low clutch HONDA CR-V 1999 RD1-RD3 / 1.G Repair Manual

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 725 of 1395

One-way Glutch

Disassembly/lnspection/Reassem bly

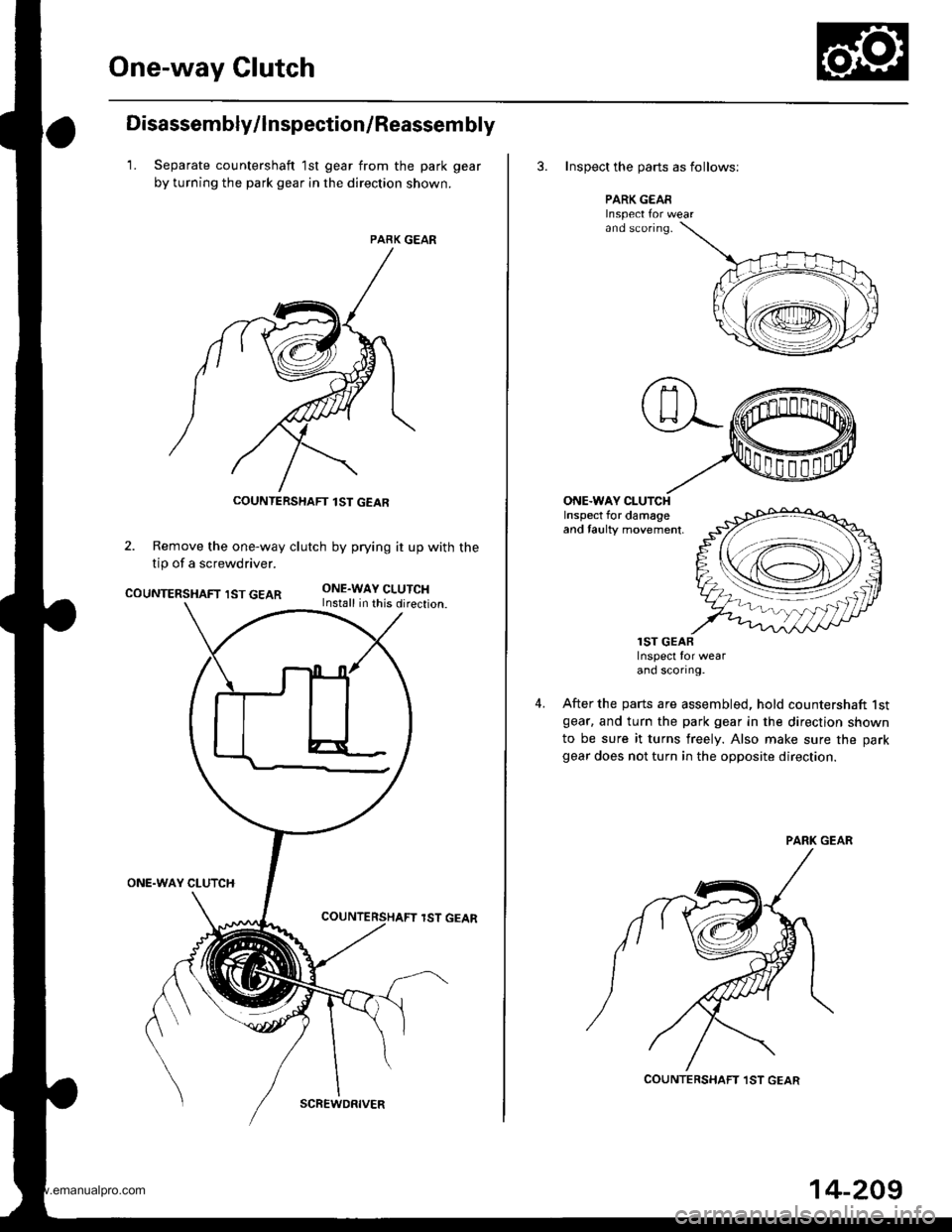

1. Separate countershaft 1st gear from the park gear

by turning the park gear in the direction shown.

PARK GEAR

2. Remove the one-way clutch by prying it up with the

tip of a screwdriver.

COUNTERSHAFT IST GEARONE.WAY CLUTCHInstall in this direction.

ONE.WAY CLUTCH

lST GEAR

COUNTERSHAFT lST GEAR

SCREWDRIVER

14-209

3. Inspect the oarts as follows;

PARK GEARInspect Ior wearand sconng.

ONE.WAY CLUTCHInspect for damageand taulty movement,

4.

lST GEARInspect for wearand scortng.

After the parts are assembled, hold countershaft lstgear. and turn the park gear in the direction shown

to be sure it turns freely. Also make sure the park

gear does not turn in the opposite direction.

COUNTERSHAFT ,IST GEAR

www.emanualpro.com

Page 734 of 1395

Glutch

Reassembly

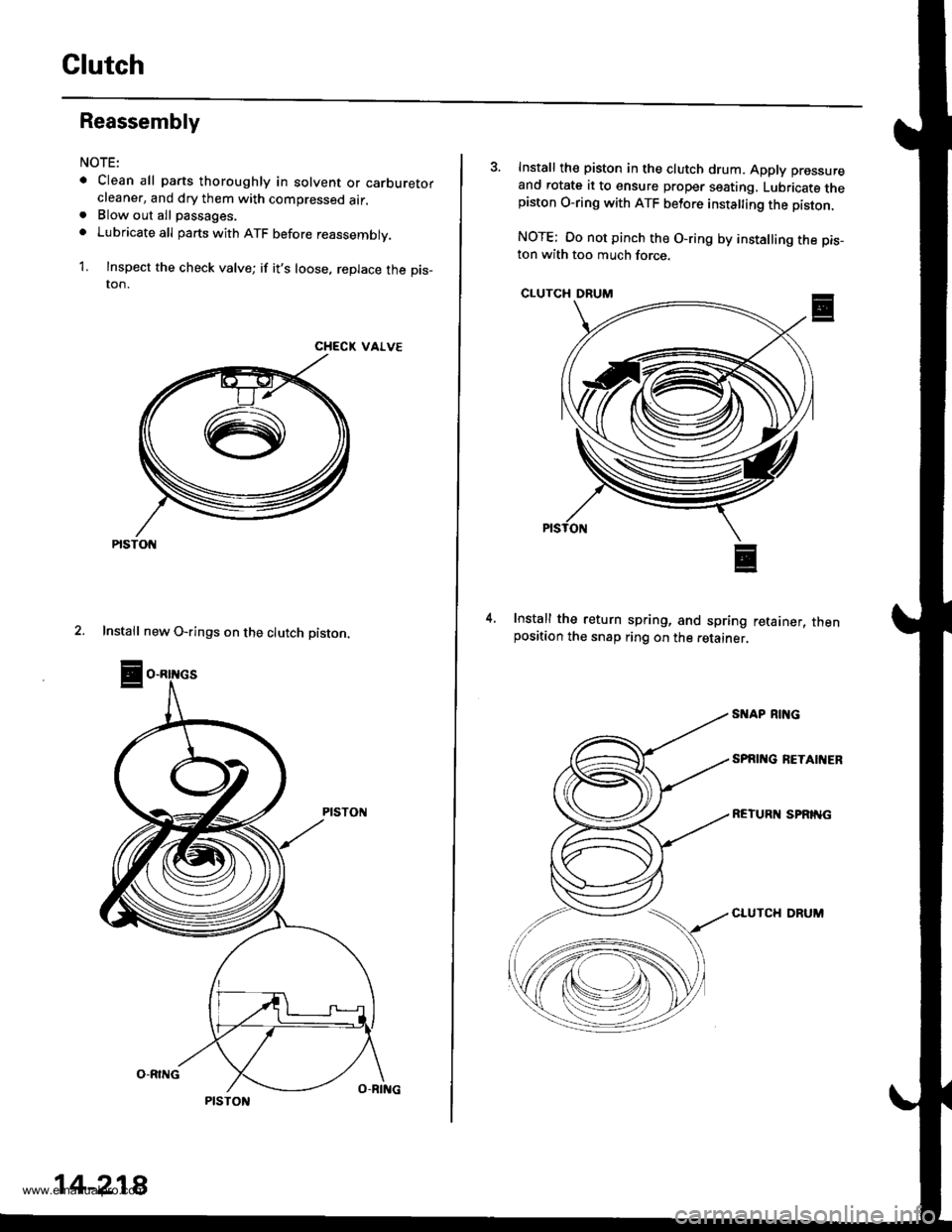

NOTE:

. Clean all parts thoroughly in solvent or carburetorcleaner, and dry them with compressed air.. Blow out all passages.

o Lubricate all parts with ATF before reassembly.

1. Inspect the check valve; if it's loose, replace the pis_ton.

CHECK VALVE

2. Install new O-rings on the clutch piston.

PtsTot{

14-218

3. Install th€ piston in the clutch drum. Apply pressure

and rotate it to ensure proper seating, Lubricate thepiston O-ring with ATF betore insta ing the piston.

NOTE: Oo not pinch the O-ring by installing the pis_ton with too much force.

CLUTCH DRUM

Install the return spring, and spring retainer, thenposition the snap ring on the retainer.

4.

SI{AP RING

SPAI'{G RETAIIIER

REIURN SPRING

CLUTCH DRUM

www.emanualpro.com

Page 737 of 1395

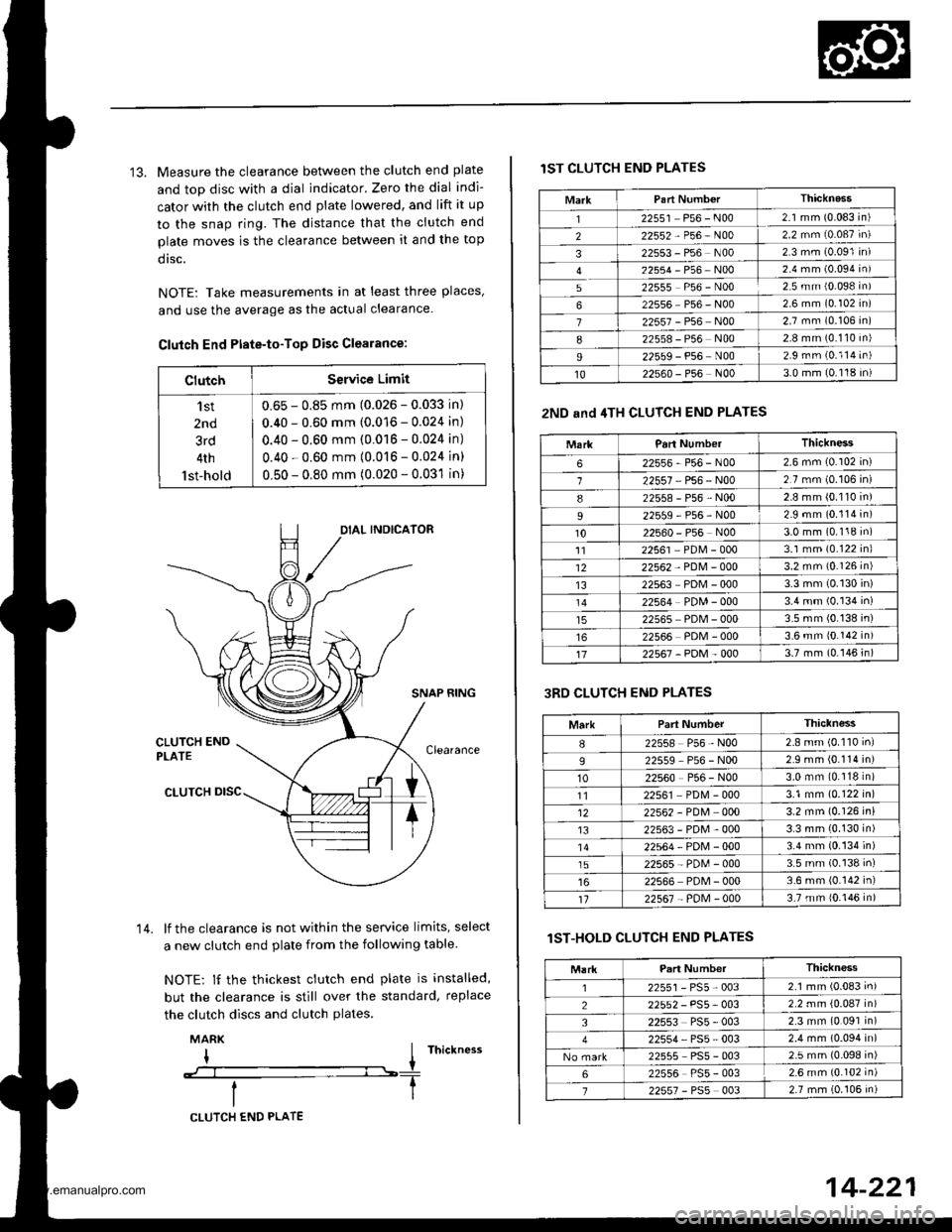

13. Measure the clearance between the clutch end plate

and top disc with a dial indicator. Zero the dial indi-

cator with the clutch end plate lowered, and lift it up

to the snap ring. The distance that the clutch end

plate moves is the clearance between it and the top

dtsc.

NOTE: Take measurements in at least three places'

and use the average as the actual clearance.

Clutch End Ptate-to-Top Disc Clearance:

ClutchService Limit

'l st

2nd

3rd

4th

lst-hold

0.65 - 0.85 mm (0.026 - 0.033 in)

0.40 - 0.60 mm (0.016 - 0.024 in)

0.40 - 0.60 mm (0.016 - 0.024 in)

0.40 - 0.60 mm (0.016 - 0.024 in)

0.50 - 0.80 mm (0.020 - 0.031 in)

SNAP RING

lf the clearance is not within the service limits, select

a new clutch end plate from the following table

NOTE: lf the thickest clutch end plate is installed,

but the clearance is still over the standard, replace

the clutch discs and clutch plates.

MARK

I I rnictness

--:--l----T

14.

CLUTCH END PLATE

14-221

lST CLUTCH END PLATES

2ND and 4TH CLUTCH END PLATES

3RD CLUTCH END PLATES

lST-HOLD CLUTCH END PLATES

MarkThicknass'I22551 P56 - N002.1 mm (0.083 in)

222552-P56-N002.2 mm (0.087 in)

322553 - P56 N002 3 mm (0.091 in)

22554-P56-NOo2.4 mm (0.094 in)

522555 P56 - N002.5 mm {0.098 in)

622556 P56 - N002 6 mm (0.102 in)

722557 - P56 N002.7 mm (0.106 in)

822558 - P56 N002.8 mm (0.110 in)

I22559 - P56 N002.9 rnm (0.114 in)

1022s60 - P56 N003.0 mm (0.118 in)

MarkParl NumberThickness

622556-P56-N002.6 mm (0.102 in)

122557 P56 - N002.7 mm (0.106 in)

822558-P56-N002.8 mm (0.110 in)

22559-P56-N002.9 mm (0.114 in)

1022560 - P56 N003.0 mm (0.118 in)'1122561 PDM - 0003.1 mm (0.122 inl

1222562 - PDM - 0003.2 mm {0.126 in)

1322563 PDM - 0003.3 mm (0.130 in)

22564 PDM - 0003.4 mm (0.134 in)

22565 PDM - 0003.5 mm (0.138 in)

22566 PDM - 0003.6 mm 10.142 in)

1722567-PDM-0003.7 mm (0.146 in)

MarkPart NumberThiclness

I22558 P56 - N002.8 mm (0.110 inl

922559 P56 - N002.9 mm (0.114 in)

1022560 P56 - N003.0 mm (0.118 in)

1122561 PD[4 - 0003.1 mm (0.122 in)

1222562 - PDM 0003.2 mm (0.126 in)

t322563-PDM-0003.3 mm (0.130 in)'1422564-PDN4-0003.4 mm (0.134 in)

1522565-PD[,l-0003.5 mm (0.138 in)

22566 PDM - 0003.6 mm (0.142 in)'t122567 - PoM - 0003.7 mm {0.146 in)

Thickness

2255r-PS5-0032.1 mm (0.083 in)

22552 - PS5- 0032.2 mm {0.087 in)

322553 PS5 - 0032.3 mm (0.091 in)

22554, PS5 - 0032.4 mm (0.094 in)

22555 PS5 - 0032.5 mm (0.098 in)

622556 PS5 - 0032.6 mm {0.102 in)

722557 - PSs 0032.7 mm (0.106 in)

www.emanualpro.com

Page 794 of 1395

Description

Rear Differential

Outline

The Real-time 4WD-Dual Pump System model has a hydraulic clutch and a differential mechanism in the rear differential

assembly. Under normal conditions, the vehicle is driven by the front wheels. However, depending on to the driving force

of the front wheels and the road conditions. the system instantly transmits appropriate driving force to the rear wheels

without requiring the driver to switch between 2WD (tront wheel drive) and 4WD (four wheel drive). The switching mecha-

nism between 2WD and 4WD is integrated into the rear differential assembly to make the system light and compact.

ln addition, the dual-pump system switches off the rear-wheel-drive force when braking in a forward gear. This allows the

braking system to work properly on models equipped with an Anti-lock Braking System (ABS).

Construction

The rear differential assembly consists of the torque control differential case assembly and the rear differential carrier

assembly. The torque control differential case assembly consists of the differential clutch assembly, the companion

flange, and the oil pump body assembly. The rear differential carrier assembly consists of the differential mechanism. The

differential drive and driven gears are hypoid gears.

The oil pump body assembly consists of the front oil pump, the rear oil pump, the hydraulic control mechanism, and the

clutch piston. The clutch piston has a disc spring that constantly provides the differential clutch assembly with a preset

torque to Drevent abnormal sound.

The clutch guide in the differential clutch assembly is connected to the propeller shaft via the companion flange, and it

receives the driving force lrom the transfer assembly. The clutch guide rotates the clutch plate and the front oil pump in

the oil pump body.

The clutch hub in the differential clutch assembly has a clutch disc that is splined with the hypoid drive pinion gear. The

hypoid drive gear drives the rear oil pump.

The front and rear oil pumps are trochoidal pumps. The rear oil pump capacity is 2.5 percent larger that the front oil pump

to handle the rotation difference between the front and rear wheels caused by worn front tires and tight corner braking.

The oil pumps are designed so the fluid intake works as a fluid discharge when the oil pumps rotate in reverse. Genuine

Honda CVT fluid is used instead of differential fluid.

Operation

When there is a difference in rotation speed between the front wheels (clutch guide) and rear wheels (hypoid driven gear),

hydraulic pressure from the front and rear oil pumps engages the differential clutch, and drive force from the transler

assembly is applied to the rear wheels.

The hydraulic pressure control mechanism in the oil pump body selects 4WD mode when the vehicle is started abruptly,

or when accelerating in a forward or reverse gear (causing rotation difference between the front and rear wheels). or

when braking in reverse gear {when decelerating). lt switches to 2WD mode when the vehicle is driven at a constant speed

in forwar! or reverse gear (when there is no rotation difference between the front and rear wheels), or when braking in a

fo rwa rd gear (when decelerating).

To protect the system, the differential clutch assembly is lubricated by hydraulic pressure generated by the oil pumps in

both 4WD and 2WD modes. Also, the thermal switch relieves the hydraulic pressure on the clutch piston and cancels 4WD

mode if the temDerature of the differential fluid rises above normal.

www.emanualpro.com

Page 796 of 1395

Description

Hydraulic Flow

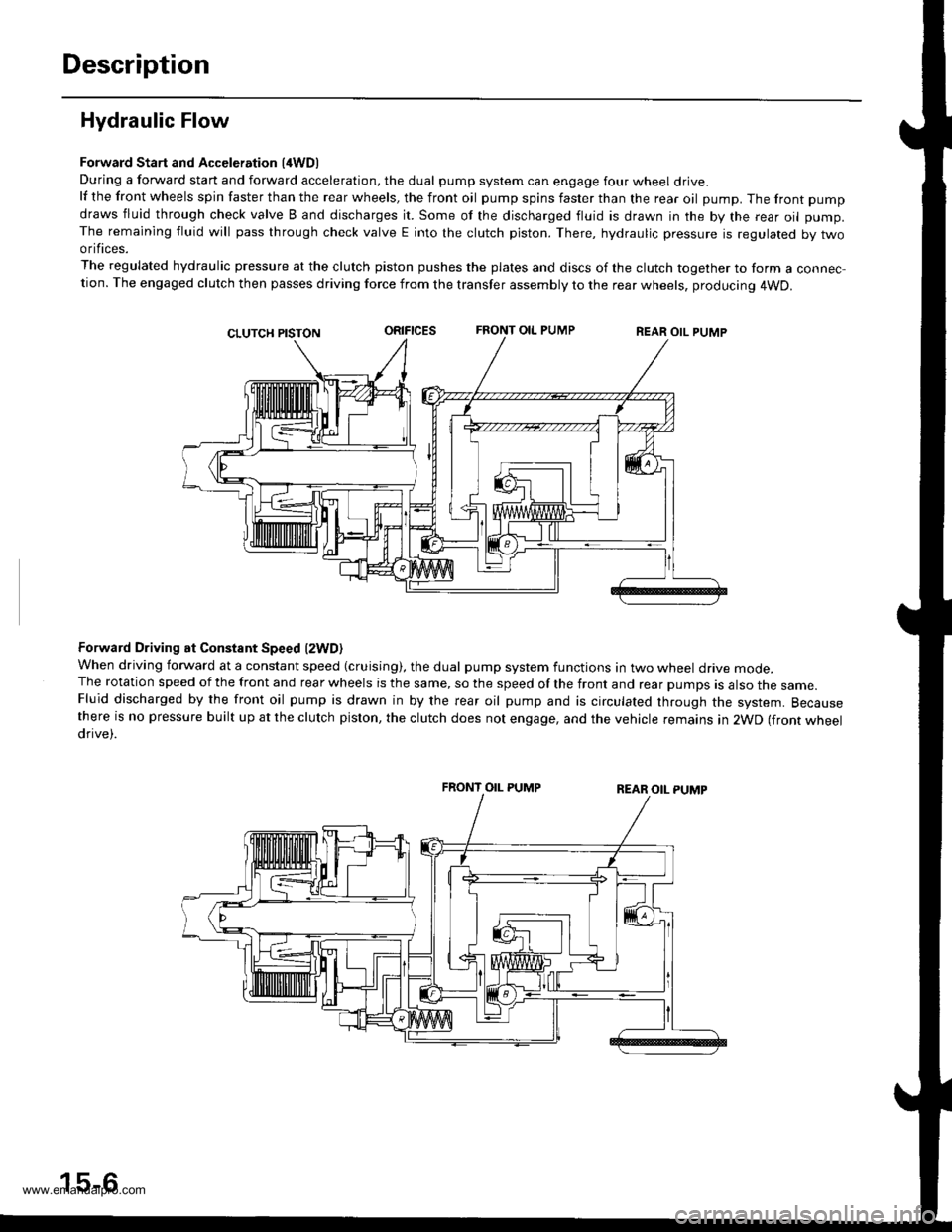

Forward Start and Acceleration l4WD)During a forward start and forward acceleration, the dual pump system can engage four wheel drive.lf the front wheels spin faster than the rear wheels, the front oil pump spins faster than the rear oil pump. The front pump

draws fluid through check valve B and discharges it. Some of the discharged fluid is drawn in the by the rear oil pump.The remaining fluid will pass through check valve E into the clutch piston. There, hydraulic pressure is regulated by twoorifices.

The regulated hydraulic pressure at the clutch piston pushes the plates and discs of the clutch together to form a connec-tion. The engaged clutch then passes driving force from the transfer assembly to the rear wheels, producing 4WD.

oRrFtcEsFRONT OIL PUMPREAR OIL PUMP

Forward Driving at Constant Speed lzWD)When driving forward at a constant speed (cruising), the dual pump system functions in two wheel drive mode.The rotation speed of the front and rear wheels is the same, so the speed of the front and rear pumps is also the same.Fluid discharged by the front oil pump is drawn in by the rear oil pump and is circulated through the system. Becausethere is no pressure built up at the clutch piston, the clutch does not engage, and the vehicle remains in 2WD (front wheeldrive).

FRONT OIL PUMP

15-6

www.emanualpro.com

Page 798 of 1395

Description

Hydraulic Flow (cont'dl

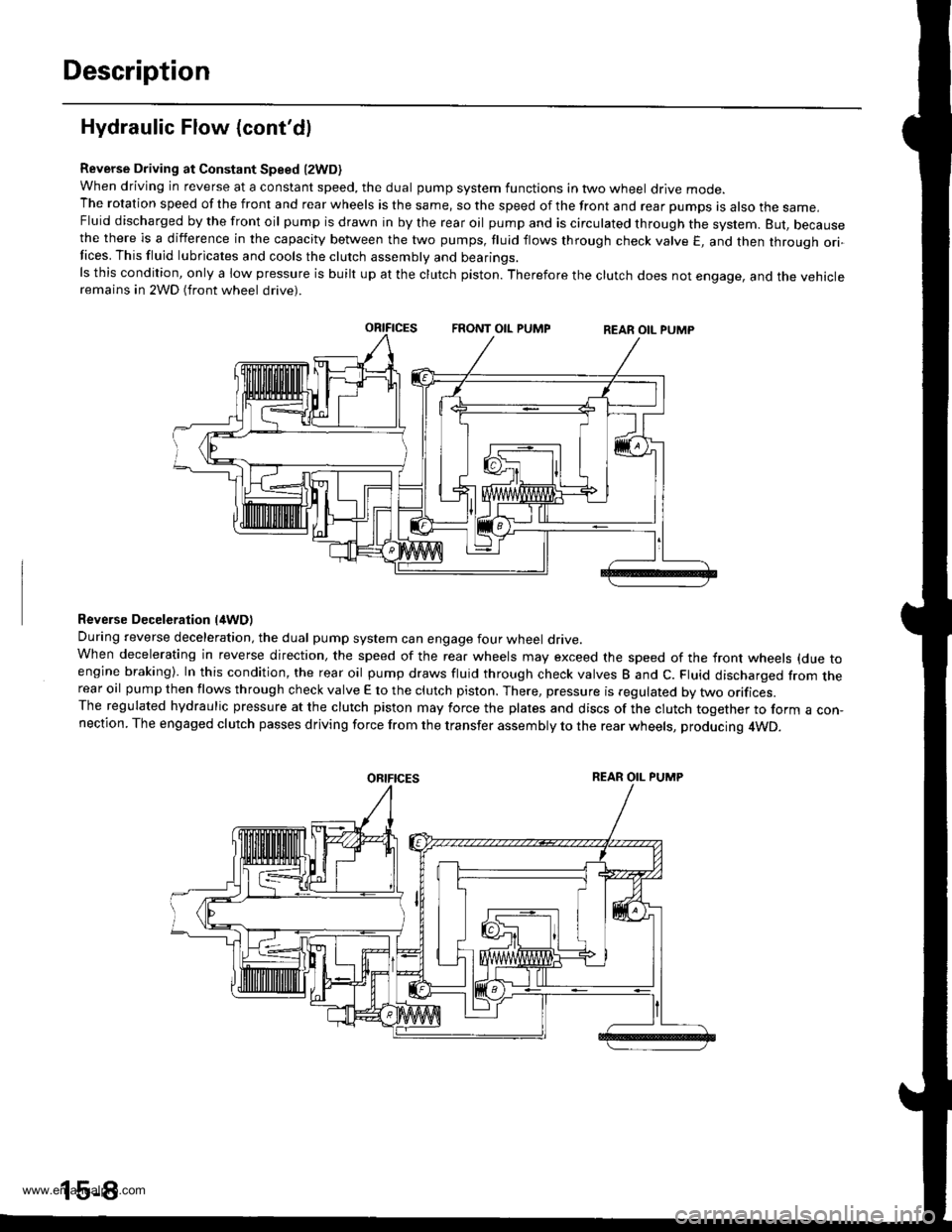

Reverse Driving at Constant Speed l2WD)when driving in reverse at a constant speed, the dual pump system functions in two wheel drive mode.The rotation speed of the front and rear wheels is the same, so the speed of the front and rear pumps is also the same,Fluid discharged by the front oil pump is drawn in by the rear oil pump and is circulated through the system. But, becausethe there is a difference in the capacity between the two pumps, fluid flows through check valve E, and then through ori-Iices. This fluid lubricates and cools the clutch assembly and bearings.ls this condition, only a low pressure is built up at the clutch piston. Therefore the clutch does not engage, and the vehicleremains in 2WD (front wheel drive).

Reverse Deceleration l/tWDl

During reverse deceleration, the dual pump system can engage four wheel drive.When decelerating in reverse direction, the speed of the rear wheels may exceed the speed of the front wheels (due toengine braking). In this condition, the rear oil pump draws fluid through check valves B and C. Fluid discharged from therear oil pump then flows through check valve E to the clutch piston. There, pressure is regulated by two orifices.The regulated hydraulic pressure at the clutch piston may force the plates and discs of the clutch together to form a con,nection. The engaged clutch passes driving force from the transfer assembly to the rear wheels, producing 4WD.

oRtFtcEsREAR OIL PUMP

www.emanualpro.com

Page 814 of 1395

Rear Differential Assembly

Reassembly (cont'dl

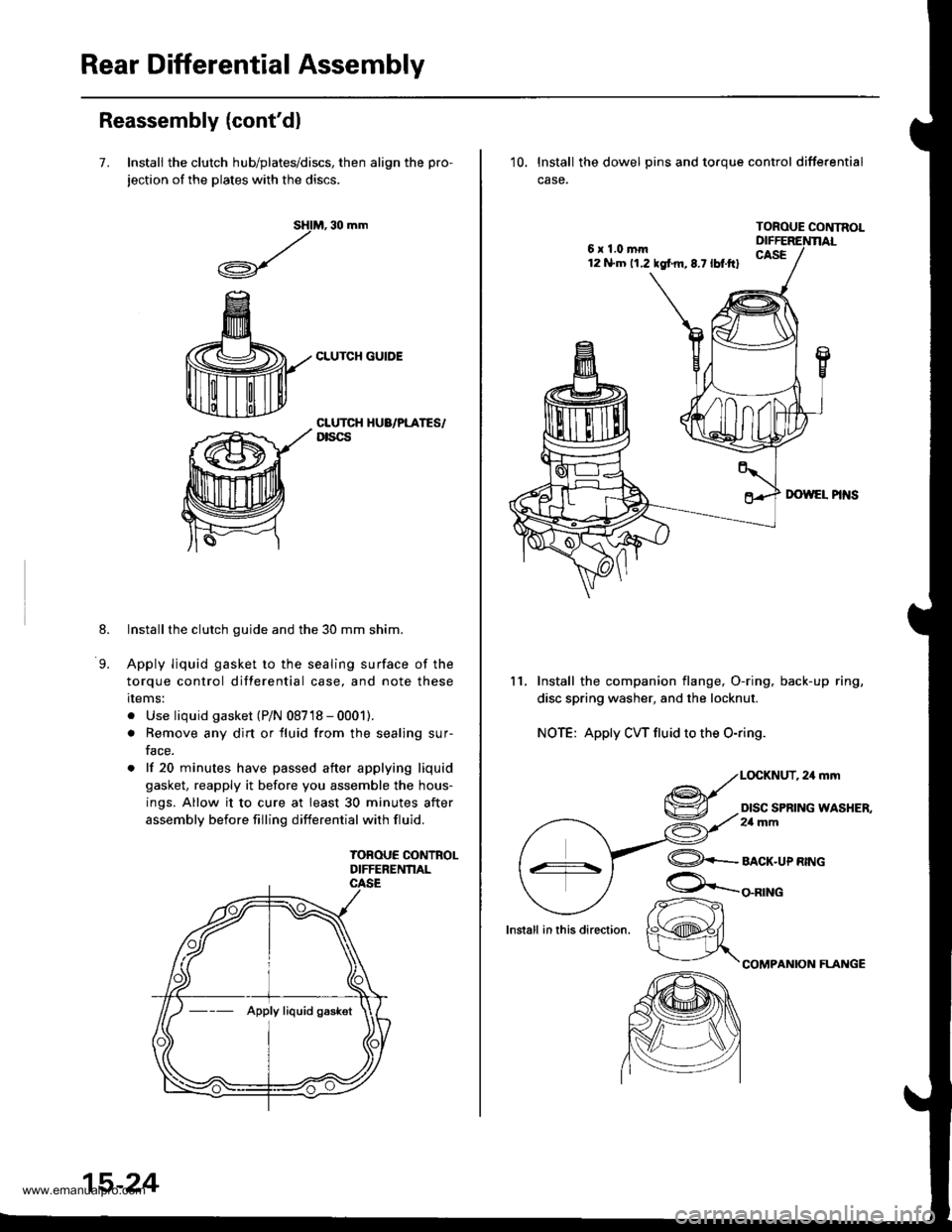

7. Install the clutch hub/plates/discs, then align the pro-

jection of the plates with the discs.

M, 30 mm

CLUTCH GUIDE

sHl

,/

.A-\,/r\-7

8.

9.

CLUTCH HUA/PLATES/Dtscs

Installthe clutch guide and the 30 mm shim.

Apply liquid gasket to the sealing surface of the

torque control differential case, and note these

rlems:

. Use liquid gasket (P/N 08718 - 0001).

. Remove any dirt or fluid from the sealing sur-

face.

. lf 20 minutes have passed after applying liquid

gasket, reapply it before you assemble the hous-

ings. Allow it to cure at least 30 minutes after

assembly before filling differential with fluid.

TOBOUE CONTROLDIFFERENNAL

--- Apply liquid gaskot

15-24

6x1.0mm12 N.m 11.2 tgf m,8.7lbt.ftl

10. lnstall the dowel pins and toroue control differential

case.

TOROUE CONTNOL

11. Install the companion flange, O-ring, back-up ring,

disc spring washer, and the locknut.

NOTE: Apply CW fluid to the O-ring.

,24mm

DISC SPRING WASHER,2a mm

lnstall in this direction.

@+-_alcr-upnwc

COMPANION FLAI{GE

/r-

K@#/

www.emanualpro.com

Page 1093 of 1395

Component Location

lndex

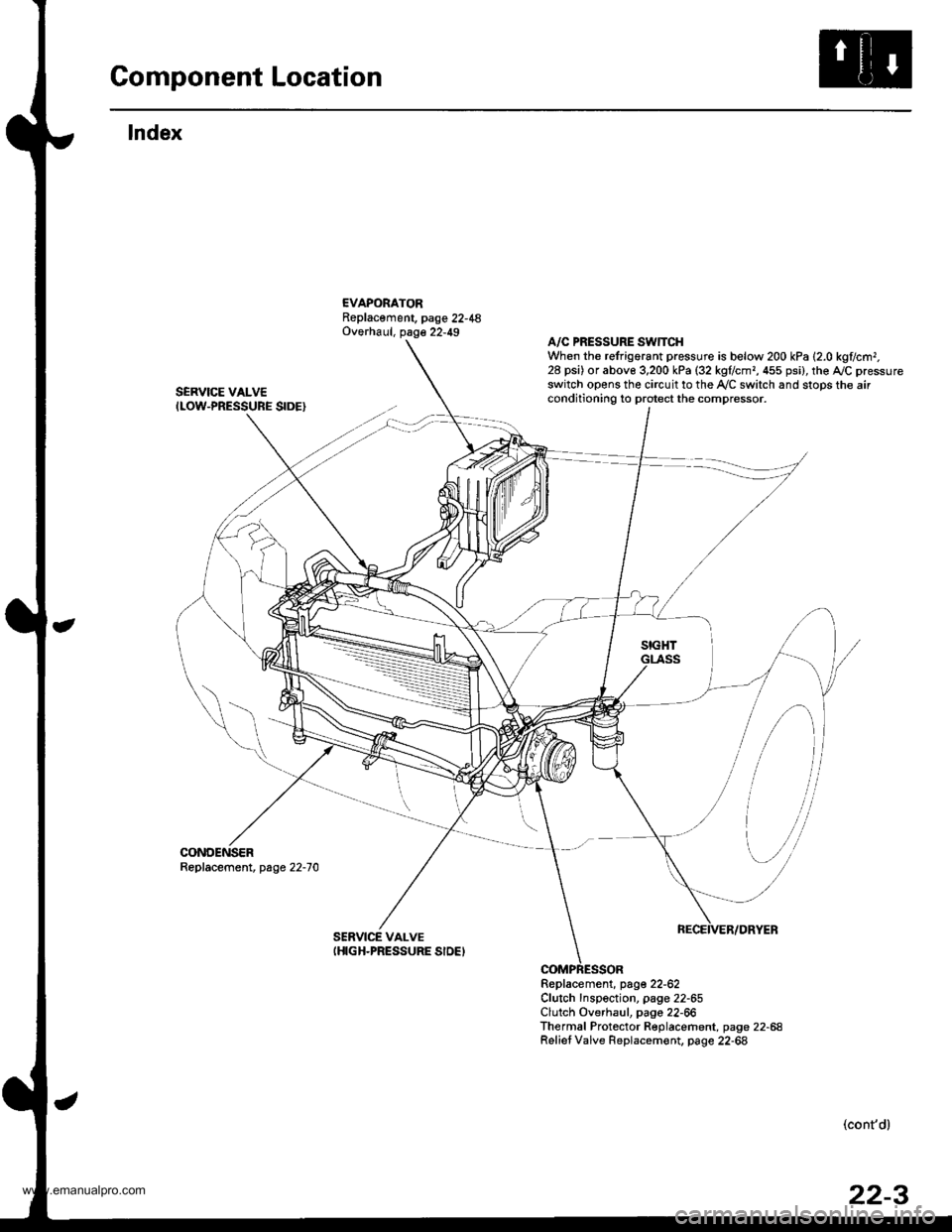

EVAPORATORReplacement, page 22-48Overhaul, page 22-49

SERVICE VALVEILOW-PRESSURE SIDE}

CONDENSERReplacement, page 22-70

A/C PRESSURE SWTTCHWhen the refrigorant pressure is below 200 kPa 12.0 kglc.r|r,28 psi) or abov€ 3,200 kPa (32 kgflcmr, 455 psi), the AJC pressureswitch opens the circuit to the Ay'C switch and stops the airconditioning to protect the compressor.

Replacement, page 22-62Clutch Inspection, page 22-65Clutch Overhaul, pago 22-66Thermal Protector Replacement, page 22-68Relief Valve Replacem€nt. page 22-68

SERVICE VALVEIHIGH-PRESSURE SIDEI

,

[\,

-il

(cont'd)

www.emanualpro.com

Page 1095 of 1395

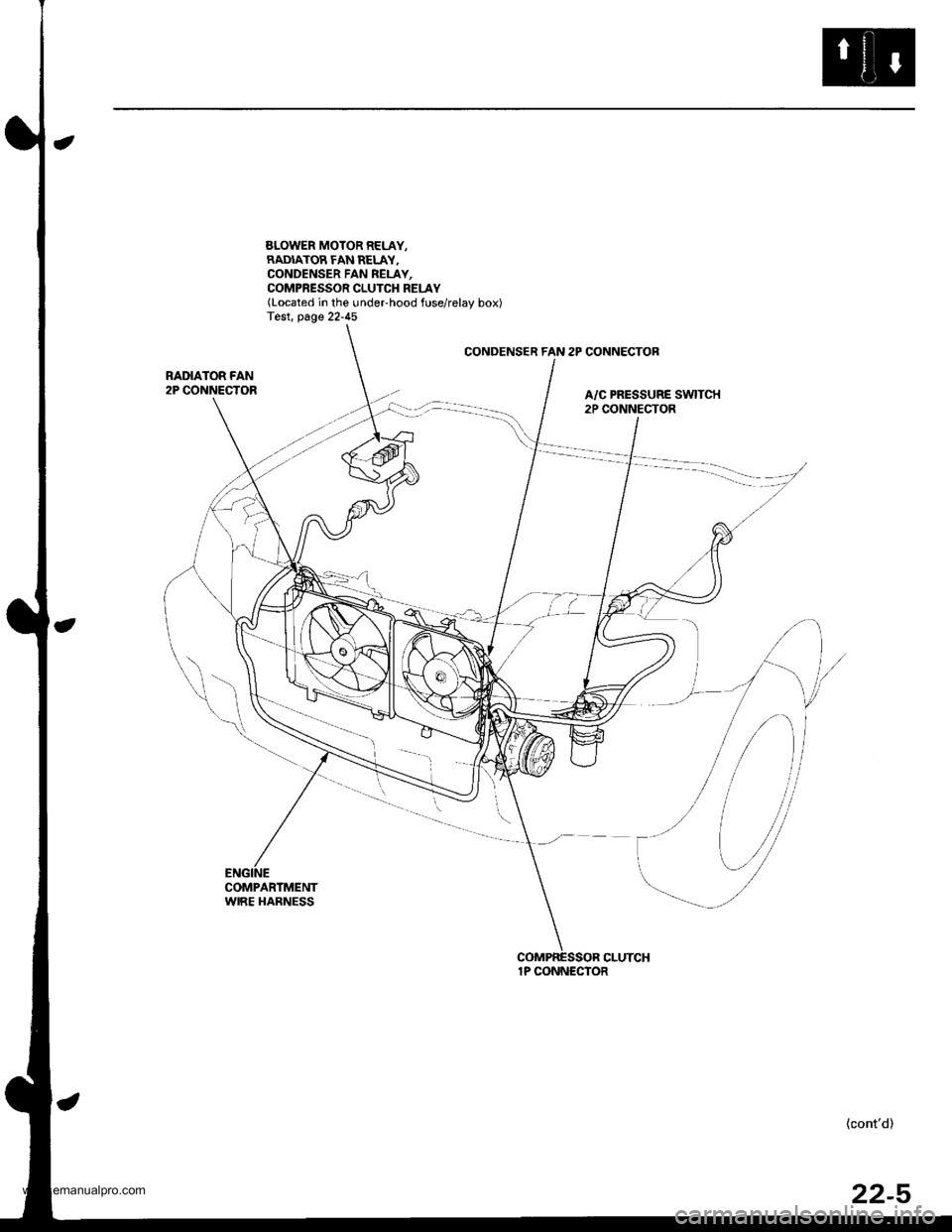

SLOWER MOTOR RELAY,RADIATOR FAN RELAY.CONDENSER FAN REI-AY,COMPRESSOR CLUTCH RELAY(Located in the undeFhood fuse/relay box)Test. page 22-45

CONDENSER FAN 2P CONNECTOB

RADIATOR FAN2P CONNECTORA/C PRESSURE SWITCH2P CONNECTOR

COMPARTMENTWIRE HARNESS

{cont'd)

1P CONNECTOR

22-5

www.emanualpro.com

Page 1100 of 1395

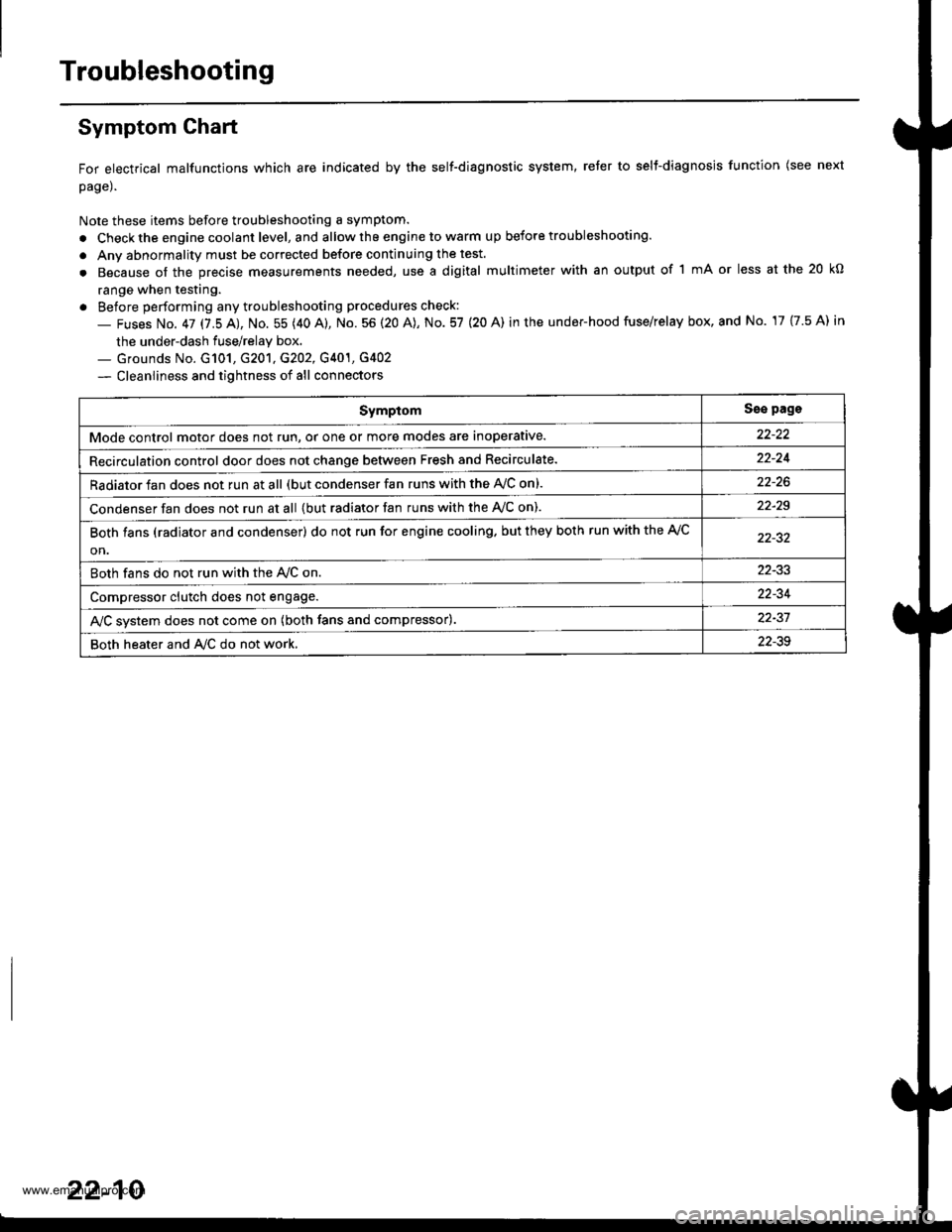

Troubleshooting

Symptom Ghart

For electrical malfunctions which are indicated by the self-diagnostic system, reter to selt-diagnosjs function (see next

page).

Note these items before troubleshooting a symptom.

. Check the engine coolant level, and allow the engine to warm up before troubleshooting.

. Anv abnormality must be corrected before continuing the test.

. Because of the precise measurements needed, use a digital multimeter with an output of 1 mA or less at the 20 kO

range when testing.

. Before performing any troubleshooting procedures check:

- Fuses No. 47 17.5 AJ, No. 55 (40 A), No. 56 (20 A), No. 57 (20 A) in the under-hood fuse/relay box, and No. 17 {7.5 A) in

the under-dash fuse/relay box.._ Grounds No. G101, G201, G202, G401, G4O2

- Cleanliness and tightness of all connectors

SymptomSse pags

Mode control motor does not run, or one or more modes are inoperative.

Recirculation control door does not change between Fresh and Recirculate.22-24

Radiator fan does not run at all (but condenser fan runs with the AVC on).

Condenser fan does not run at all {but radiator fan runs with the Ay'C on).22-29

Both fans (radiator and condenser) do not run for engine cooling. but they both run with the A,/C

on.

Both fans do not run with the Ay'C on22-33

Compressor clutch does not engage.22-34

AJC svstem does not come on (both fans and compressor).22-37

Both heater and A/C do not work,22-39

22-10

www.emanualpro.com