countershaft HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 467 of 1395

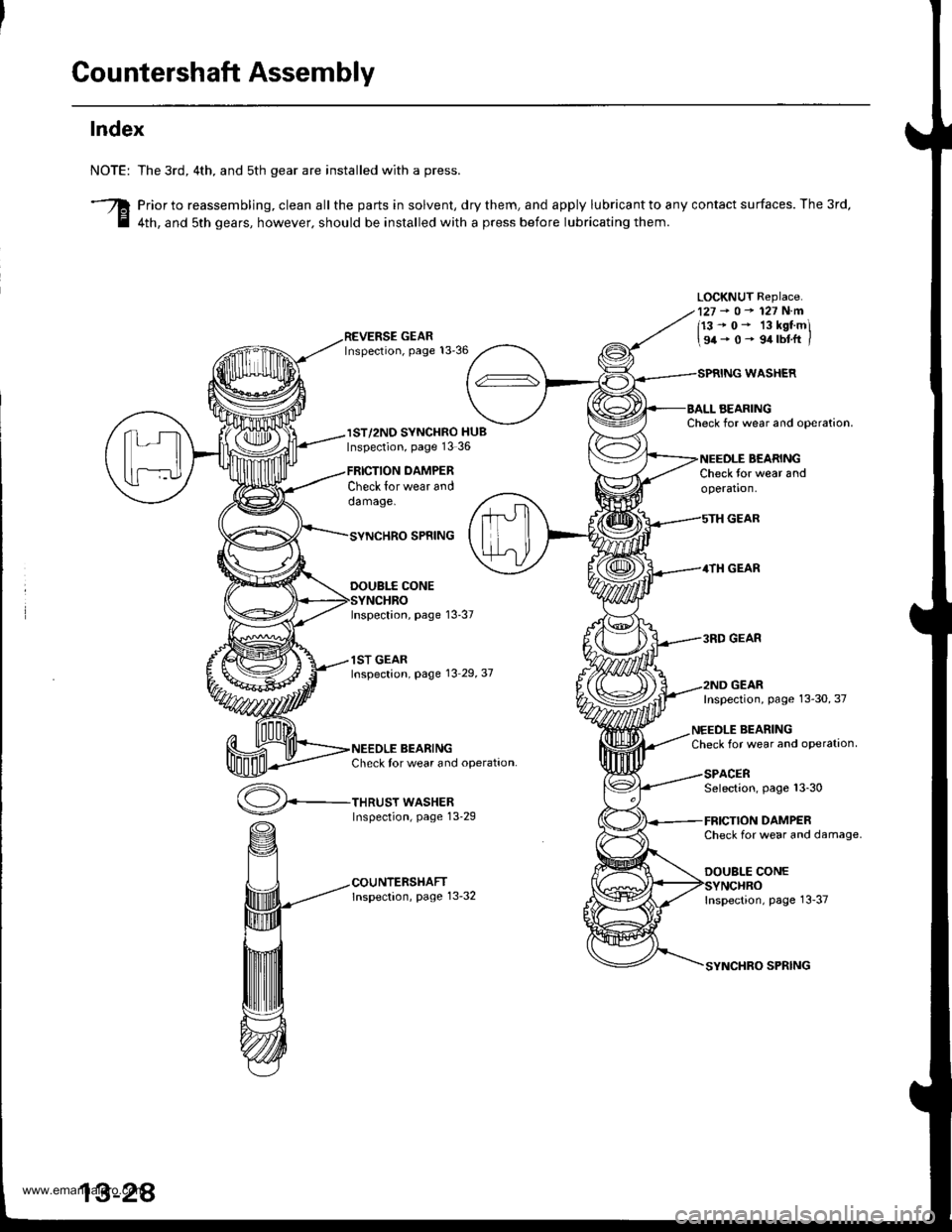

Countershaft Assembly

Index

NOTE:

3

The 3rd, 4th. and sth gear are installed with a press.

Prior to reassembling, clean all the parts in solvent, dry them, and apply lubricant to any contact surfaces. The 3rd,

4th, and sth gears, however. should be installed with a press before lubricating them.

LOCKNUT Replace.127-o-127N.m

113-0- 13kstmi

\94-0- 9.trbtft /

IST/2ND SYNCHRO HUBInspection, page 13 36

Check lor wear anddamage.

THRUST WASHERInspection, page 13-29

DAMPER

WASHER

AEARINGCheck for wear and ooeration.

BEARINGCheck for wear andoperation.

GEAR

4TH GEAR

3RD GEAR

GEAR

SPNING

DOUBI.f CONE

Inspection, page 13-37

1ST GEARInspection, page 13 29,37

BEARINGCheck tor wear and operation.

Inspection, page 13-30, 37

NEEDLE BEARINGCheck for wear and oPeration

SPACERSelection, page 13-30

DAMPERCheck for wear and damage.

DOUBLE CONE

Inspection, page 13-37

SPRING

www.emanualpro.com

Page 469 of 1395

Countershaft Assembly

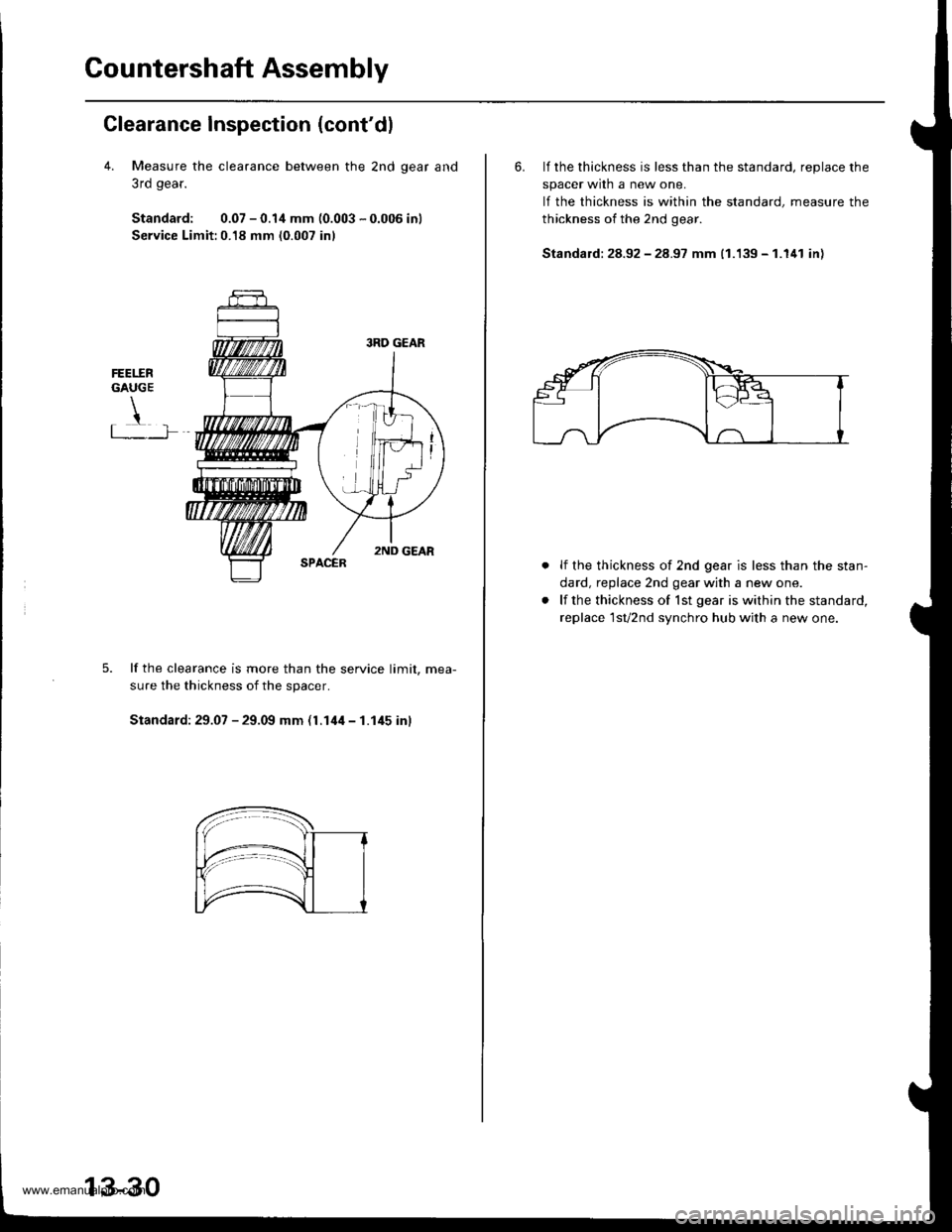

Clearance Inspection (cont'dl

4. Measure the clearance between the 2nd qear and

3rd gear.

Standard: 0.07 - 0.1,1 mm (0.003 - 0.006 inl

Service Limit:0.18 mm (0.007 inl

FEET.ERGAUGE

!t .�-]�

lf the clearance is more than the service limit. mea-

sure the thickness of the spacer.

Standard: 29.07 - 29.09 mm (l.14il - 1.145 inl

13-30

6. lf the thickness is less than the standard, reDlace the

spacer wrln a new one.

lf the thickness is within the standard, measure the

thickness of the 2nd gear.

Standald: 28.92 - 28.97 mm (1.139 - 1.141 in)

lf the thickness of 2nd gear is less than the stan-

dard, replace 2nd gear with a new one.

lf the thickness of lst gear is within the standard,

replace 1sv2nd synchro hub with a new one.

www.emanualpro.com

Page 470 of 1395

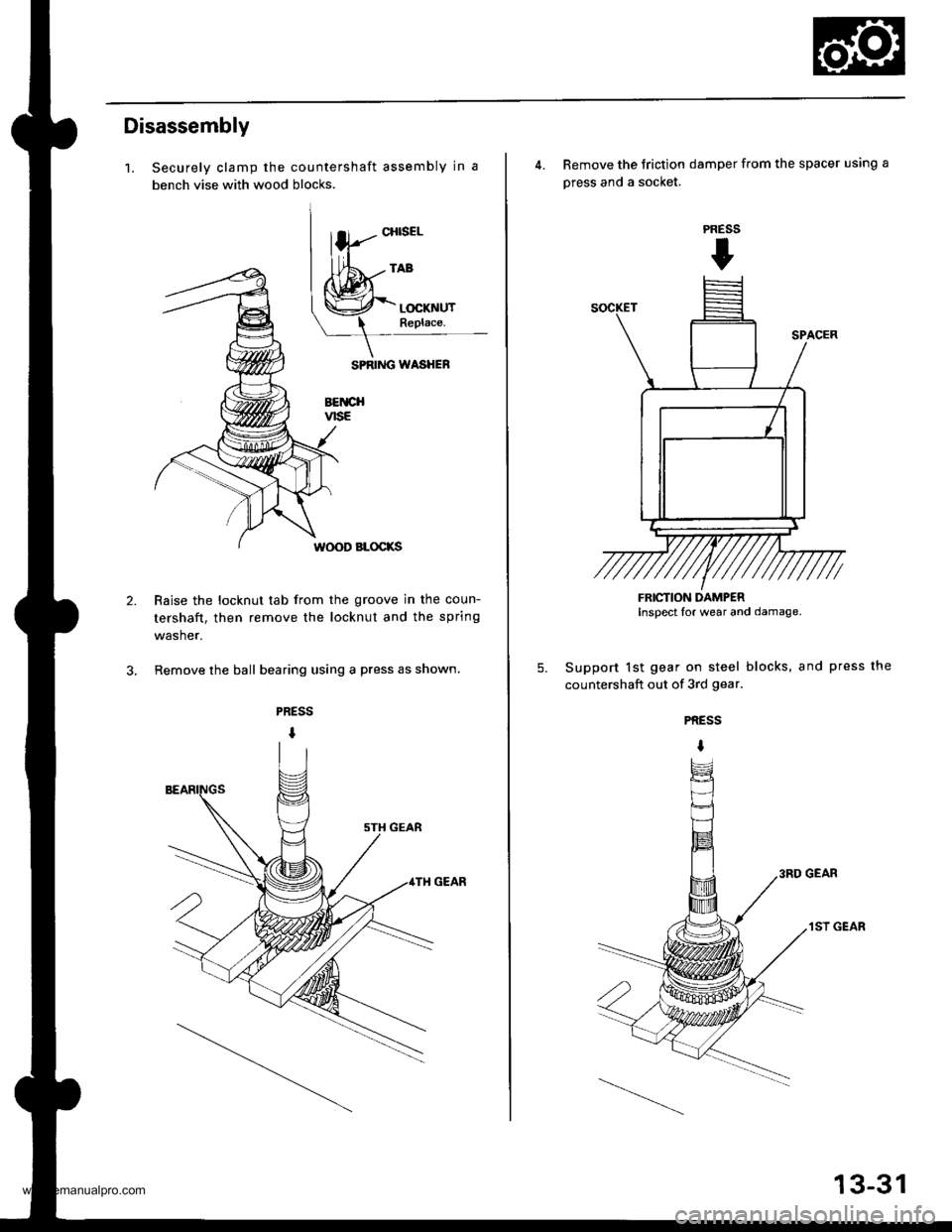

Disassembly

1.

2.

Securely clamp the countershaft assembly in a

bench vise with wood blocks.

SPRIiIG WASHEF

BETICHvtsE

W(X)D BLOCKS

Raise the locknut tab from the groove in the coun-

tershaft, then remove the locknut and the spring

washer.

Remove the ball bearing using a press as shown.

CHISEL

4. Remove the Jriction damper from the spacer using a

press and a socket.

Support lst gear on steel blocks, and press the

countershaft out of 3rd gear.

PRESS

t

5.

PRESS

I

3RD GEAR

1ST GEAR

FRICTION DAMPERInspect lor wear and damage.

13-31

www.emanualpro.com

Page 471 of 1395

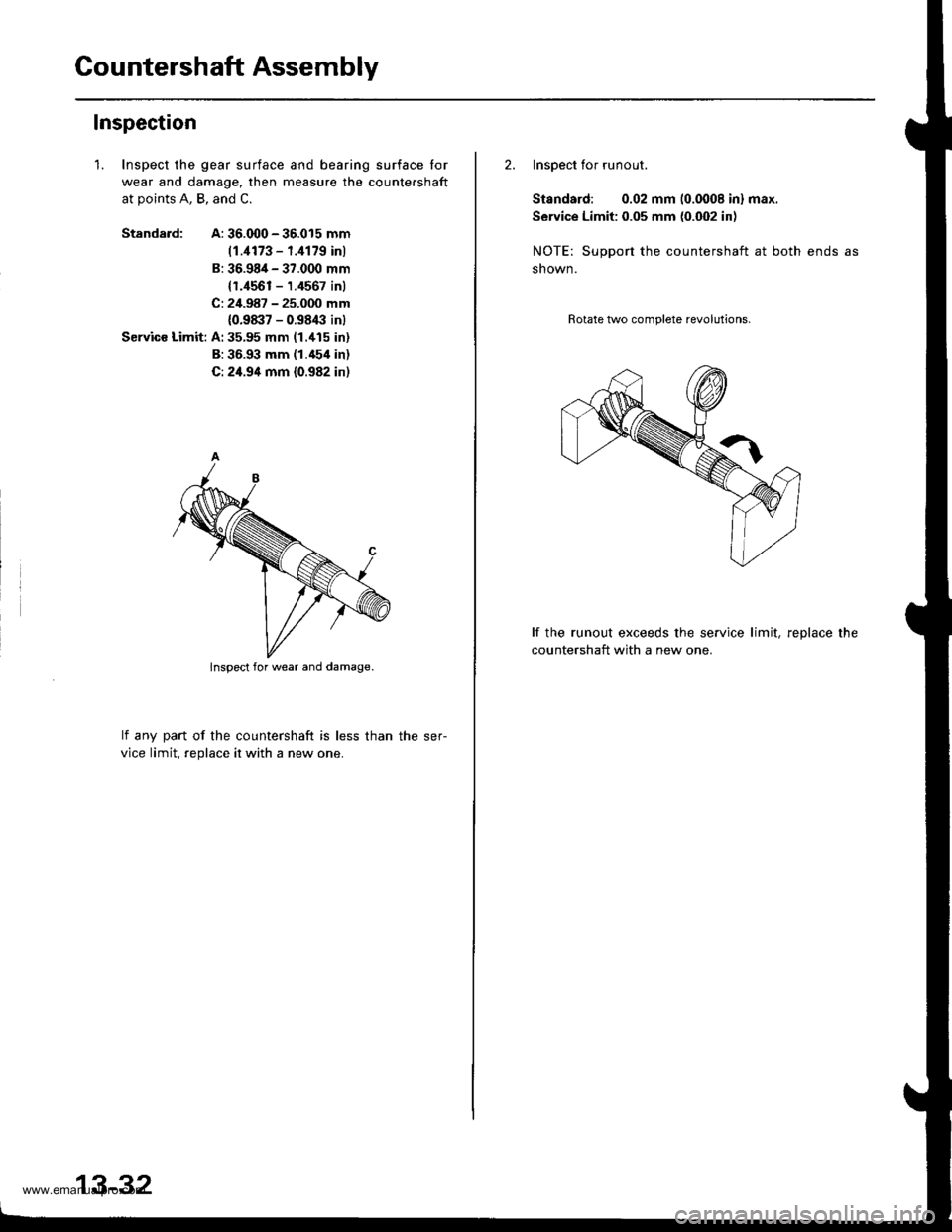

Countershaft Assembly

Inspection

1. Inspect the gear surface and bearing surface Ior

wear and damage, then measure the countershaft

at points A, B, and C.

Standa.d:A: 36.000 - 36.015 mm

11.,1173 - f.ill79 inl

B: 36.98/t - 37.000 mm

{r.4561 - 1.4567 inl

C: 24.987 - 25.000 mm

{0.98:17 - 0.9843 inl

Servics Limit: A:35,95 mm (1.'115 in)

B: 36.93 mm (1.454 in)

C: 24.94 mm (0.982 in)

lf anv part of the countershaft is less than the ser-

vice limit. reolace it with a new one.

lnspect for wear and damage.

13-32

2. Inspect for runout.

Standard: 0.02 mm 10.0008 inl max.

Service Limit: 0.05 mm {0.002 inl

NOTE: Support the countershaft at both ends as

shown.

Rotate two complete revolutions.

lf the runout exceeds the service limit, reDlace the

countershaft with a new one.

www.emanualpro.com

Page 472 of 1395

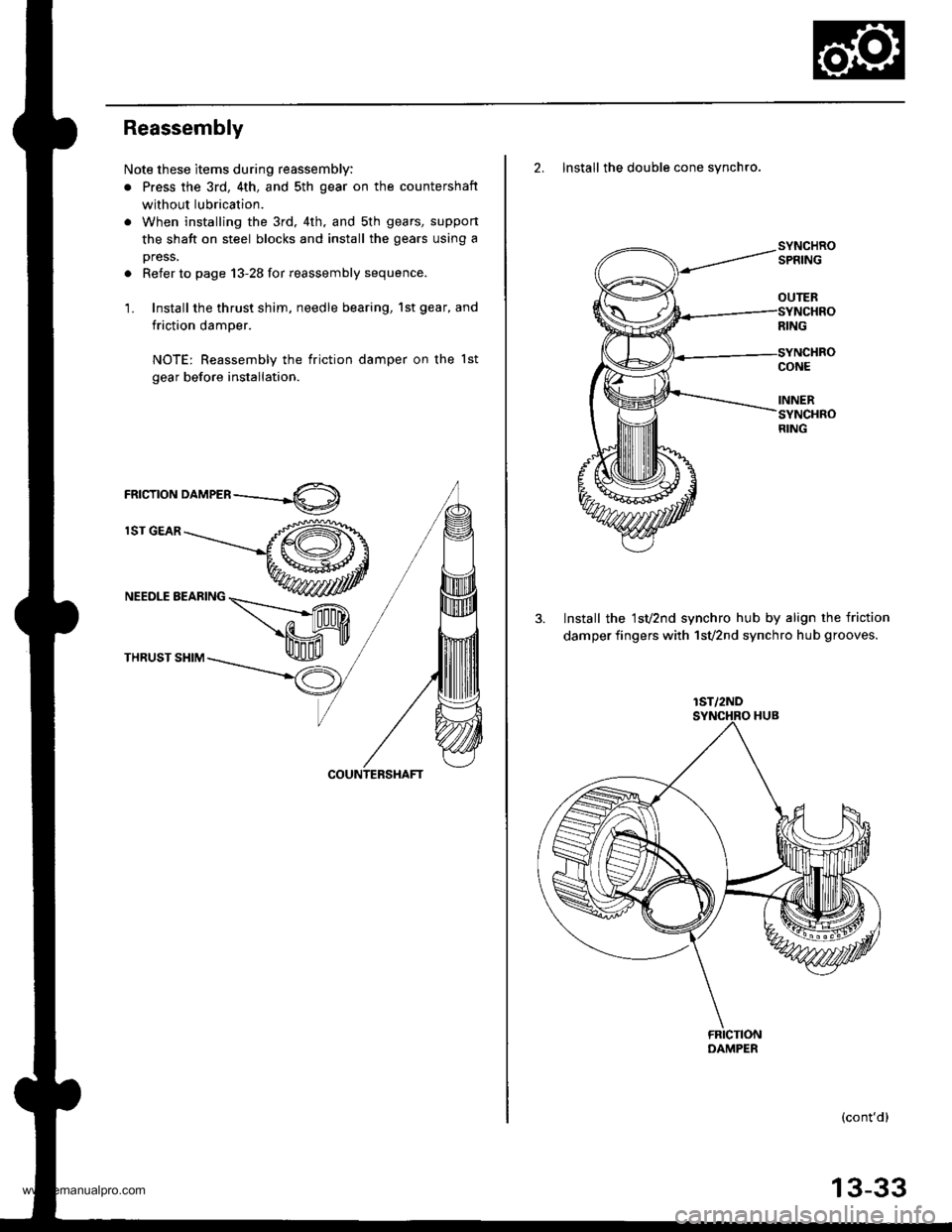

Reassembly

Note these items during reassembly:

. Press the 3rd, 4th, and sth gear on the countershaft

without lubrication.

. When installing the 3rd, 4th. and sth gears, suppon

the shaft on steel blocks and install the gears using a

press.

. Refer to page 13-28 for reassembly sequence.

1. Install the thrust shim, needle bearing, 1st gear, and

friction damper.

NOTE: Reassembly the friction damper on the lst

gear before installation.

rnrcrroru orn,leen ----.-4O)

lST GEAR

NEEDLE BEARING

THRUST SHIM

2. Install the double cone synchro.

3. Install the 1sv2nd synchro hub by align the friction

damper fingers with 1svznd synchro hub grooves.

(cont'd)

OUTER

lST/2ND

13-33

www.emanualpro.com

Page 473 of 1395

Countershaft Assembly

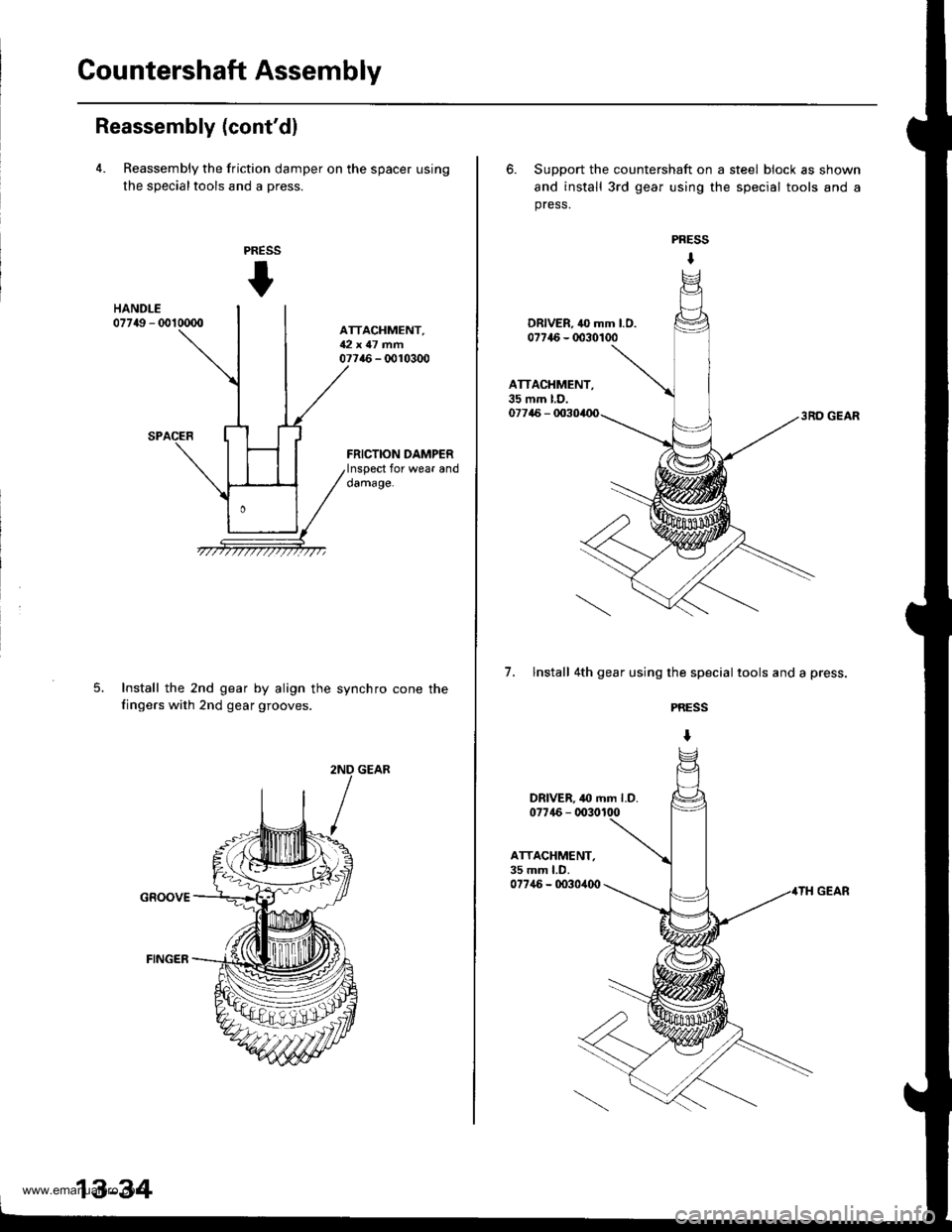

Reassembly (cont'dl

4. Reassembly the friction damper on the spacer using

the sDecialtools and a Dress.

PRESS

t

ATTACHMENT,U2t 47 mfi07716 - 0010300

FRICTION DAMPERInspect for wear anddamage.

Install the 2nd gear by align the

fingers with 2nd gear grooves.

synchro cone the

GROOVE

13-34

6. Support the countershaft on a steel block as shown

and install 3rd gear using the special tools and a

press.

3RO GEAR

7. lnstall 4th gear using the special tools and a press.

PRESS

I

PRESS

t

ATTACHMENT,35 mm LD.07746 - 0030,100

www.emanualpro.com

Page 474 of 1395

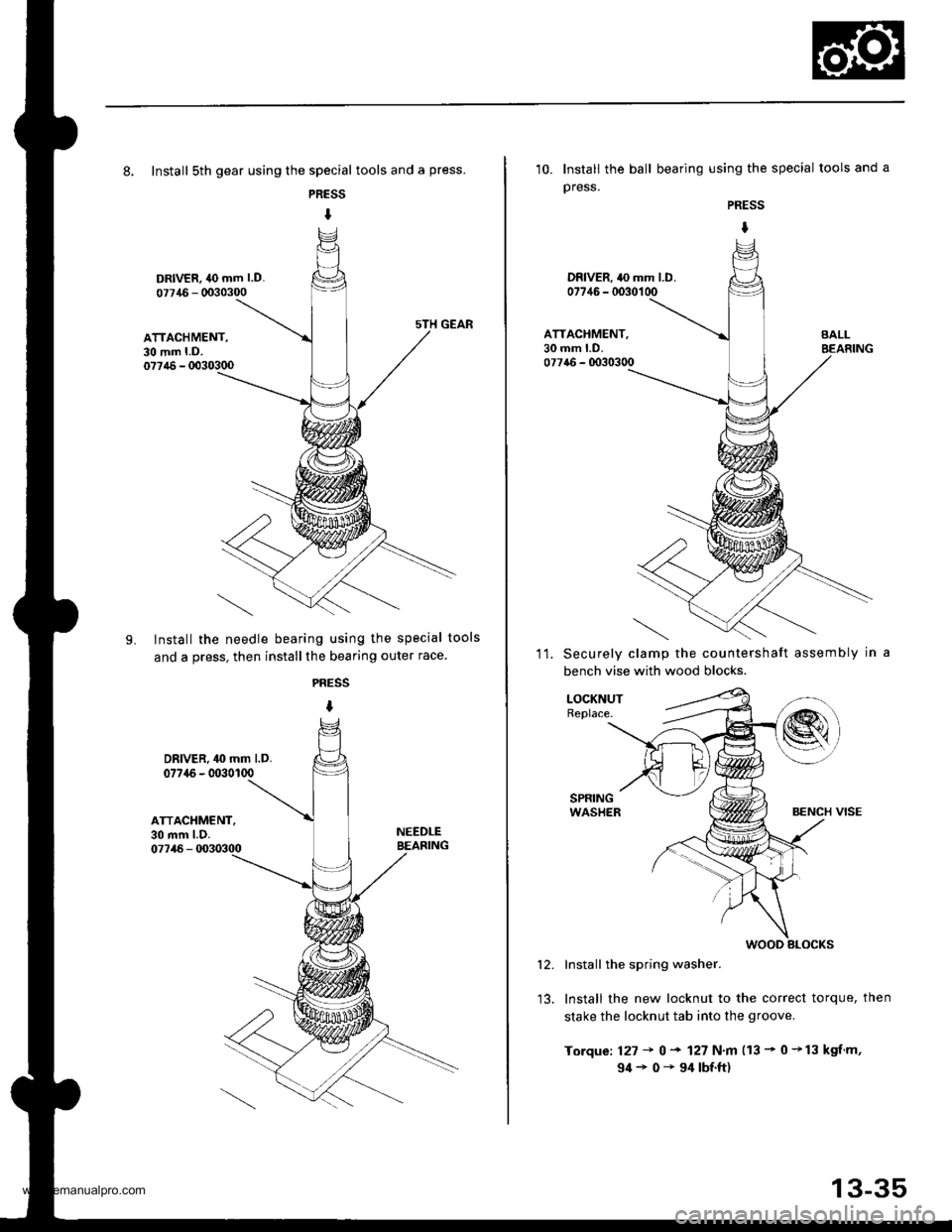

8. Install sth gear using the special tools and a press.

PRESS

I

DRIVER, 40 mm l.D.

07715 - 0030300

ATTACHMENT,30 mm LD.077,16 - 0030300

LInstall the needle bearing using the special tools

and a press, then installthe bearing outer race

PRESS

I

DRIVER. 40 mm l.D.077{6 - 0030100

ATTACHMENT,30 mm l.D.07746 - 0030300

NEEDLEBEASING

10. Install the ball bearing using the special tools and a

press.

PRESS

I

DRIVER. 40 mm LD.07746 - 0030100

ATTACHMENT,30 mm LD.077a6 - 0030300

11.Securely clamp the countershaft assembly in

bench vise with wood blocks.

LOCKNUTReplace.

Install the spring washer.

Install the new locknut to the correct torque, then

stake the locknut tab into the groove.

Torque: 127 + 0 + 127 N.m 113 - 0 +13 kgf.m,

94+0-94|bf.ft)

12.

wooD slocKs

13-35

www.emanualpro.com

Page 480 of 1395

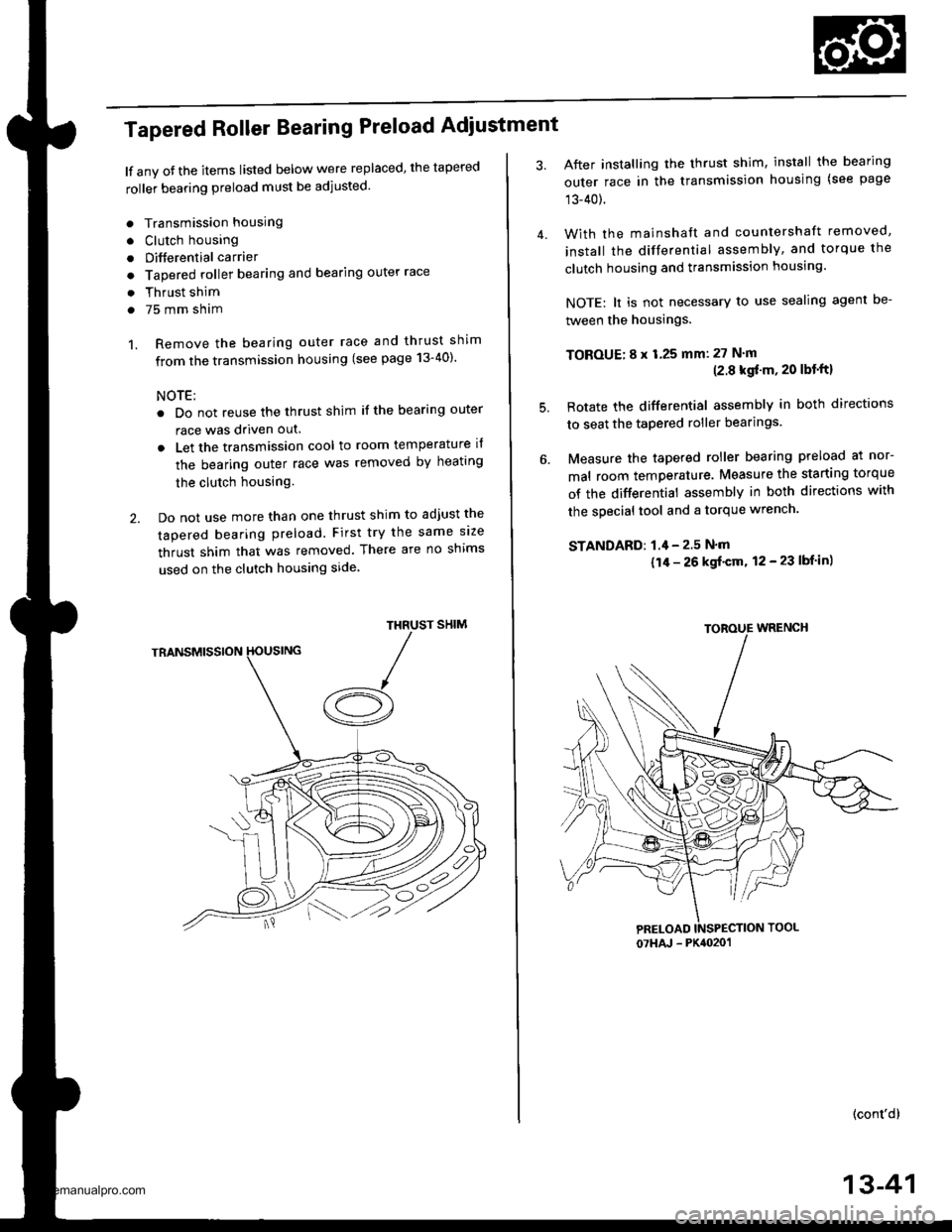

Tapered Roller Bearing Preload Adiustment

lf any oJ the items listed below were replaced, the tapered

roller bearing preload must be adjusted.

. Transmission housing

. Clutch housing

. Differential carrier

o Tapered roller bearing and bearing outer race

. Thrust shim

. 75 mm sham

1. Remove the bearing outer race and thrust shim

from the transmission housing (see page 13-40)'

NOTE:

. Do not reuse the thrust shim if the bearing outer

race was driven out.

. Let the transmission cool to room temperature il

the bearing outer race was removed by heating

the clutch housing.

2. Do not use more than one thrust shim to adjust the

tapered bearing preload. First try the same size

thrust shim that was removed. There are no shims

used on the clutch housing side

SHIMTHRUST

/A

After installing the thrust shim, install the bearing

outer race in the transmission housing (see page

13-40).

With the mainshaft and countershaft removed,

install the differential assembly, and torque the

clutch housing and transmission housing.

NOTE: lt is not necessary to use sealing agent be-

tween the housings.

TOBOUE; 8 x 1.25 mm: 27 N'm(2.8 kgf'm, 20 lbt'ftl

Rotate the differential assembly in both directions

to seat the tapered roller bearings.

Measure the tapered roller bearing preload at nor-

mal room temperature. Measure the starting torque

of the differential assembly in both directions with

the special tool and a torque wrench.

STANDAFD: 1.4 - 2.5 N'm

{1/r - 26 kgf'cm, 12 - 23 lbf in)

(cont'd)

4.

5.

07HAJ - PK4020'�1

13-41

www.emanualpro.com

Page 506 of 1395

Transmission Assembly

Reassembly

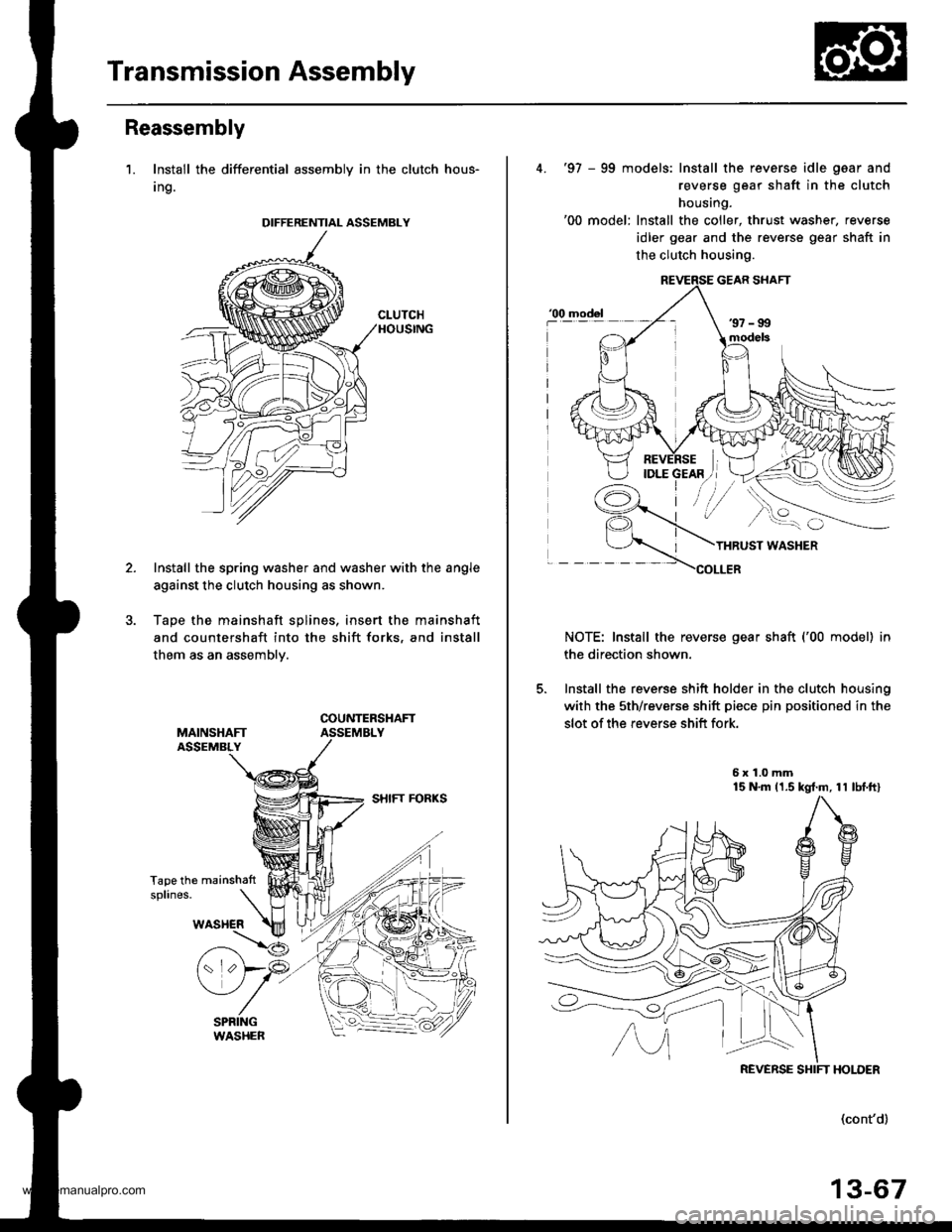

1. Install the differential assembly in the clutch hous-

Ing.

Install the spring washer and washer with the angle

against the clutch housing as shown.

Tape the mainshaft splines. insert the mainshaft

and countershaft into the shift forks, and install

them as an assemblv.

Tape the mainshattsplines.

DIFFERENTIAL ASSEMBLY

4. '97 - 99 models: Install the reverse idle gaar and

reverse gear shaft in the clutch

housing.'00 model: Install the coller, thrust washer, reverse

idler gear and the reverse gear shaft in

the clutch housing.

THRUST WASHER

COLLER

NOTE: Install the reverse gear shaft ('00 model) in

the direction shown.

5. Install the reverse shift holder in the clutch housing

with the sth/reverse shift piece pin positioned in the

slot of the reverse shift fork.

5x1.0mm15 N'm 11.5 kgt.m, 11 lbf.ftl

model

REVERSE SHIFT HOLDER

(cont'd)

13-67

www.emanualpro.com

Page 508 of 1395

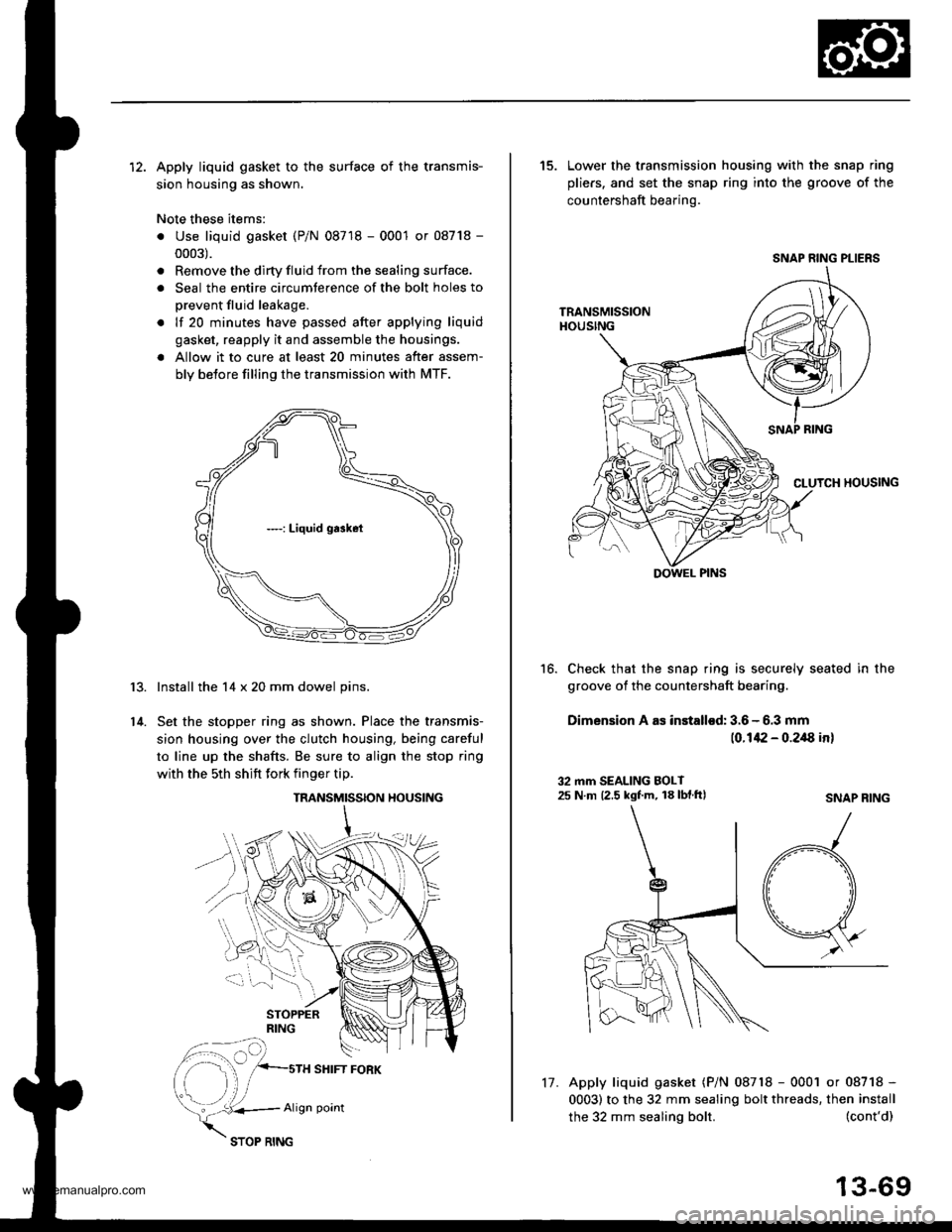

12. Apply liquid gasket to the surface of the transmis-

sion housing as shown.

Note these items:

. Use liquid gasket (P/N 08718 - 0001 or 08718 -

0003).

. Remove the dirty fluid from the sealing surface.

. Seal the entire circumterence of the bolt holes to

prevent fluid leakage.

. lf 20 minutes have passed after applying liquid

gasket, reapply it and assemble the housings.

a Allow it to cure at least 20 minutes after assem-

bly betore filling the transmission with MTF.

Install the 14 x 20 mm dowel pins.

Set the stopper ring as shown. Place the transmis-

sion housing over the clutch housing, being careful

to line up the shafts. Be sure to align the stop ring

with the 5th shift fork finger tip.

r3.

14.

TRANSMISSION HOUSING

SHIFT FORK

vk..*,

Align point

17.

the 32 mm sealing bolt.

15. Lower the transmission housing with the snap ring

pliers. and set the snap ring into the groove of the

countershaft bearing.

Check that the snap ring is securely seated in the

groove of the countershaft bearing.

Dimension A as installod: 3.6 - 6.3 mm

(0.142 - 0.2/8 in)

16.

32 mm SEALING BOLT25 N m 12.5 kgf.m, 18 lbf.ftlSNAP RING

(cont'd)

13-69

Apply liquid gasket (P/N 08718 - 0001 or 08718 -

0003) to the 32 mm sealing bolt threads, then install

SNAP RING PLIERS

DOWEL PINS

www.emanualpro.com