transmission harness HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1998, Model line: CR-V, Model: HONDA CR-V 1998 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 102 of 1395

Engine Removal/lnstallation

Removal (cont'd)

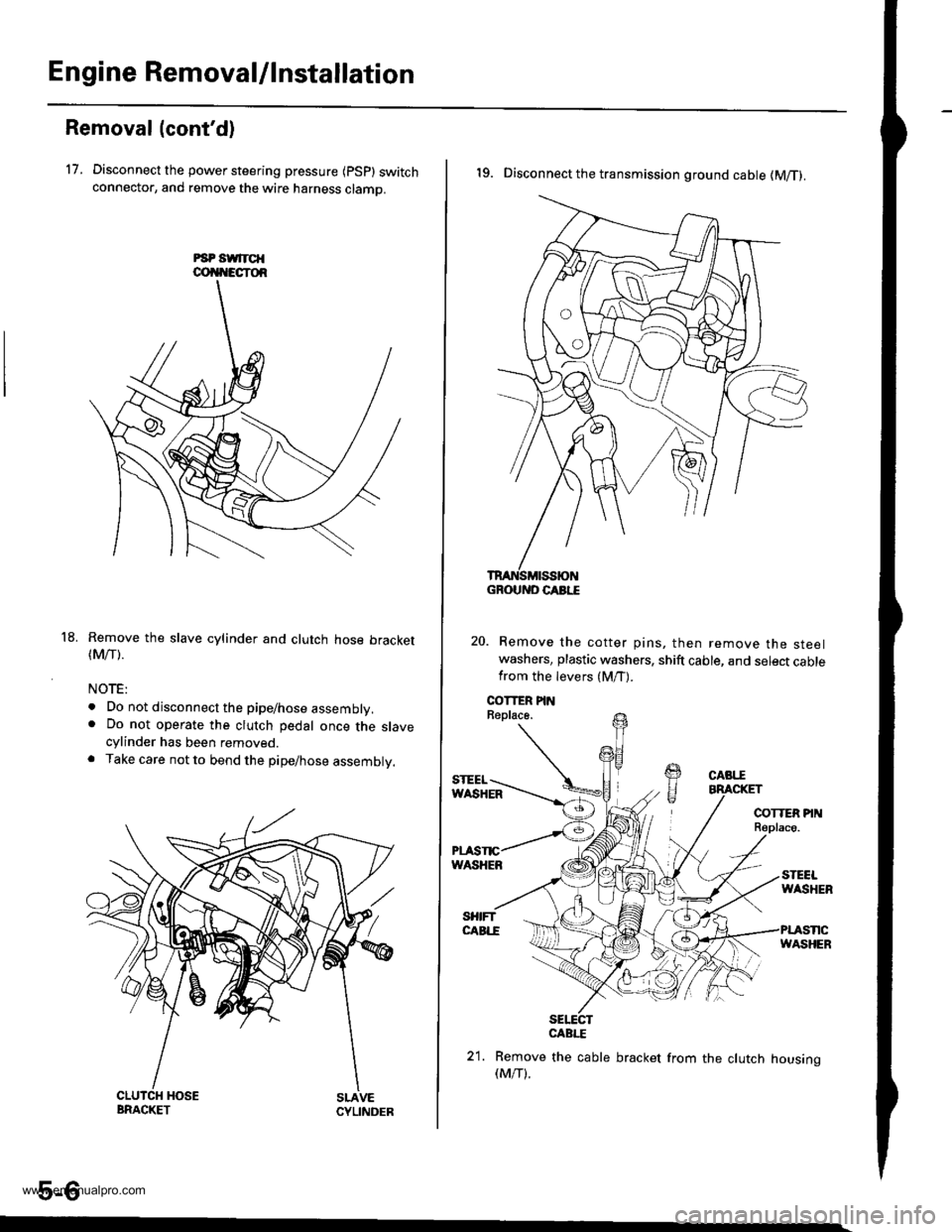

17. Disconnect the power steering pressure {psp} switchconnector, and remove the wire harness clamo.

Remove the slave cylinder and clutch hose bracket(Mrr).

NOTE:

. Do not disconnect the pipe/hose assembly.. Do not operate the clutch pedal once the slavecylinder has been removed.. Take care not to bend the pipe/hose assembly.

5-6

18.

19. Disconnect the transmission ground cable (M/T).

Remove the cotter pins, then remove the steelwashers, plastic washers, shift cable, and select cablefrom the levers (M/T).

sElEcrCABI."E

21. Remove the cable bracket from the clutch housing(M/T).

GROUND CABI."E

www.emanualpro.com

Page 390 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

Fuel Supply System

PGM-FI Main Relay (contdl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,TilI A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PG HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

Fuel Supply System

PGM-FI Main Relay (contdl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,TilI A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PG](/img/13/5778/w960_5778-389.png)

Fuel Supply System

PGM-FI Main Relay (cont'dl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,Til'I A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PGM-FI mainrelay and relay harness,

Check fo. an open in the wireIGND linol:1. Turn the ignition switch OFF.2. Disconnect the PGM Fl mainrelay 7P connector.3. Check for continuity betweenthe PGM'FI main relay 7P con-nector terminal No. 3 and bodyground.

Repair opcn in th€ wire betweenthe PGM-FI main relav and G101.

Check tor an open or short in thewiro (BAT line):Measure voltage between thePGM'FI main relay 7P connectorterminal No. 7 and body ground.- Repai. open or short in lhewir6 belween the PGM-FImain relay and the Fl E/M (15Al fu3e.- Replace th6 FIE/M (15 Altus6in th€ under-hood fuse/.6lay

ls there baftery voltage?

Check lor an open or short in thewire (lGl line):L Turn the ignition switch ON (ll).2. Measure the voltage betweenthe PGM-FI main relay 7P connectorterminal No. 5 and bodyground.- Repair open or shorl in thewire between the FGM-FI mainrelay and the No. 13 FUELPUMP 115 A) tuse.- Replaco the No. 13 RJEL PUMP115 A) luse in the und6.-d$hfuso/ relav box.Check for an open or short in thewire {STS line):1. Turn the ignition switch to theSTART (lll) position.NOTE:. M/T: Clutch pedal must bedepressed.. A/T: Transmission in E orElposition.2. Measure the voltage betweenthe PGM-Fl main retay 7Pconnector terminal No. 2 andbody ground.- Repair open or short in thewire betwe€n the PIGM-FI m.inrclay and th€ No. 31 STARTERSlGllAL 17.5 A) tuse.- Repl.ce the No. 31 STARTERSIGNAL 17.5 Al tuse in theunder-dash tuse/relay box.('97 model: To page 11-189)('98 00models:To page 1l 190)

1 1-188

www.emanualpro.com

Page 446 of 1395

Transmission AssemblY

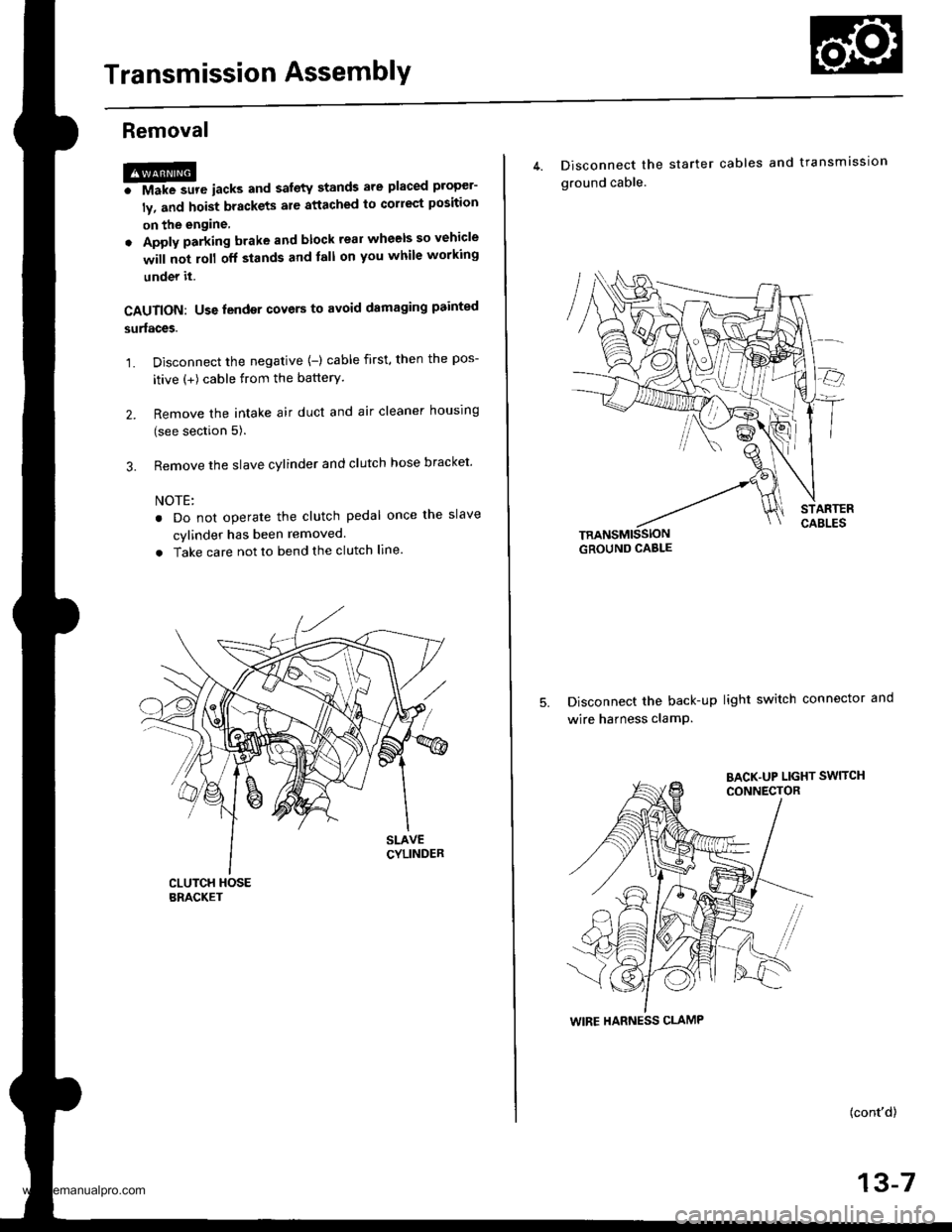

Removal

@FMak. sw. iack" and safety stands are placed propel-

ly, and hoist brackets are attached to collect position

on the engine,

. Apply parking brake and block rear wheels so vehicle

will not roll off stands and lall on you while working

under it.

CAUTION: Use fender covers to avoid damaging painted

surfaces.

1. Disconnect the negative {-) cable first, then the pos-

itive (+) cable from the batterY.

2. Remove the intake air duct and air cleaner houslng

(see section 5).

3. Remove the slave cylinder and clutch hose bracket'

NOTE:

. Do not operate the clutch pedal once lhe slave

cvlinder has been removed.

. Take care not to bend the clutch line.

4. Disconnect the

ground cable.

starter cables and transmission

TRANSMISSIONGROUND CABLE

Disconnect the back-up light switch connector and

wire harness clamP.

(cont'd)

13-7

WIRE HARNESS CLAMP

www.emanualpro.com

Page 514 of 1395

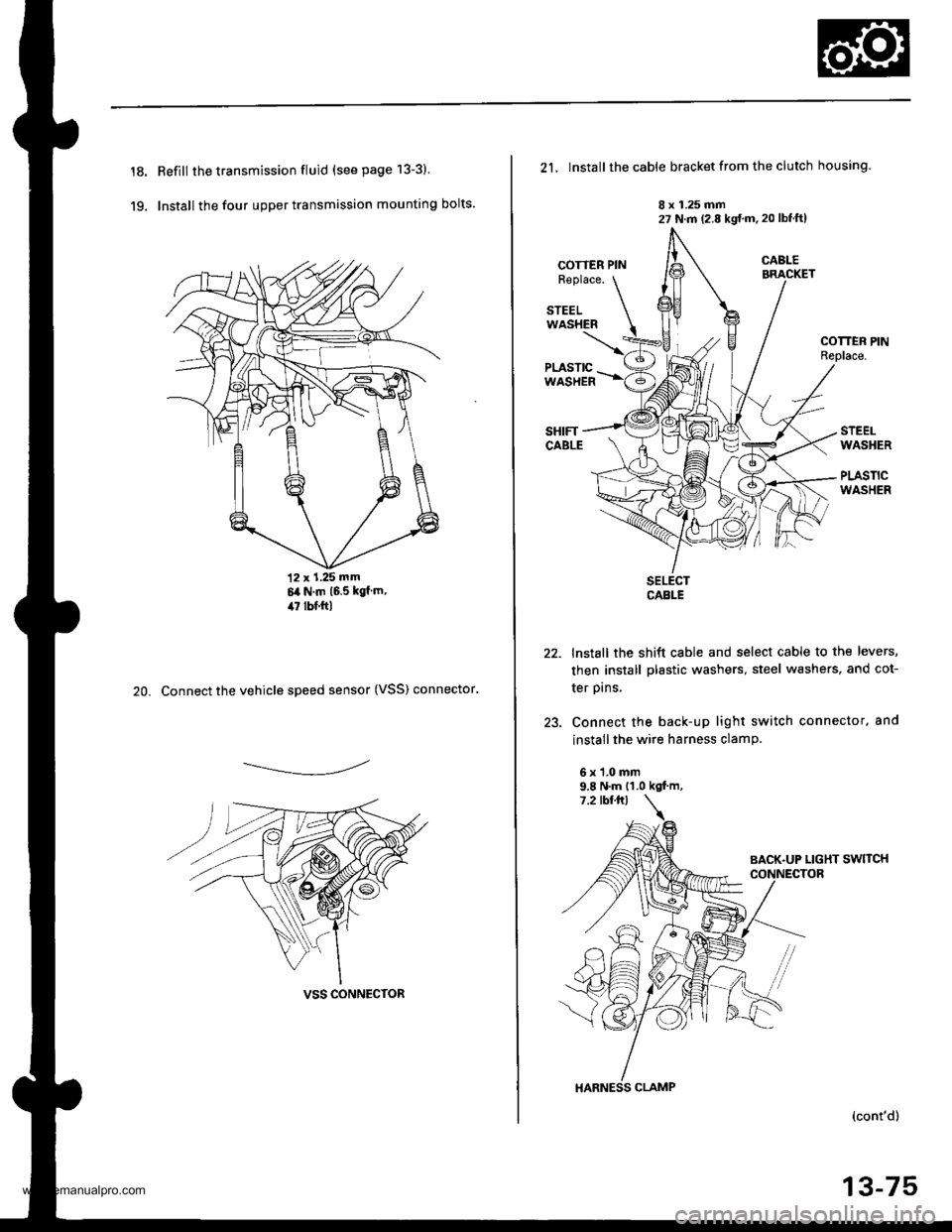

18.

19.

Refill the transmission fluid (see page 13-3)

Install the four upper transmission mounting bolts.

12 x 1.25 mm6it N.m 16.5 kgf m,il7 lbf.ftl

20. Connect the vehicle speed sensor (VSS) connector.

------------,-

VSS CONNECTOR

21, Install the cable bracket from the clutch housing.

8 x 1.25 mm27 N.m (2.8 kgt'm. 20 lbtftl

COTTER PINR€place.

STEELWASHER

COTTEN PINReplace.

STEELWASHER

PLASTICWASHER

22.

)a

SELECTCABLE

lnstall the shift cable and select cable to the levers,

then install plastic washers, steel washers, and cot-

ter prns,

Connect the back-up light switch connector. and

install the wire harness clamP.

6x1.0mm9.8 N.m {1.0 kgf.m,

HARNESS CLAMP

(cont'd)

13-75

www.emanualpro.com

Page 685 of 1395

Transmission

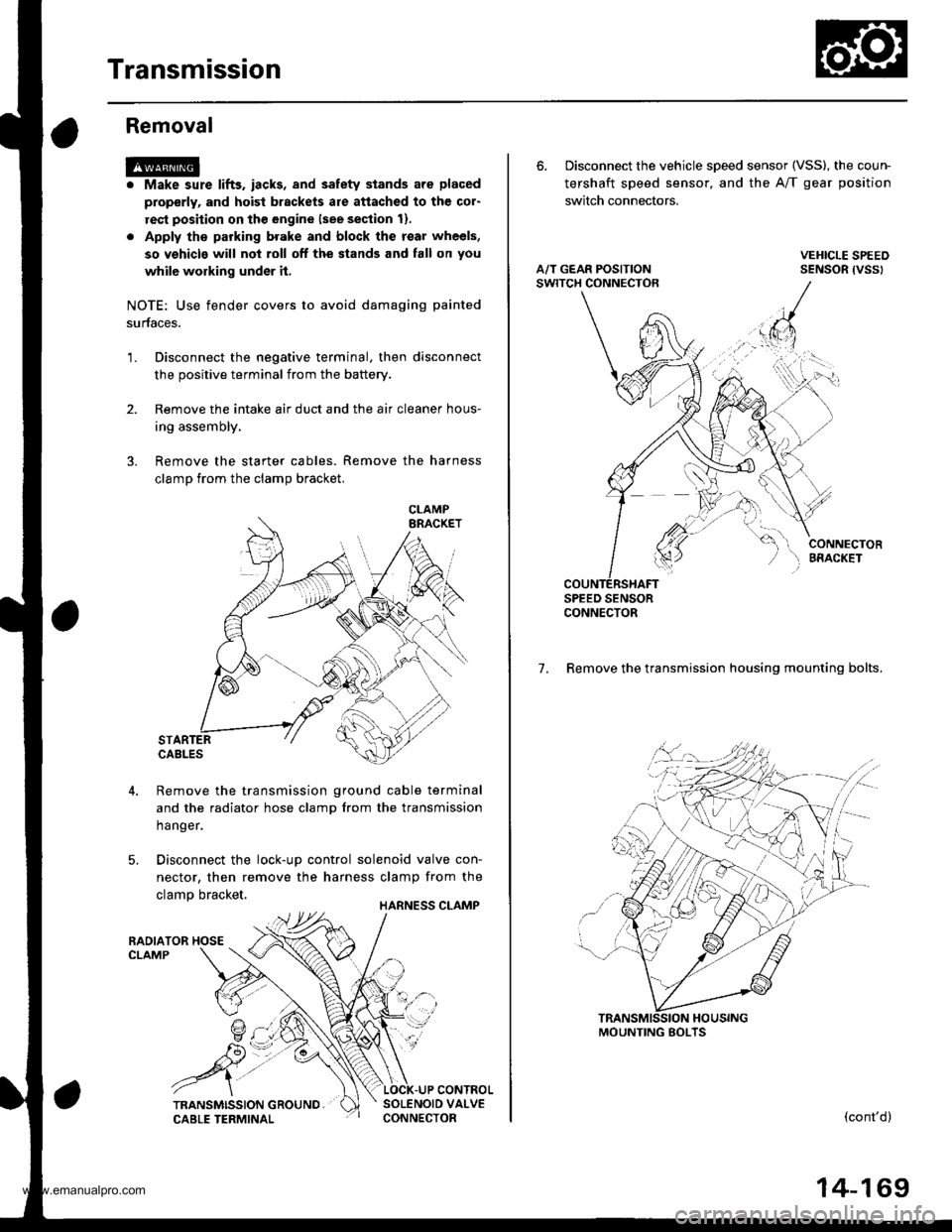

Removal

@

2.

'1.

Make sure lifts. iacks, and safety stands aro placed

properly, and hoist brackets are attached to the col-

rest position on the engine lsee section 11.

Apply th€ parking brake and block the r€ar wheels,

so vehicls will noi roll off the stands and fall on you

while working under it.

NOTE: Use fender covers to avoid damaging painted

surfaces.

Disconnect the negative terminal, then disconnect

the positive terminal from the battery.

Remove the intake air duct and the air cleaner hous-

ing assembly,

Remove the starter cables. Remove the harness

clamp from the clamp bracket.

5.

STARTERCABLES

Remove the transmission ground cable terminal

and the radiator hose clamp lrom the transmission

hanger.

Disconnect the lock-up control solenoid valve con-

nector, then remove the harness clamp from the

clamp bracket.HARNESS CLAMP

RADIATOR HOSECLAMP

CONTROLSOLENOID VALVECONNECTOR

CLAMP

6. Disconnect the vehicle speed sensor (VSS), the coun-

tershaft speed sensor, and the A/T gear position

switch connectors.

A/T GEAR POSITIONSWITCH CONNECTOR

VEHICLE SPEEDSENSOR |VSS'

CONNECTORBfiACKET

SPEED SENSORCONNECTOR

7. Remove the transmission housing mounting bolts.

MOUNTING BOLTS

(cont'd)

14-169

www.emanualpro.com

Page 693 of 1395

![HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

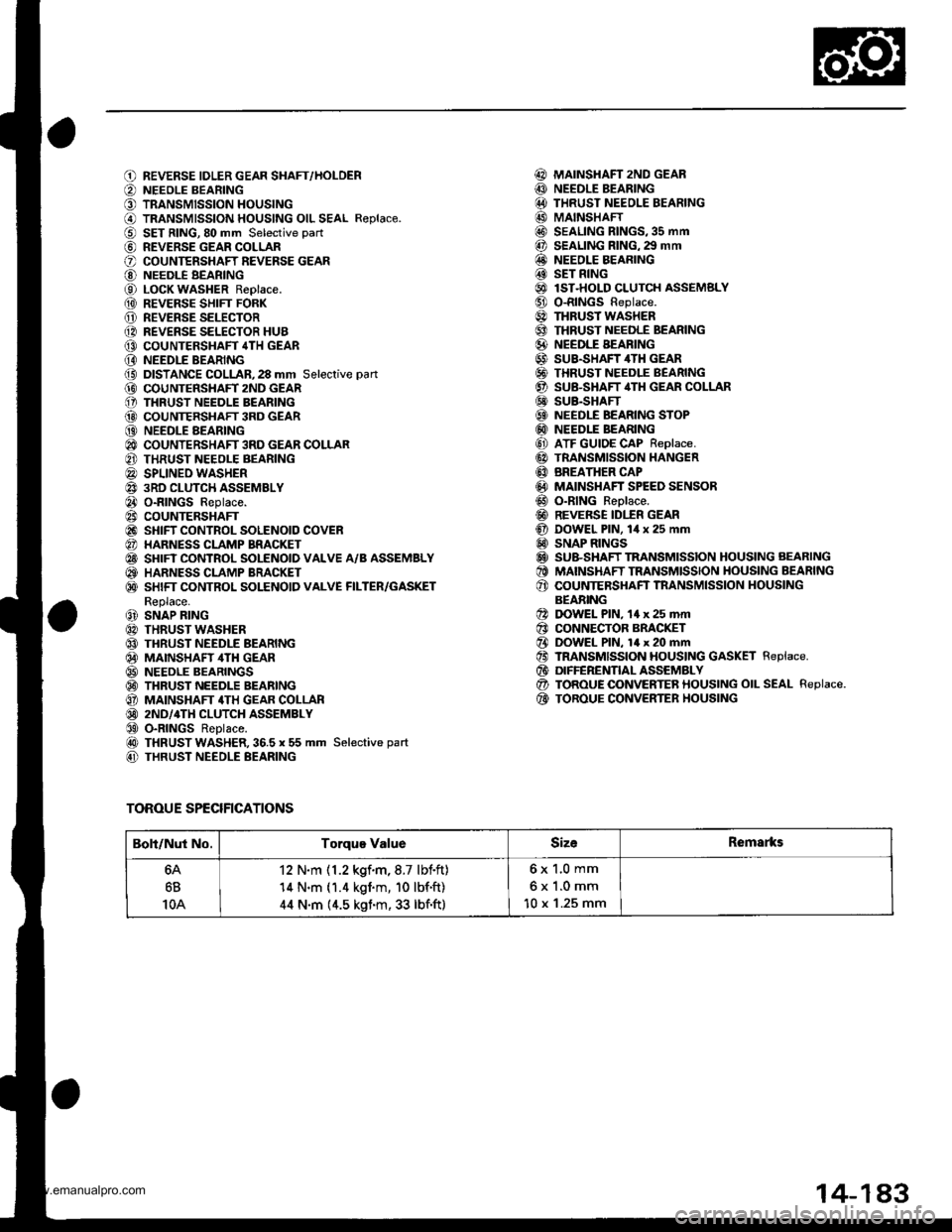

r] REVERSE IDLER GEAR SHAFT/HOLDERA N€EDLE BEARING

..] TRANSMISSION HOUSING

al TRANSMISSION HOUSING OIL SEAL Replace.g SET BING.80 mm Selecrive part

O REVERSE GEAR COLLABE couNTERSHAFT REVERSE GEA HONDA CR-V 1998 RD1-RD3 / 1.G Workshop Manual

r] REVERSE IDLER GEAR SHAFT/HOLDERA N€EDLE BEARING

..] TRANSMISSION HOUSING

al TRANSMISSION HOUSING OIL SEAL Replace.g SET BING.80 mm Selecrive part

O REVERSE GEAR COLLABE couNTERSHAFT REVERSE GEA](/img/13/5778/w960_5778-692.png)

r] REVERSE IDLER GEAR SHAFT/HOLDER'A N€EDLE BEARING

..] TRANSMISSION HOUSING

al TRANSMISSION HOUSING OIL SEAL Replace.g SET BING.80 mm Selecrive part

O REVERSE GEAR COLLABE couNTERSHAFT REVERSE GEAB

.9,] NEEDLE BEARINGi9 LOCK WASHER Replace..1!i REVERSE SHIFT FORKO REVERSE SELECToRiJ. REVERSE SELECTOR HUBii' COUNTERSHAFT 4TH GEAR.14 NEEDLE BEARINGiD D|STANCE coLLAR,28 mm Selective part(i3 COUNTERSHAFT 2NO GEABi7-] THRUST NEEDLE BEARING(10 COUNTERSHAFT 3RD GEAR(9 NEEDLE BEARINGE9 COUNTERSHAFI3RD GEAB COLLAR.li THRUST NEEDLE BEARING.?) SPLINEO WASHER,,O 3RD CLUTCH ASSEMBLY

€1 O-RING Beplace.i23 COUNTERSHAFT

4i SHIFT CONTROL SOLENOID COVER

?Z] HARNESS CLAMP BRACKET

?9] SHIFT CONTROL SOLENOID VALVE A/B ASSEMBLY

8 HARNESS CLAMP BRACKET

GI SHIFT CONTROL SOLENOID VALVE FILTER/GASKET

(4 MAINSHAFT 2ND GEARi49 NEEDLE BEARING

@ THRUST NEEDLE BEARING(49 MAINSHAFT

@r SEAL|NG R|NG,35 mm

O SEALING RING,29 mm

@ NEEDLE BEARING

.49 SET RING

€) lST.HOLD CLUTCH ASSEMBLY

O o-RING Replace.6E THRUST WASHER

€9 THRUST NEEDLE BEARING

6' NEEDLE EEARING

€ir SUB-SHAFT 4TH GEAR

6 THRUST NEEDLE BEARING

@ SUB.SHAFT 4TH GEAR COLLAR@ sUB-sHAFf

6I NEEDI-E B€ARING STOP

@ NEEDLE BEARING(6t ATF GUIDE CAP Replace.(64 TRANSMISSION HANGEB

@ BREATHER CAP

i@ MAINSHAFT SPEED SENSOR

6i O-RING Replace.

6D REVERSE IDLER GEAR

@r DOWEL PlN, 14 x 25 mm.6d SNAP RINGS

QlI SUB.SHAFT TRANSMISSION HOUSING BEARING

E) MAINSHAFT TRANSMISSION HOUSING BEABING.2, COUNTERSHAFI TRANSMISSION HOUSINGBEARING

@[E

t,n9t0@)@),lD

04

@

@@:���������������.ro)

ai

Replace-SNAP RINGTHRUST WASHEBTHRUST NEEDLE BEARINGMAINSHAFT 4TH GEARNEEDLE BEARINGSTHRUST NEEDLE BEARINGMAINSHAFT 4TH GEAB COLLAR2NO/4TH CLUTCH ASSEMBLYO-RING Replace.THRUST WASHER,36.5 x 55 mm Selective partTHRUST NEEOLE BEARING

DOWEL PlN, 14 x 25 mmCONNECTOR BRACKETATF MAGNETDOWEL PlN, 14 x 20 mmTRANSMISSION HOUSING GASKET Replace.DIFFERENTIAL ASSEMBLYDOWEL PlN, 10 x 12 mmO-RING Replace.TRANSFER ASSEMBLYTOROUE CONVERTER HOUSING OIL SEAL Replace.TOROUE CONVERTER HOUSING

TOROUE SPECIFICATIONS

Bolt/Nut No.Torque ValueSizeRgmarks

6A

6B

10A

12 N.m (1.2 kgf.m,8.7 lbf.ft)

14 N.m (1.4 kgf.m, 10 lbift)

44 N.m (4.5 kgf.m,33 lbf.ft)

6x 1.0 mm

6x 1.0 mm

10 x 1.25 mm

14-177

www.emanualpro.com

Page 699 of 1395

oatl,6

@!.,

ao6l

@o@@@@@o@@@)@@@@@@@@@@)

@@@@)@@@@@@@

REVERSE IDLER GEAR SHAFT,/HOLDERNEEOLE BEARINGTRANSMISSION HOUSINGTRANSMISSION HOUSING OIL SEAL R€place.SET RING,80 mm Selective part

REVERSE GEAR COLLARCOUNTERSHAFT REVERSE GEARNEEDLE BEARINGLOCK WASHER Replace.REVERSE SHIFT FORKREVERSE SELECTORREVERSE SELECTOR HUBCOUNTERSHAFT 4TH GEARNEEDLE BEARINGDISTANCE COLLAR,28 mm Selective pan

COUNTERSIIAFT 2ND GEARTHRUST NEEDLE BEARINGCOUNTERSHAFT 3RD GEARNEEDLE AEARINGCOUNTERSHAFT 3RD GEAR COLLARTHRUST NEEOLE BEARINGSPLINEO WASHER3RD CLUTCH ASSEMBLYO-RINGS Replace.COUNTERSHAFTSHIFT CONTROL SOLENOID COVERHARNESS CLAMP BRACKETSHIFT CONTROL SOLENOID VALVE A/B ASSEMBLYHARNESS CLAMP BRACKETSHIFT CONTROL SOLENOID VALVE FILTER/GASKETReplace.SNAP RINGTHRUST WASHERTHRUST NEEDLE BEARINGMAINSHAF ,ITH GEARNEEDLE BEARINGSTHRUST NEEDLE BEARINGMAINSHAFT 4TH GEAR COLLAR2ND/4TH CLUTCH ASSEMBLYO-RINGS ReDlace.THRUST WASHER,36.5 x 55 mm Selective part

THRUST NEEDLE BEARING

MAINSHAFT 2ND GEARNEEDLE BEARINGTHRUST NEEOLE BEARINGMAINSHAFTSEALING RINGS,35 mmSEALING RING. 29 mmNEEDLE BEARINGSET RINGlST-HOLD CLUTCH ASSEMSLYO-RINGS Replace.THRUST WASHERTHRUST NEEDLE BEARINGNEEDLE BEARINGSUB.SHAFT 4TH GEARTHRUST NEEDLE BEARINGSU&SHAFT,ITH GEAR COLLARSUB.SHAFTNEEDLE BEARING STOPNEEDLE BEARINGATF GUIDE CAP Replace.TRANSMISSION HANGERBREATHER CAPMAINSHAFT SPEED SENSORO-RING Reolace.REVERSE IDI.fR GEARDOWEL PlN, lil x 25 mmSNAP RINGSSU&SHAFT TRANSMISSION HOUSING AEARINGMAINSHAFT TRANSMISSION HOUSING BEARINGCOUNTERSHAFT TNANSMISSION HOUSINGBEABINGDOWEL PlN, 14 x 25 mrnCONNECTOR BRACKETDOWEL PlN, 14 x 20 mmTRANSMISSION HOUSING GASKET Replace.DIFFERENTIAL ASSEMBLYTOROUE OONVERTER HOUSING OIL SEAL Replace.TOROUE CONVERTER HOUSING

@@@@@@@@@@@@@@@@@@@@@@@)@@@@@@@

@@@@@@@

TOROUE SPECIFICATIONS

Boli/Nut No.Torque ValueSizeRemarks

6B

10A

12 N.m (1.2 kgf.m,8.7 lbf.ft)'14 N.m (1.4 kgim, 10 lbf'ft)

44 N.m (4.5 kgim, 33 lbf.ft)

6x 1.0 mm

6x1.0mm

10 x '1.25 mm

14-1A3

www.emanualpro.com

Page 702 of 1395

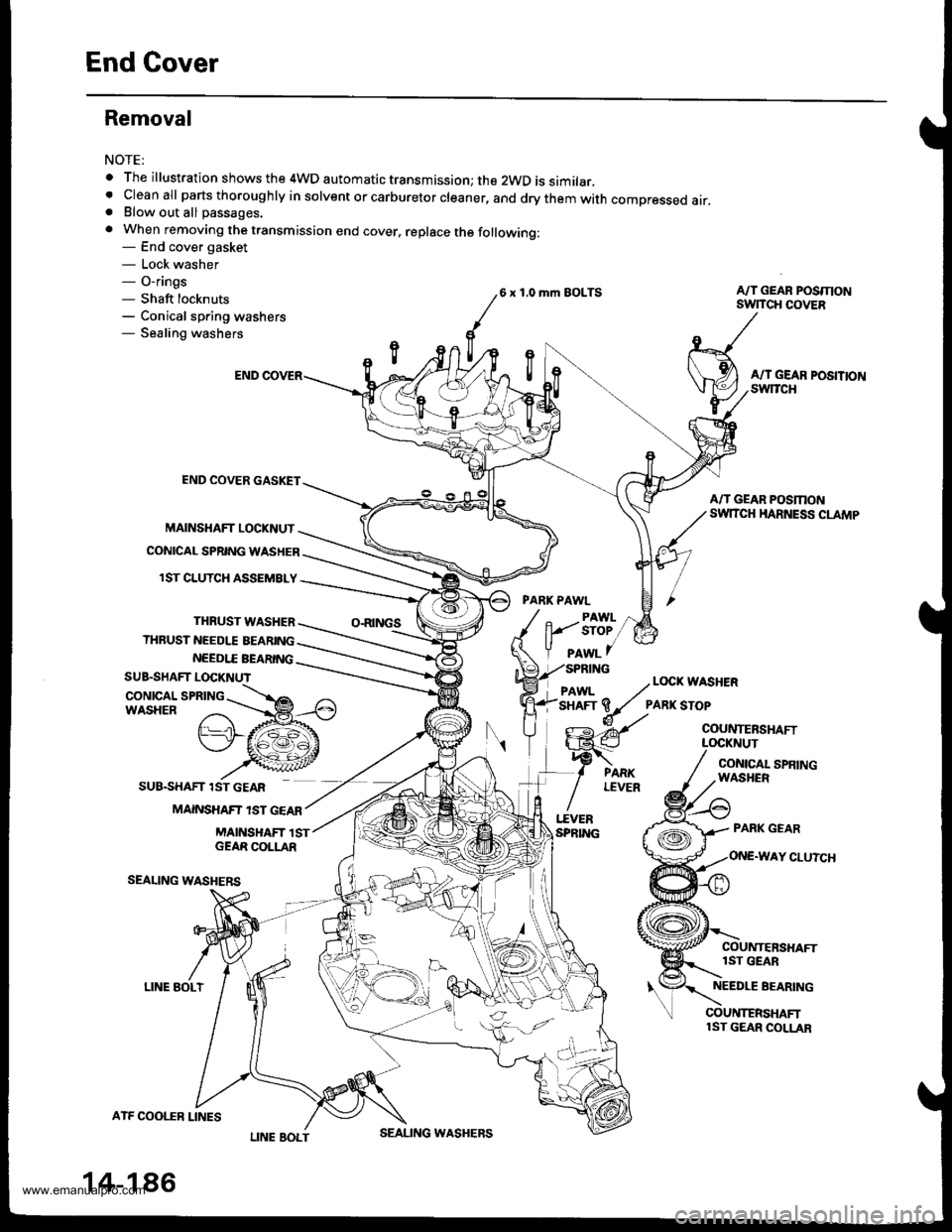

End Cover

Removal

NOTE:

o The illustration shows the 4WD automatic transmission; the 2WD is similar.. cleanall parts thoroughly in solvent or carburetor cleaner, and drythem with compressed air.. Blow out all passages.

. When removing the transmission end cover, replace the following:- End cover gasket- Lock washer- O-rings- Shaft locknuts- Conical spring washers- Sealing washers

END COVER GASKET

MAINSHAFT LOCKNUT

CONICAL SPRING WASHER

6 x 1 .0 rhm EOLTS

PARK PAWL

A/T GEAR POSMONSwlTCH COVER

NEEDI.T BEARING

SUB.SHAFT LOCKNUT

CONICAL SPRINGWASHER

LINE AOLT

ATF COOI.f B LINES

14-186

PAwL 7// Locx wASHER

'sHAFr 9/ ?ARK srop

o-- Ay' couNTERsHAFr

G-€ LocKNUr!€ / ..t,"o, "oo

A/T GEAR POSMONSW|TCH HARNESS CLAMP

CONICAL SPRINGWASHCR

A/T GEAR POSITION

PARK GEAR

Y CLUTCH

lST GEAR

NEEDLE BEARING

1ST CLUTCH ASSEMBLY

THRUST WASHER

THRUST NEEDLE AEARING

O.RINGS

\\

SUB.SHAFT 1ST GEAR

MAINSHAF? 'ST GEAR

MAINSHAFT 1STGEAR COLLAR

SEALING WASHERS

!€'-l

I"EVERSPRING

COUNTERSHAFTlST GEAR COLLAR

PAWL

lt1/ sroe

Y plwl f

L/'SPRING

LOCKNUT

LINE BOLTSEALING WASHERS

www.emanualpro.com

Page 703 of 1395

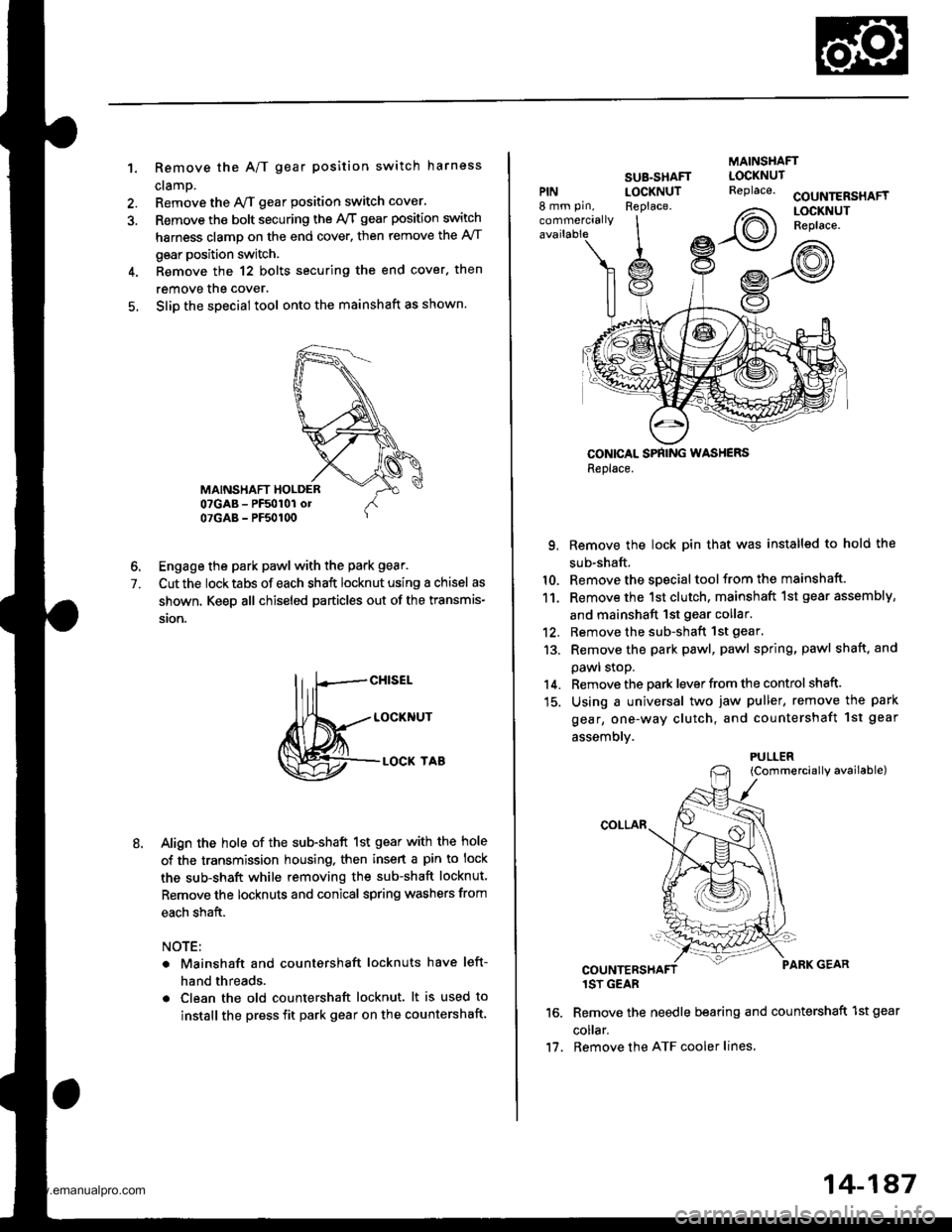

1. Remove the A/T gear position switch harness

cramp.

Remove the y'VT gear position switch cover.

Remove the bolt securing the ly'T gear position switch

harness clamp on the end cover, then remove the A/T

gear position switch.

Remove the 12 bolts securing the end cover. then

remove the cover.

Slip the special tool onto the mainshaft as shown.

6. Engage the park pawl with the park gear.

7. Cut the locktabs of each shaft locknut using a chisel as

shown. Keep all chiseled particles out of the transmis-

ston.

M=tt"

Align the hole of the sub-shaft 1st gear with the hole

of the transmission housing. then insert a pin to lock

the sub-shaft while removing the sub-shaft locknut.

Remove the locknuts and conical spring washers from

each shaft.

NOTE:

Mainshaft and countershaft locknuts have left-

hand threads.

Clean the old countershaft locknut. lt is used to

install the press fit park gear on the countershaft.

MAINSHAFT

PIN8 mm pin,

commercially

SUB-SHAFTLOCKNUTReplace.COUNTERSHAFTLOCKNUTReplace.

CONICAL SPNING WASHERSReplace.

9. Remove the lock pin that was installed to hold the

sub-shaft.

10. Remove the special tool from the mainshaft.

11. Remove the 1st clutch, mainshaft 1st gear assembly,

and mainshaft 1st gear collar.'12. Remove the sub-shaft 1st gear.

13. Remove the park pawl, pawl spring, pawl shaft. and

pawl stoP.

14. Remove the park lever from the control shaft.

15. Using a universal two jaw puller, remove the park

gear, one-way clutch, and countershaft 1st geal

assemblv.

{Commercially available)

1SY GEAR

Remove the needle bearing and countershaft 1st gear

co ar.

Remove the ATF cooler lines,

LOCKNUTReplace.

2\

Irot)

PULLER

11.

14-187

www.emanualpro.com

Page 773 of 1395

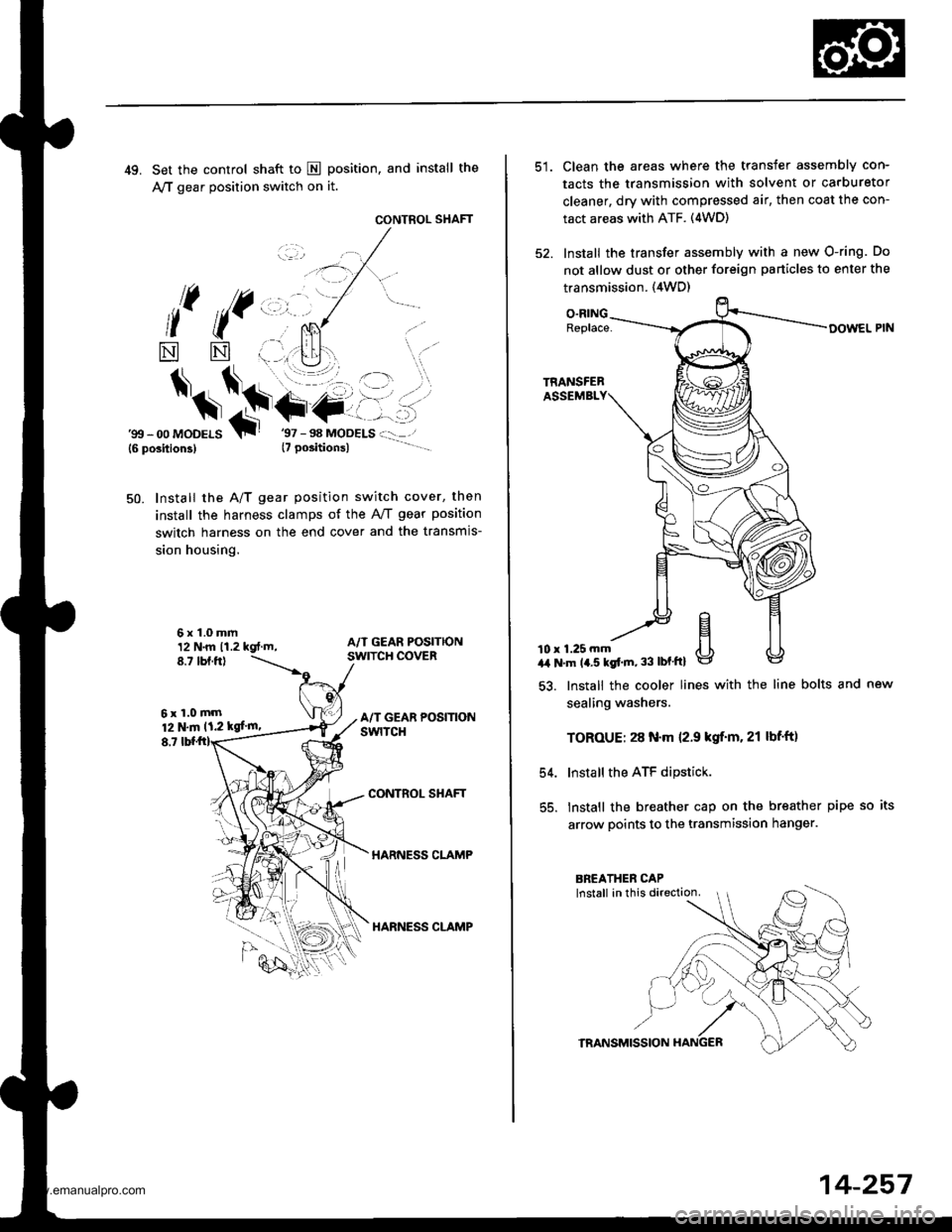

49. Set the control shaft to E position, and install the

A,/T gear position switch on it.

CONTROL SHAFT

l( ((,,, ,.

*

$*\.t+-

NN

6x1.0mm12 N.m 11.2 kgt.m,8.7 tbf.ftl

6xl.0mm12 N.m 11.2 kgf'm,

8,7

'gtt - 00 MoDELS{6 position3}T

Install the A/T gear position switch cover, then

install the harness clamps of the AviT gear position

switch harness on the end cover and the transmis-

sion housing.

50.

CONTROL SHAFT

HARNESS CLAMP

HARNESS CLAMP

Clean the areas where the transfer assembly con-

tacts the transmission with solvent or carburetor

cleaner, dry with compressed air, then coat the con-

tact areas with ATF. (4WD)

Install the transfer assembly with a new O-ring. Do

not allow dust or other foreign particles to enter the

transmission. {4WD)

O.RINGReplace-

10 r 1.25 mma,a N'm 14.5 kgt'm, 33 lbf'ftl

54.

55.

lnstall the cooler lines with the line bolts and new

sealing washers.

TOROUE: 28 N.m 12.9 kgif'm. 21 lbf'ft)

Install the ATF dipstick.

lnstall the breather cap on the breather pipe so its

arrow points to the transmission hanger.

TRANSMISSION

14-257

www.emanualpro.com