drive pulley HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 115 of 1395

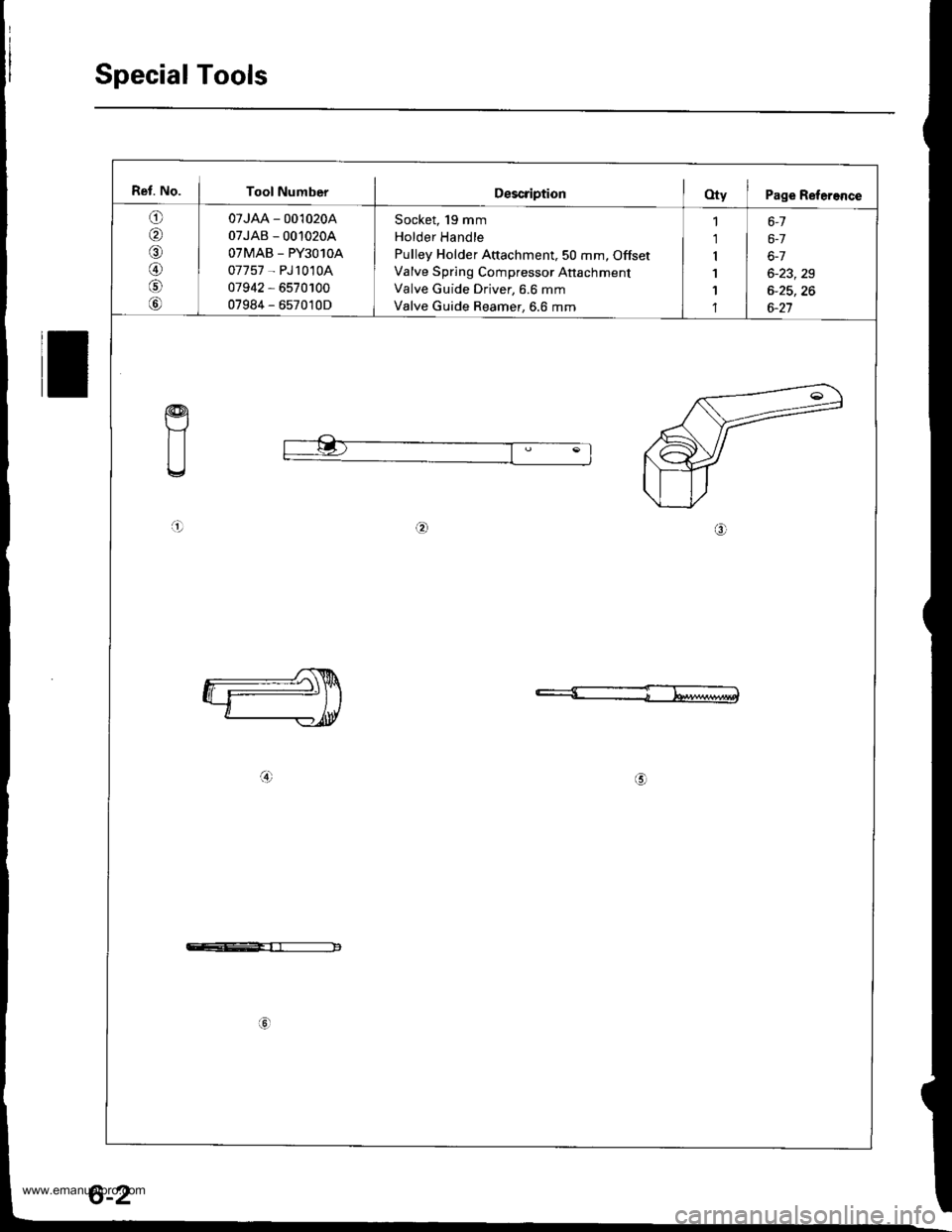

Special Tools

Ref. No. I Tool NumberDescription(Xy I Page Refereflce

o

,61

A)

07JAA - 001020A

07JAB - 00'10204

OTMAB _ PY3O1OA

07757 - PJ1010A

07942 - 6570100

07984 - 657010D

Socket, 19 mm

Holder Handle

Pulley Holder Attachment,50 mm, Offset

Valve Spring Compressor Anachment

Valve Guide Driver, 6.6 mm

Valve Guide Reamer, 6.6 mm

1 6-1

1 | 6-7

r I 6-7

1 6-23,29

1 I 6-25,26'l | 6-27

a!)

a!)

c--E-rr------------

6-2

www.emanualpro.com

Page 123 of 1395

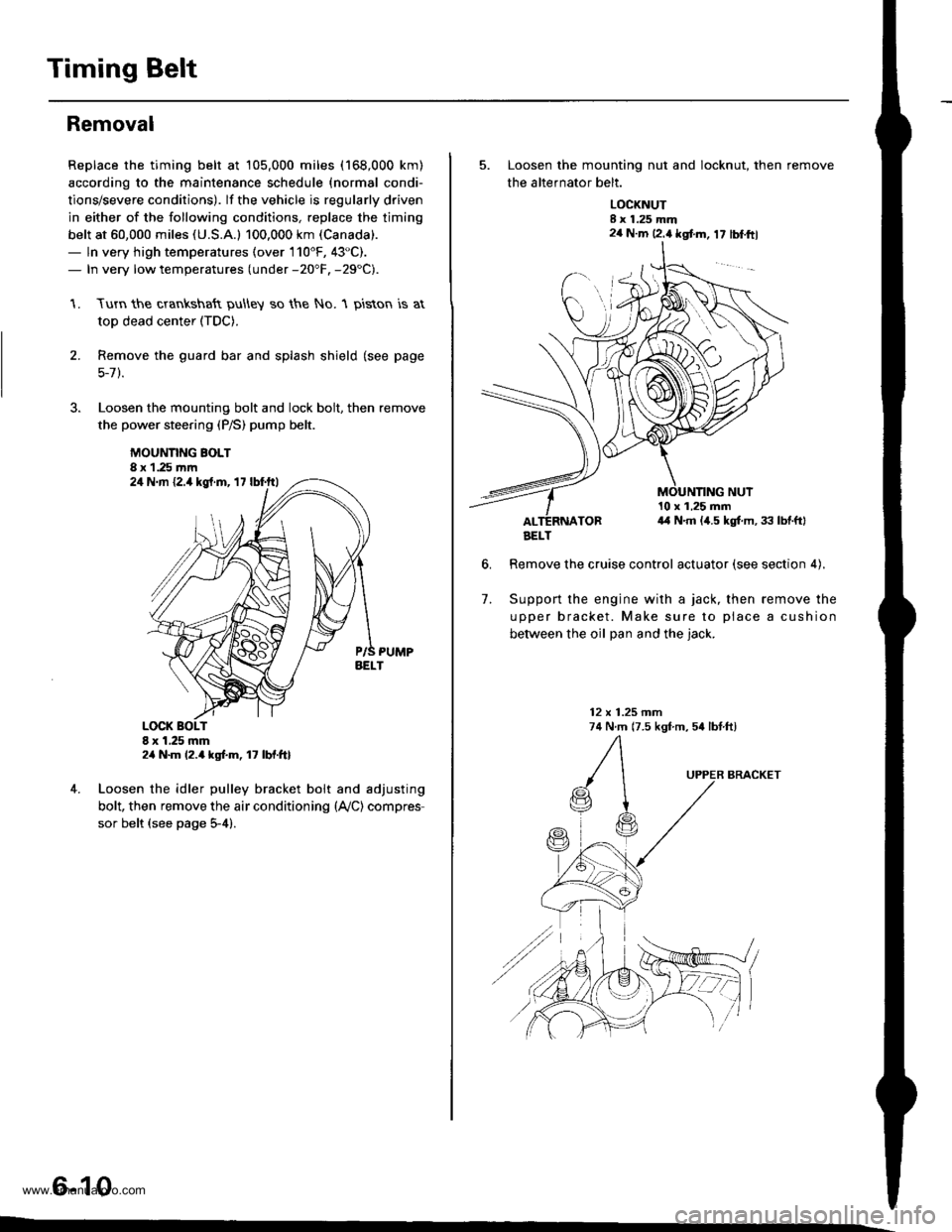

Timing Belt

Removal

Replace the timing belt at 105,000 miles (168,000 km)

according to the maintenance schedule {normal condi-

tions/severe conditions). lf the vehicle is regularly driven

in either of the following conditions, replace the timing

belt at 60,000 miles (U.S.A.l 100.000 km (Canada).

- ln very high temperatures (over 110'F, 43"C).- In very low temperatures (under -20"F. -29"C).

Turn the crankshaft pu\ley so the No. 1 piston is at

top dead center (TDC).

Remove the guard bar and splash shield (see page

5-7 ).

Loosen the mounting bolt and lock bolt. then remove

the power steering (P/S) pump belt.

MOUNNNG BOLT8 x 1.25 rnm

1.

2.

,l

4. Loosen the idler pulley bracket bolt and adjusting

bolt, then remove the air conditioning (lVC) compres

sor belt (see page 5-4).

6-10

24 N.m {2.4 kgt.m, 17 lbf.ftl

24 N.m 12.4 kgf.m, lt lbf.ftl

5. Loosen the mounting nut and locknut, then remove

the altefnator belt.

LOCKNUTI x 1.25 mm2a N.m 12.4 kgt m, 17 lblftl

6.

10 x 1,25 mm4,1 N.m (,1.5 kgt m, 33 lbtftl

Remove the cruise control actuator (see section 4).

Support the engine with a jack, then remove the

upper bracket. Make sure to place a cushion

between the oil Dan and the iack.

12 x 1.25 mm74 N.m (7.5 kgf m, 54 lbtftl

7.

BRACKET

AELT

www.emanualpro.com

Page 124 of 1395

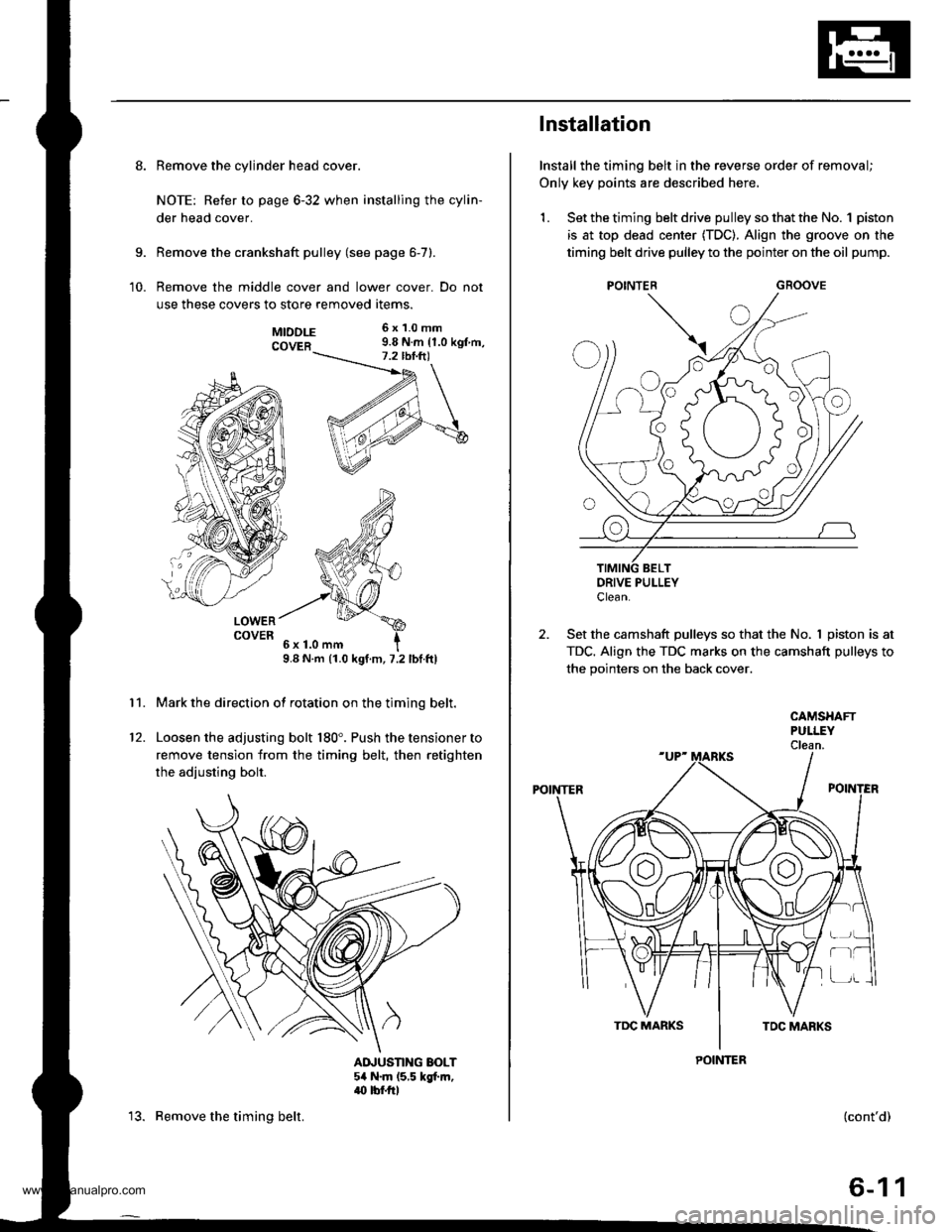

8. Remove the cylinder head cover.

NOTE: Refer to page 6-32 when installing the cylin-

der head cover.

Remove the crankshaft pulley (see page 6-7).

Remove the middle cover and lower cover. Do not

use these covers to store removed items.

9.

10.

11.

MTDDLE 6x1.0mm

COVER 9.8 N.m {1.0 kgt m,

LOWERCOVER

9.8 N.m (1.0 kgt.m, 7.2 lbf.ftl

Mark the direction of rotation on the timing belt.

Loosen the adjusting bolt 180'. Push the tensioner to

remove tension from the timing belt, then retighten

the adiusting bolt.

AINUSTING BOLT54 N.m (5,5 kgt m,.(} tbf.rrl

12.

13. Remove the timing belt.

Installation

Install the timing belt in the reverse order of removal;

Only key points are described here,

1. Set the timing belt drive pulley so that the No. 1 piston

is at top dead center (TDC). Align the groove on the

timing belt drive pulley to the pointer on the oil pump.

GROOVE

DRIVE PULLEYClean.

2. Set the camshaft pulleys so that the No. I piston is at

TDC. Align the TDC marks on the camshaft pulleys to

the pointers on the back cover.

POINTER

CAMSHAFTPULLEYClean.

POINTER

r-t

(cont'd)

6-11

www.emanualpro.com

Page 125 of 1395

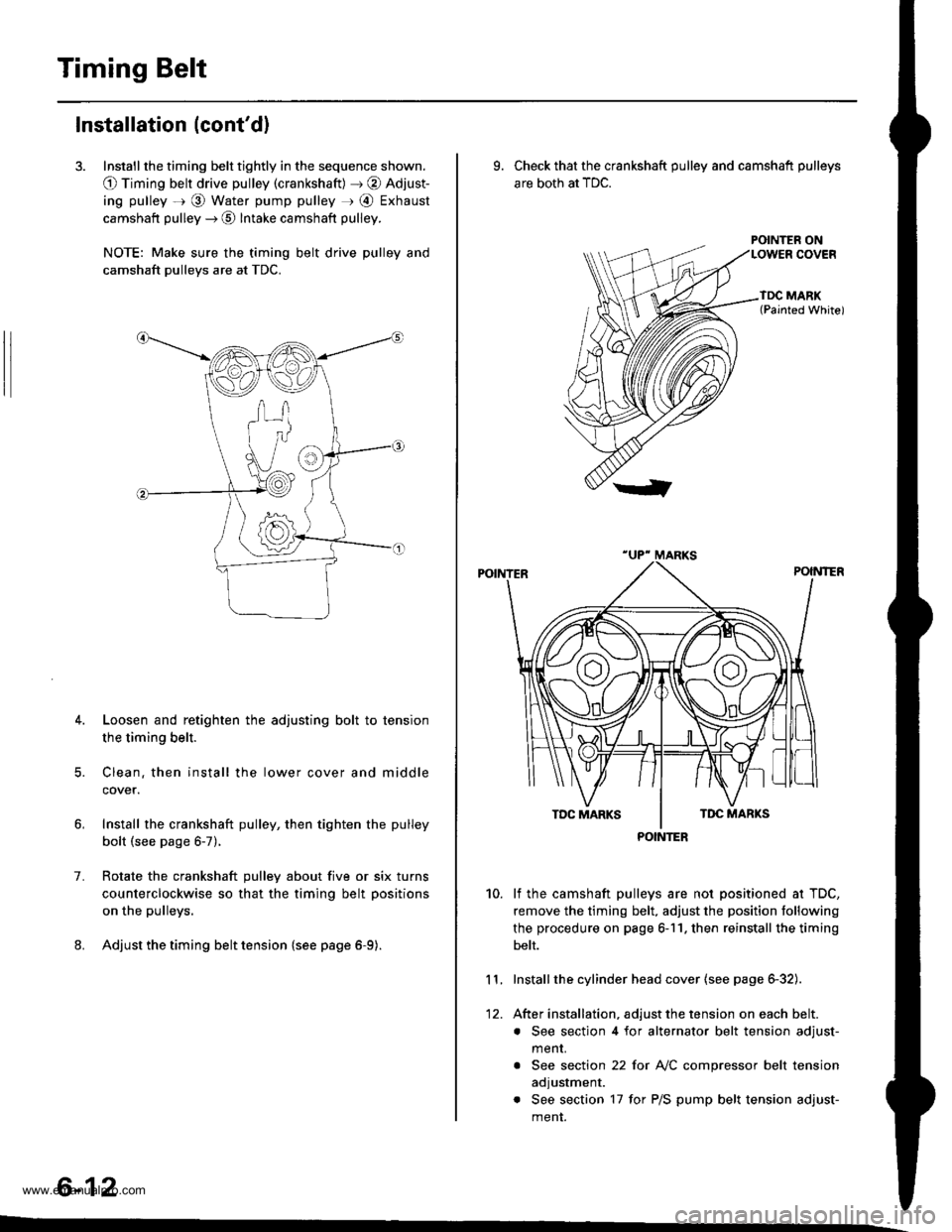

Timing Belt

Installation (cont'd)

3. Install the timing belt tightly in the sequence shown.

O Timing belt drive pulley (crankshaft) J @ Adjust-

ing pulley =r @ Water pump pulley r @ Exhaust

camshaft pulley --) @ Intake camshaft pulley.

NOTE: Make sure the timing belt drive pulley and

camshaft pulleys are at TDC.

4. Loosen and retighten the adjusting bolt to tension

the timing belt.

5. Clean. then install the lower cover and middle

cover.

Install the crankshaft pulley, then tighten the pulley

bolt (see page 6-7).

Rotate the crankshaft pulley about five or six turns

counterclockwise so that the timing belt positions

on the pulleys.

Adjust the timing belt tension {see page 6-9).

1.

6-12

9. Check that the crankshaft pulley and camshaft pulleys

are both at TDC.

POINTER ON

lf the camshaft pulleys are not positioned at TDC,

remove the timing belt. adjust the position following

the procedure on page 6-11. then reinstall the timing

belt.

Installthe cylinder head cover (see page 6-32).

After installation, adjust the tension on each belt.

. See section 4 for alternator belt tension adjust-

menr.

. See section 22 for NC compressor belt tension

adjustment.

. See section 17 for P/S pump belt tension adjust-

ment.

10.

11.

12.

POINTER

www.emanualpro.com

Page 169 of 1395

Oil Seals

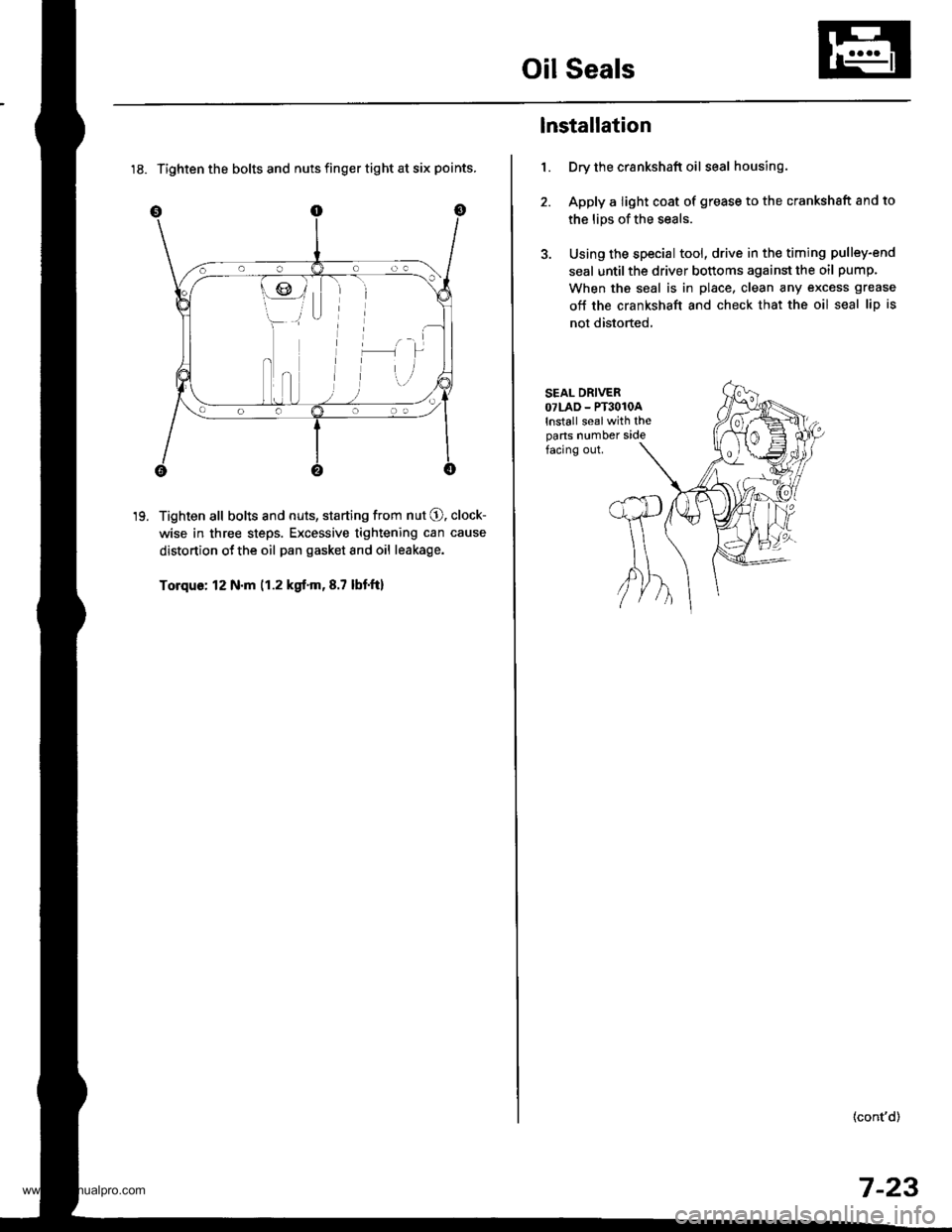

18. Tighten the bolts and nuts finger tight at six points.

Tighten all bolts and nuts, starting from nut O. clock-

wise in three steps. Excessive tightening can cause

distortion ot the oil pan gasket and oil leakage.

Torque: 12 N.m (1.2 kgt.m,8.7 lbtft)

19.

1.

lnstallation

Dry the crankshaft oil seal housing.

Apply a light coat of grease to the crankshsft and to

the lips of the seals.

Using the special tool, drive in the timing pulley-end

seal until the driver bottoms against the oil pump.

When the seal is in place, clean any excess grease

off the crankshaft and check that the oil seal lip is

not distorted,

SEAL DRIVEROTLAD - PT3O1OAlnstall sealwith theparts number sidefacing out.

(cont'd)

7-23

www.emanualpro.com

Page 179 of 1395

1.

2.

3.

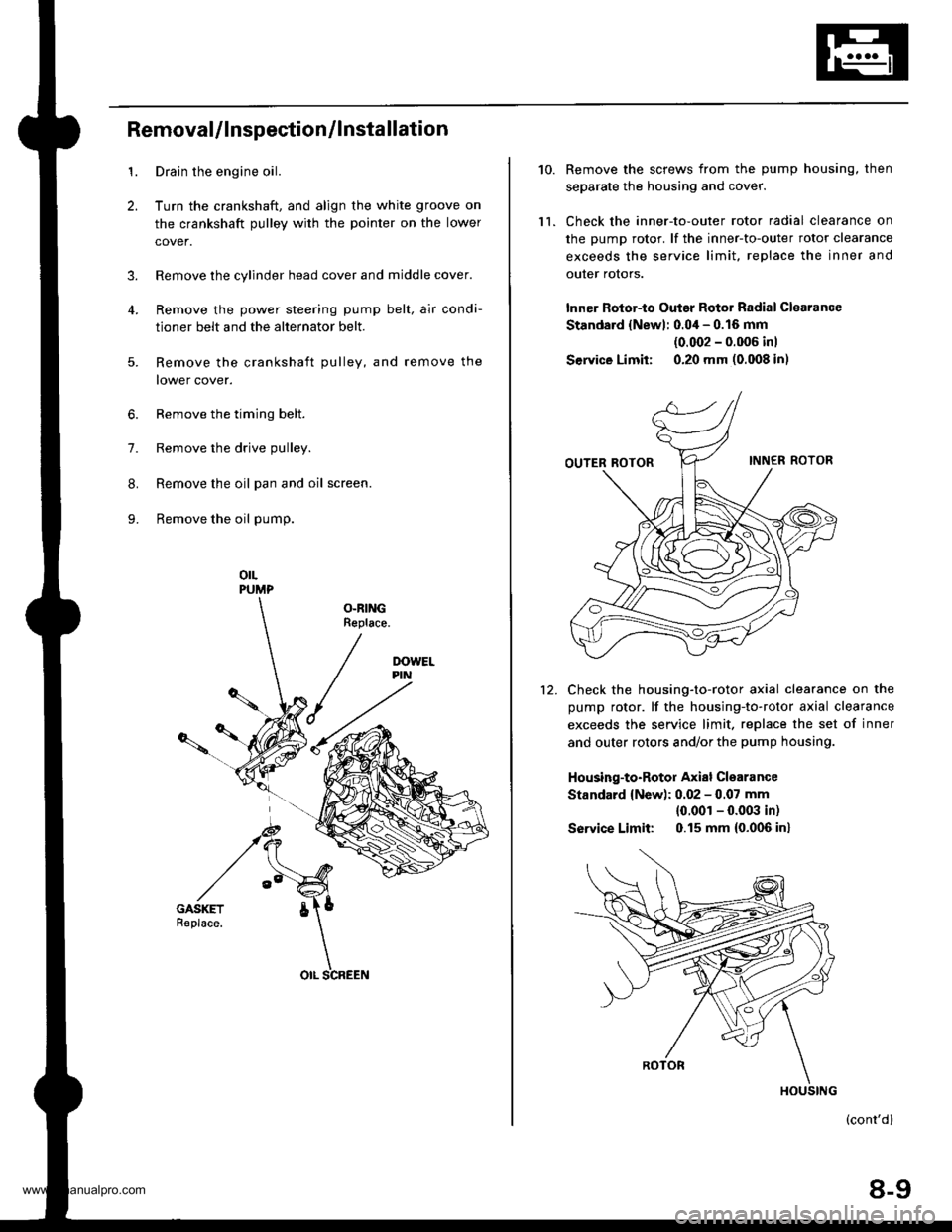

RemovaUlnspection/lnstallation

Drain the engine oil.

Turn the crankshaft, and align the white groove on

the crankshaft pulley with the pointer on the lower

cover.

Remove the cylinder head cover and middle cover.

Remove the power steering pump belt, air condi-

tioner belt and the alternator belt.

Remove the crankshaft pulley, and remove the

lower cover.

6. Remove the timing belt.

7. Remove the drive pulley.

8. Remove the oil pan and oil screen.

9. Remove the oil pump.

orLPUMP

OLRINGReplace.

5.

OIL SCREEN

10.

ll.

Remove the screws from the pump housing, then

separate the housing and cover.

Check the inner-to-outer rotor radial clearance on

the pump rotor. lf the inner-to-outer rotor clearance

exceeds the service limit. replace the inner and

outer rotors.

lnner Rotor-to Outar Rotor Radial Clearance

Standard {Newl: 0.04 - 0.16 mm

{0.002 - 0.006 inl

Service Limit: 0.20 mm (0.008 in)

Check the housing-to-rotor axial clearance on the

pump rotor. lf the housing-to-rotor axial clearance

exceeds the service limit. replace the set of inner

and outer rotors and/or the pump housing.

Housing-to-Rotor Axial Clearance

Standard {New): 0.02 - 0.07 mm

{0.001 - 0.003 in)

So|'�ice Limit: 0.15 mm (0.006 inl

(cont'd)

8-9

HOUSING

www.emanualpro.com

Page 688 of 1395

Transmission

21.

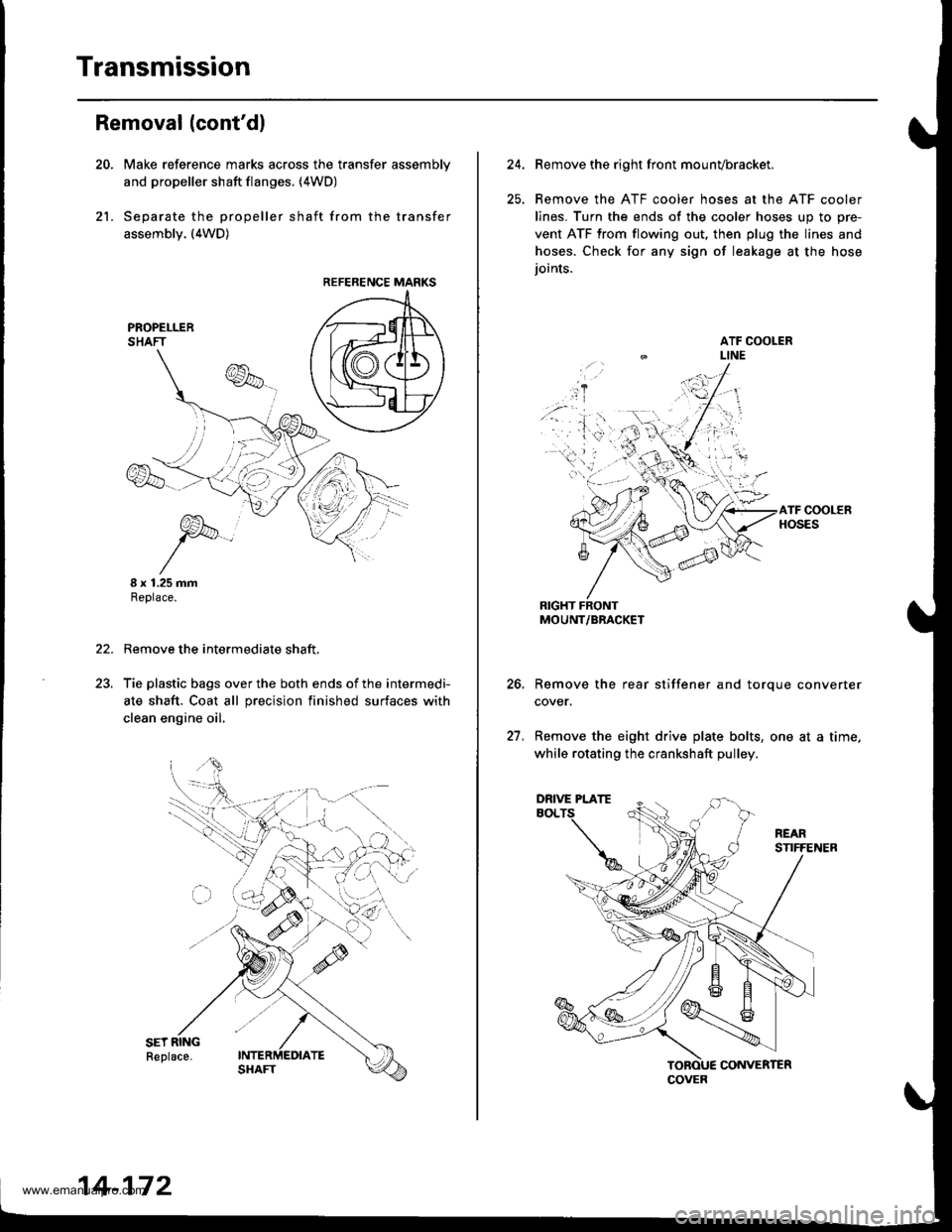

Removal (cont'dl

Make reference marks across the transfer assemblv

and propeller shaft flanges. (4WD)

Separate the propeller shaft from the transfer

assembly. (4WD)

I x 1.25 mmReplace.

Remove the intermediate shaft,

Tie plastic bags over the both ends of the intermedi-

ate shaft. Coat all precision finished surfaces with

clean engine oil.

22.

REFERENCE MARKS

14-172

24.Remove the right front mounvbracket.

Remove the ATF cooler hoses at the ATF cooler

lines. Turn the ends of the cooler hoses uo to ore-

vent ATF from flowing out, then plug the lines and

hoses. Check for any sign of leakage at the hose

ioints.

RIGHT FRONTMOUNT/BRACKET

Remove the rear stiffener and torque converter

cover.

Remove the eight drive plate bolts, one at a time.

while rotating the crankshaft pulley.

27.

COVER

DRIVE PLATE

www.emanualpro.com

Page 776 of 1395

Transmission

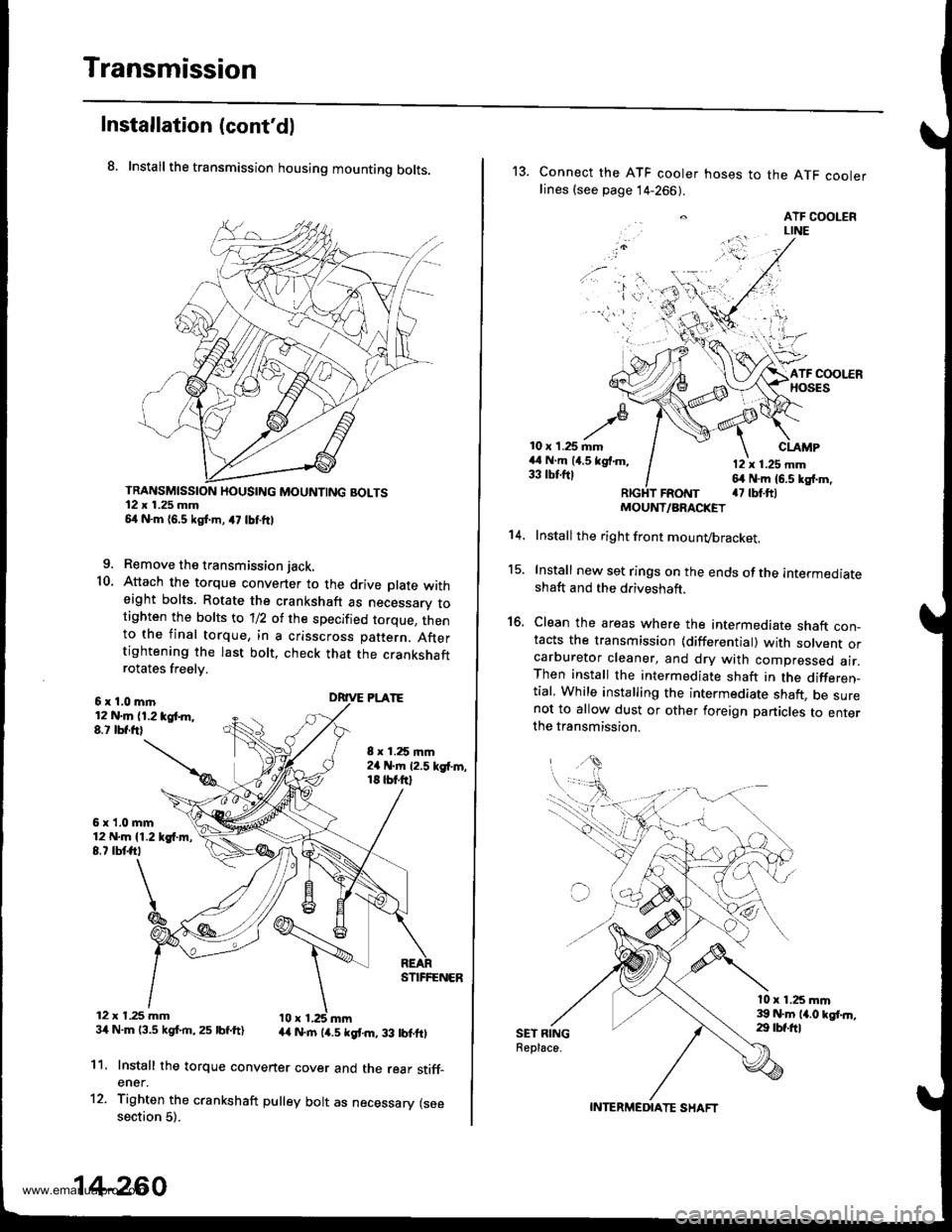

Installation (cont'dl

8. Install the transmission housing mounting bolts.

TRANSMISSION HOUSING MOUNTING BOLTS12 x 1.25 mm54 N.m 16,5 kgf.m, a7 lbtftl

9. Remove the transmission jack.

10. Attach the torque convener to the drive plate witheight bolts. Rotate the crankshaft as necessarv totighten the bolts to 'll2 of the specified torque, thento the final torque, in a crisscross pattern. Aftertightening the last bolt. check that the crankshaftrotates freelv.

6x1.0mln12 N.m (1.2 tgt m,8.t lbf.frl

6x1.0mm12 N.m {1.219{.m,8.7 tbtft,

12 x t.25 mm34 N.m 13.5 kgf.rn,25 lbf.ft)

8 x 1.25 mm2a N.m 12.5 kgf'm,18 tbt.ftl

DRIVE PLATE

STIFFENER

44 N.rn (4.5 kgt m, 33 lbtftl

11.

12.

Install the torque convener cover and the rear stiff_ener.

Tighten the crankshaft pulley bolt as necessary (seesection 5).

14-260

13. Connect the ATF cooler hoses to the ATF coolerlines (see page 14-266).

. ATF COOLERLINE

'i 'l'r',:,.) -

10 x 1.25 mm44 N.m (4.5 kgf.m,33 tbtftl

CLAMP

12 x 1.25 mm64 N.m 16.5 kg{.m,a7 tbt.ftlFRotrtT

15.

16.

't 4.

SET RINGReplace.

MOUNT/ARACKET

Install the right front mounvbracket.

Install new set rings on the ends of the intermediateshaft and the driveshaft.

Clean the areas where the intermediate shaft con_tacts the transmission {differential) with solvent orcarburetor cleaner, and dry with compressed air.Then install the intermediate shaft in the differen_tial, While installing the intermediate shaft, be surenot to allow dust or other foreign panicles to enterthe transmission.

l0 x 1.25 mm39 N.m 14.0 kgt.n,29 tbf.ftl

INTERMEDIATE SHAFT

www.emanualpro.com

Page 852 of 1395

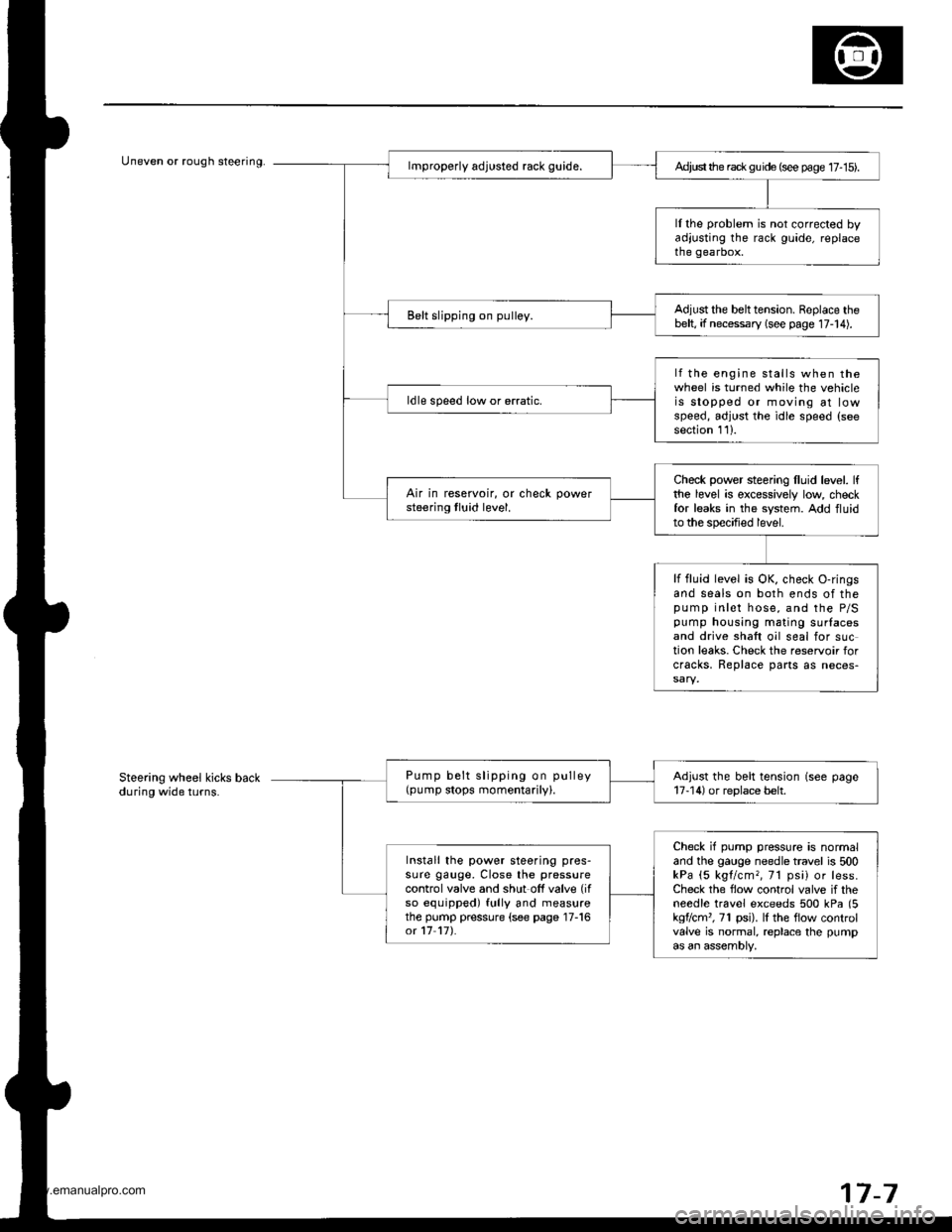

Uneven or rough steering.Ad,ust the rack gu ide (see page 17- 15).

ll the problem is not corrected byadjusting the rack guide, replacethe gearbox.

Adjust the belttension. Replace thebelt, if necessary (see page 17-14).Belt slipping on pulley.

lf the engine stalls when thewheel is turned while the vehicleis stopped or moving at lowspeed, adjust the idle speed (seesection 111.

ldle speed low or erratic.

Check power steering lluid level. lfthe level is excessively low checkfor leaks in the system. Add fluidto the specified level.

Air in reservoir, or check powersteering tluid level.

lf fluid level is OK, check O-ringsand seals on both ends of thepump inlet hose, and the P/Spump housing mating surlacesand drive shaft oil seal for suction leaks. Check the reservoir forcracks, Replace parts as neces-

Pump belt slipping on pulley(pump stops momentarily).Adjust the belt tension (see page17-14) or replace belt.

Check if pump pressure is normaland the gauge needle travel is 500kPa (5 kgl/cm,, 71 psi) or less.Check the flow control valve if theneedle travel exceeds 500 kPa (5kgflcm'�, 71 psi). lI the flow controlvalve is normal, replace the pumpas an assembly,

Install the power steering pres-sure gauge, Close the pressurecontrol valve and shut off valve (if

so equipped) fully and measurethe pump pressure (see page 17-16ot 17 17).

Steering wheel kicks backduring wide turns.

7-7

www.emanualpro.com

Page 854 of 1395

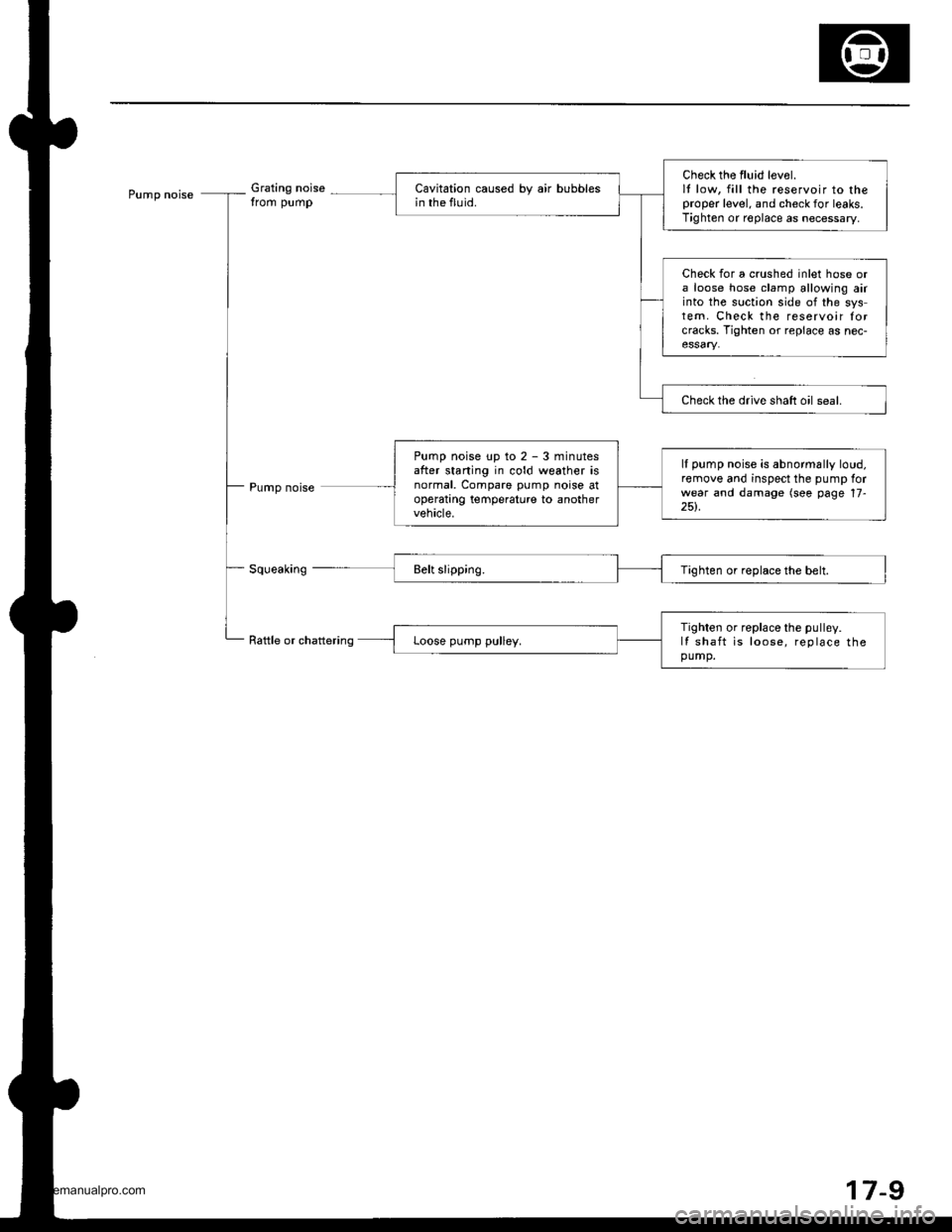

Pump noiseGrating nois€trom pump

Pump noise

Raftle or chattering

Check the fluid lev€1.lt low, fill the reservoir to theproper level. and check for leaks.Tighten or roplace as necessary,

Cavitation caused by air bubblesin the fluid.

Check for a crushed inlet hose ora loose hose clamp allowing airinto the suction side of the system. Check the reservoir forcracks. Tighten or replace as nec-

Check the drive shaft oil seal.

Pump noise up to 2 - 3 minutesafter starting in cold weather isnormal, Compare pump noise atoperatrng temperature to anothervehicle.

ll pump noise is abnormally loud,remove and inspect the pump forwear and damage (see page 17-251.

Tighten or replace the pulley.lI shaft is loose, replace thepump.

17-9

www.emanualpro.com