Pin out HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 959 of 1395

Troubleshooting Precautions

ABS lndicalor

1 lf the system is oK, the ABS indicator goes off two seconds after turning the ignition switch oN 1l) wathout staningthe engine, and then comes on again and goes off after two seconds. This occurs because the ABS control unit isturned on by the lG2 power source.2. The ABS indicator comes on when the ABS control unit detects a problem in the system. However, even thouoh thesystem is operating properly, the ABs indicator will come on too, under the following conditions:. Signal disturbance

. Wheel spin

. Only drive wheels rotate. Battery voltage fluctuates

To determine the actual cause of the problem, question the customer about the problem, taking these conditions intoconsideration:

3 When a problem is detected and the ABS indicator comes on, the indicator can stay on until the ignition switch isturned OFF, or it can automatically go off, depending on the mode.. Indicator stays on untilthe ignition switch is turned off: When the system is in the system down mode.. Indicator automatically goes off: When the system is in the control inhibition mode.4 The ABS indicator stays on when the system is reactivated without erasing the DTC, but it goes off after starting thevehicle.

When the wheel sensor system is faulty and the ABS indicator comes on. the algorithm of the system automatically turnsoff the ABS indicator after the wheel speed signal returns to the normal speed. Also, when the DTc is erased, the cpu isreset and the ABS indicator goes off when the system checked out normal by the initial diagnosis.Therefore, test-drive the vehicle after servicing the wheel sensor system. and be sure that the ABS indicator does notcome on.

5 When the ABS control unit outputs battery voltage to the gauge assembly, the ABS indicator ooes off.

Diagnostic Trouble Code (DTCI

1. The diagnostic trouble code (DTc) is memorized when a problem is detected and the ABS indicator does not go off,or when the ABS indicator comes on.The DTc is not memorized when the ABS indicator comes on unress the cpu is activated,2 The memory can hold any number of DTCs. However, when the same DTc is detected twice or more, the tater one iswritten over the old one.

Therefore, when the same problem is detected repeatedly, it is recorded as one DTC.3. The DTCs are indicated in the order of ascending number, not in the order they occur.4. The DTCS are memorized in the EEPROM (non-volatile memorv).Therefore, the memorized DTcs cannot be canceled by disconnecting the battery. perform the specified procedures toerase the DTCS.

Self-diagnosis

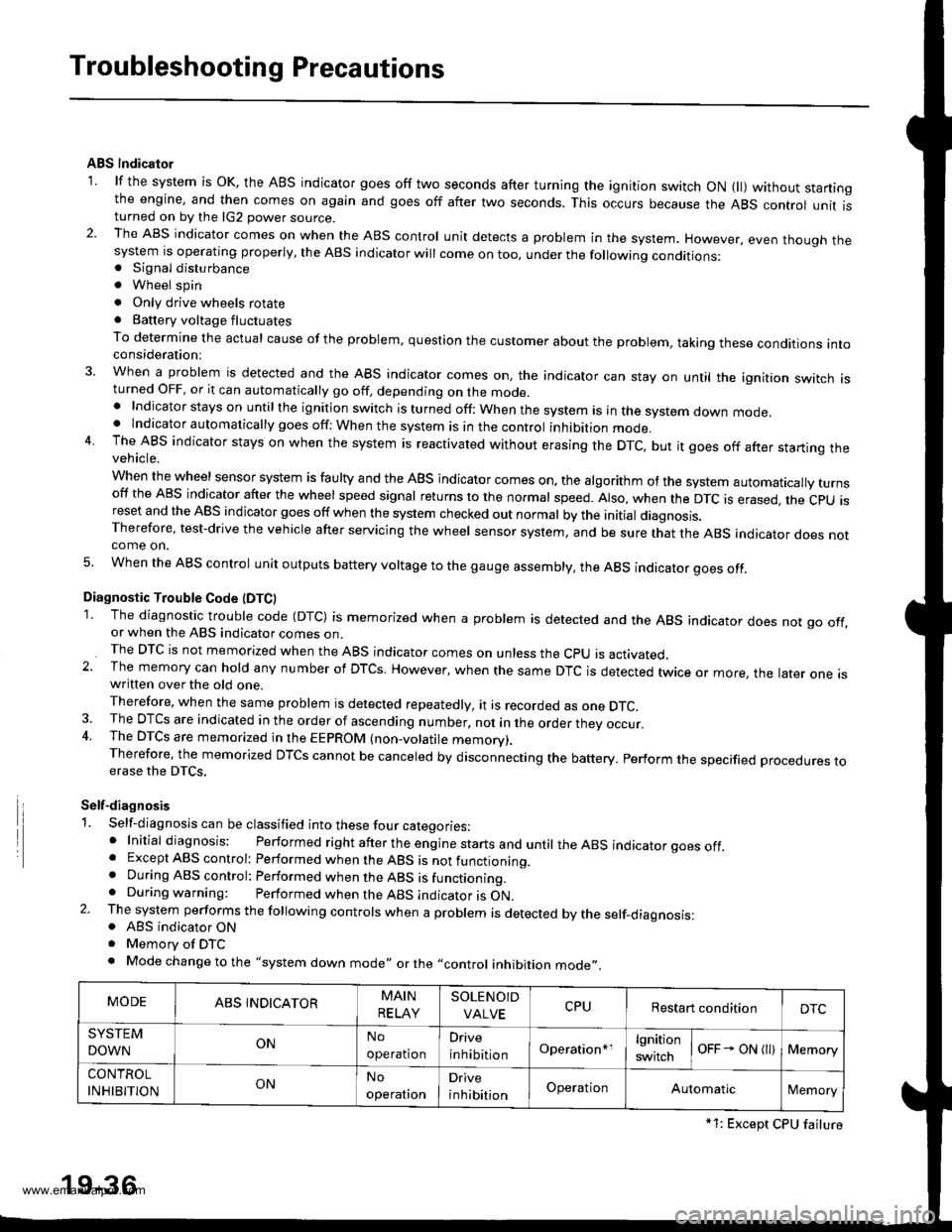

1. Self-diagnosis can be classified into these four categories:' Initial diagnosis: Performed right after the eng ine starts and untir theABS indicator goes off.. Except ABS control: Performed when the ABS is not functioning.. During ABS control: Performed when the ABS is functioning.. During warning: Performed when the ABS indicator is ON.2. The system performs the fo|owing contrors when a probrem is detected by the serf-diagnosis:. ABS indicator ON. Memorv of DTC. Mode changetothe "system down mode,, or the ,,control inhibition mode,,.

MODEABS INDICATORMAIN

RELAY

SOLENOID

VALVECPURestart conditionDTC

SYSTEM

DOWNONNo

operation

Drive

inhibitionOperation*rlgnition

switchoFF - ON l)Memory

CONTROL

INHIBITIONONNo

operal|on

Drive

inhibitionOperationAutomaticlMemory

*1: Except CPU failure

19-36

www.emanualpro.com

Page 1005 of 1395

Doors

(cont'd)

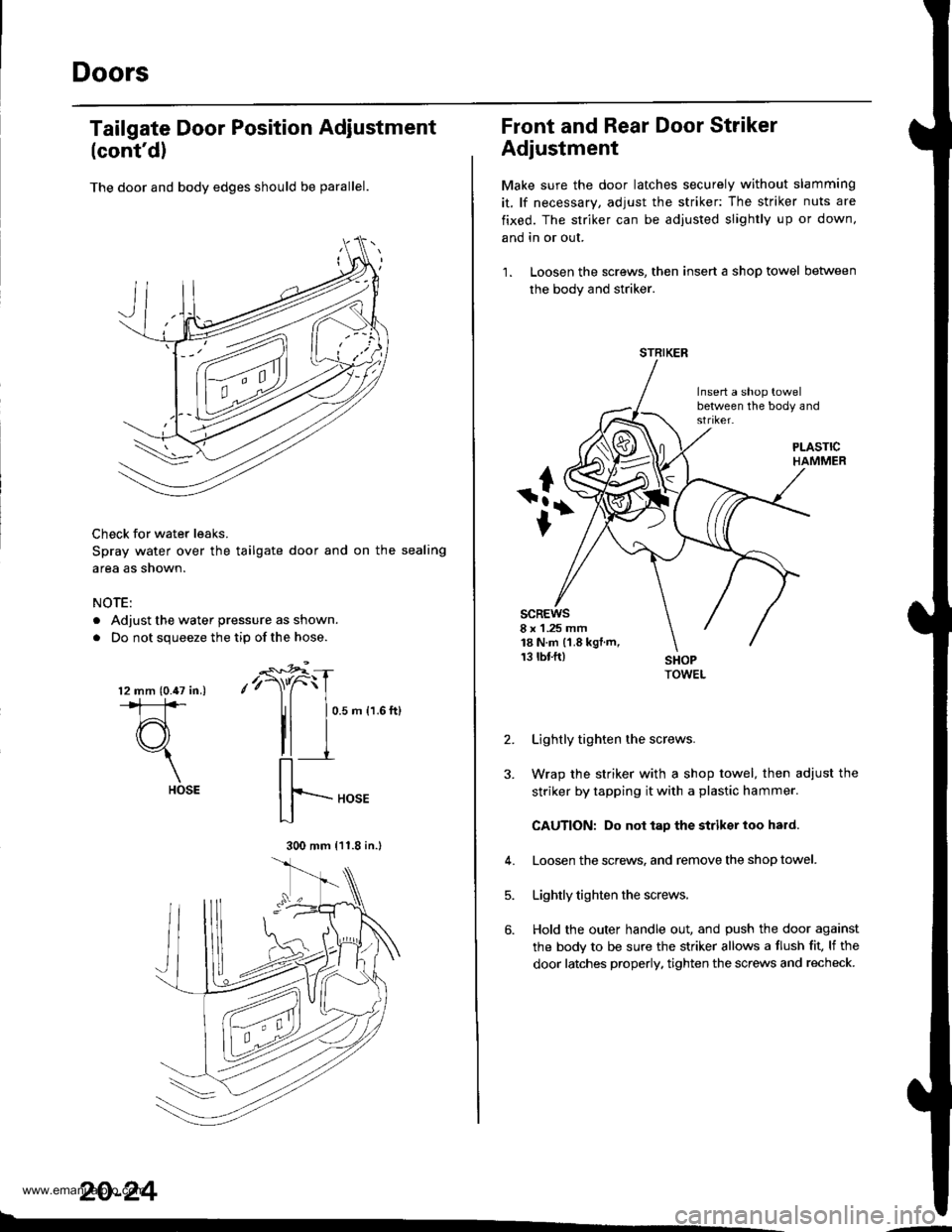

The door and body edges should be parallel.

Check for water leaks.

Spray water over the tailgate door and on the sealing

area as shown.

NOTE:

. Adjust the water pressure as shown.

. Do not squeeze the tip ofthe hose.

Tailgate Door Position Adiustment

-€*4

,'r)"C

II

0.5 m {1.6 ft}

20-24

l2 mm (0.47 in.).*1:]*

d3"1

HOSE

300 mm {11.8 in.l

Front and Rear Door Striker

Adjustment

Make sure the door latches securely without slamming

it, lf necessary, adjust the striker: The striker nuts are

fixed. The striker can be adjusted slightly up or down,

and in or out.

1. Loosen the screws, then insert a shop towel between

the body and striker.

Insert a shop towelbetween the body and

scREws8 x 1 .25 mm18 N.m (1.8 kgt.m,13 rbf.ft)

2.

J.

Lightly tighten the screws.

Wrap the striker with a shop towel, then adjust the

striker by tapping it with a plastic hammer.

CAUTION: Do not tap the striksr loo hard.

Loosen the screws. and remove the shop towel.

Lightly tighten the screws.

Hold the outer handle out, and push the door against

the body to be sure the striker allows a flush fit, lf the

door latches properly. tighten the screws and recheck.

4.

5.

6.

STRIKER

www.emanualpro.com

Page 1006 of 1395

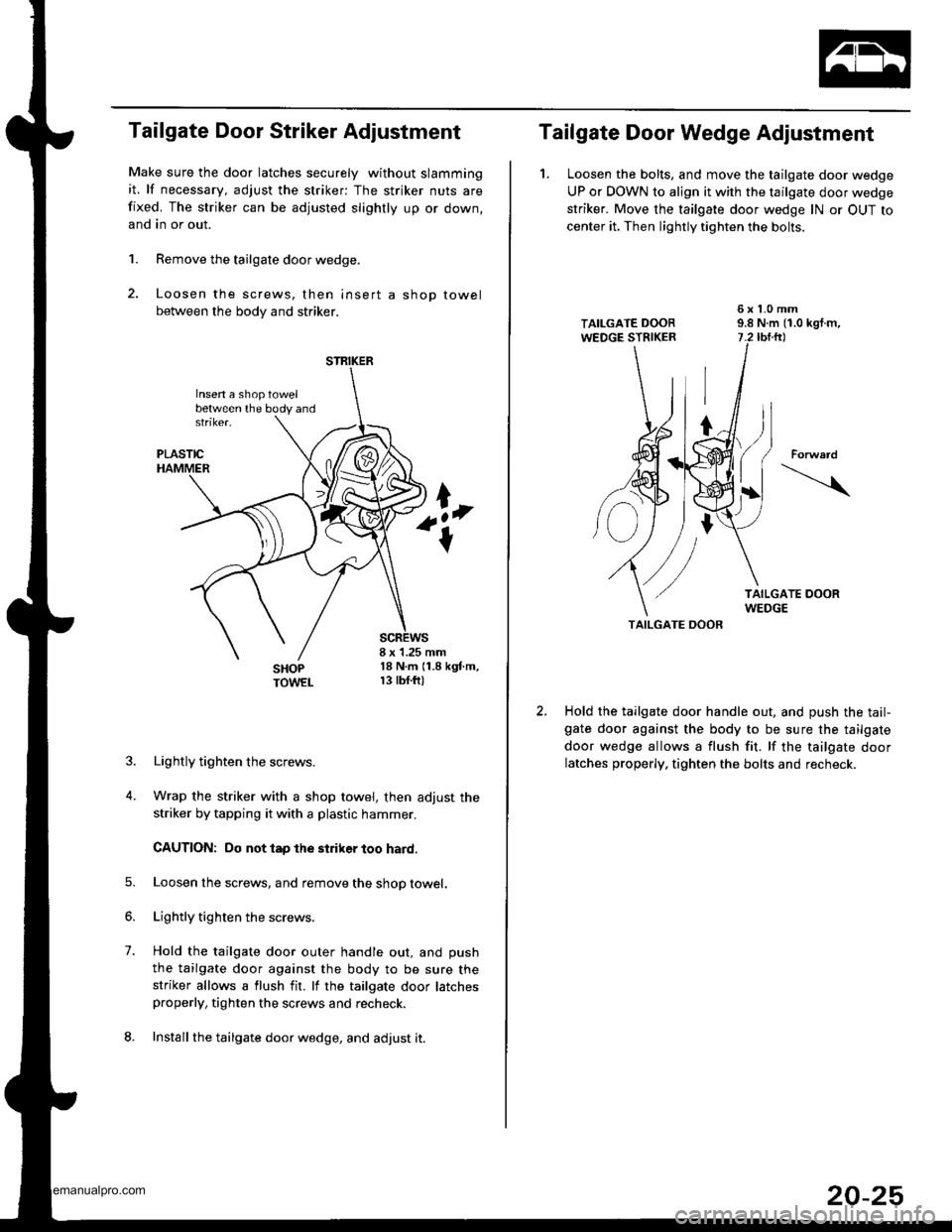

Tailgate Door Striker Adjustment

Make sure the door latches securely without slamming

it. lf necessary, adjust the striker: The striker nuts are

fixed. The striker can be adjusted slightly up or down,

and in or out.

1. Remove the tailgate door wedge.

2. Loosen the screws, then insert a shop towel

between the body and striker.

8 x 1.25 mm18 N.m (1.8 kgf.m,r 3 tbf.ft)

1.

4.

Lightly tighten the screws.

Wrap the striker with a shop towel, then adjust the

striker by tapping it with a plastic hammer.

CAUTION: Do not tap the striker too hard.

Loosen lhe screws, and remove the shop towel.

Lightly tighten the screws.

Hold the tailgate door outer handle out, and push

the tailgate door against the body to be sure thestriker allows a flush fit. lf the tailgate door latchesproperly, tighten the screws and recheck.

Install the tailgate door wedge, and adjust it.

STRIKER

Insen a shoptowelbetween the body and

Tailgate Door Wedge Adjustment

1. Loosen the bolts, and move the tailgate door wedge

UP or DOWN to align it with the tailgate door wedge

striker. Move the tailgate door wedge lN or OUT to

center it. Then lightly tighten the bolts.

TAILGATE OOOR

Hold the tailgate door handle out, and push the tail-gate door against the body to be sure the tailgate

door wedge allows a flush fit. lf the tailgate door

latches properly, tighten the bolts and recheck.

Forward

20-25

www.emanualpro.com

Page 1048 of 1395

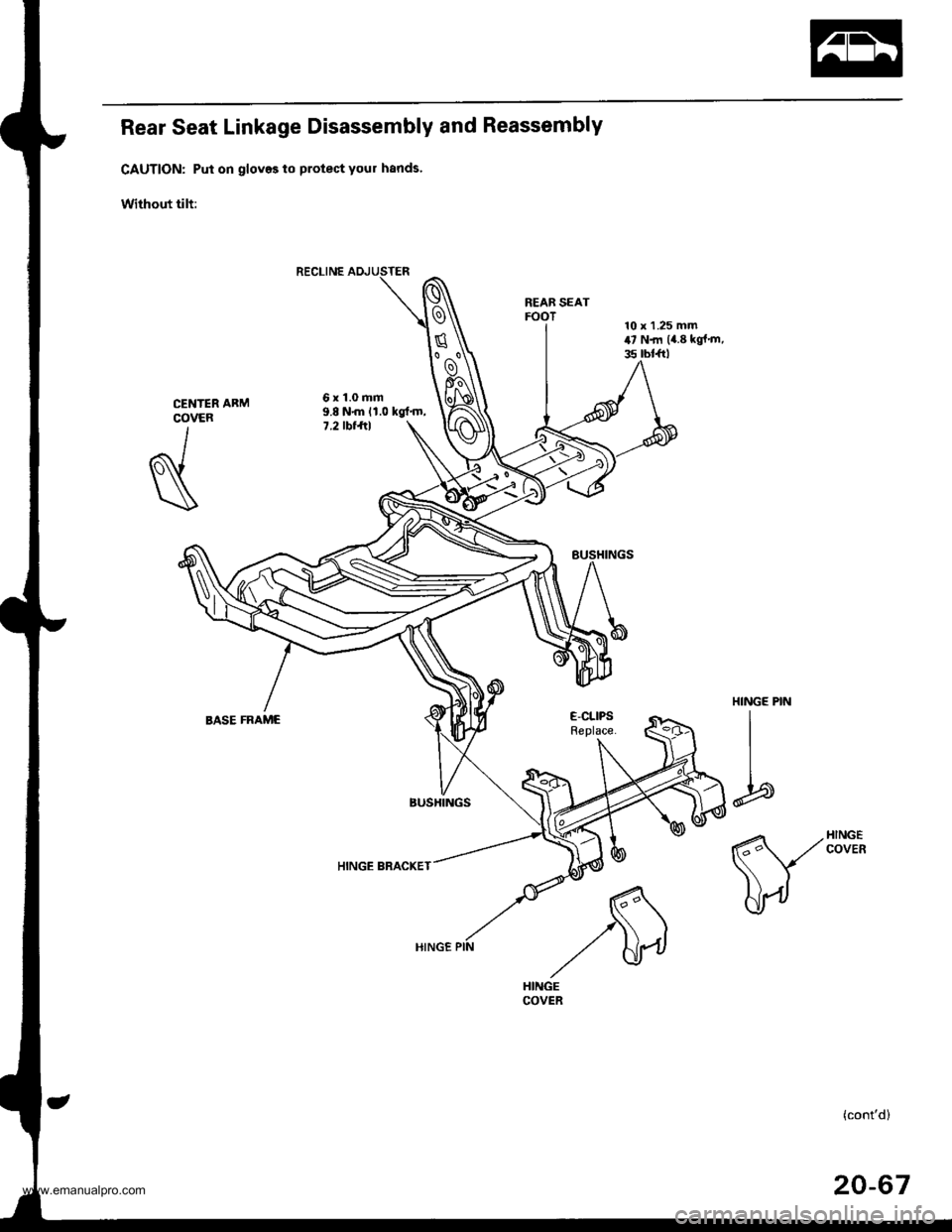

Rear Seat Linkage Disassembly and Reassembly

CAUTION: Put on gloves to protect your hands'

Without tilt:

REAB SEATFOOT

6x1.0mm9.8 N{n 11.0 kgt'm,7.2 tbt ftl

HINGE BRACKET

CENTERCOVER

I

N

HINGE PIN

I

I

b

E-CLIPSReplace.BASE FRAME

(cont'd)

20-67

www.emanualpro.com

Page 1081 of 1395

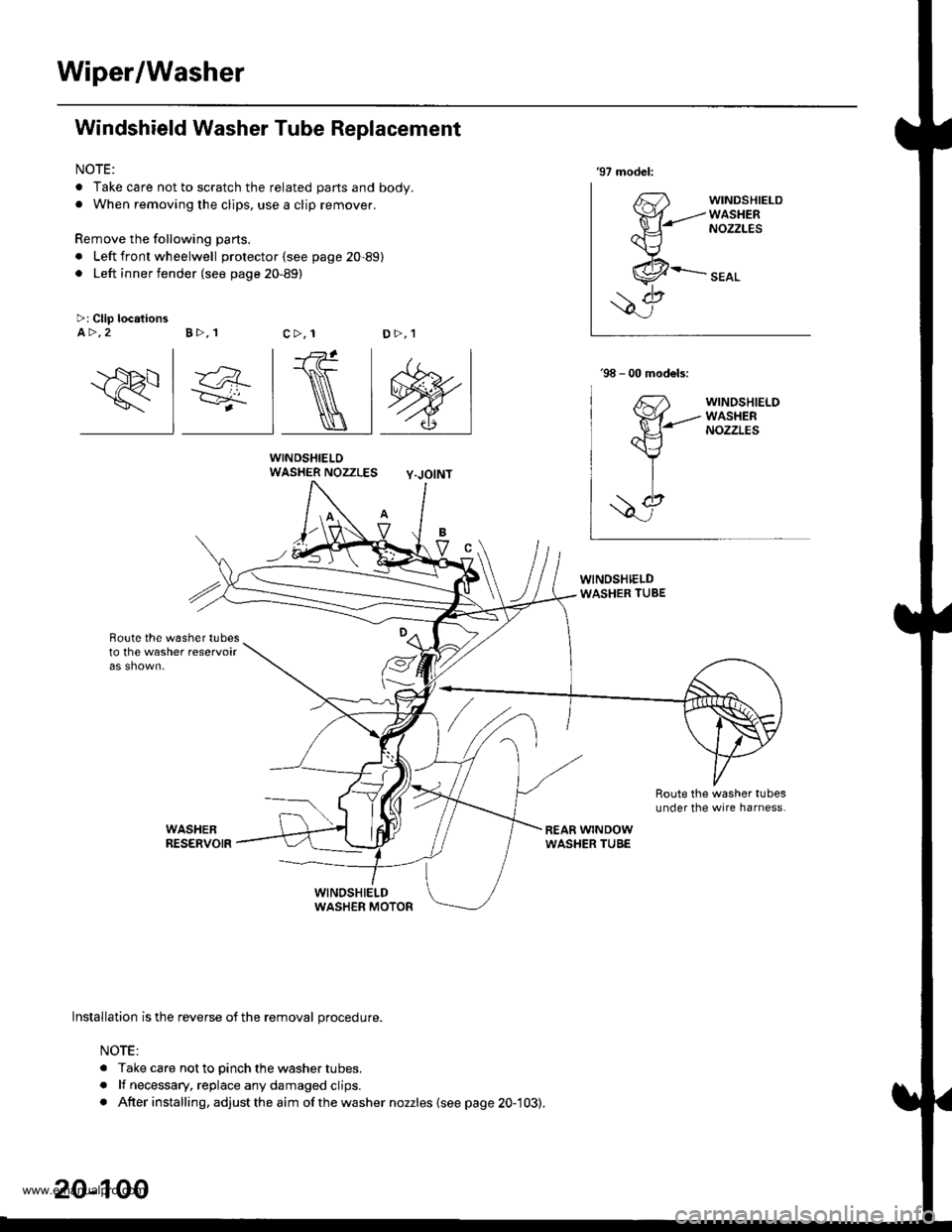

Wiper/Washer

Windshield Washer Tube Replacement

NOTE:

. Take care not to scratch the related parts and body.. When removing the clips, use a clip remover.

Remove the following parts.

. Left front wheelwell protector (see page 20-89). Left inner fender (see page 20-89)

WINDSHIELOWASHER NOZZLES Y-JOINT

Boute the w6sher tubesto the washer reservoir

'97 model:

63'fr{-------

ax---\J

,.&--

\7>: Clip locationsA >,2 B >,1c>, 1D>,1

\

lnstallation is the reverse of the removal procedure.

NOTE:

. Take care not to pinch the washer tubes.

. lf necessary, replace any damaged clips.. After installing, adjust the aim ofthe washer nozzles (see page 20-103).

20-100

www.emanualpro.com

Page 1083 of 1395

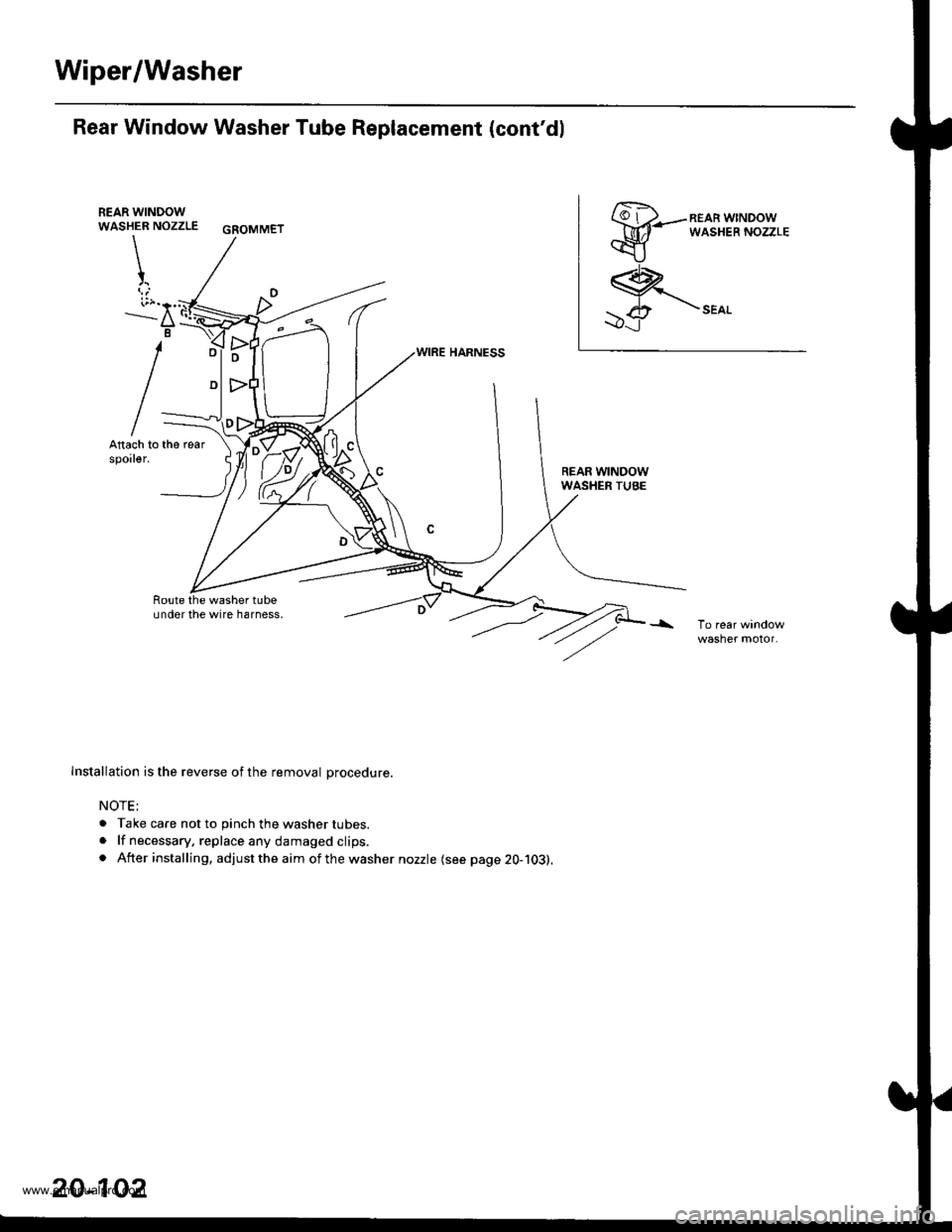

Wiper/Washer

Rear Window Washer Tube Replacement (cont'dl

REAR WINDOWWASHER NOZZLE GSOMMET

\

t

i;r."'..--a

B

REAR WINDOWWASHER TUBE

Route the washer tubeundor the wire harness,

Installation is the reverse of the removal Drocedure.

NOTE;

. Take care not to pinch the washer tubes.. lf necessary, replace any damaged clips.. After installing, adjust the aim of the washer nozzle (see page 20-103).

20-102

www.emanualpro.com

Page 1139 of 1395

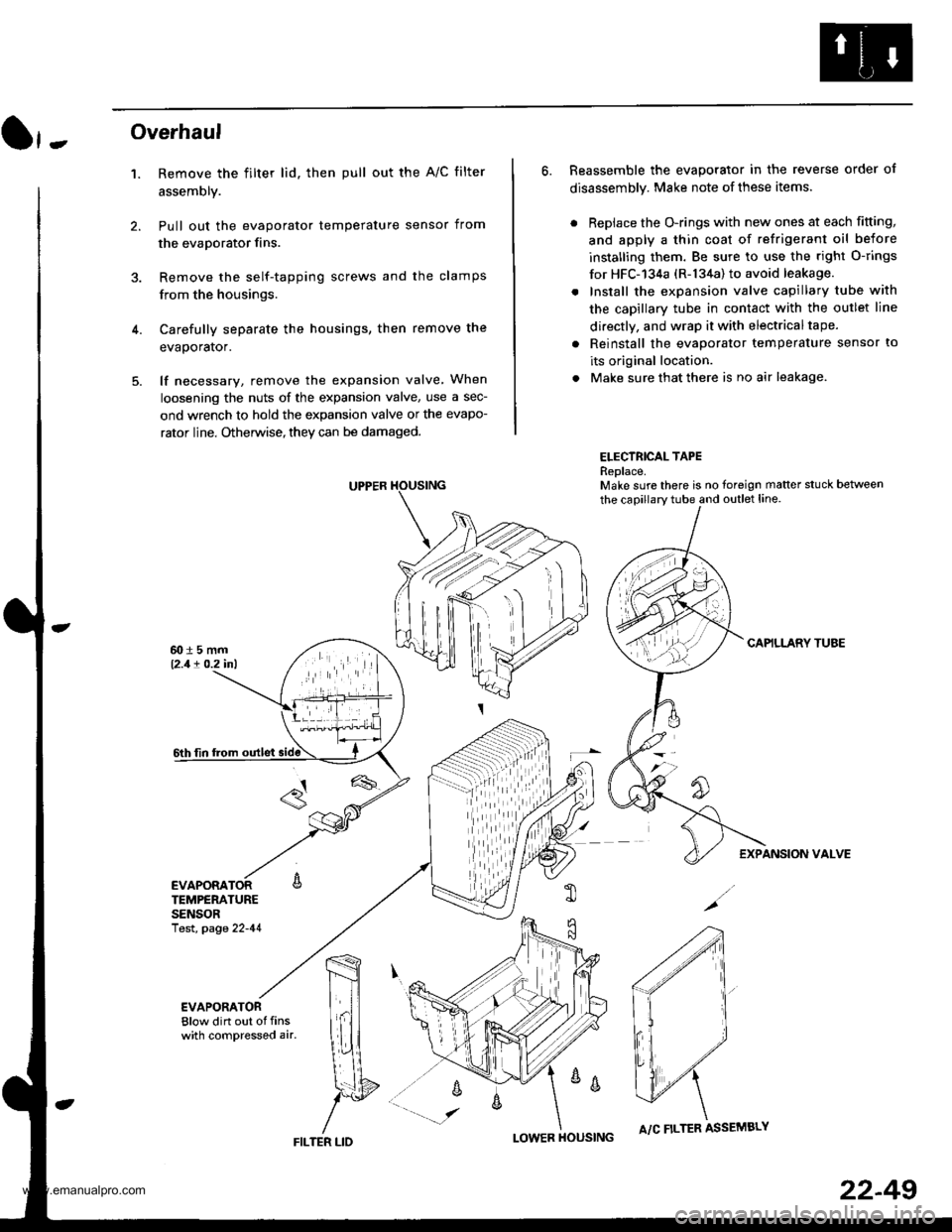

}-Overhaul

1. Remove the filter lid. then pull out the A/C filter

assembly.

Pull out the evaporator temperature sensor from

the evaporator fins.

Remove the self-tapping screws and the clamps

from the housings.

Carefully separate the housings, then remove the

evaporator.

lf necessary, remove the expansion valve When

loosening the nuts of the expansion valve, use a sec-

ond wrench to hold the expansion valve or the evapo-

rator line. Otherwise, they can be damaged.

6. Reassemble the evaporator in the reverse order of

disassembly. Make note of these items.

. Replace the O-rings with new ones at each fitting,

and apply a thin coat of refrigerant oil before

installing them. Be sure to use the right O-rings

for HFC-'134a (R-134a) to avoid leakage.

. Install the expansion valve capillary tube with

the capillary tube in contact with the outlet line

directly, and wrap it with electricaltape.

. Reinstall the evaporator temperature sensor to

its original location.

. Make sure that there is no air leakage.

ELECTRICAL TAPEReplace.Make sure there is no foreign matter stuck between

the capillary tube and outlet line.

CAPILLARY TUAE

EXPANSION VALVE

4.

TEMPERATURESENSORlest, page 22-41

,m

\!{

YFILTER LID

;

I-OWER HOUSINGA/C FILTER ASSEMBLY

22-49

www.emanualpro.com

Page 1142 of 1395

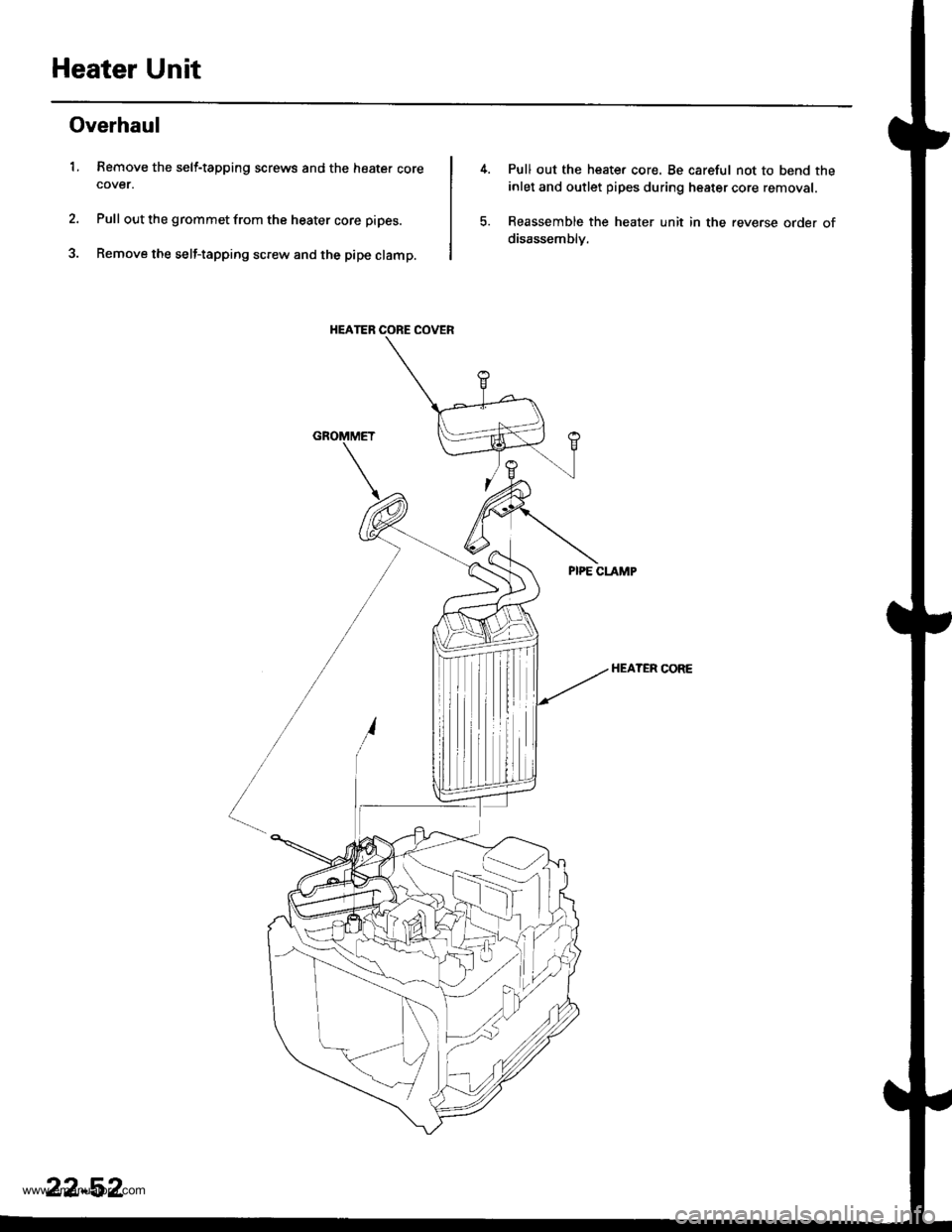

Heater Unit

Overhaul

1. Remove the self-tapping screws and the heater corecover.

Pull out the grommet from the heater core pipes.

Remove the self-tapping screw and the pipe clamp.

HEATER CORE COVER

Pull out the heate. core. Be careful not to bend the

inlet and outlet pipes during heater core removal.

Reassemble the heater unit in the reverse order of

disassemblv.

HEATER CORE

22-52

www.emanualpro.com

Page 1148 of 1395

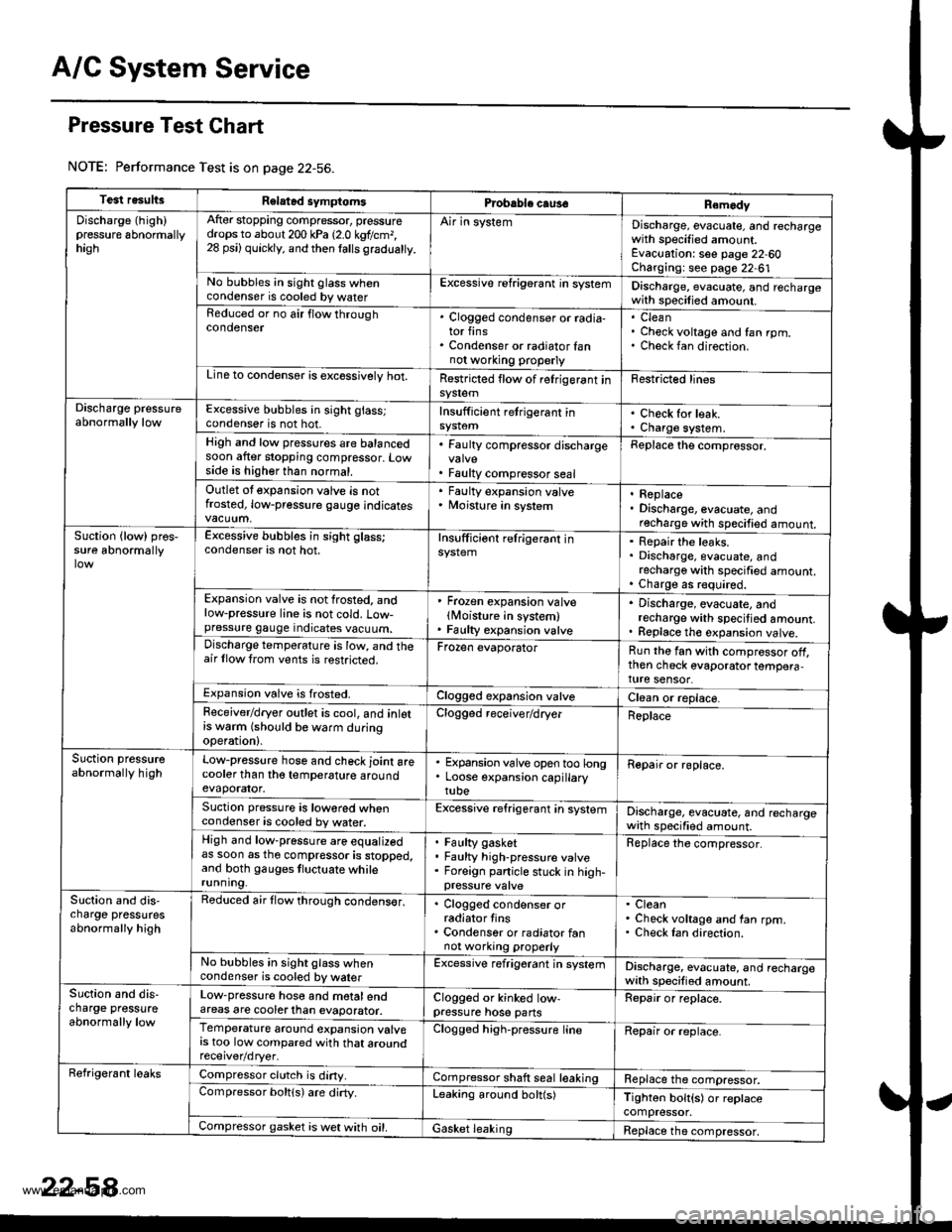

A/C System Service

Pressure Test Chart

NOTE: Performance Test is on page 22-56.

Test resultsRelatad symptomsPrcbable caus€Remody

Discharge (high)pressure 6bnormallyhagh

After stopping compressor, pressuredrops to about 200 kPa 12.0 kgtlcm,,28 psi) quickly, and then lalls gradualty.

Air in systemDischarge, evacuate, and rechargewith specified amount.Evacuation: see page 22-60Charging: see page 22-61No bubbles in sight glass whencondenser is cooled by waterExcessive refrigerant in systemDischarge, evacuate, and rechargewith specilied amount.Reduced or no air flow throughcondenser. Clogged condenser or radia-tor fins. Condenser or radiator fannot wo.king properly

CleanCheck voltage and fan rpm.Check fan direction.

Line to condensor is excossivelv hot.Restricted flow of relrigerant insy$emFestricted lines

Discharge pressureabnormally lowExcessive bubbles in sight glass;condenser is not hot.Insufficient retrigerant inCheck for leak.Charge system.High and low pressures are balancedsoon after stopping compressor. Lowside is higher than normal.

. Faulty compressor discharge

. Faulty compressor seal

Replace the comprossor.

Outlet ot expansion valve is notfrosted, low-pressure gauge indicates

' Faulty expansion valve. Moisture in system. Replace. Discharge, evacuate, andrecharge with specified amount.Suction {low) pros,sure abnormallyExcessive bubbles in sight glass;condenser is not hot.Insufficiont relrigerant inRepair the leaks.Discharge, evacuate, andrecharge with specified amount.Charge as r€quired.Expansion valve is not frosted, andlow-pressure line is not cold. Low-pressure gauge indicates vacuum.

' Frozen expansion valvelMoisture in system). Faulty expansion valve

. Discharge, evacuate, andrecharge with specitied amount.. Replace th€ expansion valve.Discharge temperature is low, and theair llow trom vents is restricted.Frozen evaporatorRun the fan with compressor off,then check evaporator tempera,ture sensor.Expansion valve is frosted.Clogged expansion valveClean or replace.Feceiver/dryer outlet is cool, and inlotrs w6rm (should be warm duringoperation).

Clogged receiver/dryerReplace

Suction pressureabnormally highLow-pressure hose and check joint arecooler than tho temperature aroundevaporator.

. Expansion valve open too long. Loose expansion capillarytube

Repair or roplace.

Suction pressure is lowored whencondenser is cooled by water.Excessive refrigerant in systemDischarge, evacuate, and rechargewath specified amount.High and low-pressure are equalizedas soon as tho compressor is stopped,and both gauges tluctuate whilerunning.

Faulty gasketFaulty high-pressure valveForeign panicle stuck in high-

Replace the compressor.

Slction and dis,charge pressutesabnormally high

Reduced air flow through condens€r,. Clogged condenser orradiator tins. Condenser or radiator fannot working properly

CleanCheck voltage and fan rpm.Check Ian direction.

No bubbles in sight glass whencondenser is cooled by walerExcessive refrigerant jn systemDischarge, evacuate, and rechargewith specified amount.Suction and dis-charge pressureabnormally low

Low-pressure hose and motalendareas are cooterlhan evaporator.Clogged or kinked low-pressure hose pansRepair or replace.

Temperature around expansion valvers too low compared with that aroundClogged high-pressure lineRepair or replace.

Refrigerant leaksCompressor clutch is diny.Compressor shaft seal leakingReplace the compressor.Compressor boltls) are dirty.Leaking around bolt(s)Tighton bolt{s) or replacecompressor.Compressor gasket is wet with oil.Gasket leakingReplace the compressor,

www.emanualpro.com

Page 1196 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

Connector ldentification and Wire Harness Routing

Hoat6r Sub-harness

Connector or

Tgrminal

Numbsr ot

CavitiesLocalionConnects toNotes

c73�]

c731

c732

c733

c734

c735

c736

c737

c738

c739

c7 40

c7 40

5 HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

Connector ldentification and Wire Harness Routing

Hoat6r Sub-harness

Connector or

Tgrminal

Numbsr ot

CavitiesLocalionConnects toNotes

c73�]

c731

c732

c733

c734

c735

c736

c737

c738

c739

c7 40

c7 40

5](/img/13/5778/w960_5778-1195.png)

Connector ldentification and Wire Harness Routing

Hoat6r Sub-harness

Connector or

Tgrminal

Numbsr ot

CavitiesLocalionConnects toNotes

c73'�]

c731

c732

c733

c734

c735

c736

c737

c738

c739

c7 40

c7 40

5

7

7

24

1

Under middle of dash

Under middle of dash

Behind middle of dash

Behind middle of dash

Behind glove box

Behind glove box

Behind glove box

Behind glove box

Behind glove box

Behind glove box

Behind middle of dash

Behind middle of dash

Main wire harness {C436)

Main wire harness (C436)

Mode control motor

Dashboard wire harness (C522)

Air mix control motor

Evaporator temperature sensor

Blower motor high relay

Blower motor

Power transistor

Recirculation control motor

Dashboard wire harness (C523)

Dashboard wire harness (C523)

'97 model'98 - 00

modsls

'97 model'98 - 00

mooels

Combination Switch Sub-harness

Conneqtor ol

Terminal

Number of

CavitiesLocationConnests toNotos

c751

c753

c754

c755

c756

c757

c758

c760

c760

6

7

12

10

2

7

6

8

5

Above under-dash fuse/relay box

Above under-dash fuse/relay box

Under left side of dash

Under left side of dash

Behind steering column

Behind steering column

Behind steering column

Behind steering column

Behind steering column

Behind steering column

Under left side of dash

Under left side of dash

Under-dash fuse/relay box (C914)

Under-dash fuse/relay box {C915)

Main wire harness (C413)

Main wire harness (C413)

Shift lock solenoid

Parking pin switch

Combination light switch

Combination light switch

Wiper/washer switch

Wiper/washer switch

Main wire harness (C442)

Main wire harness (C442)

'97 - 98

mod6ls'99 - 00

models

'97 - 98

models'99 - 00

models

23-36

,

www.emanualpro.com