oil. HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 41 of 1395

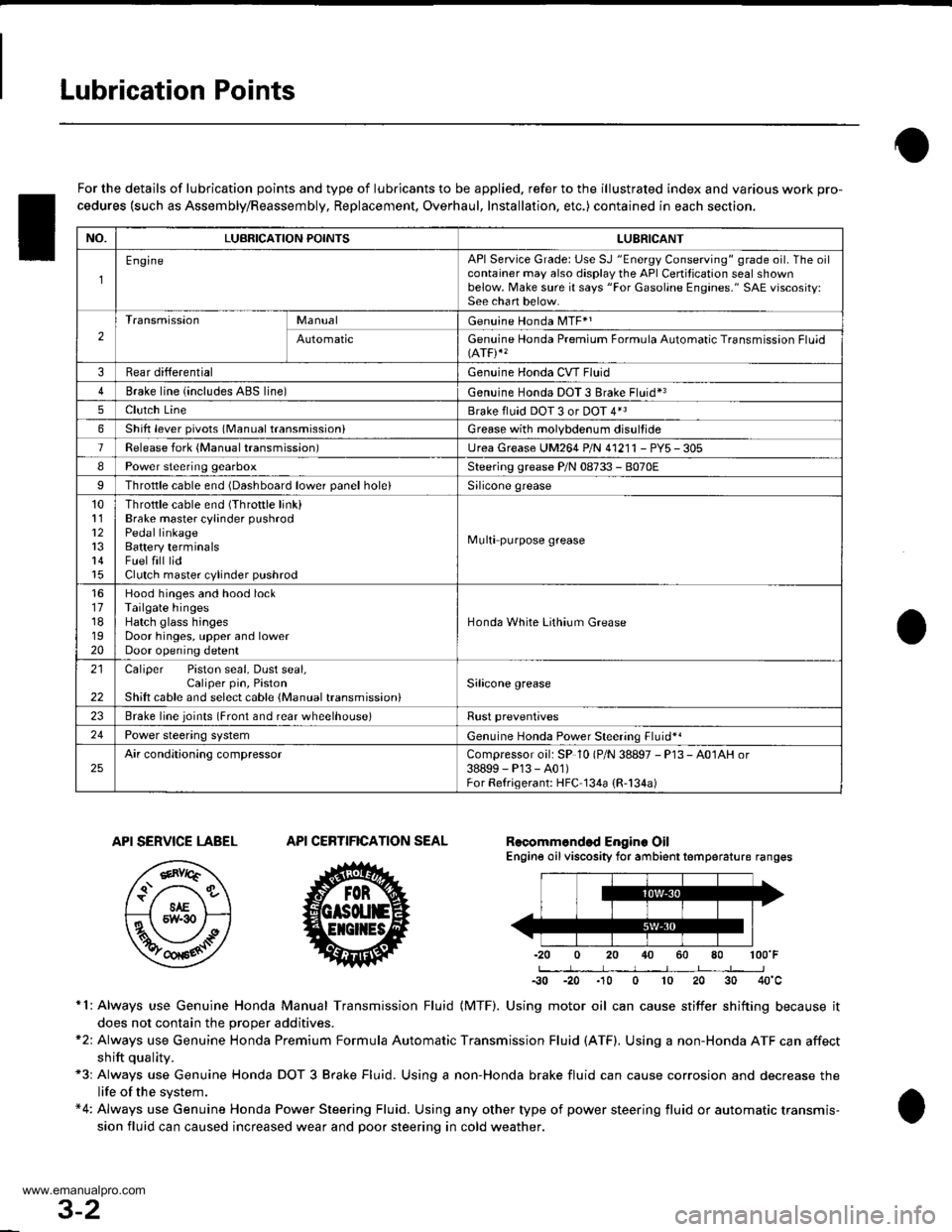

Lubrication Points

For the details of lubrication points and type of lubricants to be applied. refer to the illustrated index and various work pro-

cedures (such as Assembly/Reassembly, Replacement, Overhaul, Installation, etc.) contained in each section.

Recomm6nded Engine OilEngine oil viscosity for ambient temperature ranges

100'F

-30 -20 .10 0 10 20 30 40'c

r1: Always use Genuine Honda Manual Transmission Fluid {MTF). Using motor oil can cause stiffer shifting because it

does not contain the orooer additives.*2: Always use Genuine Honda Premium Formula Automatic Transmission Fluid (ATF). Using a non-Honda ATF can affect

shift qualitv.+3r Always use Genuine Honda DOT 3 Brake Fluid. Using a non-Honda brake fluid can cause corrosion and decrease the

life of the system.*4: Always use Genuine Honda Power Steering Fluid. Using any other type of power steering fluid or automatic transmis-

sion fluid can caused increased wear and poor steering in cold weather.

API SERVICE LABEL

/,.*-G\

/.'z-\e\t/6AE\ll-;-1 5w-30 /---l

w

API CERTIFICATION SEAL

ffi-20 0 20

NO.LUBRICATION POINTSLUBRICANT

EngineAPI Service Grade: Use SJ "Energy Conserving" grade oil. The oilcontainer may also display the API Certitication seal shownbelow. Make sure it says "For Gasoline Engines." SAE vjscosity:See chart below.

2

TransmissionManualGenuine Honda MTF*1

AutomaticGenuine Honda Premium Formula Automatic Transmission Fluid(ATF)*'

3Rear differentialGenuine Honda CVT Fluid

4Brake line (includes ABS line)Genuine Honda DOT 3 Brake Fluid*3

5Clutch LineBrake fluid DOT 3 or DOT 4*3

6Shift lever pivots (Manual transmission)Grease with molybdenum disultide

1Release fork (Manual transmission)LJrea Grease UM264 P/N 4'1211 - PYs - 305

IPower steering gearboxSteering grease P/N 08733 - B070E

Throttle cable end {Dashboard lower panel holelSilicone grease

10l112

14

Throttle cable end (Throttle link)Brake master cylinder pushrodPedal linkageBattery terminalsFuelfill lidClutch master cylinder pushrod

Multi purpose grease

1617181920

Hood hinges and hood lockTailgate hingesHatch glass hingesDoor hinges, upper and lowerDoor opening detent

Honda White Lithium Grease

21

22

Caliper Piston seal, Dust seal,Caliper pin, PistonShilt cable and select cable {Manual transmission)Silicone grease

23Brake line ioints (Front and rear wheelhouse)Rust preventives

24Power steering systemGenuine Honda Power Steering Fluid-.

25Air conditioning compressorCompressor oil: SP 10 lP/N 38897 - P13 - A0lAH or38899-P13-A01)For Refrigerant: HFC 134a (R,134a)

3-2

www.emanualpro.com

Page 69 of 1395

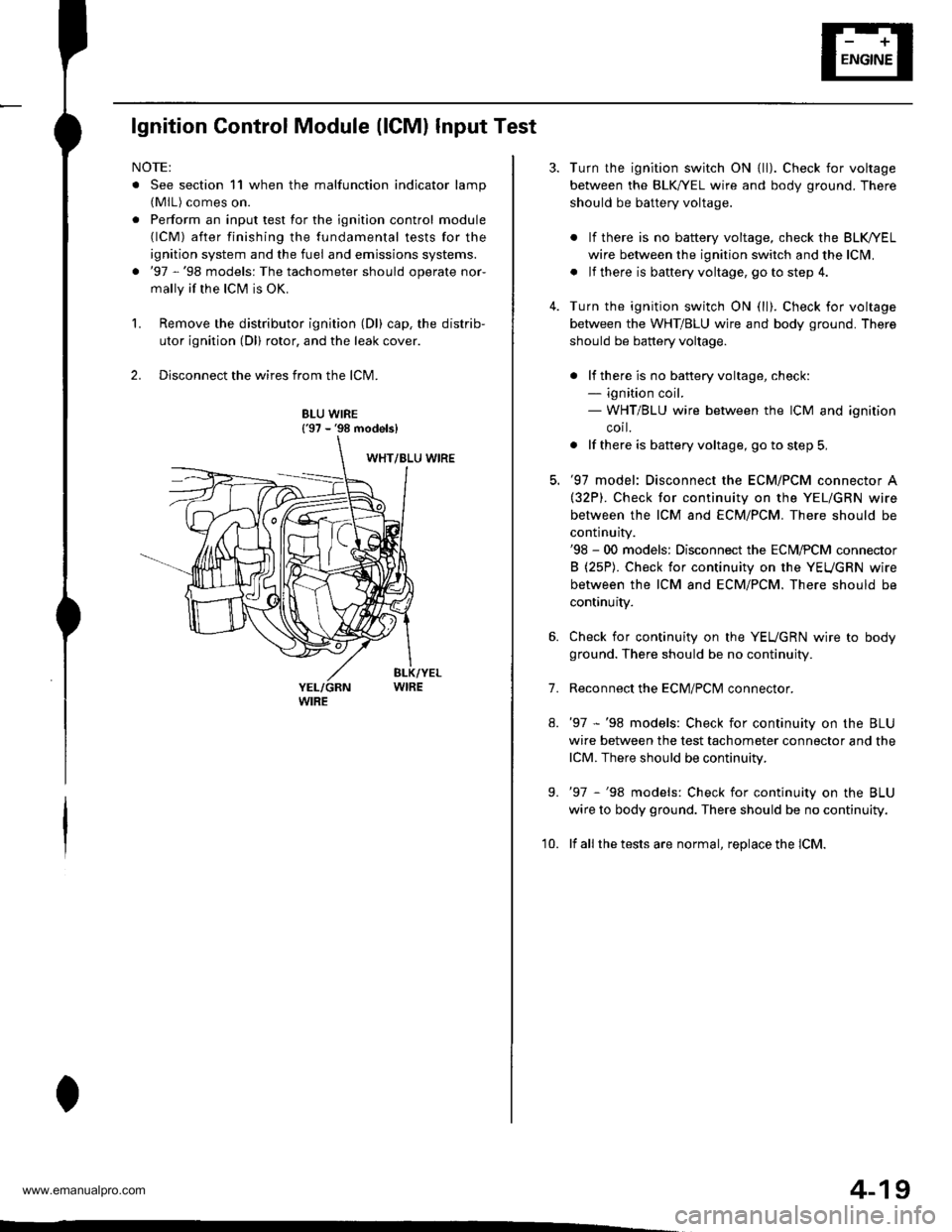

lgnition Control Module (lCMl Input Test

NOTE:

. See section 11 when the malfunction indicator lamp(MlL) comes on.

. Perform an input test for the ignition control module(lCM) after finishing the fundamental tests for the

ignition system and the fuel and emissions systems.

. '97 -'98 models: The tachometer should operate nor-

mally if the ICM is OK.

L Remove the distributor ignition (Dl) cap, the distrib-

utor ignition (Dl) rotor, and the leak cover.

2. Disconnect the wires from the lCM.

8LU WIRE{'97 - '98 models}

4-19

7.

Turn the ignition switch ON {ll). Check for voltage

between the BLK,^/EL wire and body ground. There

should be battery voltage.

. lf there is no battery voltage, check the BLK/rEL

wire betlveen the ignition switch and the lclvl.

. lf there is baftery voltage, go to step 4.

Turn the ignition switch ON (ll). Check for voltage

between the WHT/BLU wire and body ground. There

should be battery voltage.

. lf there is no batteryvoltage, check:- ignition coil.- WHT/BLU wire between the ICM and ignition

corl.

. lf there is battery voltage, go to step 5,

'97 model: Disconnect the ECM/PCM connector A(32P). Check for continuity on the YEL/GRN wire

between the ICM and ECM/PCM. There should be

continuity.'98 - 00 models: Disconnect the ECM,PCM connector

B (25P). Check for continuity on the YEUGRN wire

between the ICM and ECM/PCM. There should be

continuity.

Check for continuity on the YEUGRN wire to body

ground. There should be no continuity.

Reconnect the ECM/PClvl connector.

'97 -'98 models: Check for continuity on the BLU

wire between the test tachometer connector and the

lCM. There should be continuity.

'97 -'98 models: Check for continuity on the BLU

wire to body ground. There should be no continuity.

lf all the tests are normal, replace the lCM.

9.

'10.

www.emanualpro.com

Page 70 of 1395

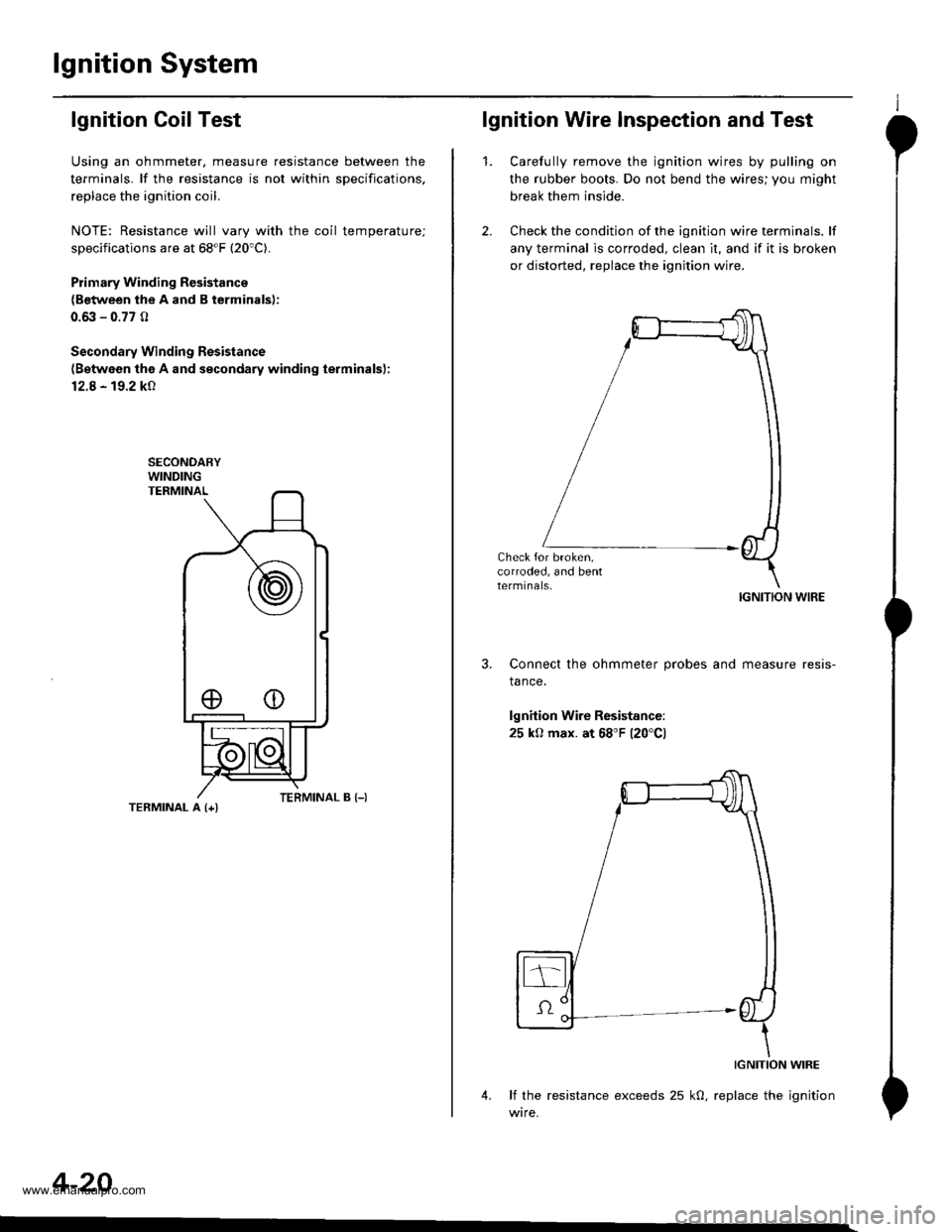

lgnition System

lgnition Coil Test

Using an ohmmeter, measure resistance between the

terminals. lf the resistance is not within sDecifications,

replace the ignition coil.

NOTE: Resistance will vary with the coil temperature;

specifications are at 68"F (20'C).

Plimary Winding Resistance

{Between the A and B terminals):

0.6it - 0.77 0

Secondary Winding Resistance

{Between the A and secondary winding terminals):

12.8 - 19.2 kO

TERMINAL A {+l

4-20

eo

lgnition Wire Inspection and Test

1.Carefully remove the ignition wires by pulling on

the rubber boots. Do not bend the wires; you might

break them inside.

Check the condition of the ignition wire terminals. lf

any terminal is corroded, clean it, and if it is broken

or distorted, replace the ignition wire.

IGNITION WIRE

Connect the ohmmeter probes and measure resis-

tance.

lgnition Wire Resistance:

25 kO max. at 68'F 120'Cl

IGNITION WIRE

4. lf the resistance exceeds 25 kO, replace the ignition

wire.

www.emanualpro.com

Page 103 of 1395

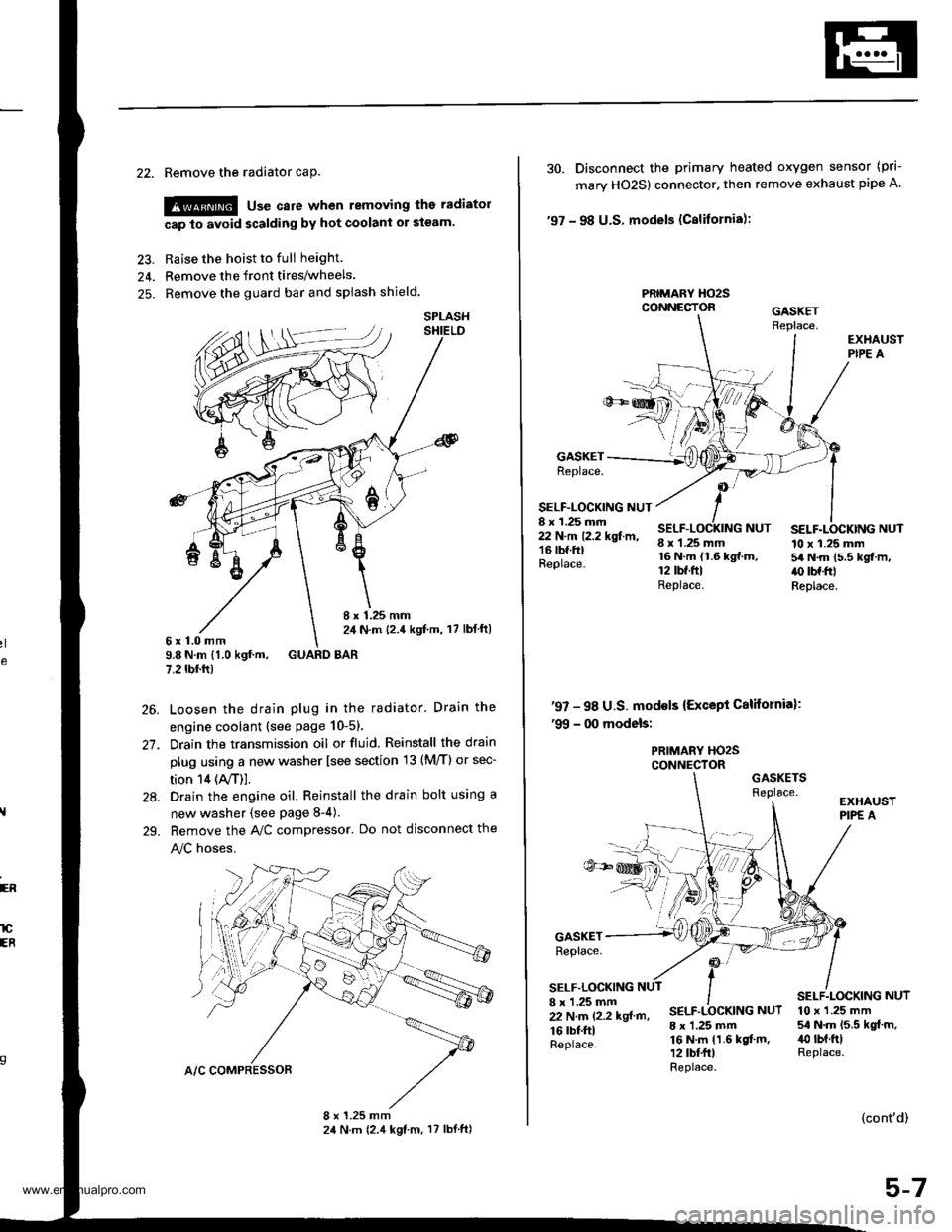

22. Remove the radiator caP.

!@ use care when removing the radiatol

cap to avoid scalding by hot coolani or steam.

23. Raise the hoist to full height

24. Remove the front tires/wheels.

25. Remove the guard bar and splash shield.

8 x 1.25 mm2,1 N.m {2.4 kgf,m, 17 lbl ft)6x1.0mm9.8 N.m {1.0 kgf.m, GUARD BAR7.2 tbf.rr)

Loosen the drain plug in the radiator. Drain the

engine coolant (see page 10-51.

Drain the transmission oil or fluid. Reinstall the drain

plug using a new washer lsee section 13 (M/T) or sec-

tion 14 (ly'T)].

Drain the engine oil. Reinstall the drain bolt using a

new washer {see page 8-4).

Bemove the A,/C compressor. Do not disconnect the

!y'C hoses.

SPLASH

26.

27.

28.

29.

ER

lCEB

30. Disconnect the primary heated oxygen sensor (prl-

mary HO2S) connector. then remove exhaust pipe A

'97 - 98 U.S. models (Cslifornia):

PRIMARY HO2SCONNECTOR

GASKETReplace.

SELF-LOCKING NUT8 x 1.25 mm22 N.m 12.2 kgf.m,16 lbf.ftlReplace.

8 x 1.25 mm16 N.m {1.6 kgf.m.12 tbt.ftlReplace.

SELF.LOCKING NUT10 x 1.25 mm54 N.m 15.5 kgf.m,.() tbf.frlReplace.

NUT

'97 - 98 U.S. mod€ls {Except California):'99 - 00 models:

PRIMARY HO2SCONNECTORGASKETSReplace.

GASKETReplace.

SELF.LOCKING8 x 'l.25 mm22 N.m (2.2 kgf m,

16 rbf.ftlReplace.

SELF.LOCKING NUT

8 x 1.25 mm16 N.m 11.6 kgf.m,12 tbt fr)Replace.

10 x 1.25 mm54 N.m 15.5 kgt.m,40 rbt.ftlReplace.

{cont'd)

5-7

www.emanualpro.com

Page 104 of 1395

Engine RemovaUlnstallation

OOI{TROL PI

Removal (cont'dl

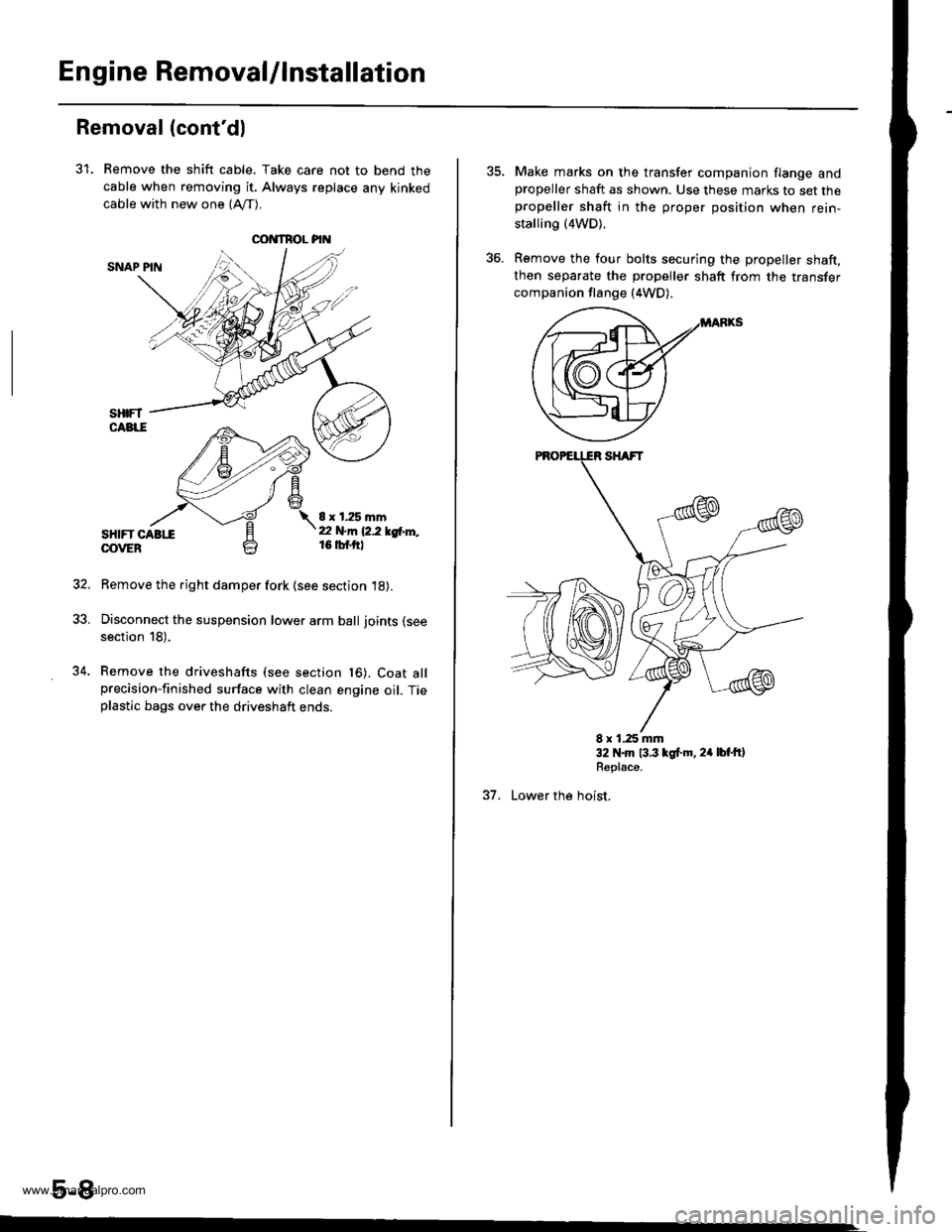

31. Remove the shift cable. Take care not to bend the

cable when removing it. Always replace any kinked

cable with new one (Afl-).

SNAP PIN

sHtFT CABttOOVEB

8 x 1.25 mmt2 N.m 12.2 lgtr'l'',,16 tbf.ftl

Remove the right damper fork (see section 18).

Disconnect the suspension lower arm ball joints (see

section 18),

Remove the driveshafts (see section t6). Coat allprecision-finished surface with clean engine oil. Tieplastic bags over the driveshaft ends.

5-8

34.

Make marks on the transfer companion flange andpropeller shaft as shown. Use these marks to set thepropeller shaft in the proper position when rein-

stalling (4WD).

Remove the four bolts securing the propeller shaft,then separate the propeller shaft from the transfer

companion flange (4WD).

E x 1.25 mm32 N.m 13.3 lgt.m, 24 lbt'ftlRepl€ce.

37. Lower the hoist,

www.emanualpro.com

Page 140 of 1395

Cylinder Head

Reaming

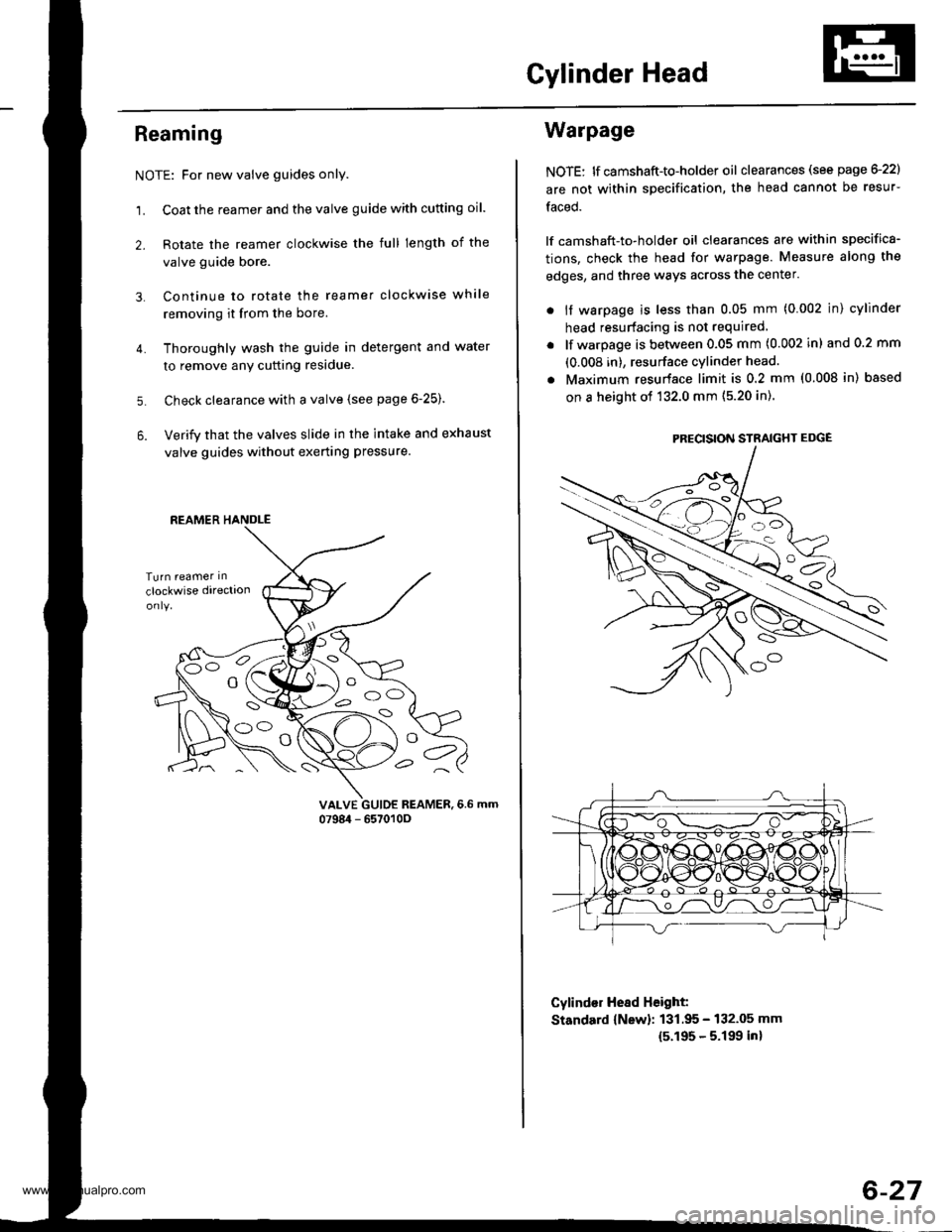

NOTE: For new valve guides only.

1. Coat the reamer and the valve guide with cutting oil.

2. Rotate the reamer clockwise the full length of the

valve guide bore.

Continue to rotate the reamer clockwise while

removing it from the bore.

Thoroughly wash the guide in detergent and water

to remove anY cutting residue.

Check clearance with a valve (see page 6-25).

Verify that the valves slide in the intake and exhaust

valve guides without exerting pressure.

3.

4.

5.

6.

vALvE GUIDE REAMER,6.6 mm0798i1 - 657010O

REAMER HANDLE

e

Warpage

NOTE: lf camshaft-to-holder oil clearances (see page G22)

are not within specification, the head cannot be resur-

faced.

lf camshaft-to-holder oil clearances are within specifica-

tions, check the head for warpage. Measure along the

edges, and three ways across the center.

. if warpage is less than 0.05 mm (0.002 in) cylinder

head resurfacing is not required

lf warpage is between 0.05 mm (0.002 in) and 0.2 mm

(0.008 in), resurface cylinder head.

Maximum resurface limit is 0.2 mm (0.008 in) based

on a height of 132.0 mm (5.20 in).

Cylind€r Hesd Height:

Standard {New}: 131.95 - 132.05 mm

15.195 - 5.199 inl

PRECISION STRAIGHT EDGE

6-27

www.emanualpro.com

Page 142 of 1395

Valves, Valve Springs and Valve Seals

lnstallation

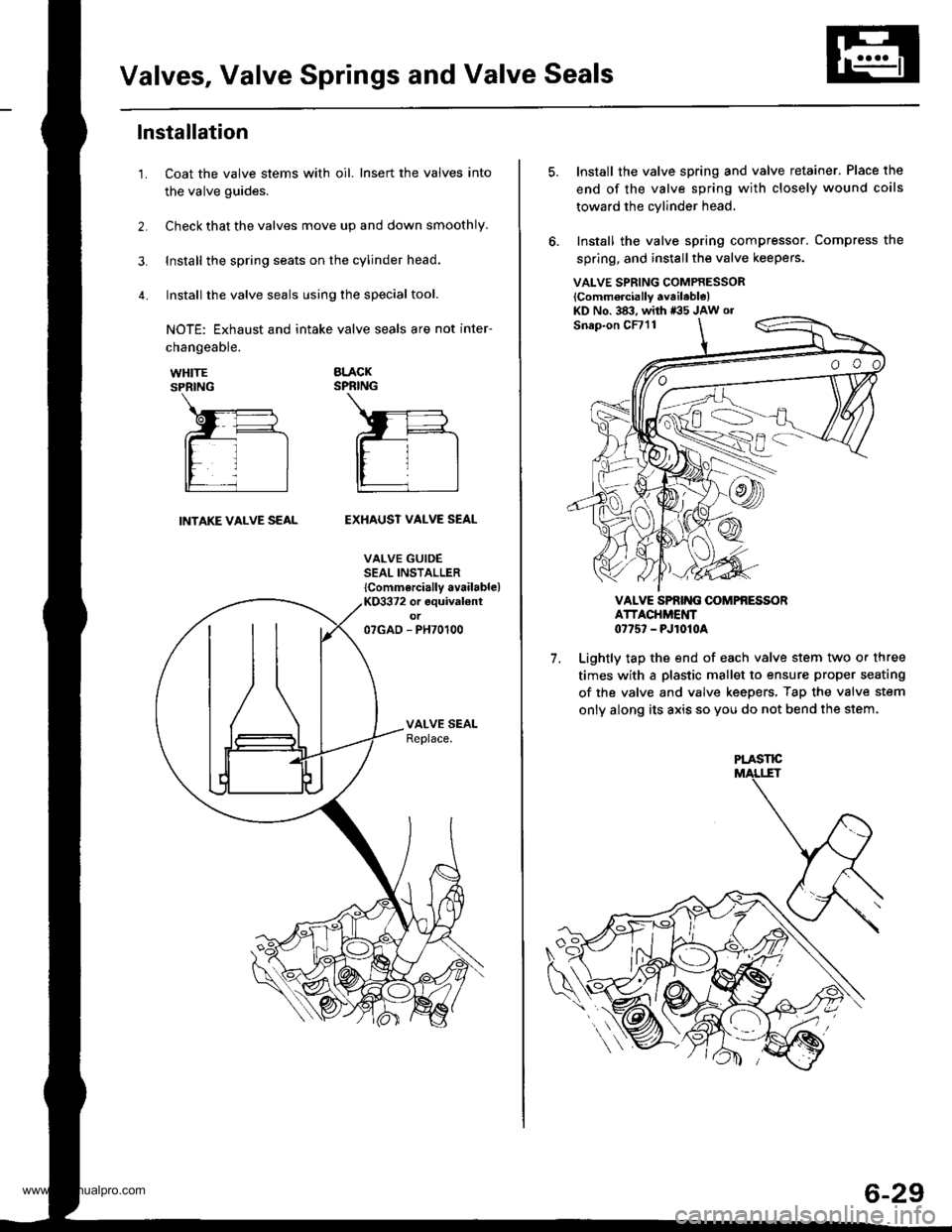

Coat the valve stems with oil. Insert the valves into

the valve guides.

Check that the valves move up and down smoothly.

Install the spring seats on the cylinder head.

Install the valve seals using the special tool.

NOTE: Exhaust and intake valve seals are not inter-

1.

changeable.

WHITESPRING

BLACKSPRING

INTAKE VALVE SEALEXHAUST VALVE SEAL

VALVE GUIDESEAL INSTALLER

lCommercially available)KO3372 or equival€ntot07GAD - PH70100

VALVE SPRING COMPRESSOR

lComm6rcially available)KD No. 383, with *35 JAw or

7.

Install the valve spring and valve retainer. Place the

end of the valve spring with closely wound coils

toward the cylinder head,

Install the valve spring compressor. Compress the

spring, and install the valve keepers.

VALVE SPRIT{G OOMPfi ESSORATTACHMENT0775' - PJ1010A

Lightly tap the end of each valve stem two or three

times with a plastic mallet to ensure proper seating

of the valve and valve keepers, Tap the valve stem

only along its axis so you do not bend the stem.

PLASTE

6-29

www.emanualpro.com

Page 146 of 1395

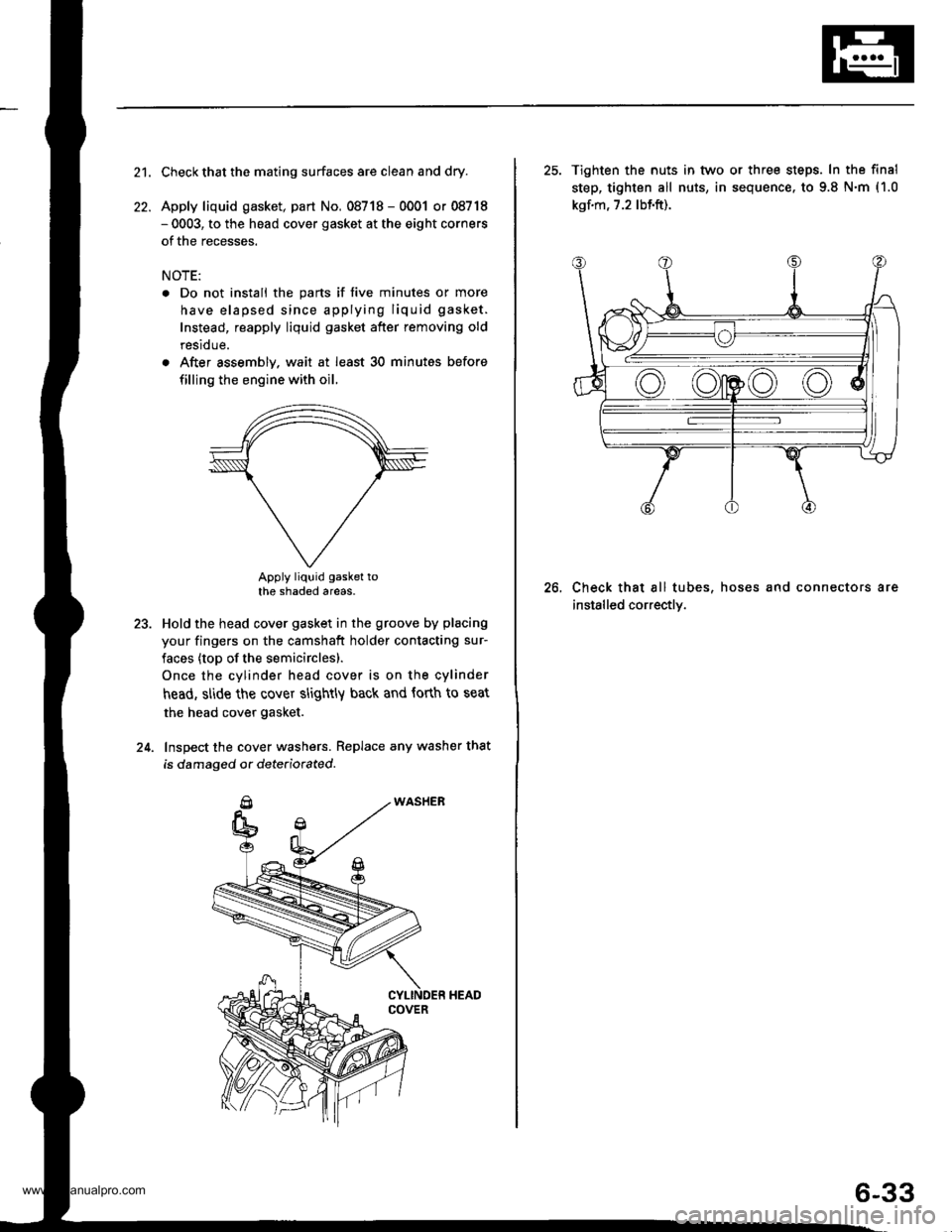

21.

22.

Check that the mating surfaces are clean and dry.

Apply liquid gasket, part No. 08718 - 0001 or 08718- 0003, to the head cover gasket at the eight corners

of the recesses.

NOTE:

. Do not install the parts if five minutes or more

have elapsed since applying liquid gasket.

Instead, reapply liquid gasket after removing old

residue.

. After assembly. wait at least 30 minutes before

filling the engine with oil.

Apply liquid gasket tothe shaded areas.

Hold the head cover gasket in the groove by placing

your fingers on the camshaft holder contacting sur-

faces (top of the semicirclesl.

Once the cylinder head cover is on the cylinder

head, slide the cover slightly back and forth to seat

the head cover gasket.

Inspect the cover washers. Replace any washer that

is damaged or dete(iorated.

23.

24.

25. Tighten the nuts in tvvo or three steps. In the final

step, tighten all nuts, in sequence. to 9.8 N.m (1.0

kgf.m, 7.2 lbf.ft).

Check that all tubes, hoses and connectors are

installed correctly.

26.

6-33

www.emanualpro.com

Page 167 of 1395

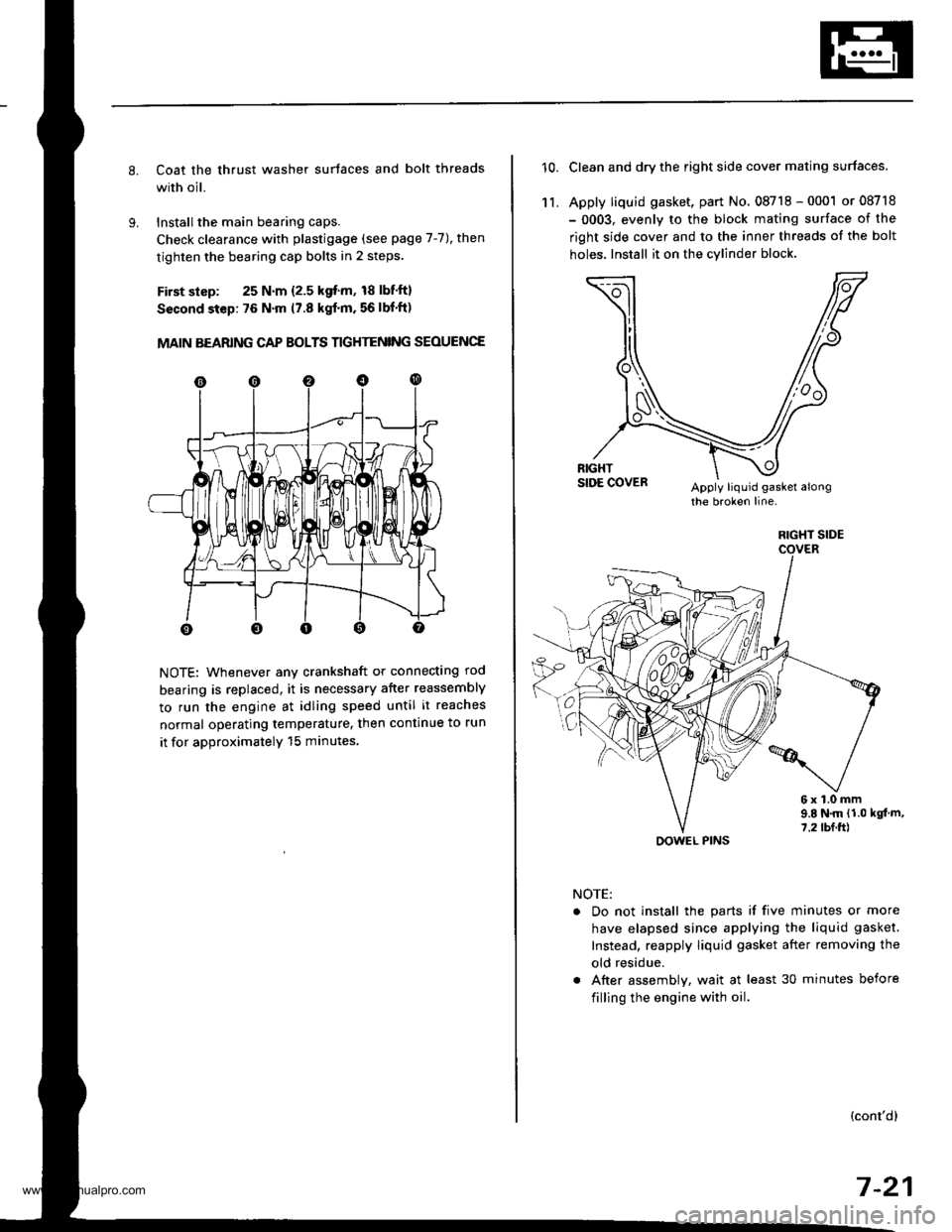

Coat the thrust washer surtaces and bolt threads

with oil.

Installthe main bearing caps.

Check clearance with plastigage (see page 7-7), then

tighten the bearing cap bolts in 2 steps.

First slsp: 25 N.m {2.5 kgf'm, 18 lbf'ft}

Sscond step: 76 N'm (7.8 kgf'm. 56 lbf'ft)

MAIN BEARING CAP BOLTS TIGHTENING SEOUENCE

NOTE: Whenever any crankshaft or connecting rod

bearing is replaced, it is necessary after reassembly

to run the engine at idling speed until it reaches

normal operating temperature, then continue to run

it for approximatelY 15 minutes.

10.Clean and dry the right side cover mating surfaces.

Apply liquid gasket, part No. 08718 - 0001 or 08718

- 0003, evenly to the block mating surface of the

right side cover and to the inner threads of the bolt

holes. Install it on the cylind€r block

11,

6x1.0mm9.E N.m {1.0 kgt m,7.2 tbf.ft)

NOTE:

. Do not install the parts if five minutes or more

have elapsed since applying the liquid gasket.

Instead, reapply liquid gasket after removing the

old residue.

. After assembly, wait at least 30 minutes before

filling the engine with oil.

(cont'dl

7-21

RIGHT SIDE

OOWEL PINS

www.emanualpro.com

Page 174 of 1395

Engine Oil

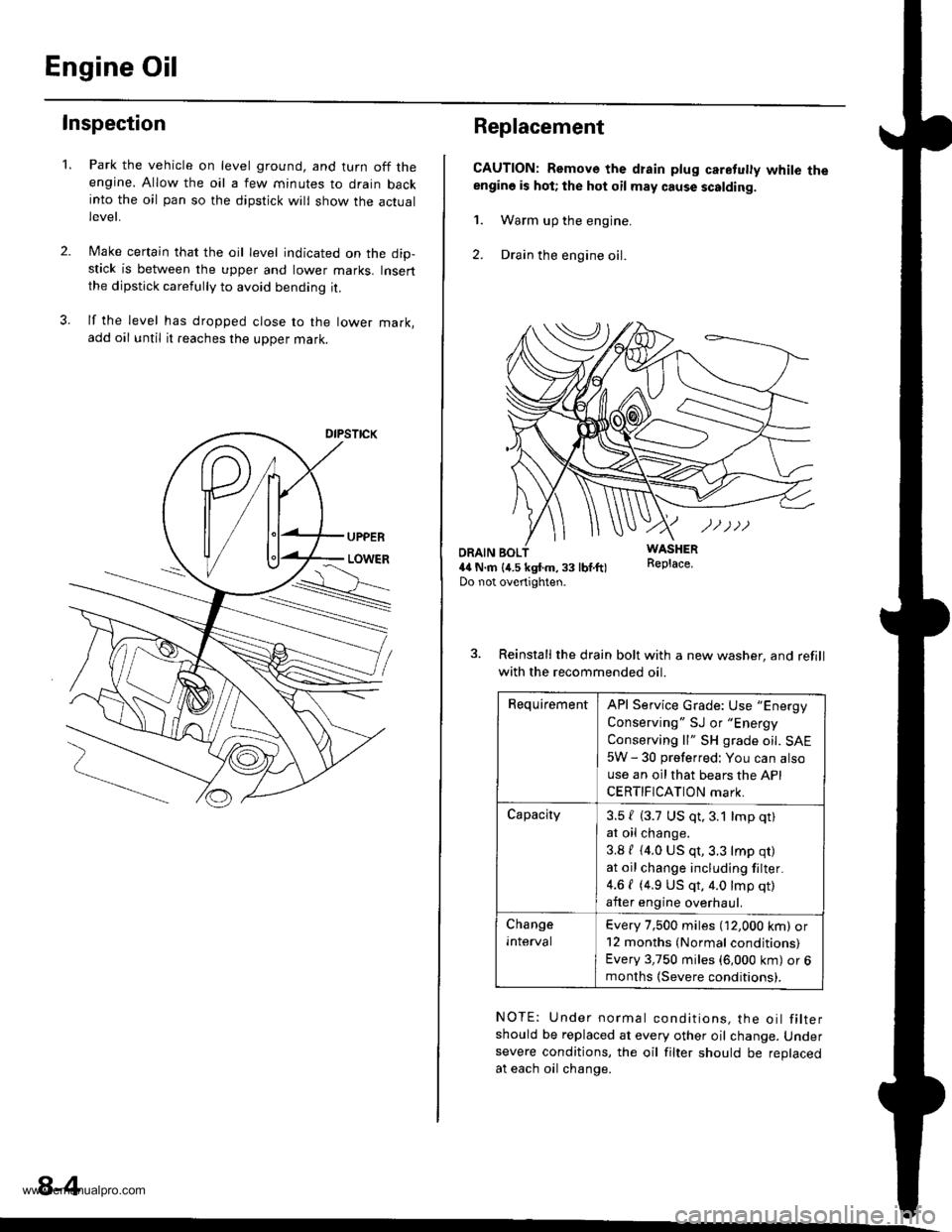

Inspection

2.

1.Park the vehicle on level ground, and turn off theengine. Allow the oil a few minutes to drain backinto the oil pan so the dipstick will show the actuallevet,

Make certain that the oil level indicated on the dip-stick is between the upper and lower marks. Insertthe dipstick carefully to avoid bending it.

lf the level has dropped close to the lower mark,add oil until it reaches the upper mark.

8-4

Replacement

CAUTION: Remove the drain plug caretuly white theengino is hot; the hot oil may cause scalding.

1. Warm up the engine.

2. Drain the engine oil.

WASHERR€place.ORAIN BOL4il N.m {4.5 kgtm,33 lbf.ft)Do not overtighten.

3. Reinstall the drain bolt with a new washer, and refill

with the recommended oil.

RequirementAPI Service Grade: Use "Energy

Conserving " SJ or "Energy

Conserving ll" SH grade oil. SAE

5W - 30 preferred: You can also

use an oil that bears the API

CERTIFICATION mark.

Capacity3.5 { (3.7 US qt,3.1 lmp qt)

at oil change.

3.8 / (4.0 US qt,3.3 lmp qr)

at oil change including filter.

4.6 { (4.9 US qt, 4.0 lmp qt)

after engine overhaul.

Change

Inlerval

Every 7,500 miles (12,000 km) or12 months (Normal conditions)

Every 3,750 miles (6,000 km) or 6months (Severe conditions).

NOTE: Under normal conditions, the oil filtershould be replaced at every other oil change. Undersevere conditions, the oil filter should be replacedat each oil change.

www.emanualpro.com