idle speed HONDA CR-V 1999 RD1-RD3 / 1.G Owner's Guide

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 672 of 1395

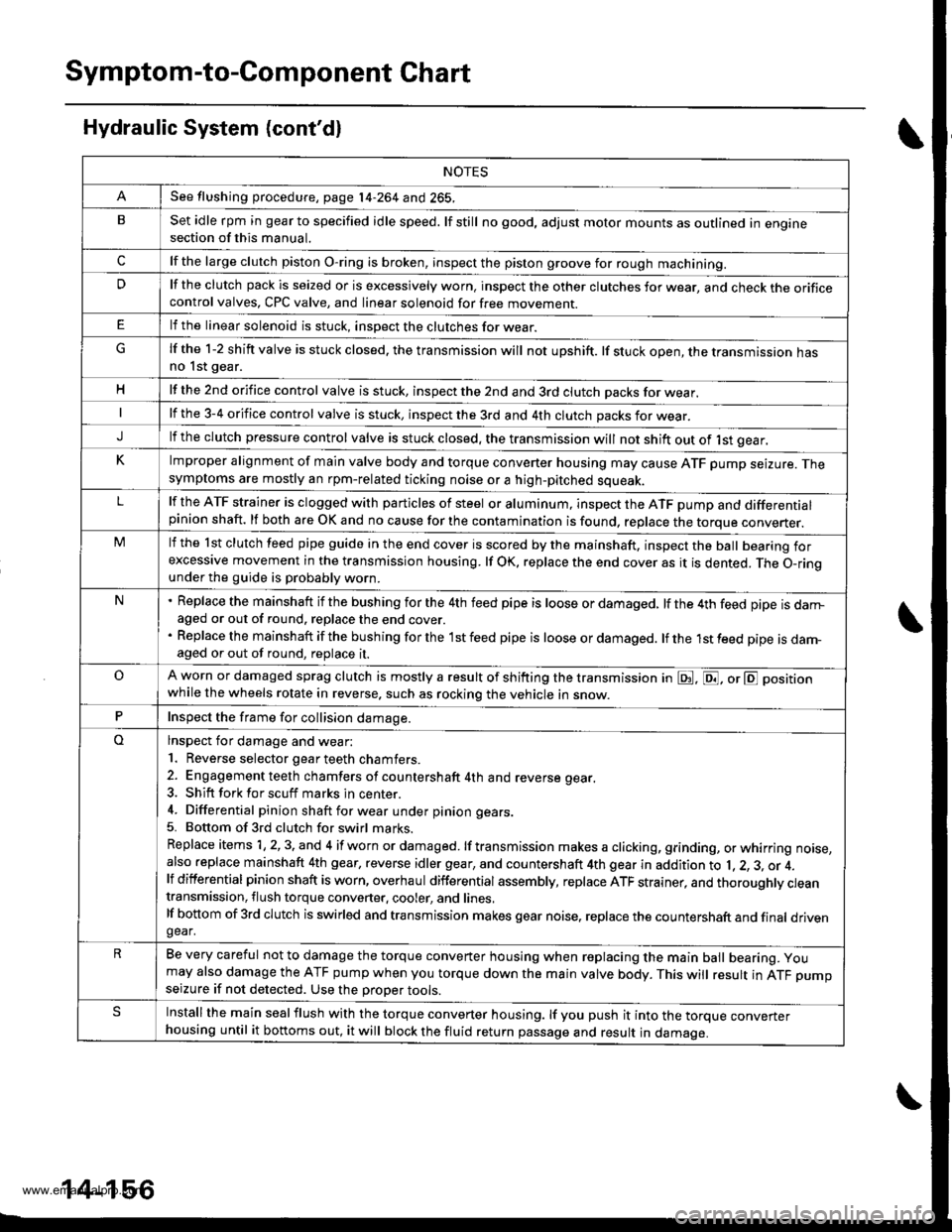

Symptom-to-Com ponent Chart

Hydraulic System (cont'd)

NOTES

See flushing procedure, page l4-264 and 265,

BSet idle rpm in gear to specified idle speed. lf still no good, adjust motor mounts as outlined in enginesection of this manual.

clf the large clutch piston O-ring is broken, inspect the piston groove for rough machining.

Dlf the clutch pack is seized or is excessively worn. inspect the other clutches fot wear, and check the orificecontrol valves, CPC valve, and linear solenoid for free movement.

lf the linear solenoid is stuck, inspect the clutches for wear.

lf the 1-2 shift valve is stuck closed. the transmission will not upshift. lf stuck open, the transmission hasno lst gear.

Hlf the 2nd orifice control valve is stuck, inspect the 2nd and 3rd clutch Dacks for wear.

lf the 3-4 orifice control valve is stuck, inspect the 3rd and 4th clutch packs for wear.

Jlf the clutch pressure control valve is stuck closed. the transmission will not shift out of lst gear.

Klmproper alignment of main valve body and torque converter housing may cause ATF pump seizure. Thesymptoms are mostly an rpm-related ticking noise or a high-pitched squeak.

Llf the ATF strainer is clogged with particles of steel or aluminum, inspect the ATF pump and differentialpinion shaft. lf both are OK and no cause for the contamination is found, replace the torque converter.

Mlf the lst clutch feed pipe guide in the end cover is scored by the mainshaft. inspect the ball bearing forexcessive movement in the transmission housing. lf oK, replace the end cover as it is dented. The o-rinounder the guide is probably worn.

N' Replace the mainshaft if the bushing for the 4th feed pipe is loose or damaged, lf the 4th feed pipe is darrFaged or out of round. replace the end cover.' Replace the mainshaft if the bushing for the l st feed pipe is loose or damaged. lf the 1st feed pipe is dam-aged or out of round, replace it.

oA worn or damaged sprag clutch is mostly a result of shifting the transmission in E!. E, or E positionwhile the wheels rotate in reverse. such as rocking the vehicle in snow.

PInspect the frame for collision damage.

lnspect for damage and wear:

l. Reverse selector gear teeth chamfers.

2. Engagement teeth chamfers of countershaft 4th and reverse gear.

3. Shift fork for scuff marks in center.

4. Differential pinion shaft for wear under pinion gears.

5. Bottom of 3rd clutch for swirl marks.

Replace items 1, 2, 3. and 4 if worn or damaged. lf transmission makes a clicking, grinding, or whirring noise,also replace mainshaft 4th gear, reverse idler gear, and countershaft 4th gear in addition to 1,2, 3, or 4.lf differential pinion shaft is worn, overhaul differential assembly, replace ATF strainer, and thoroughly cjeantransmission, flush torque converter. cooler, and lines,lf bottom of 3rd clutch is swirled and transmission makes gear noise. replace the countershaft and final drivenoear,

Be very careful not to damage the torque converter housing when replacing the main ball bearing. you

may also damage the ATF pump when you torque down the main valve body. This will result in ATF pumpseizure if not detected. Use the Drooer tools.

SInstall the main seal flush with the torque converter housing. lf you push it into the torque converterhousing until it bottoms out, it will block the fluid return passage and result in damage.

www.emanualpro.com

Page 693 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G Owners Guide

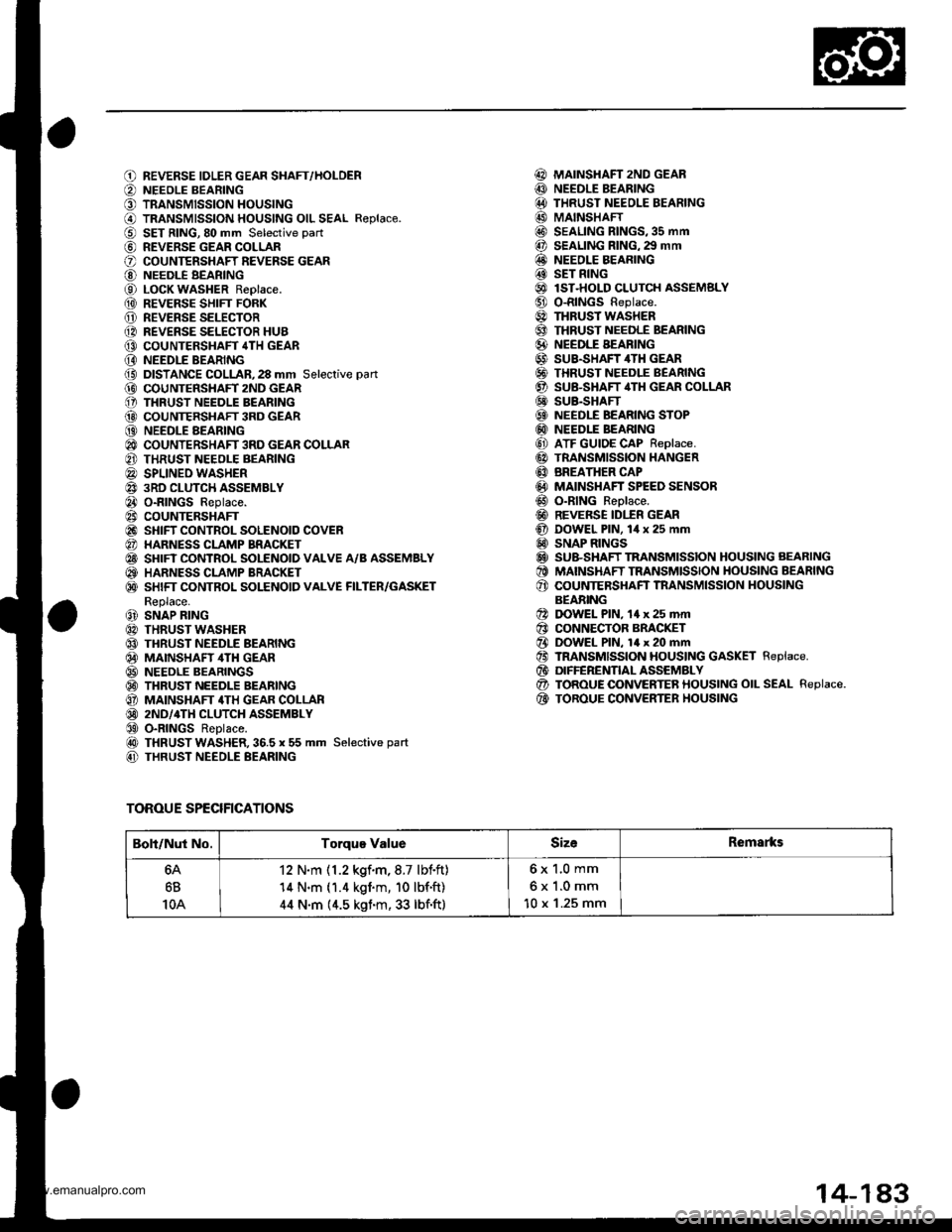

r] REVERSE IDLER GEAR SHAFT/HOLDERA N€EDLE BEARING

..] TRANSMISSION HOUSING

al TRANSMISSION HOUSING OIL SEAL Replace.g SET BING.80 mm Selecrive part

O REVERSE GEAR COLLABE couNTERSHAFT REVERSE GEA HONDA CR-V 1999 RD1-RD3 / 1.G Owners Guide

r] REVERSE IDLER GEAR SHAFT/HOLDERA N€EDLE BEARING

..] TRANSMISSION HOUSING

al TRANSMISSION HOUSING OIL SEAL Replace.g SET BING.80 mm Selecrive part

O REVERSE GEAR COLLABE couNTERSHAFT REVERSE GEA](/img/13/5778/w960_5778-692.png)

r] REVERSE IDLER GEAR SHAFT/HOLDER'A N€EDLE BEARING

..] TRANSMISSION HOUSING

al TRANSMISSION HOUSING OIL SEAL Replace.g SET BING.80 mm Selecrive part

O REVERSE GEAR COLLABE couNTERSHAFT REVERSE GEAB

.9,] NEEDLE BEARINGi9 LOCK WASHER Replace..1!i REVERSE SHIFT FORKO REVERSE SELECToRiJ. REVERSE SELECTOR HUBii' COUNTERSHAFT 4TH GEAR.14 NEEDLE BEARINGiD D|STANCE coLLAR,28 mm Selective part(i3 COUNTERSHAFT 2NO GEABi7-] THRUST NEEDLE BEARING(10 COUNTERSHAFT 3RD GEAR(9 NEEDLE BEARINGE9 COUNTERSHAFI3RD GEAB COLLAR.li THRUST NEEDLE BEARING.?) SPLINEO WASHER,,O 3RD CLUTCH ASSEMBLY

€1 O-RING Beplace.i23 COUNTERSHAFT

4i SHIFT CONTROL SOLENOID COVER

?Z] HARNESS CLAMP BRACKET

?9] SHIFT CONTROL SOLENOID VALVE A/B ASSEMBLY

8 HARNESS CLAMP BRACKET

GI SHIFT CONTROL SOLENOID VALVE FILTER/GASKET

(4 MAINSHAFT 2ND GEARi49 NEEDLE BEARING

@ THRUST NEEDLE BEARING(49 MAINSHAFT

@r SEAL|NG R|NG,35 mm

O SEALING RING,29 mm

@ NEEDLE BEARING

.49 SET RING

€) lST.HOLD CLUTCH ASSEMBLY

O o-RING Replace.6E THRUST WASHER

€9 THRUST NEEDLE BEARING

6' NEEDLE EEARING

€ir SUB-SHAFT 4TH GEAR

6 THRUST NEEDLE BEARING

@ SUB.SHAFT 4TH GEAR COLLAR@ sUB-sHAFf

6I NEEDI-E B€ARING STOP

@ NEEDLE BEARING(6t ATF GUIDE CAP Replace.(64 TRANSMISSION HANGEB

@ BREATHER CAP

i@ MAINSHAFT SPEED SENSOR

6i O-RING Replace.

6D REVERSE IDLER GEAR

@r DOWEL PlN, 14 x 25 mm.6d SNAP RINGS

QlI SUB.SHAFT TRANSMISSION HOUSING BEARING

E) MAINSHAFT TRANSMISSION HOUSING BEABING.2, COUNTERSHAFI TRANSMISSION HOUSINGBEARING

@[E

t,n9t0@)@),lD

04

@

@@:���������������.ro)

ai

Replace-SNAP RINGTHRUST WASHEBTHRUST NEEDLE BEARINGMAINSHAFT 4TH GEARNEEDLE BEARINGSTHRUST NEEDLE BEARINGMAINSHAFT 4TH GEAB COLLAR2NO/4TH CLUTCH ASSEMBLYO-RING Replace.THRUST WASHER,36.5 x 55 mm Selective partTHRUST NEEOLE BEARING

DOWEL PlN, 14 x 25 mmCONNECTOR BRACKETATF MAGNETDOWEL PlN, 14 x 20 mmTRANSMISSION HOUSING GASKET Replace.DIFFERENTIAL ASSEMBLYDOWEL PlN, 10 x 12 mmO-RING Replace.TRANSFER ASSEMBLYTOROUE CONVERTER HOUSING OIL SEAL Replace.TOROUE CONVERTER HOUSING

TOROUE SPECIFICATIONS

Bolt/Nut No.Torque ValueSizeRgmarks

6A

6B

10A

12 N.m (1.2 kgf.m,8.7 lbf.ft)

14 N.m (1.4 kgf.m, 10 lbift)

44 N.m (4.5 kgf.m,33 lbf.ft)

6x 1.0 mm

6x 1.0 mm

10 x 1.25 mm

14-177

www.emanualpro.com

Page 699 of 1395

oatl,6

@!.,

ao6l

@o@@@@@o@@@)@@@@@@@@@@)

@@@@)@@@@@@@

REVERSE IDLER GEAR SHAFT,/HOLDERNEEOLE BEARINGTRANSMISSION HOUSINGTRANSMISSION HOUSING OIL SEAL R€place.SET RING,80 mm Selective part

REVERSE GEAR COLLARCOUNTERSHAFT REVERSE GEARNEEDLE BEARINGLOCK WASHER Replace.REVERSE SHIFT FORKREVERSE SELECTORREVERSE SELECTOR HUBCOUNTERSHAFT 4TH GEARNEEDLE BEARINGDISTANCE COLLAR,28 mm Selective pan

COUNTERSIIAFT 2ND GEARTHRUST NEEDLE BEARINGCOUNTERSHAFT 3RD GEARNEEDLE AEARINGCOUNTERSHAFT 3RD GEAR COLLARTHRUST NEEOLE BEARINGSPLINEO WASHER3RD CLUTCH ASSEMBLYO-RINGS Replace.COUNTERSHAFTSHIFT CONTROL SOLENOID COVERHARNESS CLAMP BRACKETSHIFT CONTROL SOLENOID VALVE A/B ASSEMBLYHARNESS CLAMP BRACKETSHIFT CONTROL SOLENOID VALVE FILTER/GASKETReplace.SNAP RINGTHRUST WASHERTHRUST NEEDLE BEARINGMAINSHAF ,ITH GEARNEEDLE BEARINGSTHRUST NEEDLE BEARINGMAINSHAFT 4TH GEAR COLLAR2ND/4TH CLUTCH ASSEMBLYO-RINGS ReDlace.THRUST WASHER,36.5 x 55 mm Selective part

THRUST NEEDLE BEARING

MAINSHAFT 2ND GEARNEEDLE BEARINGTHRUST NEEOLE BEARINGMAINSHAFTSEALING RINGS,35 mmSEALING RING. 29 mmNEEDLE BEARINGSET RINGlST-HOLD CLUTCH ASSEMSLYO-RINGS Replace.THRUST WASHERTHRUST NEEDLE BEARINGNEEDLE BEARINGSUB.SHAFT 4TH GEARTHRUST NEEDLE BEARINGSU&SHAFT,ITH GEAR COLLARSUB.SHAFTNEEDLE BEARING STOPNEEDLE BEARINGATF GUIDE CAP Replace.TRANSMISSION HANGERBREATHER CAPMAINSHAFT SPEED SENSORO-RING Reolace.REVERSE IDI.fR GEARDOWEL PlN, lil x 25 mmSNAP RINGSSU&SHAFT TRANSMISSION HOUSING AEARINGMAINSHAFT TRANSMISSION HOUSING BEARINGCOUNTERSHAFT TNANSMISSION HOUSINGBEABINGDOWEL PlN, 14 x 25 mrnCONNECTOR BRACKETDOWEL PlN, 14 x 20 mmTRANSMISSION HOUSING GASKET Replace.DIFFERENTIAL ASSEMBLYTOROUE OONVERTER HOUSING OIL SEAL Replace.TOROUE CONVERTER HOUSING

@@@@@@@@@@@@@@@@@@@@@@@)@@@@@@@

@@@@@@@

TOROUE SPECIFICATIONS

Boli/Nut No.Torque ValueSizeRemarks

6B

10A

12 N.m (1.2 kgf.m,8.7 lbf.ft)'14 N.m (1.4 kgim, 10 lbf'ft)

44 N.m (4.5 kgim, 33 lbf.ft)

6x 1.0 mm

6x1.0mm

10 x '1.25 mm

14-1A3

www.emanualpro.com

Page 769 of 1395

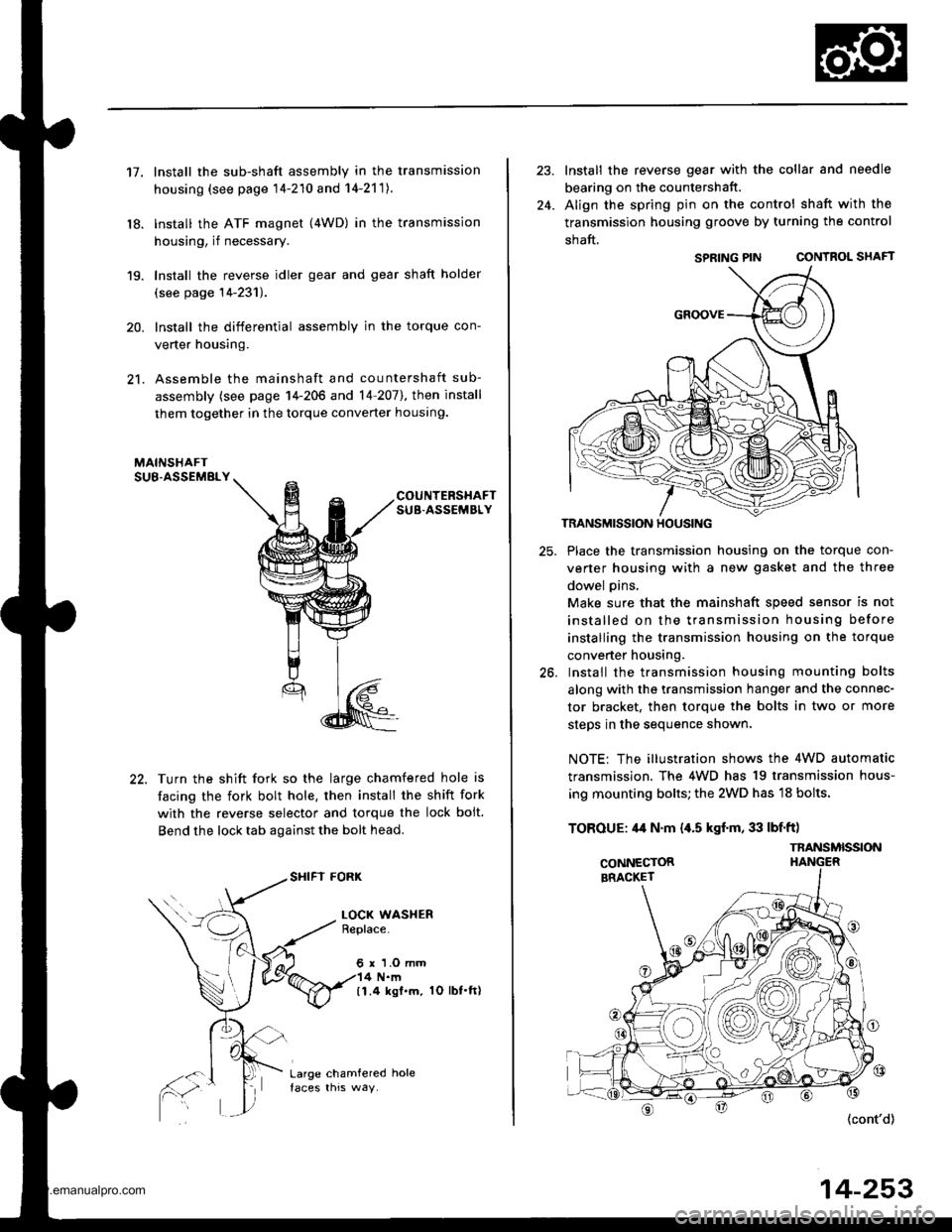

17.

18.

19.

20.

21.

Install the sub-shaft assembly in the transmission

housing (see page 14-210 and 14-2'111.

lnstall the ATF magnet (4WD) in the transmission

housing, if necessary.

Install the reverse idler gear and gear shaft holder

(see page 14-231).

Install the differential assembly in the torque con-

verter housing.

Assemble the mainshaft and countershaft sub-

assembly (see page 14-206 and 14 207],, then install

them together in the torque converter houslng.

COUNTERSHAFTSUB-ASSEMBLY

Turn the shift fork so the large chamfered hole is

facing the fork bolt hole. then install the shift fork

with the reverse selector and torque the lock bolt.

Bend the lock tab against the bolt head.

SHIFI FORK

LOCK WASHERBeplace.

6 r 'l.O mm4 N.m(1.4 ksl.m. 1O lbt.ft)

Large chamfered hole

24.

Install the reverse gear with the collar and needle

bearing on the countershatt.

Align the spring pin on the control shaft with the

transmission housing groove by turning the control

shaft.

SPRING PIN CONTROL SHAFT

TRANSMISSION HOUSING

25. Place the transmission housing on the torque con-

verter housing with a new gasket and the three

dowel pins,

Make sure that the mainshaft speed sensor is not

installed on the transmission housing before

installing the transmission housing on the torque

converter housing.

26. Install the transmission housing mounting bolts

along with the transmission hanger and the connec-

tor bracket, then torque the bolts in two or more

steos in the seouence shown.

NOTE: The illustration shows the 4WD automatic

transmission. The 4WD has 19 transmission hous-

ing mounting bolts; the 2WD has 18 bolts.

TOROUE: 44 N.m {,[.5 kgf.m, 33 lbf'ft)

{cont'd)

14-253

SPRING PIN

TNANSMISSION

www.emanualpro.com

Page 849 of 1395

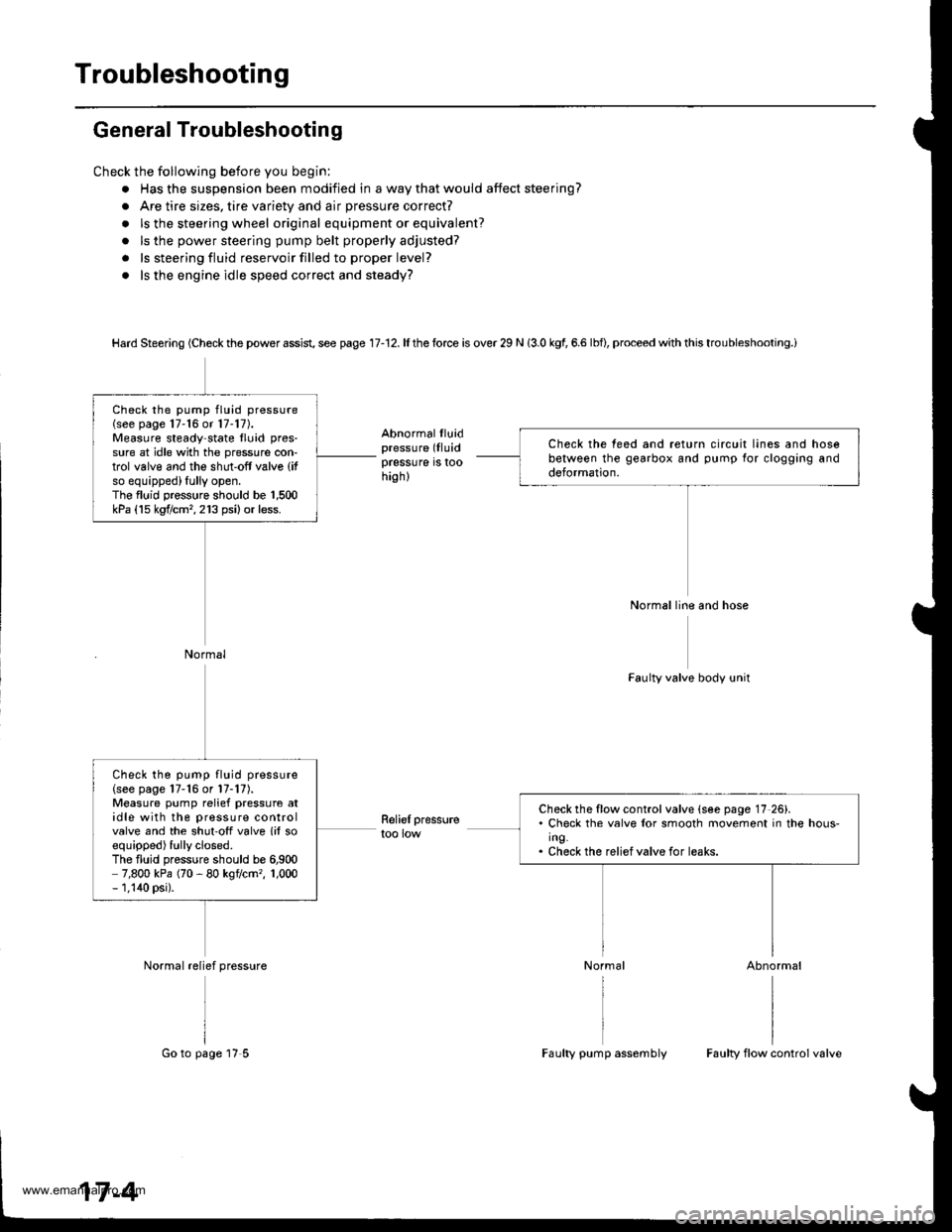

Troubleshooting

General Troubleshootin g

Check the following before you begin:

. Has the suspension been modified in a way that would affect steering?

. Are tire sizes, tire variety and air pressure correct?

. ls the steering wheel original equipment or equivalent?

. ls the power steering pump belt properly adjusted?

. ls steering fluid reservoir filled to proper level?

. ls the engine idle speed correct and steady?

Hard Steering (Check the power assist, see page 17-12. lf the force is over 29 N (3.0 kgl 6.6 lbfl, proceed with this troubleshooting.i

Abnormalthiidpressure (Iluidpressure is toohigh)

Relief pressuretoo low

Faulty valve body unit

Abnormal

Check the teed and return circuit lines and hosebetween the gearbox and pump for clogging anddeformation.

Normal line and hose

Check the pump fluid pressure(see page 17-16 or 17-17).Measure steady state lluid pres-

sure at idle with the pressure con-trol valve and the shut-off valve (it

so equipped) fully open.The fluid pressure should be 1,500kPa (15 kgf/cm,,213 psi)or less.

Normal

Check the flow control valve (see page 17 26).. Check the valv€ lor smooth movement in the hous-ing.. Check the relief valve for leaks.

Check the pump fluid pressure(see page 17-16 or l7-17).Measure pump relief pressure atidle with the pressure controlvalve and the shut'off valve lil soequipped) fully closed.The fluid pressure should be 6,9007,800 kPa (70 - 80 kgflcm,, 1,000- 1,140 psi).

Normal relief pressure

17-4

Go to page 17 5Faulty pump assemblyFaulty flow control valve

www.emanualpro.com

Page 852 of 1395

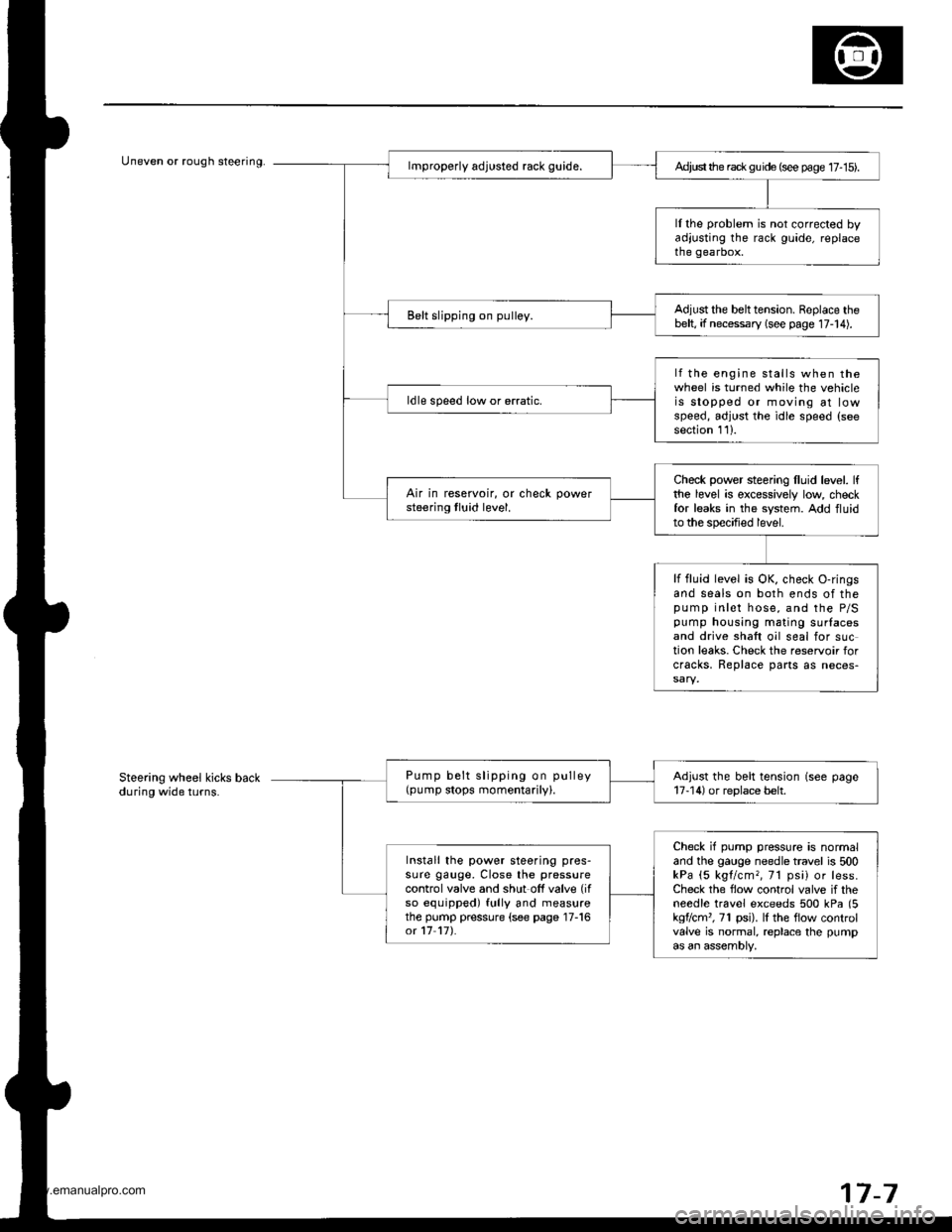

Uneven or rough steering.Ad,ust the rack gu ide (see page 17- 15).

ll the problem is not corrected byadjusting the rack guide, replacethe gearbox.

Adjust the belttension. Replace thebelt, if necessary (see page 17-14).Belt slipping on pulley.

lf the engine stalls when thewheel is turned while the vehicleis stopped or moving at lowspeed, adjust the idle speed (seesection 111.

ldle speed low or erratic.

Check power steering lluid level. lfthe level is excessively low checkfor leaks in the system. Add fluidto the specified level.

Air in reservoir, or check powersteering tluid level.

lf fluid level is OK, check O-ringsand seals on both ends of thepump inlet hose, and the P/Spump housing mating surlacesand drive shaft oil seal for suction leaks. Check the reservoir forcracks, Replace parts as neces-

Pump belt slipping on pulley(pump stops momentarily).Adjust the belt tension (see page17-14) or replace belt.

Check if pump pressure is normaland the gauge needle travel is 500kPa (5 kgl/cm,, 71 psi) or less.Check the flow control valve if theneedle travel exceeds 500 kPa (5kgflcm'�, 71 psi). lI the flow controlvalve is normal, replace the pumpas an assembly,

Install the power steering pres-sure gauge, Close the pressurecontrol valve and shut off valve (if

so equipped) fully and measurethe pump pressure (see page 17-16ot 17 17).

Steering wheel kicks backduring wide turns.

7-7

www.emanualpro.com

Page 1152 of 1395

Compressor

Replacement

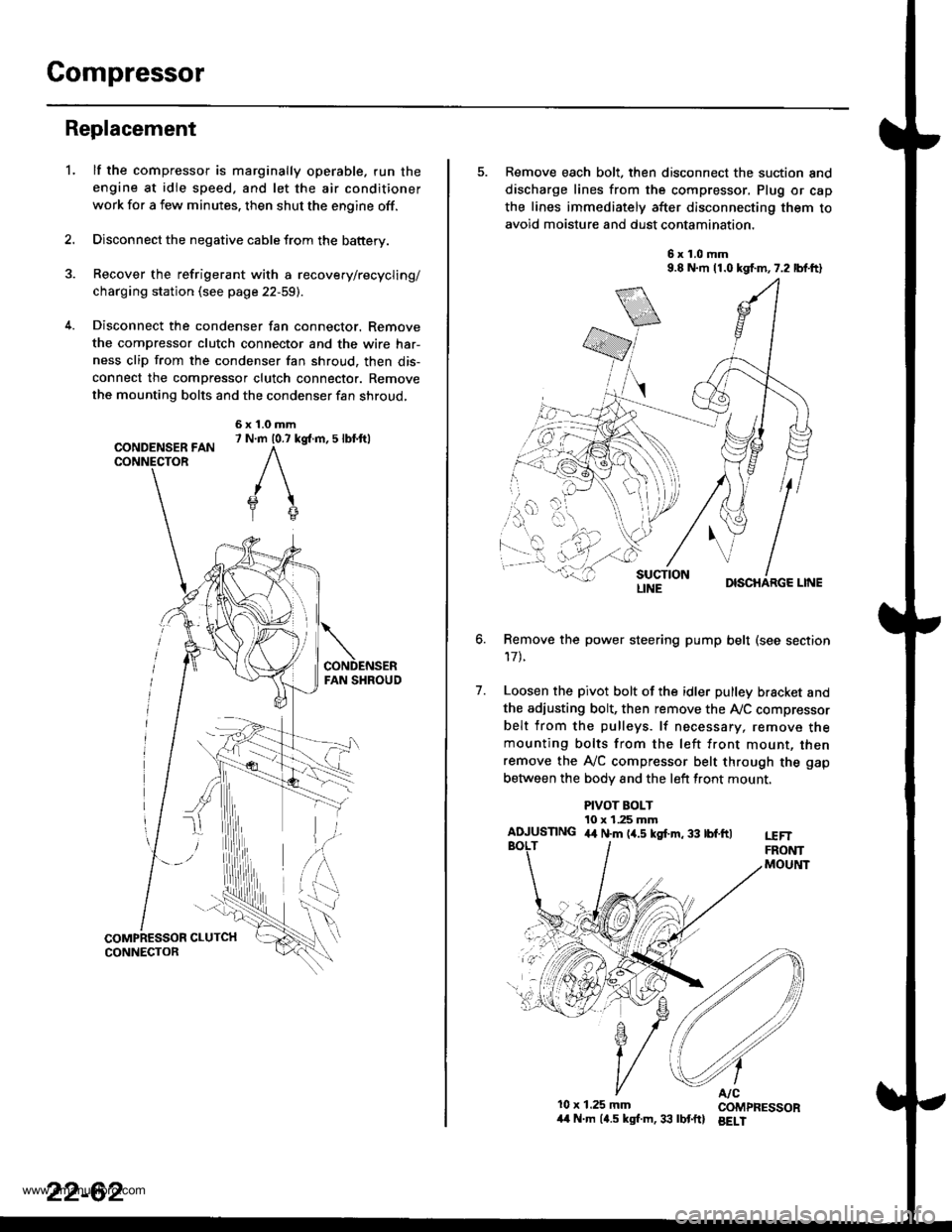

lf the compressor is marginally operable. run the

engine at idie speed, and let the air conditioner

work for a few minutes. then shut the engine off.

Disconnect the negative cable from the battery.

Recover the refrigerant with a recovery/recycling/

charging station (see page 22-59).

Disconnect the condenser fan connector. Remove

the compressor clutch connector and the wire har-

ness clip from the condenser fan shroud, then dis-

connect the compressor clutch connector. Remove

the mounting bolts and the condenser fan shroud,

CONDENSER FANCONNECTOR

6x1.0mm7 N.m 10.7 kg{.m, 5 lbl.ftl

'L

2.

5. Remove each bolt, then disconnect the suction and

discharge lines from the compressor. Plug or cap

the lines immediately after disconnecting them to

avoid moisture and dust contamination,

6x1.0mm9.8 N.m 11.0 kgf.m,7.2 lbf.ft)

DISCHARGE LINE

Remove the power steering pump belt (see section

17t.

Loosen the pivot bolt of the idler pulley bracket and

the adiusting bolt, then remove the Ay'C compressor

belt from the pulleys. lf necessary, remove themounting bolts from the left front mount, thenremove the A,/C compressor belt through the gap

between the bodv and the left front mount.

6.

7.

PIVOT BOLT10 x 1.25 mmAIUUSTING 4,t N.m (4.5 kgf.m, 33 tbf.ftlt€FTFRONTMOUltlT

10x 1.25 mm COMPRESSOR/t4 N.m (4.5 kgl.m,33 lbtftl BELI

LINE

www.emanualpro.com