page 195 HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 27 of 1395

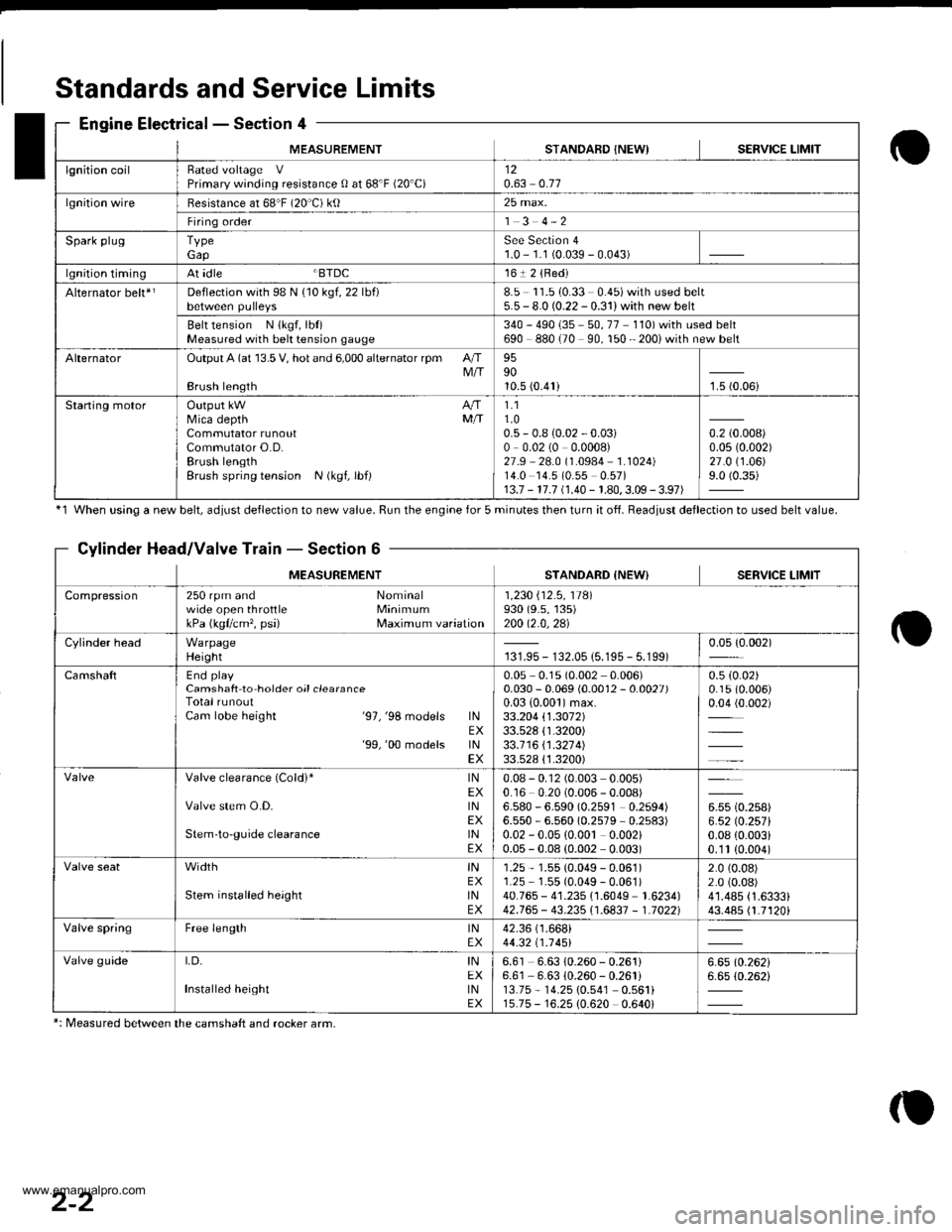

MEASUREMENTSTANDAFD INEWISERVICE LIMIT

lgnition coilRated voltage VPrimary winding resistance 0 at 68'F (20'C)120.63 0.77

lgnition wireBesistance at 68"F (20 C) ktl25 max.

Firing order1 3 4-2

Spark plugTypeGapSee Section 41.0 - 1.1 (0.039 - 0.043)

lgnition timingAt idle BTDC161 2 {Red)

Alternator belt*rDeflection with 98 N {10 kgf, 22 lbf)8.5 11.510.33 0.45)with used belt5.5 - 8.0 (0.22 - 0.31) with new belt

Belt tension N {kgf, lbt)Measured with bek tension gauge340 - 490 {35 - 50, 77 110) with used belt690 880 (70 90, 150 - 200i with new belt

AlternatorOutput A (at 13.5 V, hot and 6,000 alternator rpm AIIM/IBrush length

959010.5 (0.41)1.5 (0.06i

Staning motorOutput kW A/fMica depth MfiCommutator runoutCommutator O.D.Brush lengthBrush spring tension N (kgf, lbf)

1.11.00.5 - 0.8 {0.02 - 0.03)0,0.02 (0 0.0008)27.9 28.0 (1.0984 1.1024)14.0 14.5 (0.55 0.57)13.7 - 17.7 (1.40 - 1.80,3.09 - 3.97)

0.2 (0.008)

0.0s (0.002)

27.0 (1.06)

9.0 (0.35)

Standards and Service Limits

Engine Electrical - Section 4

'1 When using a new belt, ddiust deflection to new value. Run the engine for 5 minutes then turn it of{. Beadiust deflection to used belt value.

Cylinder Head/Valve Train - Section 6

MEASUREMENTSTANDARD {NEW} SERVICE LIMIT

Compression250 rpm and Nominalwide open throttle MinimumkPa (kgflcm'�, psi) Maximum variation

1 ,230 i'12 .5 , 11Al930 (9.s, 135)200 12.0,2al

Cylinder headWarpageHeight131.95 - 132.05 {5.195 - 5.199)0.05 {0.002)

CamshaftEnd playCamshaft to hoider oil clearanceTotal runoutCam lobe height '97,'98 models lNEX'99,'00 models lNEX

0.05 0.1s (0.002 0.006)0.030 - 0.069 (0.0012 - 0.0027)0.03 {0.001)max.33.204 \1.3072133.528 {1.3200)33.1 16 \1 .321 4)33.528 {'1.3200)

0.5 (0.02)

0.15 (0.006)

0.04 (0.002)

Valve clearance (Cold)* lNEXValve stem O.D. lNEXStem'to-guide clearance lNEX

0.08 - 0.12 (0.003 0.005)0.16 0.20 (0.006 - 0.008)6.580 - 6.590 (0.2591 0.2594)6.550 - 6.560 (0.2579 0.2s83)0.02 - 0.05 {0.00t 0.002)0.05 - 0.08 (0.002 0.003)

u* to.rutt6.52lO.257l0.08 {0.003i0.'1t (0.004)

width tNEXStem installed height lNEX

1.25 - 1.55 (0.049 - 0.061)1.25 1.55 (0.049 - 0.061)40.765 - 41.235 {1.6049 1.6234)42.765 - 43.235i'1.6837 - 1.70221

2.0 (0.08)

2.0 (0.08)

41.485 {1.6333}43.485 {1.7120i

Valve springFree length lNEX42.36 (1.668i

44.32 t1 .1 451

Valve guideI,D, INEXInstalled height tNEX

6.61 6.63 10.260 - 0.261)6.61 6.63 {0.260 - 0.261i13.75 - 14.25 10.541 0.561i15.75 - 16.25 {0.620 0.640i

6.6510.26216.65 (0.262i

*: Measured between the camshaft and rocker arm,

2-2

www.emanualpro.com

Page 140 of 1395

Cylinder Head

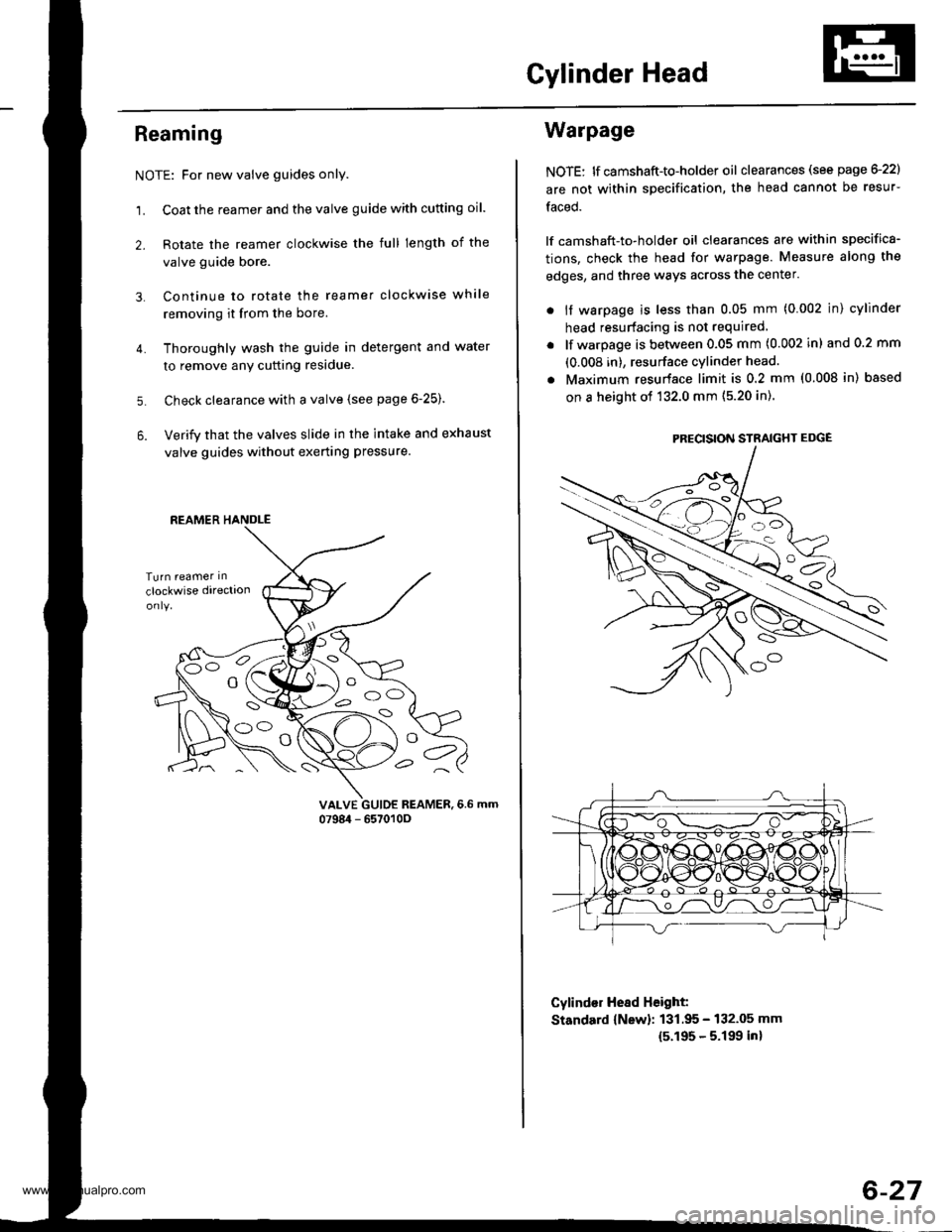

Reaming

NOTE: For new valve guides only.

1. Coat the reamer and the valve guide with cutting oil.

2. Rotate the reamer clockwise the full length of the

valve guide bore.

Continue to rotate the reamer clockwise while

removing it from the bore.

Thoroughly wash the guide in detergent and water

to remove anY cutting residue.

Check clearance with a valve (see page 6-25).

Verify that the valves slide in the intake and exhaust

valve guides without exerting pressure.

3.

4.

5.

6.

vALvE GUIDE REAMER,6.6 mm0798i1 - 657010O

REAMER HANDLE

e

Warpage

NOTE: lf camshaft-to-holder oil clearances (see page G22)

are not within specification, the head cannot be resur-

faced.

lf camshaft-to-holder oil clearances are within specifica-

tions, check the head for warpage. Measure along the

edges, and three ways across the center.

. if warpage is less than 0.05 mm (0.002 in) cylinder

head resurfacing is not required

lf warpage is between 0.05 mm (0.002 in) and 0.2 mm

(0.008 in), resurface cylinder head.

Maximum resurface limit is 0.2 mm (0.008 in) based

on a height of 132.0 mm (5.20 in).

Cylind€r Hesd Height:

Standard {New}: 131.95 - 132.05 mm

15.195 - 5.199 inl

PRECISION STRAIGHT EDGE

6-27

www.emanualpro.com

Page 208 of 1395

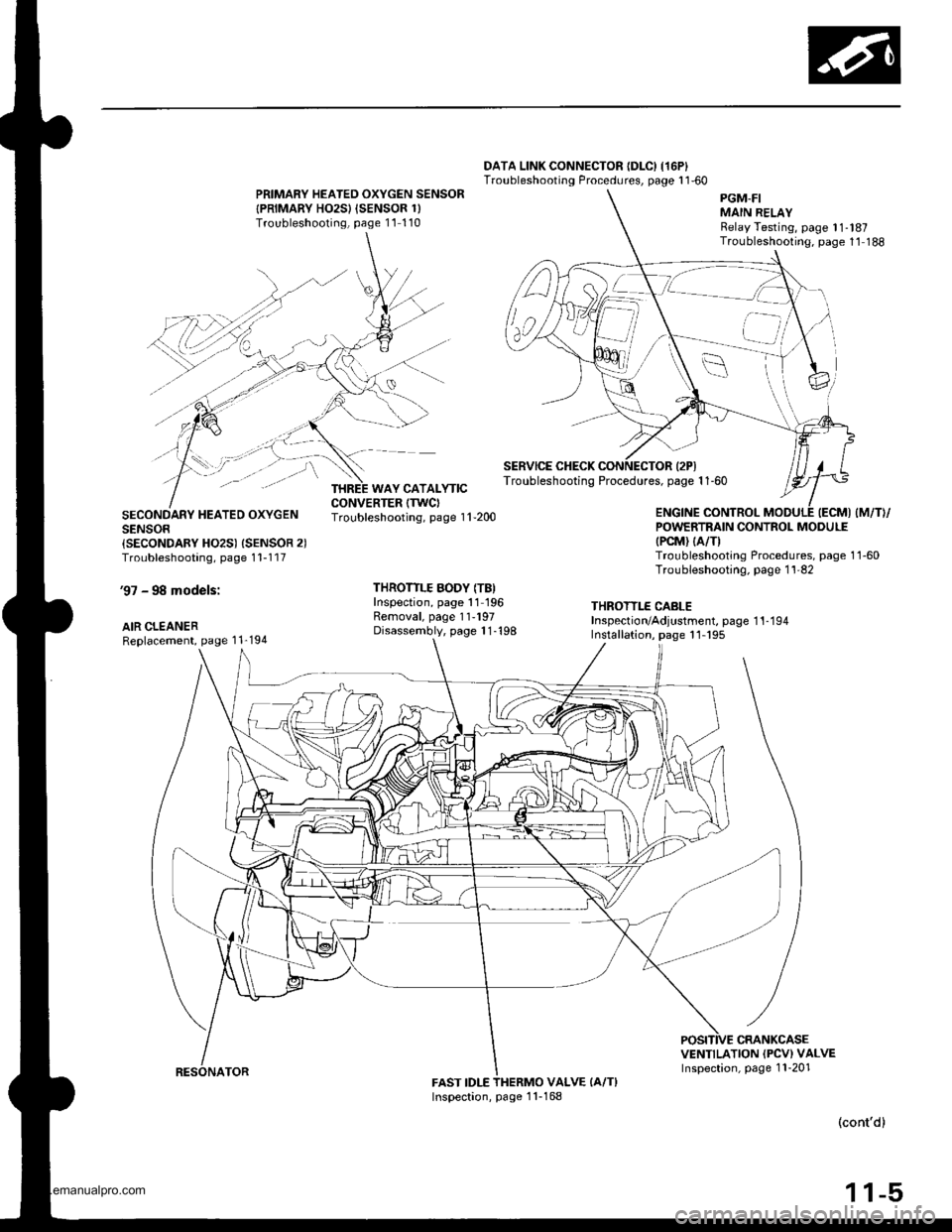

DATA LINK CONNECTOR {DLC) I16P}Troubleshooting Procedures, page 1 1'60PRIMARY HEATED OXYGEN SENSOR

{PRIMARY HO2SI {SENSOR 1)Troubleshooling, page 11 110

SECONDARY HEATED OXYGENSENSOR{SECONDARY HO2S) {SENSOR 2)Troubleshooting, page 1 1-1 17

'97 - 98 models:

AIR CLEANERReplacement, page 1 1'194

Troubleshooting, page 1 'l -200

THROTTLE BODY (TB)Inspection, page 11 196Removal, page 11-197Disassembly, page 1 1-'198

POWERTRAIN CONTROL MODULE(PCM) (A/TI

Troubleshooting Procedures, page 1 1-60Troubleshooting. page 1 1'82

THROTTLE CABLEInspection/Adjustment, page 1 1-1 94Installation, page 11- 195

VENTILATION (PCV) VALVEInspection, page 1 1-201FAST IDLEVALVE (A/T}

(cont'd)

1 1-5

PGM-FIMAIN RELAYRelay Testing, page 11-l87Troubleshooting. page 1'1 188

SERVICE CHECK CONNECTOR {2PITroubleshooting Procedures, page 1 1-60

,a'=_-_

WAY CATALYTIC

Inspection, page 1 1-168

www.emanualpro.com

Page 209 of 1395

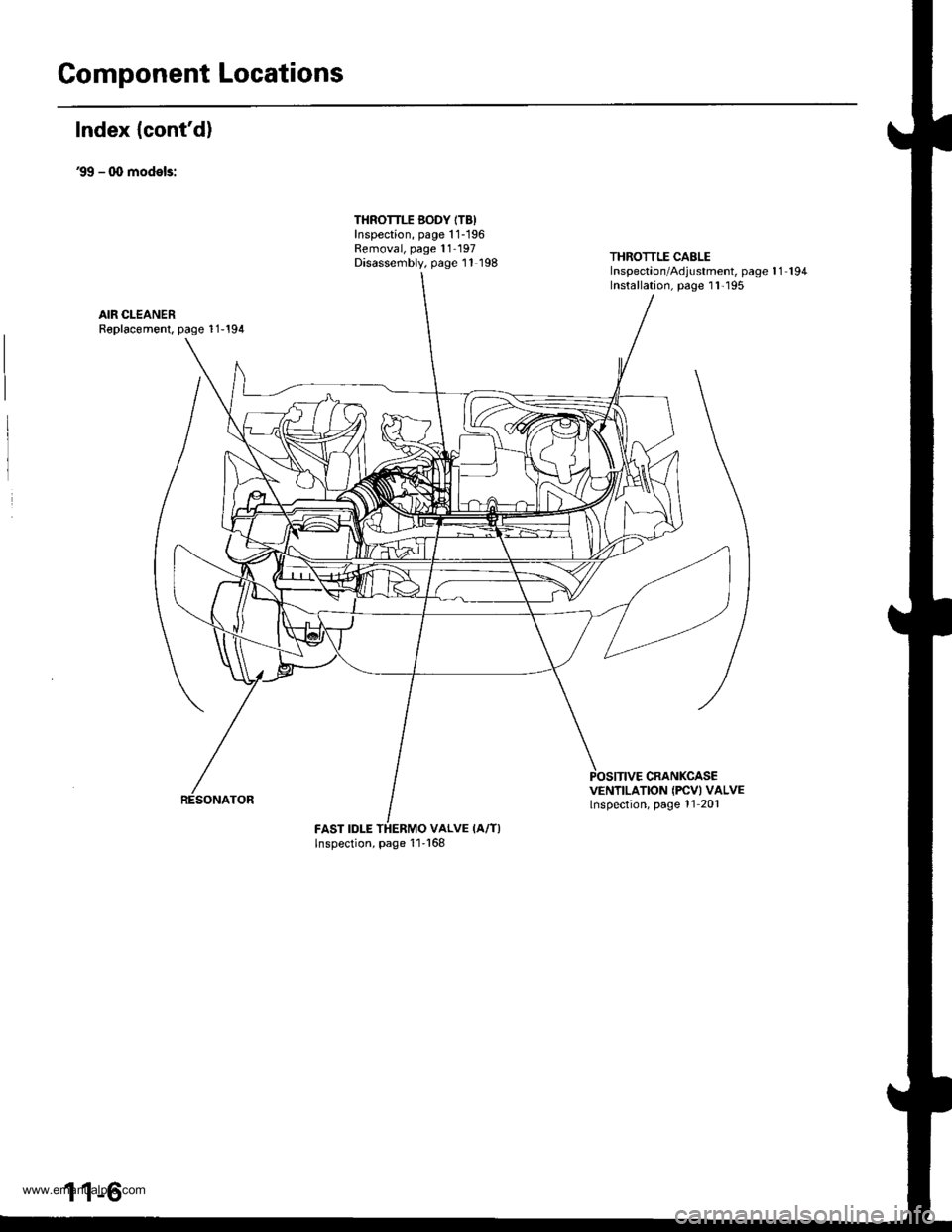

Component Locations

Index {cont'd)

39 - q, models:

THROTTLE BODY ITB)Inspection, page 1 1-196Removal, page 11- 197Disassembly, page 11 198THROTTLE CABLEInspectaon/Adjustment, page 1 1 194Installation, page I l'195

AIR CLEANERR€placomenl, page 1 1-194

CRANKCASEVENTILATION IFCVI VALVElnspection, page 11 201

FAST IDLE THERMO VALVE IA/T)Inspection, page 11'168

1 1-6

www.emanualpro.com