Eld HONDA CR-V 1999 RD1-RD3 / 1.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 1210 of 1395

Battery

Test

@M. Battery fluid (eleqtrolyte) contains sulturic acid. lt may couse sevore burns if it gets on your skin or in your eyes. Wearprotective clothing and a fac6 shield.- lf elestrolyte gets on your skin o. clothos, rinse it otf with wator imm€diately.- lf €leqtrolyte gets in your eyes. tlush it out by splashing water in your syes for at least 15 minutes; call a physicianimmediately.

. A battery gives off hydrogon gas. lf ignited, the hydrogen will €xplode and could crack the battery case and splatt€racid on you. Kgop sparks. flamss, and cigarettes away from the batt€ry,. Overcharging will raise the tomperatute of the electrolyte. This may torcs electrolyto to spray out of the battEry vents,Follow the charger manutacturer's instructions, and charge the battery at a proper ral€,

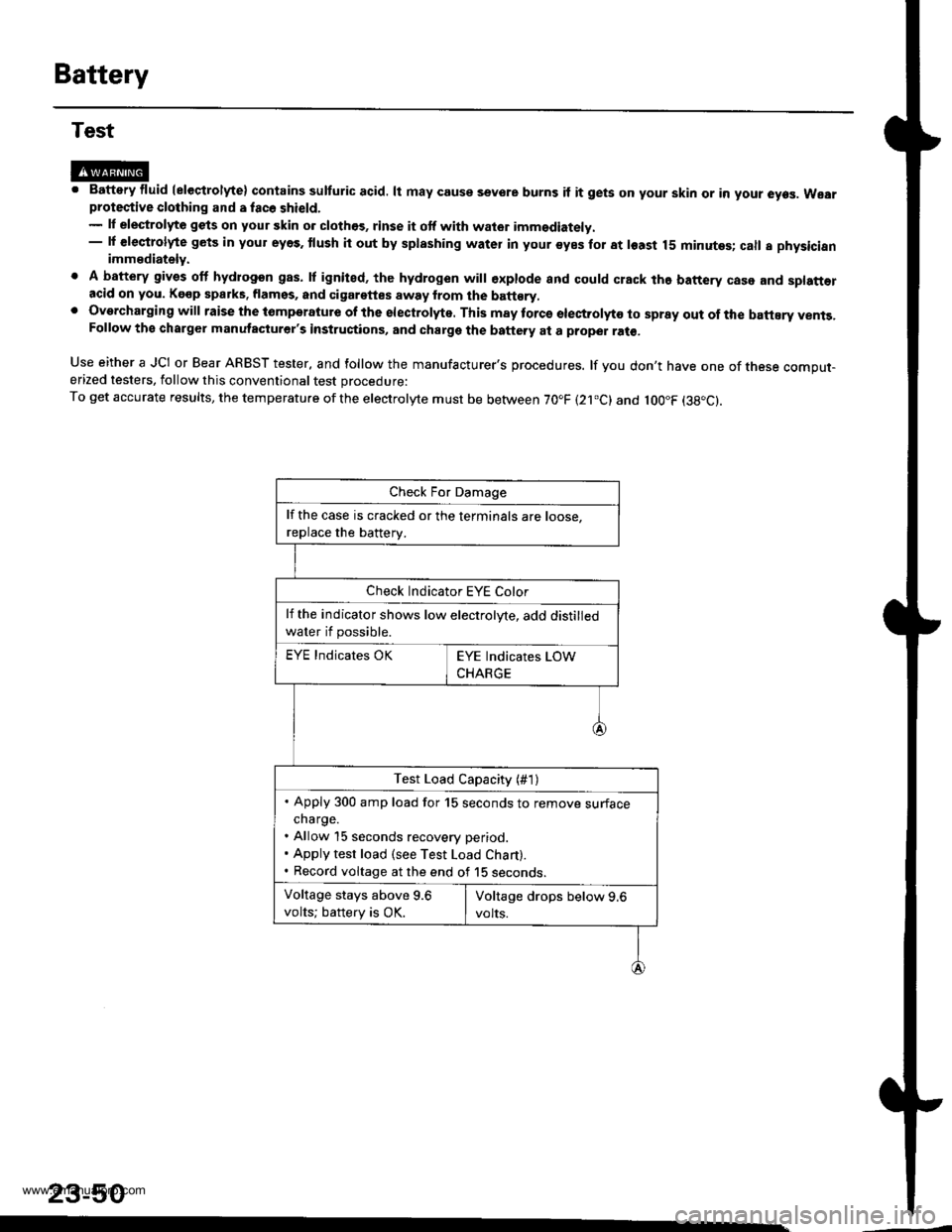

Use either a JCI or Bear ARBST tester, and follow the manufacturer's procedures. lf you don't have one of tnese comput-erized testers, follow this conventional test procedure:

To get accurate results, the temperature ofthe electrolyte must be between 70.F (21.c) and loo"F (38"c).

23-50

lf the case is cracked or the terminals are roose.

replace the batterv.

Check Indicator EYE Color

lf the indicator shows low electrolyte, add distilled

water if possible.

EYE Indicates OK

Test Load Capacity (#1)

. Apply 300 amp load for 15 seconds to remove surfacecharge.. Allow 15 seconds recovery period.. Apply test load (see Test Load Chart).. Record voltage at the end of 15 seconos.

Voltage stays above 9.6

volts; battery is OK.

www.emanualpro.com

Page 1224 of 1395

Integrated Gontrol Unit

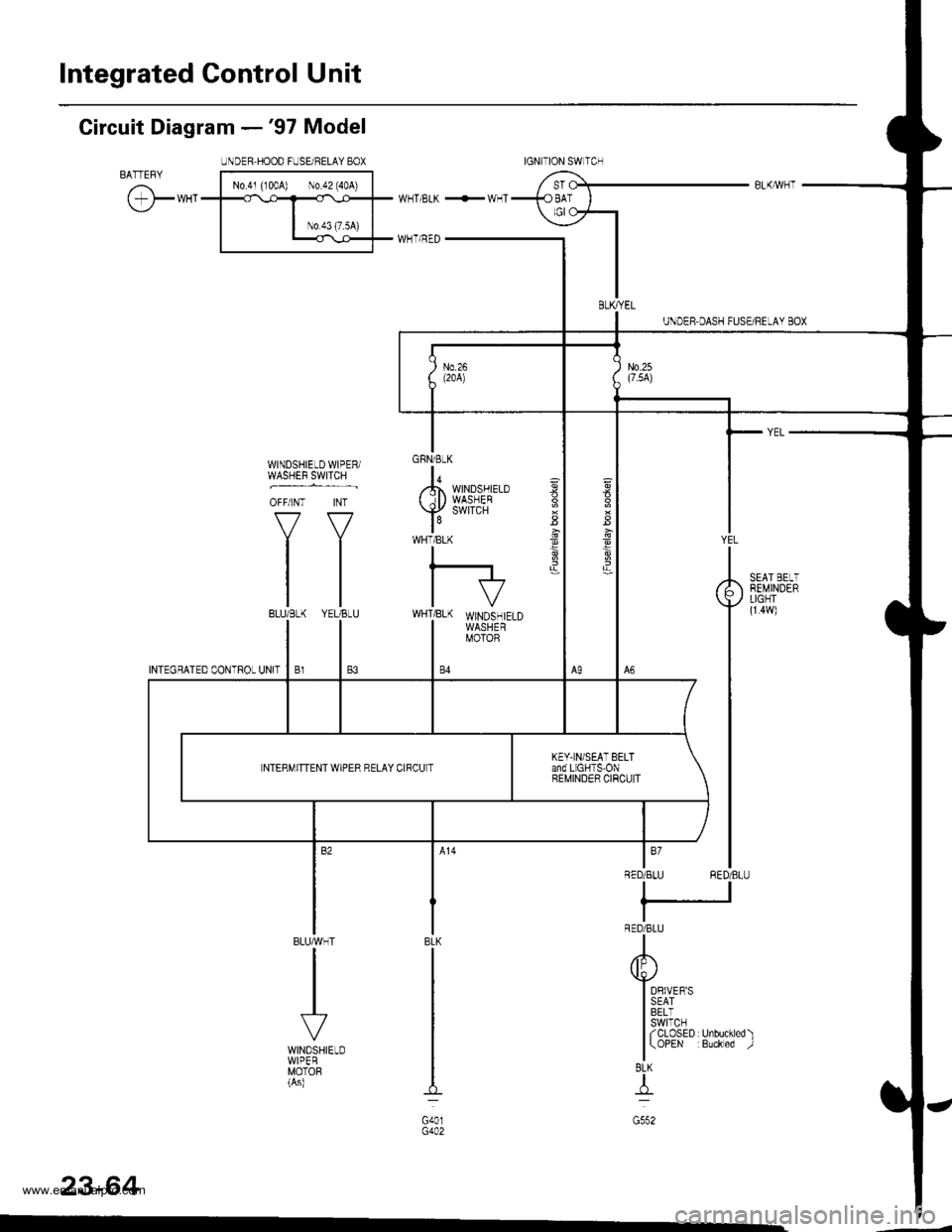

Circuit Diagram -'97 Model

UNDER.HOOD FUSEi RELAY 8OXBATTEFYI No.4' {'004) \0.d2'40A) |

cr*"

l__*l;;T

w_T ELK +!v_T

I H-uTr.r--i=r-

GFNi BLK

lo,,.h WINDSHIELD( il) WASHEB

Y

SWITCH

WHTiBLK

I

l-IVWHT]BLK WINDSHIELDI WASHERI MOTOB

WINDSHIELD WIPER/WASHEF 9WTTCH ,

OFF/INT INT

VV

tltltl

tl

BLUMHT

VWINDSHIELDWIPERMOTOR(As)

ag

3

YEL

RED/BLU

DRIVER'SSEATBELTswtTcHf CLOSED r Unbuckled )(OPEN :Buckled -.1

BEMINDEBLIGHT(r 4w)

BLK

G401

BL(I-tr-l

G552

23-64

tGNITtON SW lCrl

BLKryEL

KEY.IN/SEAT BELTand LIGHTS-ONBEMINDER CIRCUITNTERMITTENT WIPER RELAY CIRCUlT

www.emanualpro.com

Page 1226 of 1395

Integrated Control Unit

UNOER,HOOD FUSE/BELAY 8OX

N0.41 (100A) N0.42 (40A)

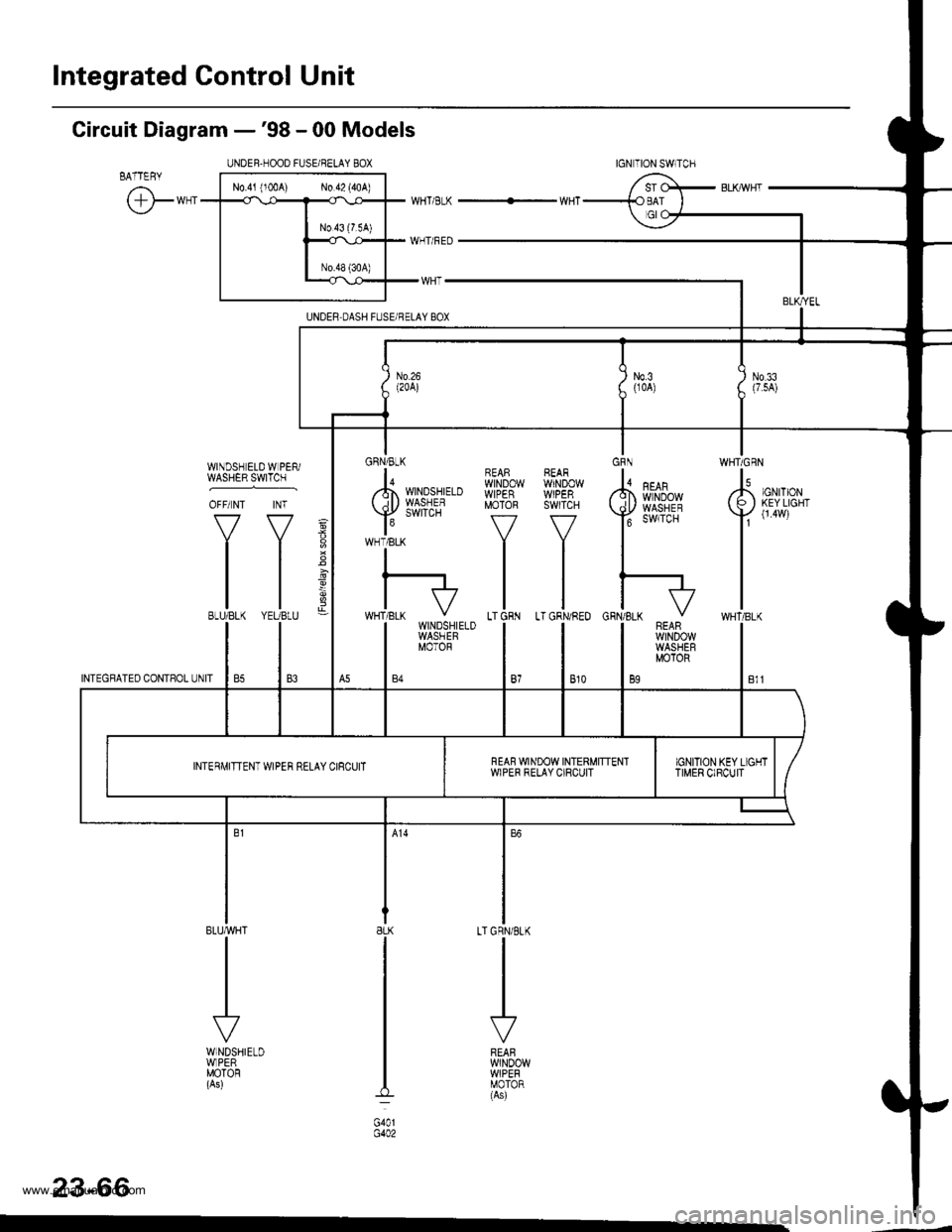

Circuit Diagram -'98 - 00 Models

EATTERY

@*"WHT/BLK -....+ WHT

WHT/RED

IJNDER DASH FUSEi BELAY BOX

WINDSH ELD W PER/gsHERlIrTcH .

OFF/ NT INT

f7 f7

tltl

tl

tlBLU/BLK YEUBLU

GRN/BLK

lo/.Fn WINDSHIELD( il) WASHEF

Y

SWITCH

WHT/BLK

REASWINDOWWIPERMOTOR

f7

ILT GRN

t,,

-9

INTEGFATED coNTsoL UNIT I 85 I 83

23-66

8LK

G401G402

WHT/BLKWINDSHIELDWASHEFMOTOR

INTERIT,IITTENT WIPER RELAY CIRCUITNEAF WINDOW INTERMITTENTWIPER RELAY CIRCUIT

www.emanualpro.com

Page 1229 of 1395

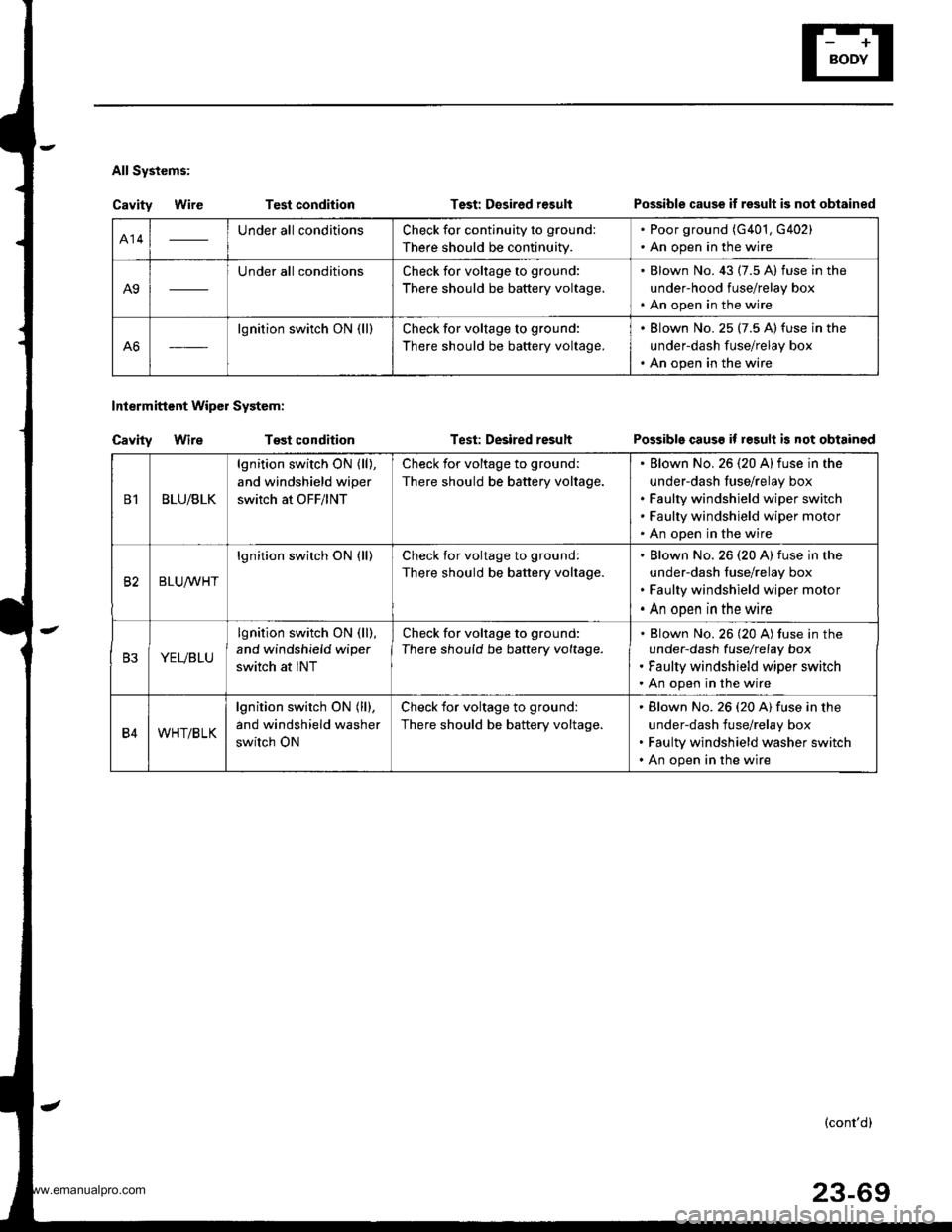

All Systems:

Cavity WireTest condition

Tost condition

Test: Desired r€sult

Test: Desired result

Intermittent Wipol System:

Cavity Wire

Possible cause if result is not obtained

Possible causs if result is not obtained

414Under all conditionsCheck for continuity to ground:

There should be continuity.

. Poor ground (G401, G402). An open in the wire

A9

Under all conditionsCheck for voltage to ground:

There should be battery voltage.

. Blown No. 43 (7.5 A) fuse in the

under-hood fuse/relay box. An open in the wire

A6

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

. Blown No. 25 (7.5 A)fuse in the

underdash fuse/relay box. An open in the wire

B1BLU/BLK

lgnition switch ON (ll),

and windshield wiper

switch at OFF/lNT

Check for voltage to ground:

There should be battery voltage.

Elown No. 26 (20 A)fuse in the

under-dash fuse/relay box

Faulty windshield wiper switch

Faulty windshield wiper motor

An open in the wire

82BLUrur'HT

lgnition switch ON (ll)Check for voltage to ground:

There should be battery voltage.

Blown No.26 (20 A) fuse in the

under-dash fuse/relay box

Faulty windshield wiper motor

An open in the wire

B3YEVBLU

lgnition switch ON (ll),

and windshield wipe.

switch at INT

Check for voltage to ground:

There should be battery voltage.Blown No. 26 (20 A) tuse in theunder-dash fuselrefay box

Faulty windshield wiper switch

An open in the wire

B4WHT/BLK

lgnition switch ON (ll),

and windshield washer

switch ON

Check for voltage to ground:

There should be battery voltage.

Blown No. 26 (20 A) fuse in the

under-dash fuse/relay box

Faulty windshield washer switch

An open in the wire

(cont'd)

23-69

www.emanualpro.com

Page 1274 of 1395

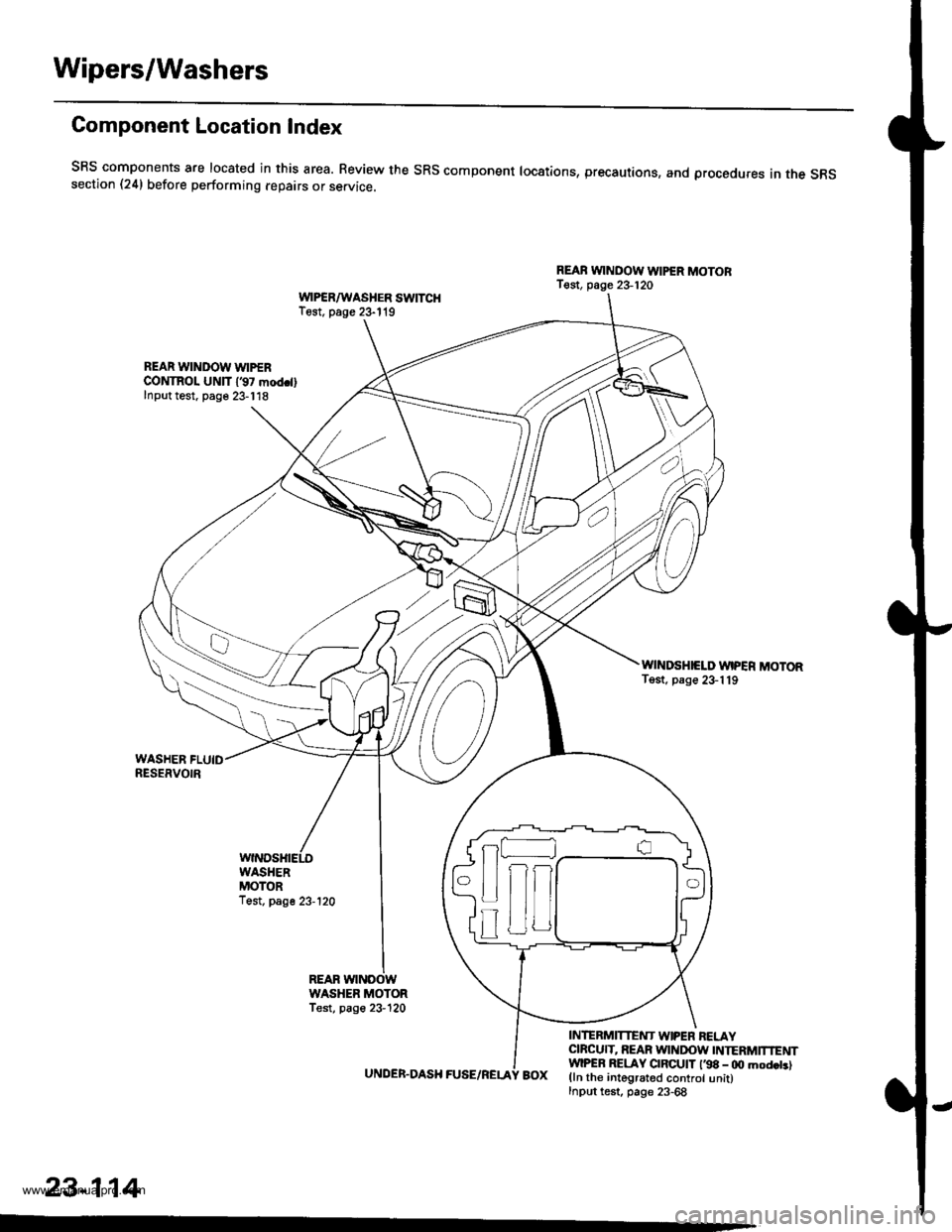

Wipers/Washers

Component Location Index

SRS components are located in this area. Review the SRs component locations, precautions, and procedures in the s6ssection (24) before performing repairs or service.

REAB WINDOW WIPER MOTOBT€st, page 23-120WPSR/WASHER SWITCHTest. page 23- l't9

REAR WINDOW WIPERCONTROL UNlT 137 mod.llInput test. page 23-118

WINDSHIELD WIPER MOTORTost, page 23-119

UNDER.DASH FUSE/RELA

INTERMITTENT W|PEN RELAYCIBCUIT, REAR WINDOW INTERMTNENTwlPER RELAY CIBCUIT l'98 - 0O mod.t.lBOX (ln the integrated control unit)Input test, page 23-68

23-114

-

n

tff

www.emanualpro.com

Page 1275 of 1395

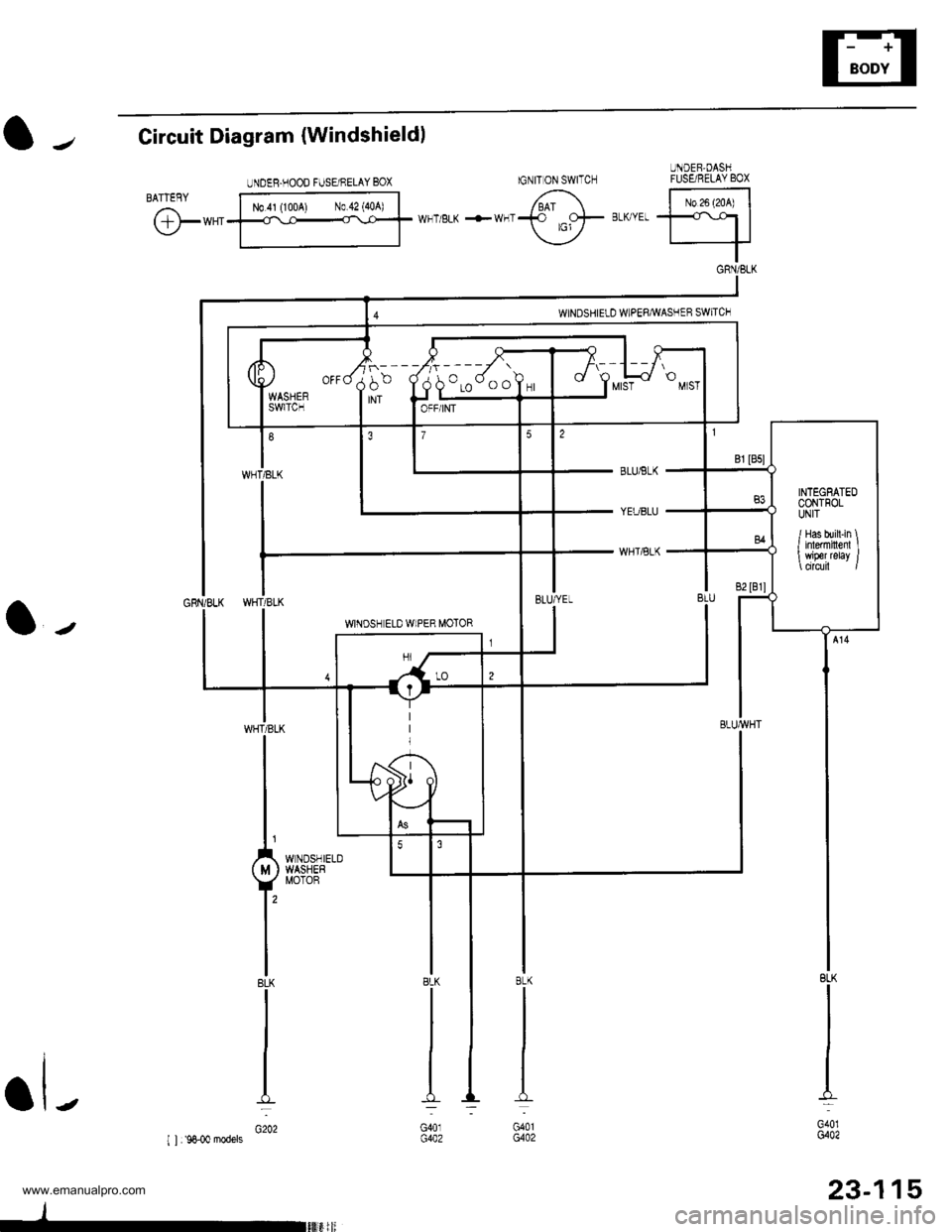

UNDEB,DASHFUSENELAY BOXIGNITON SWITCH

l-Circuit Diagram {Windshieldl

@*"

BLUiBLK

YEUBLU

WHTiBLK

l-

BLK

I

I

I

I_L

G401G402

23-115

8LK

G401G402

BLK

G401G402

UNDEB.HOOD FUSE/NELAY BOX

N0.41 (1004) N0.42 {40A)

INTEGEATEDCONTFOLUNIT

/ Has bui[-in \I inlermiltenl I wiper relay /

www.emanualpro.com

Page 1279 of 1395

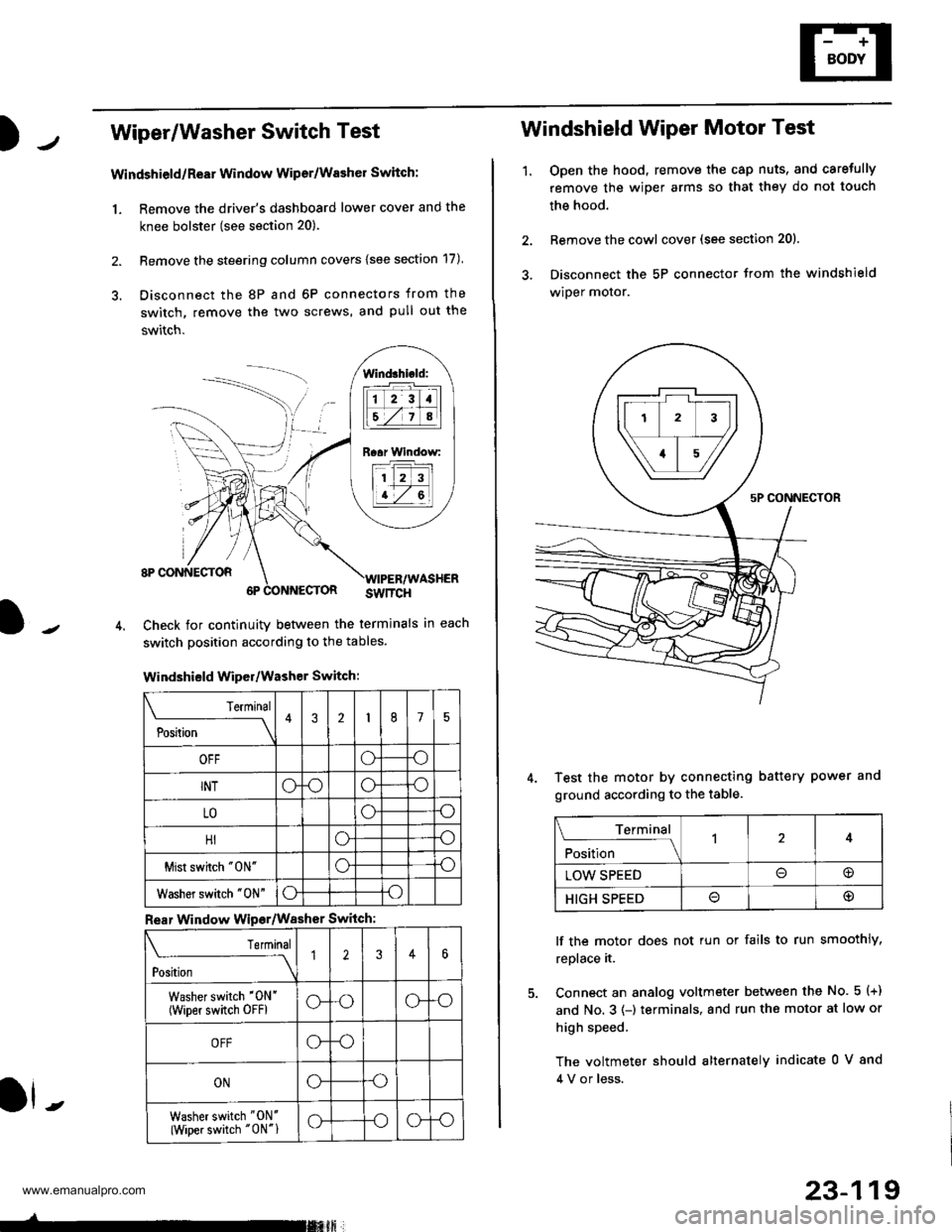

Wiper/Washer Switch Test

Windshield/ReEr Window Wiper/Washer Switch:

1. Remove the driver's dashboard lower cover and the

knee bolster (see section 20).

2. Remove the steering column covers {see section 17)

3. Disconnect the 8P and 6P connectors from the

switch, remove the two screws, and pull out the

switch.

J-

lind3hi.ld:

tilt-rltl

IEZIA

Raar Window:

11 2 3

I t-7 al

ll -

Check for continuity betlveen the termlnals in each

switch position according to the tables.

Windshield Wiper/Washer Switch:

Terminal

P*t-

---__\432175

OFFoo

INToooo

LOoo

HIoo

Mist swhch "0N"oo

Washer switch "0N"oo

Rear Window Wipsr/Washer Switch

Teminal

ti'"

---\12346

Washer switch '0N'

(wiper switch oFFlG-oG-o

OFFG-o

ONGo

Washer switch "ON'

(Wiper switch "0N"1G-oG-o

-rmxft

23-119

1.

Windshield Wiper Motor Test

Open the hood, remove the cap nuts, and caretully

remove the wiper arms so that they do not touch

the hood.

Remove the cowl cover (see section 201.

Disconnect the 5P connector trom the windshield

wiper motor.

Test the motor by connecting battery power and

ground according to the table.

lf the motor does not tun or fails to run smoothly,

replace it.

Connect an analog voltmeter between the No. 5 (+)

and No. 3 (-) terminals, and run the motor at low or

high speed.

The voltmeter should alternately indicate 0 V 8nd

4 V or less.

Terminal

;fi;"

-l4

LOW SPEED@

HIGH SPEED@

www.emanualpro.com

Page 1317 of 1395

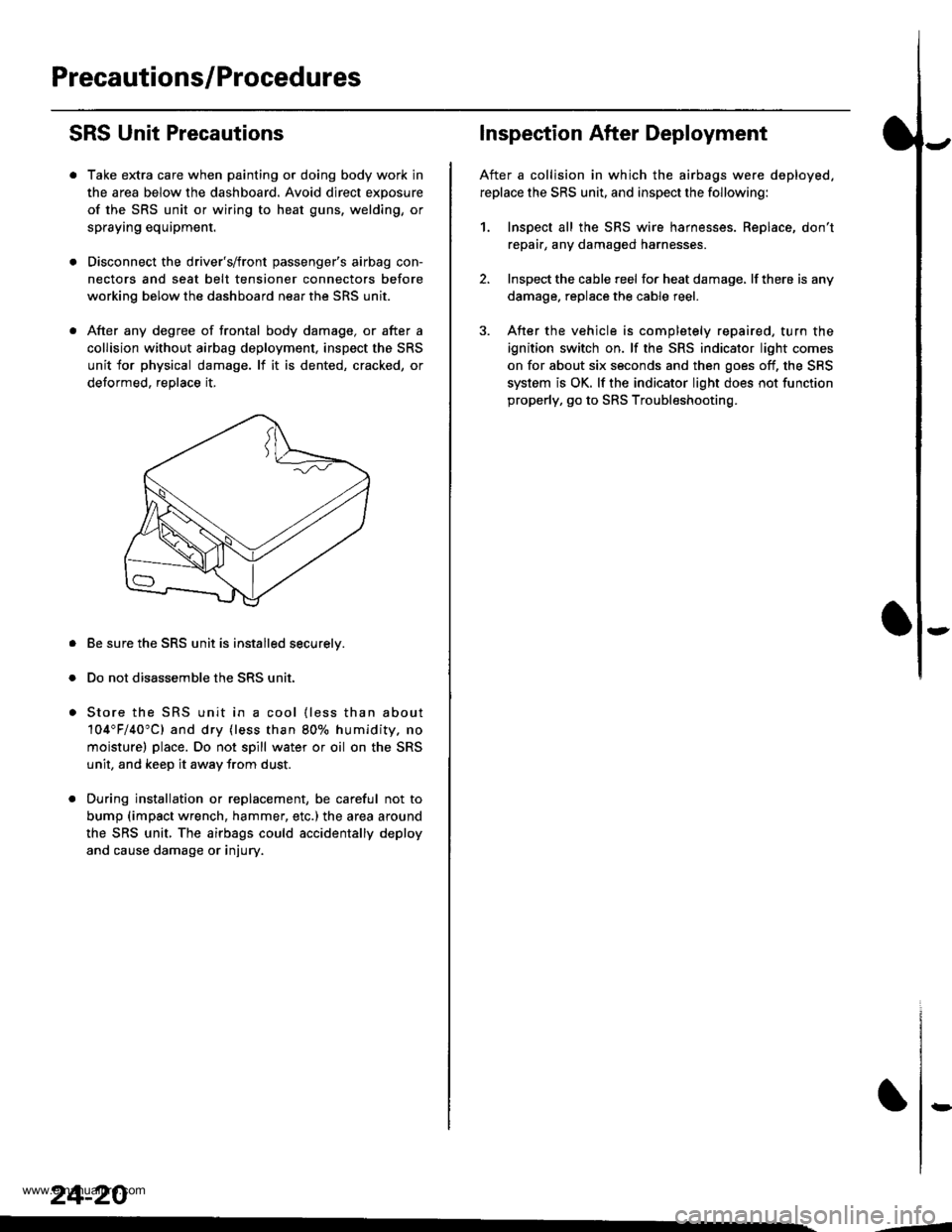

Precautions/Procedures

SRS Unit Precautions

Take extra care when painting or doing body work in

the area below the dashboard. Avoid direct exposure

of the SRS unit or wiring to heat guns, welding, or

spraying equipment.

Disconnect the driver's/front passenger's airbag con-

nectors and seat belt tensioner connectors before

working below the dashboard near the SRS unit.

After any degree of frontal body damage, or after a

collision without airbag deployment, inspect the SRS

unit for physical damage. lf it is dented, cracked, or

detormed, reolace it,

Be sure the SRS unit is installed securelv.

Do not disassemble the SRS unit.

Store the SRS unit in a cool {less than about

104"F/40"C) and dry {less than 80o/o humidity. no

moisture) place. Do not spill water or oil on the SRS

unit, and keep it awav from dust.

During installation or replacement, be careful not to

bump (impact wrench, hammer, etc.) the area a[ound

the SRS unit, The airbags could accidentally deploy

and cause damage or injury.

24-20

,..4

Inspection After Deployment

After a collision in which the airbags were deployed.

replace the SRS unit, and inspect the following:

1. Inspect all the SRS wire harnesses. Replace, don't

repair, any damaged harnesses

2. Inspect the cable reel for heat damage, lf there is any

damage. replace the cable reel.

3. After the vehicle is completely repaired, turn the

ignition switch on. lf the SRS indicator light comes

on for about six seconds and then goes off, the SRS

system is OK. lf the indicator light does not function

properly, go to SRS Troubleshooting.

rD

www.emanualpro.com

Page 1395 of 1395

Airbag/Seat Belt Tensioner

1.

Disposal (cont'dl

Connect a 12 volt battery to the tool'

. It the green light on the tool comes on, the air-

bag igniter circuit is defective and cannot deploy

the airbag. Go to Damaged Airbag Special

Procedure.

.lftheredlightonthetool comes on, the airbag is

ready to be deployed.

Push the tool's deployment switch. The airbag

should deploy (deployment is both highly audible

and visible; a loud noise and rapid inflation of the

bag, followed by slow deflation).

. lf the airbags deploy and the green light on the

tool comes on, continue with this procedure.

. lf an airbag doesn't deploy, yet the green light

comes ON, its igniter is defective. Go to Dam-

aged Airbag Special Procedure.

. During deployment, the airbag can become hot

enough to burn you, Wait thirty minutes after

deployment before touching the airbag.

Dispose of the complete airbag. No part of it can be

reused. Place it in a sturdy plastic bag, and seal it

securety.

CAUTION:

. Wear a faco shield and gloves when handling a

deployed airbag.

. Wash your hands and rinse them well with

water after handling a deployed airbag.

24-98

Deploying tho Airbag: Out-ot.vohicle

lf an intact airbag has been removed from a scrapped

vehicle, or has been found defective or damagsd during

transit. storage or seryice, it should be deployed as fol-

lows:

'L Confirm that the special tool is functioning properly

by following the check procedure on this page or on

the tool label.

2. Position the airbag face up, outdoors on flat ground

at least thirty feet (10 m) from any obstacles or peo-

Dte,

3. Follow steps 6, 7, 8. and 9 of the in-vehicle deploy-

ment proceoure.

Dlmaged Airbsg {or Seat Beh Ten3ion6r} Sp6cial

Procgdure

!@ r an airbag {or seat Beh rensioner} cannol

be doployod, it should not be treated as normal scrap; it

should still be considered a pot€ntially explosive device

lhat can cause serious iniury.

1. lf installed in a vehicle. follow the removal proce-

dure on page 24-3 and 24-87 through 90.

2. In all cases, make a short circuit by twisting together

the two airbag inflator wires.

3. Package the airbag in exactly the same packaging

that the new reDlacement Dart came in.

4. Mark the outside of the box "DAMAGED AIRBAG

{or TENSIONER) NOT DEPLOYED" so it does not

get confused with your parts stock.5. Contact your Honda District Service Manager forhow and where to return it for disposal.

Deployment Tool: Check Procedure

Connect the yellow clips to both switch protector

handles on the tool; connect the tool to a battery.

Push the operation switch: green means the tool is

OK: red means the tool is faultv.

Disconnect the baftery and the yellow clips.

I

t

l.

www.emanualpro.com