Circuit HONDA CR-V 1999 RD1-RD3 / 1.G Workshop Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1338 of 1395

)

From page 24-39(D)

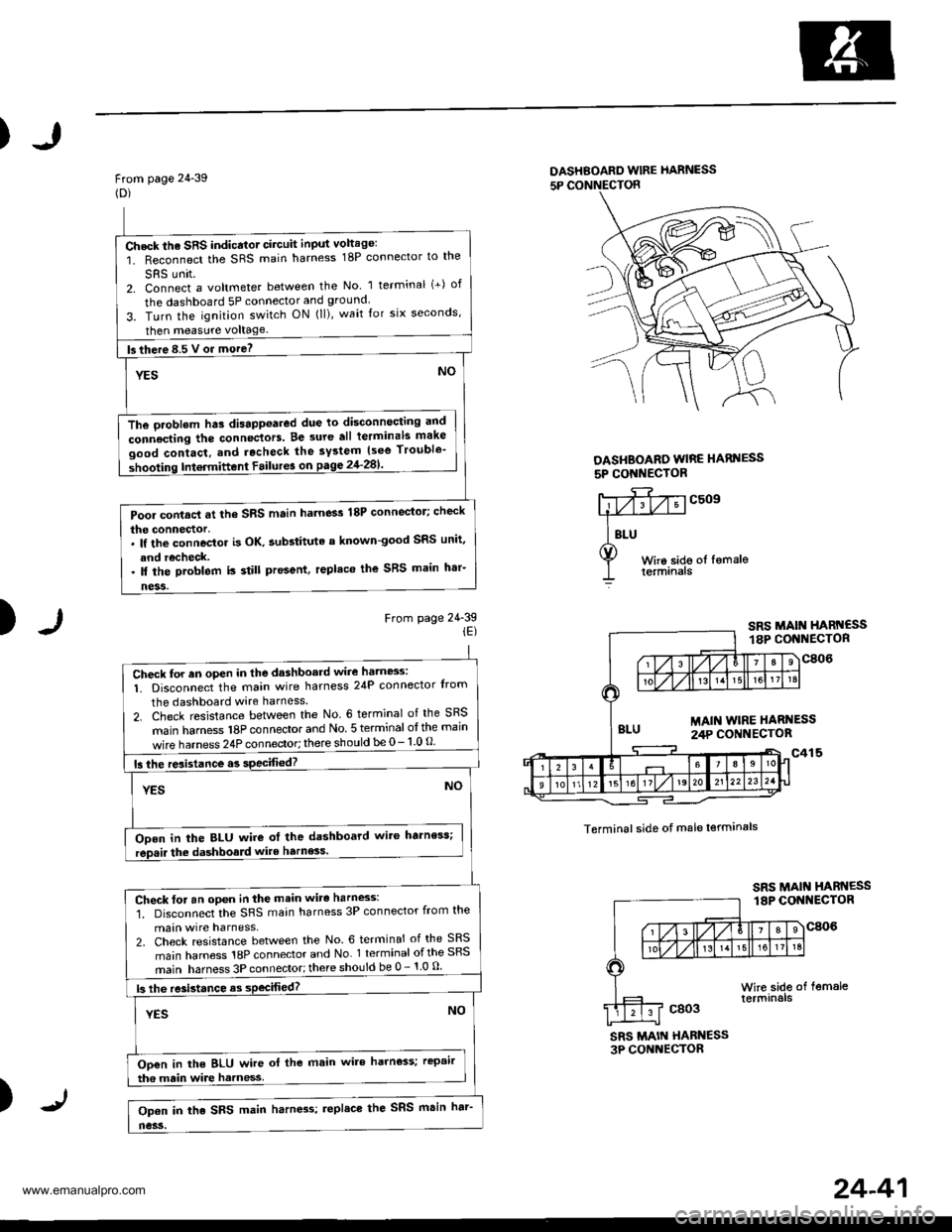

DASHBOARD wlRE hARNESS

5P CONNECTON

DASHBOARO WIRE HARI{ESS

5P CONI{EC'OR

)From page 24-39iE)

c509

Terminal side of male lerminals

SRS MAIN HABN€SS3P CONNECTOR

)

Check the SRS indicator circuit input voltage:

1. Reconnect the SRS main harness 18P connector to the

SRS unit2. Connect a voltmeter between the No 1 terminal (+) of

the dashboard 5P connector and ground.

3. Turn the ignition switch ON (ll), wait for six seconds,

then measure voltage

fs there 8.5 V or more? -

YESNO

The oroblem hts disappoared due to disconnocting and

connecting the connectors. Be 3ure all terminals make

good contact, and rocheck the system {see Trouble'

shooting Intermittent Failur6 on pagg 2'l-281'

Pool contacl at the SRS main harness 18P connector; check

the connector.. lf the connoctor is OK. aubstituta a known-good SRS unit,

and recheck.. ll the problem is still present, replaco the SRS main h'r-

ness.

Check for an oPen in the dashboard wire hatn8s:

1. Disconnect the main wire harness 24P connector Irom

the dashboard wire harness

2. Check resistance between the No. 6 terminal of the SRS

main hamess 18P connector and No 5 terminal otthe main

wire harness 24P connector; there should be 0- 1 0 O

15 the resistance.s specified?

YESNO

ODen in the BLU wire ot the dashboard wit6 harness;

rep.ir the dashboald wite harness.

Check for an open in the main wirc harness:'1. Disconnect the SRS main harness 3P connector from the

main wire harness,2. Check resistance between the No. 6 terminal of the SRS

main harness 18P connector and No 1 terminal ofthe SRS

main harness 3P connector;there should be 0 - 1 0 u

|3 lhe re3istance as sPecifiod?

YESNO

Oo€n in the BLU wire ol the main wire harness; rcpair

tha main wire harness

Op€n in the SRS main harn4s; replace the SRS msin har'

no3s.

24-41

www.emanualpro.com

Page 1341 of 1395

Troubleshooting

The SRS Indicator Light Doesn't Go Off -'99 - 00 models (cont,d)

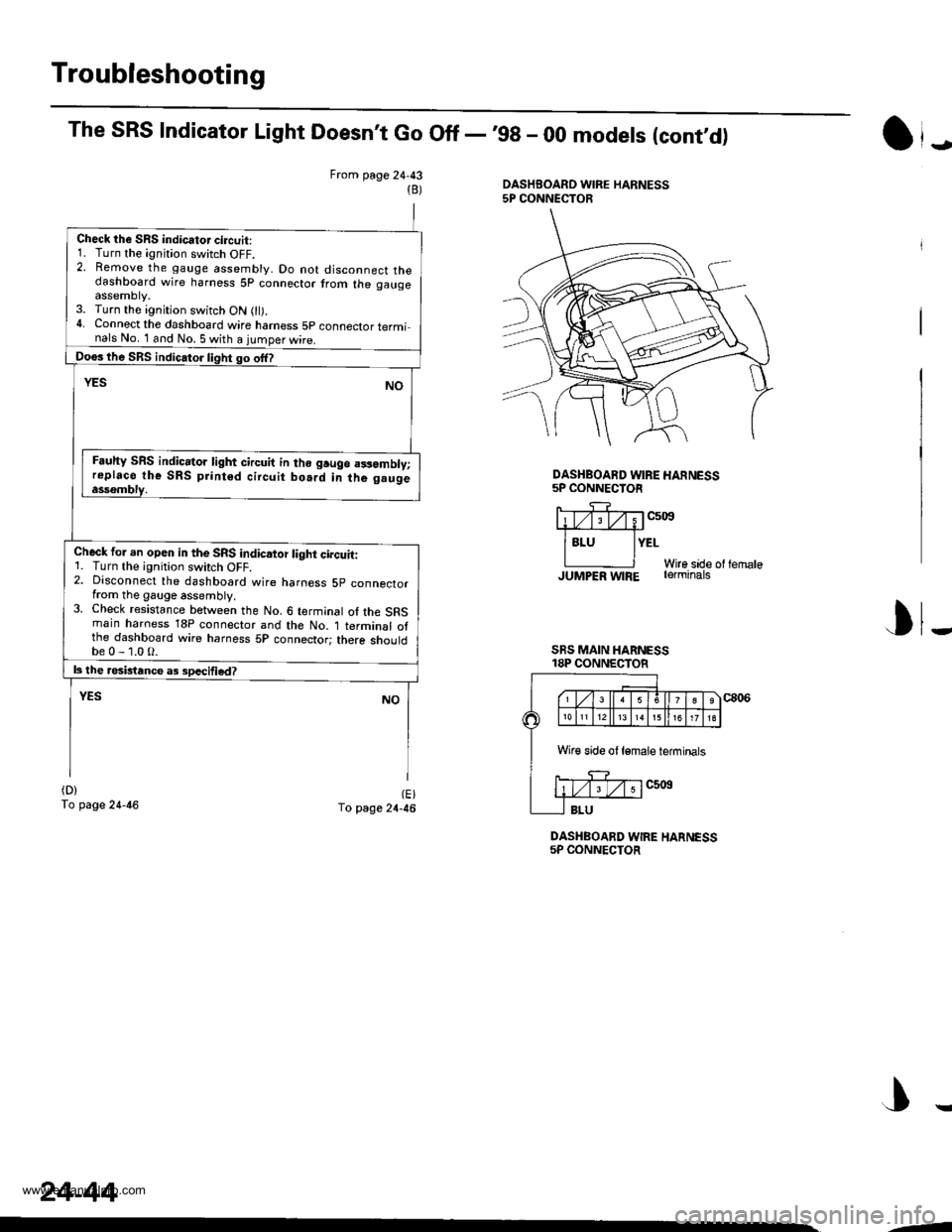

From page 24,43DASHBOARD WIRE HARNESS5P CONNECTOR(B)

Check the SRS indicator circuit:1. Turn the ignition switch OFF.2. Remove the gauge assembly. Do not disconnect thedashboard wire harness 5p connector trom the gaugeassemDty.3. Turn the ignition switch ON 0l).4. Connect the dashboard wire hamess 5p connector terminals No. 1 and No. 5 with a iumoer wire.

Doos lhe SRS indic.tor light go offl

YESNO

Fauhy SRS indic.tor light circuit in lho gruge a3samblv;replaco the SRS print6d circuit bo.rd in the g.ugeassombly.

Check for an opeo in the SRS indicaior light circuit:1. Turn the ignition swirch OFF.2. Disconnect the dashboard wire harness 5p connectorfrom the gauge assembly.3. Check resistance between the No. 6 terminal of the SRSmain haroess 18P connector and the No. 1 terminal otthe dashboard wire harness 5P connector; there shouldbe0-1.0O.

|3 the rosbtance a3 sDecified?

YESNO

(D)

To page 24-46(E)To page 24-46

DASHBOARD WIRE HARNESS5P CONNECTOR

J

DASHBOARD WIRE HANNESS5P CONNECTOR

liTv;Tv;1c5i0s#

lsru lYErWire sade ol lernaleJUMPER w|RE rerminats

I

SRS MAIN HARNESS18P CONNECTOR

J

Wir€ side ot lemale ieminals

24-44

,-

www.emanualpro.com

Page 1343 of 1395

Troubleshooting

The SRS Indicator Light Doesn't Go Off -,99 - 00 models (cont,d)

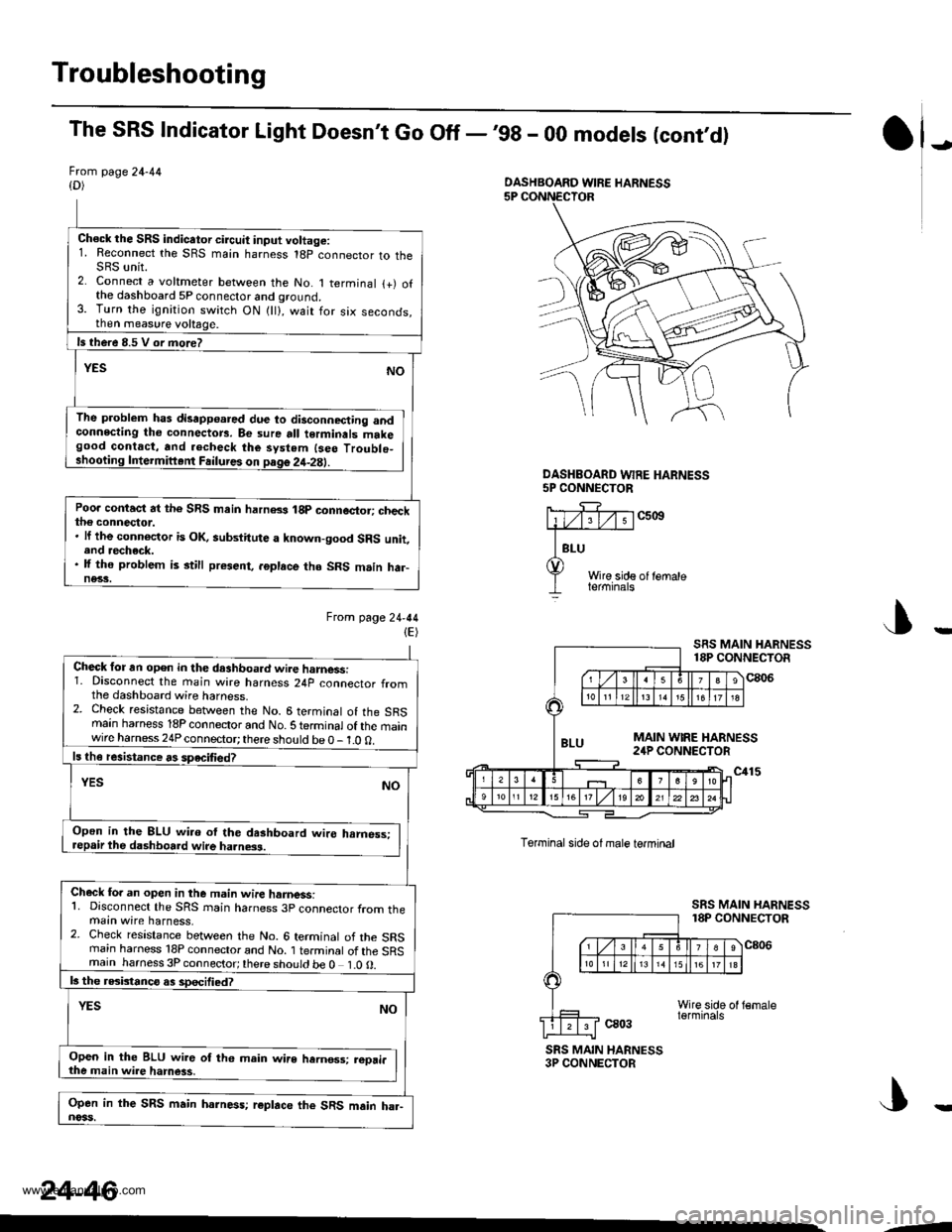

Frcm page 24-44{D)

Ch€ck the SRS indicator circuit input voltage:1. Reconnect the SRS main harness 18p connector to theSRS unit.2. Connect a voltmeter between the No. 1 terminal {+) ofthe dashboard 5P connector and ground.3. Turn the ignition switch ON {ll}, wait for six seconds,then measure voltage.

ls there 8.5 V or more?

YESNO

The problem has disapp€ared due to disconnecting andconnecting tho connectors. Be sure all terminals makegood contact, and .echeck the system {seo Troublo_shooting Intermiftent Failures on page 2it-2E).

Poo. contact at the SRS main harn8s 18p connector; checkthe connector.. lf the connoctor is OK, aubstitute a known-good SRS unit,end recheck.. lf the problem is still present, .6place tho SRS m.in har-ne33.

Ftom lage24-44(E)

J)

DASHEOARD WFE HARNESS5P CONNECTOR

c5ott

Wire side of lemaleterminals

J

Torminal side ol male termtnal

ca03

SRS MAIN HARNESS18P CONNECTOR

c806

SRS MAIN HARNESS3P CONNECTOR

DASHBOARD WIRE HARNESS

Check for an open in the dashboa.d wire harnessi1. Disconnect the main wire harness 24p connector fromthe dashboard wire harness.2. Check resistance between the No. 6 terminal of the SRSmain harness 18P connector and No. S te.minal of the mainwire harness 24P connector; there should be 0 - 1.0 0.

ls th€ resistance rs speciliedT

YESNO

Open in the 8LU wi.o ol the dashboard wire hrmess:repair the dashboard wire ha.ness.

Check fo. an open in the m.in wire hamess:1. Disconnect the SRS rnain harness 3p connector from themain wire harness,2. Check resistance between the No. 6 terminal of the SRSrnain harness 18P connector and No. 1 terminal of the SRSmain harness 3P connector;there should be 0 1.0O.

b the rGbtanco as sDecified?

NOYES

Open in the BLU wir6 of th6 main wire hernos3; reori.the main wire hamess,

Open in the SRS main harness; r€place the SRS main ha.-noss.

24-46

--

www.emanualpro.com

Page 1395 of 1395

Airbag/Seat Belt Tensioner

1.

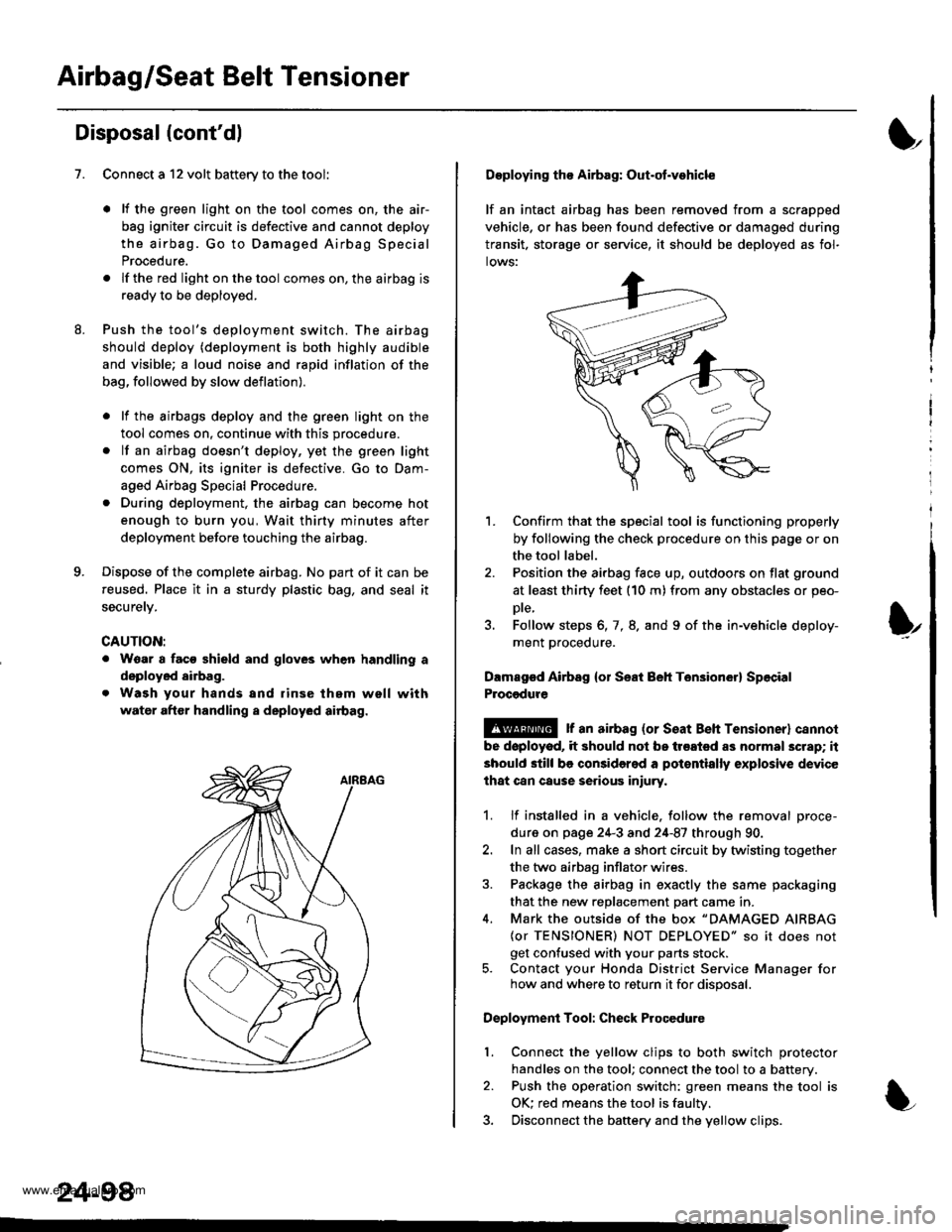

Disposal (cont'dl

Connect a 12 volt battery to the tool'

. It the green light on the tool comes on, the air-

bag igniter circuit is defective and cannot deploy

the airbag. Go to Damaged Airbag Special

Procedure.

.lftheredlightonthetool comes on, the airbag is

ready to be deployed.

Push the tool's deployment switch. The airbag

should deploy (deployment is both highly audible

and visible; a loud noise and rapid inflation of the

bag, followed by slow deflation).

. lf the airbags deploy and the green light on the

tool comes on, continue with this procedure.

. lf an airbag doesn't deploy, yet the green light

comes ON, its igniter is defective. Go to Dam-

aged Airbag Special Procedure.

. During deployment, the airbag can become hot

enough to burn you, Wait thirty minutes after

deployment before touching the airbag.

Dispose of the complete airbag. No part of it can be

reused. Place it in a sturdy plastic bag, and seal it

securety.

CAUTION:

. Wear a faco shield and gloves when handling a

deployed airbag.

. Wash your hands and rinse them well with

water after handling a deployed airbag.

24-98

Deploying tho Airbag: Out-ot.vohicle

lf an intact airbag has been removed from a scrapped

vehicle, or has been found defective or damagsd during

transit. storage or seryice, it should be deployed as fol-

lows:

'L Confirm that the special tool is functioning properly

by following the check procedure on this page or on

the tool label.

2. Position the airbag face up, outdoors on flat ground

at least thirty feet (10 m) from any obstacles or peo-

Dte,

3. Follow steps 6, 7, 8. and 9 of the in-vehicle deploy-

ment proceoure.

Dlmaged Airbsg {or Seat Beh Ten3ion6r} Sp6cial

Procgdure

!@ r an airbag {or seat Beh rensioner} cannol

be doployod, it should not be treated as normal scrap; it

should still be considered a pot€ntially explosive device

lhat can cause serious iniury.

1. lf installed in a vehicle. follow the removal proce-

dure on page 24-3 and 24-87 through 90.

2. In all cases, make a short circuit by twisting together

the two airbag inflator wires.

3. Package the airbag in exactly the same packaging

that the new reDlacement Dart came in.

4. Mark the outside of the box "DAMAGED AIRBAG

{or TENSIONER) NOT DEPLOYED" so it does not

get confused with your parts stock.5. Contact your Honda District Service Manager forhow and where to return it for disposal.

Deployment Tool: Check Procedure

Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

Push the operation switch: green means the tool is

OK: red means the tool is faultv.

Disconnect the baftery and the yellow clips.

I

t

l.

www.emanualpro.com