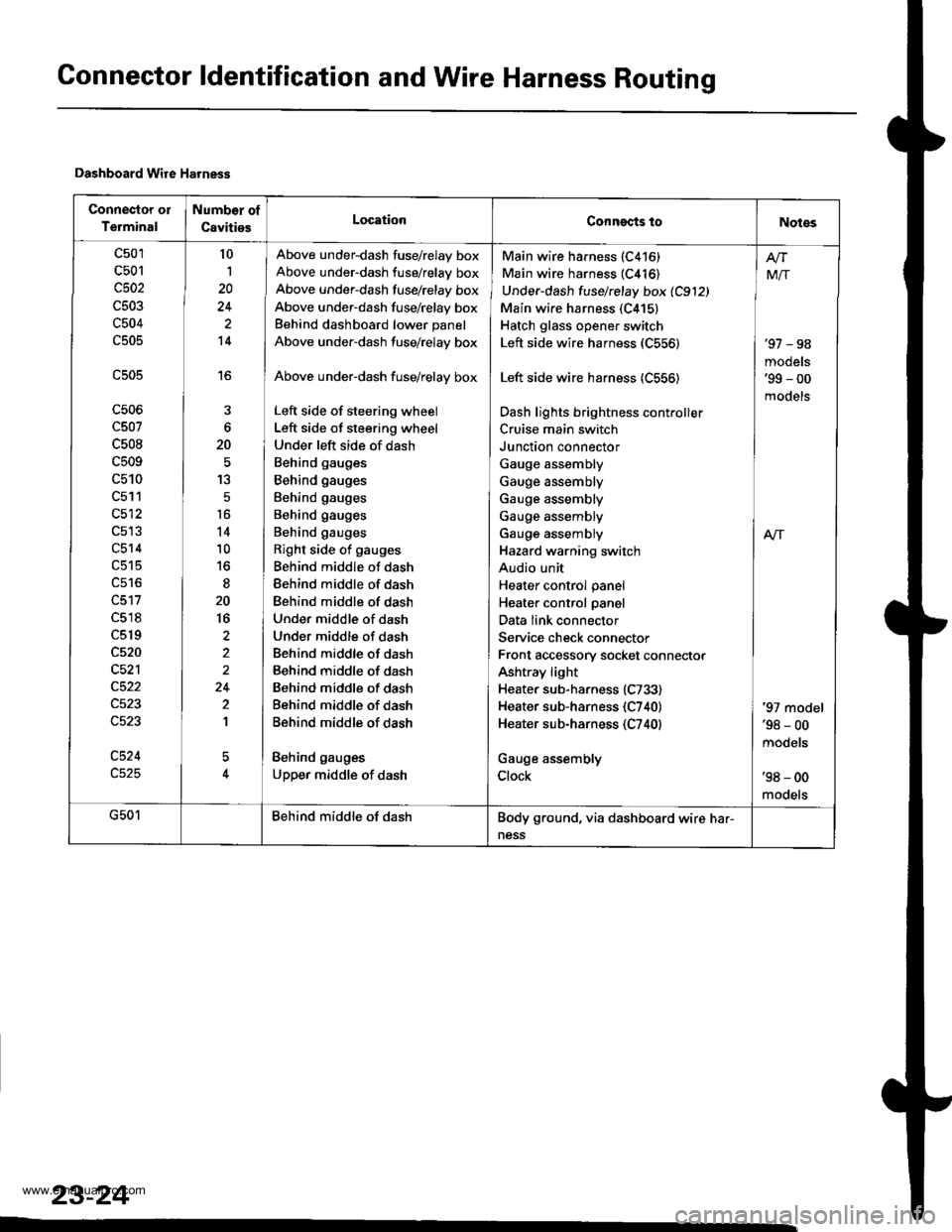

Connector ldentification and Wire Harness Routing

Dashboard Wire Harness

Connector ol

Terminal

Numb€r of

CavitiesLocationConngcts toNotes

c501

c501

c502

c503

c504

c505

c506

c507

c508

c509

c510

c511

c512

c514

c518

c519

c520

c521

c524

10

1

20

14

16

6

20

13

5

t6

14

10

to

20

16

2

24

2

1

5

Above under-dash fuse/relay box

Above under-dash fuse/relay box

Above under-dash fusehelay box

Above under-dash fuse/relay box

Behind dashboard lower panel

Above under-dash fuse/relay box

Above under-dash fuse/relay box

Left side of steering wheel

Left side of steering wheel

Under left side of dash

Behind gauges

Behind gauges

Behind gauges

Behind gauges

Behind gauges

Right side of gauges

Behind middle of dash

Behind middle of dash

Behind middle of dash

Under middle of dash

Under middle of dash

Behind middle of dash

Behind middle of dash

Behind middle of dash

Behind middle of dash

Behind middle of dash

Behind gauges

Upper middle of dash

Main wire harness (C416)

Main wire harness (C416)

Under-dash fuse/relay box 1C912)

Main wire harness (C415)

Hatch glass opener switch

Left side wire harness (C556)

Left side wire harness (C556)

Dash lights brightness cont.oller

Cruise main switch

Junction connector

Gauge assembly

Gauge assembly

Gauge assembly

Gauge assembly

Gauge assembly

Hazard warning switch

Audio unit

Heater control panel

Heater control panel

Data link connector

Service check connector

Front accessory socket connector

Ashtray light

Heater sub-harness (C733)

Heater sub-harness {C740}

Heater sub-harness (C740)

Gauge assembly

Clock

'97 - 98

models'99 - 00

models

Mir

A/r

'97 model'98 - 00

mooets

'98 - 00

models

G501Behind middle of dashBody ground, via dashboard wire har-

ness

23-24

www.emanualpro.com

Page 1186 of 1395

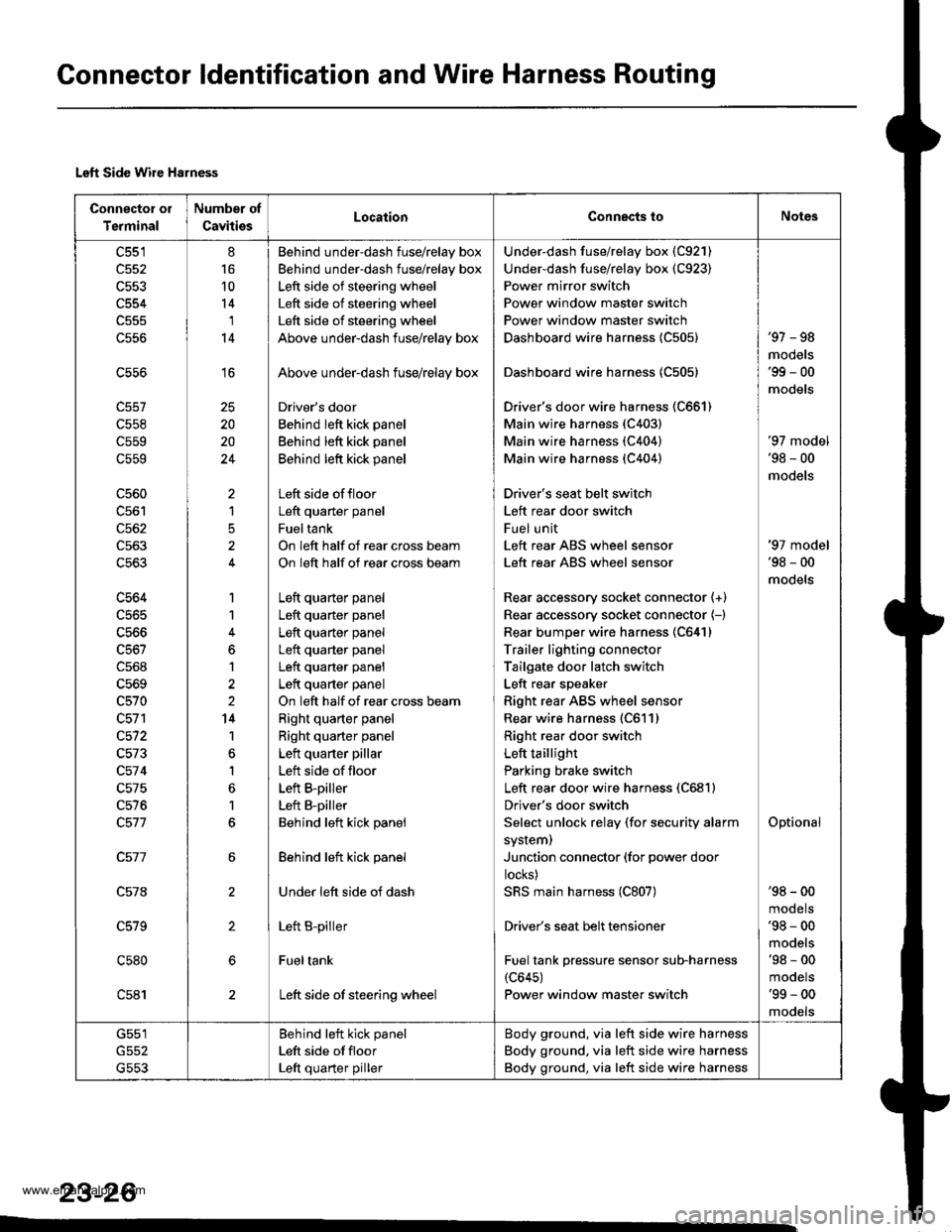

Connector ldentification and Wire Harness Routing

Left Side Wire Harness

Connector oI

Terminal

Number of

CavitiesLocaiionConnects toNot6s

c551

c552

c554

c556

c558

c559

c559

c560

c562

c563

c563

c564

c565

c566

c568

c569

c570

c572

c573

c57 4

c575

c576

c578

c579

c580

c581

8

16

10

14'I

14

16

20

20

24

)

1

5

1

1

6

1

2

14

1

1

6

1

6

Behind under-dash fuse/relay box

Behind under-dash fuse/relay box

Left side of steering wheel

Left side of steering wheel

Left side of steering wheel

Above under-dash fuse/relay box

Above under-dash fuse/relay box

Driver's door

Behind left kick panel

Behind left kick panel

Behind left kick panel

Left side offloor

Left quaner panel

Fueltank

On left half of rear cross beam

On left half of rear cross beam

Left quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

Left quarter panel

On left half of rear cross beam

Right quarter panel

Right quarter panel

Left quarter pillar

Left side of floor

Left B-piller

Left B-piller

Behind left kick panel

Behind left kick panel

Under left side of dash

Left B-piller

Fueltank

Left side of steering wheel

Under-dash fuse/relay box (C921)

Under-dash fuse/relay box (C923)

Power mirror switch

Power window master switch

Power window master switch

Dashboard wire harness {C505)

Dashboard wire harness 1C505)

Driver's door wire harness (C661)

Main wire harness (C403)

Main wire harness (C404)

Main wire harness (C404)

Driver's seat belt switch

Left rear door switch

Fuel unit

Left rear ABS wheel sensor

Left rear ABS wheel sensor

Rear accessory socket connector {+}

Rear accessory socket connector (-)

Rear bumper wire harness 1C641)

Trailer lighting connector

Tailgate door latch switch

Left rear speaker

Right rear ABS wheel sensor

Rear wire harness (C611)

Right rea. door switch

Left taillight

Parking brake switch

Left rear door wire harness (C681)

Driver's door switch

Select unlock relay (for security alarm

system)

Junction connector (for power door

locks)

SRS main harness (C807)

Driver's seat belt tensioner

Fuel tank pressure sensor sub-harness(c645)

Power window master switch

'97 - 98

mooets'99 - 00

models

'97 model'98 - 00

models

Optional

'97 model'98 - 00

models

'98 - 00

mooets'98 - 00

models'98 - 00

mooets'99 - 00

mooets

G551

G553

Behind left kick panel

Left side ot floor

Left quarter piller

Body ground, via left side wire harness

Body ground, via left side wire harness

Body ground, via left side wire harness

23-26

www.emanualpro.com

Page 1266 of 1395

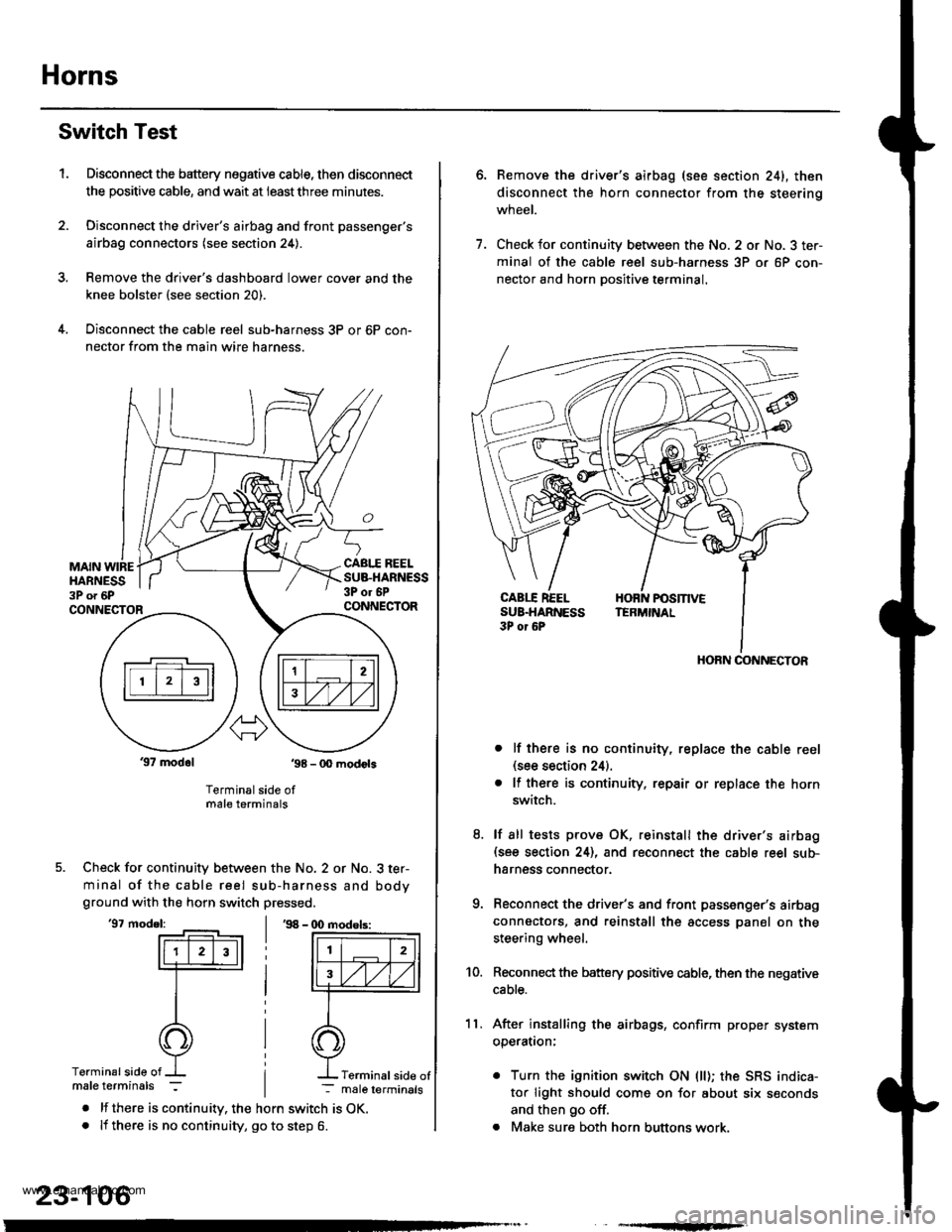

Horns

Switch Test

Disconnect the battery negative cable, then disconnect

the positive cable, and wait at ieastthree minutes.

Disconnect the driver's airbag and front passenger's

airbag connectors (see section 24).

Remove the drive.'s dashboard lower cover and the

knee bolster (see section 20).

Disconnect the cable reel sub-harness 3P or 6P con-

nector from the main wire harness.

1.

MAIN WIREHARNESS3P o. 6P

CABI.I REELSUB.HARNESS3P or 6PCONNECTORCONNECTOR

37 modol ,98 - 0O modots

Terminal side ofmale terminals

Check for continuity between the No. 2 or No. 3 ter-

minal of the cable reel sub-harness and bodyground with the horn switch pressed.

'97 model:'98 - (X) modols:

Terminalside of

. lf there is continuity. the horn switch is OK.. lf there is no continuity, go to step 6.

23-106

Terminal side of

6.Remove the driver's airbag (see section 241, then

disconnect the horn connector from the steerinq

wneet.

Check for continuity between the No. 2 or No. 3 ter-

minal of the cable reel sub-harness 3P or 6P con-

nector and horn Dositive terminal.

lf there is no continuity, replace the cable reel(see section 24).

lf there is continuity. repair or replace the horn

switch.

lf sll tests prove OK, reinstall the driver's airbag(see section 24), and reconnect the cable reel sub-

harness connector.

Reconnect the driver's and front passenger's airbag

connectors, and reinstall the access panel on the

steering wheel.

Reconnect the battery positive cable, then the negative

cable.

After installing the airbags, confirm proper system

operatron:

. Turn the ignition switch ON (ll); the SRS indica-

tor light should come on for about six seconds

and then go off.

. Make sure both horn buttons work.

7.

11.

8.

9.

10.

HORN CONNECTOR

www.emanualpro.com

Page 1316 of 1395

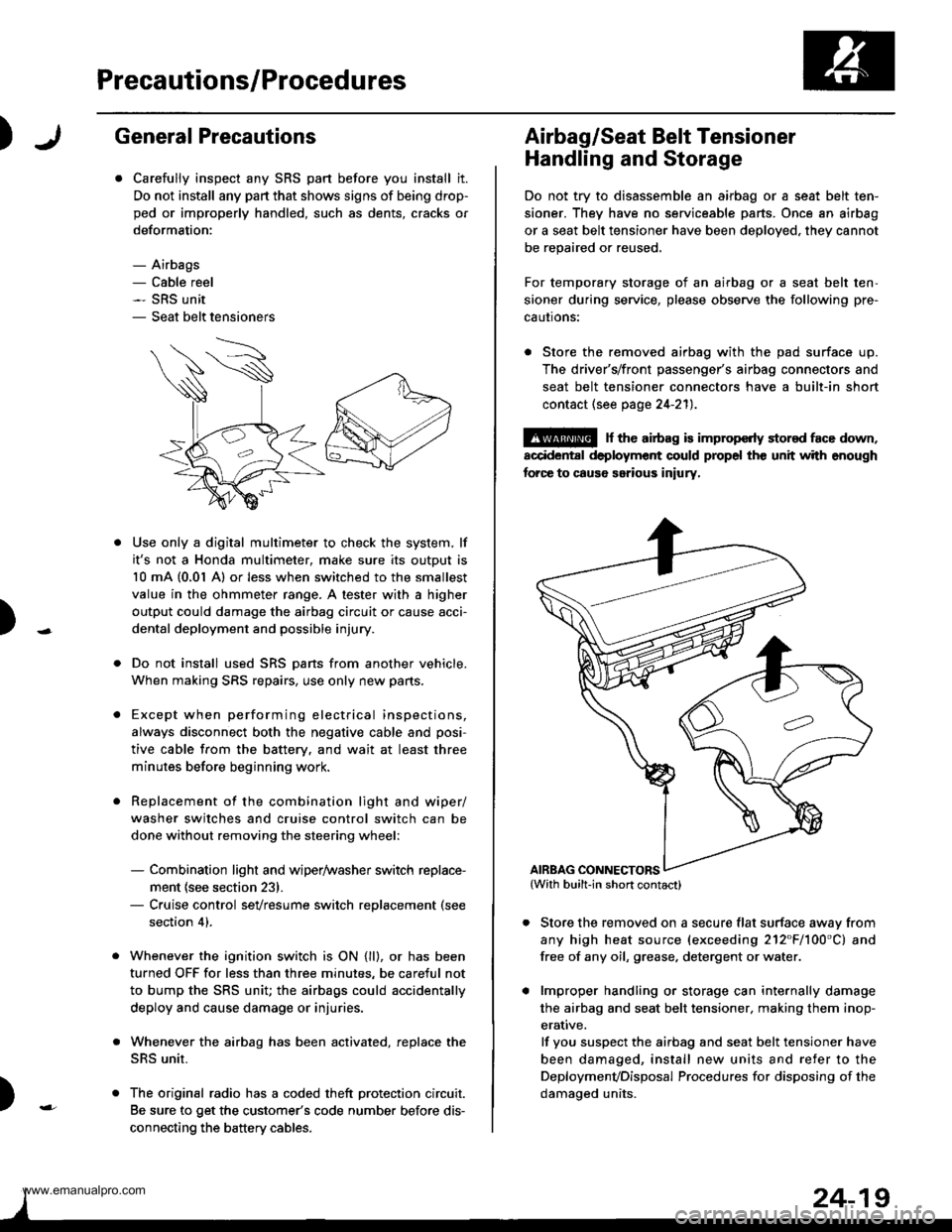

Precautions/Procedures

)General Precautions

Carefully inspect any SRS part before you install it.

Do not install any part that shows signs of being drop-

ped or improperly handled, such as dents, cracks or

deformation:

- Airbags- Cable reel- SRS unit- Seat belt tensioners

N

)-

Use only a digital multimeter to check the system, lf

it's not a Honda multimeter, make sure its output is

10 mA (0,01 A) or less when switched to the smallest

value in the ohmmeter range. A tester with a higher

output could damage the airbag circuit or cause acci-

dental deployment and possible injury.

Do not install used SRS Dans from another vehicle,

When making SRS repairs, use only new pans.

Except when performing electrical inspections,

always disconnect both the negative cable and posi-

tive cable from the batterv. and wait at least three

minutes before beginning work.

Replacement of the combination light and wiper/

washer switches and cruise control switch can be

done without removing the steering wheel:

- Combination light and wiper/washer switch replace-

ment {see section 231.- Cruise control sevresume switch replacement (see

section 41.

Whenever the ignition switch is ON {ll}, or has been

turned OFF for less than three minutes, be careful not

to bump the SRS unit; the airbags could accidentally

deploy and cause damage or injuries.

Whenever the airbag has been activated, replace the

SRS unit.

The original radio has a coded theft protection circuit.

Be sure to get the customer's code number before dis-

connecting the battery cables.

)

Airbag/Seat Belt Tensioner

Handling and Storage

Do not try to disassemble an airbag or a seat belt ten-

sioner. They have no serviceable parts. Once an airbag

or a seat belt tensioner have been deployed. they cannot

be repaired or reused.

For temporary storage of an airbag or a seat belt ten-

sioner during service, please observe the following pre-

cautons:

. Store the removed airbag with the pad surface up.

The driver's/front passenger's airbag connectors and

seat belt tensioner connectors have a built-in short

contact (see page 24-211.

@ r th€ airb.g is impropcrty stor€d face down,

accidental deployment could propel the unit with enough

forc€ to caus6 serious iniury,

Store the removed on a secure flat surface awav from

any high heat source (exceeding 212"F/100'C) and

free of any oil, grease. detergent or water.

lmproper handling or storage can internally damage

the airbag and seat belt tensioner. making them inop-

erative.

lf you suspect the airbag and seat belt tensioner have

been damaged, install new units and refer to the

Deploymenvoisposal Procedures for disposing of the

damaoed units.

AIRBAG CONNECTORS

www.emanualpro.com

Page 1322 of 1395

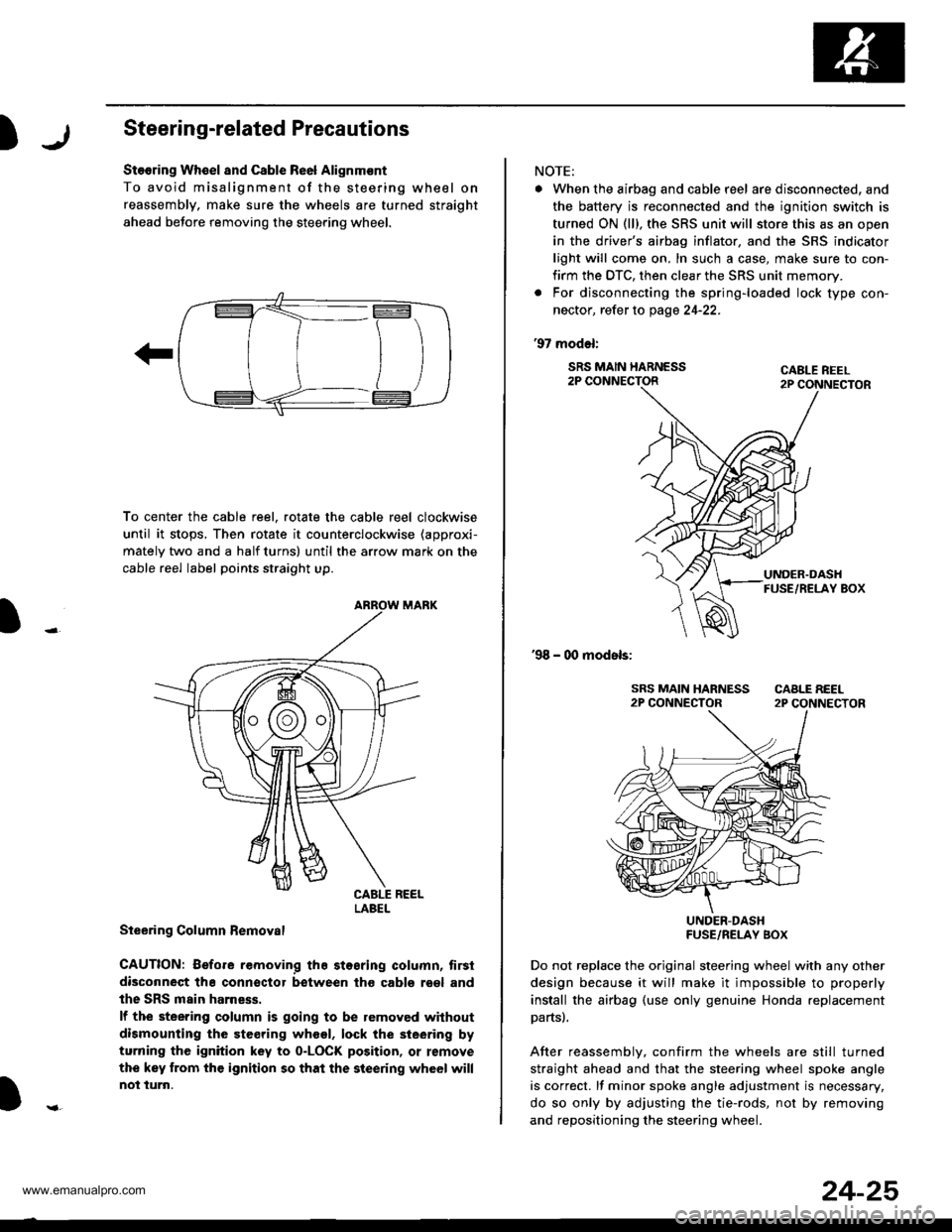

)Steering-related Precautions

Stooring Wh€el and Csble Re6l Alignm€nt

To avoid misalignment of the steering wheel on

reassembly, make sure the wheels are turned straight

ahead beJore removing the steering wheel.

To center the cable reel, rotate the cable reel clockwise

until it stops, Then rotate it counterclockwise (approxi-

mately two and a half turns) until the arrow mark on the

cable reel label points straight up.

Steering Column Bemoval

CAUTION: Before removing the stosring column, tirsi

disconneqt tha connsctor between tho cabls roel and

the SRS main harness.

lf the steering column is going to be removed without

dismounting the steering wheel, lock the sieering by

turning the ignition key to o-LOCK position, or remove

the key trom the ignition so that the steering wheel will

not turn.

LABEL

NOTE:

. When the airbag and cable r6el are disconnected, and

the battery is reconnected and the ignition switch is

turned ON (ll), the SRS unit will store this as an open

in the driver's airbag inflator, and the SRS indicator

light will come on, In such a case, make sure to con-

firm the DTC, then clear the SRS unit memory.

. For disconnecting the spring-loaded lock type con-

nector, refer to page 24-22.

'97 model:

SRS MAIN HARNESS2P CONNECTORCABLE REEL2P CONNECTOR

'98 - 00 models:

UNDER-DASHFUSE/RELAY BOX

Do not replace the original steering wheel with any other

design because it will make it impossible to properly

install the airbag (use only genuine Honda replacement

partsl.

After reassemblv, confirm the wheels are still turned

straight ahead and that the steering wheel spoke angle

is correct. lf minor spoke angle adjustment is necessary,

do so only by adjusting the tie-rods, not by removing

and repositioning the steering whee .

24-25

www.emanualpro.com

Page 1325 of 1395

Troubleshooting

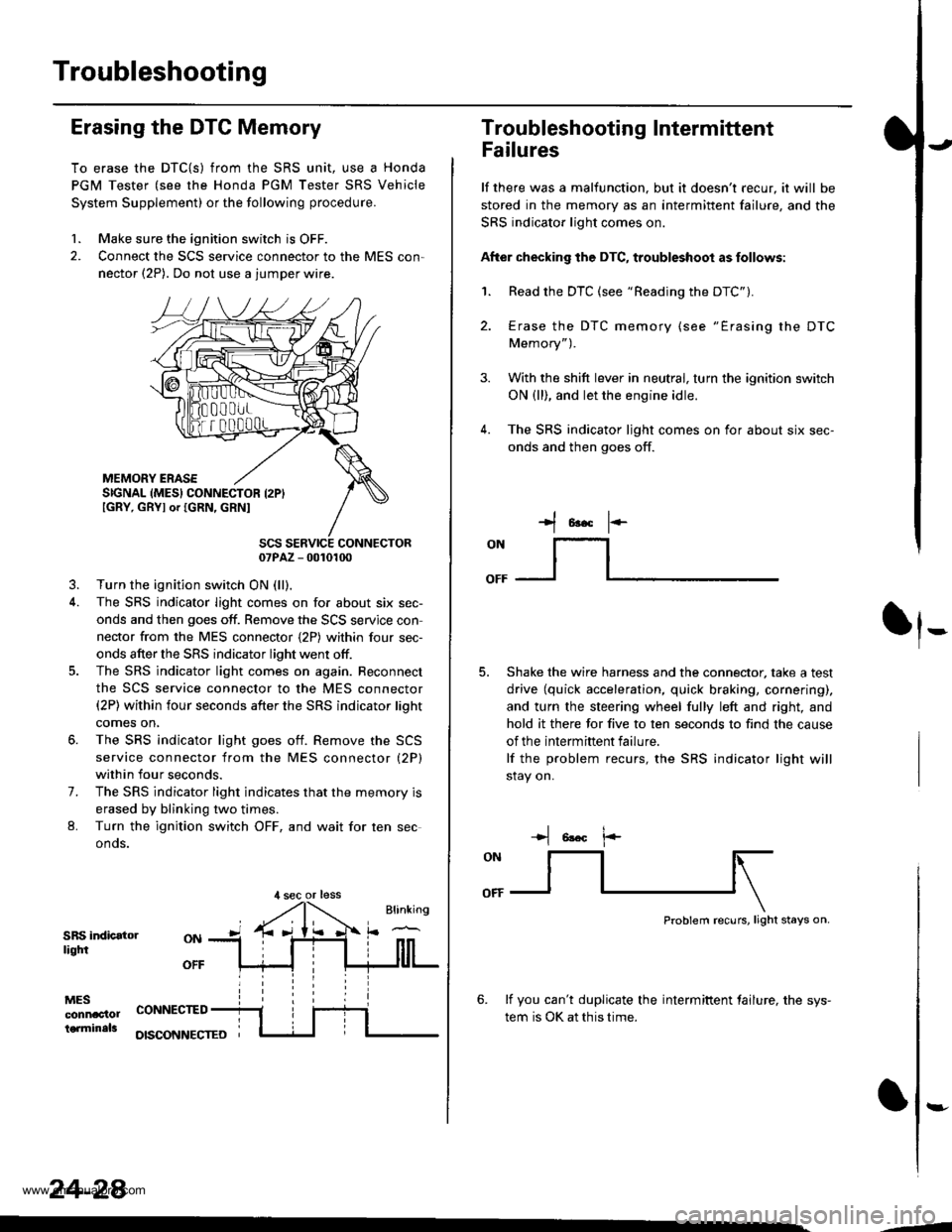

Erasing the DTC Memory

To erase the DTC{S) from the SRS unit, use a Honda

PGM Tester (see the Honda PGM Tester SRS Vehicle

System Supplement) or the following procedure.

1. Make sure the ignition switch is OFF.

2. Connect the SCS service connector to the MES con,

nector (2P). Do not use a jumper wire.

MEMORY ERASESIGNAL (MES} CONNECTOR I2PIIGRY, GRYI or IGRN, GRNI

SCS SERVICE CONNECTOR07PAZ - 0010100

3. Turn the ignition switch ON (ll),

4. The SRS indicator light comes on for about six sec-

onds and then goes off. Remove the SCS servjce con

nector from the MES connector {2P) within four sec-

onds after the SRS indicator light went otf.

5. The SRS indicator light comes on again. Reconnect

the SCS service connector to the MES connector(2P) within four seconds after the SRS indicator lioht

comes on,

6. The SRS indicator light goes otf. Remove the SCS

service connector from the MES connector (2P)

within four seconds.

7. The SRS indicator light indicates that the memory is

erased by blinking two times.

L Turn the ignition switch OFF, and wait for ten sec

onos.

SRS indicatorliqtfi

MESconnac'lolterminals

OFF

CONNECTED

OISCONNECTEO

24-28

,l sec or less

3.

Troubleshooting Intermittent

Failures

lf there was a malfunction. but it doesn't recur, it will be

stored in the memory as an intermittent failure, and the

SRS indicator light comes on.

After checking the DTC, troubleshoot as follows:

1. Read the DTC (see "Reading the DTC").

4.

Erase the DTC memory (see "Erasing the DTC

Memory").

With the shift lever in neutral, turn the ignition switch

ON (ll), and let the engine idle.

The SRS indicator ljght comes on for about six sec-

onds and then goes off.

t*F

ON

lt--- _l

Shake the wire harness and the connector, take a test

drive (quick acceleration, quick braking, cornering),

and turn the steering wheel fully left and right, and

hold it there for five to ten seconds to find the cause

of the intermittent failure.

lf the problem recurs, the SRS indicator light will

stay on.

-+t 6!.c l.-

Problem recurs, light stays on.

6. lf you can't duplicate the intermiftent tailure, the sys-

tem is OK at this time.

:-

-4

www.emanualpro.com

Page 1385 of 1395

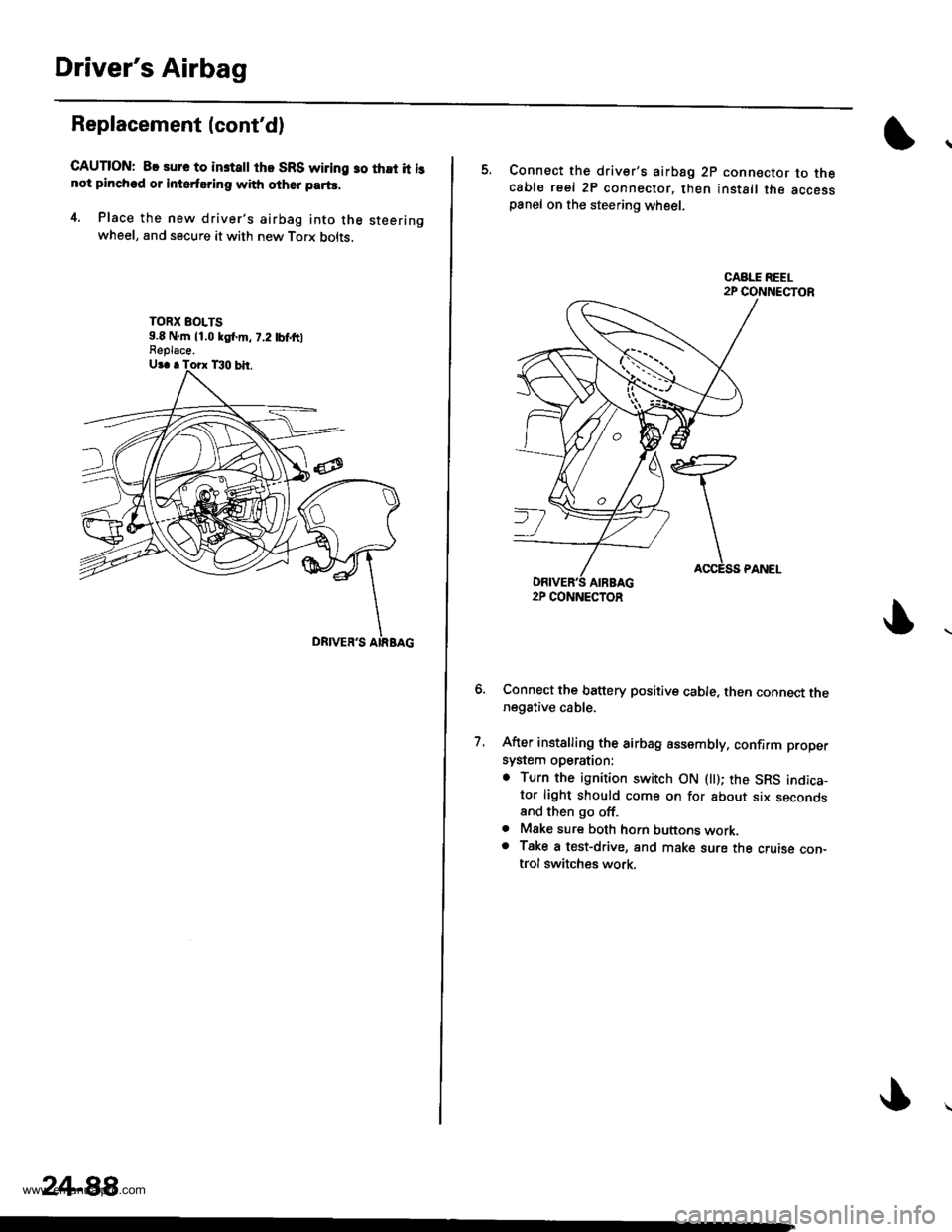

Driver's Airbag

Replacement lcont'd)

CAUTION: 8. sure to instattthe SRS wiring so that it isnot plnched or inlerfsring with other parts.

4. Place the new driver's airbag into the steeringwheel, and secure it with new Torx bolts.

TORX EOLTS9.8 N,m 11.0 kgl.m, 7.2 tbf,ftlFeplace.

24-88,

5. Connect the driver's airbsg 2p connector to thecable reel 2P connector, then install the accesspanel on the steering wheel.

Connect the battery positive cable. then connect thenegative cable.

After installing the airbag assembly, confirm proper

system operation:

. Turn the ignition switch ON llt); the SRS indica-tor light should come on for about six secondsand then go off.. Mske sure both horn buttons work.o Take a test-drive, and make sure the cruise con-trol switches work.

7.

2P CONNECTOR

www.emanualpro.com