cts HONDA CR-V 1999 RD1-RD3 / 1.G User Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 276 of 1395

Troubleshooting

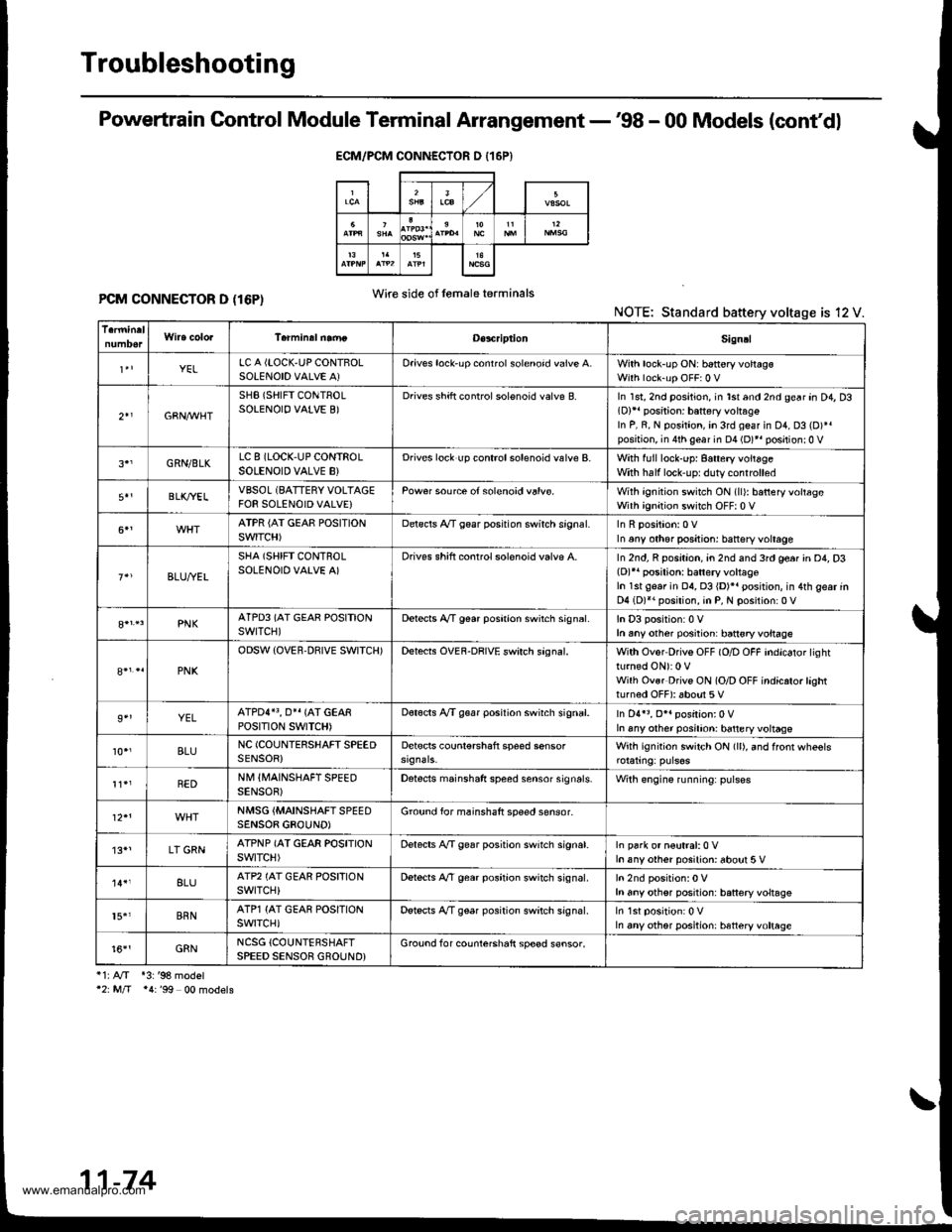

Powertrain Control Module Terminal Arrangement -'98 - 00 Models (cont'dl

PCM CONNECTOR D (16P)NOTE: Standard battery voltage is 12 V.

i1:A/T *3:'98 model'2: M/T *4:'99 00 models

ECM/PCM CONNECTOR D {16P}

Wire side of lemaleterminals

D€s4riptionSign!l

YELLC A {LOCK,UP CONTBOLSOLENOID VALVE A)Oriv€s lock'up conrrol solenoid valve A.With lock-up ON: b6ttery voltagsWith lock-up OFF:0 V

2+1GBN,M/HT

SHB (SHIFT CONTROLSOLENOIO VALVE B)Drives shift controlsolenoid valve B.In 1st, 2nd position, in lst and 2nd gear an D4, D3(D)11 position: battery vohag€In P, R, N position, in 3rd geaf in D1, D3 (D)*.position, in 4th gear in D4 (D)*r positionr0 V

GRN/BLKLC 8 (LOCK,UP CONTROLSOLENOID VALVE B}Drives lock up controlsolenoid valve B.With full lock-up: 8attery voitageWith half lock'uprduty controlled

BLK/YELVBSOL (BATTERY VOLTAGEFOR SOLENOID VALVE}Pow€r source of solenoid valvs.With ignition switch ON (ll): batteryvoltageWith ignition switch OFF| 0 V

ATPR {AI GEAE POSITIONSWITCH)Delscls A/T gear posrtion swirch srgnal.In any other positjon: battsry voltage

BLU,ryEL

SHA (SHIFT CONTROLSOLENOID VALVE A)Drives shift conrrol solenoid valvp A.In 2nd, R position, an 2nd and 3rd ge6r in D4, D3(D)r' posilion: batlery voltageIn 1st gear in 04, 03 {D)}. position, in 4th gear inD4 (D)*. position, in P, N position:0 V

PNKATPD3 (AT GEAR POSITIONswrTcH)Detects A,/T g€ar poshion swirch sign6l.In D3 position:0 Vh any other posiiion: ban€ryvoltage

PNK

ODSW (OVER.DBIVE SWITCH)Detects OVEF-DRIVE swirch sagnal.With Ovor Drivs OFF (O/D OFF indicator lightturned ON): 0 VWilh Ovsr Drivs ON (O/D OFF indicrto.lashtturned OFF): about 5 V

9''YELATPDI}3, O}I {AT GEARPOStTtON SWTTCH)Dot€cts A/T g€ar position swirch signal.In D4r3, O*. position:0 VIn any other posilion: battery voltage

10.,BLUNC (COUNIERSHAFT SPEEDSENSOR)Detscts counl€rshaft speed sensorWith ignition switch ON (ll), and ffonr wheels

REDNM IIVAINSHAFT SPEEDSENSOB)Detects mainshaft speed sensor sign6ls.Wilh engine running: pulses

NMSG {MAINSHAFTSPEEDSENSOB GBOUND)Ground for mainshaft speed sensor-

'13*1LT GRNATPNP (AT GEAR POSITIONswtTcH)Delects A,/T gear position switch signat.In park or n€utral:0 Vh any other posilion: about 5 V

8LUATP2 (AT GEAR POSFIONswrTcH)Dstects A,/T gear position switch signal.h any othsr position: battery voltsgs

15.'BRNATP1 {AT GEAR POSITIONswrTcH)Detscts A/T gear position switch signal.In any other position: htteryvoltage

t6''GRNNCSG {COUNTERSHAFTSPEED SENSOR GROUND}Grouod for counterchaft sp€ed s€nsor.

11-74

www.emanualpro.com

Page 281 of 1395

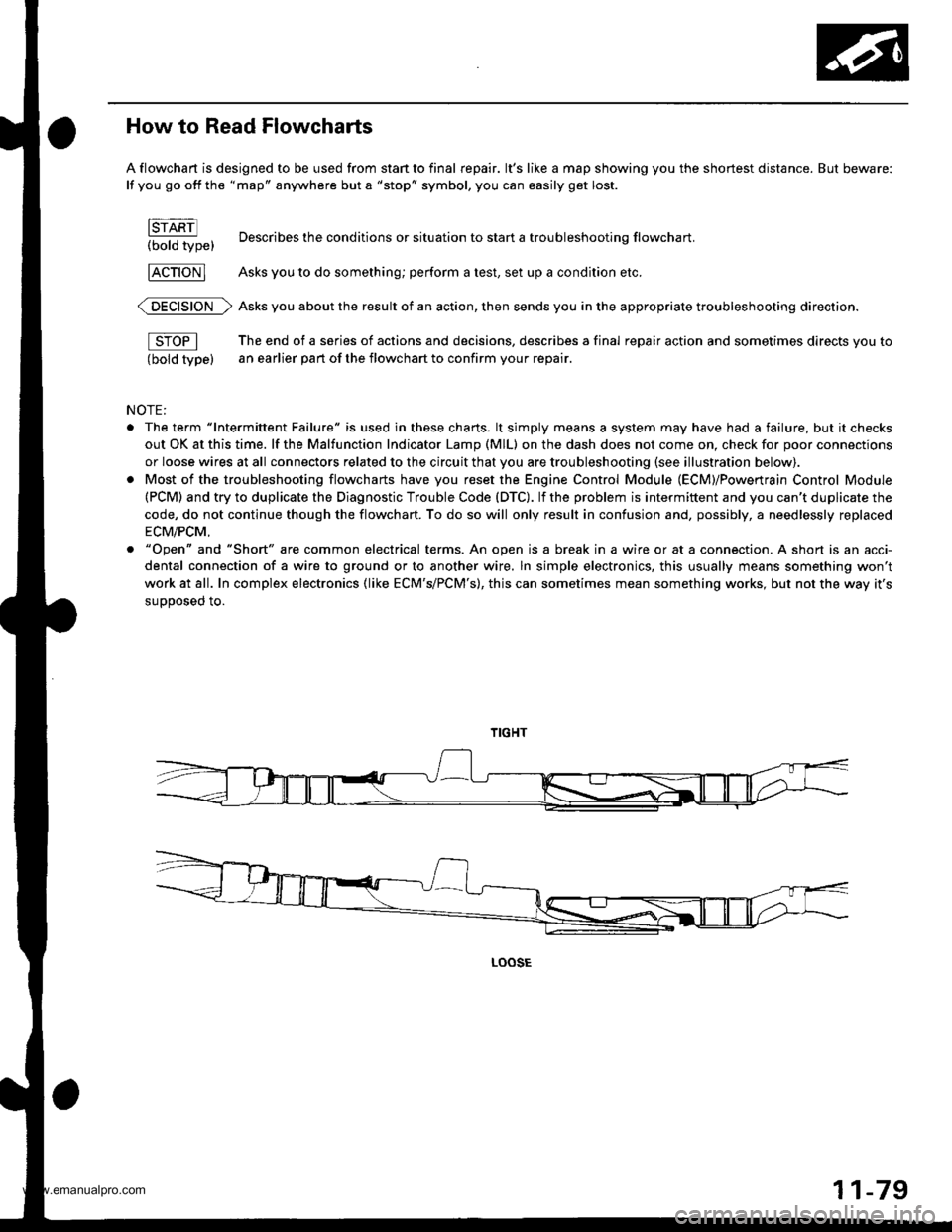

How to Read Flowcharts

A flowchart is designed to be used from start to final repair. lt's like a map showing you the shortest distance. But beware:

lf you go off the "map" anywhere but a "stop" symbol, you can easily get lost.

brARn

t.-OotO tw"t Describes the conditions or situation to start a troubleshooting flowchart.

FcTloNl Asks you to do something; perform a test, set up a condition etc.

@ Asks you about the result of an action, then sends you in the appropriate troubleshooting direction.

fS-OPl The end of a series of actions and decisions, describes a final repair action and sometimes directs you to

(bold type) an earlier part of the flowchart to confirm your repair.

NOTE:

. The term "lntermittent Failure" is used in these charts. lt simply means a system may have had a failure, but it checks

out OK at this time. lf the Malfunction Indicator Lamp (MlL) on the dash does not come on, check for poor connections

or loose wires at all connectors related to the circuit that you are troubleshooting (see illustration below).

. Most of the troubleshooting flowcharts have you reset the Engine Control Module (EcM)/Powertrain Control Module(PCM) and try to duplicate the Diagnostic Trouble Code (DTC). lf the problem is intermittent and you can't duplicate the

code, do not continue though the flowchart. To do so will only result in confusion and, possibly, a needlessly replaced

ECM/PCM,

o "Open" and "Short" are common electrical terms. An open is a break in a wire or at a connection. A short is an acci-

dental connection of a wire to ground or to another wire. ln simple electronics, this usually means something won't

work at all. In complex electronics (like ECM'S/PCM'S), this can sometimes mean something works, but not the way it's

suooosed to.

LOOSE

11-79

www.emanualpro.com

Page 333 of 1395

tro-rsl

1Tffi61

tF136t

fPfa6r-1

tF138tl

I-Pi382l

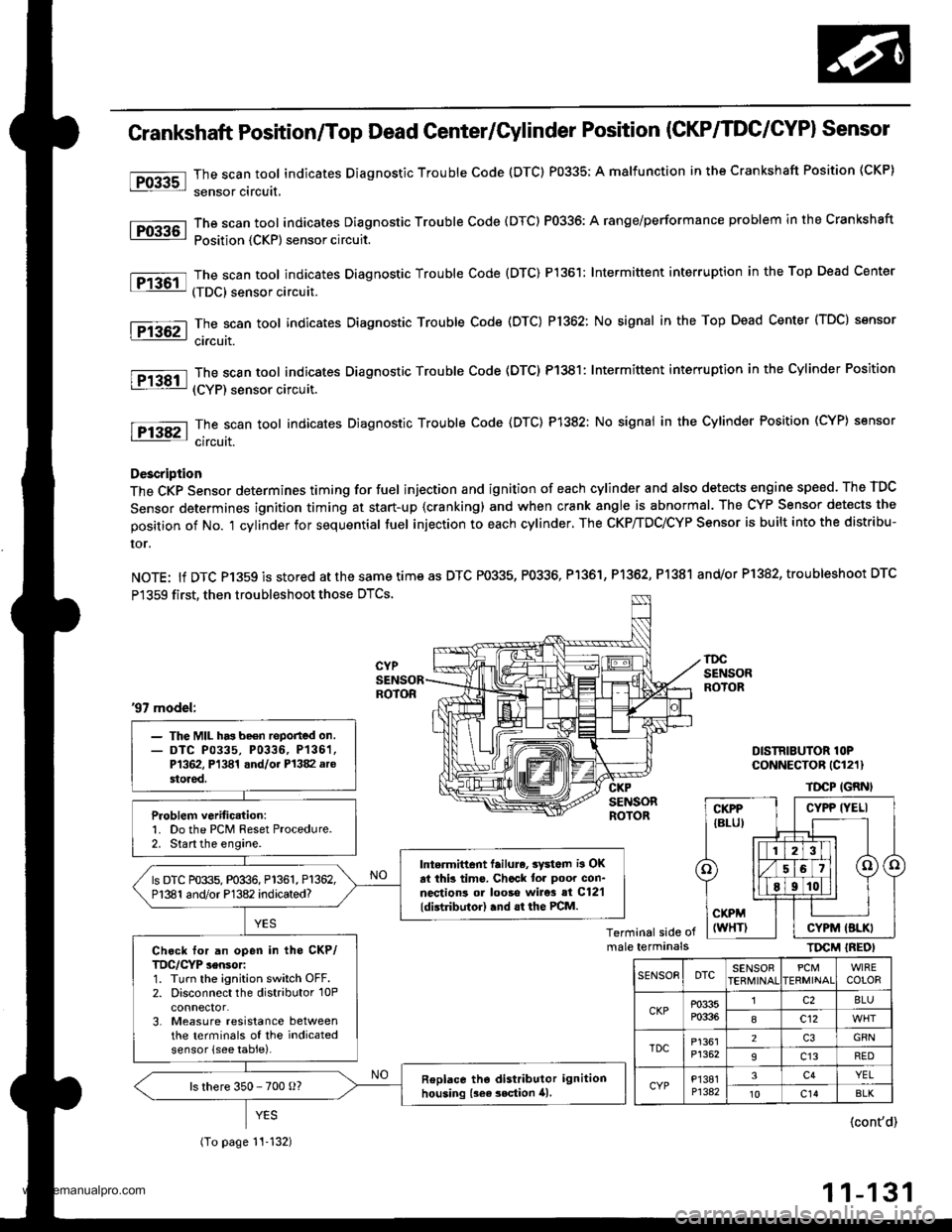

Crankshaft Position/Top Dead Genter/Gylinder Position (CKP/TDC/CYPI Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0335; A malfunction in the Crankshaft Position (CKP)

sensor circuit,

The scan tool indicates Diagnostic Trouble Code (DTC) P0336: A range/performance problem in the Crankshaft

Position {CKP) sensor circuit.

The scan tool indicates Diagnostic Trouble Code {DTC) P1361: Intermittent interruption in the Top Dead Center

(TDC) sensor circuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1362: No signal in the Top Dead Center (TDC) sensor

ci.cuit.

The scan tool indicates Diagnostic Trouble Code (DTC) P1381: Intermittent interruption in the Cylinder Position

(CYP) sensor circuit.

The scan toot indicates Diagnostic Trouble Code {DTC) P1382: No signal in the Cylinder Position (CYP} sensor

circuit.

Description

The CKP Sensor determines timing for fuel injection and ignition of each cylinder and also detects engine speed. The TDC

Sensor determines ignition timing at start-up {cranking) and when crank angle is abnormal. The CYP Sensor detects the

position of No. 't cylinder for sequential fuel injection to each cylinder. The CKP/TDC/CYP Sensor is built into the distribu-

ror.

NOTE: lf DTC P1359 is stored atthesametimeas DTC P0335, P0336, Pl361, P1362, P1381 and/or P1382, troubleshoot DTC

P1359 first, then troubleshoot those DTCS.

DISTRIBUTOR lOPCoNNECTOR (Cl211

TDCP IGRNI

Terminal side ofmale terminalsTIrcM IREOI

'97 model:

- The MIL has be€n reported on.- DTC P0335, P0336, P136'�1,P1362, Pl341 and/oi P1382 arestored.

Problem verific.tion:1. Do the PCM Reset Procedure.2. Start the engine.

Intermittent lailure, 3yd6m i3 OKat thb tims. Chcck tor poor con-nections ol looso wire3 si C12'l

ldistributor) .nd .t the PCM.

ls DTC P0335, P0336, P1361, P1362,P1381 and/or P1382 indicated?

Ch.ck for an open in tho CKP/TDC/CYP sensor:1. Turn the ignition switch OFF.2. Disconnect the distributor 10Pconnector.3. Measure resistance betweenthe terminals of the indicatedsensor (see table).

Replace tho distributor ignitionhousing {sea 3ection 41.ls there 350 - 700 o?

(To page 11-132)

CYPP IYELI

CYPM (BLKI

SENSOEDTCSENSOBPCMERMINAIWIRECOLOR

CKPP0335P0336

lc28LU

8c12

TDCP1361P1352

2GRN

9c13RED

CYPP'�I381P1342

3c4YEL't0c14BLK

{cont'd)

11-131

www.emanualpro.com

Page 370 of 1395

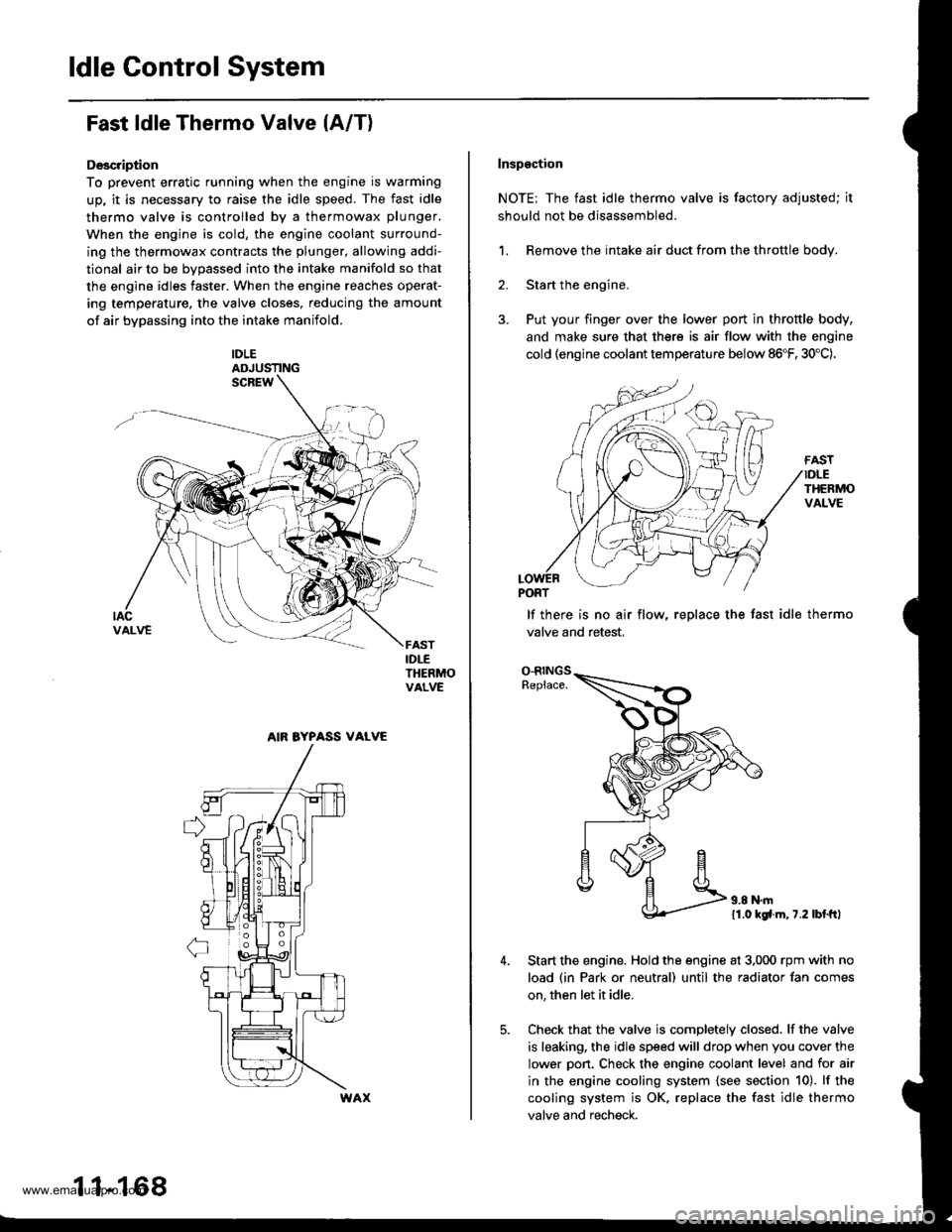

ldle Control System

Fast ldle Thermo Valve lA/T)

Description

To prevent erratic running when the engine is warming

up, it is necessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surround-

ing the thermowax contracts the plunger, allowing addi-

tional air to be bvDassed into the intake manifold so that

the engine idles faster. When the engine reaches operat-

ing temperature. the valve closes, reducing the amount

of air bypassing into the intake manifold.

IDLEADJUSTING

IDLETHERMOVALVE

AIR BYPASS VALVE

11-168

Inspgction

NOTE: The fast idle thermo valve is factory adjusted; it

should not be disassembled.

1. Remove the intake air duct from the throttle body.

2. Start the engine,

3. Put your finger over the lower port in throttle body,

and make sure that there is air flow with the engine

cold (engine coolant temperature below 86"F, 30'C).

lf there is no air flow, replace the fast idle thermo

valve and retest,

O-RINGSReplace.

11.0 kgfl.m, 7.2 lbl.ftl

Start the engine. Hold the engine at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on, then let it idle.

Check that the valve is completely closed. lf the valve

is leaking, the idle speed will drop when you cover the

lower pon. Check the engine coolant level and for air

in the engine cooling system {see section 10). lf the

cooling system is OK, replace the fast idle thermo

valve and recheck.

www.emanualpro.com

Page 377 of 1395

Fuel Tube/Ouick-Gonnect Fittings

Procautions

@ Do not smoke whils working on the fuel

syst6m, Koop open flames away from your work ar9a.

The fuel tube/quick-connect fittings assembly connects

the in-tank fuel pump with the fuel feed pipe. For remov-

ing or installing the fuel pump and fuel tank, it is neces-

sary to disconnect or connect the quick-connect fittings.

Pay attention to following;

. The fuel tube/quick-connect fittings assembly is not

heat-resistant; be careful not to damage it during weld-

ing or other heat-generating procedures.

. The fuel tube/quick-connect fittings assembly is not

acid-proof; do not touch it with a shop towel which

was used for wiping battery electrolyte. R€place the

fuel tube/quick-connect fittings assembly if it came

into contact with electrolyte or somethino similar.

. When connecting or disconnecting the fuel tube/quick-

connect fittings assembly, be careful not to bend or

twist it excessively, Replace it if damaged,

A disconnected quick-connect fittings can be reconnected,

but the retainer on the mating pipe cannot be reused once

it has been removed from the pipe. Replace tha retainer

. replacing the fuel pump.

. replacing the fuelfeed pipe,

. it has been removed from the Dioe,

. it is damaged.

RCTAINERFUEL TUBE

CONNECTOR

CONNECTOR

RETAINER

11-175

Disconnection

!@ Do not smoke while working on the fuel

syst6m. Keep open flames away from your work area.

1. Disconnect the battery negative cable.

2. Remove the fuel fill cap to relieve fuel pressure in

the tank.

3. Relieve fuel pressure (see page 11-178).

4. Check the fuel quick-connect fittings for dirt, and

clean if necessary.

5. Hold the connector with one hand and press down

the retainer tabs with the other hand. then pull the

connector off.

NOTE:

. Be careful not to damage the pipe or other parts.

Do not use tools,

. lf the connector does not move, keep the retainer

tabs pressed down, and alternately pull and push

the connector until it comes off easily.

. Do not remove the retainer from the pipe; once

removed, the retainer must be replaced with a

new one.

LOCKII{G PAWL

RETANEN TAB

@NNCCTOR

Press down.

6. Check the contact area of the pipe for dirt and dam-

age.

. lf the surface is dirW, clean it

. lf the surface is rusty or damaged, replace the fuel

pump or fuel feed pipe,

CONTACT ANEA

{cont'd}

www.emanualpro.com

Page 431 of 1395

Clutch Pedal

Adiustment

NOTE:

. To check the clutch interlock switch and clutch

switch, see section 23.

. The clutch is self-adjusting to compensate for wear.

CAUTION: lf there is no clearance bstwa€n the mas-

ter cylinder piston and push rod, ths roloase bearingis held againsi the diaphragm spring, which canresuh in clutch slippage or other clutch probloms.

1. Loosen locknut A, and back off the clutch switch (or

sdjusting bolt) until it no longer touches the clutchpeoar.

2. Loosen locknut C, and turn the push rod in or out toget the specified stroke (@) and height (@) at theclutch oedal.

3. Tighten locknut C.

4. Thread in the clutch swirch (or adjusting bolt) untilit contacts the clutch oedal.

7.

5.

8.

q

Turn the clutch switch {or adjusting bolt} in an addi-

tional 3/4 to 1 full turn.

Tighten locknut A.

Loosen locknut B on the clutch interlock switch.

Measure the clearance between the floor board and

clutch pedalwith the clutch pedal fully depressed.

Release the clutch pedal 15 - 20 mm (0.59 - 0.79 in)

from the fully depressed position and hold it there,Adjust the position of the clutch interlock switch sothat the engine will start with the clutch pedal in

this position.

Tighten locknut B.10.

LOCKNUT B9.8 N.m 11.0 kgf.m, 7.2 lbf.ftl

CLUTCH INTERLOCK SWITCH

CLUTCH SWTTCH{or ADJUSTING BOLTI

L(rcKNUT A9.8 N.m {1.0 kg{.m,7.2 lbf.ftl

CLUTCH MASTER CYLINDER

PUSH ROD

Pedal in contact with swhch

LOCKNUT C18 N.m (1.8 kgf.m, 13lbtftl

@ {STROKE at PEDAL): 135 - 1its mm (5.31 - 5.71 in}

@ (TOTAL CLUTCH PEDAL FREE PLAY)i7 -22mm (0.28-0.87 in) inctude the pedat ptay 1 - 9 mm (0.0it- 0.35 inl@ (GLUTC,H PEDAL HE|GHTI: ltxt mm (7.20 inl ro rhe ftoor

o (CLUTCH PEDAL DTSENGAGEMENT HEtcHTl: 72 mm {2.txt inl minimum to the floor

\,/a_-_--/

12-4

www.emanualpro.com

Page 445 of 1395

Transfer Assembly

lnstallation

1. Install a new O-ring on the transfer assembly.

8 x 1.25 mm24 N.m (2.4 kgt m,17 rbt.ftl

10 x 1.25 mm44 N.m (4.5 kgJ.m,

2.

DOWEL PIN

Replace.TRANSFEBASSEMBLY

Clean the areas where the transfer assembly con

tacts the transmission with solvent or carburetor

cleaner, and dry with compressed air. Then apply

MTF to the contact areas.

Installthe transfer assembly on the transmission.

NOTE: While installing the transfer assembly on

the transmission, do not allow dust or other foreign

particles to enter the transmission.

lnstall the rear stiffener.

Install the propeller shaft to the transfer assembly

by aligning the reference marks,

8 x1.25 mm32 N.m 13.3 kg{.m,24 tbf.ftl

REFERENCE MARKS

6. Install the exhaust pipe A,

GASKETEXHAUST PIPE A

HO2S CONNECTOR

10 x 1 .25 mm54 N.m (5.5 kgt m,40 tbtfttReplace.

SELF.LOCKING

NUT8 x 1.25 mm16 N.m {1.6 kgf.m,12 tbt.ft)Replace.8 x 1.25 mmzzN.m l2.2kg!-m,16 rbf.trtReplace.

7.Connect the heated oxygen sensor (HO2S) connector.

Relill the transmission with MTF (see page 13-3).

Start the engine, and run it to normal operating tem-

perature (the radiator tan comes on). Turn the

engine off. and check fluid level.

8.

9.

www.emanualpro.com

Page 505 of 1395

Mainshaft Thrust Clearance

Adjustment (cont'dl

-7. Slide the mainshaft base over the mainshaft.

Attach the mainshaft holder to the mainshaft as

follows:

NOTE:

. Back-out the mainshaft holder bolt and

loosen the two hex bolts.

. Fit the holder over the mainshaft so its lip is

towards the transmission.

. Align the mainshaft holder's lip around the

groove at the inside of the mainshaft

splines, then tighten the hex bolts.

MAINSHAFT HOLDERBOLT

MAINSHAFT EASE07GAJ - PG20130

-9. Seat the mainshaft fully by tapping its end with

a plastic hammer.

-10. Thread the mainshaft holder bolt in until it just

contacts the wide surface of the mainshaft

base.

07GAJ - PG20130

-8.

t--E-Hlf\f,A l\. xex

l"\y I aors

t____=__)"n-____"8

\

MAINSHAFTHOLDER07GAJ - PG20110

- 11. Zero a dial gauge onthe end ofthe mainshait.

-12. Turn the mainshaft holder bolt clockwise; stop

turning when the dial gauge has reached its

maximum movement, The reading on the dial

gauge is the amount of mainshaft end play.

NOTE: Turning the mainshaft holder bolt more

than 60 degrees after the needle of the dial

gauge stops moving may damage the transmis-

sion.

MAINSHAFT HOLDER07cru - PG20110

-13. lf the reading is within the standard, the clear-

ance rs correct.

lf the reading is not within the standard,

recheck the shim thickness.

Standard: 0.11 - 0.18 mm (0.00i1- 0.007 inl

DIAL GAUGEMAGNET STAND AASE07979 - PJ40001

www.emanualpro.com

Page 543 of 1395

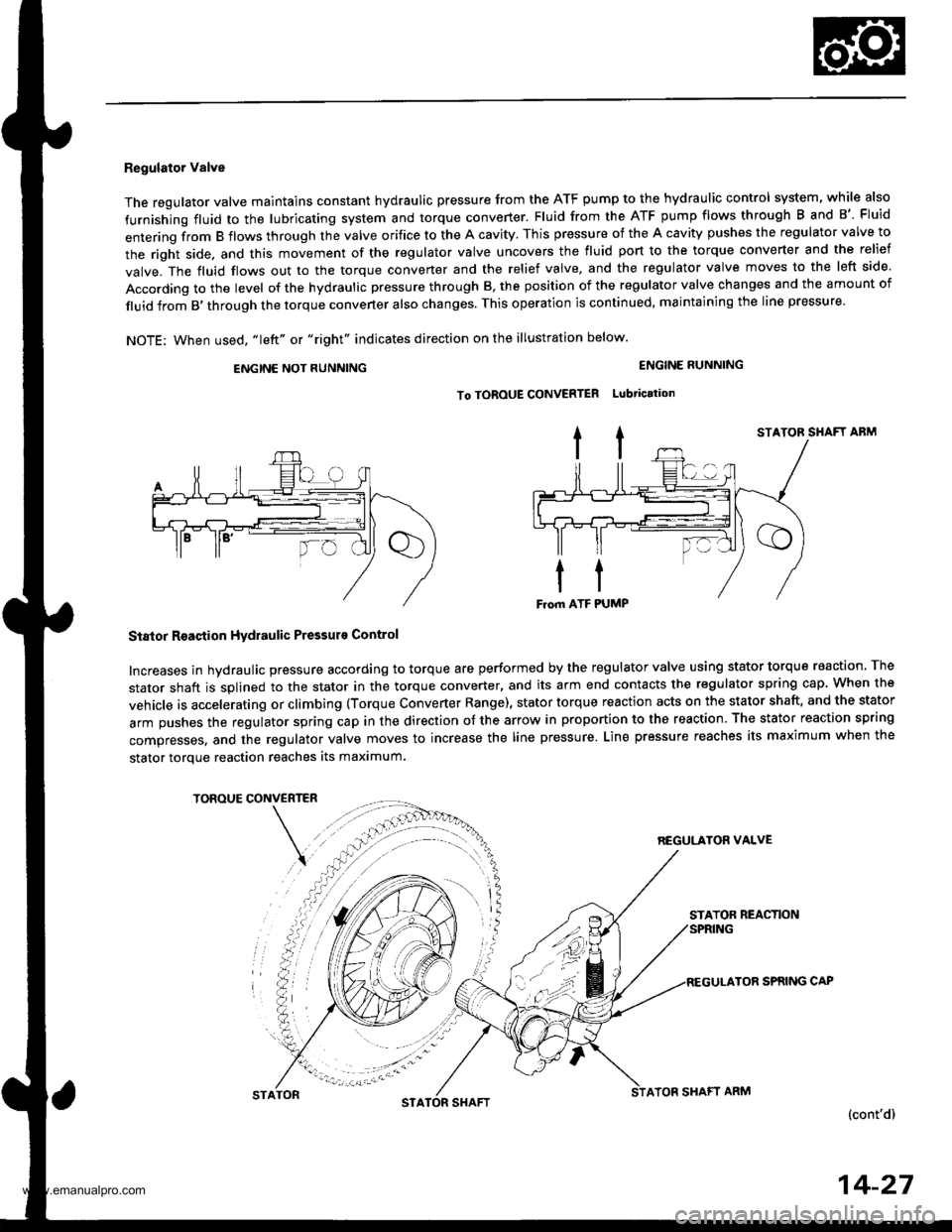

Regulator Valve

The regulator valve maintains constant hydraulic pressure from the ATF pump to the hydraullc control system, while also

furnishing fluid to the lubricating system and torque converter. Fluid from the ATF pump flows through B and B'. Fluid

entering from B flows through the valve orifice to the A cavity. This pressure of the A cavity pushes the regulator valve to

the right side. and this movement of the regulator valve uncovers the fluid port to the torque converter and the relief

valve. The fluid flows out to the torque converter and the relief valve, and the regulator valve moves to the left side.

According to the level of the hydraulic pressure through B, the position of the regulator valve changes and the amount of

fluid from B,through the torque converter also changes. This operation is continued, maintaining the line pressure.

NOTE; When used, "|eft" or "right" indicates direction on the illustration below.

ENGINE NOT RUNNING

STATOR SHAFT ABM

Stator Reaction Hydraulic Pressurs Control

Increases in hydraulic pressure according to torque are performed by the regulator valve using stator torque reaction. The

stator shaft is splined to the stator in the torque converter, and its arm end contacts the regulator spring cap When the

vehicle is accelerating or climbing (Torque Converter Range), stator torque reaction acts on the stator shaft, and the stator

arm pushes the regulator spring cap in the direction of the arrow in proportion to the reaction. The stator reaction spring

compresses, and the regulator valve moves to increase the line pressure. Line pressure reaches its maximum when the

stator torque reaction reaches its maximum.

TOROUE CONVERTER

REGULATON VALVE

STATOR REACTION

TOR SPRING CAP

(cont'd)

ENGINE RUNNING

To TOROUE CONVERTER Lubtication

STATONSTASHAFTATOF SHAFT ARM

14-27

www.emanualpro.com

Page 633 of 1395

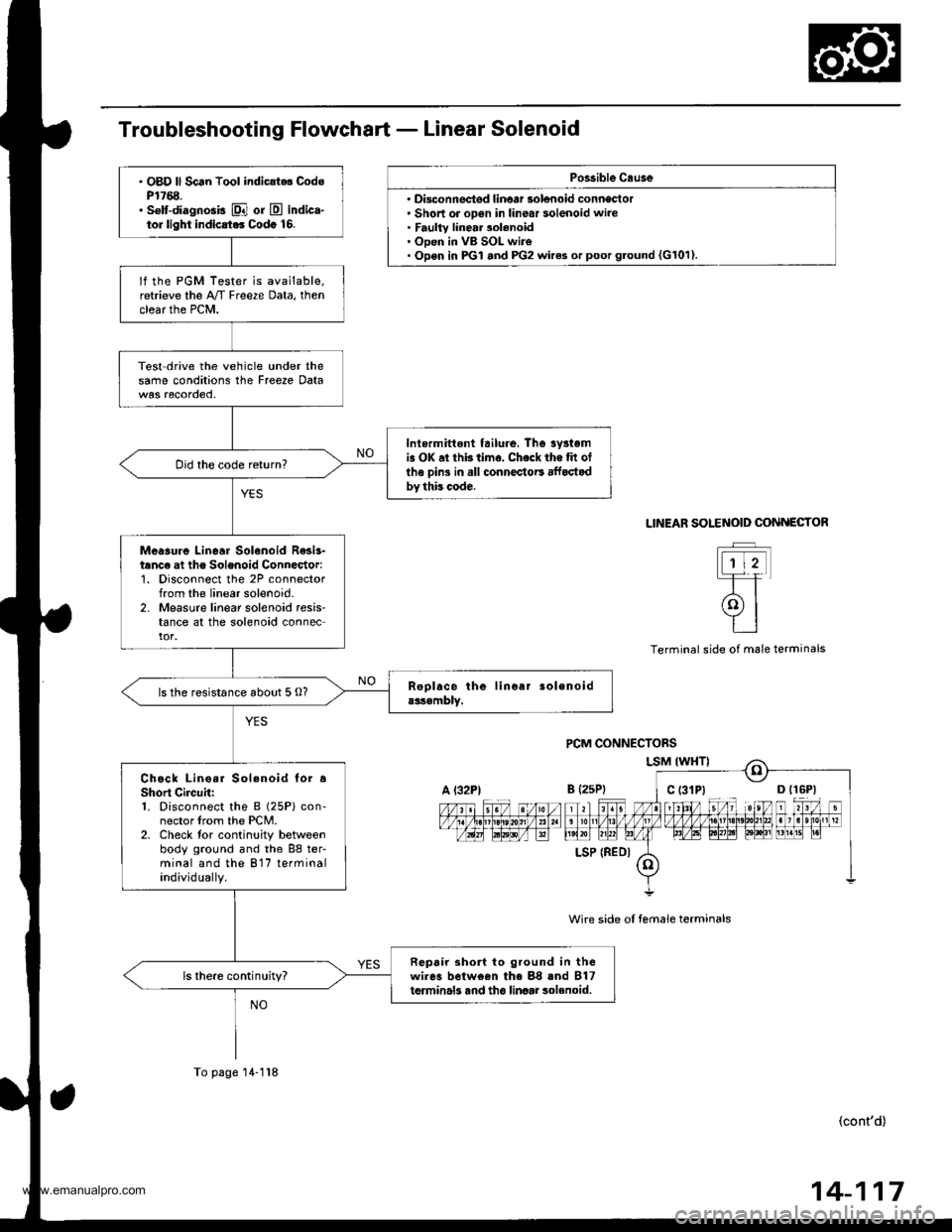

Po$ible Cau3e

' Disconnectsd linoar solenoid conneclol. Short or open in linear solenoid wire. Faulty linear 3olenoid. Open in VB SOL wire. Open in PGI and PG2 wires or poot g.ound {G101).

. OBD ll Scan Tool indic{t.. CodsP1768.. selt-diagnosis El or E indica-tor light indicrt.. Codo 16.

lf the PGM Tester is available.retrieve the A/T Freeze Data, thenclear the PCM.

Test drive the vehicle under thesame conditions the Freeze Data

Inlermittont tailure, The 3yrtomis OK at thb time. Check the tit otlhe oins in all connectoE affoctodby this code.

Did the code return?

Meaaure Linear Solenoid R€sis-tanc€ at the Solenoid Connector:1. Disconnect the 2P connectorfrom the linear solenoid-2. Measure linear solenoid resis-tance at the solenoid connector.

ls the resistance about 5 O?

Chock Lino.r Sol.noid to. aShort Circuh:1. Disconnect the B (25P) con-nector lrom the PCM.2. Check tor continuity betweenbody ground and the 88 ter-minal and the 817 terminalindividually.

Repair 3ho to ground in thewires belween the 88 rnd B17terminals and tho linaar 3olenoid.ls there continuity?

A l32PtB {2sP)

LSP (REDI

To page 14-118

SOLENOID COiINECTOR

t-rtt

(9l

tt

LINEAR

Terminal side ol male terminals

wire side oI temale terminals

(cont'd)

14-117

www.emanualpro.com