ground HONDA CR-V 1999 RD1-RD3 / 1.G Manual PDF

[x] Cancel search | Manufacturer: HONDA, Model Year: 1999, Model line: CR-V, Model: HONDA CR-V 1999 RD1-RD3 / 1.GPages: 1395, PDF Size: 35.62 MB

Page 362 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G Manual PDF

ldle Gontrol System

Alternator (ALT) FR Signal (contdl

98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr FllltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female termi HONDA CR-V 1999 RD1-RD3 / 1.G Manual PDF

ldle Gontrol System

Alternator (ALT) FR Signal (contdl

98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr FllltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female termi](/img/13/5778/w960_5778-361.png)

ldle Gontrol System

Alternator (ALT) FR Signal (cont'dl

'98 - 00 modols:

ALT CONNECTOR (C1I}5I

4P

rH] Arr Fl'l'ltwHr/REo)l3laF1

I JUMPER WIRE JUMPER+ WIRE

ECM/PCM CONNECTORS

Wire side of female terminals

ECM/PCM CONNECTOR C {31PI

Wire side of female terminals

Wire side of female terminals

ECM/PCM CONNECTOR C {31P}

": Canada

1 1-160

B (25P)

Insp€ction of ALT FR Signsl.

Check fo. a shon in th. wire {ALTF linel:1. Disconn6ct the 4P (3P)* con-nector from the ALT.2. Turn the ignition switch ON {ll).3. Measure voltage between ECM/PCM connector terminals C5and 820.Ch€ck for a sho.t in iho wirc lAlTF lino):1. Turn the ignition switch OFF.2. Disconnecl the negative bat,tery cable from the battery.3. Disconnect ECM,PCM connec-torC (31P).

4. Check for continuity betwoenbody ground and ECM/PCMconnector terminal c5.

ls there approx. 5 V7

Check the opcration of the ALT:1. Turn the ignitioo switch OFF.2. Reconnect rhe ALT 4P (3P)*connector to the ALT.3. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neutral) untilthe radiator lan comes on,then let it idle.4. Measure voltage between ECM/PCM connector terminals C5and 820.

Roprir lhort in tho wirc bstweentho ECM/PCM {Csl and the ALT.

Substitut. r known-good ECM/PCM and roch.ck. It Droscrib.dvoltage b now lvrilabls, .eplaccth. o.igin!l ECM/PCM.

Does the voltage decrease whenheadlights and rear defogger areturned on?ALT FR 3ignol is OK,

Chock lor an opon in tha wire (ALTF linel:1. Turn the ignition switch OFF.2. Disconnect the negative bat-tery cable from the battery.3. Disconnect ECM/PCM con-nector C (31P).4. Disconnect the 4P 13P)* con,nector from the ALT.5. Connect the ALT 4P {3P)* con-nector terminal No. 4 1No. 1)*to body ground with a jumper

6. Check for continuity betwe€nbody ground and ECM/PCMconnector terminal C5.

Rsprir opan wiro batw.en thoECM/PCM lcsl .nd th. ALT.ls there continuity?

AI.T F IWHT/REDI

ALT F {WHT/REDI

Wire side ot Iemale terminals

www.emanualpro.com

Page 365 of 1395

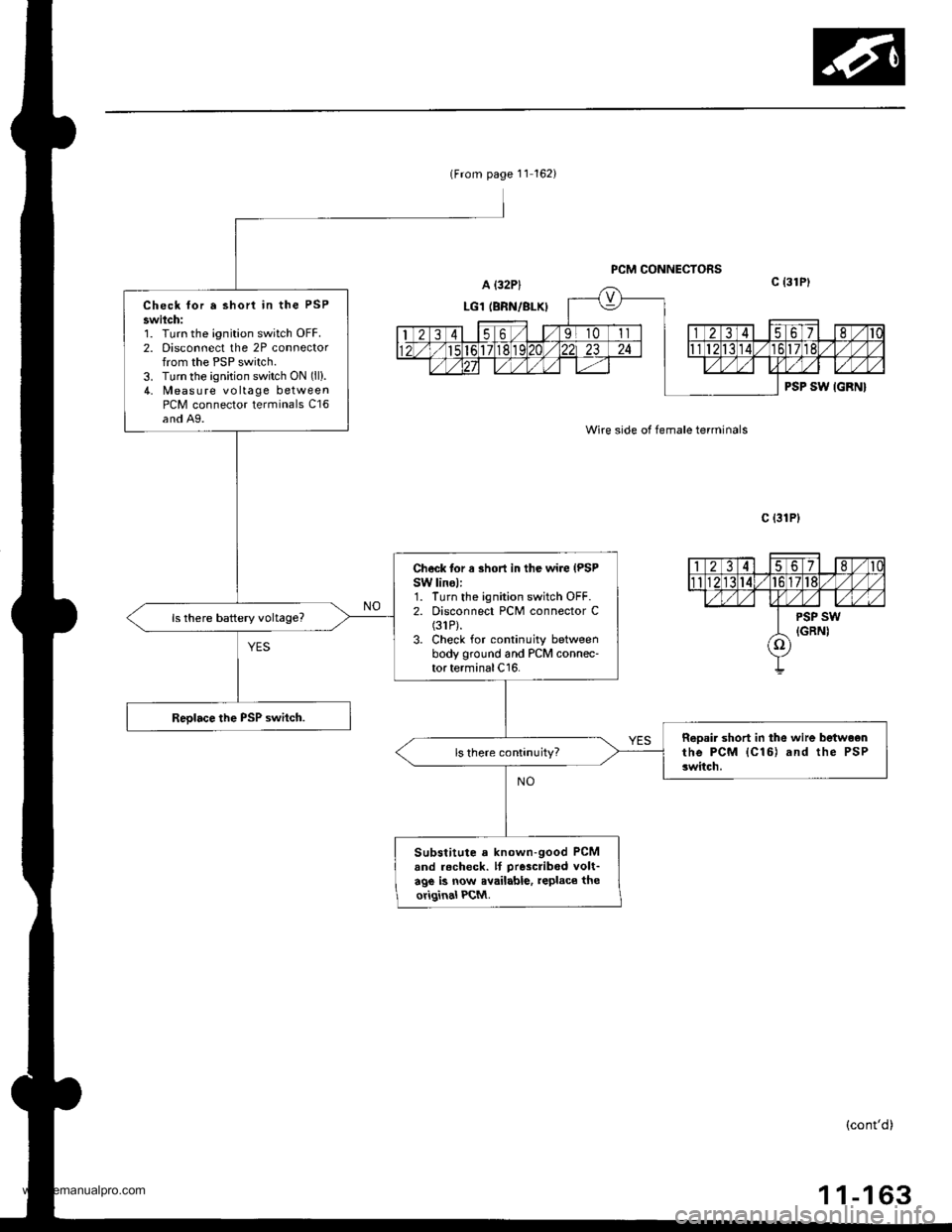

{From page 11 162)

PCM CONNECTORS

Wire side of female terminals

c t3lPl

Check for a short in the PSP

swilch:1. Turn the ignition switch OFF.2. Disconnect the 2P connectorfrom the PSP switch.3. Turn the ignition switch ON (ll).

4. lleas u re voltage betweenPCM connector terminals C16and A9.

Check tor a short in the wire (PSP

SW linol:1. Turn the ignition switch OFF.2. Disconnect PCM connector C(31P).

3. Check for continuity betweenbody ground and PCM connec-tor terminal C16.

Reoair short in the wire betwoonrhe PCM {C16) and the PSP3witch.

Substitute a known-good PCM

and rocheck. lf proscribod volt-age b now available, replace theoriginal PCM.

(cont'd)

-16311

www.emanualpro.com

Page 367 of 1395

{From page 11 164i

Check for a short in the PSPswitch:1. Turn the ignition switch OFF.2, Disconnect the 2P connectorfrom the PSP switch.3. Turn the ignition switch ON (ll).

4. Measure voltage betlveen ECM/PCM connector terminals A26and 820.

Check lor e 3hort in the wire IPSPSW linell1. Turn the ignition switch OFF.2. Disconnect ECM/PCM con-nector A (32P).

3. Check for continuity betweenbody ground and ECM/PCMconnector terminal A26.

ReDair short in the wir€ bstweenthe ECM/PCM (A26) and the PSPswitch.

Substitute a known-good ECM/PCM and rechock. It Drescribodvoltago is now available, roplacethe origin.l ECM/PCM,

ECM/PCM CONNECTORS

A l32Pl

Wire side of female terminals

Wire side of female terminals

1 1-165

www.emanualpro.com

Page 385 of 1395

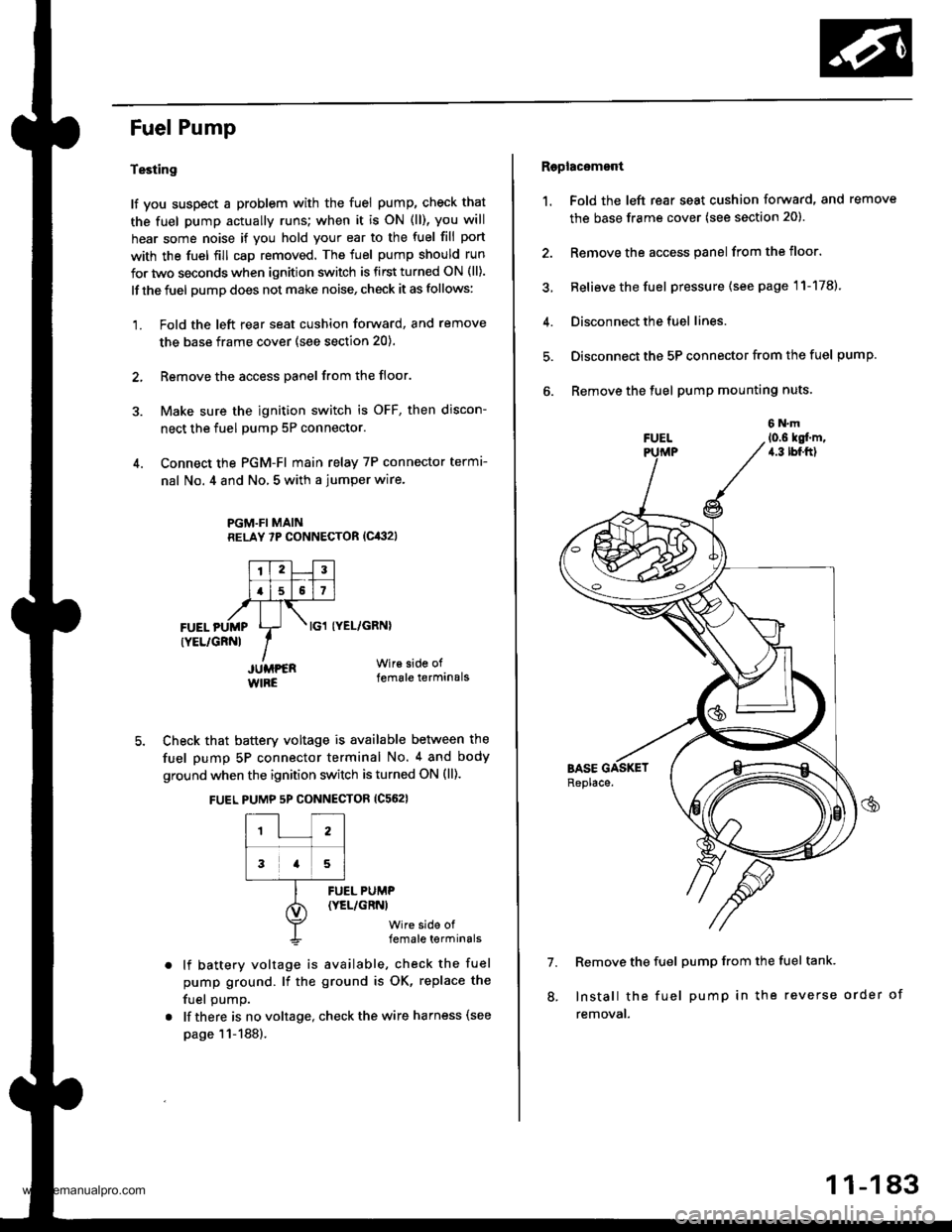

Fuel Pump

Testing

lf you suspect a problem with the fuel pump, check that

the fuel pump actually runs; when it is oN (ll), you will

hear some noise if you hold your ear to the fuel fill port

with the fuel fill cap removed. The fuel pump should run

for two seconds when ignition switch is first turned ON (ll).

lf the fuel pump does not make noise, check it as follows:

1. Fold the left rear seat cushion forward, and remove

the base frame cover (see section 20).

2, Remove the access panel from the floor.

3. Make sure the ignition switch is OFF, then discon-

nect the fuel pumP 5P connector.

4. Connect the PGM-FI main relay 7P connector termr-

nal No. 4 and No, 5 with a jumper wire.

PGM.FI MAINRELAY 7P CONNECTOR (Cit:}2l

I'TtlJilt f -r'-r ll.l5l517l,frTt-,at\FUEL pUMp Lr- . tcl tyEL/cRNl

rYEL/cRNl IIJUMPER Wir€ side of

WIRE female terminals

5. Check that battery voltage is available between the

fuel pump 5P connector terminal No. 4 and body

ground when the ignition switch is turned ON (ll).

FUEL PUMP 5P CONNECTOR {C562}

12

3a5

lf battery voltage is available, check the fuel

pump ground. lf the ground is OK, replace the

fuel oumo.

lf there is no voltage, check the wire harness (see

page 11-188).

FUEL PUMP(YEL/GRNI

wire side offemale terminals

Raplac6mont

1. Fold the left rear seat cushion forward, and remove

the base frame cover (see section 20).

2. Remove the access panel from the floor.

3, Relieve the fuel pressure (see page 11-178).

4. Disconnect the fuel lines.

5. Disconnect the 5P connector from the fuel pump.

6. Remove the fuel pump mounting nuts.

7. Remove the fuel pump from the fuel tank.

Install the fuel pump in the reverse order of

removal.

8.

11-183

www.emanualpro.com

Page 386 of 1395

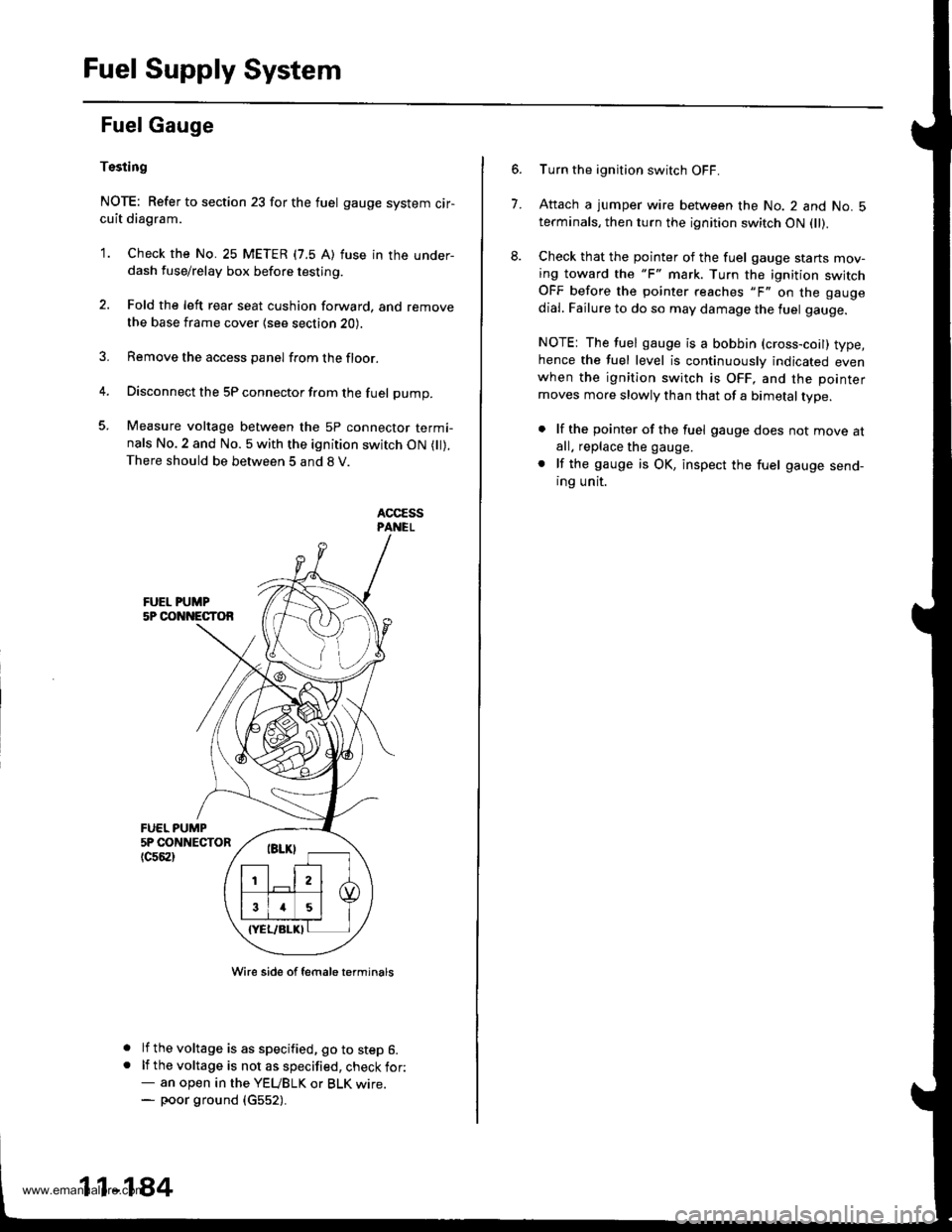

Fuel Supply System

Fuel Gauge

Tssting

NOTE: Refer to section 23 for the fuel gauge system cir-cuit diagram.

'1. Check the No. 25 METER (7.5 A) fuse in the under-dash fuse/relay box before testing.

2. Fold the left rear seat cushion forward, and remove

the base frame cover {see section 20).

3. Remove the access panel from the floor.

4. Disconnect the 5P connector from the fuel pump.

5. Measure voltage between the 5P connector termi-nals No.2 and No. 5 with the ignition switch ON ( ).There should be between 5 and 8 V.

FUEL PUMP5P CONNECTOR

tc56al

a

a

Wire side of female t€rminals

lf the voltage is as specified, go to step 6.lf the voltage is not as specified, check for:- an open in the YEUBLK or BLK wrre.- poor ground (c552).

11-184

7.

Turn the ignition switch OFF.

Attach a jumper wire between the No. 2 and No. 5terminals, then turn the ignition switch ON fll).

Check that the pointer of the fuel gauge starts mov-ing toward the "F" mark. Turn the ignition switchOFF before the pointer reaches "F" on the gauge

dial. Failure to do so may damage the luel gauge.

NOTE: The fuel gauge is a bobbin (cross-coil) type,hence the fuel level is continuously indicated evenwhen the ignition switch is OFF, and the pointer

moves more slowly than that of a bimetal type.

. lf the pointer of the fuel gauge does not move atall. replace the gauge.

. lf the gauge is OK, inspect the fuel gauge send-ing unit.

www.emanualpro.com

Page 388 of 1395

Fuel Supply System

Low Fuel Indicator System

Indicator Light Testing

NOTE: Refer to section 23forthe lowfuel lndicator circuit

clragram.

1. Check the No. 25 METER (7.5 A) fuse in the under-

dash fuse/relay box before testing.

2. Park the vehicle on level ground.

@ Do not smoke while working on the

fuel system. Keep open flame away trom the work

aroa. Drain fuel only into an approved container.

Drain the fuel into an aoDroved container. Then

install the drain bolt with a new washer.

Add less than 8 f (2.1 U.S. Gal. 1.8 lmp. Gal) of fuel,

and turn the ignition switch ON {ll). The low fuel indi-

cator light should come on within four minutes.

INDICATON LIGHT

. lf the light comes on within four minutes, go tostep 8.

. lf the light does not come on within four min-

utes. go to step 5.

Remove the seat cushion (see section 20).

Remove the fuel tank access panel from the floor,

and disconnect the 5P connector from the fuel pump,

Connect the No. 1 and No. 2 terminals with a jumper

wire.

. lf the lightcomeson, checkthe sending unit.. lf the light does not come on, check for:- an open in the GRN/yEL wire between thefuel unit and fuel gauge assembly.- blown bulb.- poor ground (G552).

FUEI- PUMP 5P CONNECTOR (C562)

JUMPER WIRE

IGRN/YEL}

7.

1 1-1 86

Wire sid€ ol tem€le terminals

8. Add 4 / of fuel (1.1 U.S. Gal, 0.9 lmp. Gal). The light

should go off within four minutes.

. lJ the light does not go off, check for:- a short in the GRNA/EL wire between the fuel

gauge sending unit and fuel gauge assembly.- faulty gauge assembly.

. lf the light goes off, the low fuel indicator light is

oK.

www.emanualpro.com

Page 389 of 1395

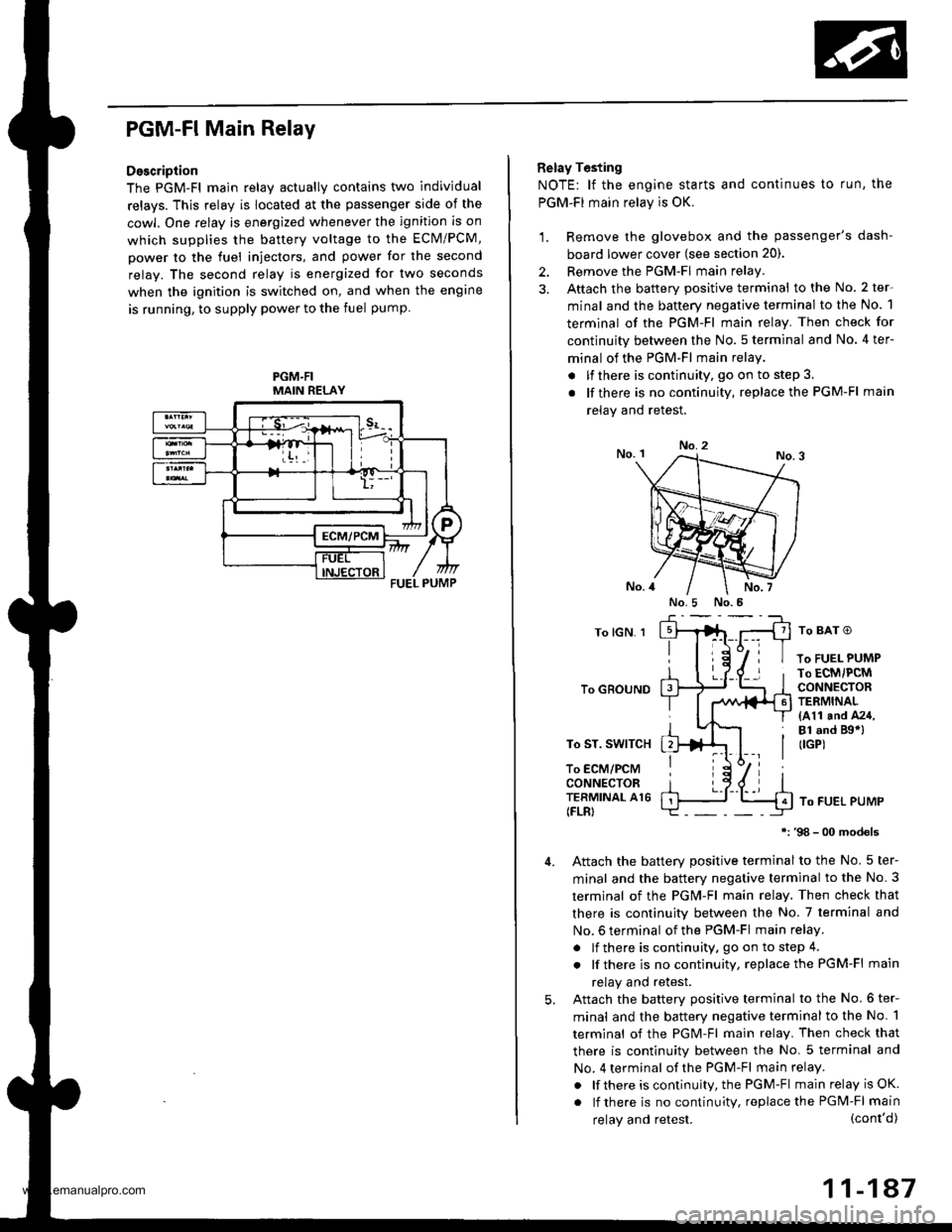

PGM-FI Main Relay

Description

The PGM-Fl main relav actuallv contains two individual

relays. This relay is located at the passenger side of the

cowl. One relay is energized whenever the ignition is on

which supplies the battery voltage to the ECM/PCM,

power to the fuel injectors, and power for the second

relay. The second relay is energized for two seconds

when the ignition is switched on, and when the engine

is running, to supply power to the fuel pump

PGM.FIMAIN RELAY

Belay Testing

NOTE: lf the engine starts and continues to run, the

PGM-FI main relay is OK.

1. Remove the glovebox and the passenger's dash-

board lower cover (see section 20).

2. Remove the PGM-FI main relay

3. Aftach the battery positive terminal to the No. 2 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM-Fl main relay. Then check for

continuity between the No. 5 terminal and No. 4 ter-

minal of the PGM-FI main relay

. lfthere is continuity, go on to step 3.

. lf there is nocontinuity, replacethe PGM-Fl main

relav and retest.

No.2

To lGN. 1

To GROUND

To ST. SWITCH

To ECM/PCMCONNECTORTERMINAL A16(FLR)

To BAT O

To FUEL PUMPTo ECM/PCMCONNECTORTERMINAL(411 and A24,Bl .nd Bgal(IGP)

To FUEL PUMP

98 - 00 models

Attach the batterv Dositive terminal to the No. 5 ter-

minal and the battery negative terminal to the No. 3

termjnal of the PGM-Fl main relay. Then check that

there is continuity between the No. 7 terminal and

No. 6 terminal of the PGM-FI main relay.

. lf there is continuity, go on to step 4.

. lf there is nocontinuity, replacethe PGM-Fl main

relay and retest.

Attach the batterv oositive terminal to the No.6 ter-

minal and the battery negative terminal to the No. 1

terminal of the PGM-Fl main relay. Then check that

there is continuitv between the No. 5 terminal and

No. 4 terminal of the PGM-Fl main relay.

. lf there is continuity, the PGM-Fl main relay is OK.

. lf there is nocontinuity, replacethe PGM-FI main

5.

(cont'd)

11-147

No.5 No.5

relay and retest.

www.emanualpro.com

Page 390 of 1395

![HONDA CR-V 1999 RD1-RD3 / 1.G Manual PDF

Fuel Supply System

PGM-FI Main Relay (contdl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,TilI A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PG HONDA CR-V 1999 RD1-RD3 / 1.G Manual PDF

Fuel Supply System

PGM-FI Main Relay (contdl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,TilI A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PG](/img/13/5778/w960_5778-389.png)

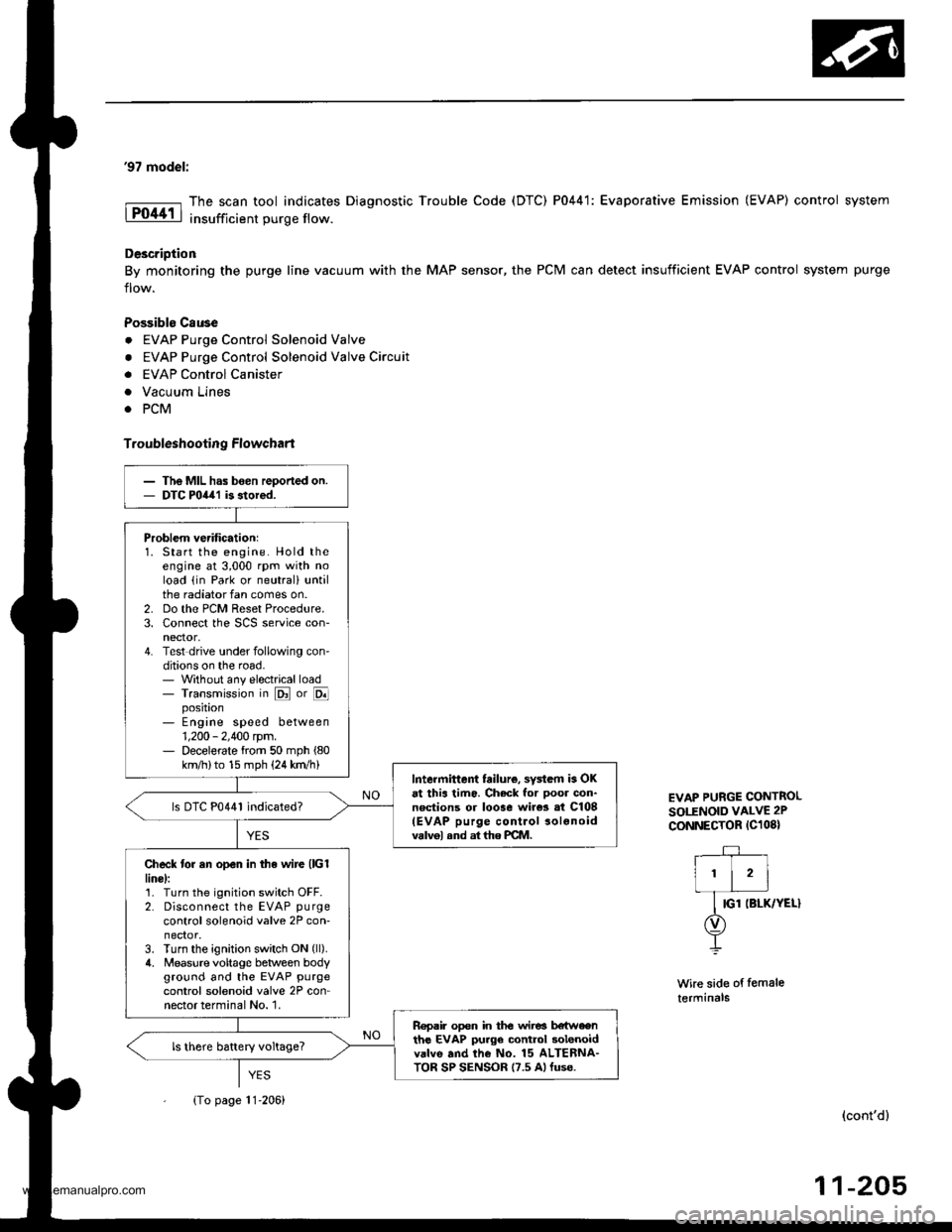

Fuel Supply System

PGM-FI Main Relay (cont'dl

Troubleshooting

lc(}21PGM.FI MAIN RELAY 7P CONNECTOR

GND

trTr]--Flq

FI,Til'I A

Y

Wire side ot female terminals

- Engine will not start.- InsDection ol PGM-FI mainrelay and relay harness,

Check fo. an open in the wireIGND linol:1. Turn the ignition switch OFF.2. Disconnect the PGM Fl mainrelay 7P connector.3. Check for continuity betweenthe PGM'FI main relay 7P con-nector terminal No. 3 and bodyground.

Repair opcn in th€ wire betweenthe PGM-FI main relav and G101.

Check tor an open or short in thewiro (BAT line):Measure voltage between thePGM'FI main relay 7P connectorterminal No. 7 and body ground.- Repai. open or short in lhewir6 belween the PGM-FImain relay and the Fl E/M (15Al fu3e.- Replace th6 FIE/M (15 Altus6in th€ under-hood fuse/.6lay

ls there baftery voltage?

Check lor an open or short in thewire (lGl line):L Turn the ignition switch ON (ll).2. Measure the voltage betweenthe PGM-FI main relay 7P connectorterminal No. 5 and bodyground.- Repair open or shorl in thewire between the FGM-FI mainrelay and the No. 13 FUELPUMP 115 A) tuse.- Replaco the No. 13 RJEL PUMP115 A) luse in the und6.-d$hfuso/ relav box.Check for an open or short in thewire {STS line):1. Turn the ignition switch to theSTART (lll) position.NOTE:. M/T: Clutch pedal must bedepressed.. A/T: Transmission in E orElposition.2. Measure the voltage betweenthe PGM-Fl main retay 7Pconnector terminal No. 2 andbody ground.- Repair open or short in thewire betwe€n the PIGM-FI m.inrclay and th€ No. 31 STARTERSlGllAL 17.5 A) tuse.- Repl.ce the No. 31 STARTERSIGNAL 17.5 Al tuse in theunder-dash tuse/relay box.('97 model: To page 11-189)('98 00models:To page 1l 190)

1 1-188

www.emanualpro.com

Page 407 of 1395

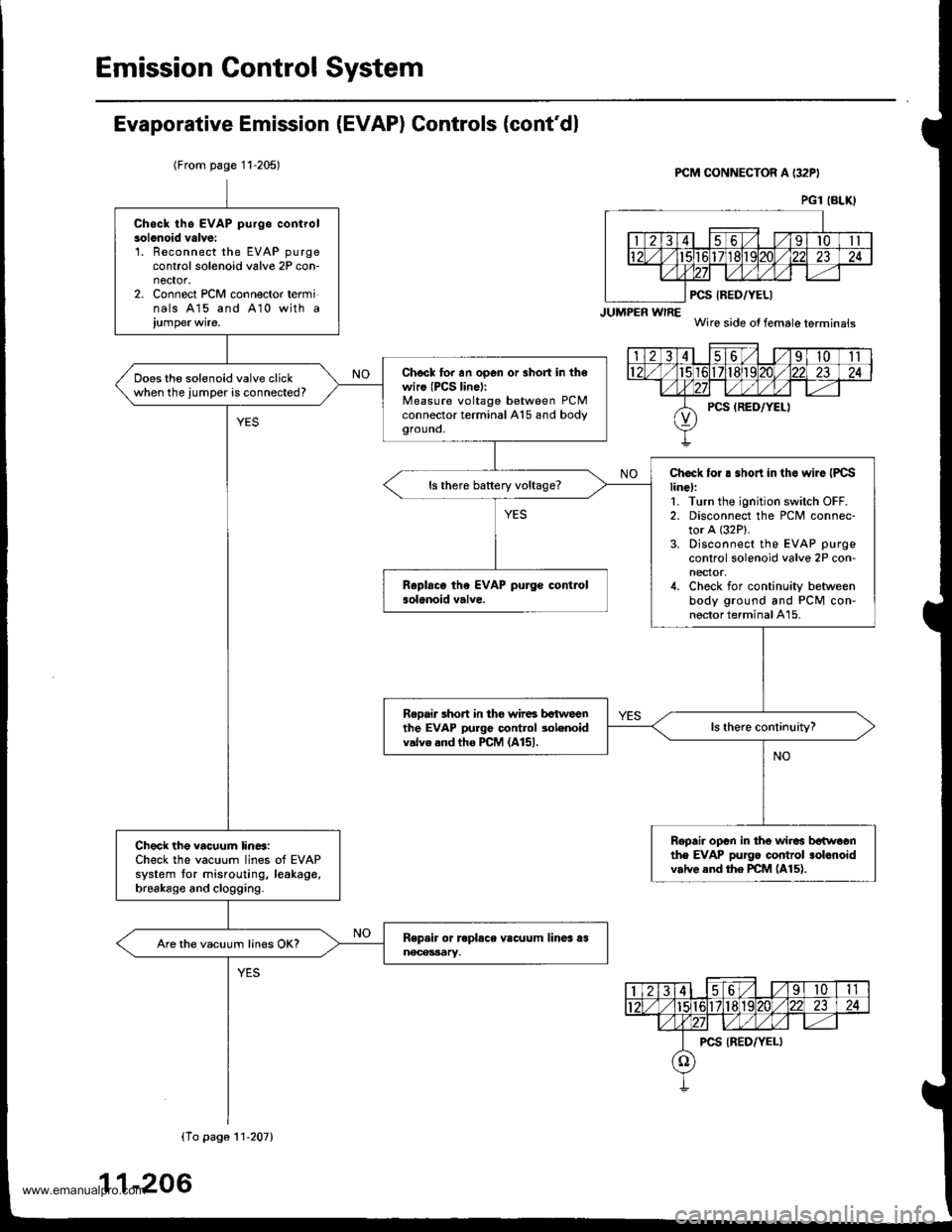

'97 model:

The scan tool indicates Diagnostic Trouble Code (DTC) P0441: Evaporative Emission (EVAP) control system

insufficient purge flow.

Description

By monitoring the purge line vacuum with the MAP sensor, the PCM can detect insufficient EVAP control system purge

flow.

Possiblo Cause

. EVAP Purge Control Solenoid Valve

. EVAP Purge Control Solenoid Valve Circuit

. EVAP Control Canister

. Vacuum Lines

. PCM

Troubleshooting Flowchart

EVAP PURGE CONTROL

SO1TNOID VALVE 2P

CoNNECTOR (C108)

(v)

YL

Wire side of female

termrnals

(cont'd)

11-205

Th€ MIL has b€en reooited on.DTC P0441 is .tored.

Problem verificationl1. Start the engine. Hold theengine at 3,000 rpm with noload (in Park or neut.al) untilthe radiator fan comes on.2. Do the PCM Reset Procedure.3. Connect the SCS service con-nector,4. Test drive under following con'ditions on the road.- without any electrical load- Transmission in @ or @position- Engine speed between1 ,2OO - 2,4OO rpfi.- Decelerate from 50 mph (80

km/h)to 15 mph (24 km/h)Intermittent trilure, sydern is OKat this time. Check for Door con-nections or loose wir€3 at C108

IEVAP purge control solonoidvalvol .nd at the PCM.

ls DTC P0441 indicated?

Check tor an open in the wire (lcl

linel:1. Turn the ignition switch OFF.2. Disconnect the EVAP purge

control solenoid valve 2P con-nector.3. Turn the ignition switch ON (ll).

4. Measure voltage between bodyground and the EVAP purge

control solenoid valve 2P con-nector terminal No. '1,

R€pafu open in thc wir6 b€tw€enthG EVAP purge control solenoidvalve and the No. 15 ALTEBNA-TOR SP SENSOR (7.5 A)fuse.

ls there batlery voltage?

(To page 11'206)

www.emanualpro.com

Page 408 of 1395

Emission Control System

Evaporative Emission (EVAP) Controls (cont'dl

(From page 11-205)PCM CONNECTOR A (32PI

JUMPER wlRE

PCS IRED/YELI

Wire side of female terminais

PG1 (BLKI

Chsck th6 EVAP purgo controlsolonoid valve:'L Reconnect the EVAP purgecontrol solenoid valve 2P con-nector.2. Connect PCM connector terminals 415 and A10 with a

Chscl to. an op6n or 3hort in th€wiro (PCS lin6):Measure voltage between PCMconnector terminal A15 and bodygrouno,

Does the solenoid valve clickwhen the jumper is connected?

Chock for . .hort in tho wiJe IPCSline):1. Turn the ignition switch OFF.2. Disconnect the PCM connec-tor A (32P).

3. Disconnect the EVAP purge

control solenoid valve 2P con-nector,4. Check for continuity betweenbody ground and PCM con-nector terminal A15.

ls there battery voltage?

Rooair short in tho wir6 bctweenthe EVAP purge control 3olenoidvalvo and tho PCM (A151.

Ropair open in the wir6 betwoonthe EVAP pu]go control .olonoidv.lve end the PCM (A15).

Check the vacuum lin6:Check the vacuum lines of EVAPsystem tor misrouting, leakage,brsakago and clogging.

Are the vacuum lines OK?

(To pago 11'207)

11-206

www.emanualpro.com