Valve HONDA CR-V 1999 RD1-RD3 / 1.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 352 of 1395

ldle Control System

ldle Control System

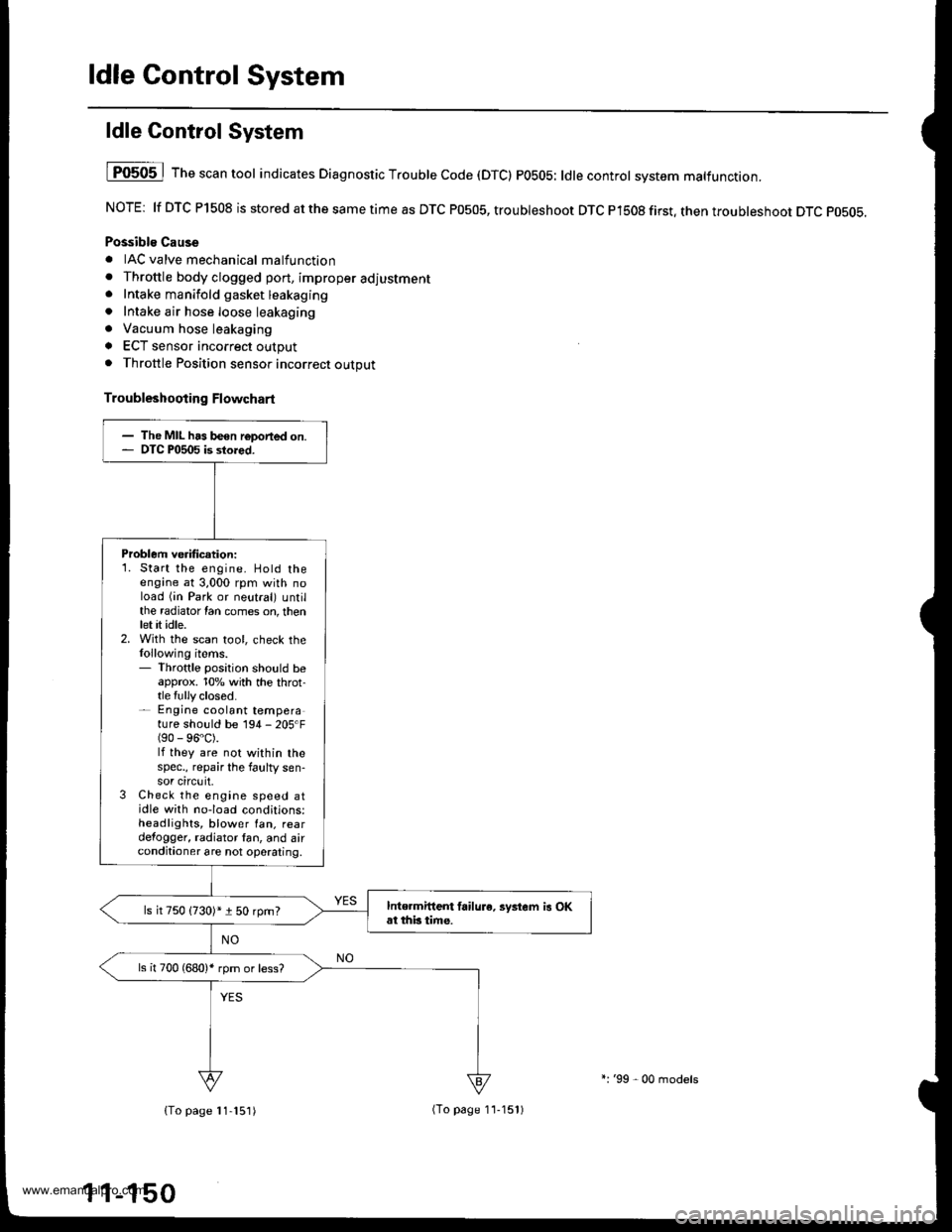

I P0505 | The scan tool indicates Diagnostic T.ouble Code (DTCI PO5O5: ldlecontrol svstem mattunction.

NOTE: lf DTC P1508 is stored at the same time as DTC P0505, troubleshoot DTC P1508 first. then troubleshoot DTC p0505.

Possibls Cause

. IAC valve mechanical malfunction. Throttle body clogged port, improper adlustment. Intake manifold gasket leakaging. Intake air hose loose leakaging. Vacuum hose leakaging

a ECT sensor incorrect output. Throttle Position sensor incorrect output

Troubleshooting Flowchart

The MIL has been reDorted on.DTC P0505 is sto.ed.

Problem verificationi1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator Ian comes on, thenlet it idle.2. With the scan tool, check thelollowing items.- Throttle position should beapprox. 10% with the throt-tle {ully closed.- Engine coolant temperature shorJld be 194 - 205'F(90 - 96"C).lf they are not within thespec., repair the faulty sen-sor circuit.3 Check the engine speed atidle with no-load conditions:headlights, blower fan. reardefogger, radiator lan, and airconditioner are not operaling,

Inte.mittent failure. syltem is OKat this time.ls it 750 {730)* i 50 rpm?

ls il 700 (680)' rpm or less?

{To page 11-151)(To page 1'l-151)

l:'99 - 00 models

www.emanualpro.com

Page 353 of 1395

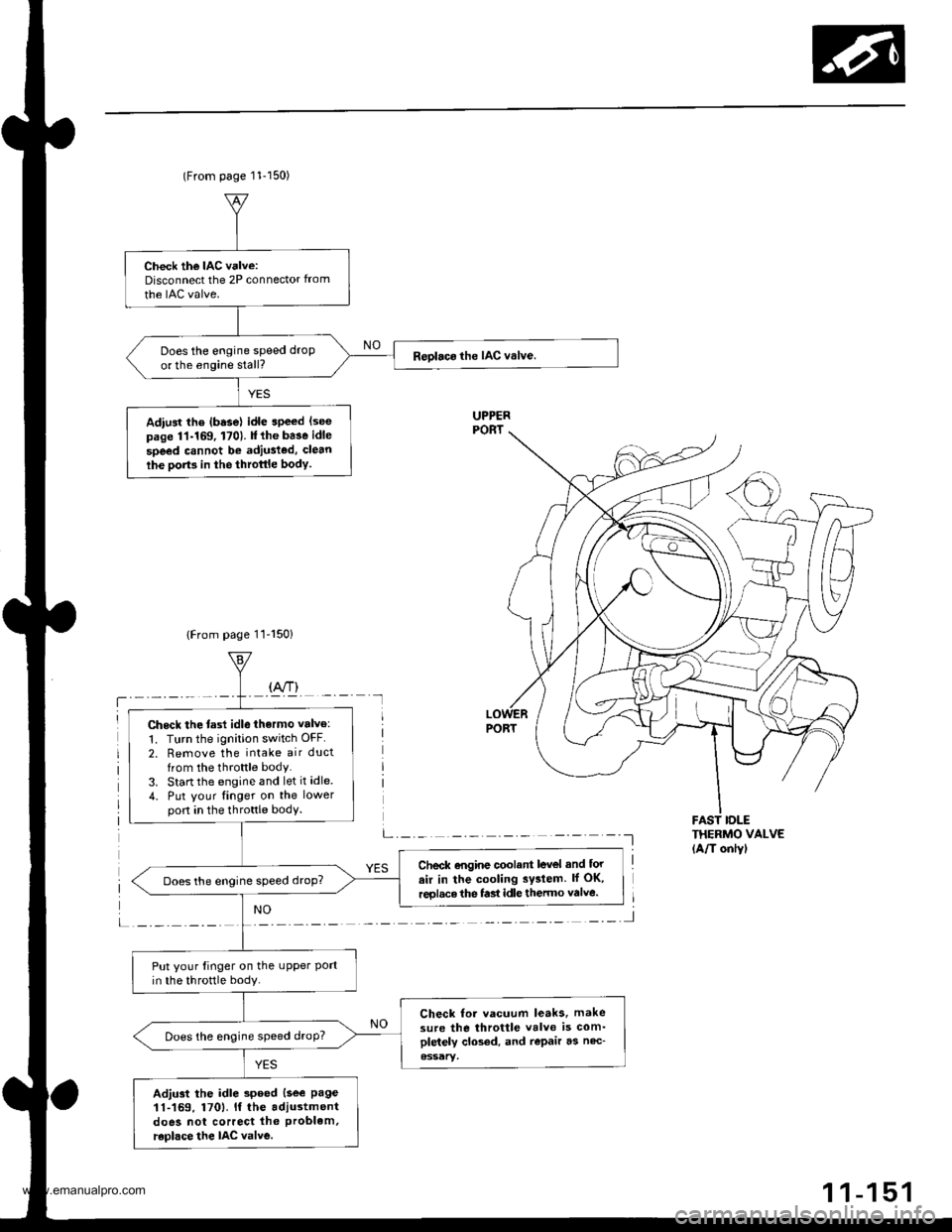

(From page 11-150)

{From page 11-150}

THERMO VALVE(A/T onlyl

Check the IAC valve:Disconnect the 2P connector from

the IAC valve.

Does the engine speed droP

or the engine stall?

Adiust the (basel idl€ speed lseepage 11-169, 1t0). Itihe ba3e idle

speed cannot be adiust€d, clean

the Dorts in the throttle body.

UPPER

Check the tast idle lhermo valve:

1. Turn the ignition switch OFF.

2. Remove the intake air ductfrom the throttle body.3. Start the engine and let it idle.

4. Put your finger on the lowerpon in the throttle body.

Check engine cool.nt level and for

air in the cooling sy3lem. lf OK,

reolace the f.st idle thermo valve.Does the engine speed drop?

Put your Iinger on the uPPer Portin the throttle body.

Check for vacuum leaks, make

sure the throttle valve is com'pletely clo3ed. and repair as nec-Does the engine speed droP?

Adjust the idle spoed lsee Page11-169. 1701. lf the adiustmentdoes not correct lhe problem,

r.olace the IAC valve.

www.emanualpro.com

Page 354 of 1395

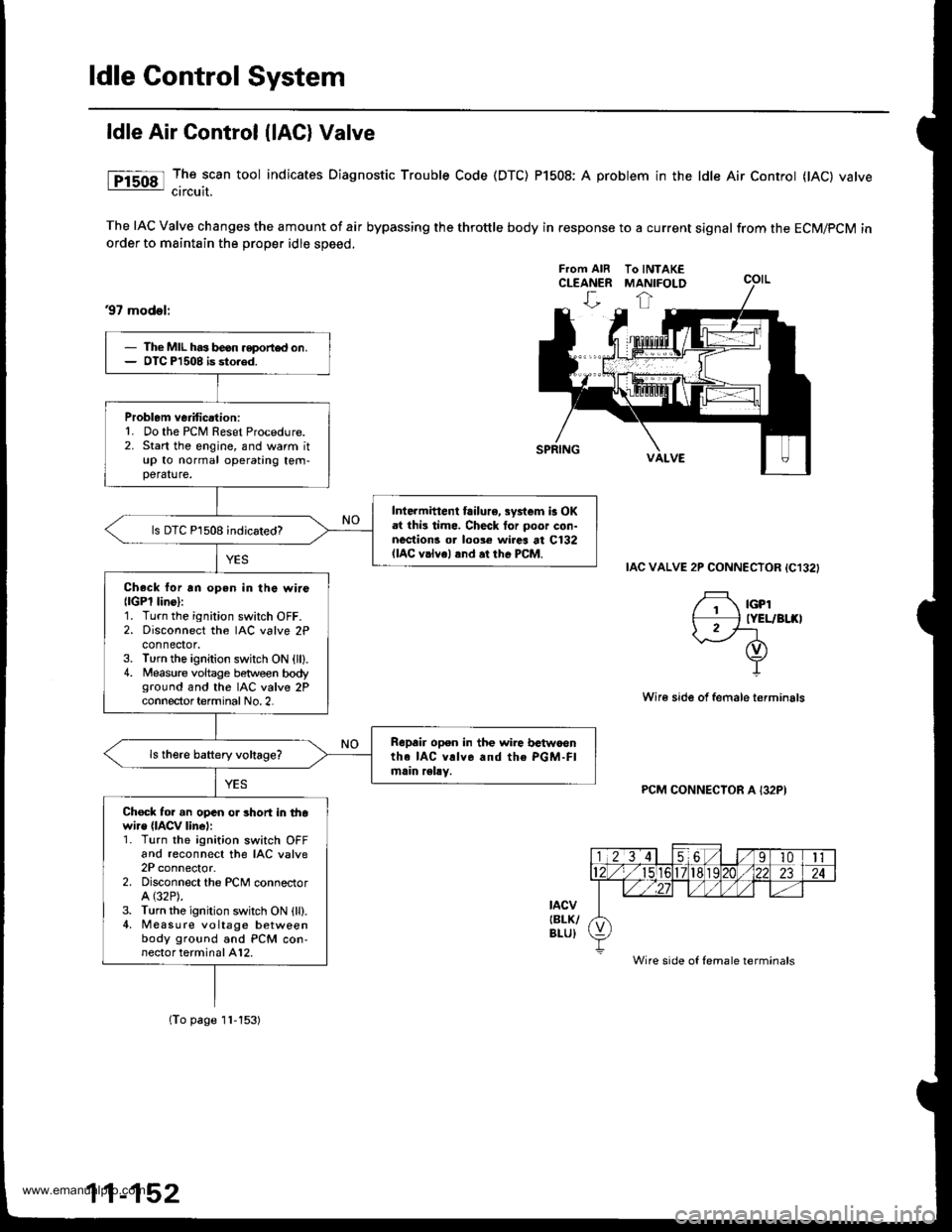

ldle Control System

ldle Air Control llAC) Valve

The scan tool indicates Diagnostic Trouble Code (DTC) Pl508: A probtem in the ldle Air Controt flAC) varvecircuit.

The IAC Valve changes the amount of air bypassing the throttle body in response to a current signal from the ECM/PCM inorder to maintain the proper idle speed.

37 model;

IAC VALVE 2P CONNECTOR {C132}

,f rcp'# IYEL/BI.(II2f-1-d)

Y

Wir€ side of female terminals

PCM CONNECTOR A I32PI

tacvIBLK/BLU)

From AIR To INTAKECLEANER MANIFOLD

Wire side of female terminals

The MIL has beon .eport€d on.OIC Pl508 is sto.ed.

Problem veiification:1. Do the PCM Reset Procedure.2. Start the engine, and warm itup to normal operating tem-perature.

Inte.mittent failure, systcm b OKat thi3 time. Check tor poo. con-nections or loose wircs at C132(lAC v.lvel and at the PCM.

ls DTC Pl508 indicated?

Check lor an open in the wir6{lGPl lins}:1. Turn the ignition switch OFF.2. Disconnect the IAC valve 2Pconnector.3. Turn the ignition switch ON {ll).4. Measure voltage between bodyground and the IAC valve 2Pconnector term inal No.2.

Repair open in the wire trctwoontha IAC v!lv6 and the PGM-Flmain relly.

Chock for an opan o. short in thowi.e (lACv linel:1. Turn the ignition switch OFFand reconnect the IAC valve2P connector.2. Disconnect the PCM conneclorA (32P).

3. Turn the ignition switch ON {ll).4, Measure voltage betweenbody ground and PCM con-nector terminal A12.

{To page 1l-153)

www.emanualpro.com

Page 355 of 1395

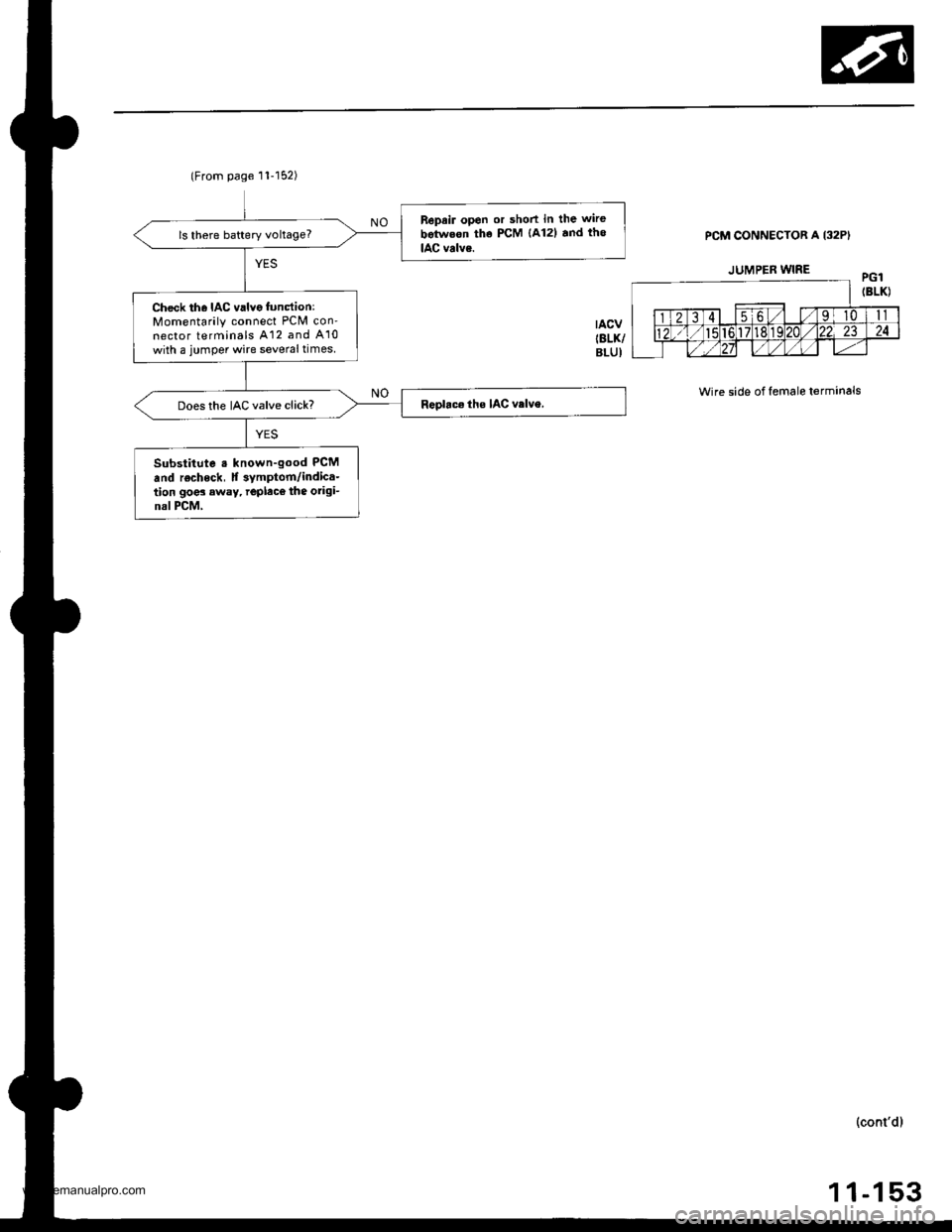

Bepair op€n or short in the wire

betweon th€ PCM {A121 and the

IAC vrlve.ls there baftery voltage?

Check the IAC valve function:Momentarily connect PCM con'nector terminals A12 and A10with a iumoer wire severaltimes,

Does the IAC valve click?

Substitute . known-good PCM

and r€check, lt 3ymptom/indica-tion goes away, replaco the origi_nalPCM,

(From page 11-152)

Wire side of female terminals

1-153

www.emanualpro.com

Page 356 of 1395

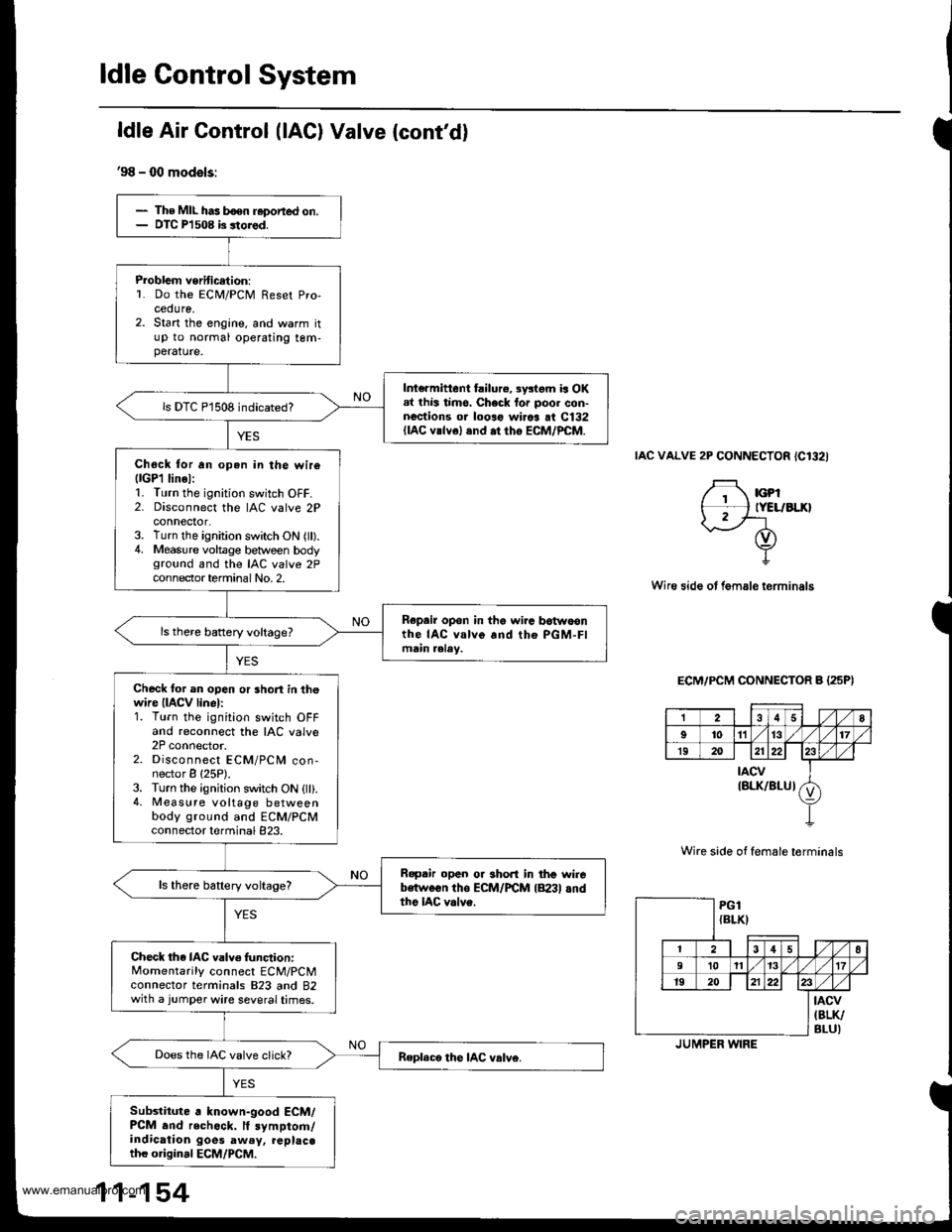

The MIL has boen r.ported on.DIC Pl 508 b 3tored.

Problem veritication:L Do the ECM/PCM Reset Pro-cedure.2. Start the engine, and warm itup to normal operating tem-perature.

Int€rmittent failure, systom is OKal lhis timo. Check lor poor con-nections or looro wirca at C132(lAc vrlvel and .t rho EcM/PcM.

ls DTC P1508 indicated?

Chock tor an open in the wir6llGPl linel:1. Turn the ignition switch OFF.2. Disconnect the IAC valve 2Pconnector,3. Turn the ignition switch ON (ll).4. Measure voltage between bodyground and the IAC valve 2Pcon nector termina I No, 2.

Repair opon in the wira botwoonthe IAC valve and tho PGM-FImain aalay.

Check tor an open or short in thewire (IACV linel:1. Turn the ignition switch OFFand reconnect the IAC valve2P connector.2. Disconnect ECM/PCM con-nector B {25P).3. Turn the ignition switch ON {ll}.4. Measure voltage betweenbody ground and ECM/PCMconnector terminal 823.

Ropair open or short in thg wirebetween tho ECM/FCM lB23l andthe IAC valve.

ls there battery voltage?

Check the IAC valve func,tion:Momentarily connect ECM/PCMconnector terminals 823 and 82with a jumper wire several times.

Does the IAC valve click?

Subslitute . known-good ECM/PCM .nd rechock. lf symptom/indication goes aw.y, replac.th€ original ECM/PCM.

ldle Air Control (lAC) Valve {cont'd}

'98 - 00 models:

IAC VALVE 2P CONNECTOR {C132I

F rcpt*l tYELrBLxlI2/'-- rf)

Y

Wire side ot fem.le terminals

ECM/PCM CONNECTOR B (25PI

Wire side of female torminals

258

9'to1l13t7

1920212223

tAcv(BLK/BLUIv

PG1{BLKI

12 | t3 4 58

910 111317

1920 | 121)22

tAcv(BLK/

BLU)JUMPER WIRE

www.emanualpro.com

Page 370 of 1395

ldle Control System

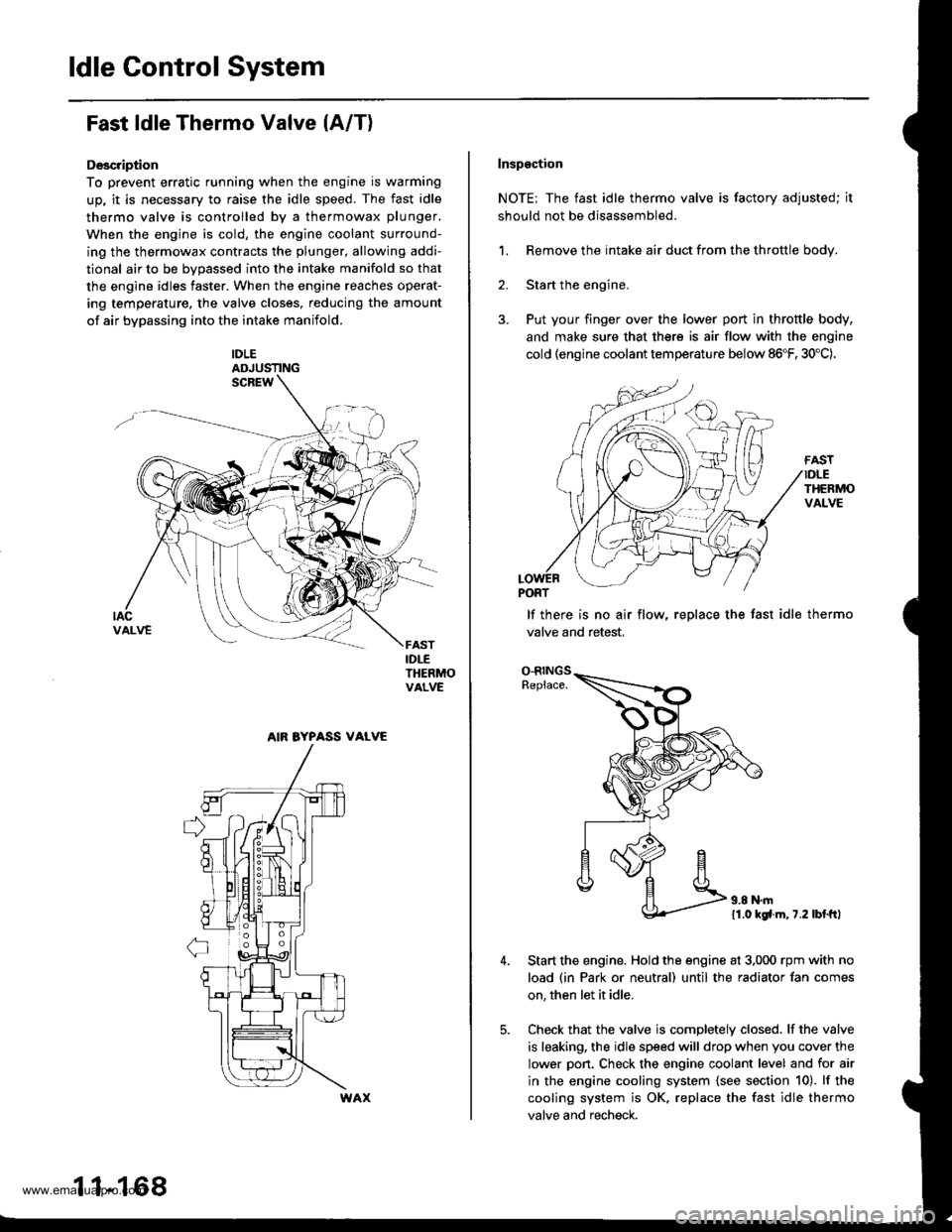

Fast ldle Thermo Valve lA/T)

Description

To prevent erratic running when the engine is warming

up, it is necessary to raise the idle speed. The fast idle

thermo valve is controlled by a thermowax plunger.

When the engine is cold, the engine coolant surround-

ing the thermowax contracts the plunger, allowing addi-

tional air to be bvDassed into the intake manifold so that

the engine idles faster. When the engine reaches operat-

ing temperature. the valve closes, reducing the amount

of air bypassing into the intake manifold.

IDLEADJUSTING

IDLETHERMOVALVE

AIR BYPASS VALVE

11-168

Inspgction

NOTE: The fast idle thermo valve is factory adjusted; it

should not be disassembled.

1. Remove the intake air duct from the throttle body.

2. Start the engine,

3. Put your finger over the lower port in throttle body,

and make sure that there is air flow with the engine

cold (engine coolant temperature below 86"F, 30'C).

lf there is no air flow, replace the fast idle thermo

valve and retest,

O-RINGSReplace.

11.0 kgfl.m, 7.2 lbl.ftl

Start the engine. Hold the engine at 3,000 rpm with no

load (in Park or neutral) until the radiator fan comes

on, then let it idle.

Check that the valve is completely closed. lf the valve

is leaking, the idle speed will drop when you cover the

lower pon. Check the engine coolant level and for air

in the engine cooling system {see section 10). lf the

cooling system is OK, replace the fast idle thermo

valve and recheck.

www.emanualpro.com

Page 371 of 1395

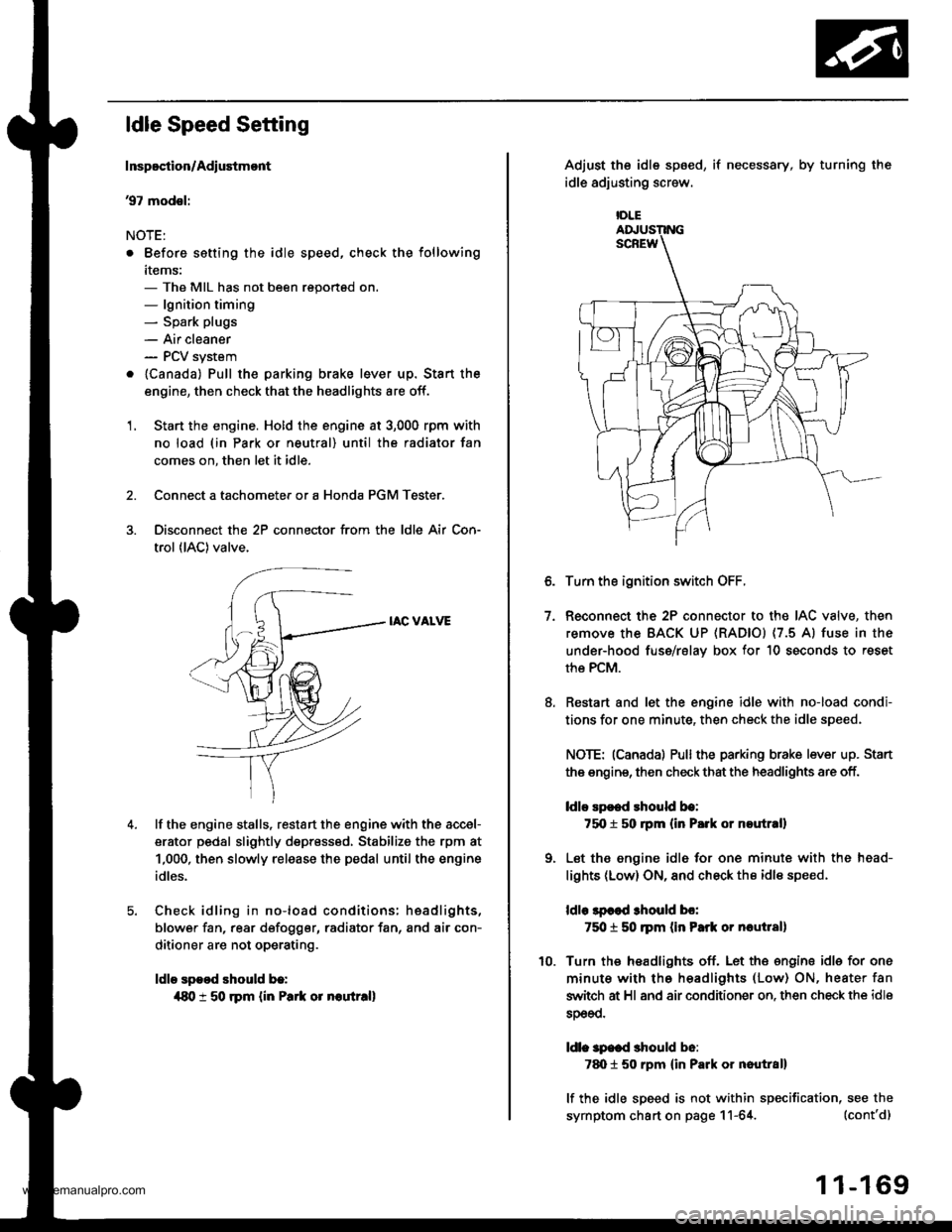

ldle Speed Setting

Inspoction/Adiustmont

37 modsl:

NOTE:

. Before setting the idle speed, check the following

items:- The MIL has not been reportsd on.- lgnition timing- Spark plugs

- Air cleaner- PCV system

. lcanada) Pull the parking brake lever up. Stan the

engine, then check that the headlights are off.

1. Start the engine. Hold the engine at 3,000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Connect a tachometer or a Honda PGM Tester.

Disconnect the 2P connector from the ldle Air Con-

trol (lAC) valve.

IAC VALVE

lf the engine stalls, restart the engine with the accel-

erator pedal slightly depr6ss6d, Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Check idling in no-load conditions: hsadlights,

blower fan, rear d€fogger, radiator fan, and air con-

ditioner are not operating.

ldle spood should b.:

{80 t 50 rpm {in Park or noutr.ll

IDLE

7.

Adjust the idle sp6ed,

idle adjusting screw.

if necessary, by turning the

Turn the ignition switch OFF.

Reconnect the 2P connector to the IAC valve, then

remove the BACK UP (RAD|Ol (7.5 Al fuse in the

under-hood fuse/rslav box for 10 seconds to reset

the PCM.

Restart and let the engine idle with no-load condi-

tions for one minute, then check the idle speed.

NOTE: (Canadal Pullthe parking brake lever up. Stan

the engine, then check that the headlights are off.

ldlo Ep€ed rhould be:

75O t 50 rpm (in P.rk or noutr.ll

Let the engine idl6 for one minute with the head-

lights (Low) ON, and check th€ idl€ speed.

ldle lpcod 3hould bo:

750 t 50 ]pm (in Park or nautlal)

Turn the headlights off. Let th€ engine idle for one

minute with the headlights (Low) ON, heater fan

switch at Hl and air conditioner on. then check the idle

sDeeo.

ldl. specd should b6:

7d) 1 50 rpm {in Park or nautral}

lf the idle speed is not within specification, see the

symptom chart on page 11-64. (cont'd)

1 1-169

www.emanualpro.com

Page 372 of 1395

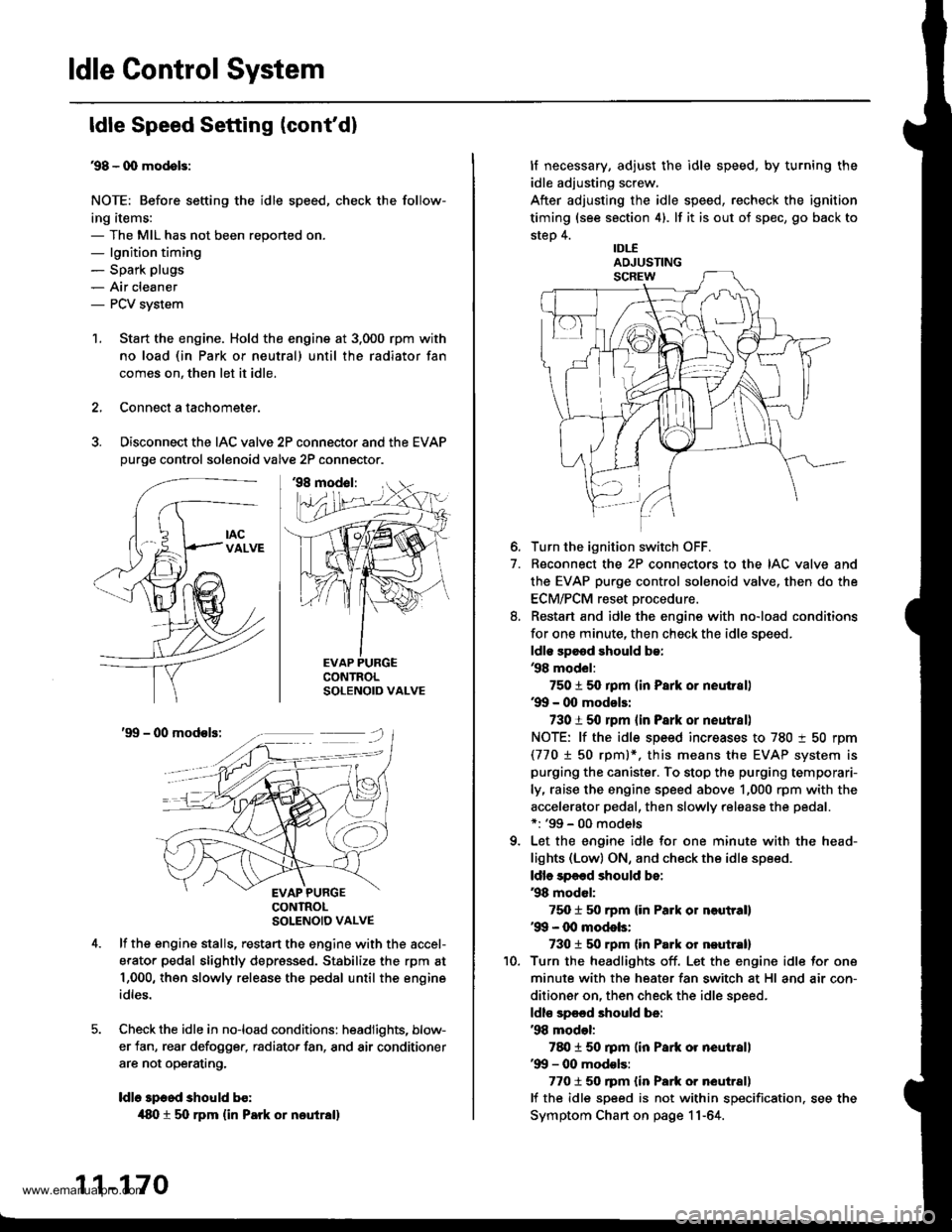

ldle Control System

ldle Speed Setting (cont'd)

38 - 0O mod6l3:

NOTE: Before setting the idle speed, check the follow-

ing items:- The MIL has not been reported on.- lgnition timing- Spark plugs

- Air cleaner- PCV system

1. Start the engine. Hold the engine at 3.000 rpm with

no load (in Park or neutral) until the radiator fan

comes on, then let it idle.

Connect a tachometer.

Disconnect the IAC valve 2P connector and the EVAP

purge control solenoid valve 2P connector.

CONTROLSOLENOID VALVE

SOLENOID VALVE

lf the engine stalls, restart the engine with the accel-

erato. pedal slightly depressed. Stabilize the rpm at

1,000, then slowly release the pedal until the engine

idles.

Che€k the idle in no-load conditions: headlights, blow-

er fan, rear defogger, radiator fan, and air conditioner

are not operating,

ldle speed should bo:

480 t 50 rpm {in PErk or noutrall

11-170

lf necessary, adjust the idle speed, by turning the

idle adjusting screw.

After adjusting the idle speed, recheck the ignition

timing (see section 4). lf it is out of spec, go back to

steo 4.tDt.E

6. Turn the ignition switch OFF.

7. Reconnect the 2P connectors to the IAC valve and

the EVAP purge control solenoid valve, then do the

ECM/PCM reset procedure.

8. Restart and idle the engine with no-load conditions

for one minute, then check the idle speed.

ldle speod should be:,98 model:

750 t 50 rpm tin Park or neutral)'9!l - 00 modsls:

730 i 50 lpm lin Psrk or neutral)

NOTE: lf the idle speed increases to 780 t 50 rpm(770 1 50 rpml*, this means the EVAP system is

purging the canister. To stop the purging temporari-

ly, raise the engine speed above 1,000 rpm with the

accelerator pedal, then slowly release the pedal.*: '99 - 00 models

9. Let the engine idle for one minute with the head-

lights (Low) ON, and check the idle speed.

ldle speed should be:

38 mod6l:

750 f 50 rpm (in Palk or neutrall'99 - 00 modols:

730 t 50 rpm (in Palk or neutral)

10. Turn the headlights off. Let the engine idle for one

minute with the heater fan switch at Hl and air con-

ditioner on, then check the idle speed.

ldls spqed should be:'98 model:

780 t 50 rpm (in Park or neutrall'99 - 00 mod€ls:

7701 50 rpm lin Park or neutral)

lf the idle speed is not within specification. see the

Symptom Chart on page 11-64.

ADJUSTING

www.emanualpro.com

Page 381 of 1395

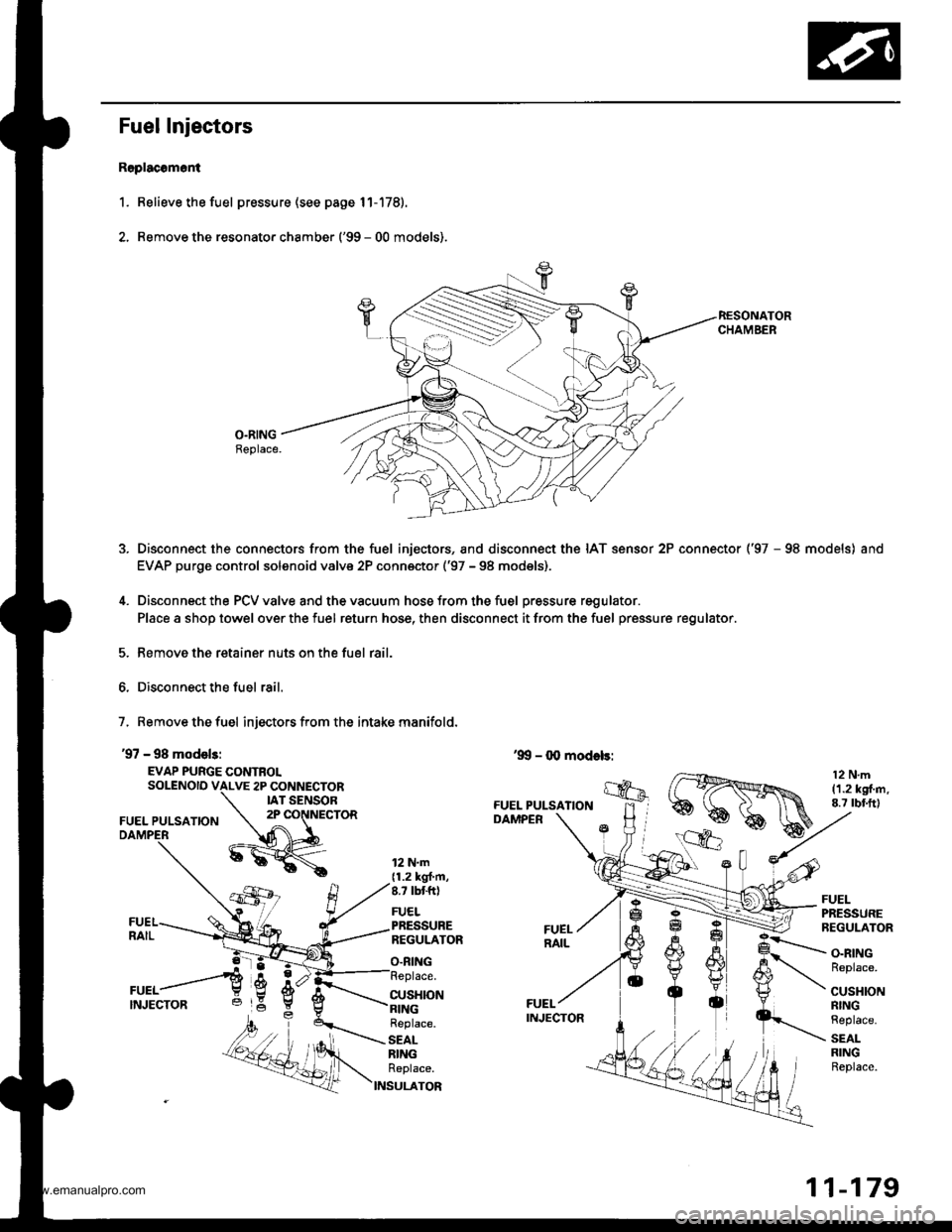

Fuel Injectors

R6placomoni

1. Relieve the fuel pressure (see page 11-178).

2. Remove the resonato. chamber ('99 - 00 models).

O.RINGBeplace.

Disconnect the connectors from the fuel injectors, and disconnect the IAT sensor 2P connector ('97 - 98 models) and

EVAP purge control solenoid valve 2P conn€ctor ('97 - 98 models),

Disconnect the PCV valve and the vacuum hose from the fuel pressure regulator.

Place a shop towel over the fuel return hose, then disconnect it from the fuel pressure regulator.

Remove the retainer nuts on the fuel rail.

Disconnect the fuel rail.

7, Remove the fuel injectors from the intake manifold.

'97 - 98 model3:

EVAP PURGE CONTROLSOLENOID VALVE 2P CONNECTORIAT SENSOR

FUEL PULSATION2P CONNECTOR

12 N.m{1.2 kgt'm,8.7 tbtft)

FUELPRESSUREREGULATOR

O.RING

FUELPRESSUREREGULATOR

CUSHION

O.RINGReplace.

CUSHIONRINGReplace.

SEALRINGReplace.

Replace.

SEALRINGReplace.

S

11-179

www.emanualpro.com

Page 382 of 1395

Fuel Supply System

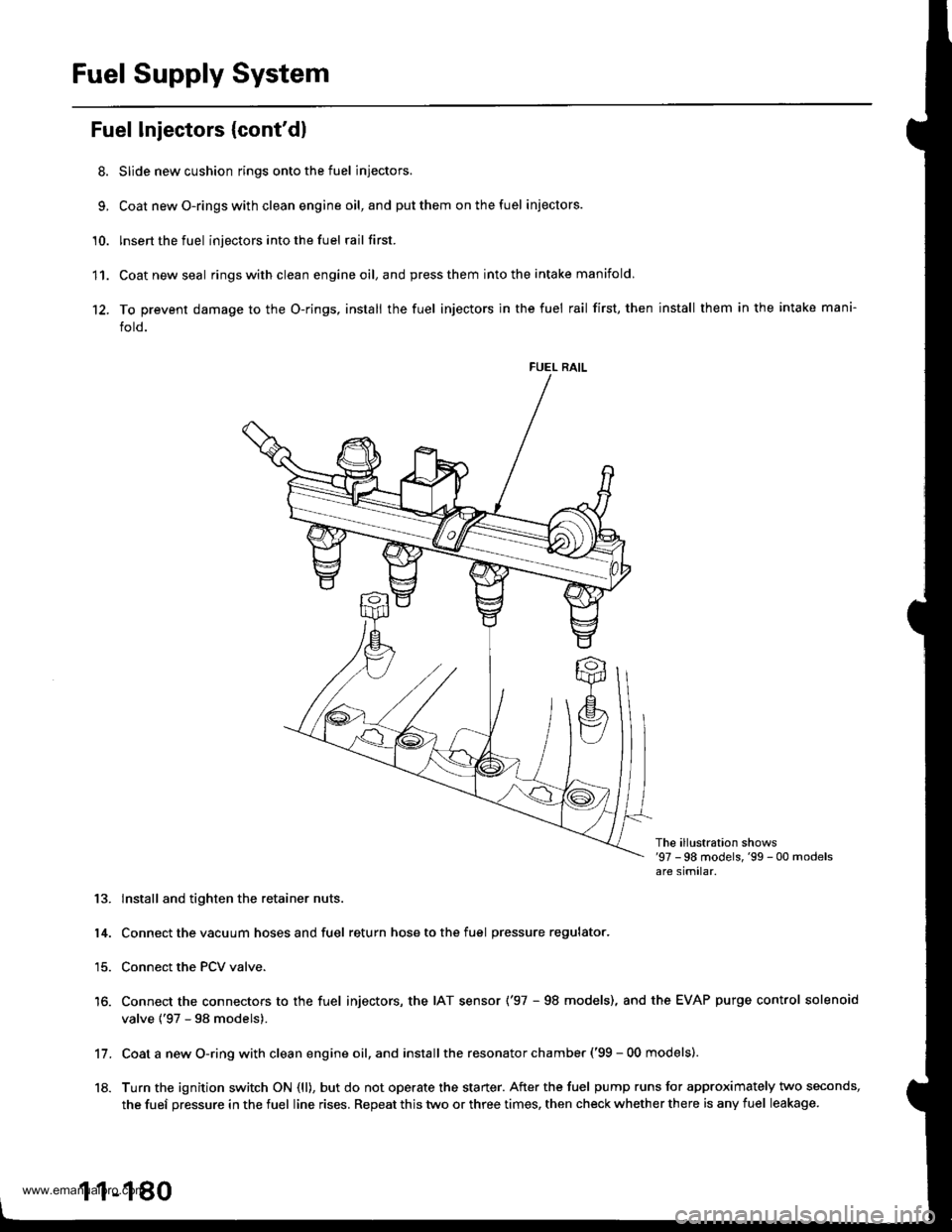

Fuel Injectors {cont'dl

8. Slide new cushion rings onto the fuel injectors.

9, Coat newO-ringswith clean engine oil,and putthem onthefuel iniectors.

'10. lnsert the fuel injectors into the fuel rail first.

11. Coatnewseal ringswithclean engineoil,and press them into the intake manifold

12. To prevent damage to the O-rings, install the fuel injectors in the fuel rail first, then install them in the intake mani-

fold.

FUEL RAIL

The ill!stration shows'97 -98 models,'99 - 00 modelsare similar.

13. lnstall and tighten the retainer nuts.

14. Connect the vacuum hoses and fuel return hose to the fuel pressure regulator.

15. Connect the PCV valve.

16. Connect the connectors to the fuel injectors, the IAT sensor ('97 - 98 models), and the EVAP purge control solenoid

valve {'97 - 98 models).

Coat a new O-ring with clean engine oil, and install the resonator chamber ('99 - 00 models).

Turn the ignition switch ON (ll), but do not operate the starter. After the fuel pump runs for approximately two seconds,

the fuef pressure in the fuel line rises. Repeat this two or three times, then check whether there is any fuel leakage.

11.

18.

1 1-180

www.emanualpro.com