cable HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 919 of 1395

Raise the rear of the vehicle, and make sure it is

securely supponed.

Remove the rear wheel.

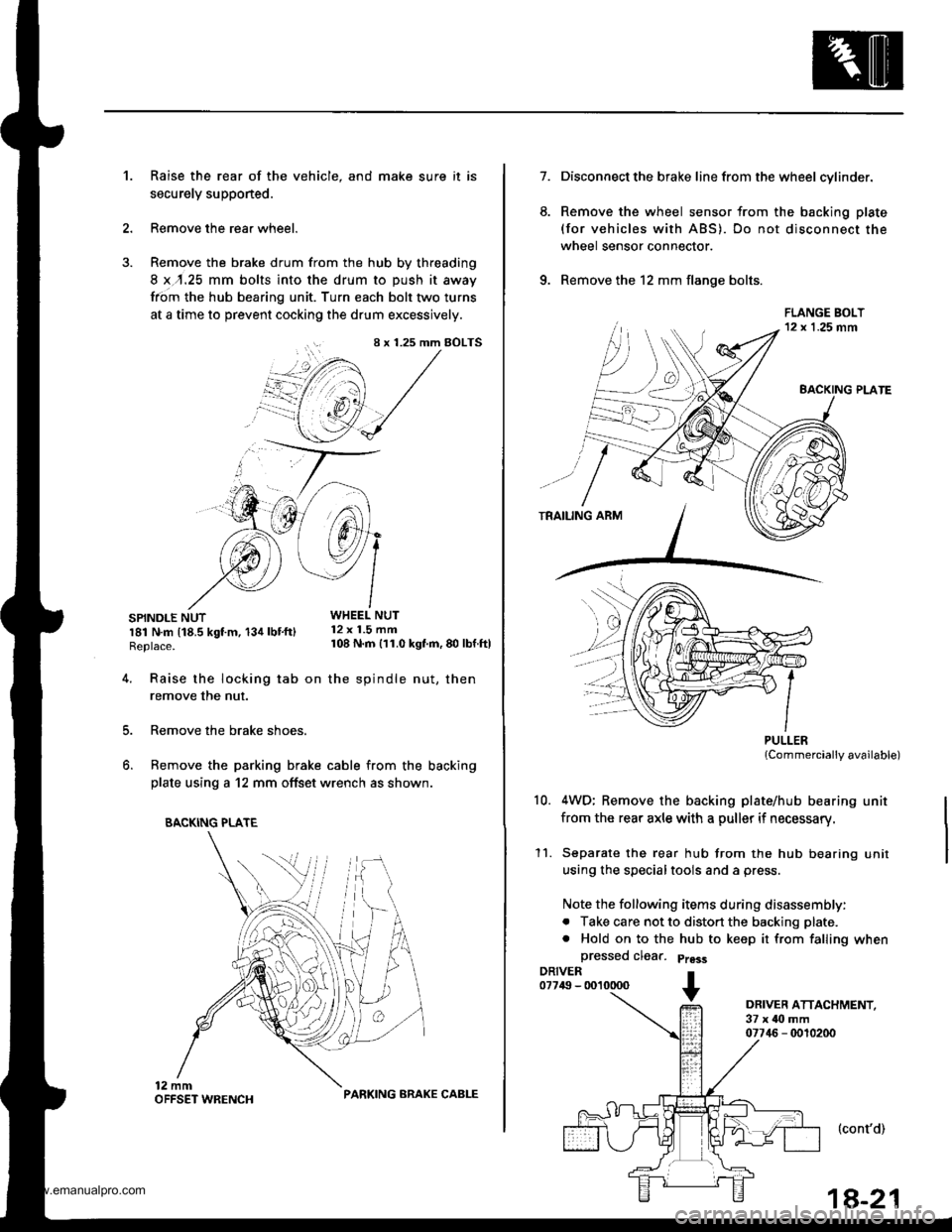

Remove the brake drum from the hub by threading

8 x,r.25 mm bolts into the drum to push it away

from the hub bearing unit. Turn each bolt two turns

at a time to prevent cocking the drum excessively.

SPINDLE NUTWHEEL NUT

r81 N.m t18.5 kgt m, 134 lbt'ftl 12 x 1.5 mm

Replace. 108 N m 111.0 kgf'm, 80 lbf ftl

't.

4.

8 x 1.25 mm BOLTS

i+/3 /',1

"@,1 /

.'--7 J-->-

5.

6.

Raise the locking tab on the spindle nut, then

remove the nut.

Remove the brake shoes.

Remove the parking brake cable from the backing

plate using a 12 mm offset wrench as shown.

BACKING PLATE

PARKING ARAKE CABLE

1a-21

7.

6.

Disconnect the brake line from the wheel cylinder.

Remove the wheel sensor from the backing plate

(for vehicles with ABS). Do not disconnect the

wheel sensor connector.

Remove the 12 mm flange bolts.

PULLERlCommercially available)

4WD; Remove the backing plate/hub bearing unit

from the rear axle with a puller if necessary.

Separate the rear hub from the hub bearing unit

using the specialtools and a press.

Note the following items during disassembly:

. Take care not to distort the backing plate.

. Hold on to the hub to keep it from falling when

a

10.

11.

DRIVER ATTACHMENT,37 x ilo mm07746 - 0010200

(cont'd)

www.emanualpro.com

Page 925 of 1395

Brakes

Special Tools ............. 19-2

Component Locations

lndex ................ ...... 19-3

Inspection and Adlustment

Brake System Rubber Parts

and Brake Booster ..........,,,.......... 19-4

Brake Pedal ............ 19-5

Parking Brake ........ 19-6

Bleeding ................. 19'7

Brake System Indicator ................... 19-8

Front Brake Pads

Inspection and Replacement .......... 19-9

Front Brake Disc

Disc Runout Inspection ................... 19-11

Disc Thickness and

Parallelism Inspection ........,........ 19-1 1

Front Brake Caliper

Disassembly/Reassembly ............... 19-12

Master Cylinder/Brake Booster

Removal/lnstallation ....................... 19-13

Master Cylinder

Inspection/Disassembly .............. 19-14

Pushrod Clearance Adiustment ...... 19-14

Brake Booster Inspection ...,.,,,,....... 1 9-1 5

Rear Drum Brakes

Inspection .............. 19-15

Brake Shoes

Replacement ..... 19-r 8

Wheel Cylinder Replacement ......... 19-20

Brake Hoses/Lines

Inspection/Torque Specifications ... 19-21

Hose Replacement ....,...,............. ..,,, 19-22

Parking Brake Cable

Inspection and Replacement .......... 19-23

www.emanualpro.com

Page 942 of 1395

Rear Drum Brakes

Brake Shoes Replacement

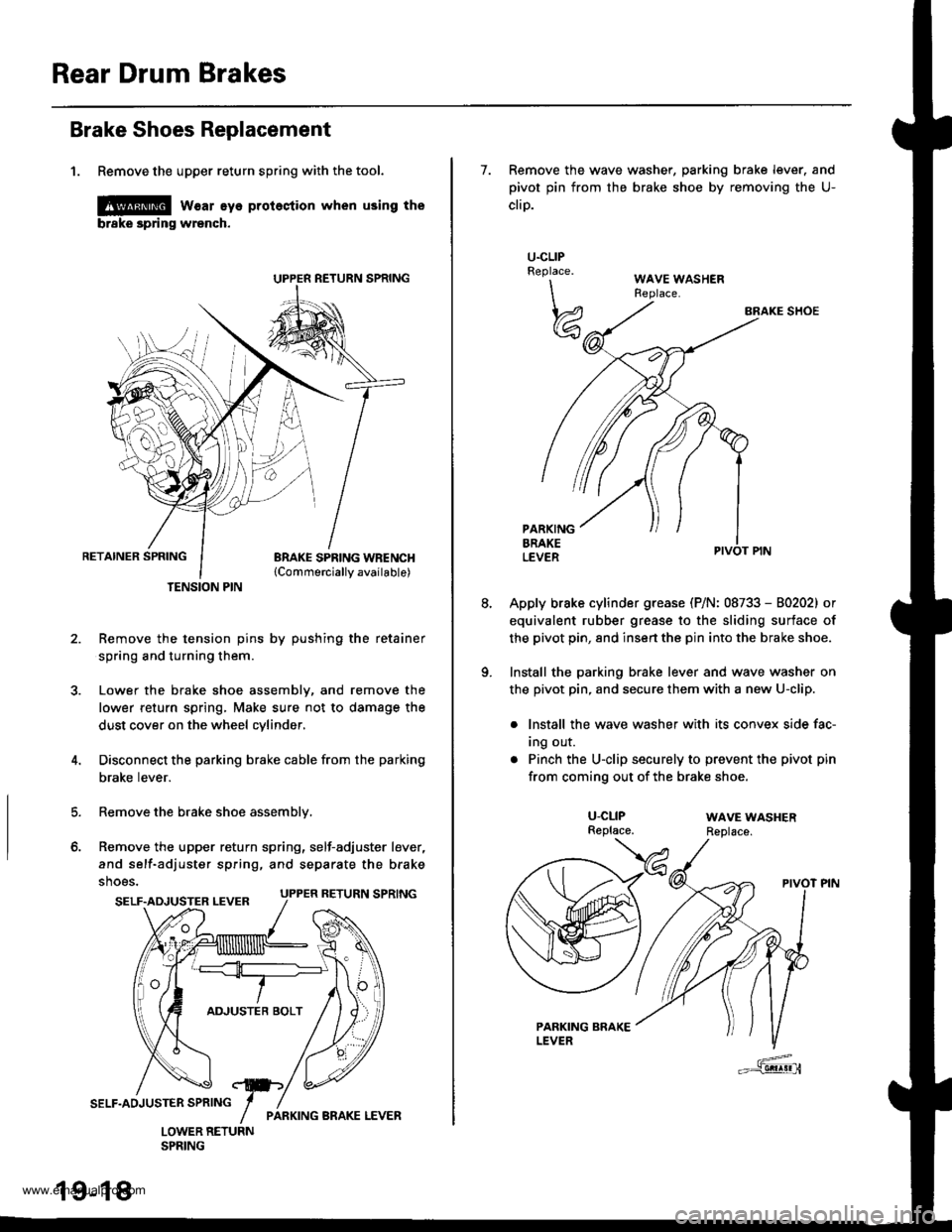

1. Remove the upper return spring with the tool.

l@ w€ar eye protestion when using the

brske spring wrench.

RETAINER SPRINGBRAKE SPRING WBENCH{Commerciallv available)

Remove the tension pins by pushing the retainer

spring and turning them.

Lower the brake shoe assembly, and remove the

lower return spring, Make sure not to damage the

dust cover on the wheel cylinder,

Disconnect the parking brake cable from the parking

brake lever.

Remove the brake shoe assembly,

Remove the upper return spring, self-adjuster lever,

and self-adjuster spring, and separate the brake

shoes.

TENSION PIN

5.

o.

SELF.ADJUSTER LEVER UPPER RETURN SPRING

19-18

7. Remove the wave washer, parking brake lever. and

pivot pin from the brake shoe by removing the U-

cliD.

BRAKE SHOE

Apply brake cylinder grease (P/N: 08733 - 80202) or

equivalent rubber grease to the sliding surface of

the pivot pin, 8nd insert the pin into the brake shoe.

Install the parking brake lever and wave washer on

the pivot pin, and secure them with a new U-clip.

. lnstall the wave washer with its convex side fac-

Ing our.

. Pinch the U-clip securely to prevent the pivot pin

from coming out of the brake shoe.

U.CLIPReplace.

\\

w

U-CLIPReplace.WAVE WASHERReplace.

www.emanualpro.com

Page 943 of 1395

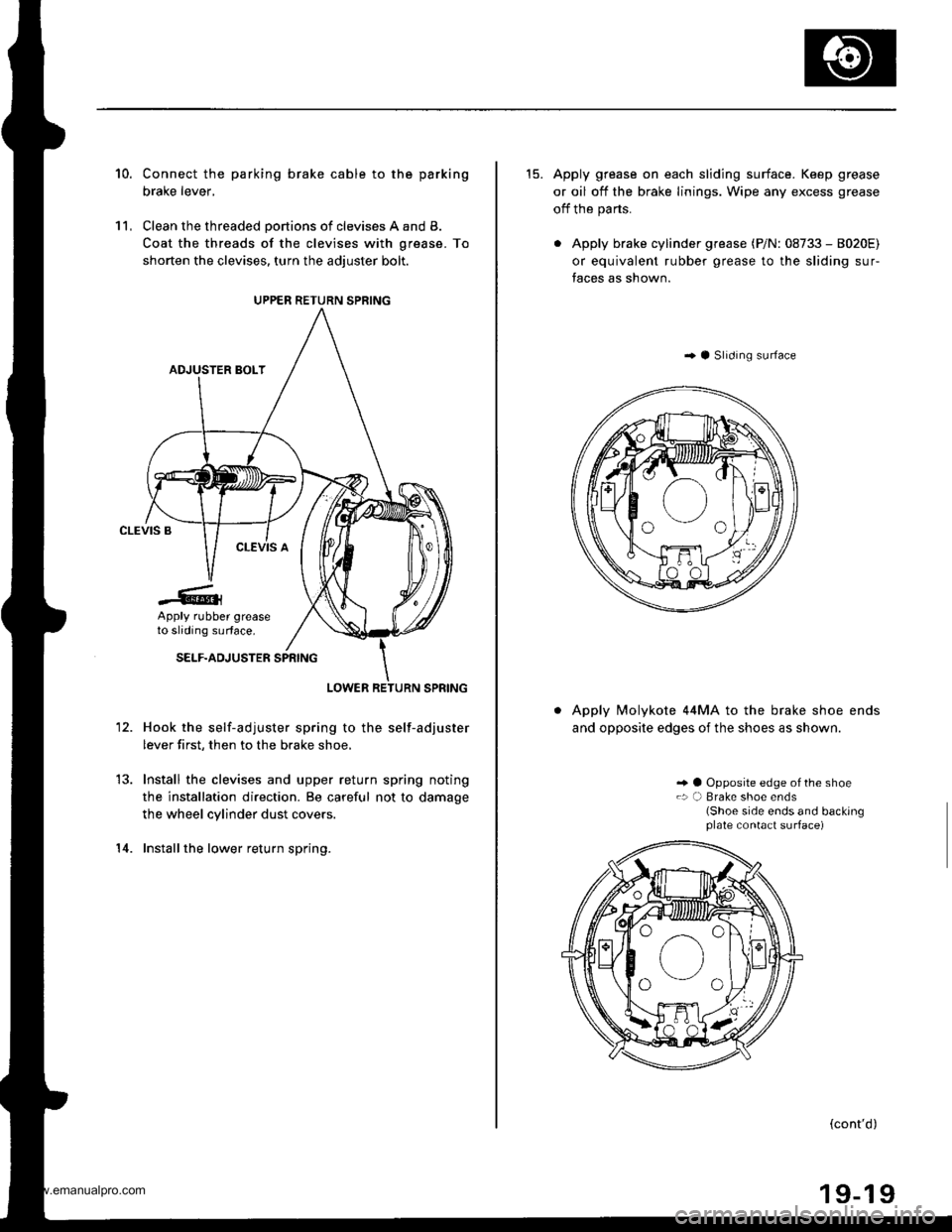

10.

11,

Connect the parking brake cable to the parking

brake lever,

Clean the threaded portions of clevises A and B.

Coat the threads of the clevises with grease. To

shorten the clevises, turn the adiuster bolt.

Hook the self-adjuster spring to the self-adjuster

lever first, then to the brake shoe,

Install the clevises and upper return spring noting

the installation direction. Be careful not to damage

the wheel cylinder dust covers.

Installthe lower return spring.

12.

14.

UPPER RETURN SPRING

Apply rubber greaseto sliding surface.

15. Apply grease on each sliding surface. Keep grease

or oil off the brake linings. Wipe any excess grease

off the parts.

. Apply brake cylinder grease (P/N: 08733 - 8020E)

or equivalent rubber grease to the sliding sur-

faces as shown.

..4 Slrdrng surface

Apply Molykote 44MA to the brake shoe ends

and opposite edges of the shoes as shown.

.. a Opposite edge of the shoe.: a) Brake shoe ends(Shoe side ends and backingplate contact surface)

(cont'd)

www.emanualpro.com

Page 947 of 1395

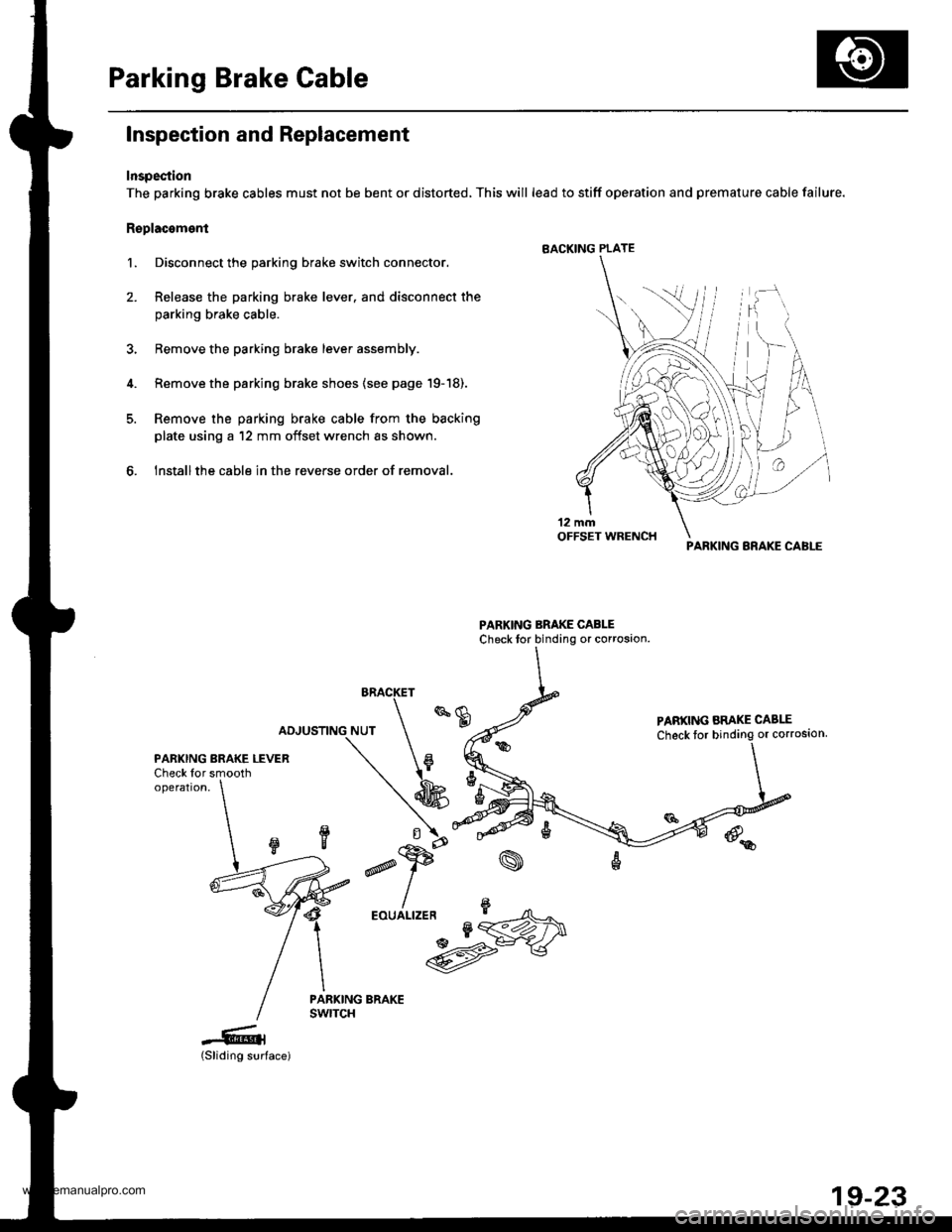

Parking Brake Cable

Inspection and Replacement

Inspection

The parking brake cables must not be bent or distorted, This will lead to stiff operation and premature cable failure.

Replacoment

l. Disconnect the parking brake switch connector.

2. Release the parking brake lever. and disconnect the

parking brake cable.

3, Bemove the parking brake lever assembly.

4. Remove the parking brake shoes {see page '19-18).

5. Remove the parking brake cable from the backing

plate using a '12 mm offset wrench as shown.

6. Installthe cable in the reverse order of removal.

BRACKET

PABKING ARAKE CABLE

Check toror corroston,

PARKING BRAKE LEVERCheck for smoothoperation,

d

,"u/n*UM

-6l(Sliding surface)

PARKING BRAKE CABI-E

19-23

www.emanualpro.com

Page 1034 of 1395

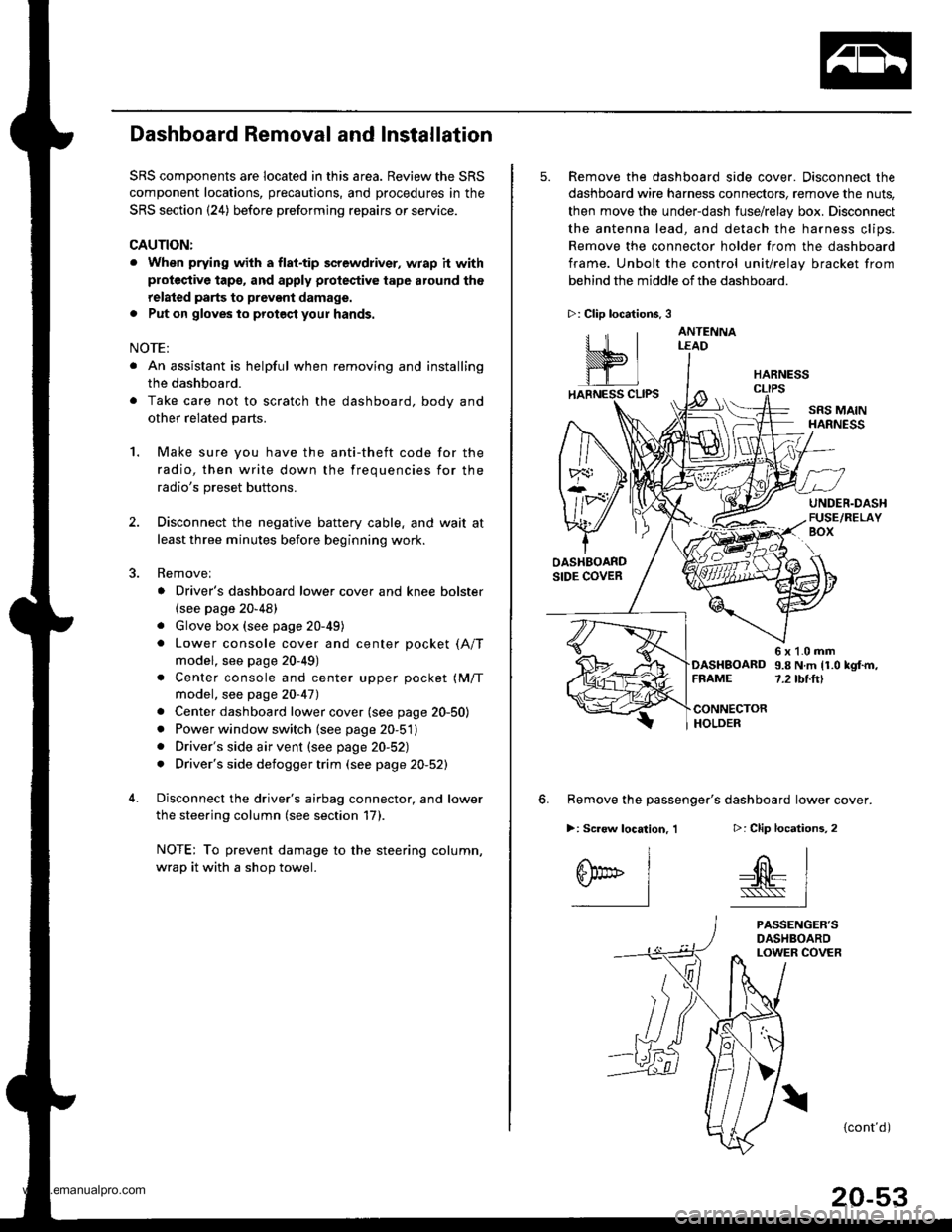

Dashboard Removal and Installation

SRS components are located in this area. Review the SRS

component locations, precautions, and procedures in the

SRS section {24) before preforming repairs or service.

CAUTION:

. When prying with a flat-tip screwdriver, wrap h withprotective tap€, and apply protective tape around the

related parts to prevgnt damage.

. Put on gloves to prot€ct your hands.

NOTE:

. An assistant is helpful when removing and installing

the dashboard.

. Take care not to scratch the dashboard, bodv and

other related parts.

1.Make sure you have the anti-theft code for the

radio, then write down the frequencies for the

radio's preset buttons.

Disconnect the negative battery cable. and wait at

least three minutes before beginning work.

Removei

a Driver's dashboard lower cover and knee bolster(see page 20-48)

. Glove box (see page 20-49)

. Lower console cover and center pocket (A/T

model, see page 20-49)

. Center console and center upper pocket (M/T

model, see page 20-47)

. Center dashboard lower cover (see page 20-50)

. Power window switch (see page 20-51)

. Driver's side air vent (see page 20-52)

. Driver's side defogger trim (see page 20-52)

Disconnect the driver's airbag connector, and lower

the steering column (see section 17)

NOTE: To prevent damage to the steering column,

wrap it with a shop towel.

2.

5. Remove the dashboard side cover. Disconnect the

dashboard wire harness connectors, remove the nuts,

then move the under-dash fuse/relay box. Disconnect

the antenna lead, and detach the harness clips.

Remove the connector holder from the dashboard

frame. Unbolt the control unit/relay bracket from

behind the middle of the dashboard.

HARNESS

6. Remove the passenger's dashboard lower cover.

D: Clip locations,

nl

-$t- Issj

I

ANTENNALEAD

>: Clip locations.

rttl

slllll

>: Scr€w location, 1

I

SF:oo I-l

SRS MAINHARNESS

UNDER.DASHFUSE/RELAYBOX

OASHBOARDSIDE COVER

6x1.0mm9.8Nm11.0kgf.m,7.2tbt.ftlDASHBOARDFFAME

CONNECTORHOLDER

PASSENGER'SDASHBOARDLOWER COVER

{cont'd)

www.emanualpro.com

Page 1049 of 1395

Seats

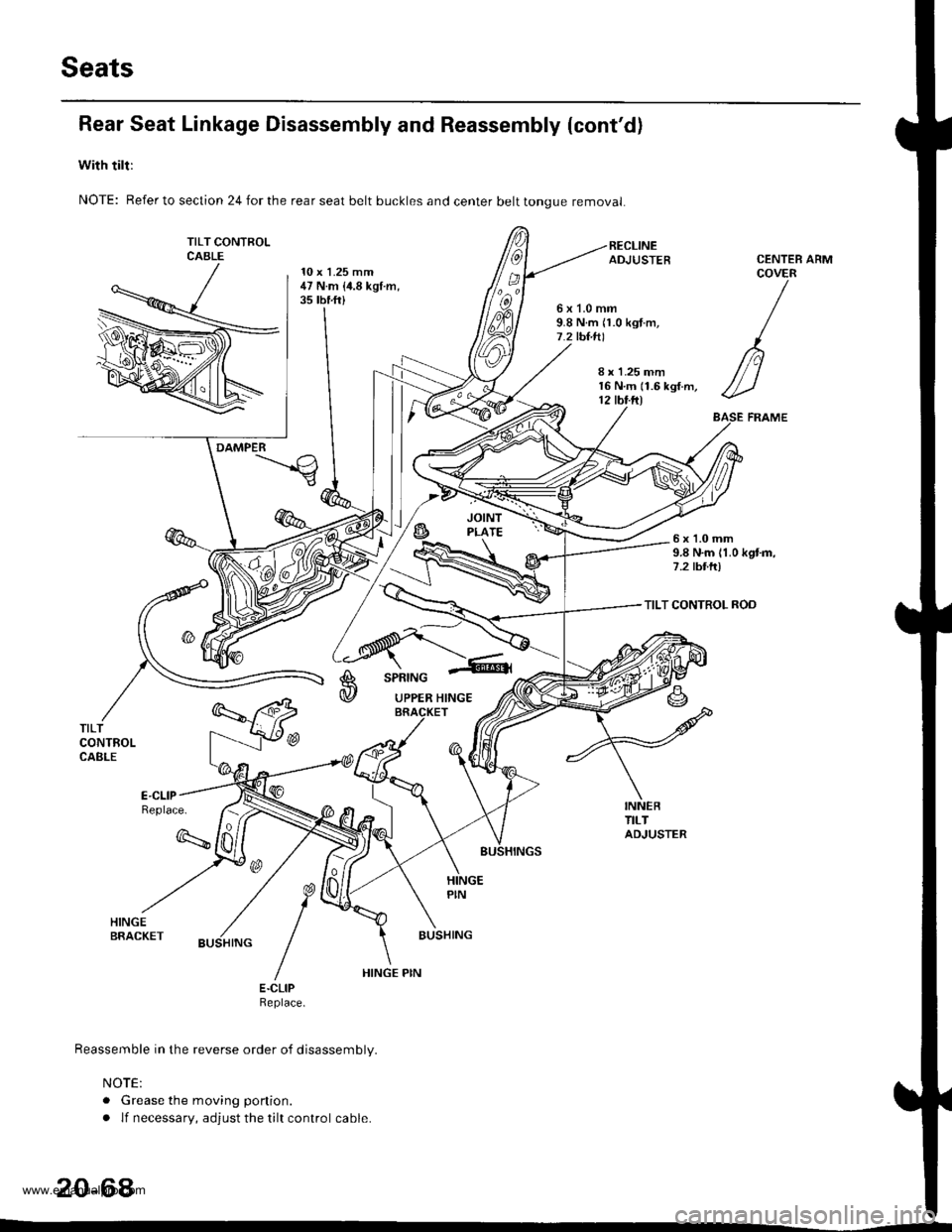

Rear Seat Linkage Disassembly and Reassembly (cont'd)

with tilt:

NOTE: Refer to section 24 for the rear seat belt buckles and center belt tongue removal

TILT CONTFOLCABLE10 x 1.25 mm47 N.m {i1.8 kgt.m,35 tbf.ft)

ARM

6x1.0mm9.8 N.m n.0 kgt.m,7.2 tbt.tll

CENTEBCOVER

/

n

//-)

ASE FRAME

8 r 1.25 mm16 N.m (1.6 kgf.m,12 tbt.ftl

DAMPER

6x1.0mm9.8 N.m 11.0 kgtm,7.2 tbttr)

TILT CONTROL ROD

A

@

SPRING

UPPER HINGE

TILTCONTROLCABLE

Replace.

q

BUSHING

E.CLIPReptace.

Reassemble in the reverse order of disassembly.

NOTE:

. Grease the moving ponion.

. lf necessary, adjust the tilt control cable.

20-64

HINGE PIN

www.emanualpro.com

Page 1073 of 1395

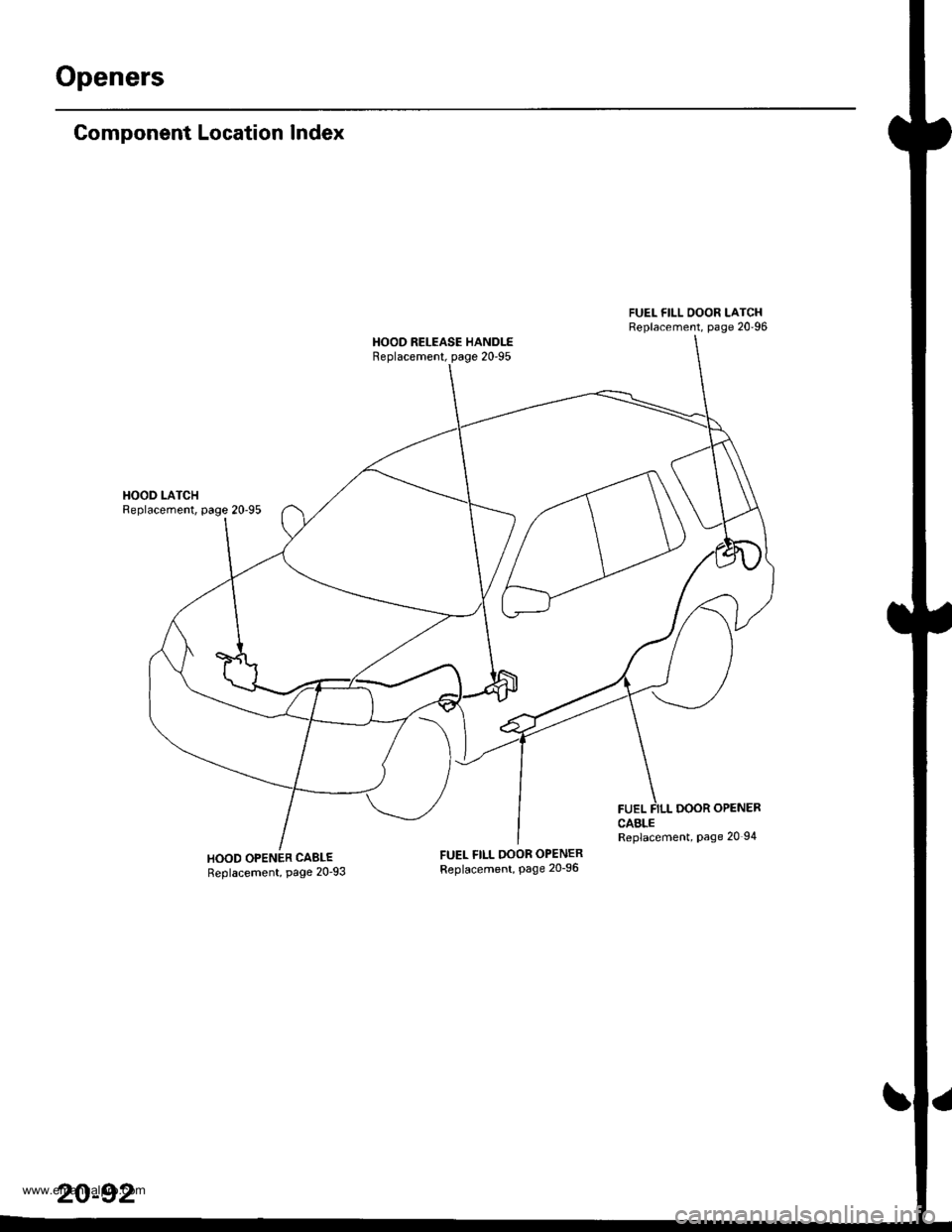

Openers

Component Location Index

HOOD LATCHReplacement, page 20'95

HOOD OPENER CABLEReplacement, page 20'93

FUEL FILL OOOR LATCHReplacement, page 20'96

HOOD RELEASE HANDLEReplacement, page 20'95

FUELDOOR OPENERCABLEReplacement, Page 20 94

FUEL FILL OOOR OPENERReplacement, Page 20_96

20-92

www.emanualpro.com

Page 1074 of 1395

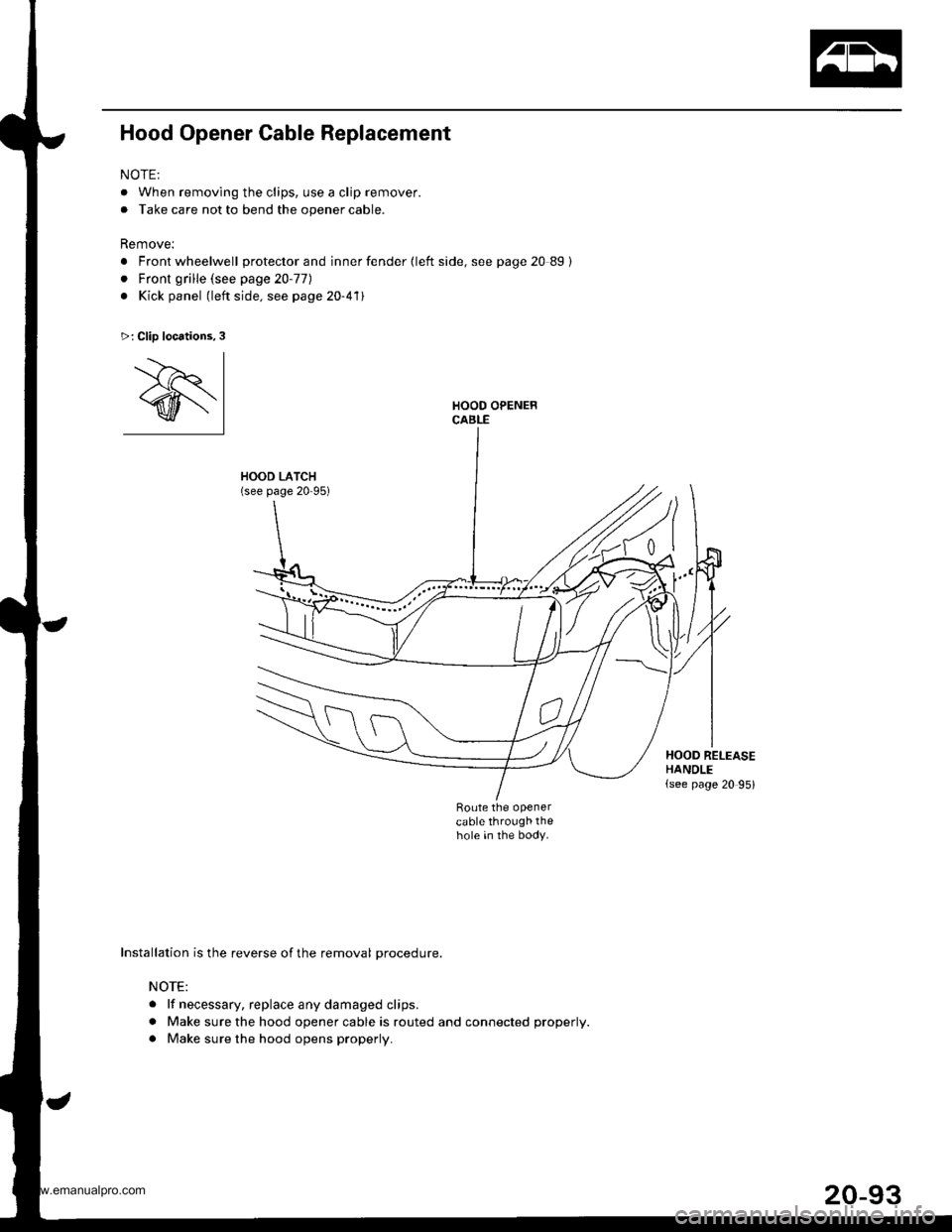

Hood Opener Cable Replacement

NOTE:

. When removing the clips, use a clip remover.

. Take care not to bend the opener cable.

Remove:

. Front wheelwell protector and inner fender {left side, see page 20 89}

. Front grille (see page 20-77)

. Kick panel (left side. see page 20-411

HOOD LATCH(see page 20-95)

Route the openercable through thehole in the body.

>: Clip locations,3

'.--)r I

@l

Installation is the reverse of the removal procedure.

NOTE:

. lf necessary. replace any damaged clips.

. Make sure the hood opener cable is routed and connected properly.

. Make sure the hood opens properly.

t"

HOOD RELEASEHANDLE(see page 20 95)

www.emanualpro.com

Page 1075 of 1395

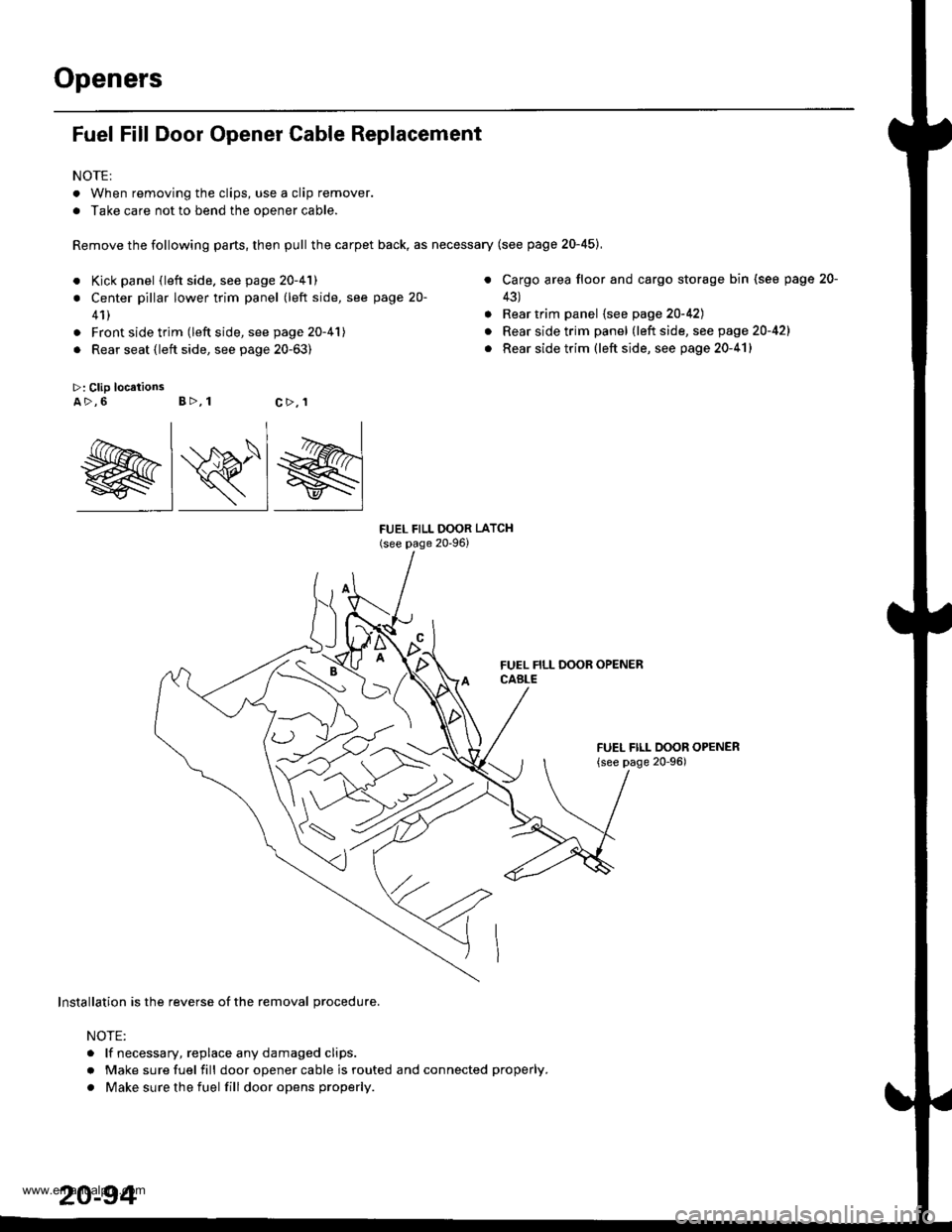

Openers

Fuel Fill Door Opener Cable Replacement

NOTE:

. When removing the clips, use a clip remover.

. Take care not to bend the opener cable.

Remove the following parts, then pull the carpet back, as necessary (see page 20-45),

a

>: Clip locationsA>,6 B>, 1

a

a

FUEL FILL OOOR LATCH(see page 20-96)

Kick panel (left side. see page 20-41)

Center pillar lower trim panel (left side, see page 20-

41)

Front side trim (left side, see page 20-41)

Rear seat (left side, see page 20-63)

Cargo area floor and cargo storage bin (see page

43)

Rear trim panel {see page 20-42)

Rear side trim panel (left side, see page 20-421

Rear side trim (left side, see page 20-41)

FUEL FILL DOOR OPENER

{see page 20-96)

20-

c>,1

@lRlg

Installation is the reverse of the removal procedure.

NOTE:

. lf necessary, replace any damaged clips.

r Make sure fuel fill door opener cable is routed and connected properly.

. Make sure the fuel fill dooropens properly.

www.emanualpro.com