Temperature sensor HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 300 of 1395

PGM-FI System

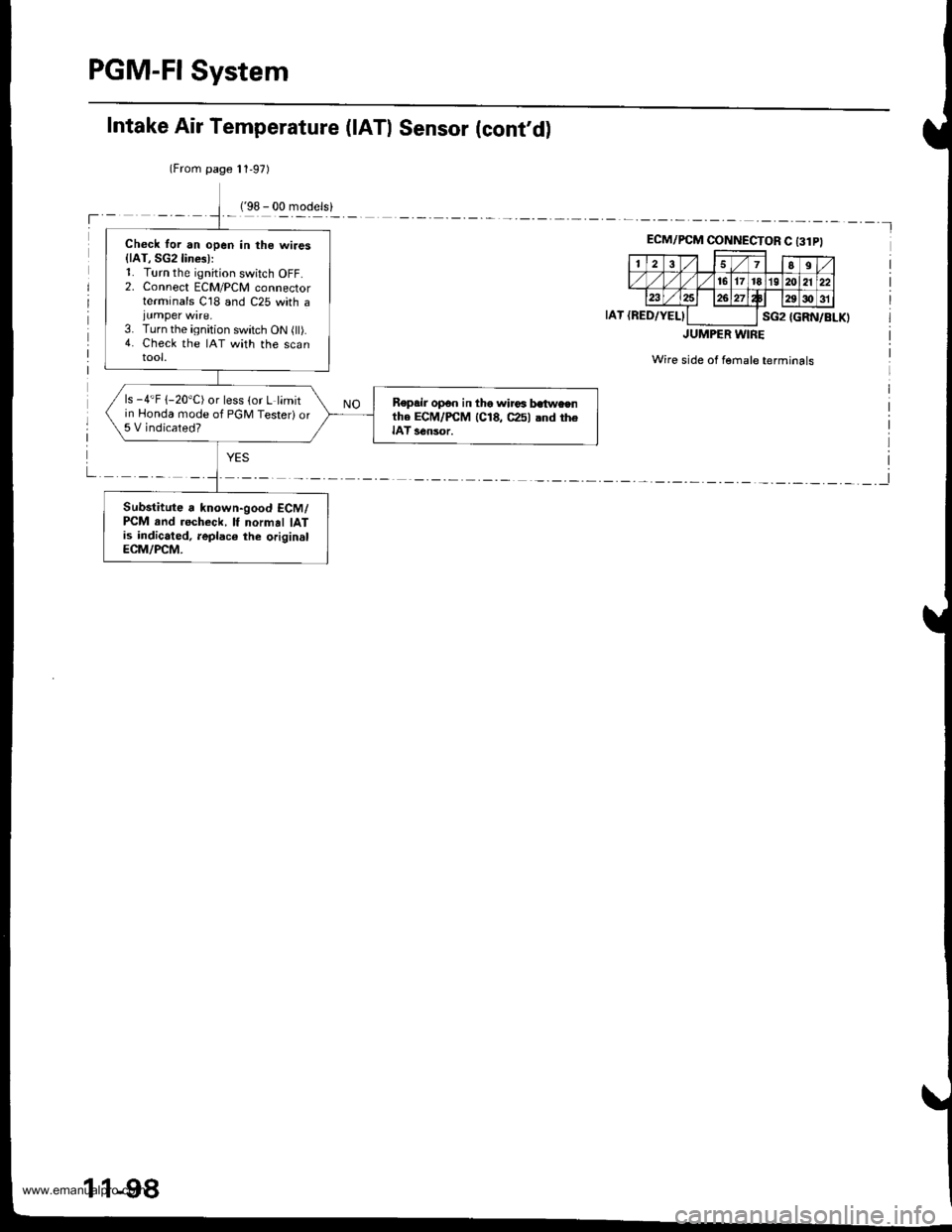

Check for an open in the wires{lAT, SG2lines):1. Turn the ignition switch OFF.2. Connect ECM/PCM connectorterminals C18 and C25 with ajumper wire.3. Turn the ignition switch ON (ll).4. Check the IAT with the scantool.

ls -4'F 1-20"C) or less (or L limitin Honda mode of PGM Testeri or5 V indicated?

Repsir op€n in the wirca batweenthe ECM/PCM 1C18, C25l and theIAT s€nsor.

Substitute a known-good ECM/PCM rnd recheck, lf normal IATis indicated, leplaco the originslECM/PCM.

Intake Air Temperature (lATl Sensor (cont'd)

(From page 11,97)

'l

ECM/PCM CINNECTOR C t3lPl

257II

./ 16171819 202122234 Wp,29c)31

sG2IAT {RED/YELI{GRN/BLK)

JUMPER WIRE

Wire side of fernale terminals

I

1 1-98

www.emanualpro.com

Page 301 of 1395

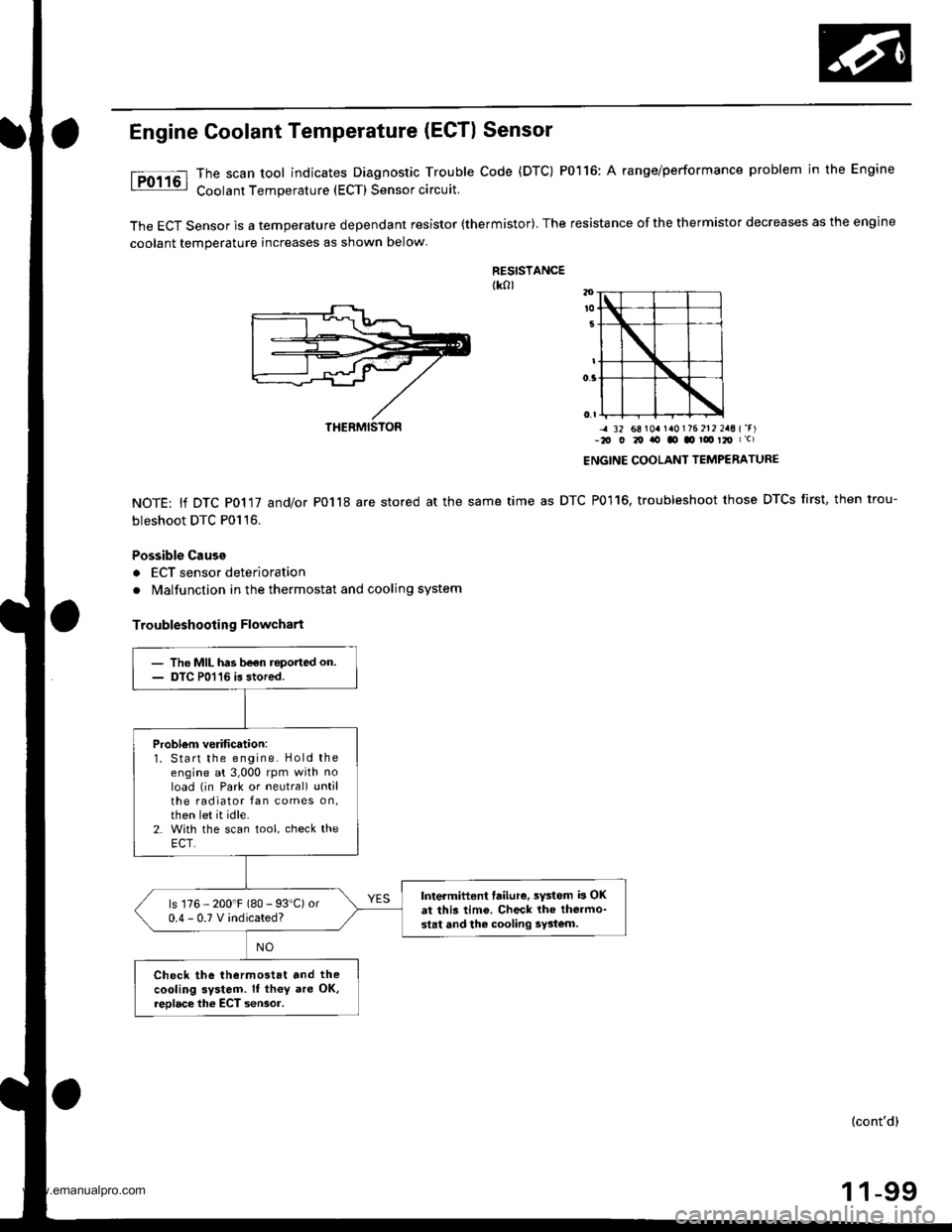

Engine Goolant Temperature (ECTI Sensor

The scan tool indicates Diagnostic Trouble Code (DTC) P0116: A range/performance problem in the Engine

Coolant Temperature (ECT) Sensor circuit.

The ECT Sensor is a temperature dependant resistor (thermistor). The resistance of the thermistor decreases as the engine

coolant temperature increases as shown below

RESISTANCEtk0l

NOTE: lf DTC P0117 and/or P0118 are stored at the same

bleshoot DTC P0116.

Possible Cause

a ECT sensor deterioration

. Malfunction in the thermostat and cooling system

Troubleshooting Flowchart

-4 32 68 r0a r a0176 212 2aE {'r)-2O O 20 ito tO .o ! t2O I c)

ENGINE COOLANT TEMPERATURE

time as DTC P0116, troubleshoot those DTCS first, then trou-

THERMISTON

- The MIL has be€n roported on.- DTC P01'16 is stored.

Probl6m verification:1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator fan comes on,then let it idle.2. With the scan tool, check theECT.

Intermittent failure, sYstem b OKat this tim6. Check lhe thermo-stat and the cooling 5y3tom.

ls 176 - 200'F (80 - 93"C) or0.4-0.TVindicated?

Check the thermostat and the

cooling system. It th€y are OK,reolace the ECT seNor.

(cont'd)

1 1-99

www.emanualpro.com

Page 302 of 1395

PGM-FI System

Engine Coolant Temperature (ECTI Sensor {cont'd)

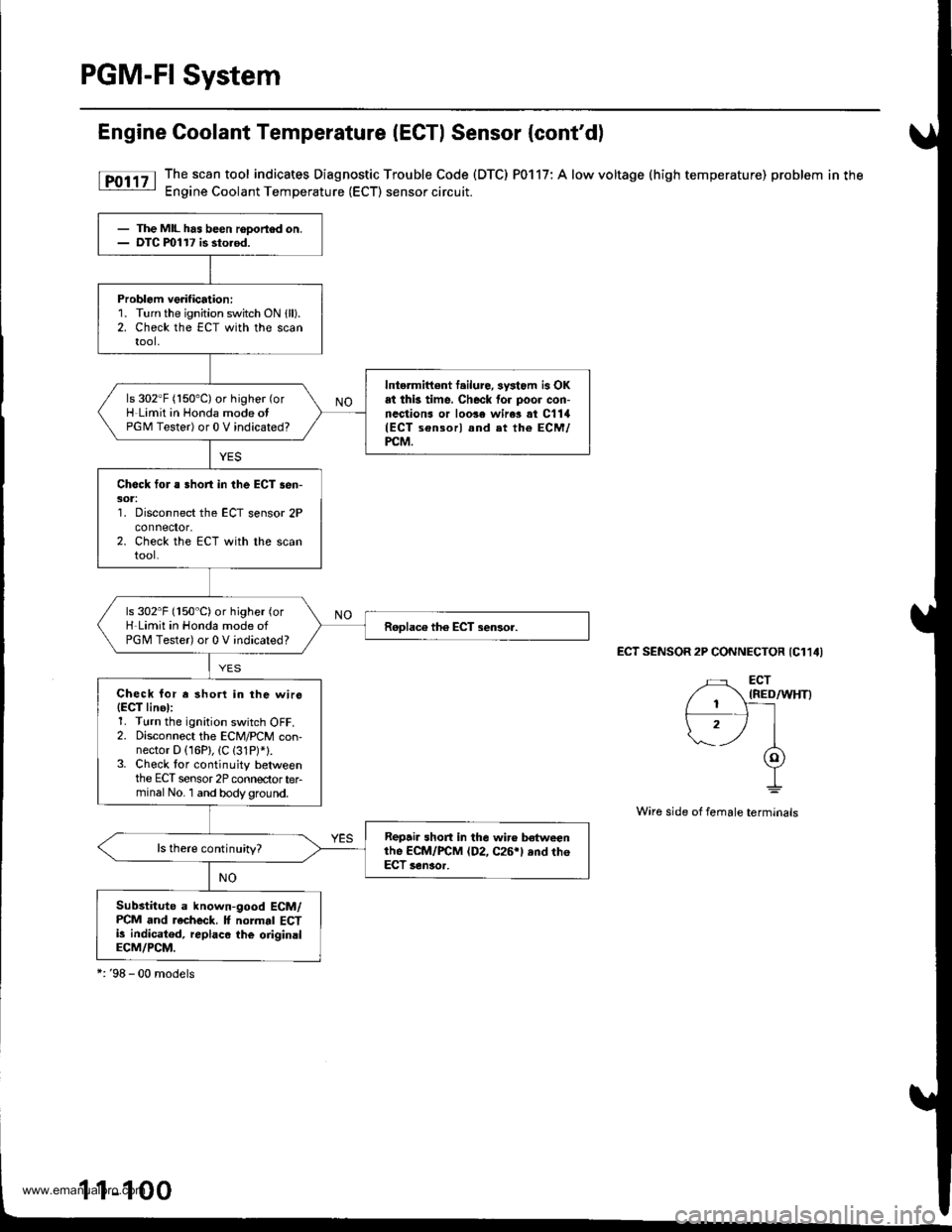

[F011' The.scan tool indicates Diagnostic Trouble Code (DTC) P0117: A low voltage (high temperature) problem in the: Engine Coolant Temperature (ECT) sensor circuit.

ECT SENSOR 2P CONNECTOR {C114I

Wire side of female terminals

- The MIL has been rooortod on.- DTC ml17 is sto.od.

Problem verification:1. Turn the ignition switch ON {ll).2. Check the ECT with the scantool,

Intermittont f.ilure, sysiom is OKat thk time. Check for poor con-nections or loo3e wire3 at C1lil(ECT sensorl and et the ECM/PCM.

ls 302"F (150'C) or higher (or

H Limit in Honda mode otPGM Tester) or 0 V indicated?

Check for a Bhort in the ECT sen-301:'1. Disconnect the ECT sensor 2Pconnefior,2. Check the ECT with the scantool.

ls 302"F (150"C)or higher (or

H-Limit in Honda mode ofPGM Tester) or 0 V indicated?

Check for r shorl in the wirs(EgT linel:1. Turn the ignition switch OFF.2. Disconnect the ECM/PCM con-nector D (16P), (C (31P)*1.3. Check tor continuity betweenthe ECT sensor 2P connectorterminal No. 1 and bodyground.

Repair short in the wir€ betweenthe ECM/FCM (D2, C26rl ,nd th6ECT senaor.

ls there continuity?

Substitute a known-good ECM/PCM and recheck. It normal ECTi! indicatod, replaco the oiiginalECM/PCM.

*:'98 - 00 models

1-1

www.emanualpro.com

Page 303 of 1395

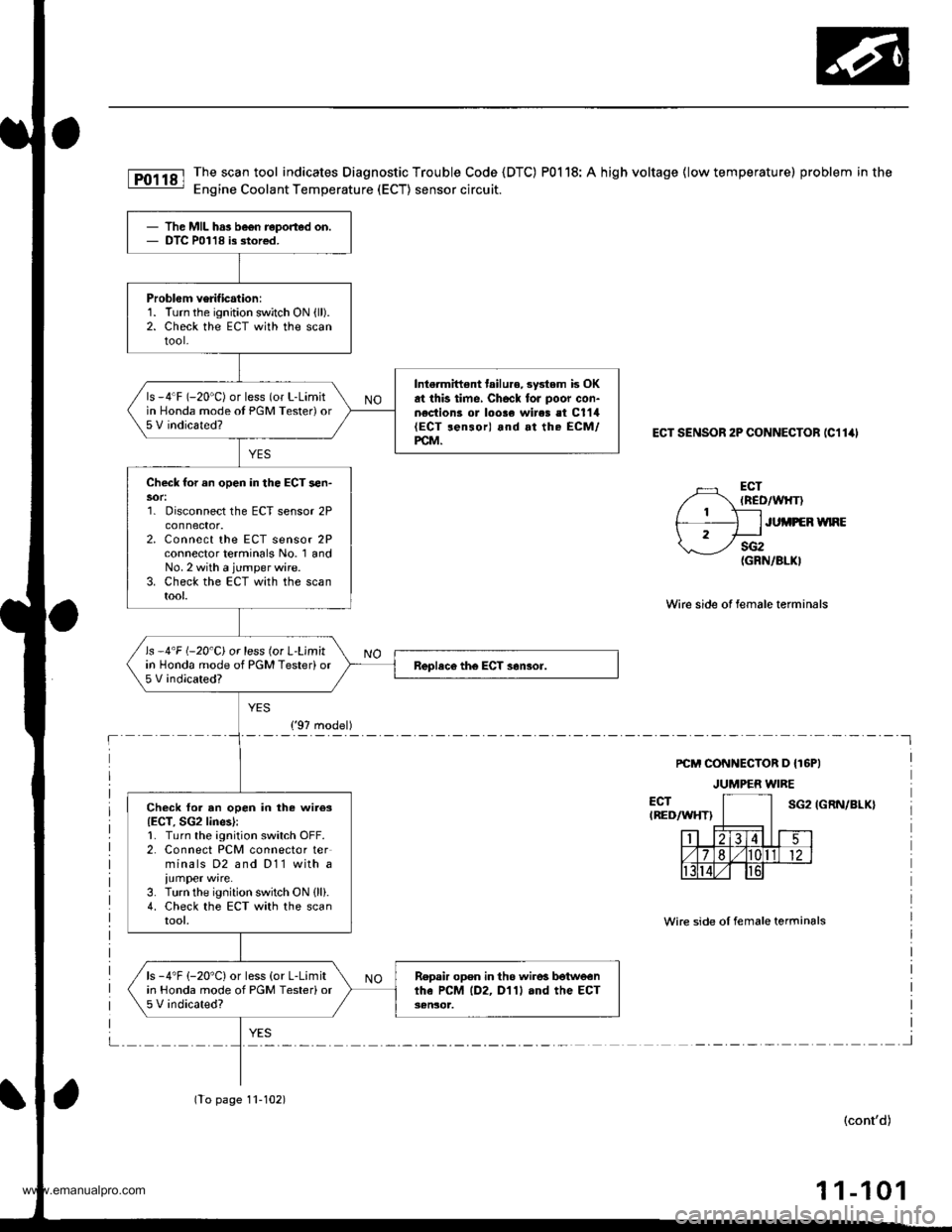

The scan tool indicates Diagnostic Trouble Code {DTC) P0118: A high voltage {low temperature) problem in the

Engine Coolant Temperature (ECT) sensor circuit.

ECT SENSOR 2P CONNECTOB (C11ill

ECT(ncD/wlrT)

ECTIREDAAIHT)

Wirc side of lemale terminals

sG2(GRN/8LKI

PCM CONNECTOR D {T6PI

JUMPER WIRE

JUi,IPEB WNE

IGRN/BLX}

Wire side oI female terminals

(cont'd)

1 1-101

The MIL has be€n reported on.DTC P01'18 is stor€d.

Problem verification:1. Turn the ignition switch ON {ll).2. Check the EcT with the scantool-

Intermiftent tailu.€,3ystem is OKat this time, Checl foJ poor con-n€ction3 or loose wires et C1'14(ECT ren3or) and at the ECM/PCM.

ls -4"F (-20'C) or less (or L-Limitin Honda mode ot PGM Tester) or5 V indicated?

Check for an open in the ECT sen-

1. Disconnect the ECT sensor 2Pconnector.2. Connect the ECT sensor 2Pconnector terminals No. 1 andNo. 2 with a jumper wire.3. Check the ECT with the scantool.

ls -4'F (-20'C) or less (or L'Limitin Honda mode of PGM Tester)or5 V indicated?

Check for an open in the wiies{ECT, SG2 lines):1. Turn the ignition switch OFF.2. Connect PCM connector terminals D2 and D11 with a

iumper wire.3. Turn the ignition switch ON {ll}.4. Check the ECT with the scantool,

ls -4"F (-20'C) or less (or L-Limitin Honda mode of PGM Testerior5 V indicated?

Repair open in th6 wire! botwe€nthe PCM lD2, D'l1l and the ECT3€n30t.

('97 model)

(To page 11-102)

www.emanualpro.com

Page 304 of 1395

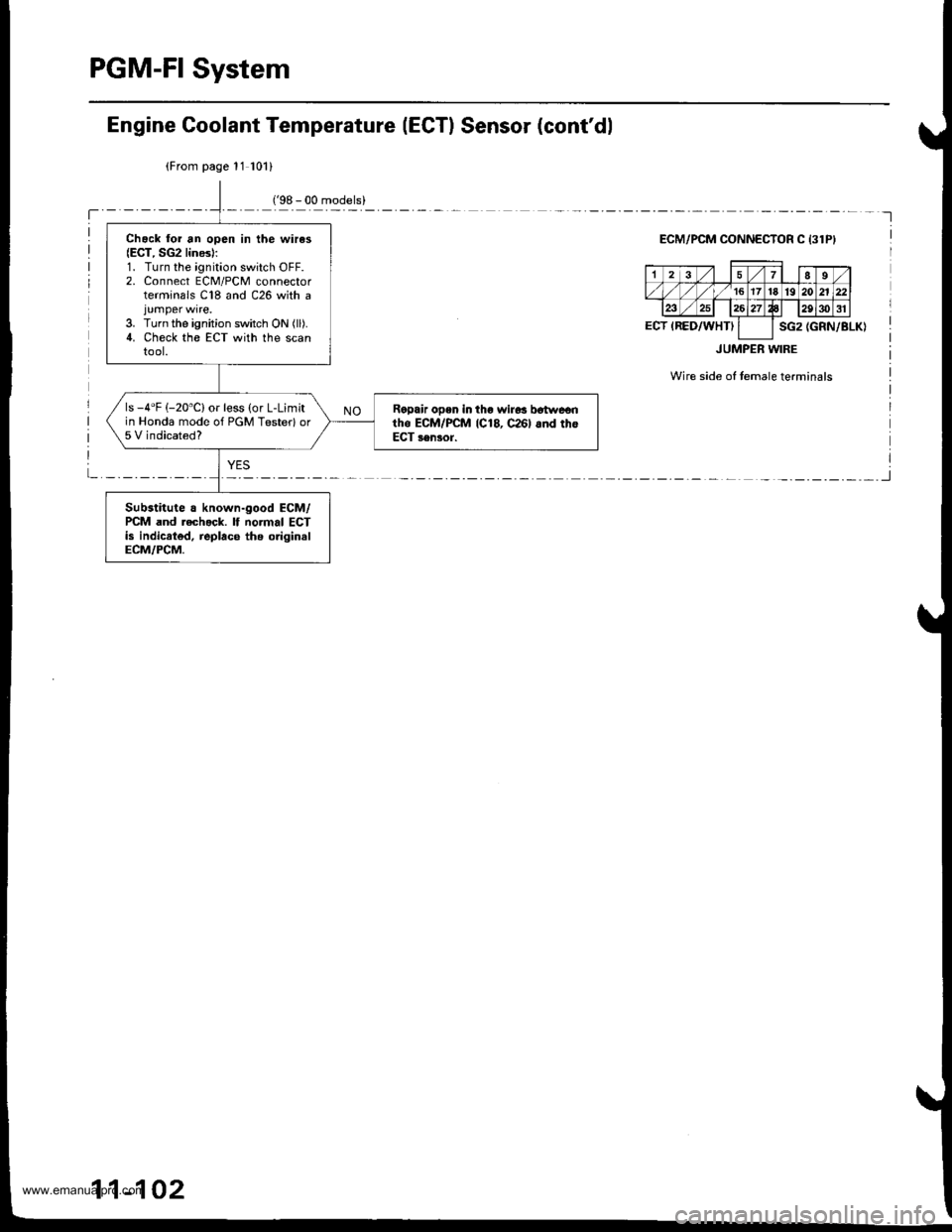

PGM-FI System

Chack lor an open in the wires(ECT, SG2 lines):1. Turn the ignition switch OFF.2. Connect ECM/PCM connectorterminals C18 and C26 with a

3. Turn the ignition switch ON (ll).

4. Check the ECT with the scantool.

ls -4"F (-20"C) or less (or L-Limitin Honda mode of PGM Testerlor5 V indicated?

Ralpair open in tho wir6s b6twe€ntho ECM/PCM 1C18, c26l 6nd thoECT sensor.

Substitute a known-good ECM/PCM and rech.ck. lf normal ECTis indicrted, replace ths originslECM/PCM.

Engine Goolant Temperature (ECTI Sensor (cont'dl

(From page 11 101)

ECM/PCM OONNECTOR C 13lPI

(GRN/BLK)

JUMPER WIRE

Wire side of temale terminals

17I9

,/ 1617't8'1920n

ECT IRED/WHTIsG2

11-102

www.emanualpro.com

Page 351 of 1395

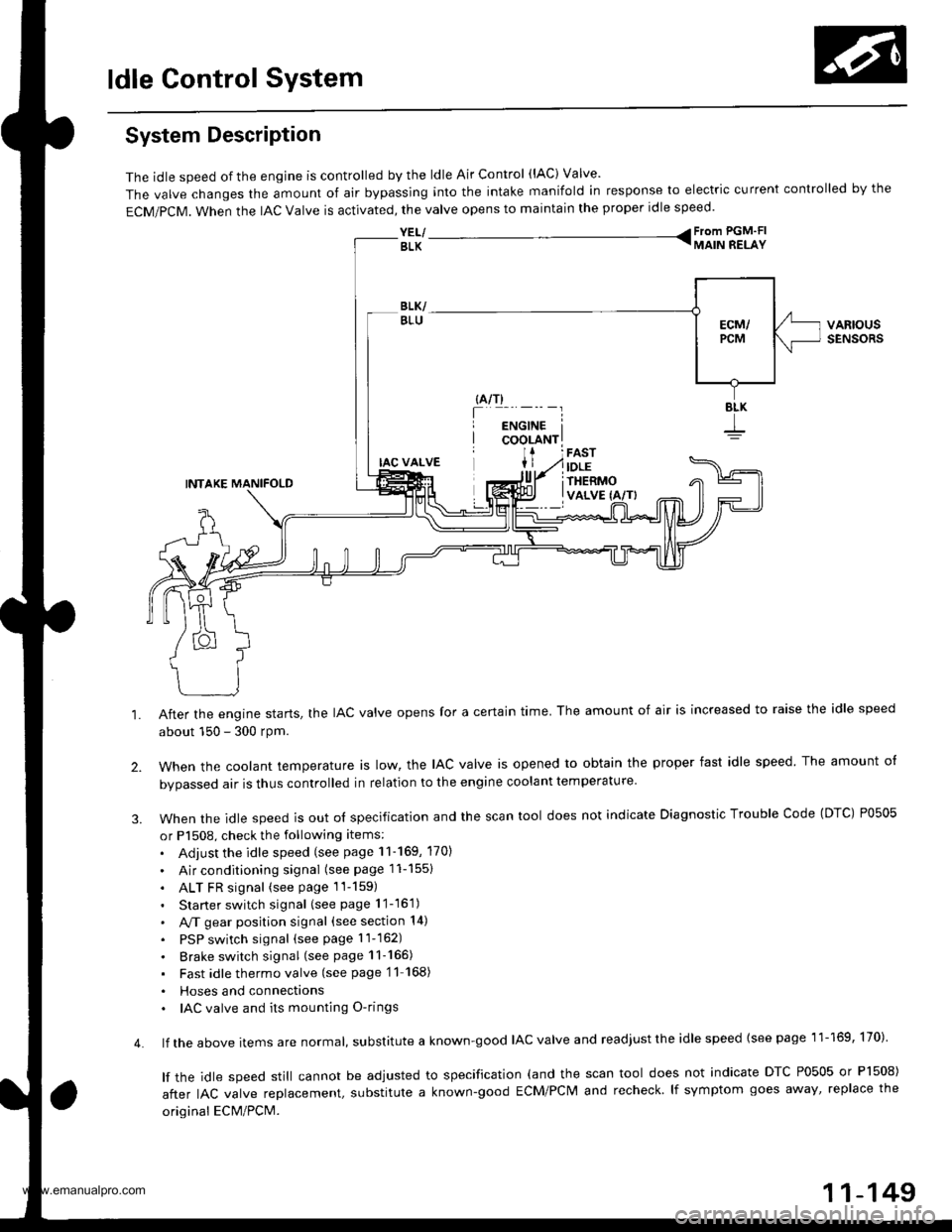

ldle Control System

System Description

The idle speed of the engjne is controlled by the ldle Air Control (lAC) Valve'

The valve changes the amount of air bypassing into the intake manifold in response to electric current controlled by the

ECM/PCM. When the lAc valve is activated, the valve opens to maintain the proper idle speed.

YEL/ From PGM'FI

BLK TMAIN RELAY

VARIOUSSENSORS

4.

IAC VALVE

INTAKE MANIFOLD

After the engine starts, the IAC valve opens for a certain time. The amount of air is increased to raise the idle speed

about 150 - 300 rpm.

when the cootant temperature ts row, the lAc valve is opened to obtain the proper fast idle speed The amount o{

bvoassed air is thus controlled in relation to the engine coolant temperature

When the idle speed is out o{ specification and the scan tool does not indicate Diagnostic Trouble Code (DTC) P0505

or P1508, check the following items:

. Adjust the idle speed (see page 11-169, 170)

. Air conditioning signal (seepagell-1551

. ALT FR signal (see page 1l-159)

. Starter switch signal (see page 11-16'1)

. A,/T gear position signal (see section 14)

. PSP switch signal (seepagell-162)

. Brake switch signal (see page 11-165)

. Fast idlethermovalve (see page'11 168)

. Hoses and connecttons. IAC valve and its mounting O-rings

lf the above items are normat, suDslitute a known-good IAC valve and readjust the idle speed {see page 11-169, 170)

lf the idle speed still cannot be adjusted to specification (and the scan tool does not indicate DTC P0505 or Pl508)

after IAC valve reolacement, substitute a known-good ECM/PCM and recheck lf symptom goes away' replace the

original ECM/PCM.

11-149

www.emanualpro.com

Page 352 of 1395

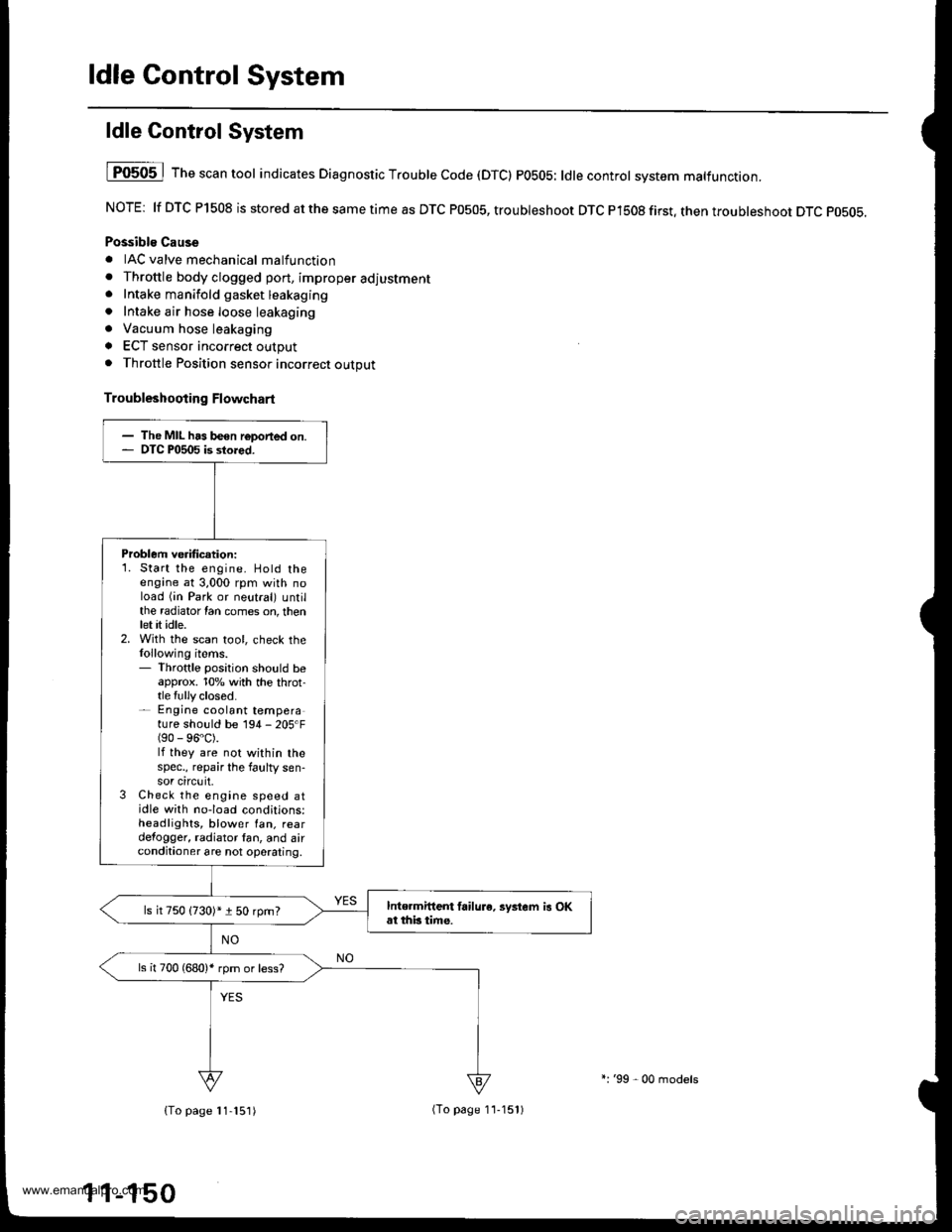

ldle Control System

ldle Control System

I P0505 | The scan tool indicates Diagnostic T.ouble Code (DTCI PO5O5: ldlecontrol svstem mattunction.

NOTE: lf DTC P1508 is stored at the same time as DTC P0505, troubleshoot DTC P1508 first. then troubleshoot DTC p0505.

Possibls Cause

. IAC valve mechanical malfunction. Throttle body clogged port, improper adlustment. Intake manifold gasket leakaging. Intake air hose loose leakaging. Vacuum hose leakaging

a ECT sensor incorrect output. Throttle Position sensor incorrect output

Troubleshooting Flowchart

The MIL has been reDorted on.DTC P0505 is sto.ed.

Problem verificationi1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator Ian comes on, thenlet it idle.2. With the scan tool, check thelollowing items.- Throttle position should beapprox. 10% with the throt-tle {ully closed.- Engine coolant temperature shorJld be 194 - 205'F(90 - 96"C).lf they are not within thespec., repair the faulty sen-sor circuit.3 Check the engine speed atidle with no-load conditions:headlights, blower fan. reardefogger, radiator lan, and airconditioner are not operaling,

Inte.mittent failure. syltem is OKat this time.ls it 750 {730)* i 50 rpm?

ls il 700 (680)' rpm or less?

{To page 11-151)(To page 1'l-151)

l:'99 - 00 models

www.emanualpro.com

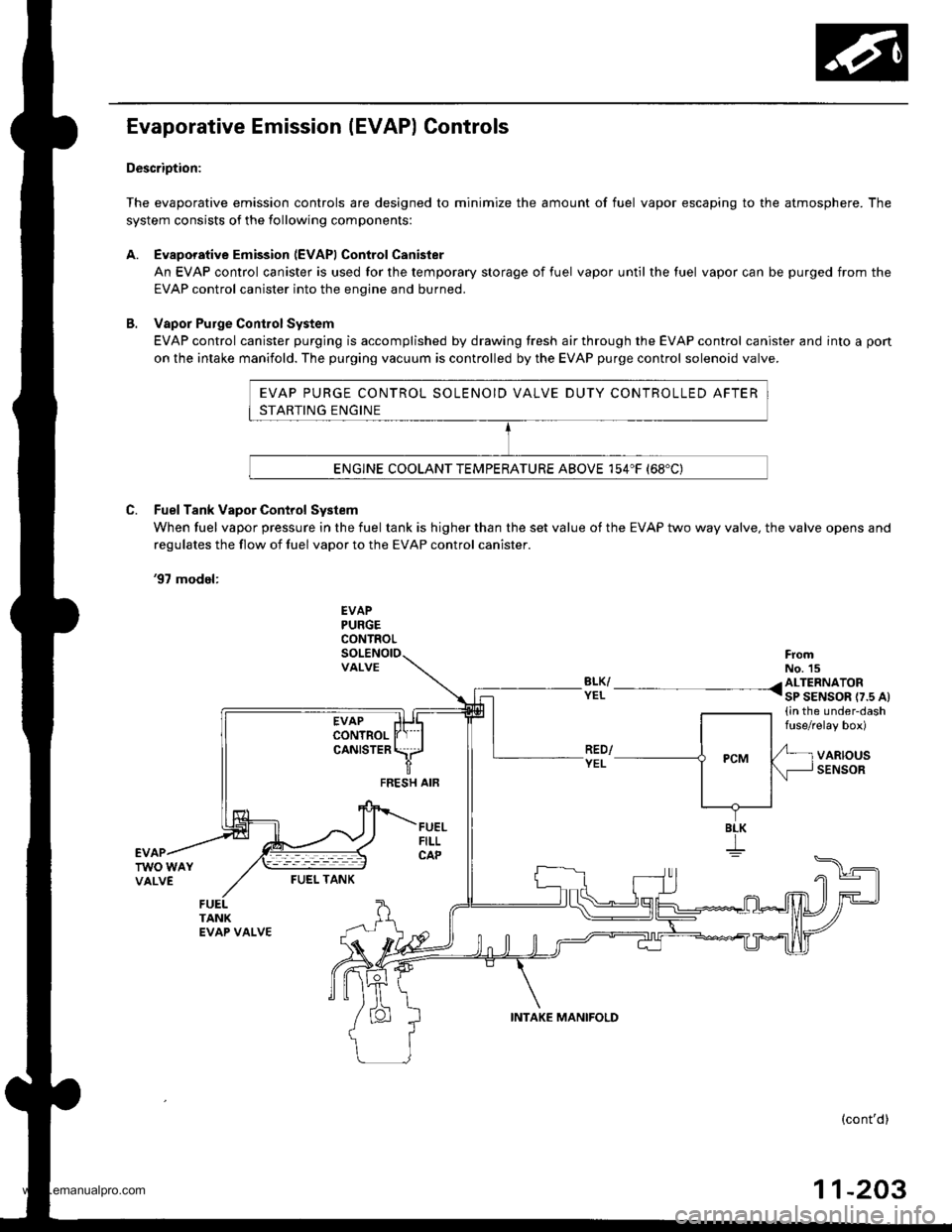

Page 405 of 1395

EVAP PURGE CONTROL SOLENOID VALVE DUTY CONTROLLED AFTER

STARTING ENGINE

ENGINE COOLANT TEMPERATURE ABOVE 154"F (68'C)

Evaporative Emission (EVAP) Controls

Description:

The evaporative emission controls are designed to minimize the amount of fuel vapor escaping to the atmosphere. The

system consists of the following components:

A. Evaporative Emission (EVAPI Control Canister

An EVAP control canister is used for the temporary storage of fuel vapor until the luel vapor can be purged from the

EVAP control canister into the enqine and burned.

B. Vapor Purge ConirolSystem

EVAP control canister purging is accomplished by drawing fresh air through the EVAP control canister and into a pon

on the intake manifold. The purging vacuum is controlled by the EVAP purge control solenoid valve.

C. Fuel Tank Vapor Control System

When fuel vapor pressure in the fuel tank is higher than the set value of the EVAP two way valve, the valve opens and

regulates the flow ot fuel vapor to the EVAP control canister.

'97 model:

EVAPPURGECONTROL

VALVEFromNo. 15BLK/ /ALTERNATORYEL I sP SENSOR r7.s At(in the under-dashfuse/relay box)

VARIOUSSENSORFEESH AIF

BLK

I

FUEI- TANK

(cont'd)

11-203

INTAKE MANIFOLD

www.emanualpro.com

Page 425 of 1395

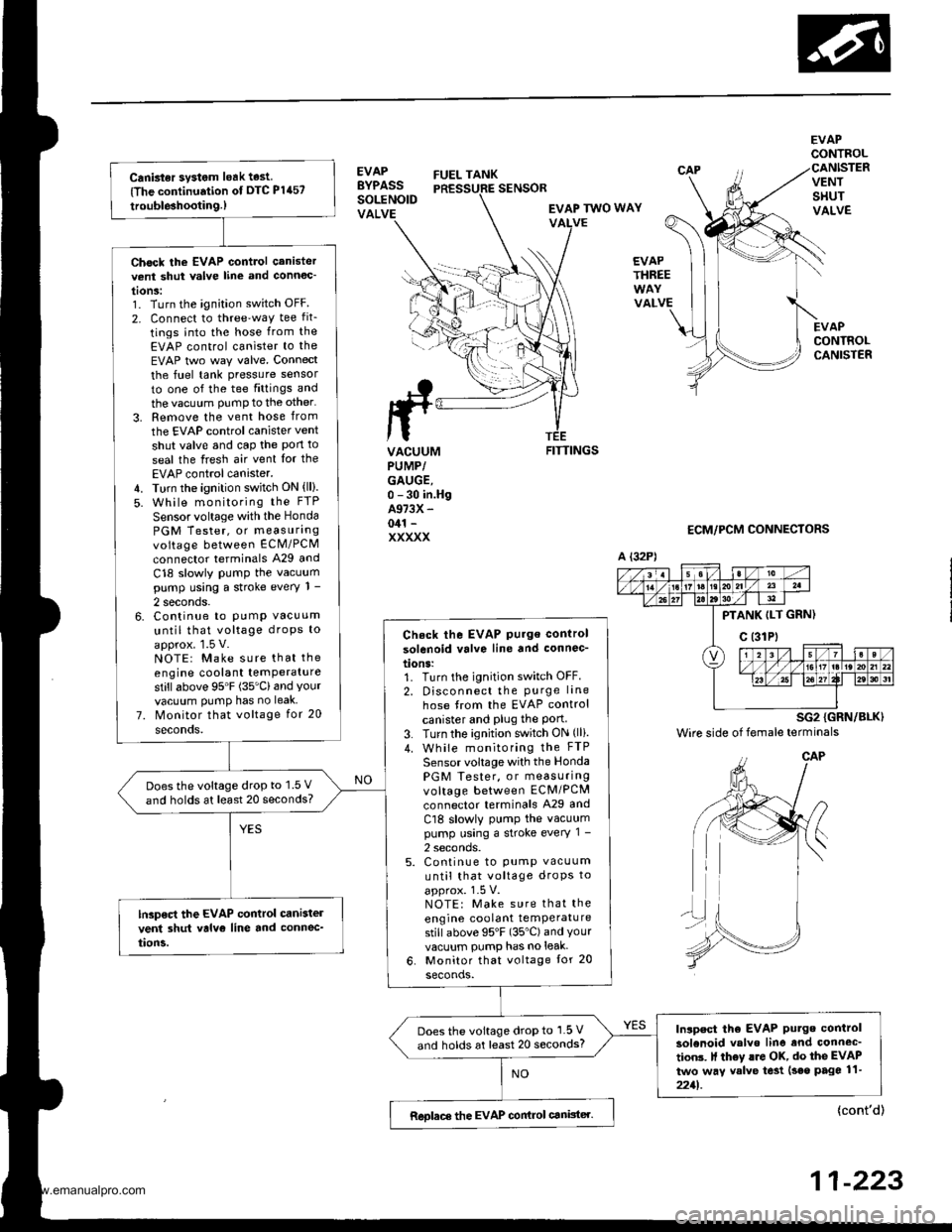

Canbter system leak test

{The continuation of DTC P1457

trouble3hootin9.)

Chock the EVAP control canistervent shut valve line and connoc'

tonS:1. Turn the ignition switch OFF

2. Connect to three'way tee fit_

tings into the hose from the

EVAP control canister to the

EVAP two way valve. Connect

the fuel tank pressure sensor

to one of the tee fittings and

the vacuum PumP to the other'

3. Remove the vent hose from

the EVAP control canister vent

shut valve and cap the Pon to

seal the fresh air vent Ior the

EVAP control canister.4. Turn the ignition switch ON (ll).

5. While monitoring the FTP

Sensor voltage with the Honda

PGM Tester, or measurangvoltage between ECM/PCM

connector terminals A29 and

C18 slowly PumP the vacuumpump using a stroke every 1 -

2 seconds.6. Continue to PumP vacuum

until that voltage droPs to

approx. 1.5 V.NOTE: Make sure that the

engine coolant temPeraturestillabove 95'F (35'Cland Yourvacuum PumP has no leak

7. Monitor that voltage for 20

seconds.

Check the EVAP Pu.ge control

solenoid valve line and connec-

tions:1. Turn the ignition switch OFF.

2. Disconnect the Purge lane

hose from the EVAP control

canister and Plug the Port3. Turn the ignition switch ON (lli.

4. While monitoring the FTP

Sensor voltage with the Honda

PGM Tester, or measuringvoltage between ECM/PCM

connector terminals A29 and

Cl8 slowly PumP the vacuumpump using a stroke every 1 -

2 seconds.5. Continue to pump vacuum

until that voltage droPs to

approx. 1-5 V.NOTE: Make sure that the

engine coolant temPeraturestill above 95'F (35"C) and Yourvacuum pump has no leak-

6. Monitor that voltage tor 20

seconds.

Doesthe voltage drop to 1.5 V

and holds at least 20 seconds?

lGp€ct the EVAP control cani3tel

vent 3hut valvo line and connec_

tion5.

Inlpect tho EVAP Putge control

solenoid valvo line and connec'

tion3. It th6y lro OK, do the EVAP

two way valve te3t (seo page 11-

2211.

Does the voltage drop to 1.5 V

and holds at least 20 seconds?

Reolace the EVAP conirol canister.

EVAPBYPASSSOLENOIDVALVE

FUEL TANK

EVAPCONTROL

VENTSHUTVALVE

EVAPCONTROLCANISTER

SENSOR

EVAP TWO WAYVALVE

EVAPTHREE

VALVE

ttrrL

ta

VACUUMPUMP/GAUGE,0 - 30 in.HgA973X -

041 -

XXXXX

FITTINGS

ECM/PCM CONNECTORS

A {32P)

PTANK ILT GRN)

c (31Pt

SG2 {GRN/BLK)

Wire side of female terminals

{cont'd)

11-223

www.emanualpro.com

Page 534 of 1395

Description

Electronic Control System (cont'dl

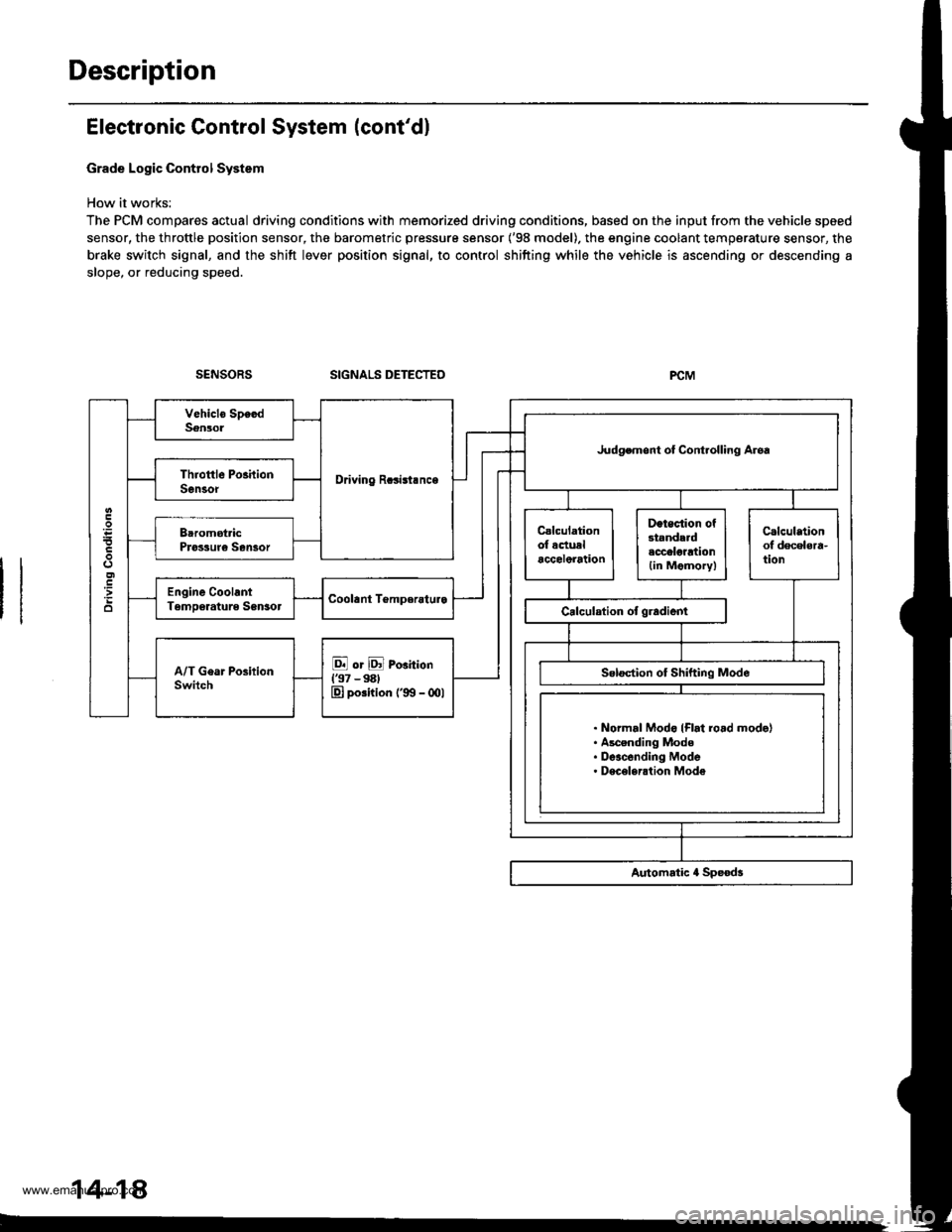

Grade Logic Control System

How it works:

The PCM compares actual driving conditions with memorized driving conditions, based on the input from the vehicle speed

sensor, the throttle position sensor, the barometric pressure sensor ('98 model). the engine coolant temperature sensor, the

brake switch signal, and the shift lever position signal, to control shifting while the vehicle is ascending or descending a

slope, or reducing speed.

SIGNALS DETECTED

Driving Rcsisl.nce

Judgemont ot Controlling Aroa

. Normal Modo {Flrt ro.d mode}. Ascending Mode. Deacending Mode. Deceleration Mode

14-14

www.emanualpro.com